Material and Process Modification to Improve Manufacturability of Low-Lead Copper Alloys by Low-Pressure Die Casting Method

Abstract

1. Introduction

- -

- Declarations on limiting lead contents in alloys, as outlined by the hygienic compliance requirements for products in contact with drinking water published by the 4 MS (Four Member State) alliance established through a partnership between Germany, Netherlands, the United Kingdom, and France [2].

- -

- The law enacted in the United States mandating the classification of lead content in faucet materials, specifically for fittings, under the topic of “lead-free materials” [3].

- -

- National Sanitation Foundation; NSF/ANSI 61-2016—Drinking Water System Components—Health Effects—With Addendum Standard [4].

- -

- National Sanitation Foundation; NSF/ANSI 372-2016—Drinking Water System Components—Lead Content Standard [5].

- -

- The EU Parliament’s Directive 2020/2184 on the quality of water intended for consumption [6].

- -

- AB the EU Parliament’s RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, published in 2006 as part of international sustainability regulations, focus on restricting the use of hazardous substances [7].

2. Materials and Methods

2.1. Alloy Preparation

- Sample: Base alloy with Al added (between 0.3 and 0.5%);

- Sample: Base alloy with Al added (between 0.7 and 0.9%);

- Sample: Base alloy with Sb added (between 0.01 and 0.03%);

- Sample: Base alloy with Sb added (between 0.03 and 0.05%);

- Sample: Base alloy with Bi added (between 0.4 and 0.6%);

- Sample: Base alloy with Bi added (between 0.9 and 1.1%).

