Effect of Nb Alloying and Solution Treatment on the Mechanical Properties of Cold-Rolled Fe-Mn-Al-C Low-Density Steel

Abstract

1. Introduction

2. Materials and Methods

3. Results

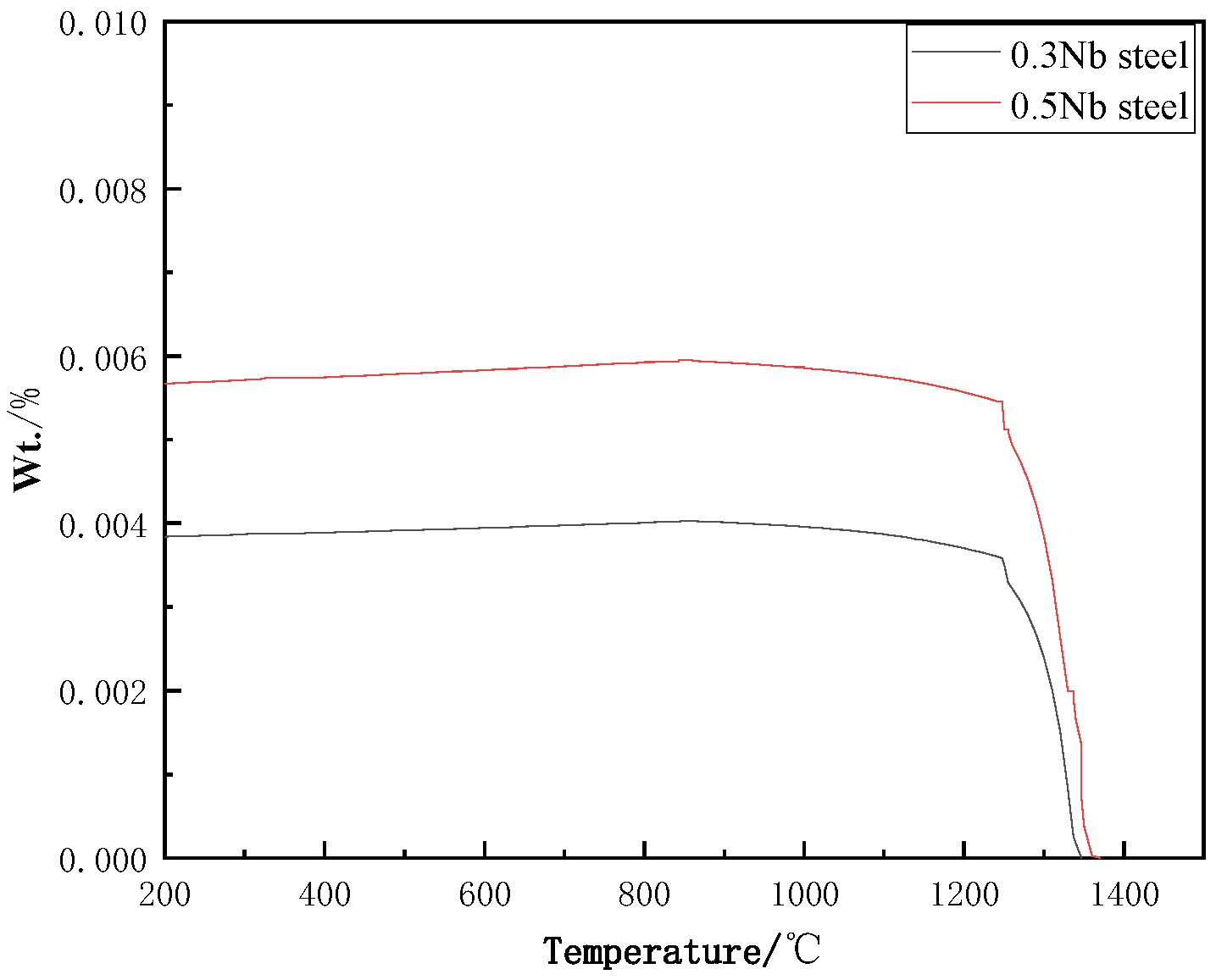

3.1. Thermodynamic Calculation of the Influence of Nb on the Phase Transition and Precipitation Behavior of Fe-28Mn-10Al-C Steel

- —carbon content in steel, %;

- —niobium (Nb) solubility in steel, %;

- —heat treatment temperature, K.

