1. Introduction

Significant wear commonly occurs on surfaces in direct contact with raw materials in large-scale industrial machinery, such as the teeth of rock crushers. This wear significantly shortens component service life by degrading functional surfaces. In crushers, however, the extent of surface wear is relatively minor compared to the overall size of the plates.

These components are typically fabricated through casting specialized materials, followed by post-casting heat treatments to achieve the required mechanical strength and surface friction properties. Given their large dimensions, replacing worn components is often prohibitively expensive. An alternative approach involves repairing worn surfaces or fabricating components from cost-effective materials and applying a high-quality surface layer. Hard-facing techniques through layered welding, followed by grinding and stress-relief heat treatment, are commonly used to achieve these objectives [

1].

Welding is applied uniformly across worn surfaces or specific points for component reconstruction, typically by moving a heat source along a joint, with or without adding filler material [

2]. When filler material is used, selecting one with superior mechanical properties enhances the weld coating’s resistance to abrasion, erosion, corrosion, or combinations thereof.

Electric arc welding is widely employed in industrial applications requiring high-strength and high-quality joints. The quality of the weld depends on factors such as the chemical composition of the filler material, the heat source, and the arc’s position [

2]. Properly applied welding techniques aim to minimize the transient thermal field’s effects. However, the intense, localized heat generated by electric arcs poses challenges in maintaining structural integrity. Improper management may lead to distortions, residual stresses, weld defects, and adverse microstructural changes [

3].

Thermal and mechanical properties evolve with heating, inducing stresses and deformations that could result in defects such as cracks, porosity, or lack of fusion. These issues can significantly compromise a component’s mechanical properties, fatigue resistance, and service life. Understanding and controlling thermal field evolution during welding is crucial for ensuring structural integrity [

4]. Achieving a uniform and controlled temperature distribution reduces thermal gradients, minimizing residual stresses and distortion [

5].

Artificial neural networks (ANNs) effectively predict key welding process variables, including distortion and residual stresses, based on parameters such as current, voltage, welding speed, and sequence [

5,

6]. ANNs facilitate real-time control by dynamically adjusting process parameters to maintain quality and reduce distortion [

6,

7]. These networks excel at modeling complex, nonlinear relationships from experimental or numerical data [

5] and adapt to different materials and geometries, making them versatile for diverse applications.

Genetic algorithms (GAs) excel at optimizing process parameters and welding sequences. They explore global solutions to minimize distortion or maximize quality, showing robustness against noise and data uncertainty [

5,

8,

9]. In complex multipass welding scenarios, GAs effectively sequence operations [

5,

10].

Combining ANNs and GAs leverage their respective strengths. ANNs predict distortion for a given sequence, while GAs optimize the sequence using ANN predictions as an objective function [

5,

8].

Monitoring temperature during welding allows dynamic adjustments to parameters such as welding speed or heat input. This control maintains temperatures within an optimal range, minimizing deformation [

6,

7]. Accurate temperature data support controlled cooling strategies, reducing residual stresses further. These practices improve quality and mechanical properties by reducing distortion.

Modeling and analyzing welding processes involve calculating the temperature field as a function of time and position. Due to the high energy density of the heat source, numerical models are commonly developed to predict and optimize the temperature distribution in the material deposition zone. Several studies have highlighted the importance of modeling thermal phenomena during welding [

11,

12]. Approaches such as finite element analysis and heat source modeling have been widely explored [

13,

14].

Improved welding process control has been achieved by optimizing parameters and trajectory selection [

15]. A key distinction between heat source models lies in their formulation, such as the Gaussian bell [

16], double ellipsoid [

17], or point heat source models [

18].

The selection of an optimal welding sequence must consider the spatial distribution of weld beads, the component’s overall thermal history, bead interactions, localized heating, and the material’s thermal sensitivity [

19]. The welding trajectory and geometric application influence the evolution of thermal fields during welding, impacting residual stresses and thermally induced deformations [

20,

21].

Recent advancements highlight the potential of hybrid methodologies that combine computational fluid dynamics (CFD) simulations with deep learning models, such as fully connected neural networks (FNNs), to optimize welding processes. These approaches overcome the limitations of traditional modeling methods, particularly in multipoint welding scenarios, where the operation sequence plays a critical role in thermal management and defect prevention [

22]. Zhou et al. proposed using machine learning to optimize computational efficiency in welding processes by predicting thermal fields in additive manufacturing processes, thus reducing computational time [

19].

Determining the optimal welding sequence from many possibilities is a complex optimization problem. This can be addressed using heuristic and metaheuristic algorithms or machine learning techniques, such as artificial neural networks, to analyze numerical simulation results and identify optimal sequences [

19]. Neural networks, capable of learning complex patterns from large datasets, have been applied in additive manufacturing to predict thermal fields [

19] and minimize deformation using reinforcement learning [

9].

Despite advancements, challenges remain in developing an integrated approach combining experimentation, modeling, and optimization to improve thermal management in complex welding applications [

14].

Other studies focus on a smaller number of welding sites, resulting in fewer possible scenarios. For example, such as [

5,

23,

24] examine configurations with eight sites. In contrast, this study tackles the optimization of thermal gradients in significantly more complex configurations by combining advanced methodologies. A matrix of 100 blind holes introduces a combinatorial challenge with

possible welding sequences, demonstrating the scale and complexity of this research.

