Abstract

Additive manufacturing is becoming a popular and effective process for lightweight high-temperature TiAl alloys, but there is a lack of understanding regarding the corresponding microstructural formation mechanisms. In this study, various Ti-47Al-2Cr-2Nb alloys were additively manufactured with different laser power values, and the related microstructures were carefully characterized. The results show that a convoluted microstructure, a nearly full α2/γ lamellar structure, and an α2/β Widmanstatten structure were obtained as the laser power was increased. Moreover, the Al content of the as-deposited specimen decreased from 47 at.% to 40 at.%, which is considered to have strongly affected microstructural formation. As the Al content decreased, the solidified microstructure transformed from hexagonal dendritic α2 to orthogonal dendritic β and cellular β, successively. Moreover, massive α → γ transformation is more likely when the Al content is high, and α → α2 transformation tends to occur when the Al content decreases. The microstructure evolution processes are evaluated in the present paper by synthesizing the experimental results with a thermodynamics analysis.

1. Introduction

Intermetallic γ-TiAl-based alloys, as innovative high-temperature structural materials, have attracted plenty of attention, especially for replacing Ni-based superalloys in low-pressure turbine blades [1]. The most important advantage of this type of intermetallic alloy is its high specific strength in the temperature range of 650~750 °C, realizing a weight reduction of as much as ~50%. More than 40,000 low-pressure TiAl turbine blades have been manufactured for GEnx 1B (Boeing 787) and GEnx 2B (Boeing 747-8) turbine engines [2]. However, the largest drawback of TiAl alloys is their low room-temperature ductility, making the manufacturing process extremely expensive, which impedes their development. Rapid developments in additive manufacturing provide an alternative approach to fabricating components with various shapes, which potentially facilitates its application.

Additive manufacturing (AM) is a sophisticated and multi-parameter process consisting of many interconnected, coupled physical events [3]. Rapid solidification and solid phase transformation occur sequentially during the AM process, which determines the eventual microstructures and mechanical properties of as-deposited materials. Ti alloys, especially Ti-6Al-4V, have been studied extensively because of their excellent suitability with this technology. Their microstructural evolution and tailoring mechanisms have been intensively explored [4,5,6,7], and excellent mechanical properties with an ultrafine lamellar microstructure were eventually obtained [7]. However, only a small number of studies focused on the microstructure and mechanical properties of additively manufactured (AMed) TiAl alloys have been conducted [8,9,10]. Additively manufacturing TiAl alloys is at its infancy for several reasons. First, TiAl alloys suffer from severe cracking during processing if the process is not elaborately controlled. Secondly, AM is an extremely complex process with multiple thermal cycles that are highly related to the scanning strategy, processing parameters, and the pre-heating state of the substrate, thus raising the difficulty of controlling the microstructures in a predictable way [11]. Furthermore, the Al evaporation phenomenon might occur during AM processing [12,13], which increases the complexity of microstructure tailoring [14]. Hitherto, there is still a lack of basic experimental information for AM TiAl alloys concerning the correlations between the processing parameters and the as-deposited microstructure, not to mention the microstructural formation mechanisms of the various microstructural features under the different processing parameters. Thus, carefully characterizing the microstructures of as-deposited TiAl alloys and exploring their corresponding formation mechanisms is the first and important step of this research, which will benefit microstructure tailoring as well.

The present work carefully characterizes the microstructures of the AMed Ti-47Al-2Cr-2Nb alloy under the effect of laser power and reveals that a significant Al loss phenomenon occurs as the laser power increases. Furthermore, the related microstructural evolution mechanisms are discussed from the perspective of thermodynamics.

2. Materials and Methods

A pre-alloyed Ti-47Al-2Cr-2Nb (at. %) alloy, also known as a GE alloy, was selected as the raw powder. To reduce the aggregated powders and improve their flowability, the powders were dried at 50 °C for about 24 h prior to use. An ytterbium fiber laser (YLS-2000, IPG, Oxford, MA, USA) with a 1070 nm wavelength was used as the heat source. The laser generates a circular beam with a diameter of 0.8 mm at the focal zone, with a near-Gaussian intensity distribution. The direct laser deposition was processed by feeding argon shielding gas through a coaxial nozzle with a flow rate of 12 L min−1. A TiAl plate was selected as the substrate, and the surface was ground and cleaned with acetone and alcohol before deposition. In this study, laser power was altered for different samples, while other processing parameters were kept constant. The scanning speed was 5 mm/s, the powder feed rate was 3 g/min, and the z-increase was 0.2 mm. Three different laser powers (400 W, 600 W, 800 W) were selected for the experiments, and the back-and-forth scanning strategy was used.

