Effect of Notches on Fatigue Crack Initiation and Early Propagation Behaviors of a Ni-Based Superalloy at Elevated Temperatures

Abstract

1. Introduction

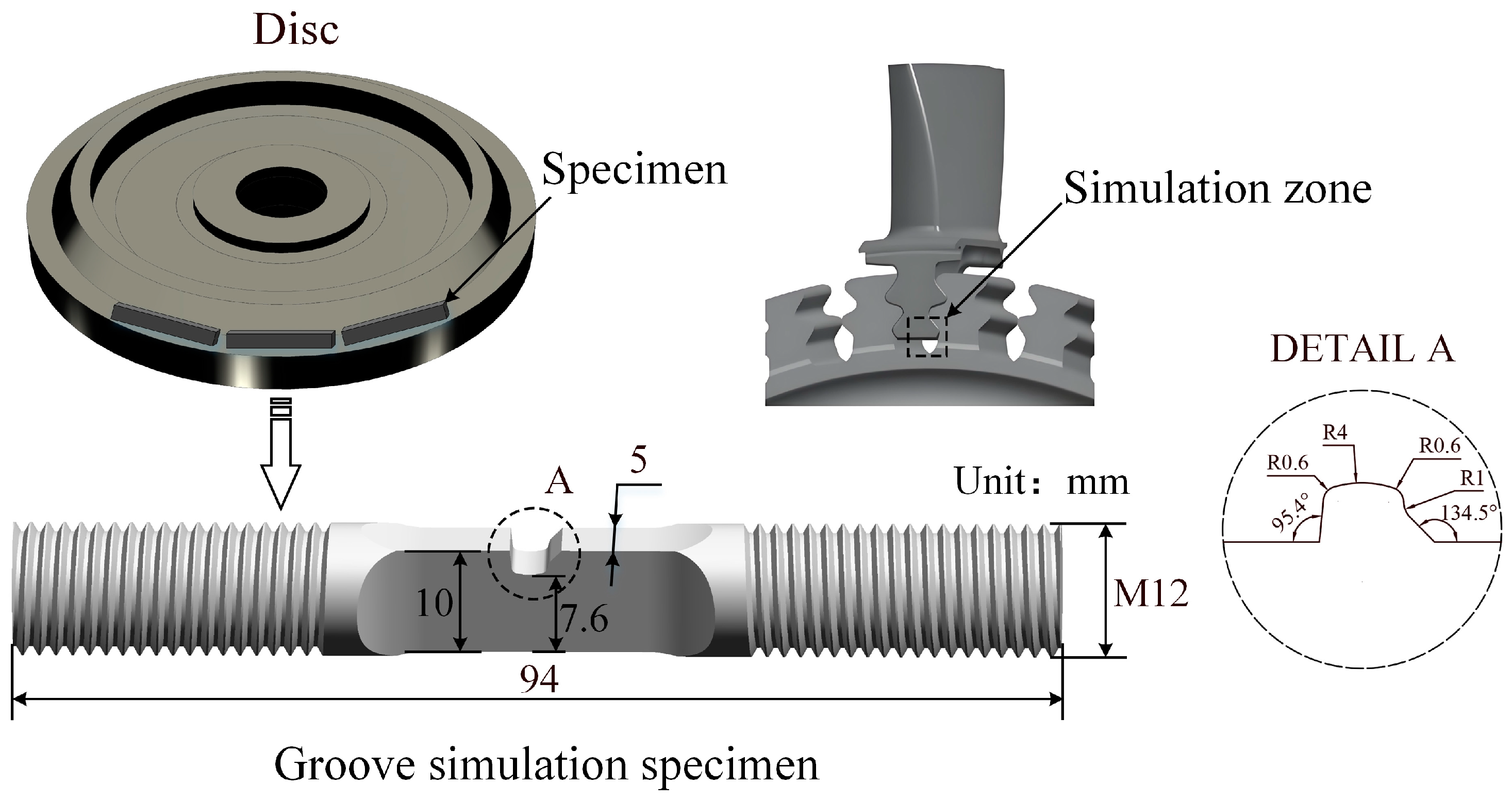

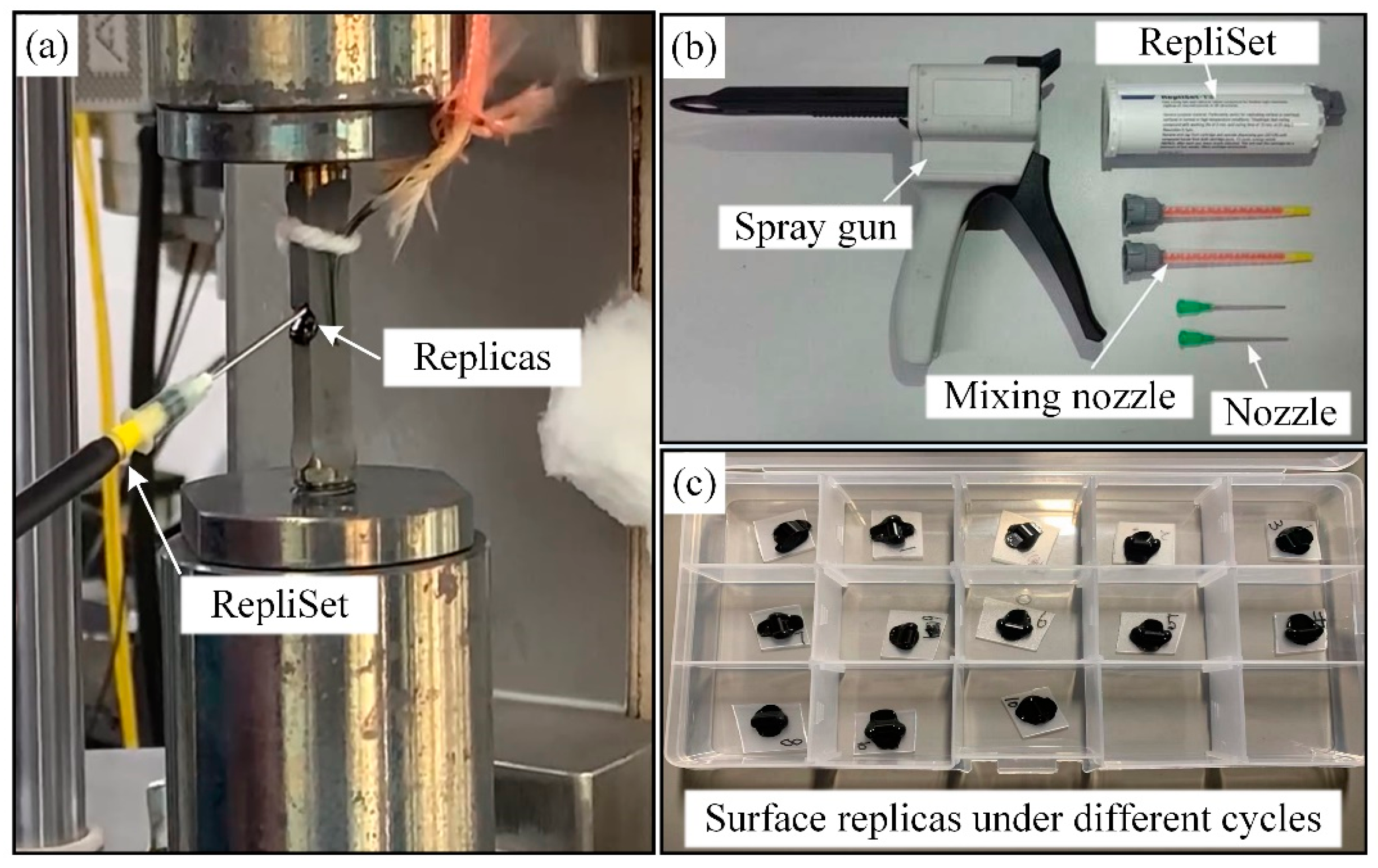

2. Materials and Methods

2.1. Materials