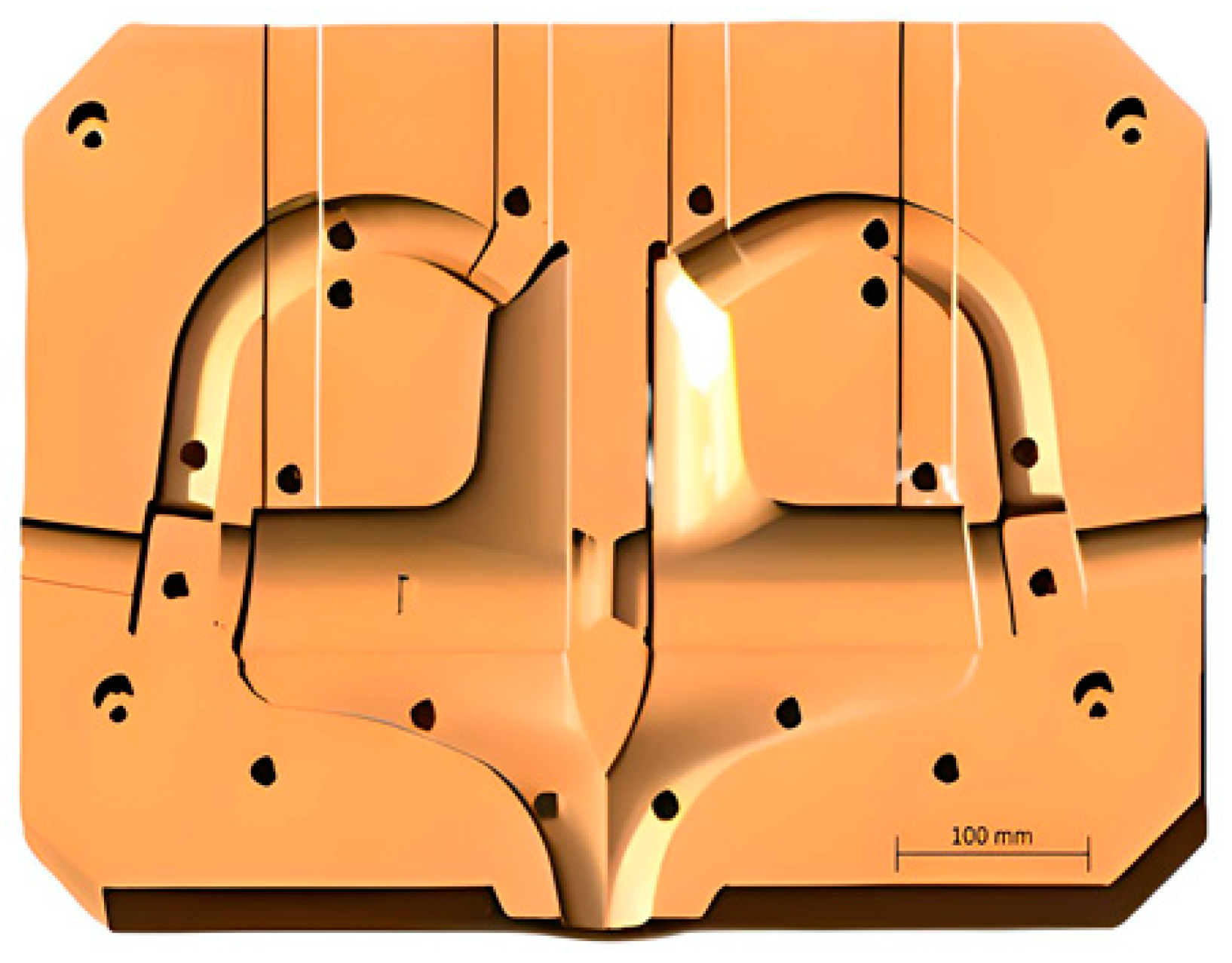

2.2. Casting Process Conditions

- -

- Furnace temperature: 1005–1015 °C;

- -

- Graphite pool temperature: 30–34 °C;

- -

- Casting tressure: 550–600 mbar;

- -

- Filling time: 4.5–7 s;

- -

- Mold temperature: 135–136 °C.

2.3. Post-Casting Analyses

- -

- Scrap rate determination: Each part obtained from the casting was examined, and defects such as incomplete filling, cracks, or surface imperfections were subjected to visual inspection under lighted inspection benches.