In order to observe the microstructures, all the deposited samples were sectioned along their building axis; then, they were ground and polished using standard metallographic techniques with an automatic polishing machine (Automet 300, Buehler, Lake Bluff, IL, USA) and etched with Keller reagent (vol. 4% HNO3, vol. 2% HF, vol. 94% H2O). An optical microscope (OM, Axio Observer.A1m, Zeiss, Jena, Germany) and scanning electron microscope (LYRA3, TESCAN, Brno, Czechia) in back-scattered electron mode (SEM-BSE) were used to investigate the microstructures. The compositions were analyzed using energy dispersive spectroscopy (SEM-EDS). The composition measurements were repeated at least five times in different regions for accuracy and credibility. Phases were identified using X-ray diffraction (XRD), with 2θ varying from 30°~90°. A transmission electron microscope (TEM, JEM2100F, JEOL, Tokyo, Japan) was used at 200 kV to gather more detailed microstructural information. TEM specimens were prepared via precision cutting and subsequently ground to a 100 μm thickness, followed by twin-jetting at ~30 V with a reagent (vol. 59% methanol, vol. 35% butanol, vol. 6% perchloric acid).

3. Results

Microstructure Characterization

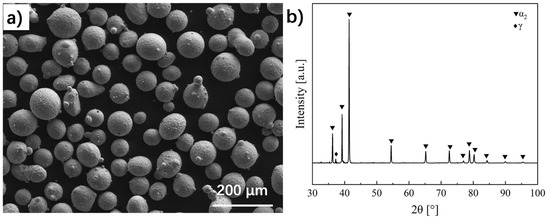

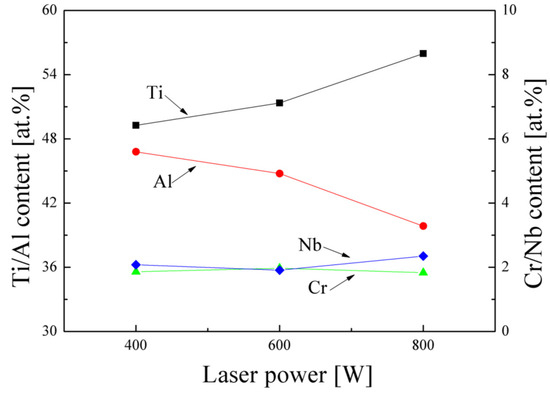

Figure 1 presents the morphologies and XRD patterns of the original powders. It shows that these powders have a highly spherical morphology with diameters ranging from tens of microns to more than one hundred microns. A small number of satellite balls can be seen around these spherical powders. The XRD results reveal that the original powders are dominated by an α2 phase (; a = 0.577, c = 0.463); only a very small diffraction peak corresponding to the γ phase (; a = 0.400, c = 0.406) can be distinguished (Figure 1b). This phase constitution largely deviates from the equilibrium state wherein the γ phase occupies the majority, and such a nonequilibrium microstructure is attributed to the rapid cooling rate (104–106 K s−1) during the atomization process [15]. Figure 2 exhibits the SEM-BSE morphologies of the as-deposited walls. Because the contrast of BSE images is highly related to the atomic number, wherein the bright contrast regions tend to show the accumulation of elements with a high atomic number while the dark contrast regions tend to show the accumulation of elements with a low atomic number, these images can, in a sense, reflect the chemical segregation in the solidification process. It is clearly seen that both the samples fabricated at 400 W and 600 W share the same dendritic morphology, implying that these samples underwent dendrite solidification processes. However, it is notable that the detailed patterns of the dendrites show some differences. As shown in Figure 2a, most of the angles between neighboring dendritic arms are 60° when the laser power is 400 W. However, the majority of the dendrites exhibit an orthogonal feature, with neighboring dendritic arms presenting 90° for the sample obtained under 600 W. The EDS results (Table 1) reveal that both Ti and Nb prefer to gather in dendrite regions, but Al and Cr tend to segregate in interdendritic regions. The chemical distribution preference is consistent with the BSE contrast shown in Figure 2. The dendritic morphology and composition segregation can be associated with the solidification process [16]. When the hexagonal α phase is the first phase to form, the solidified dendrites prefer to grow along <> [17], and the hexagonal dendrite will be generated as shown in Figure 2a. However, if the cubic β solidifies as the primary phase, it will grow along the <> direction and form an orthogonal dendrite. Nevertheless, when the laser power is further increased to 800 W, the dendritic morphology disappears, and Widmanstatten laths become the dominant morphology (Figure 2c), which is a consequence of the β → α Widmanstatten transformation. This implies that β is still the primary phase during solidification. EDS analysis shows that the average chemical composition of the as-deposited specimens varies dramatically (Figure 3). When the laser power is 400 W, the Al content is about 47 at.%, agreeing with the normal chemical composition of the raw powder. As the laser power increases, the Al content clearly decreases, but the Cr and Nb contents increase slightly.

Figure 1.

(a) SEM image and (b) XRD pattern of the morphology of the initial powders.

Figure 2.

Overall morphology of the as-deposited microstructure under BSE contrast: (a) 400 W, with its morphology exhibiting a hexagonal dendrite with dendritic arms forming 60°; (b) 600 W, with its morphology exhibiting an orthogonal dendrite with dendritic arms forming 90°; (c) 800 W, with its morphology exhibiting Widmanstatten bundling extending from the grain boundary.

Table 1.

EDS results of different regions in as-deposited specimens produced through direct laser deposition.

Figure 3.

