The Effect of Final Cooling Temperature on Nano Cu Precipitation in a Cu-Bearing High-Strength Low-Alloy Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

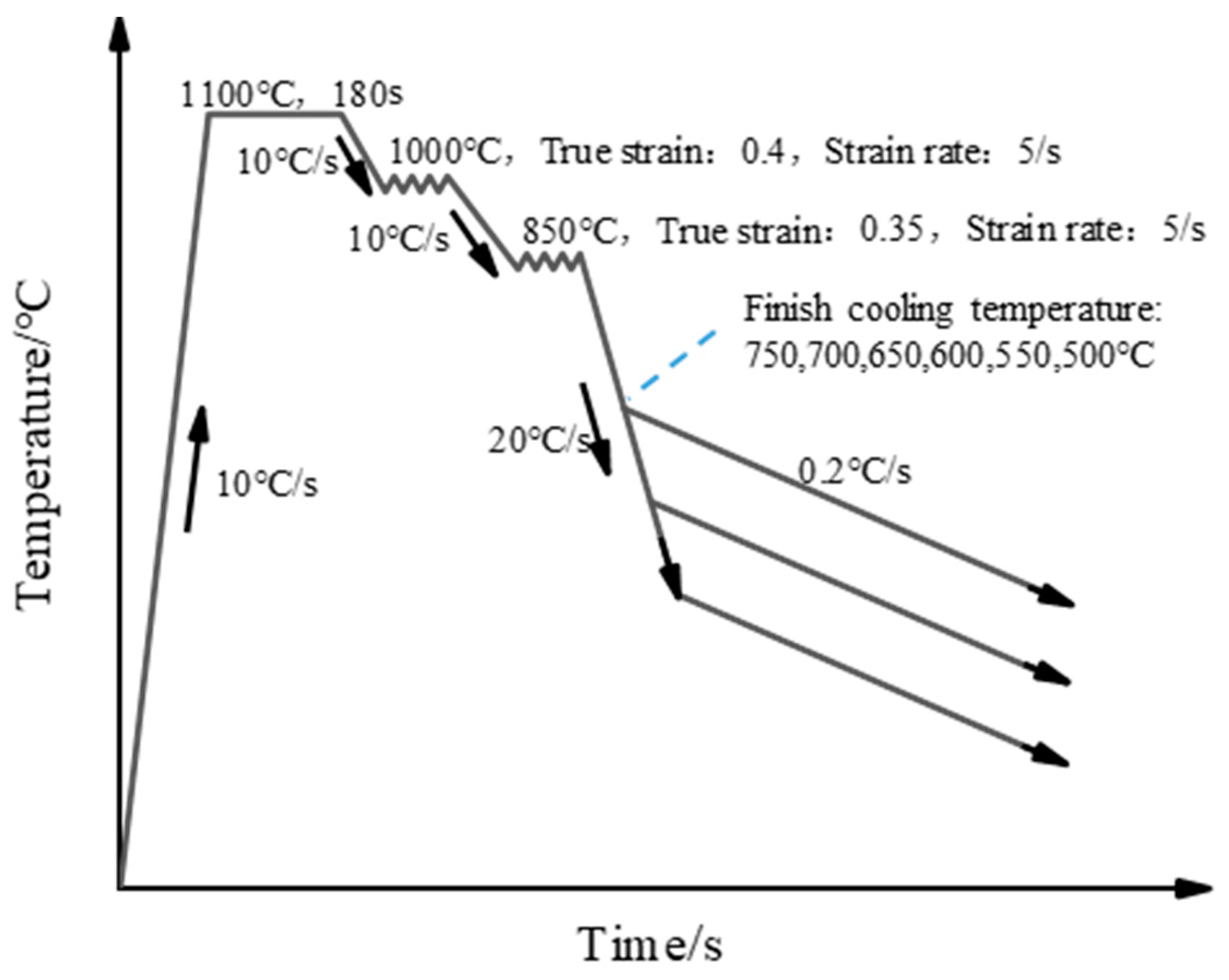

2.2. Experimental Process

2.3. Characterization

3. Results and Disscussion