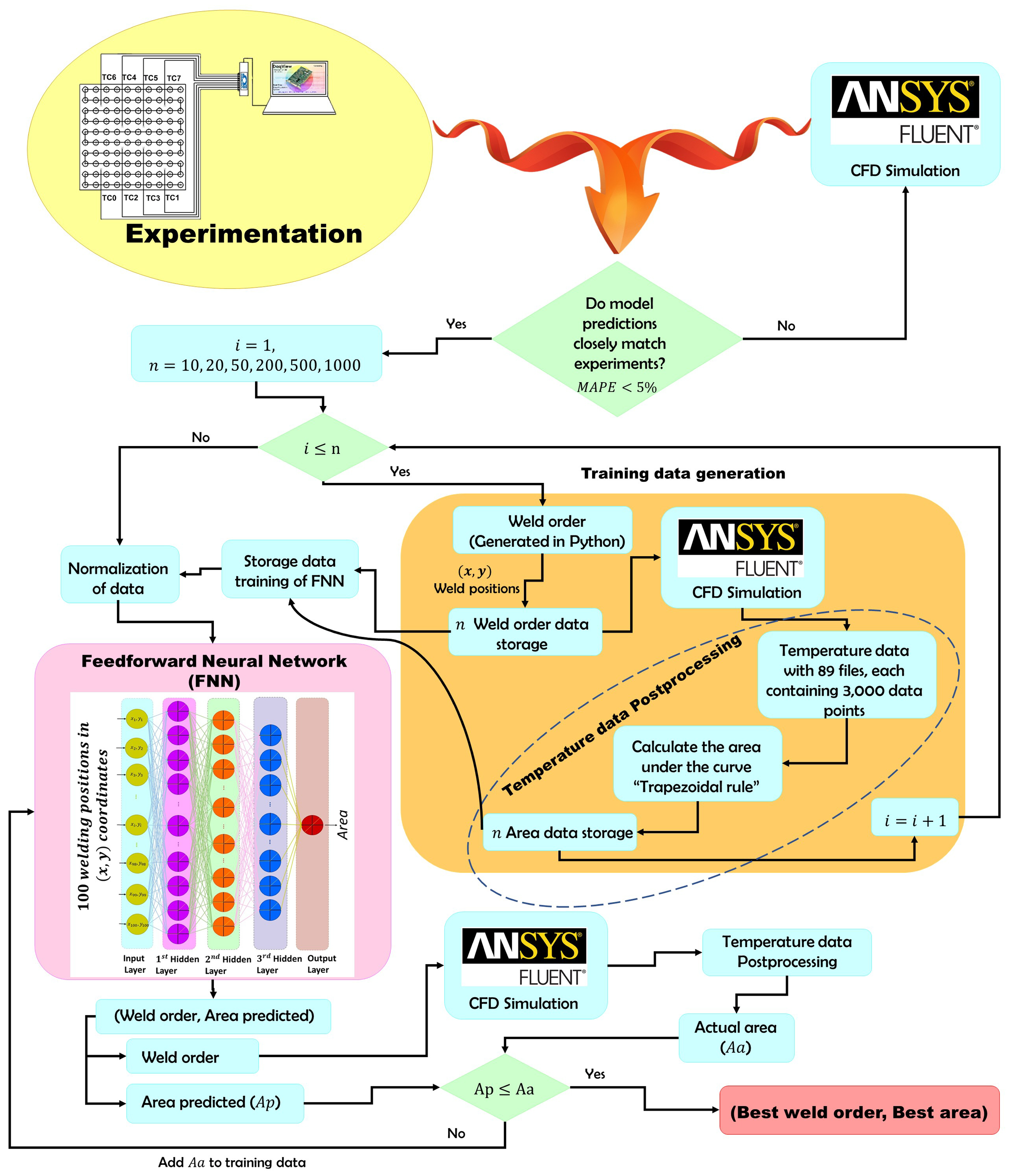

The methodology introduces several innovations: (1) The use of a three-layer neural network trained with CFD-generated data to predict and optimize areas under thermal curves, minimizing temperature gradients. (2) Parallel processing to accelerate training data generation and simulation, achieving effective integration between CFD models and deep learning. (3) The methodology proposed in this work could be easily adapted to manufacturing processes involving multisite welding or additive manufacturing processes using multilayer welding techniques, opening new possibilities for optimizing thermal efficiency and improving final quality.

