Fluid Dynamics Analysis of Coherent Jet with a Mixed Shrouding H2-CO2/N2 for EAF Steelmaking

Abstract

1. Introduction

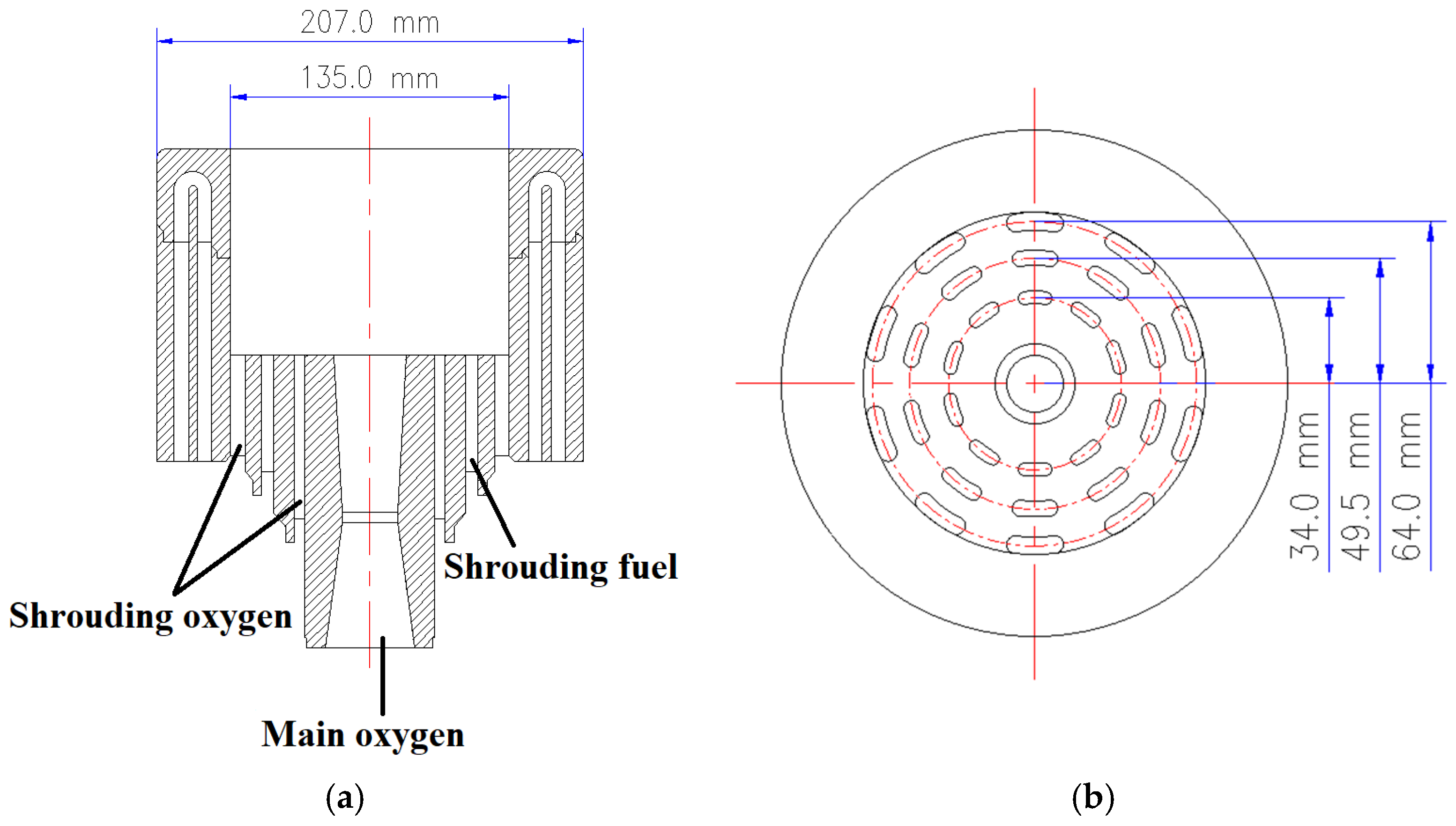

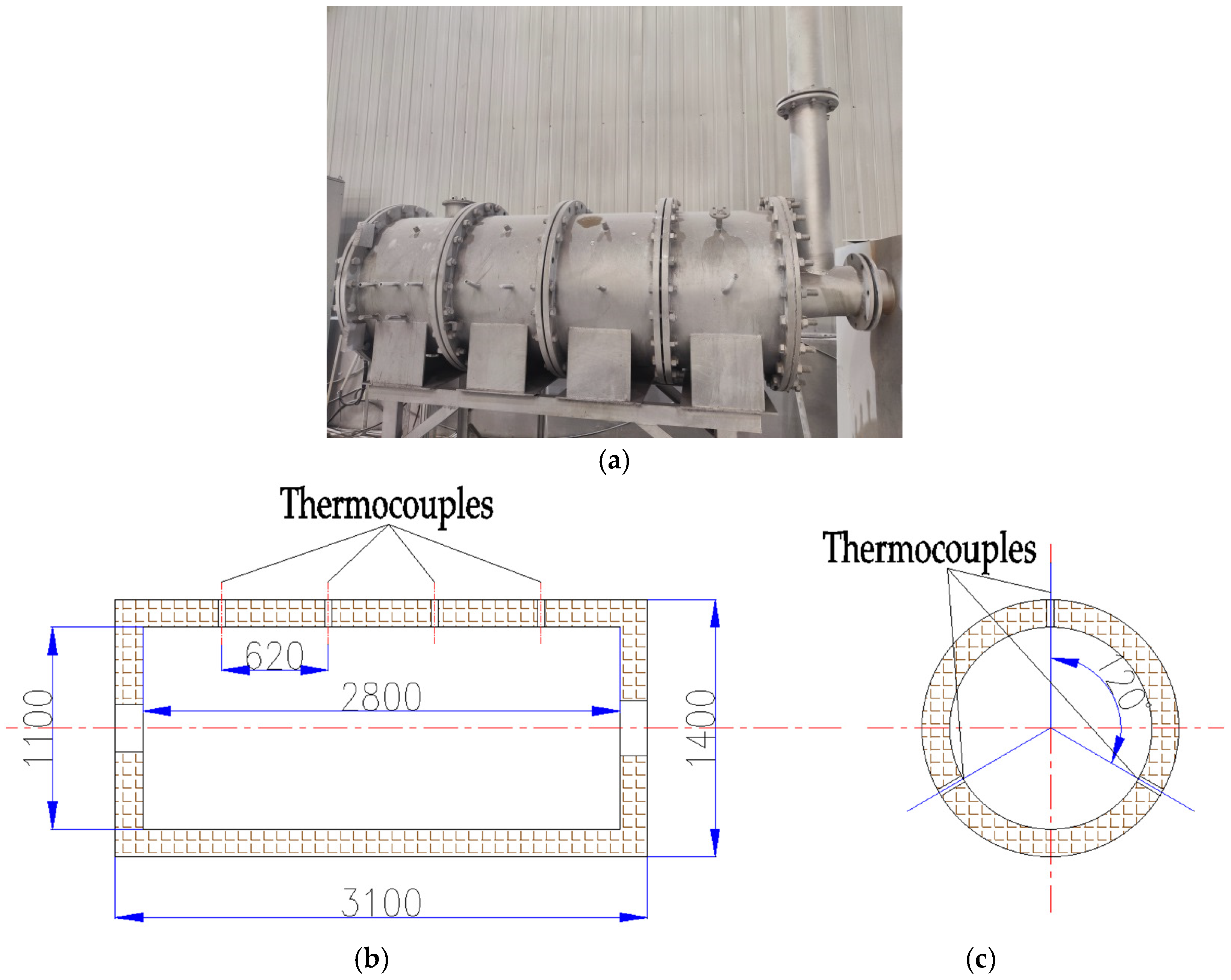

2. Coherent Lance and Experimental System

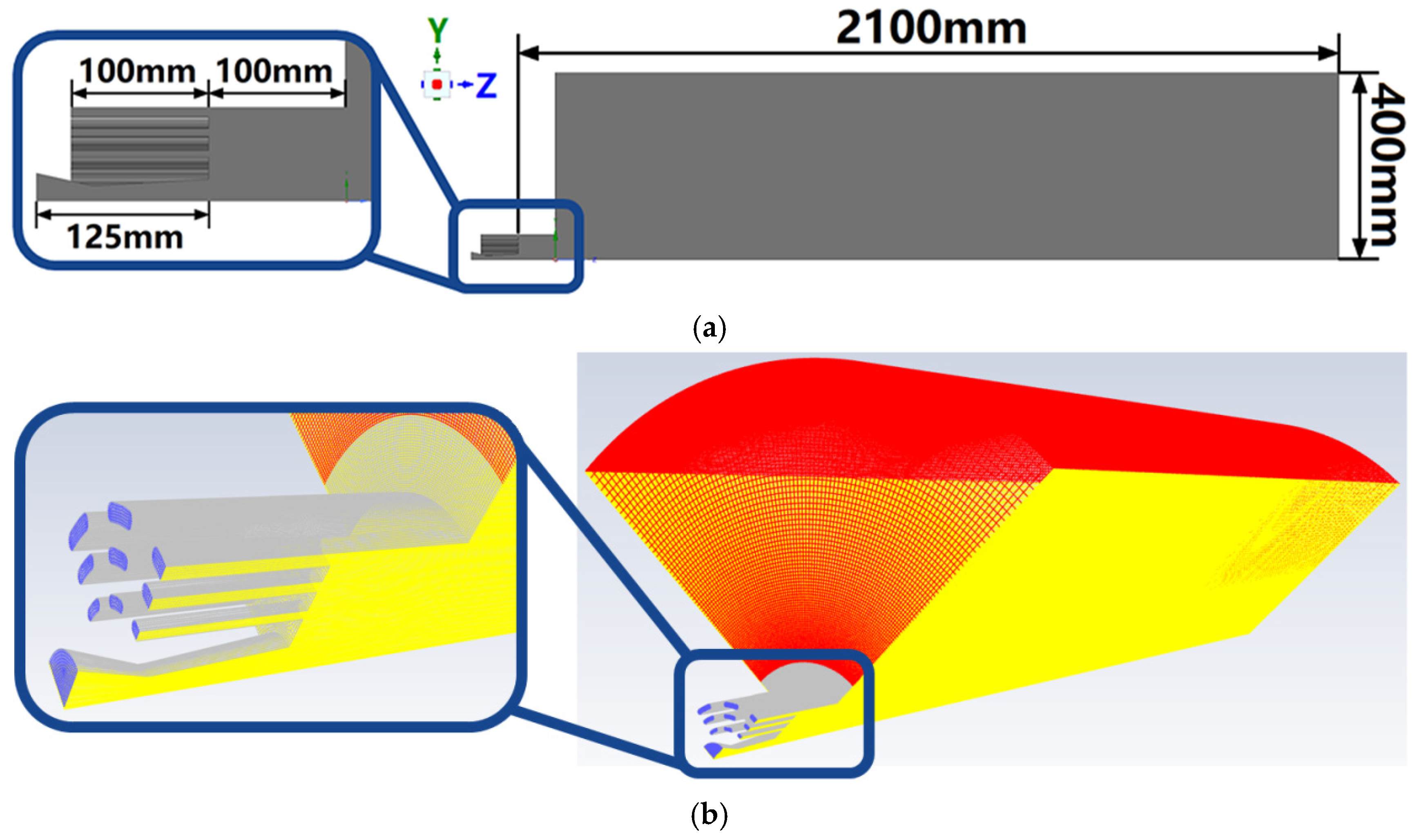

3. Numerical Model

4. Results and Discussion

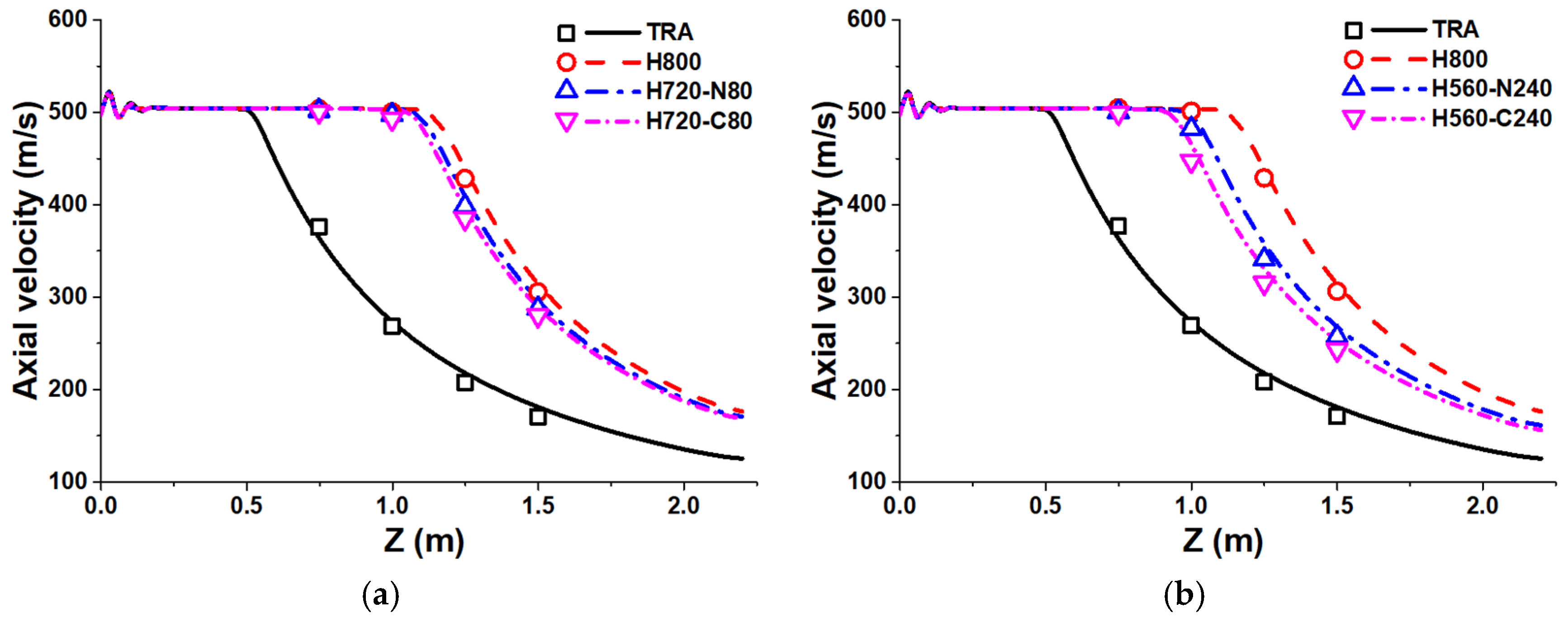

4.1. Axial Velocity Distribution

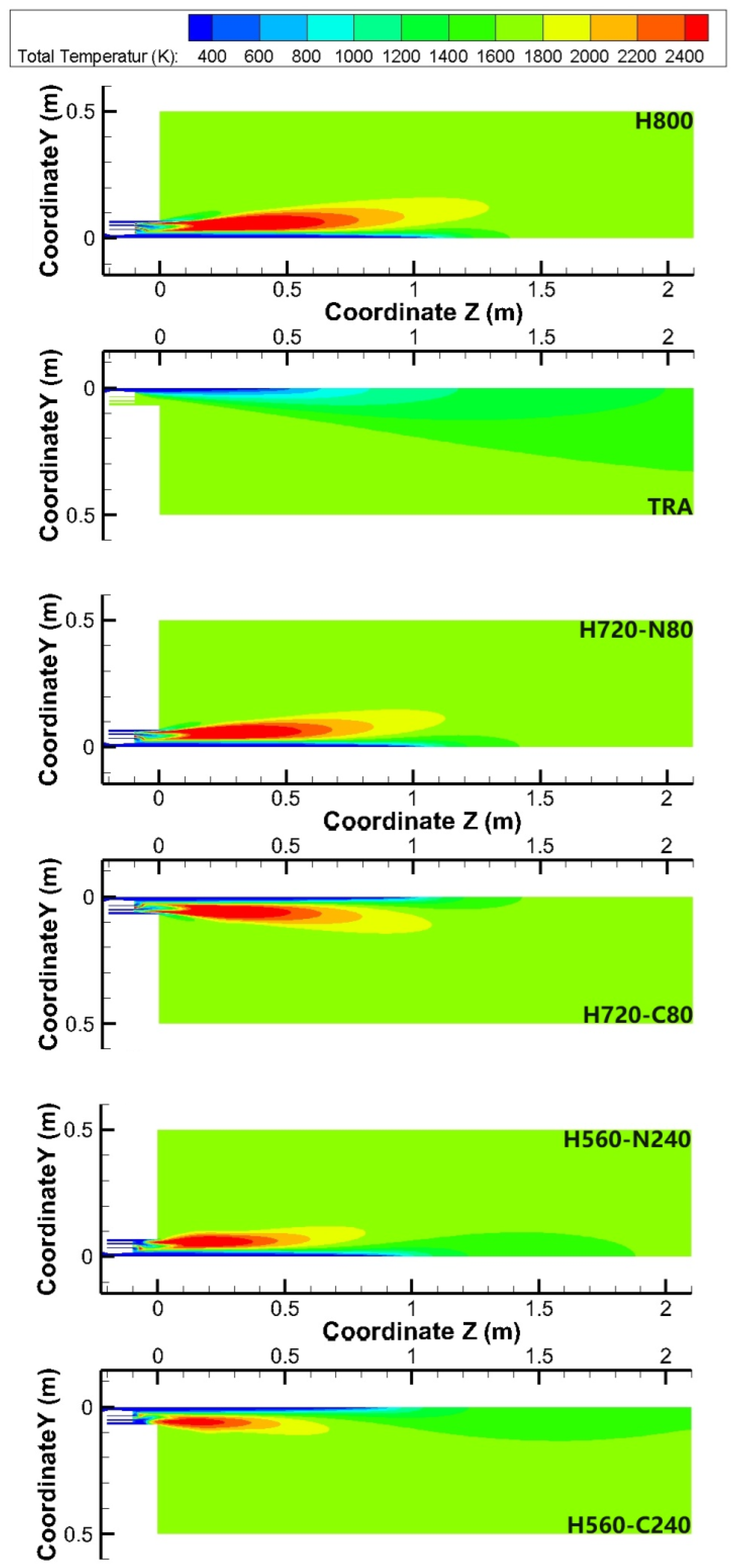

4.2. Total Temperature Distribution