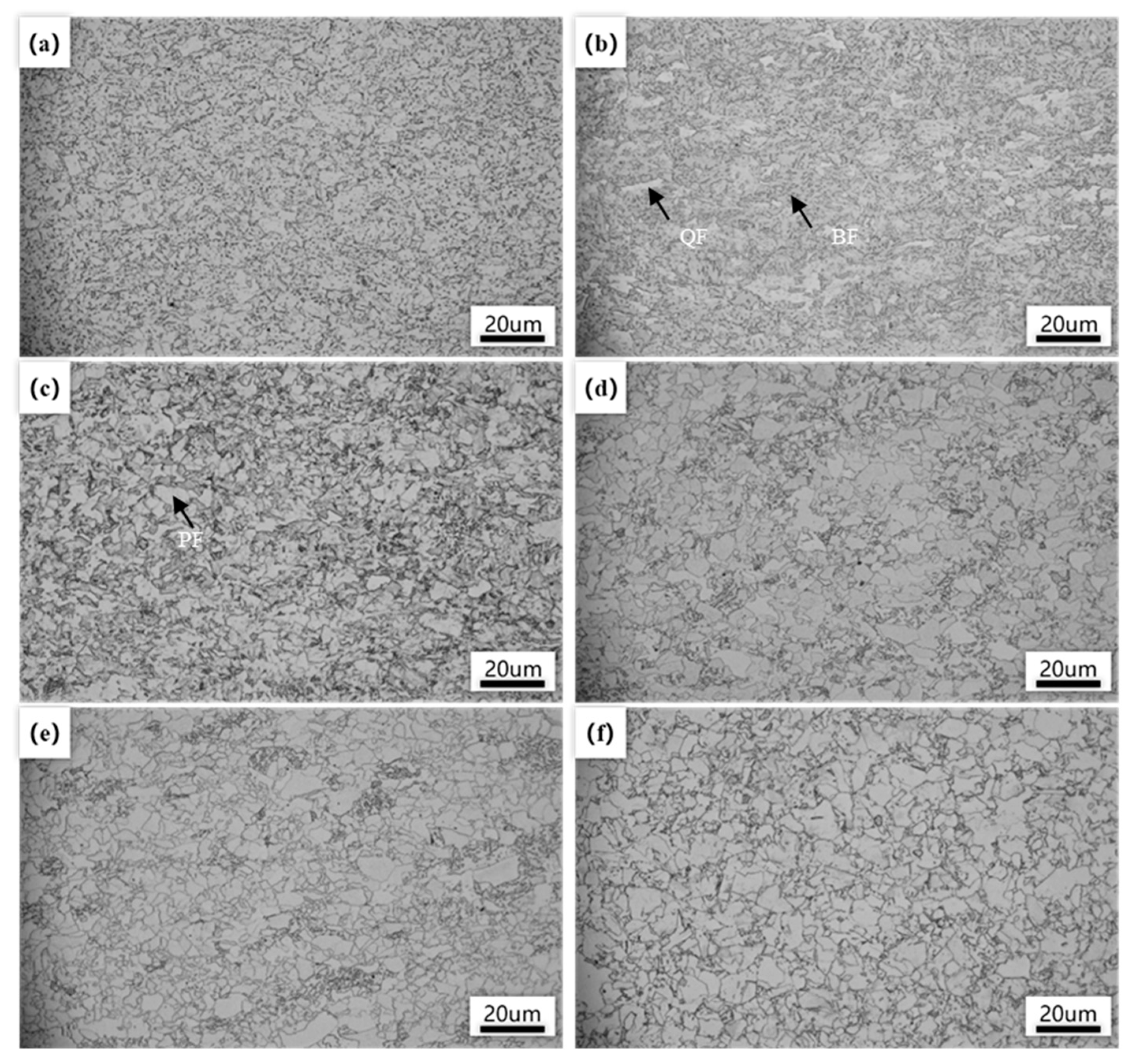

3.1. The Effect of Final Cooling Temperature on Microstructure

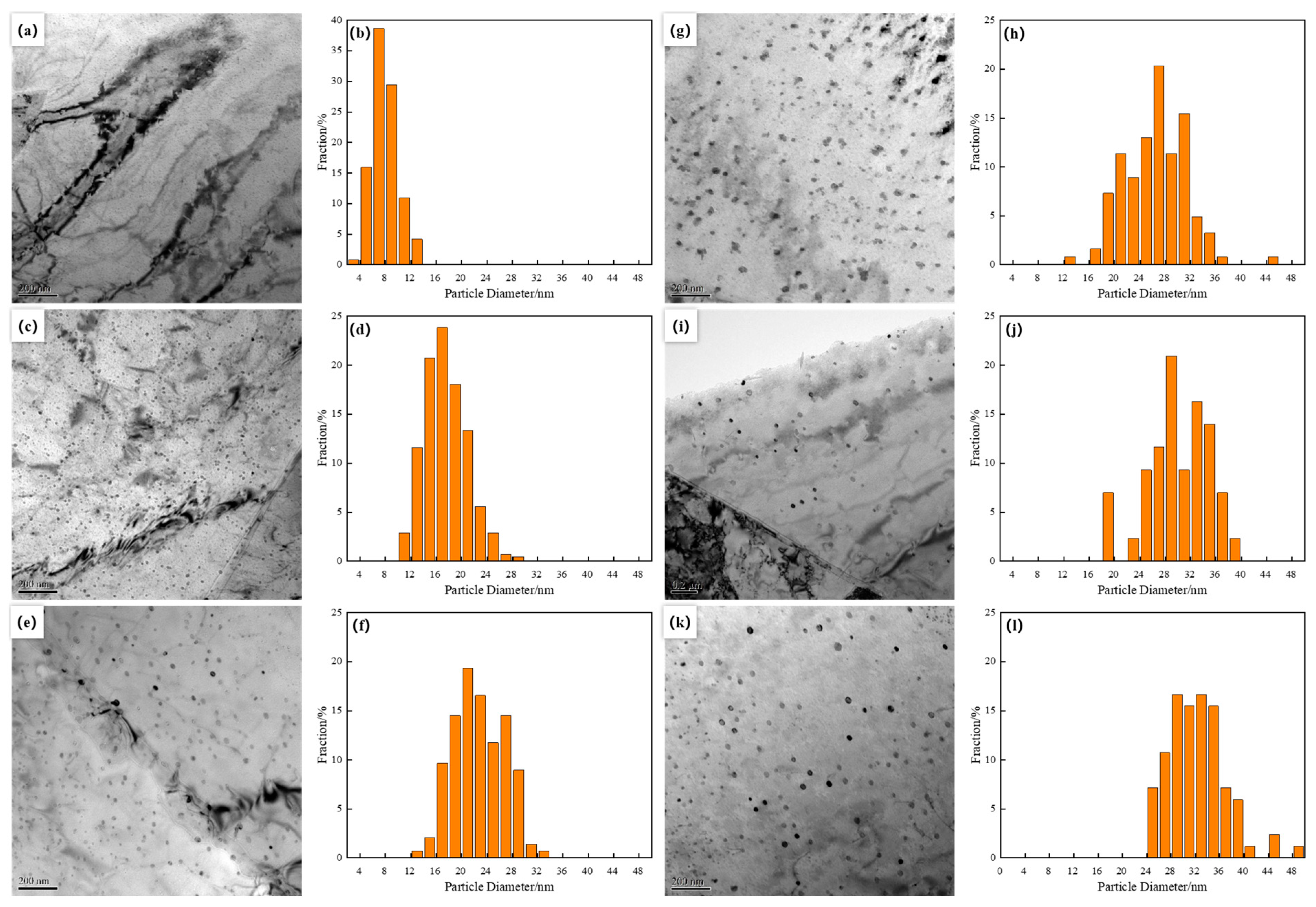

3.2. Analysis of Quantity Density of Copper Precipitation

3.3. The Effect of Final Cooling Temperature on Hardness

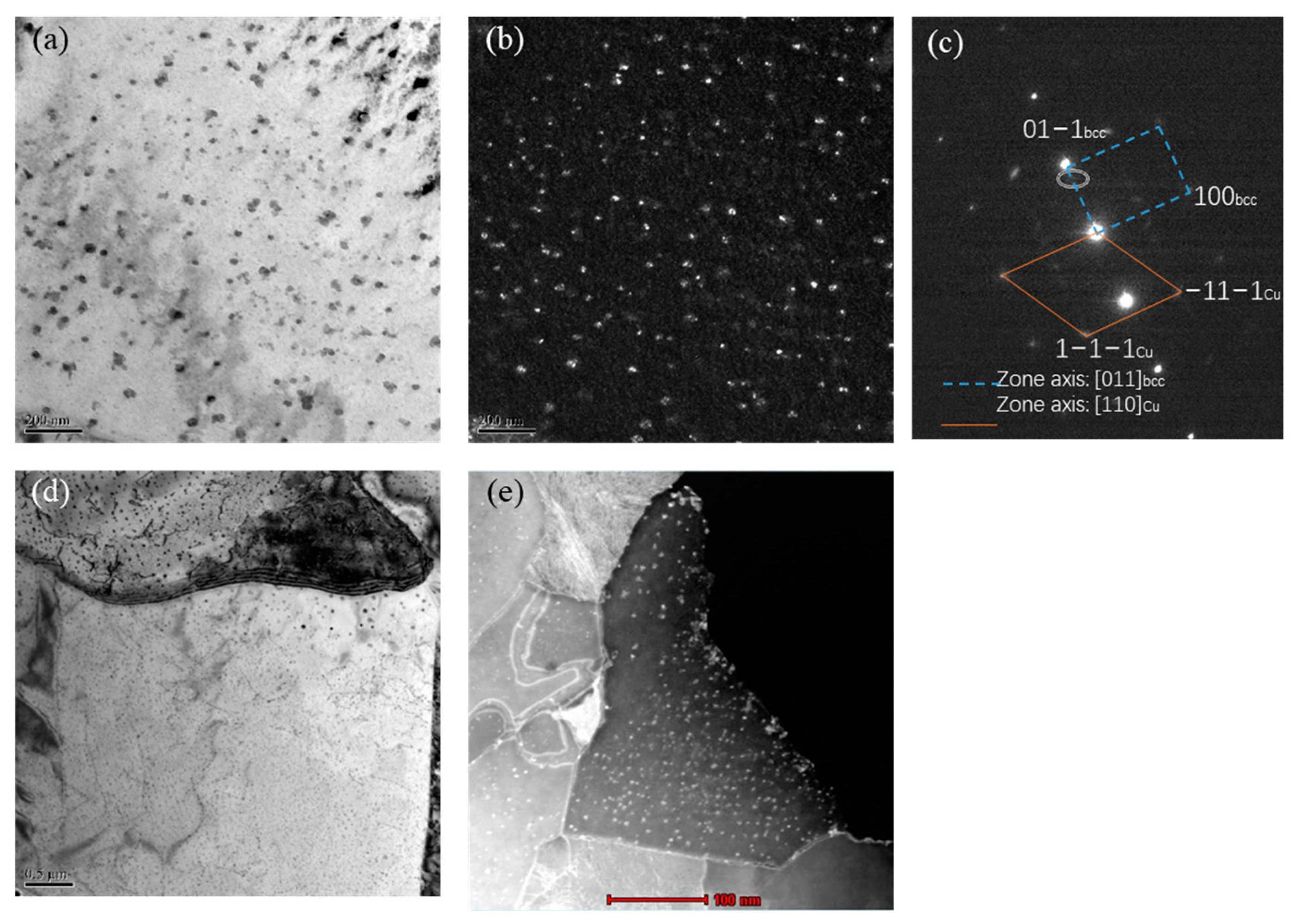

3.4. TEM Analysis of Nano Copper Precipitation

4. Conclusions

- (1)

- As the final cooling temperature increases, the microstructure of the experimental steel gradually transitions from a mixed structure of ferrite and bainite to a fully ferritic structure.

- (2)

- The continuous nucleation and coarsening process of nano Cu precipitation led to an increase and then a decrease in the microhardness of ferrite. When the final cooling temperature was 550 °C, the microhardness reached its peak, and the Vickers hardness of the ferrite was 296 HV.