- -

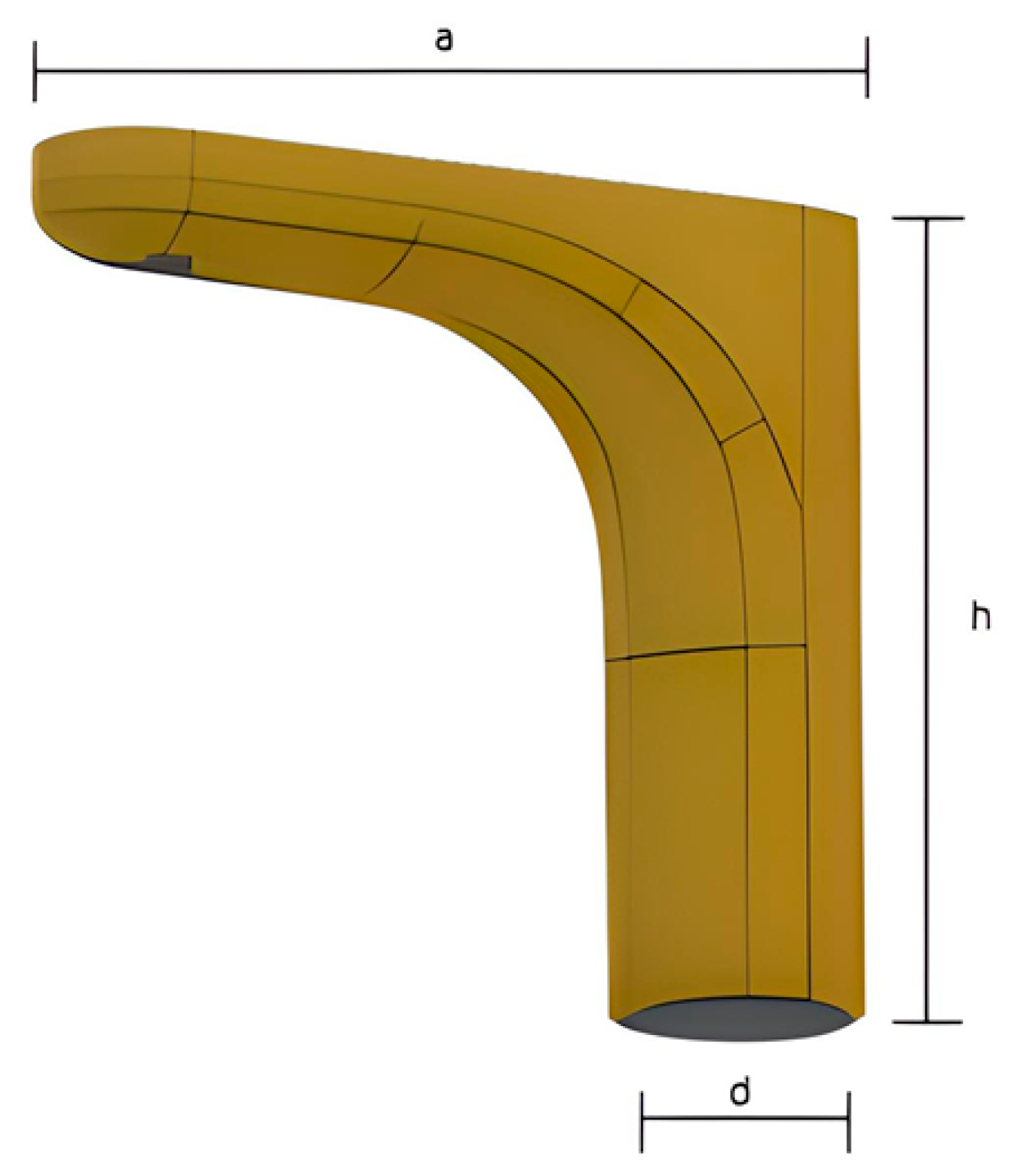

- Dimensional and geometric control: Each part obtained from the casting was subjected to dimensional and geometric controls using a coordinate measuring machine (CMM). The faucet produced from the third sample was deemed qualitatively suitable after dimensional and geometric inspection. The samples’ 3D data are given in Figure 2. This faucet is a leading member of the sink group, which is very popular in the market.

- -

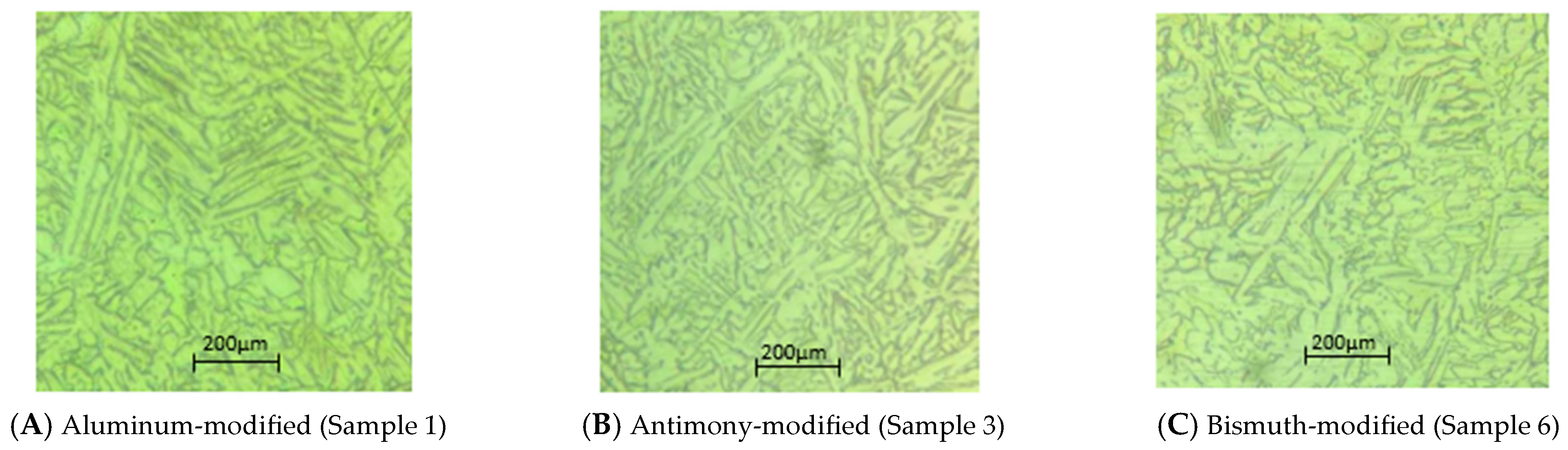

- Microstructural analyses: The cross-sections of the samples were taken, and the microstructure was examined with the help of an optical microscope. The phase distributions and grain sizes within the alloy were determined. During this process, a Nikon SMZ800 optical microscope was used.