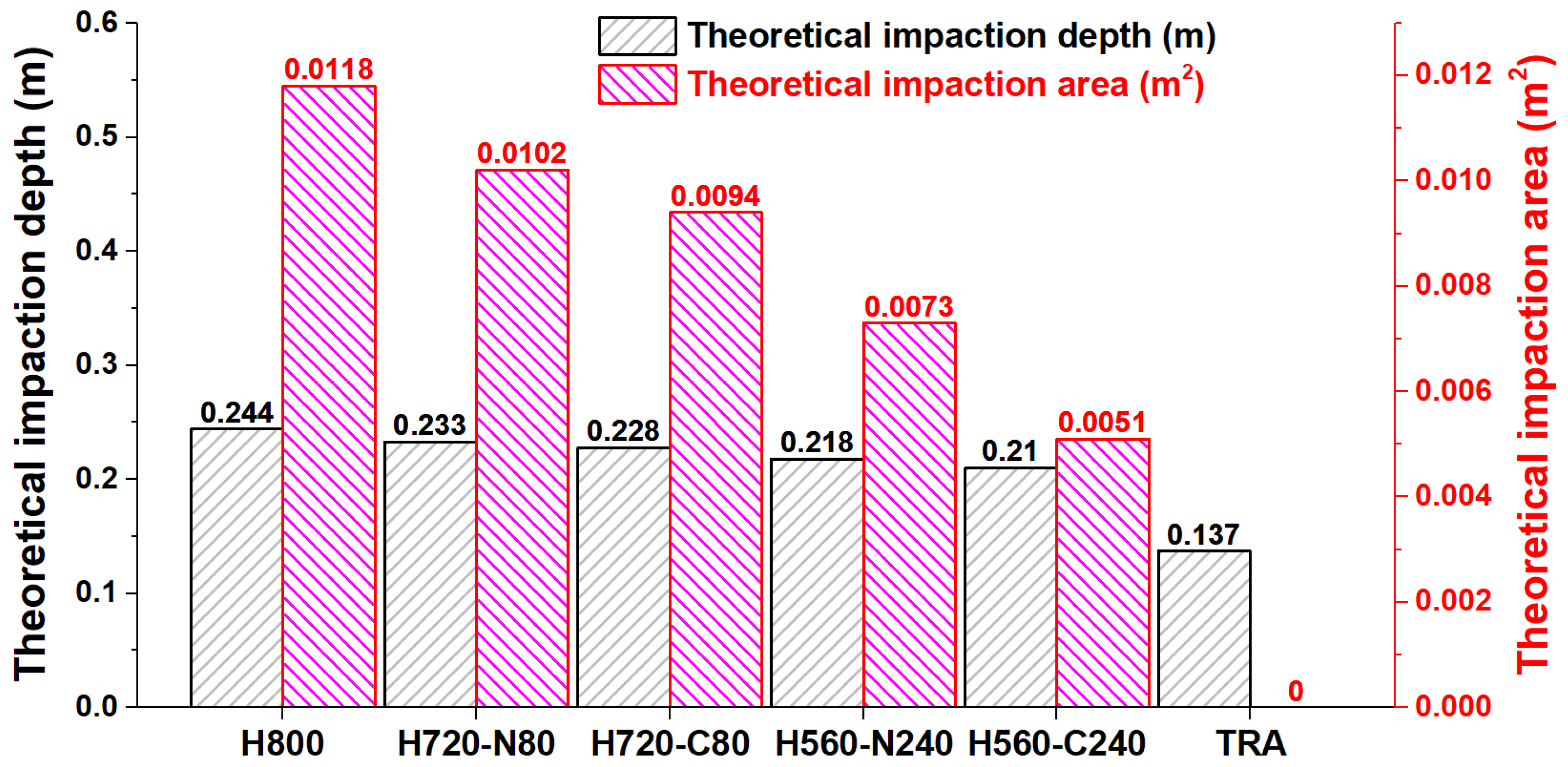

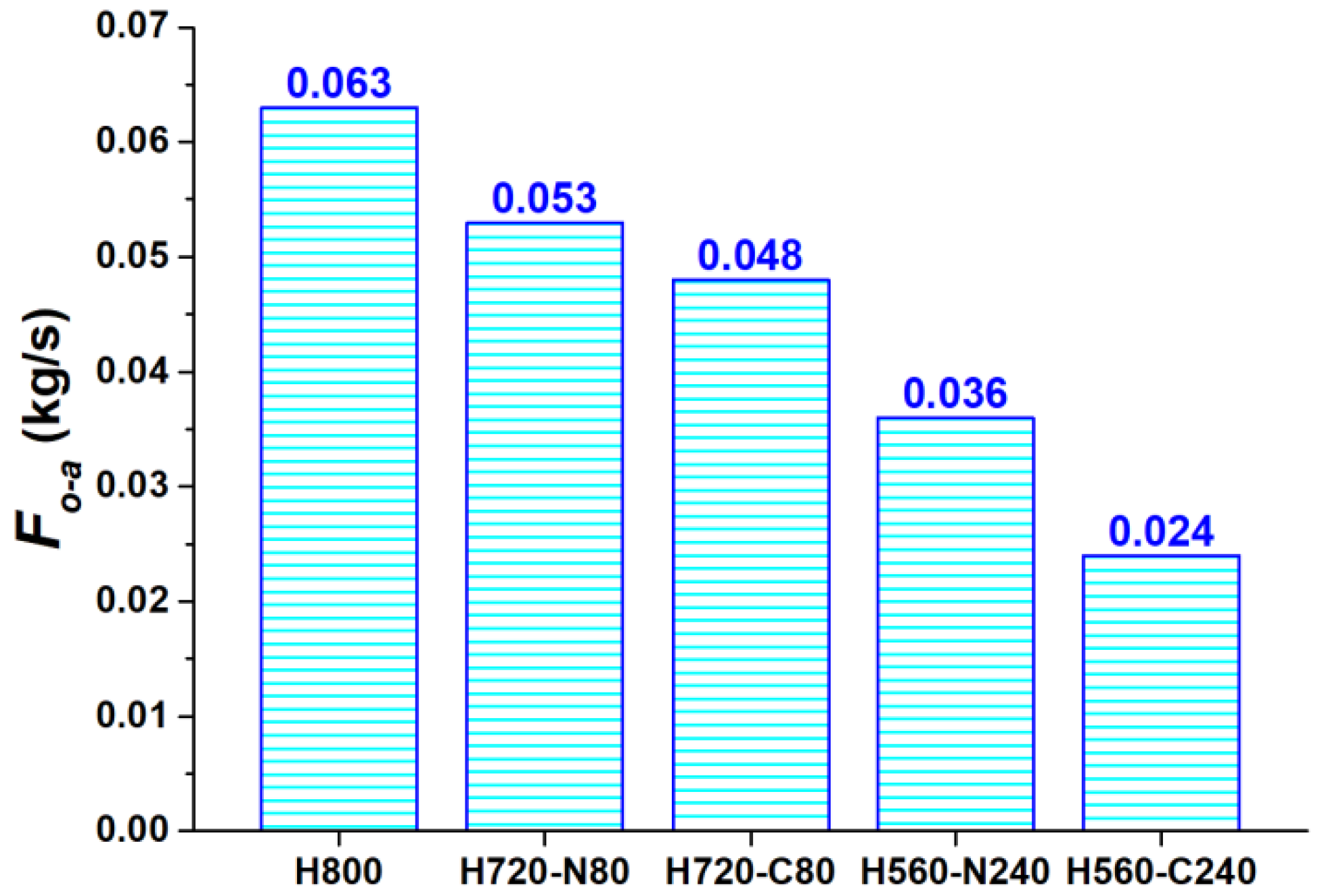

4.3. Impaction Cavity Parameters

5. Conclusions

- Comparing with the traditional coherent jet, the total heat value of shrouding fuel gas is decreased using the shrouding mixed injection method. As a result, The axial velocity potential core length, Fo-a, theoretical impaction depth and area are all reduced with a higher shrouding mixed rate.