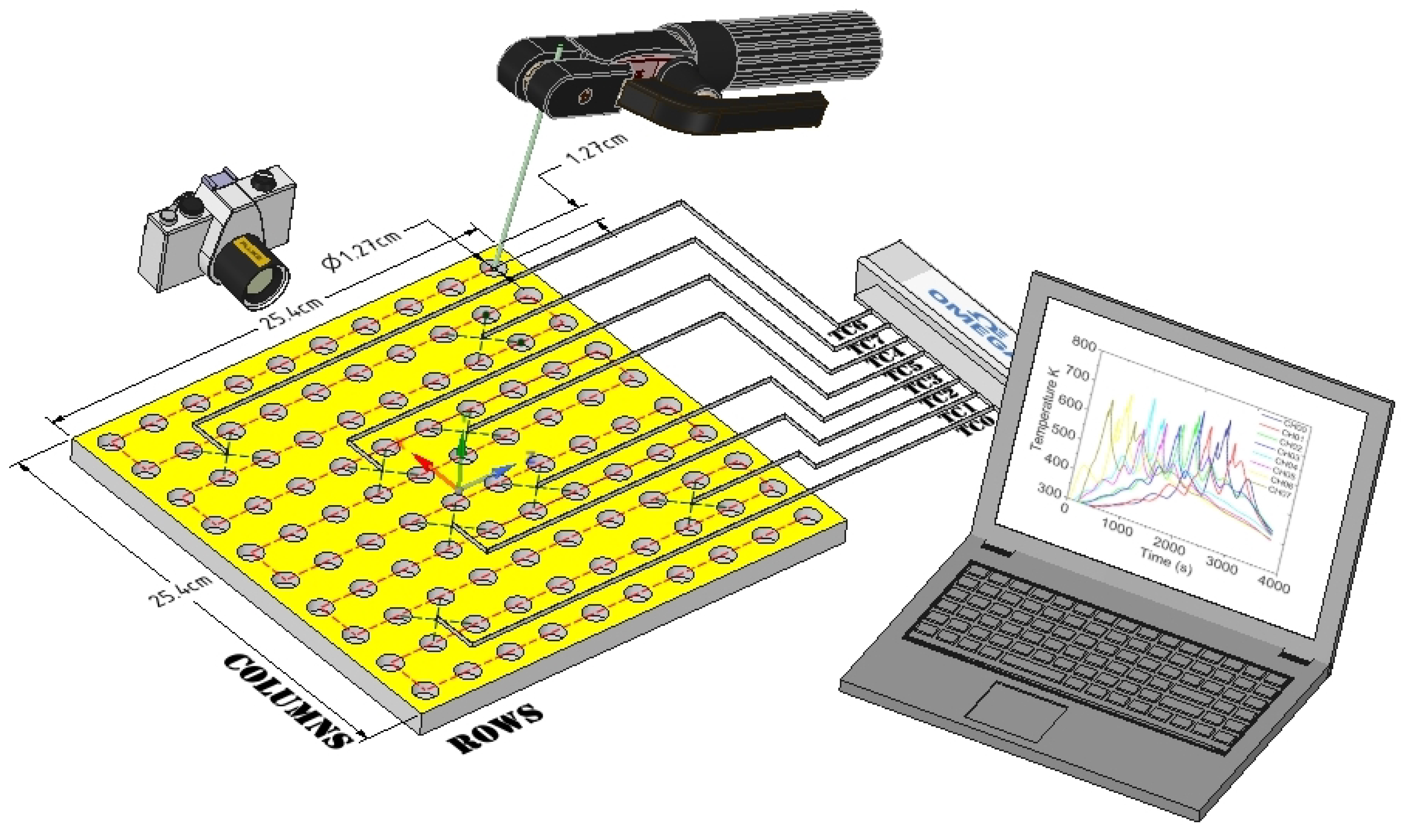

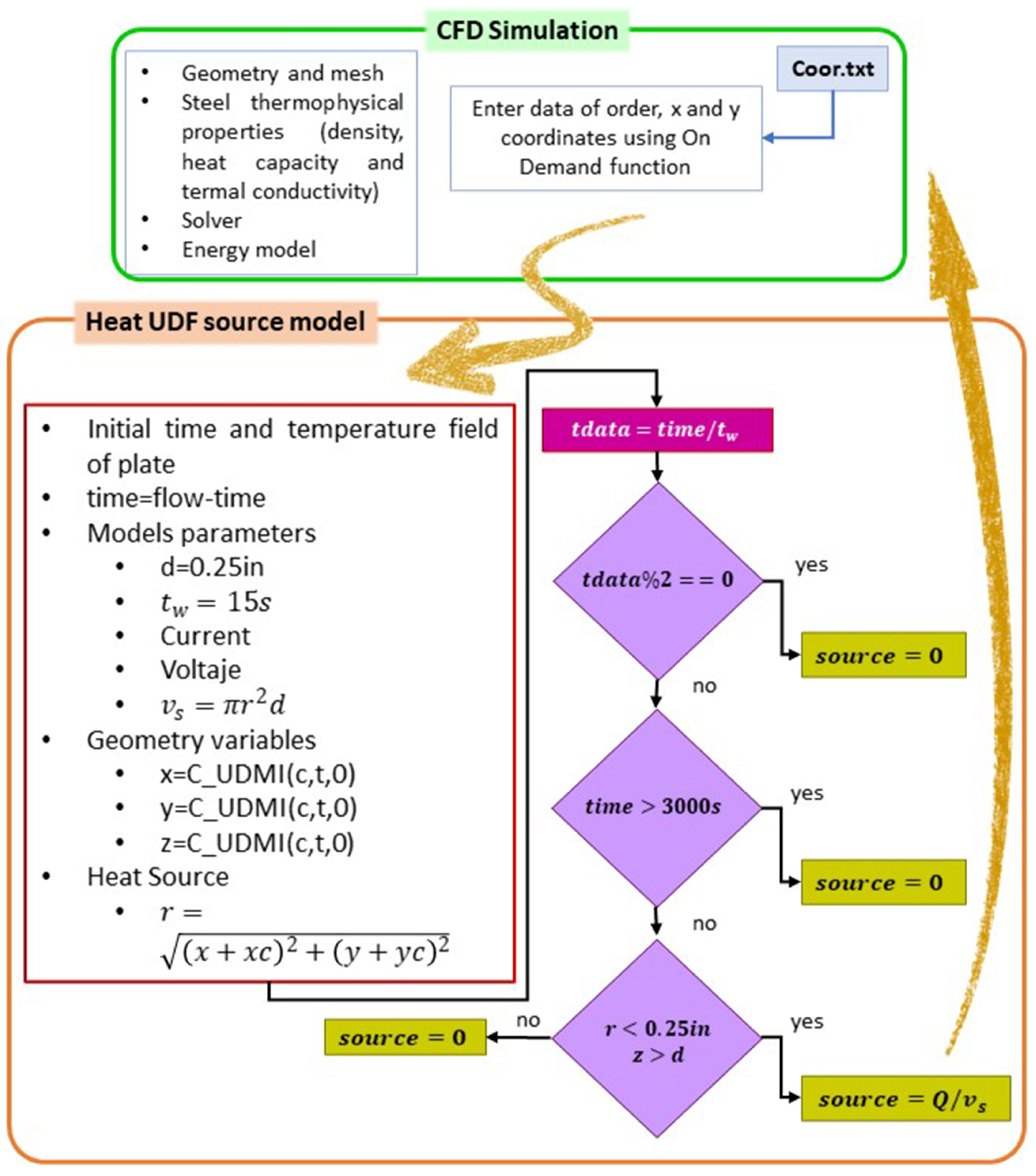

This study investigates thermal field evolution during arc welding using an integrated experimentation, modeling, and optimization approach to improve thermal management to reduce the heat-affected zone (HAZ) where the microstructural impacts, thermal stresses, and deformations affect the base materials. Welding was applied to fill blind holes, forming a matrix of weld material embedded in the base material. Experimental validation involved filling 100 blind holes on a 25.4 cm AISI 1018 steel square plate equipped with thermocouples at eight locations.

Simulations employed the same welding trajectory as the experiment to validate thermal field models. Subsequently, neural networks were proposed to optimize thermal performance and reduce temperature gradients by generating diverse welding trajectories using arc welding with a covered electrode.

2. Simulation Model

2.4. FNN Model Design

This section explains the design of the feedforward neural network (FNN) model used to predict the area under the temperature curve in the welding process. It covers the network architecture, selected hyperparameters, and the training process based on data from CFD simulations. The model’s performance relies on key quantitative indicators, including mean squared error (MSE), mean absolute percentage error (MAPE), and the coefficient of determination (). The neural network improves prediction accuracy by adjusting weights through an optimization process that minimizes error. This section also details the hyperparameters used to configure the FNN and the criteria used to assess model performance.

In general, the architecture used in this work consists of an FNN with an input layer of 100 neurons, corresponding to the values of the 100 coordinates representing the positions of the welding trajectory. The network has three hidden layers: the first with 256 neurons, the second with 128 neurons, and the third with 64 neurons. The output layer has a single neuron that predicts the area calculated under the temperature curve. The hyperparameters used in the model implementation are as follows:

Activation function: ReLU (Rectified Linear Unit) in all hidden layers. Expressed as

Identity activation function in the output layer, represented as

The model trains using the Adam optimizer (Adaptive Moment Estimation), which combines momentum optimization and RMSProp (Root Mean Square Propagation), making it suitable for deep neural networks. The mathematical equations involved with the Adam optimizer are

where

and

are the decay factors of the moments (typically

and

), and

is the gradient of the loss function concerning the parameters.

Next, the parameters correct the bias of the moments

and

using the following corrections:

Finally, update the parameters using the following rule:

where

is the learning rate, and

is a small constant value (typically

) to avoid division by zero.

This work used this method to adjust the model weights during training with a learning rate of and momentum parameters (, ).

L2 regularization (with a value of 0.001) was applied to prevent overfitting.

The Dropout (0.2) indicates that, during training, 20% of the neurons will be randomly deactivated at each step, which helps the model to better generalize.

Early stopping with patience set to 10 epochs was used to halt training when validation loss stopped improving.

Number of training epochs: 200.

Percentage of data for training: 80%, with the remaining 20% used for validation and testing.

The model trains using data generated by CFD simulations. During training, the model adjusts the neurons’ weights to minimize the mean squared error (MSE) between the network’s predictions and the actual values obtained from the simulations. The data generation process with the CFD simulation runs in parallel, taking advantage of multiple CPU cores to reduce computation time. When the CFD data generation is completed, the trapezoidal rule calculates the area under the temperature curves, ensuring an accurate estimation of the integral of the temperature curve over time.

Early Stopping is a regularization technique used to prevent overfitting during training. It promotes the model’s generalization to new, unseen data. Early Stopping was used to monitor the validation loss with a patience value of 20 epochs.

The quality criteria adopted to evaluate the trained FNNs include three key quantitative metrics: the mean absolute percentage error (MAPE), the mean squared error (MSE), and the coefficient of determination (). These are detailed below:

- 1.

Mean absolute percentage error (MAPE) measures the model’s accuracy in relative terms, showing the average difference between predicted and actual values as a percentage.

where

is the actual value,

is the predicted value, and

n is the total number of data points.

- 2.

Mean squared error(MSE) is another metric used to evaluate the difference between predicted and actual values, penalizing larger errors more significantly, and allowing assessment of the global fit of the model.

where

is the actual value,

is the predicted value, and

n is the total number of data points.

- 3.

R-squared (

) evaluates the degree of fit of the model, indicating the proportion of variance in the data explained by the model. A value of

close to 1 suggests that the model explains the data well.

where

is the actual value,

is the predicted value,

is the mean of the actual values, and

n is the total number of data points.