- -

- Mechanical tests: Hardness tests were carried out using a Brinell hardness testing machine. The effect of antimony, bismuth, and aluminum elements on the mechanical strength was evaluated. During this process, a Matsuzawa, Akita, Japan, DXT hardness measuring device was used. A load of 30 kgf was applied to the samples for a duration of 20 s. Additionally, five randomly selected castings from all charges were subjected to tensile testing on a Matest brand 10 kN universal testing machine with a strain rate of 15 mm/min for determining the tensile and yield strengths.

- -

- Chemical analyses: Spectral analysis was conducted to check the accuracy of the alloy composition. For this analysis, the Perkin Elmer, CT, USA, Lambda 35 UV/VIS spectrophotometer was used as the spectral analysis device. The chemical analysis contents for all the samples are as shown in Table 2. An average of five repeated chemical analysis has been conducted.

3. Results and Discussions

3.1. Optimum Casting Parameters

3.2. Material Scrap Rate

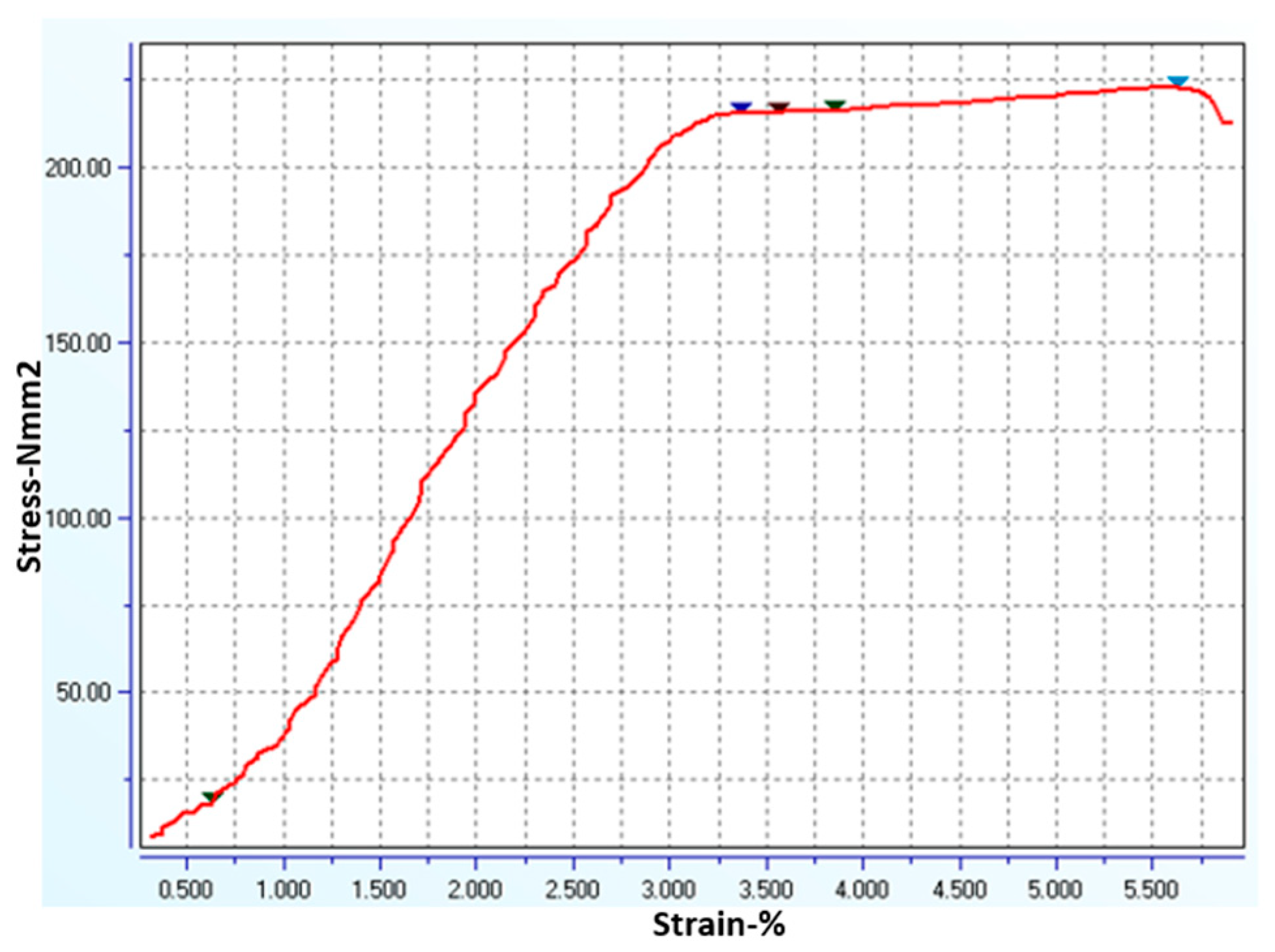

3.3. Mechanical Test Results

3.4. Optical Microscope Examinations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Istanbul Chamber of Industry. Turkish Copper and Copper Alloys Manufacturing Industry; Istanbul Chamber of Industry: Istanbul, Türkiye, 2022. [Google Scholar]

- European Commission Joint Research Center (JRC). Positive List of Metallic Materials in Contact with Drinking Water; European Commission: Brussels, Belgium, 2020; Annex 1A_4; Available online: https://susproc.jrc.ec.europa.eu/product-bureau/sites/default/files/2020-02/Annex%201A_4%20MS%20Scheme%20and%20Positive%20List%20of%20Metallic%20Materials%20in%20Contact%20with%20Drinking%20Water.pdf (accessed on 28 November 2024).

- New Hampshire Department of Environmental Service. Lead Remediation Guide; New Hampshire Department of Environmental Service: Concord, NH, USA, 2019. Available online: https://www.des.nh.gov/sites/g/files/ehbemt341/files/documents/lead-remediation-guide.pdf (accessed on 28 November 2024).