The average chemical composition of as-deposited specimens measured through EDS, which shows Al content decreasing as laser power increases.

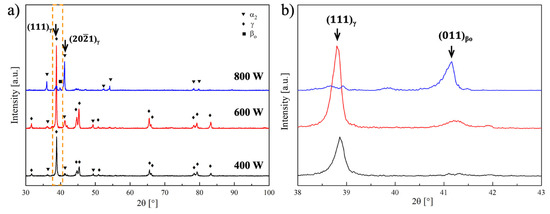

Figure 4a presents the XRD patterns of the as-deposited specimens, where the peaks corresponding to the α2, γ, and βo (, a = 0.319) phases are indexed, respectively. The figure clearly shows that both the specimens obtained under 400 W and 800 W only consist of α2 and γ phases. In these diffraction patterns, the diffraction peaks corresponding to the ()γ plane are the most remarkable, and most of the peaks belong to the γ phase, reflecting a dramatic predominance of the γ phase in the as-deposited samples obtained under 400 W and 600 W. Moreover, there are also some forked peaks, which indicate the presence of a tetragonal feature of the γ phase. When the laser power increases to 800 W, the () peak corresponding to the α2 phase located at about 41° becomes the major diffraction peak, accompanied by various weak diffraction peaks related to appearance of the α2 phase. The peaks associated with the γ phase are attenuated, and only one related to ()γ can be distinguished. Moreover, from the local magnified diffraction pattern in Figure 4b, it can be seen that a ()βo peak appears, indicating that the high-temperature β phase was retained and transformed into an ordered βo phase.

Figure 4.

(a) Overall XRD patterns of as-deposited specimens produced with different laser powers. The dashed rectangle is magnified and presented in (b).

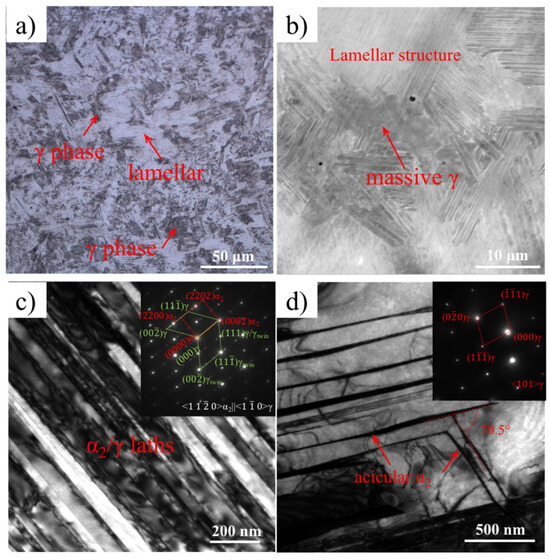

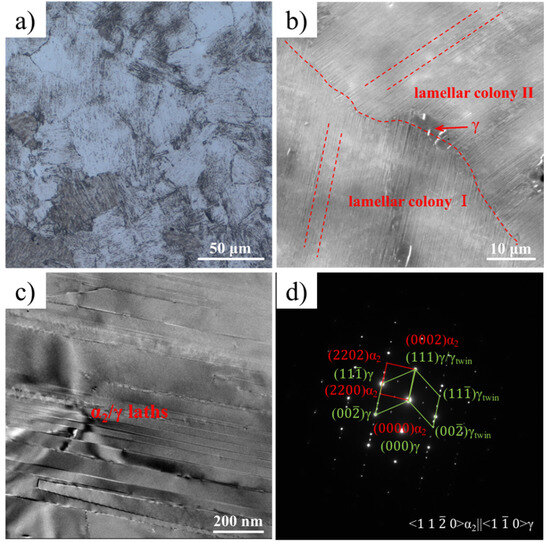

In order to investigate the detailed microstructural morphology of the as-deposited samples, microstructural characterizations were conducted at multiple scales. Figure 5 presents the microstructure of the as-deposited specimen produced with the laser power of 400 W. The convoluted microstructure comprises various orientated lamellar colonies, and the anomalous massively transformed γ is the dominant feature (Figure 5a). It is noted that lamellar microstructures are mainly located in the dendrite regions, while massive γ phases are mainly located in the interdendrite regions in the SEM-BSE image (Figure 5b). Under TEM observation, the lamellar structure was rotated to ensure that the lamella interface was along the incident electron beam and to enable the direct measurement of the width of the lamellae and the orientation relationship. According to the diffraction pattern (Figure 5c), it is clearly deduced that the lamellar structure comprises α2 and γ phases with the following orientation relationship: <>α2 || <>γ, ()α2 || ()γ. In addition, some γ laths even exhibit a twin relationship along the () plane. The mean width of a γ lath is estimated to be 61 nm with a standard deviation of 20 nm, while the width of a α2 lath appears much narrower with a mean value of 17 nm. Figure 5d presents a TEM bright-field image and the corresponding diffraction pattern of the massive γ phase. In the massive γ phase, there were differently orientated acicular α2 phase precipitates. These acicular α2 precipitates along the {} plane of the massive γ phase form an angle of 70.5°, which is in accordance with the orientation relationship between α2 and γ mentioned above. According to previous studies [18,19,20], the α2/γ lamellar structure and massive γ are usually obtained via cooling from the high-temperature disordered α phase based on the solid-state transformation α → α2 + γ or by applying an aging treatment to the supersaturated α2 phase. Regarding the lamellar structure, the precipitation of the γ phase follows the Blackburn orientation relationship with a α/α2 matrix [21], thus contributing to six kinds of variants. These variants can be classified into two twin groups of three variants, and each group is in accordance with one of the two disordered cubic variants in the () twin relationship based on the stacking sequence. However, acicular α2 precipitation cannot be observed simply by cooling from a high temperature in TiAl alloys, but rather only through a reheating treatment on supersaturated γ [22], implying that a converse γ → α2 + γ transformation occurred during the subsequent thermal cycles.