- (3)

- As the final cooling temperature increased, the shape of the precipitated particles changed from spherical to elliptical, and the particle size gradually increased. At 650 °C, there was a significant amount of interphase precipitation in the Cu-bearing high-strength low-alloy steel

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ray, P.K.; Ganguly, R.I.; Panda, A.K. Optimization of mechanical properties of an HSLA-100 steel through control of heat treatment variables. Mater. Sci. Eng. A 2003, 346, 122–131. [Google Scholar] [CrossRef]

- Misra, R.D.K.; Jia, Z.; O’Malley, R.; Jansto, S.J. Precipitation behavior during thin slab thermomechanical processing and isothermal aging of copper-bearing niobium-microalloyed high strength structural steels: The effect on mechanical properties. Mater. Sci. Eng. A 2011, 528, 8772–8780. [Google Scholar] [CrossRef]

- Timokhina, I.B.; Hodgson, P.D.; Ringer, S.P.; Zheng, R.K.; Pereloma, E.V. Precipitate characterisation of an advanced high-strength low-alloy (HSLA) steel using atom probe tomography. Scr. Mater. 2007, 56, 601–604. [Google Scholar] [CrossRef]

- Funakawa, Y.; Shiozaki, T.; Tomita, K.; Yamamoto, T.; Maeda, E. Development of high strength hot-rolled sheet steel consisting of ferrite and nanometer-sized carbides. ISIJ Int. 2004, 44, 1945–1951. [Google Scholar] [CrossRef]

- Sun, M.; Xu, Y.; Wang, J. Effect of Aging Time on Microstructure and Mechanical Properties in a Cu-Bearing Marine Engineering Steel. Materials 2020, 13, 3638. [Google Scholar] [CrossRef]

- Yang, X.; Di, X.; Liu, X.; Wang, D.; Li, C.J.M.C. Effects of heat input on microstructure and fracture toughness of simulated coarse-grained heat affected zone for HSLA steels. Mater. Char. 2019, 155, 109818. [Google Scholar] [CrossRef]

- Okamoto, R.; Borgenstam, A.; Ågren, J. Interphase precipitation in niobium-microalloyed steels. Acta Mater. 2010, 58, 4783–4790. [Google Scholar] [CrossRef]

- Tomida, T.; Imai, N.; Yoshida, M.; Fukushima, S. Effect of ultra-fast cooling after rolling in stable austenite region on grain refinement of C-Mn steel. Mater. Sci. Forum 2007, 539–543, 4708–4713. [Google Scholar] [CrossRef]

- Kamikawa, N.; Sato, K.; Miyamoto, G.; Murayama, M.; Sekido, N.; Tsuzaki, K.; Furuhara, T. Stress–strain behavior of ferrite and bainite with nano-precipitation in low carbon steels. Acta. Mater 2015, 83, 383–396. [Google Scholar] [CrossRef]

- Charleux, M.; Poole, W.; Militzer, M.; Deschamps, A. Precipitation behavior and its effect on strengthening of an HSLA-Nb/Ti steel. Metall. Mater. Trans. A 2001, 32A, 1635–1647. [Google Scholar] [CrossRef]

- Xu, C.; Dai, W.J.; Chen, Y.; Qi, Z.X.; Zheng, G.; Cao, Y.D.; Zhang, J.P.; Bu, C.C.; Chen, G. Control of dislocation density maximizing precipitation strengthening effect. J. Mater. Sci. Technol. 2022, 127, 133–143. [Google Scholar] [CrossRef]

- Mulholland, M.D.; Seidman, D.N. Nanoscale co-precipitation and mechanical properties of ahigh-strength low-carbon steel. Acta Mater. 2011, 59, 1881–1897. [Google Scholar] [CrossRef]

- Han, G.; Xie, Z.J.; Li, Z.Y.; Lei, B.; Shang, C.J.; Misra, R.D.K. Evolution of crystal structure of Cu precipitates in a low carbon steel. Mater. Des. 2017, 135, 92–101. [Google Scholar] [CrossRef]

- Wen, Y.R.; Li, Y.P.; Hirata, A.; Zhang, Y.; Fujita, T.; Liu, C.T.; Chiba, A.; Chen, M.W. Synergistic alloying effect on microstructural evolution and mechanical properties of Cu precipitation-strengthened ferritic alloys. Acta Mater. 2013, 61, 7726–7740. [Google Scholar] [CrossRef]

- Sun, M.; Zhang, W.; Liu, Z.; Wang, G. Direct observations on the crystal structure evolution of nano Cu-precipitates in an extremely low carbon steel. Mater. Lett. 2017, 15, 49–52. [Google Scholar] [CrossRef]