- NSF/ANSI 61; Drinking Water System Components—Health Effects. NSF International: Ann Arbor, MI, USA, 2020. Available online: https://d2evkimvhatqav.cloudfront.net/documents/NSF-ANSI_61_watemarked.pdf?v=1594929800 (accessed on 29 November 2024).

- NSF/ANSI 372-2016; Drinking Water System Components—Lead Content. NSF International: Ann Arbor, MI, USA, 2016. Available online: https://webstore.ansi.org/preview-pages/NSF/preview_NSF+ANSI+372-2016.pdf?srsltid=AfmBOortHIIAzEtUD-795pdgVMQsUTIs-9Ztu6UrHj1pK4_EI1hKVjAn (accessed on 29 November 2024).

- European Union. Directive (EU) 2020/2184 on the Quality of Water Intended for Human Consumption; Official Journal of the European Union: Brussels, Belgium, 2020. Available online: https://www.legislation.gov.uk/eudr/2020/2184/body#:~:text=The%20objectives%20of%20this%20Directive,water%20intended%20for%20human%20consumption (accessed on 29 November 2024).

- European Parliament and Council. Regulation (EC) No 1907/2016 of the European Parliament and of the Council of 18 December 2006 concerning the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH). Official Journal of the European Union 2006, L396, 1–849. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32006R1907 (accessed on 29 November 2024).

- Duzman, M.E. Improvement of Casting Properties in Continuous Casting of Leaded Brasses. Master’s Thesis, Yildiz Technical University, Istanbul, Türkiye, 2010. [Google Scholar]

- La Fontaine, A.; Keast, V.J. Compositional Distributions in Classical and Lead-Free Brasses. Mater. Charact. 2006, 57, 424–429. [Google Scholar] [CrossRef]

- Taha, M.A.; El-Mahallawy, N.A.; Hammouda, R.M.; Moussa, T.M.; Gheith, M.H. Machinability characteristics of lead free-silicon brass alloys as correlated with microstructure and mechanical properties. Ain Shams Eng. J. 2012, 3, 221–230. [Google Scholar] [CrossRef]

- Hsieh, C.C.; Wang, J.S.; Wu, P.T.Y.; Wu, W. Microstructural Development of Brass Alloys with Various Bi and Pb Additions. Met. Mater. Int. 2013, 19, 1173–1179. [Google Scholar] [CrossRef]

- Ayyapan, M.; Uttamchand, N.K.; Rajan, R.A. Mechanical and Wear Properties of Copper-Lead Alloy Prepared by Powder Metallurgy Processing Technique. J. Chem. Technol. Metall. 2016, 51, 465–472. [Google Scholar]