2.2. Experimental Procedure

3. Results

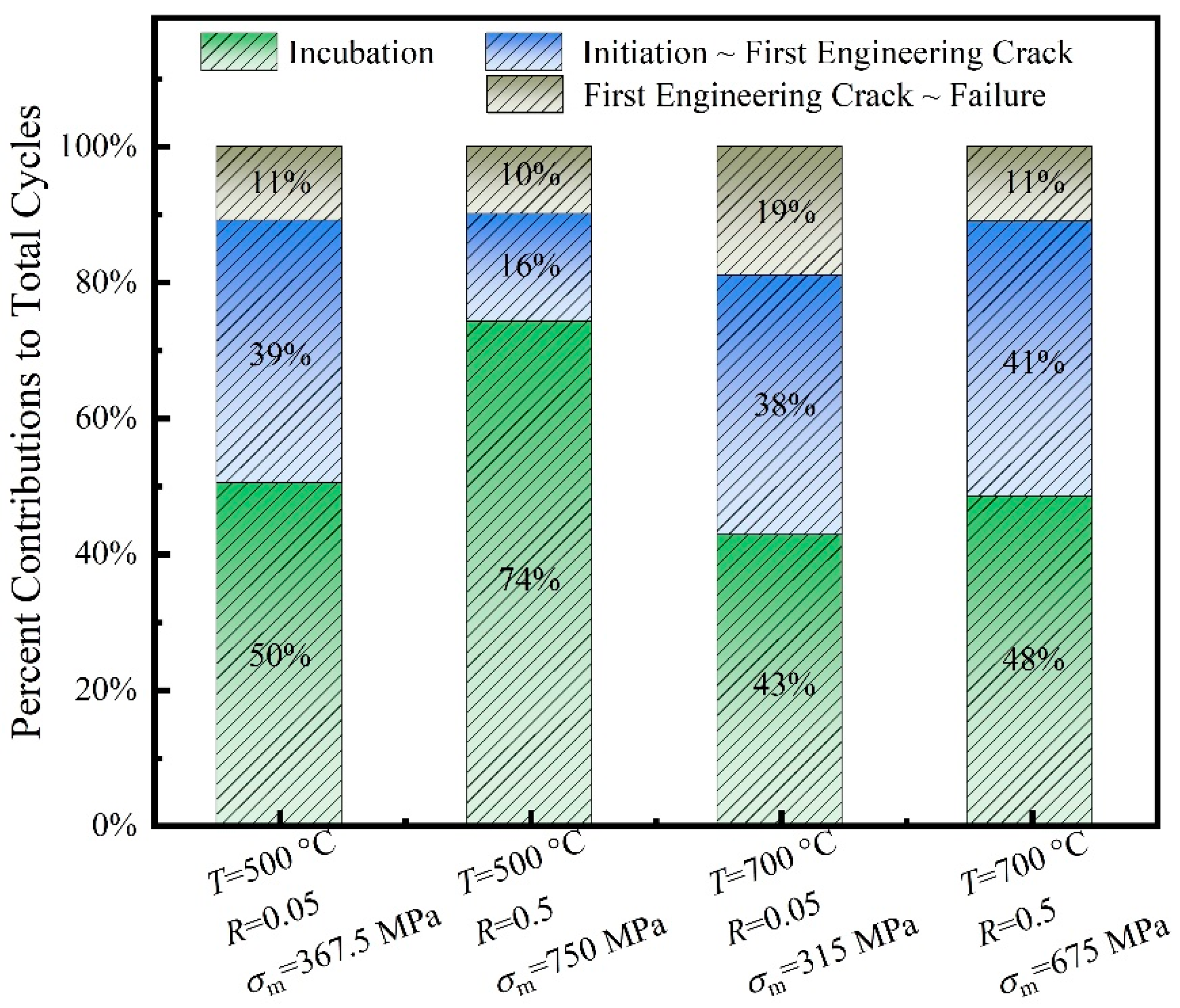

3.1. Fatigue Life

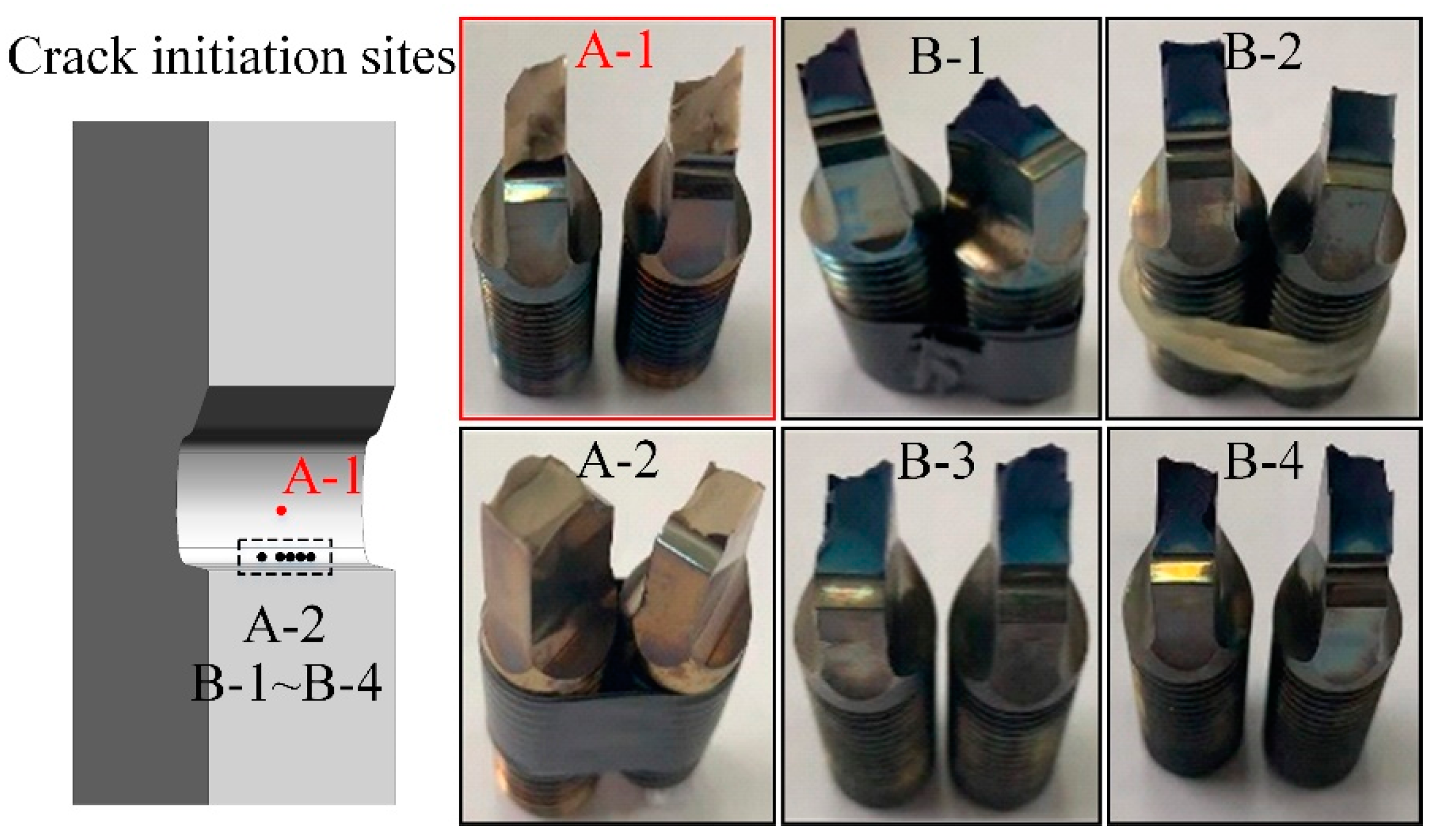

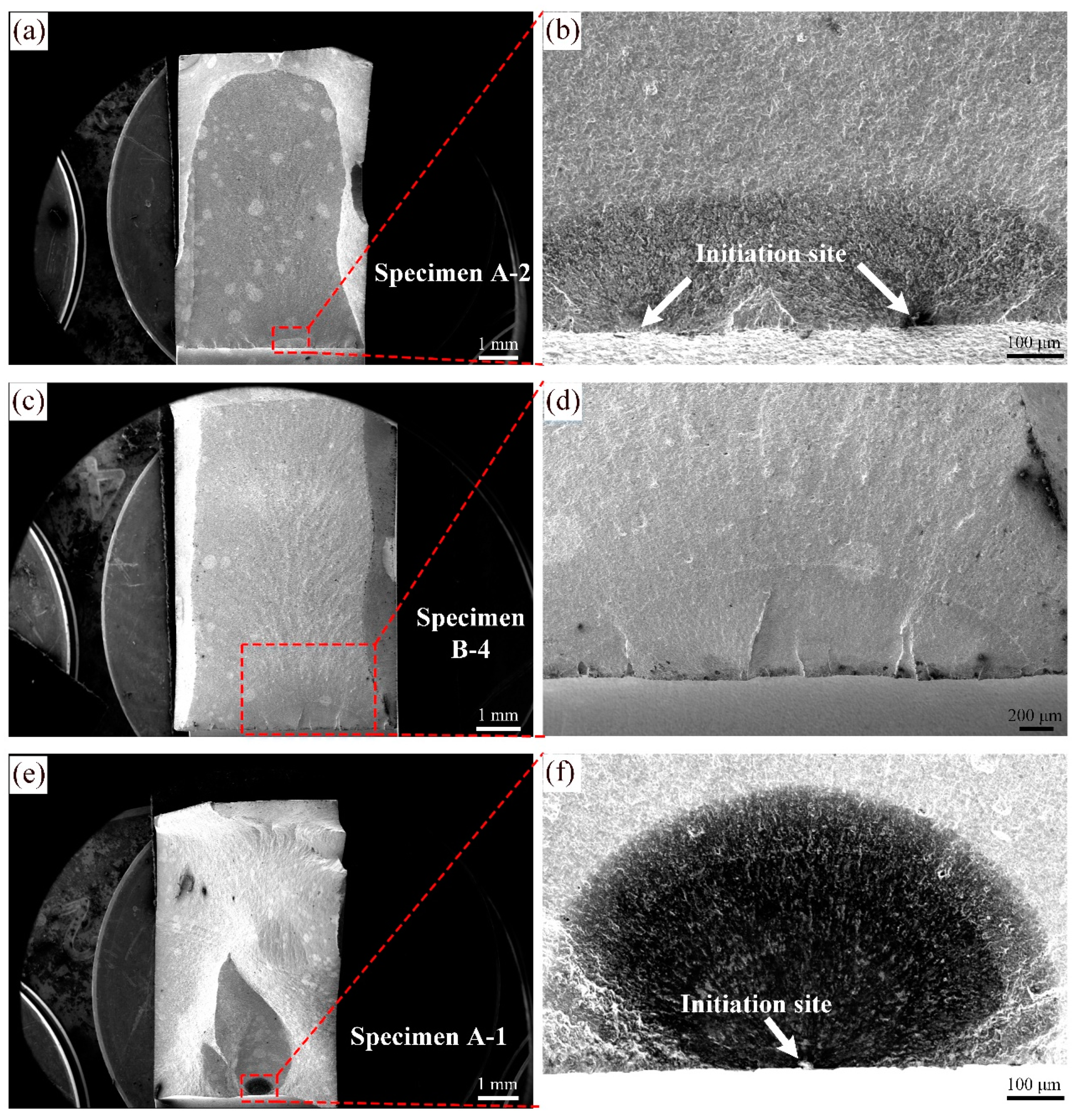

3.2. Crack Initiation

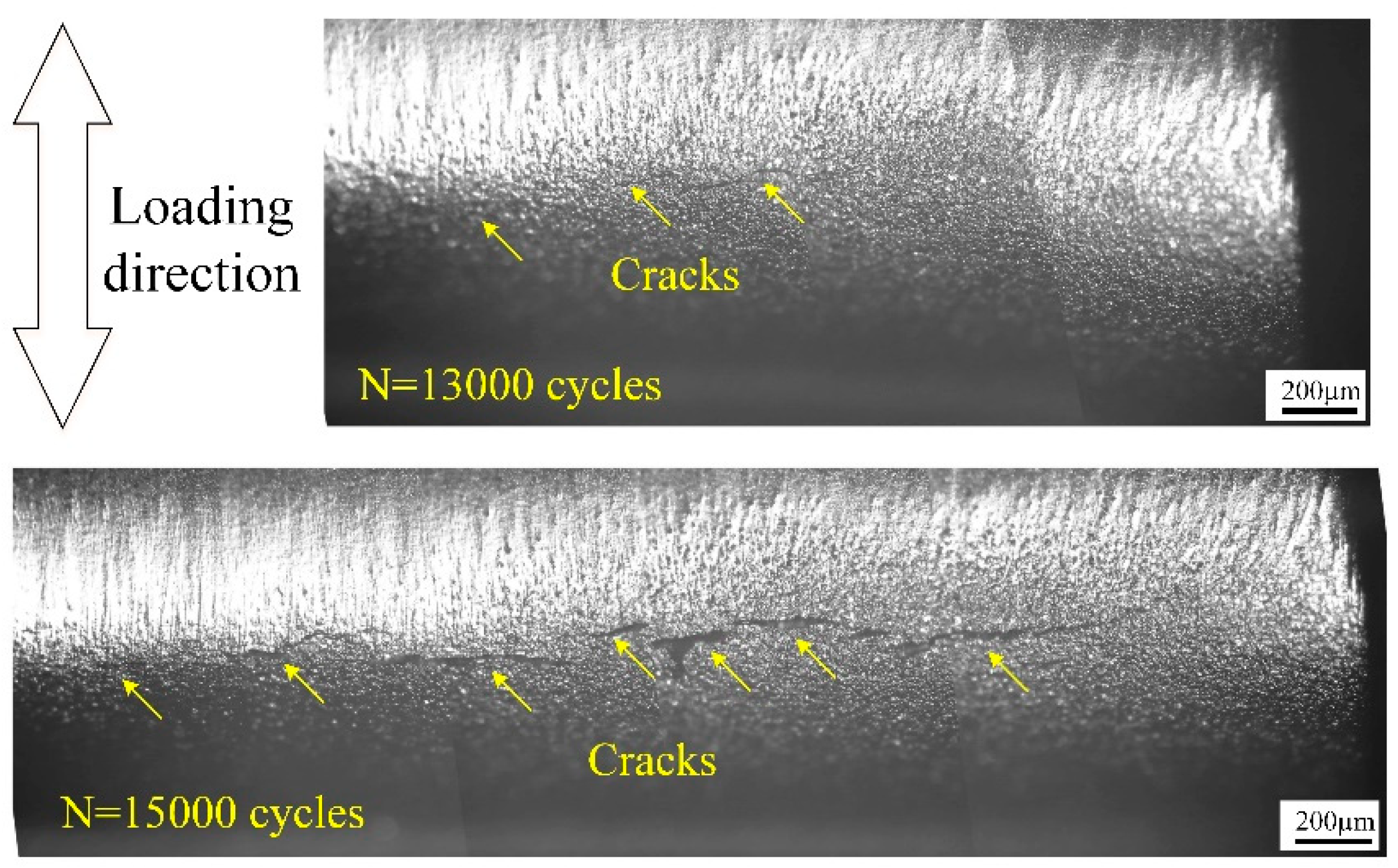

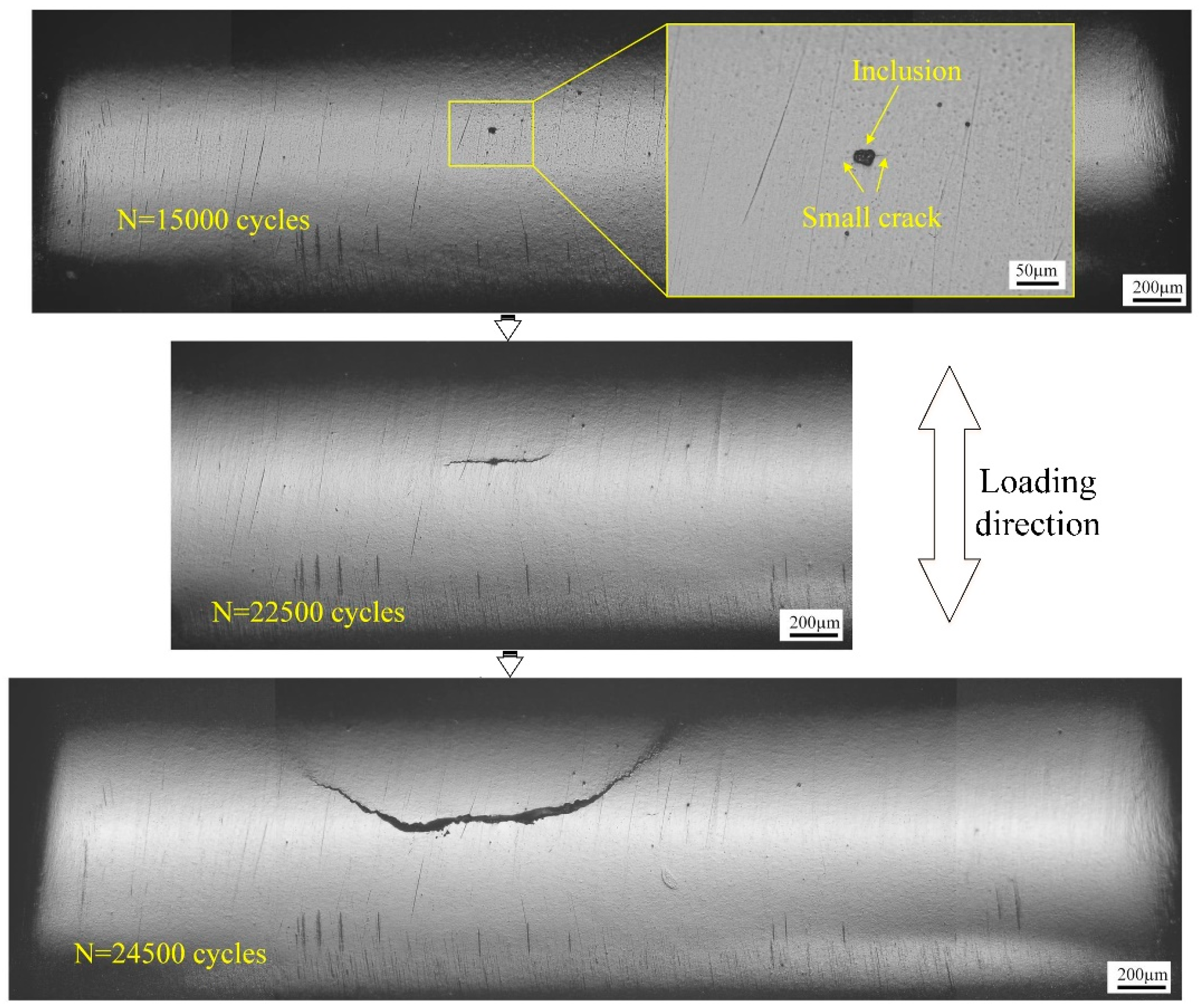