Using these three metrics allowed a comprehensive evaluation of the model’s performance.

Table 1 presents a comparative analysis of the performance of different neural network architectures with one, two, and three hidden layers, varying the number of neurons in each layer. The metrics MSE,

, and MAPE analyze the training and validation sets.

The models with a single hidden layer showed relatively high values of MSE and MAPE, as well as lower coefficients in validation, indicating lower generalization capacity. On the other hand, networks with three hidden layers achieved the best results, particularly the 256–128–64 configuration, with the lowest MSE in validation (0.0186) and the highest (0.8430), suggesting greater accuracy and stability in predictions. The training MAPE (3.6280%) and validation MAPE (4.2830%) values indicate no overfitting.

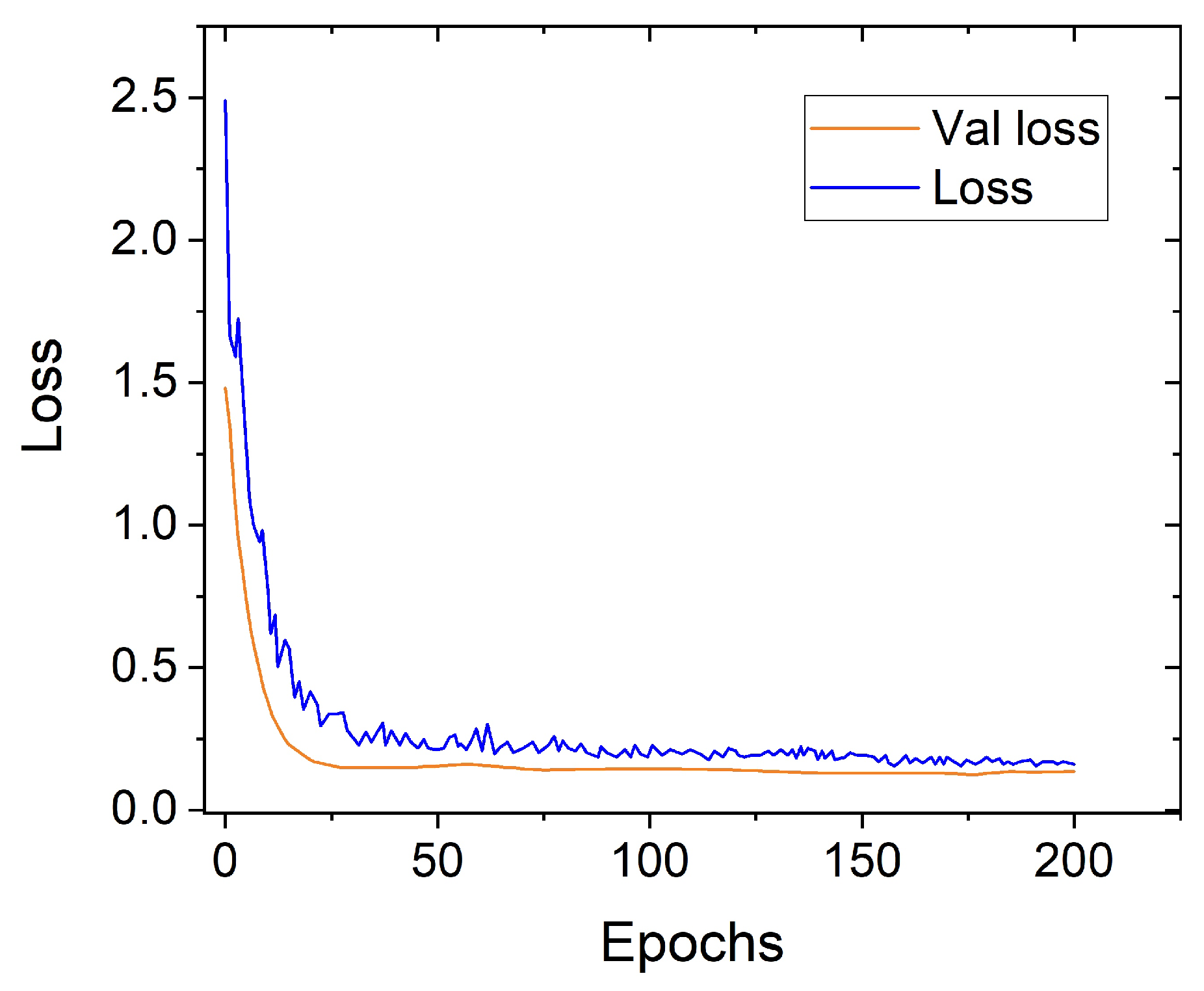

Figure 3 shows the evolution of the loss function (Loss) and validation loss (Val Loss) across the epochs. Both curves decrease quickly at the beginning and stabilize as the training progresses.

Early Stopping indicated that, in all cases, training stopped near 200 epochs, which represents optimal convergence for the model. Stopping at 200 epochs prevents overfitting and ensures the model generalizes well.