- Merola, M. Theoretical Evaluation of the Physical Properties of Copper-Lead Rheocast Alloys; Politecnico di Torino: Turin, Italy, 1996. [Google Scholar]

- Koru, M.; Serce, O. Simulation of Different Gating System Types and Vacuum Application in High-Pressure Die Casting Process. SDU Int. Technol. Sci. 2014, 6, 132–145. [Google Scholar]

- Ozdemir, A.U. Virtual and Experimental Validation of Air Entrapment in High Pressure Die Casting on a Simplified Cast Geometry. Master’s Thesis, RWTH Aachen University, Aachen, Germany, 2021. [Google Scholar]

- Dogan, A. Investigation of the Effect of Different Gas Exhaust Systems on Porosity and Process Efficiency in the Production of Aluminum Alloys by High-Pressure Die Casting. Master’s Thesis, Sakarya University of Applied Sciences, Sakarya, Türkiye, 2019. [Google Scholar]

- Celik, U. The Effects of Relevant European Union Regulations on the Castability of Pressure Die Casting Alloys; Yildiz Technical University: Istanbul, Türkiye, 2023. [Google Scholar]

- Zhang, B.; Huang, X.; Zhang, X.; Ma, B.; Wang, C. Purification of Cu-Zn Melt Based on the Migration Behavior of Lead and Bismuth under Pulsed Electric Current; University of Science and Technology Beijing: Beijing, China, 2023. [Google Scholar]

- Suzaki, K.; Goto, H.; Oishi, K. Development of Lead-Free High-Strength Copper Alloys. Mater. Trans. 2020, 61, 1684–1688. [Google Scholar] [CrossRef]

- Gao, W.; Xing, S.; Wang, Y. Effect of Lanthanum Addition on Microstructure and Hardness of Brass Alloys Produced by Rheological Squeeze Casting; Beijing Jiaotong University: Beijing, China, 2021. [Google Scholar]

- Zhang, B.; Ma, X.; Gao, Y. Purification of Cu-Zn Melts Under Electric Current; Zhengzhou University of Technology: Zhengzhou, China, 2023. [Google Scholar]

- SARBAK. Ingot Alloys. Available online: https://www.sarbak.com.tr/urunler/Kulce (accessed on 28 November 2024).

- ISO 6506-1; Metallic Materials—Hardness Test—Part 1: Test Method for Brinell Hardness. International Organization for Standardization: Geneva, Switzerland, 2014. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:6506:-1:ed-3:v1:en (accessed on 4 December 2024).

- ISO 6892-1; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. International Organization for Standardization: Geneva, Switzerland, 2019. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:6892:-1:ed-3:v1:en (accessed on 4 December 2024).

| %Al | %Cu | %Zn | %Sn | %Fe | %Ni | %Mn | %Si | %Pb |

|---|---|---|---|---|---|---|---|---|

| 0.3–0.9 | 58–63 | Remaining | 0–0.5 | 0–0.3 | 0–0.2 | 0–0.05 | 0–0.05 | 0–0.19 |

| Sample Number | %Cu | %Pb | %Zn | %Ni | %Mn | %Fe | %Si | %Al | %Bi | %Sb |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 61.96 | 0.190 | 37.18 | 0.002 | <0.001 | 0.033 | 0.009 | 0.486 | <0.003 | 0.002 |

| 2 | 62.83 | 0.194 | 36.17 | 0.003 | <0.001 | 0.036 | 0.010 | 0.727 | <0.003 | 0.002 |

| 3 | 61.96 | 0.190 | 37.18 | 0.002 | <0.001 | 0.033 | 0.009 | 0.586 | <0.003 | 0.020 |

| 4 | 61.89 | 0.194 | 37.26 | 0.002 | <0.001 | 0.035 | 0.009 | 0.557 | <0.003 | 0.040 |

| 5 | 62.76 | 0.197 | 35.95 | 0.001 | <0.001 | 0.033 | 0.008 | 0.533 | 0.483 | 0.002 |

| 6 | 61.95 | 0.283 | 36.22 | 0.001 | <0.001 | 0.035 | 0.009 | 0.516 | 0.968 | 0.002 |

| Samples | Furnace Temp. (°C) | Graphite Pool Temp. (°C) | Casting Pressure (mBar) | Filling Time (s) | Mold Temp. (°C) | Lead Rate (%Pb) |