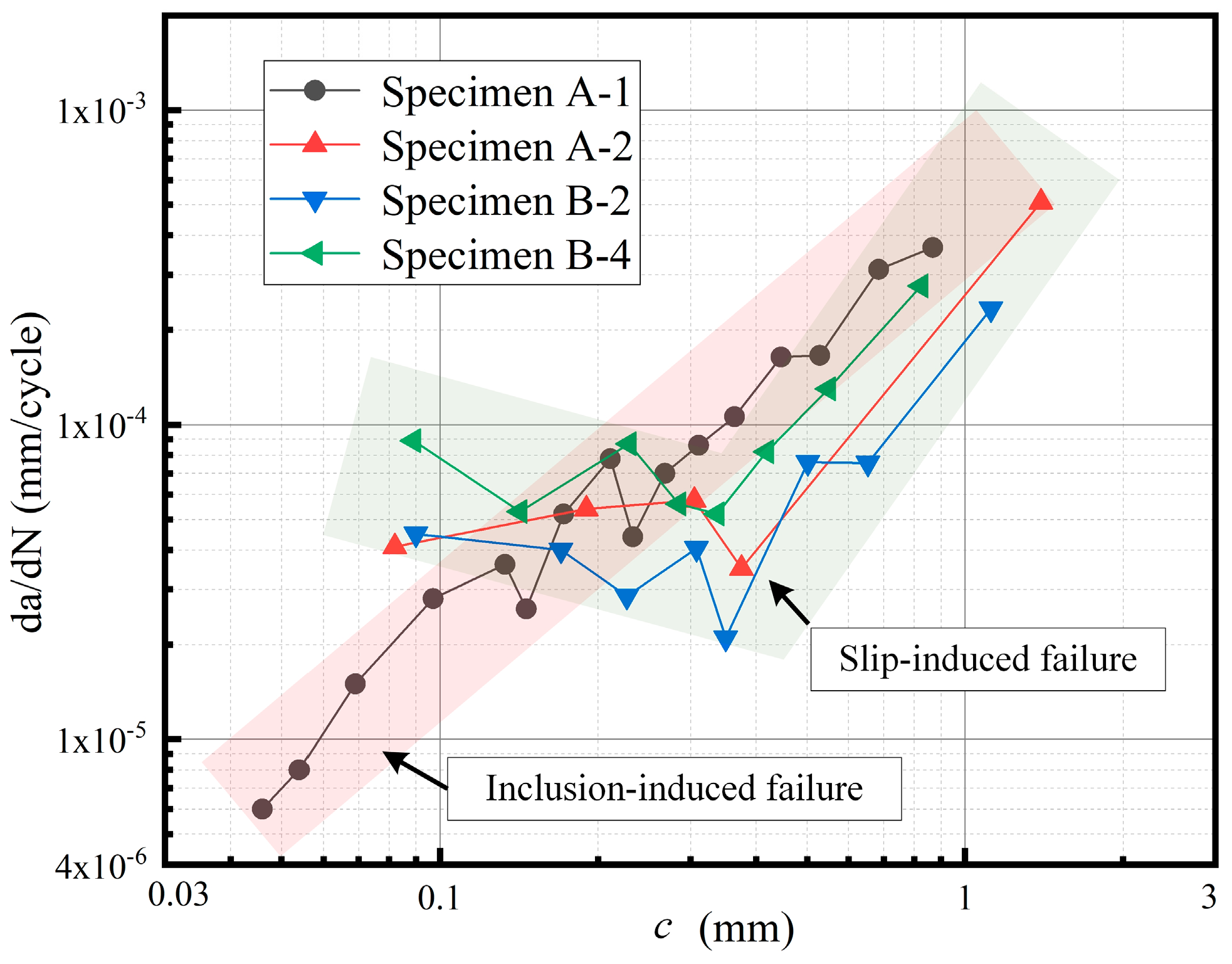

3.3. Crack Propagation

4. Discussion

4.1. Competing Crack Initiation Modes

4.2. Effect of Initiation Modes on Crack Growth Behavior

5. Conclusions

- (1)

- For groove simulation specimens, temperature increases significantly affect