3. Experimental and Numerical Results

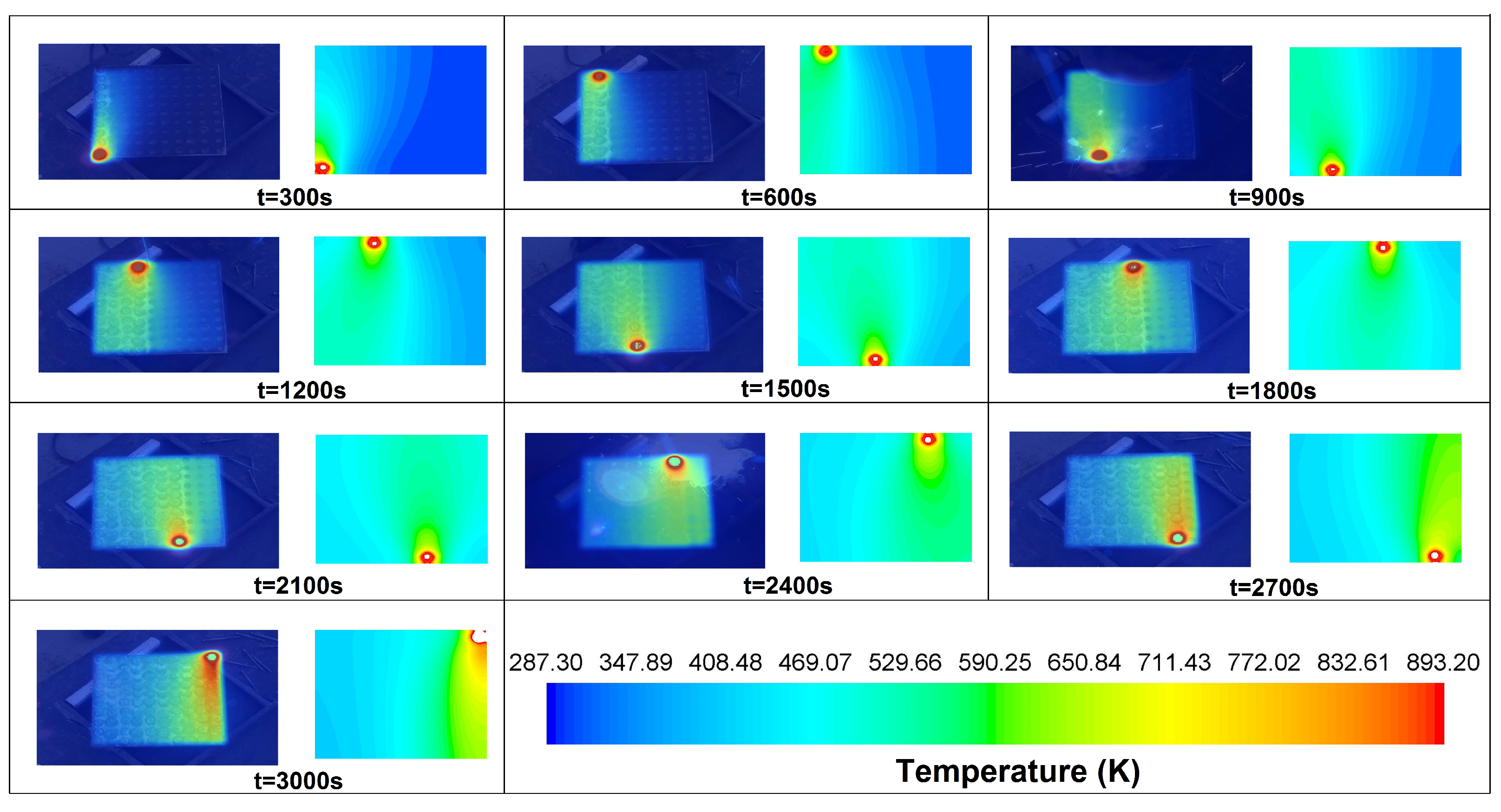

Figure 6 shows a general comparison of the temperature fields obtained. The images on the left display thermographic measurements taken during the experiments, while the images on the right show results from the simulation, with temperature values adjusted within the measurement range handled by the thermographic camera. The notable similarities between the experimental and simulated results validate the numerical model used in this study. Both methodologies accurately capture the main characteristics of heat propagation during the welding process.

The agreement in the spatial distribution of heat and the maximum and minimum temperatures demonstrates a good correspondence between the experimental and simulated results. Additionally, the thermal response times between both methods show remarkable consistency, reinforcing the reliability of the numerical model and its ability to predict thermal behavior accurately.

The simulation reproduces the thermal concentration zones and the heat dissipation paths, highlighting the robustness of the numerical approach in predicting thermal evolution. However, slight deviations appear in areas with high temperatures. Several factors may explain these differences, including simplifications of the physical model, numerical averaging, and the inherent dissipation in the algorithms, which may smooth finer details found in the experimental data [

37].

Additionally, the absence of experimental noise in the simulation results in smoother thermal transitions compared to the thermographic captures. Despite these variations, the model’s overall accuracy remains intact, as thermal trends and the spatial distribution of heat stay consistent in both approaches. This suggests that the numerical simulation effectively predicts thermal behavior in welding processes, providing valuable information for optimization.

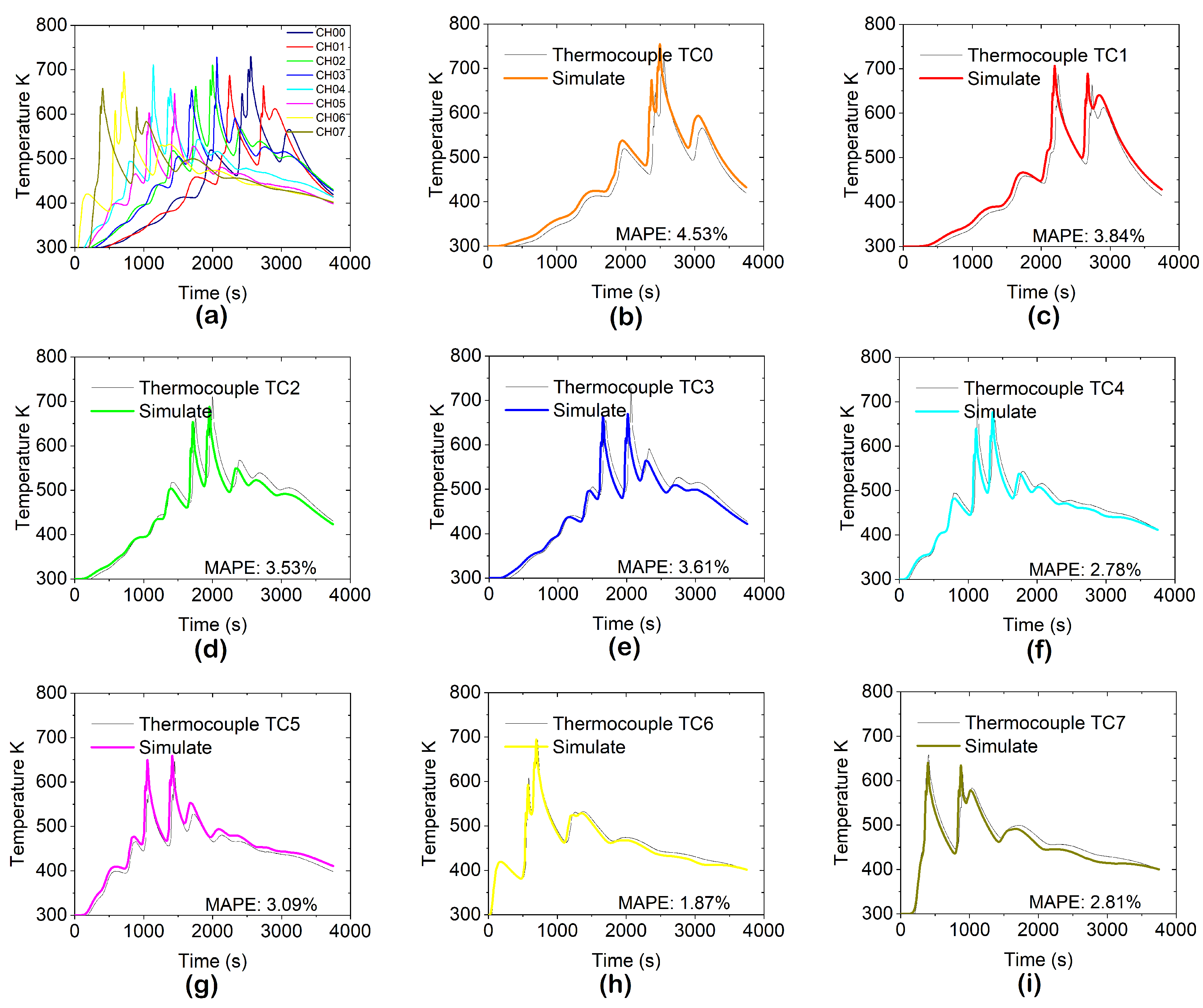

Figure 7 compares the experimental measurements and simulation results for the thermal history at eight different sites of the welding process, measured by the thermocouples TC0 to TC7. The results show significant similarities in the trends and magnitudes of the temperatures. For all thermocouples, the simulation captures the formation of the primary peaks and valleys observed in the experimental data, especially during the heating and cooling phases of the welding process.