- Oxidizing CO2 will take part in the combustion reaction of the shrouding H2, which reduces the combustion efficiency of shrouding H2, leading to decreased the protective effect of the shrouding combustion flame in the axial direction. Thus, N2 is a more suitable shrouding mixed gas type than CO2.

- The Fo-a, theoretical impaction depth and area generated by the H720-N80 is 84.0, 95.5 and 86.4% of those generated by the H800, respectively. Comparing with the H800, the H720-N80 may still lead to comparable production indexes in the EAF steelmaking process, which is still required to verify by the industrial application test.

- While the primary conclusions are derived from laboratory investigations that have not been confirmed through industrial application testing, they nonetheless provide insights into the behavior of the coherent jet produced by various shrouding mixing methods. These findings may offer valuable guidance for the utilization of H2 in the EAF steelmaking process.

- In addition to achieving low-cost and large-scale production of green hydrogen, the storage and transportation of hydrogen energy within the steel enterprises present significant challenges. Consequently, addressing or mitigating hydrogen embrittlement is critical for the widespread adoption of hydrogen energy.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mitas, B.; Schenk, J. Oxygen distribution at the hot spot in BOF steelmaking. Met. Mater. Trans. B 2024, 55, 1680–1689. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, L.; Cheng, T.; Chen, F.; Zheng, F.; Wang, S.; Guo, Y. Fluid flow characteristic of EAF molten steel with different bottom-blowing gas flow rate distributions. ISIJ Int. 2020, 60, 1957–1967. [Google Scholar] [CrossRef]

- Gokce, F.; Adar, C.; Tosun, M.A.; Isik, Z.; Gurbuz, A.E. Nitrogen control in scrap-based EAF steelmaking. In Proceedings of the AISTech 2024, Columbus, OH, USA, 6–9 May 2024; pp. 393–400. [Google Scholar]