the proportion of fatigue crack initiation life, but have less impact on the time it takes for cracks to grow to First Engineering Crack size. When the temperature increases from 500 °C to 700 °C, the crack initiation life proportion decreases from around 50–75% to 40–50%, while the life ratio for cracks reaching First Engineering Crack size remains relatively constant, at about 81–90%.

- (2)

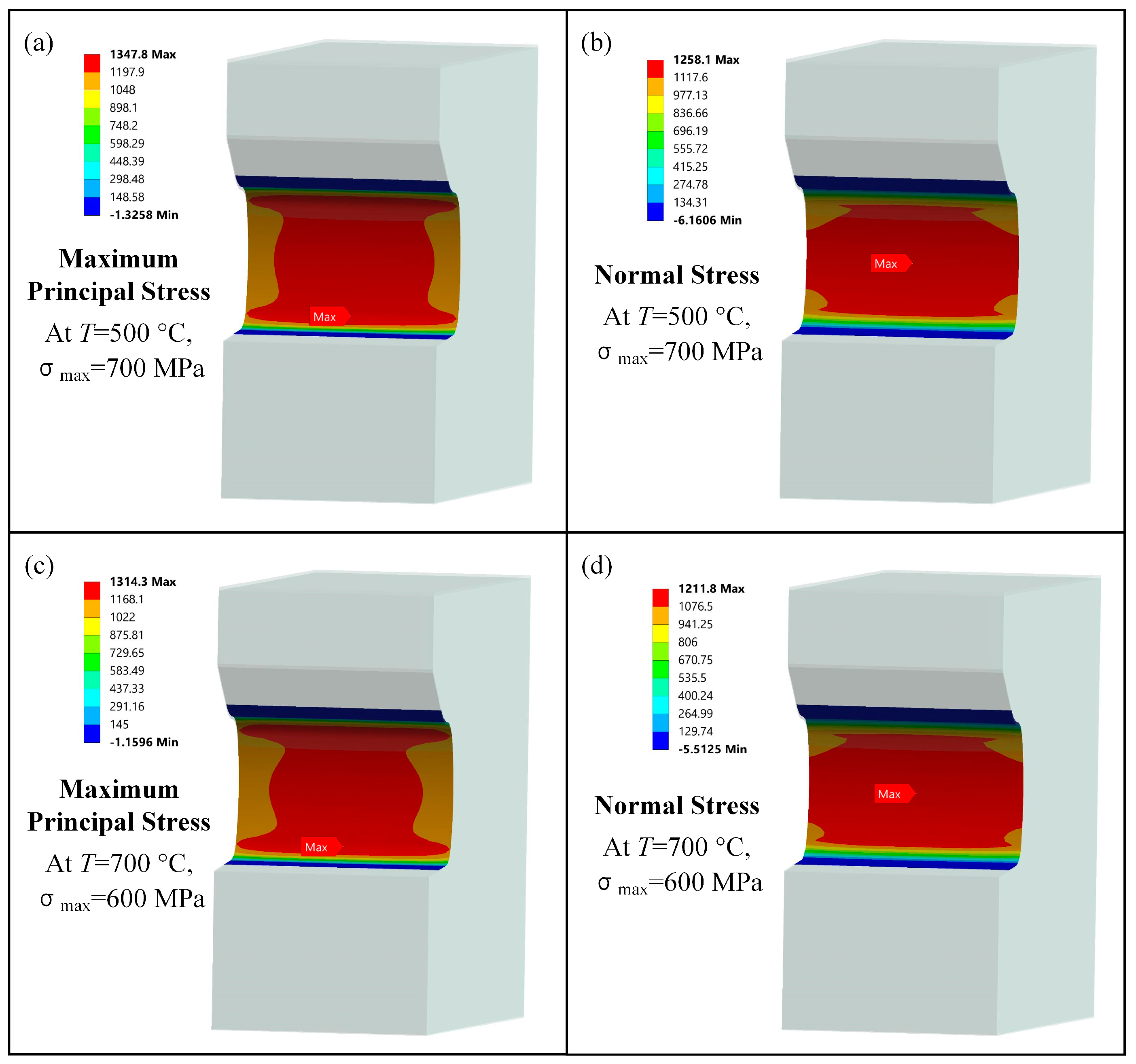

- The primary factors governing fatigue crack initiation sites in simulation specimens are the maximum principal stress and surface inclusions. The fatigue cracks tend to originate at the location of maximum principal stress, rather than the location of maximum normal stress at the notch root. Furthermore, the presence of surface inclusions is also a significant factor in determining where cracks initiate.