Although some sites show slight delays or minor differences in peak size, particularly during abrupt temperature changes, factors such as numerical averaging, geometric or temporal discretization, and inherent smoothing in the simulations likely explain these variations. These peaks typically exhibit more pronounced variations in the experimental data, as mentioned in [

37].

Despite these differences, the overall trend agreement validates the model’s predictive ability. The observed variations do not affect the model’s performance but emphasize the typical trade-offs in computational simulations, such as simplified physics and numerical dissipation, which tend to smooth sharp and localized temperature changes. Furthermore, the calculation of the MAPE errors for each monitor ranges from 1.87% to 4.53% (see

Figure 7).

Real-world sensors capture these changes more accurately but may need to be more evident in the simulations. However, both datasets are recorded at the same frequency, with one data point per second.

Ultimately, the overall agreement between the two methods demonstrates the simulation’s strength in replicating experimental conditions. This result becomes especially significant when considering the limitations and approximations inherent in numerical modeling and the experimental setup.

After selecting the optimal neural network architecture with a structure of 256–128–64 neurons in its respective hidden layers, various tests were conducted by varying the training set size. These experiments aimed to evaluate the model’s performance in terms of mean squared error (MSE), coefficient of determination (), and mean absolute percentage error (MAPE) in both the training and validation phases.

Table 2 shows the validation results for different training set sizes. The MSE decreases in training and validation phases as the training size increases, indicating higher prediction accuracy. Similarly, the

coefficient improves, suggesting a better ability to explain data variability. Moreover, the MAPE tends to decrease, reflecting a more precise relative prediction error. However, while improvements continue as dataset size increases, the additional benefits become less significant beyond

. Although the model performs best with 1000 training points, the additional gains in validation metrics are marginal considering the time and computational cost of the additional simulations. A training size between 200 and 500 data points offers an optimal trade-off between predictive accuracy and computational efficiency.

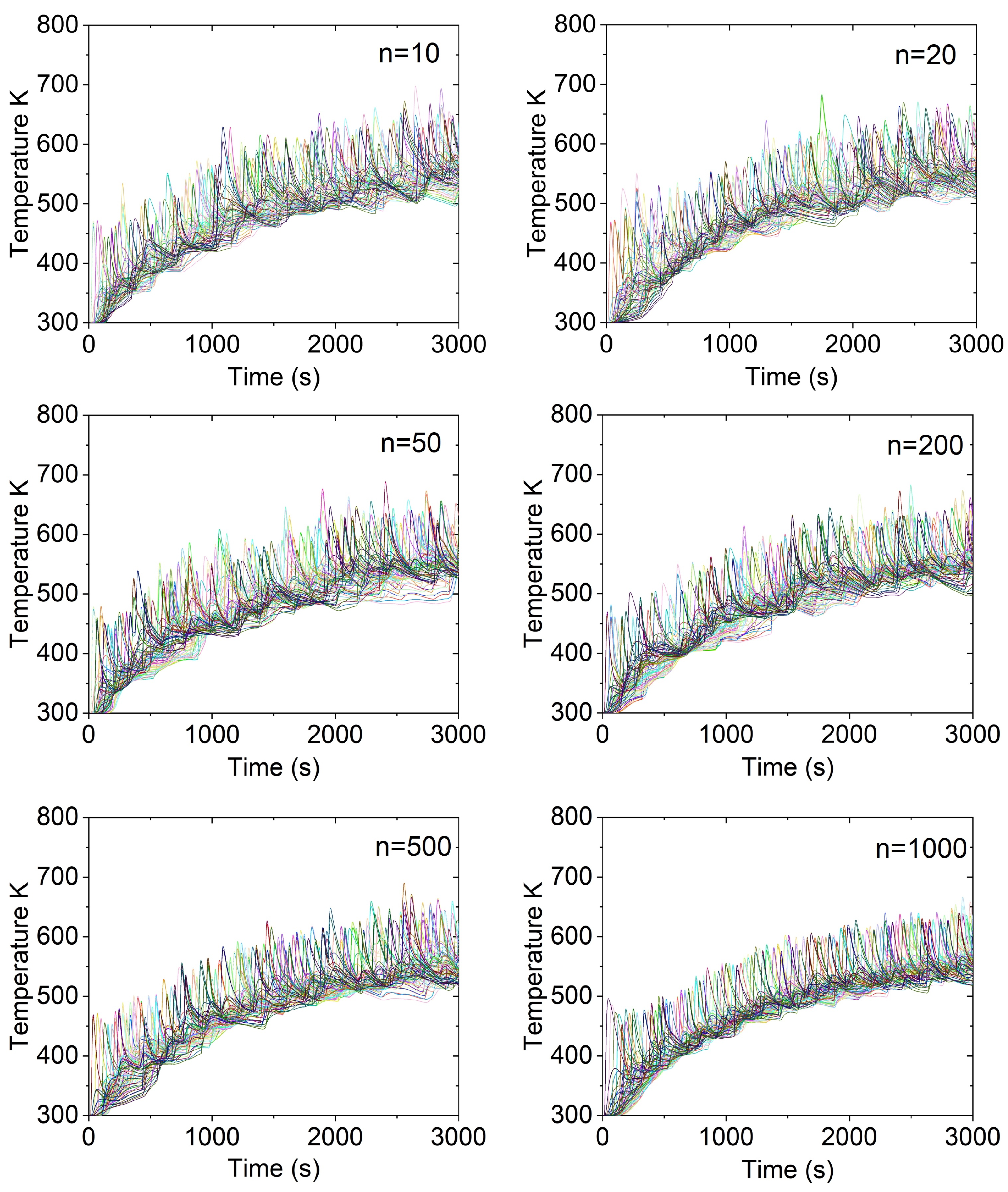

Figure 8 compares the thermal management results of training a neural network with different numbers of training data in the optimization process. The figure illustrates the temperature evolution during welding for

n dataset sizes: 10, 20, 50, 200, 500, and 1000 simulations. The training dataset used the area under the curve generated by each simulation. As the number of data increases, the neural network model becomes more accurate in optimizing thermal distribution.

The temperature curves show more scattering and higher variability in cases with fewer data points ( and ). This suggests that the model needs help to capture the complex heat transfer dynamics, resulting in suboptimal optimization outcomes. With a limited number of training data, the neural network cannot properly learn the thermal patterns of the welding process, which leads to steeper thermal gradients and a higher likelihood of overheating or thermal concentration.

As the training dataset size increases ( 50, 200, 500, 1000), the neural network progressively refines its ability to optimize the thermal coupling between welding points. This results in more uniform thermal gradients and improved heat distribution control. Larger datasets allow the model to learn more complex patterns in the thermal distribution, leading to smoother temperature variations and reduced excessive heat accumulation. Notably, cases with and 1000 show significant improvements in temperature control, suggesting that even larger datasets further enhance model performance.