- Moreira, D.D.; de Souza, R.M.; Komati, K.S.; Sperandio, K.N.; Rodrigues, D.D.; de Oliveira, J.R. Study of the slag properties in steel dephosphorization in the EAF. In Proceedings of the AISTech 2024, Columbus, OH, USA, 6–9 May 2024. [Google Scholar]

- Ramirez-Argaez, M.A.; Conejo, A.N. CFD study on the effect of the oxygen lance inclination angle on the decarburization kinetics of liquid steel in the EAF. Metall. Res. Technol. 2021, 118, 516. [Google Scholar] [CrossRef]

- Alam, M.; Naser, J.; Brooks, G.; Fontana, A. Computational fluid dynamics modeling of supersonic coherent jets for electric arc furnace steelmaking process. Met. Mater. Trans. B 2010, 41, 1354–1367. [Google Scholar] [CrossRef]

- Chen, Y.; Luo, Q.; Ryan, S.; Busa, N.; Silaen, A.K.; Zhou, C.Q. Effect of coherent jet burner on scrap melting in electric arc furnace. Appl. Therm. Eng. 2022, 212, 118596. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Yamamoto, Y.; Hagihara, Y. Functionalization of supersonic oxygen lance for EAF. In Proceedings of the AISTech 2021, Nashville, TN, USA, 29 June–1 July 2021; pp. 1592–1603. [Google Scholar]

- Tian, B.; Wei, G.; Zhu, R.; Li, X.; Zhang, H. Energy balance and deoxidation status of electric arc furnace tapping processes. Ironmak. Steelmak. 2022, 49, 699–706. [Google Scholar] [CrossRef]

- Wei, G.; Zhu, R.; Cheng, T.; Kai, D.; Yang, L.; Wu, X. Study on the impact characteristics of coherent supersonic jet and convention-al supersonic jet in EAF steelmaking process. Met. Mater. Trans. B 2018, 49, 361–374. [Google Scholar] [CrossRef]

- Jung, J.; Gabriel, T.; Partyka, A.; Pavliš, M. Application of jet-burner technology for a small-sized EAF. In Proceedings of the AISTech 2021, Nashville, TN, USA, 29 June–1 July 2021; pp. 307–316. [Google Scholar]

- Kourougianni, F.; Arsalis, A.; Olympios, A.V.; Yiasoumas, G.; Konstantinou, C.; Papanastasiou, P.; Georghiou, G.E. A comprehensive review of green hydrogen energy systems. Renew. Energy 2024, 231, 120911. [Google Scholar] [CrossRef]

- Bian, J.; Zhou, Z.; Yu, J.; Shi, X.; Huang, P.; Du, W. A comprehensive energy flow analysis method based on hydrogen energy to electric energy conversion. J. Phys. Conf. Ser. 2024, 2788, 012004. [Google Scholar] [CrossRef]

- Zaiter, I.; Ramadan, M.; Bouabid, A.; Mayyas, A.; El-Fadel, M.; Mezher, T. Enabling industrial decarbonization: Framework for hydrogen integration in the industrial energy systems. Renew. Sustain. Energy Rev. 2024, 203, 114782. [Google Scholar] [CrossRef]

- Zhu, Y.; Keoleian, G.A.; Cooper, D.R. The role of hydrogen in decarbonizing U.S. industry: A review. Renew. Sustain. Energy Rev. 2025, 214, 115392. [Google Scholar] [CrossRef]

- Feng, C.; Liu, F.; Zhu, R.; Kai, D.; Wei, G.; Tao, X. Computational investigation of coherent jet behavior generated by H2 shrouding flow. Metall. Mater. Trans. B 2024, 55, 600–611. [Google Scholar] [CrossRef]

- Mahoney, W.; Deneys, A.; Mathur, P.; Warty, S. The critical role of hydrogen in Linde’s coherent jet technology. In Proceedings of the AISTech 2023, Detroit, MI, USA, 8–11 May 2023; pp. 566–576. [Google Scholar] [CrossRef]

- Hu, S.; Zhu, R.; Dong, K.; Liu, R. Numerical simulation and industrial experimental research on the coherent jet with “CH4 + N2” mixed fuel gas. Metall. Mater. Trans. B 2018, 49, 2584–2598. [Google Scholar] [CrossRef]

- Adam, A.M.; Bahamon, D.; Kobaisi, M.A.; Vega, L.F. Molecular dynamics simulations of the interfacial tension and the solubil-ity of brine/H2/CO2 systems: Implications for underground hydrogen storage. Int. J. Hydrogen Energy 2024, 78, 1344–1354. [Google Scholar] [CrossRef]

- Vadlamudi, S.; Gugulothu, S.K.; Panda, J.K.; Chalapathi, K.S.; Mohanty, D. An ideal investigation on conventional CRDI engine for optimum paradigm analysis of performance and exhaust emissions by using oxygenated and hydrogen fuel: An experimental green dual fuel approach. Fuel 2024, 372, 132160. [Google Scholar] [CrossRef]