Figure 5.

Microstructure of as-deposited specimen produced at 400 W. (a) OM shows a convoluted microstructure; (b) SEM-BSE presents that massive γ locates at the interdendrite zone; (c) bright-field images of lamellar structure and the inserted SAED pattern, revealing that the lamellar structure comprises α2, γ, and γtwin; (d) bright-field images of massive γ, which show that the intersected acicular α2 and the inserted SAED pattern were obtained from the γ matrix.

When the laser power is increased to 600 W, equiaxed colonies fully filled with lamellar structures become the main feature (Figure 6a). Similarly to the sample fabricated with 400 W, there are also a small number of massive transformed γ grains embedded in the dark interdendrite region (Figure 6b), though the γ grain size appears much smaller. TEM observations are also presented in Figure 6c,d, and the incident electron beam direction is along <>α2 and <>γ. These show that most of the laths in the lamellar colony are below 100 nm and are much thinner than those obtained via casting [2].

Figure 6.

Microstructure of the as-deposited specimen produced at 600 W. (a) OM shows a nearly lamellar structure; (b) SEM-BSE shows two lamellar colonies and massive γ precipitated at the boundary; (c,d) bright-field image and its corresponding SAED pattern of α2/γ laths.

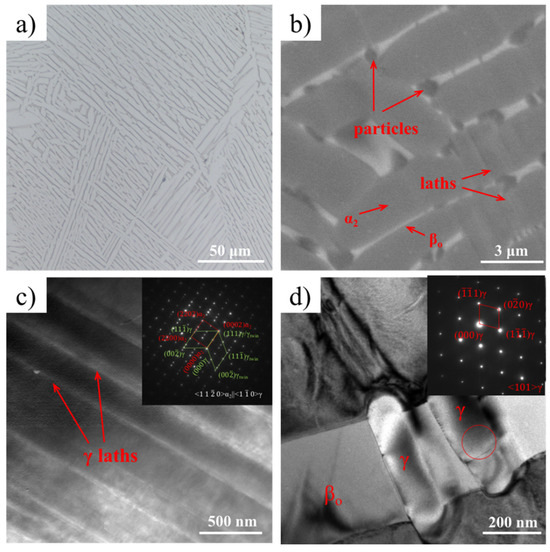

When the laser power is increased to 800 W, the microstructural morphology is completely different from that obtained at 600 W (Figure 6a,b). Coarse α2 laths and thin βo laths grow from the primary grain boundary and form lamellar blocks. This microstructural feature is considered to be a result of the β → α transformation process and is called the Widmanstatten structure in titanium alloys [23]. Moreover, it is noted that extremely thin laths and some large particles precipitate from α2 and βo laths, respectively (Figure 7b), which are both identified as the γ phase via TEM observations (Figure 7c,d). These limited γ lath colonies are located in broad α2 laths and share a Blackburn orientation relationship with the matrix.

Figure 7.

Microstructure of the as-deposited specimen produced at 800 W. (a) OM shows a Widmanstatten microstructure; (b) SEM-BSE shows γ laths and particles precipitated from α2 and βo, respectively; (c,d) TEM bright-field images of the precipitated γ laths and particles.

4. Discussion

4.1. Influence of Al Content on Phase Transformation

The above chemical measurement indicates that an obvious Al loss happened during the DLD process as the laser power increased from 400 W to 800 W. Al loss is a common phenomenon resulting from the material being heated rapidly to a high peak temperature in the melt pool. Previous studies have demonstrated that the peak temperature can reach 2000 ~ 3000 °C [24,25], which is close to or even beyond the boiling point of Al. Thus, the evaporating behavior of Al would be extremely intense. Higher laser power would contribute to a higher peak temperature, eventually resulting in more Al loss.