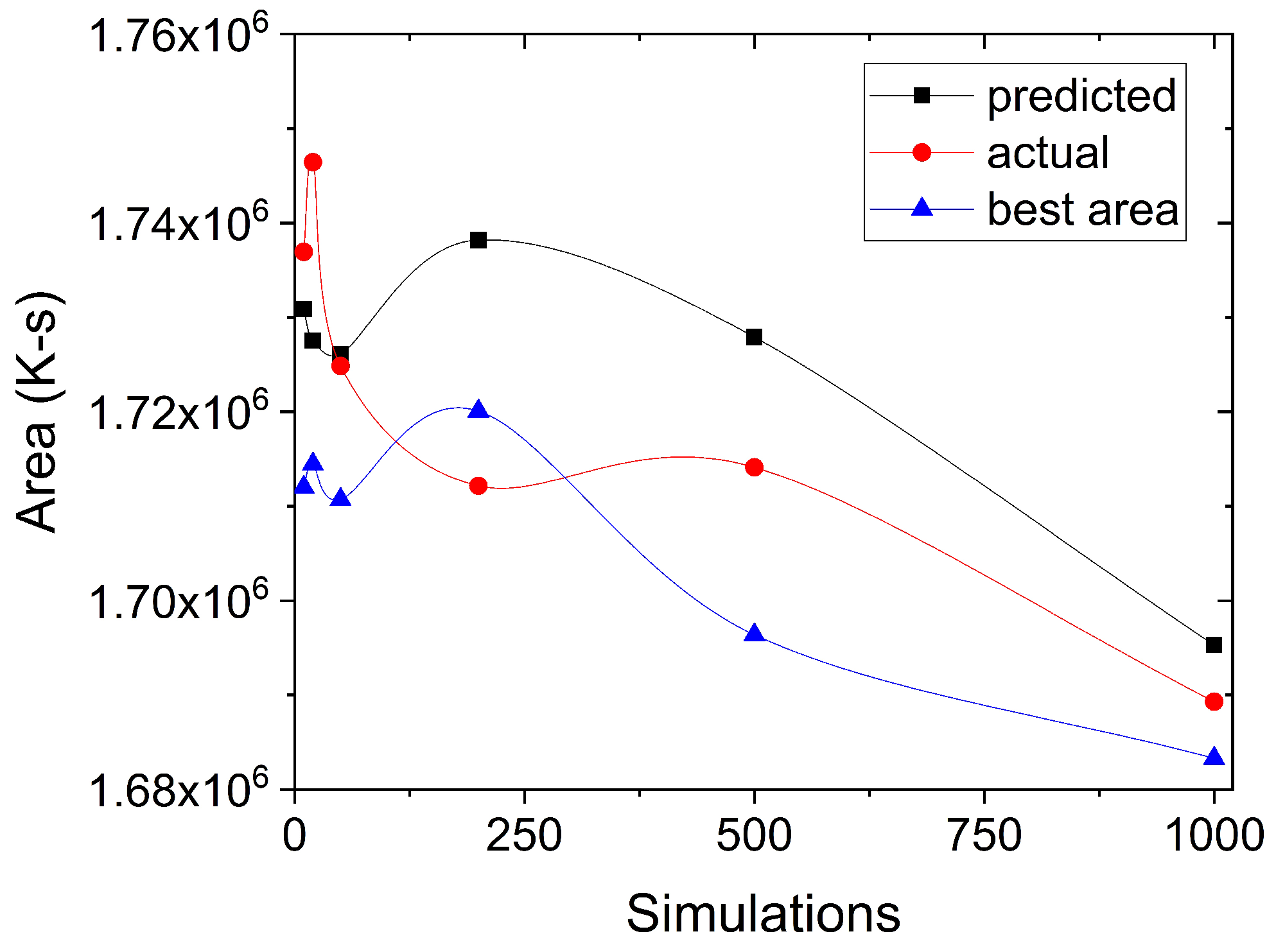

Figure 9 shows the evolution of the three types of area (the predicted area from the neural network, the actual area in the CFD model, and the optimal or best area) as the number of simulations increases.

As the simulation size increases, the three areas decrease, suggesting a progressive improvement in the model’s ability to optimize the thermal distribution.

In particular, the Best Area curve shows how the neural network finds more optimal solutions as it receives more data, reflecting a convergence towards better thermal management. The differences between the predicted and actual areas at the beginning indicate the need for a larger dataset to improve the model’s accuracy.

As the simulation increases, the model stabilizes, progressively bringing the prediction closer to the actual area. This demonstrates the neural network’s effectiveness in optimizing the thermal distribution of the welding process.

Author Contributions

Conceptualization, A.R.M.-G. and S.A.A.-V.; methodology, A.R.M.-G. and S.A.A.-V.; software, A.R.M.-G. and S.A.A.-V.; validation, A.P.-A., A.R.M.-G. and S.A.A.-V.; formal analysis, A.R.M.-G. and S.A.A.-V.; investigation, I.C.-R., A.P.-A. A.R.M.-G., and S.A.A.-V.; resources, R.S.-C. and H.J.V.-H.; data curation, A.R.M.-G. and S.A.A.-V.; writing—original draft preparation, A.R.M.-G. and S.A.A.-V.; writing—review and editing, I.C.-R., A.P.-A., A.R.M.-G. and S.A.A.-V.; visualization, I.C.-R., A.P.-A., A.R.M.-G. and S.A.A.-V.; supervision, R.S.-C. and H.J.V.-H.; project administration, R.S.-C. and H.J.V.-H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article material. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors thank Dirección de Investigación y Posgrado from UAdeC for their continuous support of the Mechanical Engineering Department. The authors thank the National Laboratory SEDEAM-CONAHCYT. The authors thank CONAHCYT and PRODEP for their continuous support to the Mechanical Engineering Department.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- De Soldadura, M. Recuperacion de un Molino Vertical Atox 32.5 para Molienda de Caliza. Sci. Tech. 2007, 13, 625–630. [Google Scholar]

- Goldak, J.; Bibby, M.; Moore, J.; House, R.; Patel, B. Computer modeling of heat flow in welds. Metall. Trans. 1986, 17, 587–600. [Google Scholar] [CrossRef]

- Cohal, V. Some considerations regarding the thermal field at welded joints. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 400, p. 042011. [Google Scholar]

- Brust, F.; Kim, D. Mitigating welding residual stress and distortion. In Processes and Mechanisms of Welding Residual Stress and Distortion; Elsevier: Amsterdam, The Netherlands, 2005; pp. 264–294. [Google Scholar]

- Wu, C.; Wang, C.; Kim, J.W. Welding sequence optimization to reduce welding distortion based on coupled artificial neural network and swarm intelligence algorithm. Eng. Appl. Artif. Intell. 2022, 114, 105142. [Google Scholar] [CrossRef]

- Girón-Cruz, J.A.; Pinto-Lopera, J.E.; Alfaro, S.C. Weld bead geometry real-time control in gas metal arc welding processes using intelligent systems. Int. J. Adv. Manuf. Technol. 2022, 123, 3871–3884. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Q.; Liu, Y. Adaptive intelligent welding manufacturing. Weld. J. 2021, 100, 63–83. [Google Scholar] [CrossRef]

- Aguado, A.; Gómez, A.; del Pozo, A. Controlador predictivo neuro-genético. Rev. Iberoam. Autom. Inform. Ind. RIAI 2007, 4, 94–108. [Google Scholar] [CrossRef]

- Waheed, R.; Saeed, H.; Butt, S.; Anjum, B. Framework for Mitigation of Welding Induced Distortion through Response Surface Method and Reinforcement Learning. Coatings 2021, 11, 1227. [Google Scholar] [CrossRef]