- (3)

- The main cause of the reduction in small-crack growth rate as crack length increases is the shielding by the cracks around the main crack. As cracks grow to a certain size, the shielding effect weakens, while the crack coalescence becomes more pronounced, resulting in a rapid acceleration of the crack growth rate.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sreenu, B.; Sarkar, R.; Kumar, S.S.S.; Chatterjee, S.; Rao, G.A. Microstructure and mechanical behaviour of an advanced powder metallurgy nickel base superalloy processed through hot isostatic pressing route for aerospace applications. Mater. Sci. Eng. A 2020, 797, 140254. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Y.Z.; Yu, Z.W.; Jiang, R.; Baxevanakis, K.P.; Roy, A.; Zhao, L.G.; Tian, G.F.; Song, Y.D. Thermo-mechanical fatigue crack growth in a nickel-based powder metallurgy superalloy. Int. J. Fatigue 2024, 186, 108413. [Google Scholar] [CrossRef]

- Jiang, J.; Yang, J.; Zhang, T.; Zou, J.; Wang, Y.; Dunne, F.P.E.; Britton, T.B. Microstructurally sensitive crack nucleation around inclusions in powder metallurgy nickel-based superalloys. Acta Mater. 2016, 117, 333–344. [Google Scholar] [CrossRef]

- Shi, Y.; Yang, X.G.; Yang, D.D.; Shi, D.Q.; Miao, G.L.; Wang, Z.F. Evaluation of the influence of surface crack-like defects on fatigue life for a P/M nickel-based superalloy FGH96. Int. J. Fatigue 2020, 137, 105639. [Google Scholar] [CrossRef]

- Hu, D.Y.; Wang, T.; Ma, Q.H.; Liu, X.; Shang, L.H.; Li, D.; Pan, J.C.; Wang, R.Q. Effect of inclusions on low cycle fatigue lifetime in a powder metallurgy nickel-based superalloy FGH96. Int. J. Fatigue 2019, 118, 237–248. [Google Scholar] [CrossRef]

- Xu, C.; Yao, Z.H.; Dong, J.X.; Jiang, Y.J. Mechanism of high-temperature oxidation effects in fatigue crack propagation and fracture mode for FGH97 superalloy. Rare Met. 2019, 38, 642–652. [Google Scholar] [CrossRef]

- Li, Z.; He, Y.; Xu, G.; Shi, D.; Yang, G. A fatigue life estimation approach considering the effect of geometry and stress sensitivity. Theor. Appl. Fract. Mech. 2021, 112, 102915. [Google Scholar] [CrossRef]

- Bache, M.R.; Hanlon, J.O.; Child, D.J.; Hardy, M.C. High temperature fatigue behaviour in an advanced nickel based superalloy: The effects of oxidation and stress relaxation at notches. Theor. Appl. Fract. Mech. 2016, 84, 64–67. [Google Scholar] [CrossRef]

- Telesman, J.; Gabb, T.P.; Ghosn, L.J.; Gayda, J. Effect of notches on creep–fatigue behavior of a P/M nickel-based superalloy. Int. J. Fatigue 2016, 87, 311–325. [Google Scholar] [CrossRef]

- Stinville, J.C.; Martin, E.; Karadge, M.; Ismonov, S.; Soare, M.; Hanlon, T.; Sundaram, S.; Echlin, M.P.; Callahan, P.G.; Lenthe, W.C.; et al. Fatigue deformation in a polycrystalline nickel base superalloy at intermediate and high temperature: Competing failure modes. Acta Mater. 2018, 152, 16–33. [Google Scholar]

- Connolley, T.; Reed, P.; Starink, J.M. Short crack initiation and growth at 600 °C in notched specimens of Inconel 718. Mater. Sci. Eng. A 2003, 340, 139–154. [Google Scholar]

- Deng, G.J.; Tu, S.T.; Zhang, X.C.; Wang, Q.Q.; Qin, C.H. Grain size effect on the small fatigue crack initiation and growth mechanisms of nickel-based superalloy GH4169. Eng. Fract. Mech. 2015, 134, 433–450. [Google Scholar]

- Deng, G.J.; Tu, S.T.; Zhang, X.C.; Wang, J.; Zhang, C.C.; Qian, X.Y.; Wang, Y.N. Small fatigue crack initiation and growth mechanisms of nickel-based superalloy GH4169 at 650 °C in air. Eng. Fract. Mech. 2016, 153, 35–49. [Google Scholar]

- Kevinsanny; Okazaki, S.; Takakuwa, O.; Ogawa, Y.; Okita, K.; Funakoshi, Y.; Yamabe, J.; Matsuoka, S.; Matsunaga, H. Effect of defects on the fatigue limit of Ni-based superalloy 718 with different grain sizes. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1203–1213. [Google Scholar]

- Maenosono, A.; Koyama, M.; Tanaka, Y.; Rid, S.; Wang, Q.H. Crystallographic selection rule for the propagation mode of microstructurally small fatigue crack in a laminated Ti-6Al-4V alloy: Roles of basal and pyramidal slips. Int. J. Fatigue 2019, 128, 105200. [Google Scholar] [CrossRef]

- Wang, J.; Wang, R.Z.; Zhang, X.C.; Ye, Y.J.; Cui, Y.; Miura, H.; Tu, S.T. Multi-stage dwell fatigue crack growth behaviors in a nickel-based superalloy at elevated temperature. Eng. Fract. Mech. 2021, 253, 107859. [Google Scholar]

- Yang, Q.Z.; Yang, X.G.; Huang, W.Q.; Shi, Y.; Shi, D.Q. Small fatigue crack propagation rate and behaviours in a powder metallurgy superalloy: Role of stress ratio and local microstructure. Int. J. Fatigue 2022, 160, 106861. [Google Scholar]