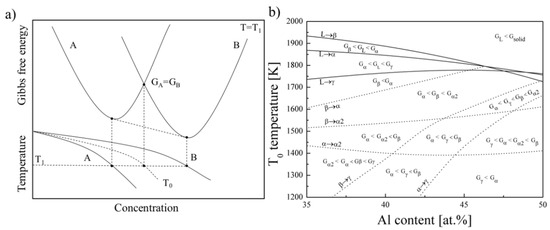

As for TiAl alloys, the eventual microstructure is sensitive to Al content; therefore, it is imperative to analyze the phase transformation process based on the Al content. Figure 8 presents a calculated phase selection hierarchy map constructed based on calculated T0 temperatures for the various phase transformations. Here, T0 represents the temperature at which the two phases with the same composition possess equal amounts of Gibbs free energy. Usually, for an equilibrium condition, the energy is coordinated to a minimum state by forming two phases with different compositions. However, under direct laser deposition, the diffusion process of solid phase transformation is strongly suppressed due to the extremely high cooling rate (103 K/s to 105 K/s), and a low-temperature phase is expected to form as soon as T < T0,A→B, where GB < GA (Figure 8a) [26]. As a result, the formed low-temperature phase is metastable and possesses relatively high energy. It will tend to transform to the equilibrium state when undergoing additional heat treatment. In considering the phase transformation during a rapid cooling process, the solidification pattern is closely related to three phase transformations, namely L → β, L → α, and L →γ, which are greatly influenced by the Al content. It has been shown that although all these T0 temperatures decrease with increases in Al content, their decreasing rate varies a lot, which contributes to three different choices when cooling from a liquid state. When increasing Al content from 35 at.% to 50 at.%, it was concluded that the liquid will primarily transform into β, α, and γ, respectively. However, when subsequently cooling from the β phase, β → α transformation is predominant because the T0 temperature for β → α is much higher than that of β → α2 or β → γ. However, competitive transformation will arise due to the different trends of the T0 temperatures for the α → γ and α → α2 phase transformations when increasing Al amounts. It is observed that T0, α → γ increases with increasing Al content, but T0, α → α2 shows an opposite tendency, which causes a different phase selection since Al-lean alloys usually experience an α → α2 ordering reaction, while Al-rich alloys are more likely to undergo massive α → γ transformation. This behavior has already been observed in solid phase transformation experiments when cooling from a single α phase region [14,27].

Figure 8.

(a) Schematic relation of Gibbs free energy, equilibrium phase diagram, and non-diffusion transformed T0 temperature. (b) Map of thermodynamic phase selection hierarchy as a function of temperature and composition based on the CALPHAD approach.

4.2. Microstructure Formation Mechanism

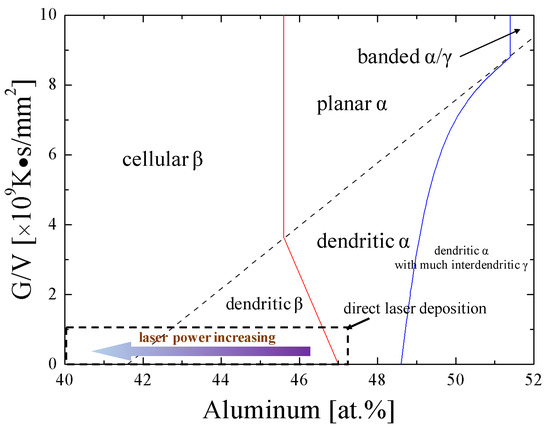

In this study, Al content decreased from 47% at.% to 40 at.% as the laser power was increased from 400 W to 800 W. The Al loss phenomenon would greatly affect the solidification pathways for TiAl alloys. According to previous reports [28,29], the microstructural morphology during solidification is a synergistic effect of the Al content and its solidifying condition. Figure 9 presents the microstructure selection map of the TiAl alloy constructed by Johnson [29]. The solidification microstructure is determined using the ratio of the temperature gradient (G) to the growth rate (V), as well as to the Al content. For the DLD process, G usually ranges from 105 to 5 × 105 K·m−1, and V ranges from 5 × 10−4 to 10−2 m·s−1, as reported by references [30,31]. Thus, G/V could be calculated as 107 to 109 m·s−1, located at the bottom of the microstructure selection map, as denoted by the dashed box in Figure 9. Conversely, due to the decrease in Al content, the solidification microstructure spans from a dendritic α zone to a dendritic β zone and even a cellular β zone, successively, which is in accordance with the BSE morphology observations.

Figure 9.

Microstructure selection map of TiAl alloy constructed by Johnson [18]. The green dashed box indicates that the microstructure spans three microstructure zones, dendritic α, dendritic β, and cellular β, with laser power increasing during the DLD process.

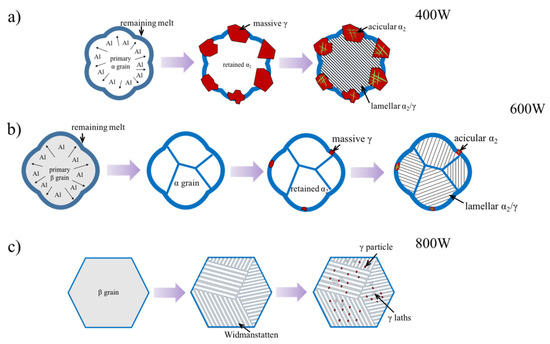

Considering the microstructure selection and phase transformation, the related microstructural evolution mechanism was determined, as schematically illustrated in Figure 10. Regarding the sample produced with a laser power of 400 W, the Al content remains at 47 at.%. The phase transformation can be reconstructed as follows: α is the dominant phase that first solidifies from the liquid in the form of hexagonal dendrites. Meanwhile, Al, as a stabilizer of the γ phase, is transported to the interdendrite zone, thus forming a dendritic segregation morphology. Subsequently, the inhomogeneity of the chemical composition will trigger regionally different phase transformations in the dendrite and interdendrite zones under the continuous cooling process. The α dendrite core where the Al content is low will transform into a retained α2 phase with an ordering reaction, but a massive γ phase will be generated at the interdendrite zone where Al accumulates. Then, under the reheating effect of multiple laser scanning, a straight γ lath and convoluted acicular α2 will precipitate from the retained α2 phase and massive transformed γ phase, respectively, with a Blackburn orientation relationship [32,33].