- Yang, H.; Shao, H. Distortion-oriented welding path optimization based on elastic net method and genetic algorithm. J. Mater. Process. Technol. 2009, 209, 4407–4412. [Google Scholar] [CrossRef]

- Zhang, H.; Li, R.; Yang, S.; Liu, Z.; Xiong, M.; Wang, B.; Zhang, J. Experimental and Simulation Study on Welding Characteristics and Parameters of Gas Metal Arc Welding for Q345qD Thick-Plate Steel. Materials 2023, 16, 5944. [Google Scholar] [CrossRef]

- Arora, H.; Singh, R.; Brar, G.S. Thermal and structural modelling of arc welding processes: A literature review. Meas. Control. 2019, 52, 955–969. [Google Scholar] [CrossRef]

- Mohanty, U.K.; Sharma, A.; Abe, Y.; Fujimoto, T.; Nakatani, M.; Kitagawa, A.; Tanaka, M.; Suga, T. Thermal modelling of alternating current square waveform arc welding. Case Stud. Therm. Eng. 2021, 25, 100885. [Google Scholar] [CrossRef]

- Mohan, A.; Ceglarek, D.; Auinger, M. Numerical modelling of thermal quantities for improving remote laser welding process capability space with consideration to beam oscillation. Int. J. Adv. Manuf. Technol. 2022, 123, 761–782. [Google Scholar] [CrossRef]

- Chen, F.F.; Xiang, J.; Thomas, D.G.; Murphy, A.B. Model-based parameter optimization for arc welding process simulation. Appl. Math. Model. 2020, 81, 386–400. [Google Scholar] [CrossRef]

- Eagar, T.; Tsai, N. Temperature fields produced by traveling distributed heat sources. Weld. J. 1983, 62, 346–355. [Google Scholar]

- Goldak, J.; Chakravarti, A.; Bibby, M. A new finite element model for welding heat sources. Metall. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

- Van Elsen, M.; Baelmans, M.; Mercelis, P.; Kruth, J.P. Solutions for modelling moving heat sources in a semi-infinite medium and applications to laser material processing. Int. J. Heat Mass Transf. 2007, 50, 4872–4882. [Google Scholar] [CrossRef]

- Zhou, Z.; Shen, H.; Liu, B.; Du, W.; Jin, J. Thermal field prediction for welding paths in multi-layer gas metal arc welding-based additive manufacturing: A machine learning approach. J. Manuf. Process. 2021, 64, 960–971. [Google Scholar] [CrossRef]

- Ren, K.; Chew, Y.; Zhang, Y.; Bi, G.; Fuh, J. Thermal analyses for optimal scanning pattern evaluation in laser aided additive manufacturing. J. Mater. Process. Technol. 2019, 271, 178–188. [Google Scholar] [CrossRef]

- Mughal, M.; Fawad, H.; Mufti, R. Finite element prediction of thermal stresses and deformations in layered manufacturing of metallic parts. Acta Mech. 2006, 183, 61–79. [Google Scholar] [CrossRef]

- Kasilingam, S.; Yang, R.; Singh, S.K.; Farahani, M.A.; Rai, R.; Wuest, T. Physics-based and data-driven hybrid modeling in manufacturing: A review. Prod. Manuf. Res. 2024, 12, 2305358. [Google Scholar] [CrossRef]

- Romero-Hdz, J.; Aranda, S.; Toledo-Ramirez, G.; Segura, J.; Saha, B. An Elitism Based Genetic Algorithm for Welding Sequence Optimization to Reduce Deformation. Res. Comput. Sci. 2016, 121, 17–36. [Google Scholar] [CrossRef]

- Yuan, M.; Liu, S.; Gao, Y.; Sun, H.; Liu, C.; Shen, Y. Immune Optimization of Welding Sequence for Arc Weld Seams in Ship Medium-Small Assemblies. Coatings 2022, 12, 703. [Google Scholar] [CrossRef]

- McAdams, W.H. Heat Transmission; McGraw-Hill Book Company: New York, NY, USA, 1954. [Google Scholar]

- López-Cornejo, M.S.; Vergara-Hernández, H.J.; Arreola-Villa, S.A.; Vázquez-Gómez, O.; Herrejón-Escutia, M. Numerical Simulation of Wire Rod Cooling in Eutectoid Steel under Forced-Convection. Metals 2021, 11, 224. [Google Scholar] [CrossRef]

- López-Martínez, E.; Hernández-Morales, J.; Solorio-Díaz, G.; Vergara-Hernández, H.; Vázquez-Gómez, O.; Garnica-González, P. Predicción del perfil de dureza en probetas jominy de aceros de medio y bajo carbono. Rev. Mex. Ing. Quím. 2013, 12, 609–619. [Google Scholar]

- Jia, L.; Zou, Y.; Zou, Z.D.; Zhao, Y.S.; Yao, Q.S. Research and application status of arc welding heat source model for T-joint numerical simulation. Adv. Mater. Res. 2011, 154, 1423–1426. [Google Scholar] [CrossRef]

- Belhadj, A.; Bessrour, J.; Masse, J.E.; Bouhafs, M.; Barrallier, L. Finite element simulation of magnesium alloys laser beam welding. J. Mater. Process. Technol. 2010, 210, 1131–1137. [Google Scholar] [CrossRef]

- Doshi, S.; Jani, D.; Gohil, A.; Patel, C. Investigations of heat source models in transient thermal simulation of pulsed MIG welding of AA6061-T6 thin sheet. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1146, p. 012015. [Google Scholar]

- Kim, C.H.; Zhang, W.; DebRoy, T. Modeling of temperature field and solidified surface profile during gas–metal arc fillet welding. J. Appl. Phys. 2003, 94, 2667–2679. [Google Scholar] [CrossRef]

- Nascimento, E.J.; dos Santos Magalhães, E.; dos Santos Paes, L.E. A literature review in heat source thermal modeling applied to welding and similar processes. Int. J. Adv. Manuf. Technol. 2023, 126, 2917–2957. [Google Scholar] [CrossRef]

- Goldak, J.A.; Akhlaghi, M. Computational Welding Mechanics; Springer Science & Business Media: Cham, Switzerland, 2005. [Google Scholar]

- Jeyakumar, M.; Christopher, T. Influence of residual stresses on failure pressure of cylindrical pressure vessels. Chin. J. Aeronaut. 2013, 26, 1415–1421. [Google Scholar] [CrossRef]

- Nadimi, S.; Khoushehmehr, R.; Rohani, B.; Mostafapour, A. Investigation and analysis of weld induced residual stresses in two dissimilar pipes by finite element modeling. J. Appl. Sci. 2008, 8, 1014–1020. [Google Scholar] [CrossRef]

- de Freitas Teixeira, P.R.; de Araújo, D.B.; da Cunha, L.A.B. Study of the Gaussian distribution heat source model applied to numerical thermal simulations of tig welding processes. Cienc. Eng. Sci. Eng. J. 2014, 23, 115–122. [Google Scholar]

- Oberkampf, W.L.; Roy, C.J. Verification and Validation in Scientific Computing; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).