- Habibi, H.R. Atomic structure of the Cu precipitates in two stages hardening in maraging steel. Mater. Lett. 2005, 59, 1824–1827. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, L.; Liu, C. Effect of step quenching on microstructures and mechanical properties of HSLA steel. Mater. Sci. Eng. A 2016, 675, 371–378. [Google Scholar] [CrossRef]

- Hwang, G.C.; Lee, S.; Yoo, J.Y.; Choo, W.Y. Effect of direct quenching on microstructure and mechanical properties of copper-bearing high-strength alloy steels. Mater. Sci. Eng. A 1998, 252, 256–268. [Google Scholar] [CrossRef]

- Ghosh, A.; Mishra, B.; Das, S.; Chatterjee, S. An ultra low carbon Cu bearing steel: Influence of thermomechanical processing and aging heat treatment on structure and properties. Mater. Sci. Eng. A 2004, 374, 43–56. [Google Scholar] [CrossRef]

- Yang, X.; Li, C.; Han, J.; Yang, Y.; Ju, Y.; Ba, L.; Wang, C.; Di, X. Effect of welding state on the re-precipitation behavior of Cu-rich and NiAl nanoparticles in HAZ of 1100 MPa grade low carbon ultra-high strength steel. Mater. Sci. Eng. A 2024, 897, 146334. [Google Scholar] [CrossRef]

- Yen, H.; Chen, P.; Huang, C.; Yang, J. Interphase precipitation of nanometer-sized carbides in a titanium-molybdenum-bearing low-carbon steel. Acta Mater. 2011, 59, 6264–6274. [Google Scholar] [CrossRef]

- Ji, F.Q.; Li, C.N.; Tang, S.; Wang, G.D. Interphase precipitation of nanometre-sized carbides in Ti bearing steels. Mater. Res. Innov. 2015, 19, S92–S97. [Google Scholar] [CrossRef]

- Ji, F.Q.; Li, C.N.; Tang, S.; Liu, Z.Y.; Wang, G.D. Effects of carbon and niobium on microstructure and properties for Ti bearing steels. Mater. Sci. Technol. 2014, 31, 695–702. [Google Scholar] [CrossRef]

- Yi, H.; Xu, Y.; Xu, Z.; Liu, Z.; Wang, G. Microstructure and properties of low cost 780 MPa hot-rolled high-strength steel. Mater. Mech. Eng. 2010, 34, 37–39. [Google Scholar]

- Sun, M.; Xu, Y.; Xu, T. Cu Precipitation Behaviors and Microscopic Mechanical Characteristics of a Novel Ultra-Low Carbon Steel. Materials 2020, 13, 3571. [Google Scholar] [CrossRef]

| C | Cu | Ni | Mn | Cr | Si | Mo | V | Al |

|---|---|---|---|---|---|---|---|---|

| 0.02 | 1.52 | 1.54 | 1.0 | 0.58 | 0.33 | 0.29 | 0.032 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, H.; Liang, H.; Sun, X.; Li, Y.; Gao, Z.; Liu, J. The Effect of Final Cooling Temperature on Nano Cu Precipitation in a Cu-Bearing High-Strength Low-Alloy Steel. Metals 2025, 15, 150. https://doi.org/10.3390/met15020150

Cui H, Liang H, Sun X, Li Y, Gao Z, Liu J. The Effect of Final Cooling Temperature on Nano Cu Precipitation in a Cu-Bearing High-Strength Low-Alloy Steel. Metals. 2025; 15(2):150. https://doi.org/10.3390/met15020150

Chicago/Turabian StyleCui, Haitao, Haicheng Liang, Xinglong Sun, Yonghua Li, Zhanjie Gao, and Jinsong Liu. 2025. "The Effect of Final Cooling Temperature on Nano Cu Precipitation in a Cu-Bearing High-Strength Low-Alloy Steel" Metals 15, no. 2: 150. https://doi.org/10.3390/met15020150

APA StyleCui, H., Liang, H., Sun, X., Li, Y., Gao, Z., & Liu, J. (2025). The Effect of Final Cooling Temperature on Nano Cu Precipitation in a Cu-Bearing High-Strength Low-Alloy Steel. Metals, 15(2), 150. https://doi.org/10.3390/met15020150