Figure 10.

Schematic of microstructure evolution mechanism during direct laser deposition with different laser powers: (a) 400 W, three stages occur for the convoluted microstructure formation: dendritic solidification with Al segregation, massive γ precipitation at the interdendrite region, and acicular α2 and α2/γ lath precipitation; (b) 600 W, four stages occur for the nearly full lamellar microstructure formation: dendritic solidification with Al segregation, β → α transformation, massive γ precipitation at interdendrite region, and acicular α2 and α2/γ lath precipitation; (c) 800 W, three stages occur for the Widmanstatten structure formation: solidification in forms of cellular, Widmanstatten lath precipitation, and γ particle and α2/γ lath precipitation.

When the laser power increases to 600 W, Al is slightly evaporated, which leads to a modification of the phase transformation (Figure 10b). The primary solidified phase turns to the β phase and will nucleate and grow in the form of an orthogonal dendrite. At the same time, Al will be enriched in interdendrite regions. During the subsequent cooling process, a β → α transformation happens first, and then α → α2 and α → γ transformations take place due to the local fluctuation of the chemical composition. It is worth mentioning that the massive γ is much smaller than that obtained with a laser power of 400 W, because the Al loss effect suppresses the tendency for α → γ transformations and eventually, a nearly full α2/γ lamellar microstructure will be achieved under the reheating effect of laser scanning.

When the laser power increases to 800 W, Al is significantly evaporated due to the higher peak temperature in the melt pool, and the primary β phase is solidified as cellular grains (Figure 10c). During the rapid cooling process, α laths precipitate from the initial β cellular grains and form an α/β Widmanstatten microstructure, followed by two ordering transformations: α → α2 and β → βo. It is rational that no massive transformed γ phase will occur due to the low Al content thoroughly suppressing the α → γ transformation. However, because the phase transformation energy is larger than , there is a high probability of γ precipitation in the β phase when it experiences a reheating process. In addition, some γ lath colonies will also form within α2 laths.

4.3. Microstructure Tailoring by Direct Laser Deposition

Previous studies have proven that the mechanical properties of TiAl alloys are sensitive to their microstructures [34,35]. The original strategy for tailoring a microstructure via direct laser deposition involves trying to accurately control the thermal history, which is of great difficulty for this sophisticated process. According to the present study, we conclude that the Al content plays an equal or more important role in microstructural evolution, which can be accurately modified by specifying the laser power. Both β and α solidification can be realized, α2 can be retained, and massive transformed γ and a near fully α2/γ lamellar structure can be achieved. Moreover, with the use of a rapid cooling process, the ultimate microstructure size is restricted to a very small level compared with those obtained through a casting process [33], which will benefit the mechanical properties of TiAl alloys according to a modified Hall–Petch-type function proposed by Dimiduk [36]:

where is the uniaxial yield stress of TiAl-based alloys with polycrystalline lamellar structures, is the intrinsic strength of the γ phase, is the colony size, and is the lath width. Meanwhile, the nanoscale lath width provides a high density of coherent boundaries, which not only obstruct the transmission of dislocations but also serve as sources or sinks of dislocations that can release the stress concentration [37], which might positively contribute to enhancing the strength and ductility. The present microstructural investigations will promote the understanding of AM TiAl alloys and benefit the tailoring of as-deposited microstructures.

5. Conclusions

TiAl alloys with different microstructures were produced with increasing laser powers, and the following conclusions were derived from the microstructure characterizations and thermodynamic analysis:

A convoluted microstructure, nearly all consisting of an α2/γ lamellar structure and an α2/β Widmanstatten structure, were obtained with increasing laser powers.

Al evaporation is easy via direct laser deposition. When the laser power increases to 800 W, Al loss can even reach 7 at.%, which is thought to significantly affect the phase transformation thermodynamics.

When the laser power is 400 W, the convoluted microstructure evolution follows three stages: (i) dendritic α solidification with Al aggregating to the interdendrite region; (ii) massive γ precipitation at the interdendrite region; and (iii) α2/γ lath precipitation in the dendrite region and acicular α2 precipitation in massive γ.

When the laser power is 600 W, the nearly fully lamellar microstructure evolves in the following four stages: (i) dendritic β solidification with Al aggregating to the interdendrite region; (ii) β → α transformation; (iii) a small amount of massive γ precipitation in the interdendrite region; and (iv) α2/γ lath precipitation and acicular α2 precipitation in massive γ.