|---|---|---|---|---|---|---|

| 1. Sample | 1005 | 30 | 550 | 7.0 | 135 | 0.190 |

| 2. Sample | 1010 | 34 | 550 | 7.0 | 136 | 0.194 |

| 3. Sample | 1010 | 30 | 525 | 7.0 | 135 | 0.190 |

| 4. Sample | 1010 | 30 | 550 | 7.0 | 135 | 0.194 |

| 5. Sample | 1015 | 30 | 600 | 4.5 | 135 | 0.197 |

| 6. Sample | 1015 | 30 | 600 | 4.5 | 135 | 0.247 |

| Samples | Quantity | Scrap Pieces | Production Efficiency (%) |

|---|---|---|---|

| 1. Sample | 100 | 68 | 32 |

| 2. Sample | 100 | 53 | 47 |

| 3. Sample | 100 | 19 | 81 |

| 4. Sample | 100 | 44 | 56 |

| 5. Sample | 100 | 56 | 44 |

| 6. Sample | 100 | 50 | 50 |

| Samples | Lead Rate (%Pb) | Brinell Hardness (HB) |

|---|---|---|

| 1. Sample | 0.190 | 88–90 |

| 2. Sample | 0.194 | 94–97 |

| 3. Sample | 0.190 | 88–90 |

| 4. Sample | 0.194 | 86–90 |

| 5. Sample | 0.197 | 77–79 |

| 6. Sample | 0.247 | 74–77 |

| Tests | 1. Sample | 2. Sample | 3. Sample | 4. Sample | 5. Sample | 6. Sample |

|---|---|---|---|---|---|---|

| Test 1 | 217.45 | 195.62 | 223.10 | 189.72 | 152.14 | 142.75 |

| Test 2 | 218.63 | 195.88 | 224.02 | 190.70 | 154.10 | 141.18 |

| Test 3 | 218.40 | 196.06 | 222.15 | 190.05 | 154.00 | 142.33 |

| Test 4 | 218.24 | 196.58 | 222.72 | 191.14 | 153.13 | 142.80 |

| Test 5 | 217.83 | 196.86 | 222.91 | 190.34 | 153.58 | 141.74 |

| St. Deviation | 0.47 | 0.51 | 0.68 | 0.55 | 0.79 | 0.69 |

| Average | 218.11 | 196.20 | 222.98 | 190.39 | 153.47 | 142.16 |

| Tests | 1. Sample | 2. Sample | 3. Sample | 4. Sample | 5. Sample | 6. Sample |

|---|---|---|---|---|---|---|

| Test 1 | 174.89 | 134.56 | 215.88 | 162.08 | 146.87 | 136.79 |

| Test 2 | 174.36 | 134.50 | 215.26 | 161.97 | 148.33 | 137.28 |

| Test 3 | 174.64 | 135.25 | 216.14 | 162.16 | 147.56 | 138.80 |

| Test 4 | 175.25 | 136.28 | 214.20 | 163.00 | 149.07 | 138.00 |

| Test 5 | 175.44 | 134.46 | 215.97 | 163.89 | 147.27 | 138.33 |

| St. Deviation | 0.44 | 0.78 | 0.79 | 0.82 | 0.88 | 0.81 |

| Average | 174.92 | 135.01 | 215.49 | 162.62 | 147.82 | 137.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vanli, A.S.; Karas, M.H. Material and Process Modification to Improve Manufacturability of Low-Lead Copper Alloys by Low-Pressure Die Casting Method. Metals 2025, 15, 205. https://doi.org/10.3390/met15020205

Vanli AS, Karas MH. Material and Process Modification to Improve Manufacturability of Low-Lead Copper Alloys by Low-Pressure Die Casting Method. Metals. 2025; 15(2):205. https://doi.org/10.3390/met15020205

Chicago/Turabian StyleVanli, Ali Serdar, and Muhammed Hakan Karas. 2025. "Material and Process Modification to Improve Manufacturability of Low-Lead Copper Alloys by Low-Pressure Die Casting Method" Metals 15, no. 2: 205. https://doi.org/10.3390/met15020205

APA StyleVanli, A. S., & Karas, M. H. (2025). Material and Process Modification to Improve Manufacturability of Low-Lead Copper Alloys by Low-Pressure Die Casting Method. Metals, 15(2), 205. https://doi.org/10.3390/met15020205