- Pang, H.T.; Reed, P.A.S. Microstructure effects on high temperature fatigue crack initiation and short crack growth in turbine disc nickelbase superalloy udimet 720Li. Mater. Sci. Eng. A 2007, 448, 67–79. [Google Scholar]

- Newman, J.A.; Willard, S.A.; Smith, S.W.; Piascik, R.S. Replica-based crack inspection. Eng. Fract. Mech. 2009, 76, 898–910. [Google Scholar]

- Jordon, J.B.; Bernard, J.D.; Newman, J.C. Quantifying microstructurally small fatigue crack growth in an aluminum alloy using a silicon-rubber replica method. Int. J. Fatigue 2012, 36, 206–210. [Google Scholar]

- Zhu, L.; Wu, Z.R.; Hu, X.T.; Song, Y.D. Investigation of small fatigue crack initiation and growth behaviour of nickel base superalloy GH4169. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 1150–1160. [Google Scholar]

- Corran, R.S.J.; Williams, S.J. Lifing methods and safety criteria in aero gas turbines. Eng. Fail. Anal. 2007, 14, 518–528. [Google Scholar] [CrossRef]

- Carroll, L.J.; Cabet, C.; CarrollM, C.; Wright, R.N. The development of microstructural damage during high temperature creep-fatigue of a nickel alloy. Int. J. Fatigue 2013, 47, 115–125. [Google Scholar] [CrossRef]

- Hu, X.A.; Shi, D.Q.; Yang, X.G. Thermomechanical fatigue experimental study on a notched directionally solidified Ni-base superalloy. Mater. Sci. Eng. A 2016, 674, 451–458. [Google Scholar]

- Sansoz, F.; Brethes, B.; Pineau, A. Propagation of short fatigue cracks from notches in a Ni base superalloy: Experiments and modelling. Fatigue Fract. Eng. Mater. Struct. 2022, 25, 41–53. [Google Scholar] [CrossRef]

- Pang, H.T.; Reed, P.A.S. Fatigue crack initiation and short crack growth in nickel-base turbine disc alloys—The effects of microstructure and operating parameters. Int. J. Fatigue 2003, 25, 1089–1099. [Google Scholar]

- Caton, M.J.; Jha, S.K. Small fatigue crack growth and failure mode transitions in a Ni-base superalloy at elevated temperature. , Int. J. Fatigue 2010, 32, 1461–1472. [Google Scholar] [CrossRef]

- Telesmana, J.; Gabba, T.P.; Kantzosb, P.T.; Bonacusea, P.J.; Barriec, R.L.; Kantzos, C.A. Effect of a large population of seeded alumina inclusions on crack initiation and small crack fatigue crack growth in Udimet 720 nickel-base disk superalloy. Int. J. Fatigue 2021, 142, 105953. [Google Scholar] [CrossRef]

- Pineau, A.; Antolovich, S.D. High temperature fatigue of nickel-base superalloys—A review with special emphasis on deformation modes and oxidation. Eng. Fail. Anal. 2009, 16, 2668–2697. [Google Scholar]

- Shin, C.S.; Smith, R.A. Fatigue crack growth at stress concentrations–the role of notch plasticity and crack closure. Eng. Fract. Mech. 1988, 29, 201–315. [Google Scholar] [CrossRef]

- Yuan, S.H.; Wang, Y.R.; Wei, D.S. Experimental investigation on low cycle fatigue and fracture behavior of a notched Ni-based superalloy at elevated temperature. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 1002–1012. [Google Scholar] [CrossRef]

- Jiang, R.; Song, Y.D.; Reed, P.A. Fatigue crack growth mechanisms in powder metallurgy Ni-based superalloys-A review. Int. J. Fatigue 2020, 141, 105887. [Google Scholar] [CrossRef]

| Temperature [°C] | Yield Strength [MPa] | Ultimate Tensile Strength [MPa] |

|---|---|---|

| 500 | 1129 | 1591 |

| 700 | 1106 | 1276 |

| Specimen ID | T [°C] | σmax [MPa] | R | Nf | Nini | cini [μm] | Nini/Nf | Nc | Nc/Nf | Test Conditions |

|---|---|---|---|---|---|---|---|---|---|---|

| A-1 | 500 | 700 | 0.05 | 25,853 | 13,000 | 40 | 50% | 23,019 | 89% | Replica |

| A-2 | 500 | 1000 | 0.5 | 40,438 | 30,000 | 82 | 74% | 36,424 | 90% | Replica |

| B-1 | 700 | 600 | 0.05 | 22,265 | - | - | - | - | - | Non-replica |

| B-2 | 700 | 600 | 0.05 | 32,839 | 14,000 | 90 | 43% | 26,599 | 81% | Replica |

| B-3 | 700 | 1000 | 0.5 | 8650 | - | - | - | - | - | Non-replica |

| B-4 | 700 | 900 | 0.5 | 16,537 | 8000 | 89 | 48% | 14,701 | 89% | Replica |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Hu, X.; Guo, Z. Effect of Notches on Fatigue Crack Initiation and Early Propagation Behaviors of a Ni-Based Superalloy at Elevated Temperatures. Metals 2025, 15, 384. https://doi.org/10.3390/met15040384

Zhao Z, Hu X, Guo Z. Effect of Notches on Fatigue Crack Initiation and Early Propagation Behaviors of a Ni-Based Superalloy at Elevated Temperatures. Metals. 2025; 15(4):384. https://doi.org/10.3390/met15040384

Chicago/Turabian StyleZhao, Zuopeng, Xuteng Hu, and Zhiwei Guo. 2025. "Effect of Notches on Fatigue Crack Initiation and Early Propagation Behaviors of a Ni-Based Superalloy at Elevated Temperatures" Metals 15, no. 4: 384. https://doi.org/10.3390/met15040384

APA StyleZhao, Z., Hu, X., & Guo, Z. (2025). Effect of Notches on Fatigue Crack Initiation and Early Propagation Behaviors of a Ni-Based Superalloy at Elevated Temperatures. Metals, 15(4), 384. https://doi.org/10.3390/met15040384