When the laser power is 800 W, the Widmanstatten structure evolves following three stages: (i) cellular β solidification; (ii) Widmanstatten lath precipitation; and (iii) γ particle and α2/γ lath precipitation.

Author Contributions

Conceptualization, X.Z., C.L. and J.G.; methodology, X.Z. and C.L.; investigation, X.Z. and C.L.; writing—original draft, X.Z.; writing—review and editing, C.L. and J.G.; supervision, J.G.; funding acquisition, X.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation for Young Scientists of China (Grant No. 52101139).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Imayev, V.M.; Trofimov, D.M.; Imayev, R.M. Microstructure, mechanical properties and oxidation resistance of β-solidifying γ-TiAl based alloys. Intermetallics 2025, 176, 108556. [Google Scholar]

- Chen, G.; Peng, Y.; Zheng, G.; Qi, Z.; Wang, M.; Yu, H.; Dong, C.; Liu, C.T. Polysynthetic twinned TiAl single crystals for high-temperature applications. Nat. Mater. 2016, 15, 876–881. [Google Scholar] [PubMed]

- Talignani, A.; Seede, R.; Whitt, A.; Zheng, S.; Ye, J.; Karaman, I.; Kirka, M.M.; Katoh, Y.; Wang, Y.M. A review on additive manufacturing of refractory tungsten and tungsten alloys. Addit. Manufac. 2022, 58, 103009. [Google Scholar]

- Chen, Y.; Mao, Y.; Jiang, M.; Chen, X.; Wei, H.; Han, T.; Wang, Z.; Lei, Z.; He, P.; Chen, Y. Achieving columnar to equiaxed transition in the as-deposited condition via coaxial wire feeding during laser directed energy deposition of Ti-6Al-4V. Addit. Manuf. 2025, 102, 104732. [Google Scholar]

- Kelly, S.M.; Kampe, S.L. Microstructural evolution in laser-deposited multilayer Ti-6Al-4V builds: Part II. Thermal modeling. Metall. Mater. Trans. A 2004, 35, 1869–1879. [Google Scholar]

- June, D.; Mayeur, J.R.; Gradl, P.; Wessman, A.; Hazeli, K. Effects of size, geometry, and testing temperature on additively manufactured Ti-6Al-4V titanium alloy. Addit. Manuf. 2024, 80, 103970. [Google Scholar]

- Xu, W.; Lui, E.W.; Pateras, A.; Qian, M.; Brandt, M. In situ, tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance. Acta Mater. 2017, 125, 390–400. [Google Scholar]

- Zhang, X.; Li, C.; Zheng, M.; Yang, X.; Ye, Z.; Gu, J. Chemical, microstructure, and mechanical property of TiAl alloys produced by high-power direct laser deposition. J. Mater. Sci. Tech. 2022, 117, 99–108. [Google Scholar]

- Wang, L.; Shen, C.; Zhang, Y.; Li, F.; Zhou, W.; Xin, J.; Ding, Y.; Hua, X. Microstructure modification of twin-wire directed energy deposition-arc fabricated γ-TiAl alloy via deposition current control. Mater. Sci. Eng. A 2022, 856, 144028. [Google Scholar]

- Cheng, F.; Wang, H.; Wu, Y.; Ma, X.; Wang, J.; Yang, J.; Cheng, X. Microstructure evolution and tensile property of TiAl alloy using continuous direct energy deposition technique. J. Alloys Compd. 2022, 906, 164309. [Google Scholar]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Schwerdtfeger, J.; Körner, C. Selective electron beam melting of Ti–48Al–2Nb–2Cr: Microstructure and aluminium loss. Intermetallics 2014, 49, 29–35. [Google Scholar] [CrossRef]

- Cormier, D.; Harrysson, O.; Mahale, T.; West, H. Freeform Fabrication of Titanium Aluminide via Electron Beam Melting Using Prealloyed and Blended Powders. Adv. Mater. Sci. Eng. 2014, 2007, 1687–6822. [Google Scholar] [CrossRef]

- Jung, J.Y.; Park, J.K.; Chun, C.H. Influence of Al content on cast microstructures of Ti–Al intermetallic compounds. Intermetallics 1990, 7, 1033–1041. [Google Scholar] [CrossRef]

- Zhang, X.; Li, C.; Wu, M.; Ye, Z.; Wang, Q.; Gu, J. Atypical pathways for lamellar and twinning transformations in rapidly solidified TiAl alloy. Acta Mater. 2022, 227, 117718. [Google Scholar] [CrossRef]

- Yang, G.; Kou, H.; Yang, J.; Li, J.; Fu, H. Microstructure control of Ti-45Al-8.5Nb-(W, B, Y) alloy during the solidification process. Acta Mater. 2016, 12, 121–131. [Google Scholar] [CrossRef]

- Flemings, M.C. Solidification Processing; McGraw-Hill: New York, NY, USA, 2013. [Google Scholar]

- Denquin, A.; Naka, S. Phase transformation mechanisms involved in two-phase TiAl-based alloys—I. Lamellar structure formation. Acta Mater. 1990, 44, 343–352. [Google Scholar] [CrossRef]