- Czylkowski, D.; Hrycak, B.; Miotk, R.; Dors, M.; Jasiński, M. Microwave plasma-assisted hydrogen production via conversion of CO2-CH4 mixture. Int. J. Hydrogen Energy 2024, 78, 421–432. [Google Scholar] [CrossRef]

- Sivells, J.C. Aerodynamic design of axisymmetric hypersonic wind-tunnel nozzles. J. Spacecr. Rocket. 1910, 7, 1292–1299. [Google Scholar] [CrossRef]

- Smith, G.P.; Golden, D.M.; Frenklach, M.; Moriarty, N.W.; Eiteneer, B.; Goldenberg, M.; Bowman, C.T.; Hanson, R.K.; Song, S.; Gardiner, W.C.; et al. GRI-Mesh 3.0. Available online: http://www.me.berkeley.edu/gri_mech/ (accessed on 5 March 2025).

- Mashruk, S.; Zhu, X.; Roberts, W.L.; Guiberti, T.F.; Valera-Medina, A. Chemiluminescent footprint of premixed ammonia-methane-air swirling flames. Proc. Combust. Inst. 2023, 39, 1415–1423. [Google Scholar] [CrossRef]

- Liu, Y.; Gong, Y.; Guo, Q.; Tian, X.; Yu, G. Numerical study on OH* chemiluminescence in CH4/NH3 diffusion flame based on chemical kinetic mechanism. Int. J. Hydrogen Energy 2025, 105, 1230–1241. [Google Scholar] [CrossRef]

- Qian, F.; Mutharasan, R.; Farouk, B. Studies of interface deformations in single- and multi-layered liquid baths due to an im-pinging gas jet. Met. Mater. Trans. B 1996, 27, 911–920. [Google Scholar] [CrossRef]

- Li, M.; Li, Q.; Kuang, S.; Zou, Z. Determination of cavity dimensions induced by impingement of gas jets onto a liquid bath. Met. Mater. Trans. B 2016, 47, 116–126. [Google Scholar] [CrossRef]

| Label | Type of Detail Conditions | Values |

|---|---|---|

| Main Laval nozzle | Flow rate (Nm3/h) | 2500 |

| Mach number | 2.20 | |

| Oxygen temperature (K) | 300 | |

| Fuel shrouding nozzle | H2 flow rate (Nm3/h) | 800/720/560 |

| N2 flow rate (Nm3/h) | 0/80/240 | |

| CO2 flow rate (Nm3/h) | 0/80/240 | |

| Gas flow temperature (K) | 300 | |

| Oxygen shrouding nozzle | Flow rate (Nm3/h) | 400/360/280 |

| Gas flow temperature (K) | 300 |

| Label | H800 | TRA | H720-C80 | H720-N80 | H560-C240 | H560-N240 |

|---|---|---|---|---|---|---|

| 1.00 m | 216.8 m/s | 134.1 m/s | 204.4 m/s | 208.7 m/s | 184.8 m/s | 194.6 m/s |

| 1.25 m | 173.0 m/s | 110.3 m/s | 163.2 m/s | 166.4 m/s | 148.1 m/s | 155.2 m/s |

| 1.50 m | 140.1 m/s | 93.5 m/s | 132.7 m/s | 135.0 m/s | 121.7 m/s | 126.7 m/s |

| 1.75 m | 114.9 m/s | 80.6 m/s | 109.6 m/s | 111.2 m/s | 101.8 m/s | 105.2 m/s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, S.; Liu, F.; Zhu, R.; Wei, G.; Dong, K. Fluid Dynamics Analysis of Coherent Jet with a Mixed Shrouding H2-CO2/N2 for EAF Steelmaking. Metals 2025, 15, 291. https://doi.org/10.3390/met15030291

Yan S, Liu F, Zhu R, Wei G, Dong K. Fluid Dynamics Analysis of Coherent Jet with a Mixed Shrouding H2-CO2/N2 for EAF Steelmaking. Metals. 2025; 15(3):291. https://doi.org/10.3390/met15030291

Chicago/Turabian StyleYan, Songtao, Fuhai Liu, Rong Zhu, Guangsheng Wei, and Kai Dong. 2025. "Fluid Dynamics Analysis of Coherent Jet with a Mixed Shrouding H2-CO2/N2 for EAF Steelmaking" Metals 15, no. 3: 291. https://doi.org/10.3390/met15030291

APA StyleYan, S., Liu, F., Zhu, R., Wei, G., & Dong, K. (2025). Fluid Dynamics Analysis of Coherent Jet with a Mixed Shrouding H2-CO2/N2 for EAF Steelmaking. Metals, 15(3), 291. https://doi.org/10.3390/met15030291