- Denquin, A.; Naka, S. Phase transformation mechanisms involved in two-phase TiAl-based alloys—II. Discontinuous coarsening and massive-type transformation. Acta Mater. 1996, 44, 353–365. [Google Scholar] [CrossRef]

- Hu, D.; Huang, A.J.; Wu, X. On the massive phase transformation regime in TiAl alloys: The alloying effect on massive/lamellar competition. Intermetallics 2007, 15, 327–332. [Google Scholar] [CrossRef]

- Dey, S.R.; Hazotte, A.; Bouzy, E. Crystallography and phase transformation mechanisms in TiAl-based alloys—A synthesis. Intermetallics 2009, 17, 1052–1064. [Google Scholar] [CrossRef]

- Clemens, H.; Bartels, A.; Bystrzanowski, S.; Chladil, H.; Leitner, H.; Dehm, G.; Gerling, G.; Schimansky, F.P. Grain refinement in γ-TiAl-based alloys by solid state phase transformations. Intermetallics 2006, 14, 1380–1385. [Google Scholar]

- Pinz, M.; Storck, S.; Montalbano, T.; Croom, B.; Salahudin, N.; Trexler, M.; Ghosh, S. Efficient computational framework for image-based micromechanical analysis of additively manufactured Ti-6Al-4V alloy. Addit. Manufact. 2022, 60, 103269. [Google Scholar]

- Cao, T.; Chen, C.; Wang, W.; Zhao, R.; Lu, X.; Yin, S.; Xu, S.; Hu, T.; Shuai, S.; Wang, J.; et al. Evolution of microstructure and mechanical property of Ti-47Al-2Cr-2Nb intermetallic alloy by laser direct deposition: From a single track, thin-wall to bulk. Mater. Charact. 2022, 190, 112053. [Google Scholar]

- Knorlein, J.; Franke, M.M.; Schloffer, M.; Korner, C. In-situ aluminum control for titanium aluminide via electron beam powder bed fusion to realize a dual microstructure. Addit. Manufact. 2022, 59, 103132. [Google Scholar]

- Valencia, J.J.; McCullough, C.; Levi, C.G.; Mehrabian, R. Solidification microstructure of supercooled Ti-Al alloys containing intermetallic phases. Acta Metall. 1989, 37, 2517–2530. [Google Scholar]

- Prasad, U.; Chaturvedi, M.C. Influence of alloying elements on the kinetics of massive transformation in gamma titanium aluminides. Metall. Mater. Trans. A 2003, 34, 2053–2066. [Google Scholar]

- Hunziker, O.; Vandyoussefi, M.; Kurz, W. Phase and microstructure selection in peritectic alloys close to the limit of constitutional undercooling. Acta Mater. 1998, 46, 6325–6336. [Google Scholar] [CrossRef]

- Johnson, D.R.; Omiya, Y.; Yamanaka, Y. Microstructural development during directional solidification of α-seeded TiAl alloys. Acta Mater. 2006, 54, 1077–1085. [Google Scholar] [CrossRef]

- Fallah, V.; Amoorezaei, M.; Provatas, N.; Corbin, S.F.; Khajepour, A. Phase-field simulation of solidification morphology in laser powder deposition of Ti–Nb alloys. Acta Mater. 2012, 60, 1633–1646. [Google Scholar]

- Ren, Y.M.; Lin, X.; Fu, X.; Tan, H.; Chen, J.; Huang, W.D. Microstructure and deformation behavior of Ti-6Al-4V alloy by high-power laser solid forming. Acta Mater. 2017, 132, 82–95. [Google Scholar]

- Guyon, J.; Hazotte, A.; Bouzy, E. Evolution of metastable α phase during heating of Ti48Al2Cr2Nb intermetallic alloy. J. Alloys Compd. 2015, 656, 667–675. [Google Scholar]

- Guyon, J.; Hazotte, A.; Wagner, F.; Bouzy, E. Recrystallization of coherent nanolamellar structures in Ti48Al2Cr2Nb intermetallic alloy. Acta Mater. 2016, 103, 672–680. [Google Scholar] [CrossRef]

- Appel, F.; Brossmann, U.; Christoph, U.; Eggert, S.; Janschek, P.; Lorenz, U.; Mullauer, J.; Oehring, M.; Paul, J.D.H. Recent Progress in the Development of Gamma Titanium Aluminide Alloys. Adv. Eng. Mater. 2010, 2, 699–720. [Google Scholar]

- Clemens, H.; Mayer, S. Design, Processing, Microstructure, Properties, and Applications of Advanced Intermetallic TiAl Alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar]

- Dimiduk, D.M.; Hazzledine, P.M.; Parthasarathy, T.A.; Mendiratta, M.G.; Seshagiri, S. The role of grain size and selected microstructural parameters in strengthening fully lamellar TiAl alloys. Metall. Mater. Trans. A 1998, 29, 37–47. [Google Scholar]

- Lu, K.; Lu, L.; Suresh, S. Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science 2009, 324, 349–352. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).