3.2. Calculation of Mis-Energy in the Test Steel Layer

- ΔGγ→ε—Gibbs free energy required for the transition from to , kJ/mol;

- Ρ—{1 1 1} surface atomic packing density, mol/cm3;

- σ—γ/ε interface energy, J/mol;

- α— lattice constant;

- N—Avogadro’s constant.

- X—mole fraction of each phase, %;

- —Gibbs free energy in the magnetic state of phase φ, kJ/mol;

- —interaction parameter between the i and j phases;

- L0—temperature-based parameter;

- L1—constant;

- Tneel—Neel temperature, K;

- β—magnetic distance, value dependent on composition.

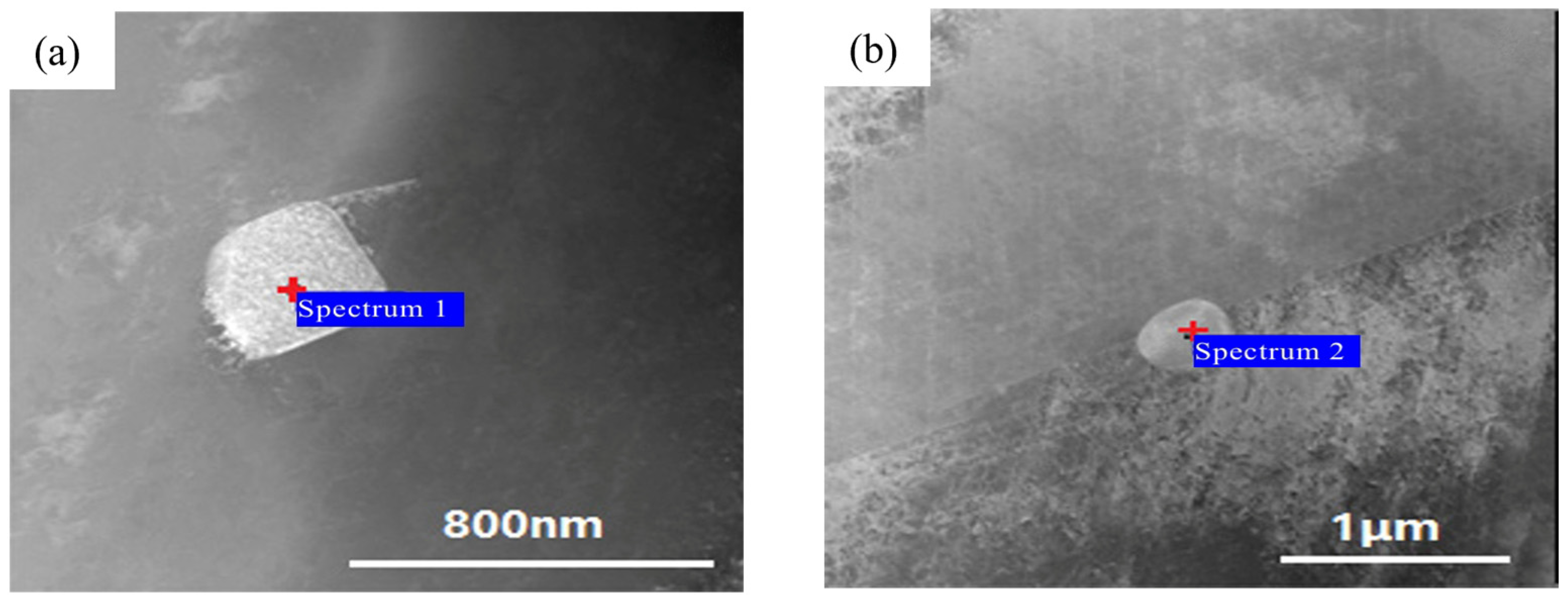

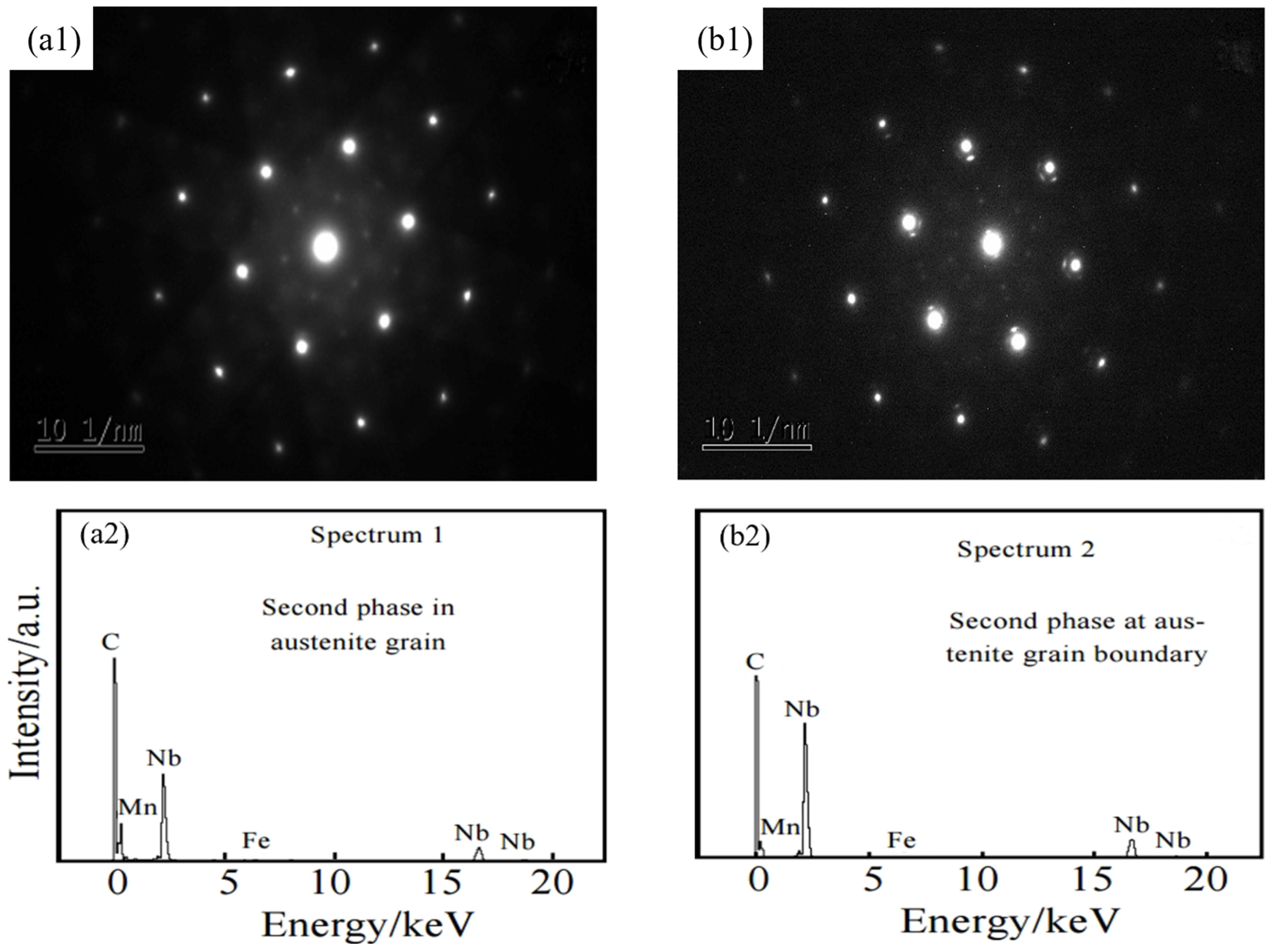

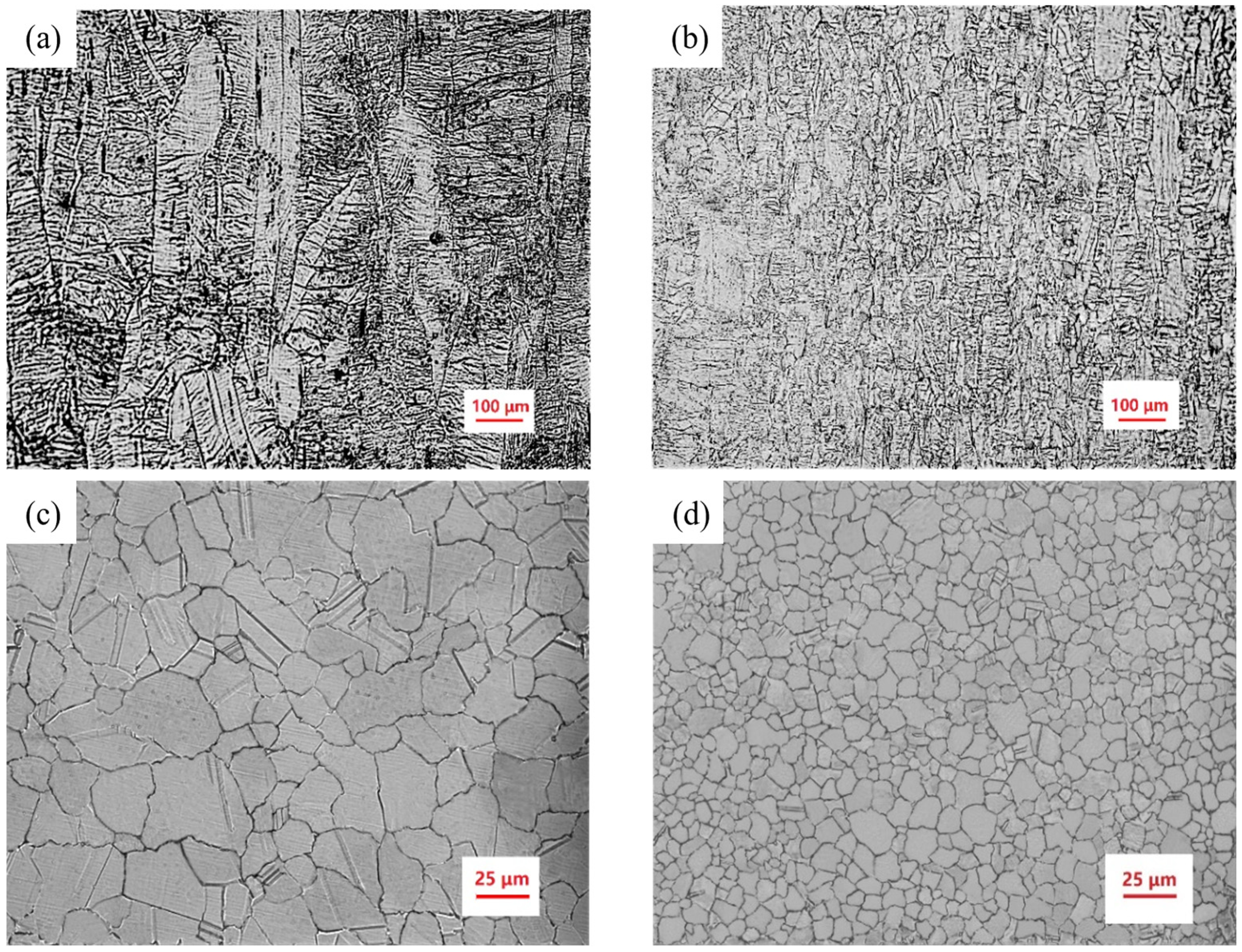

3.3. Effect of Nb Alloying and Solution Treatment on the Microstructure of Cold-Rolled Test Steels

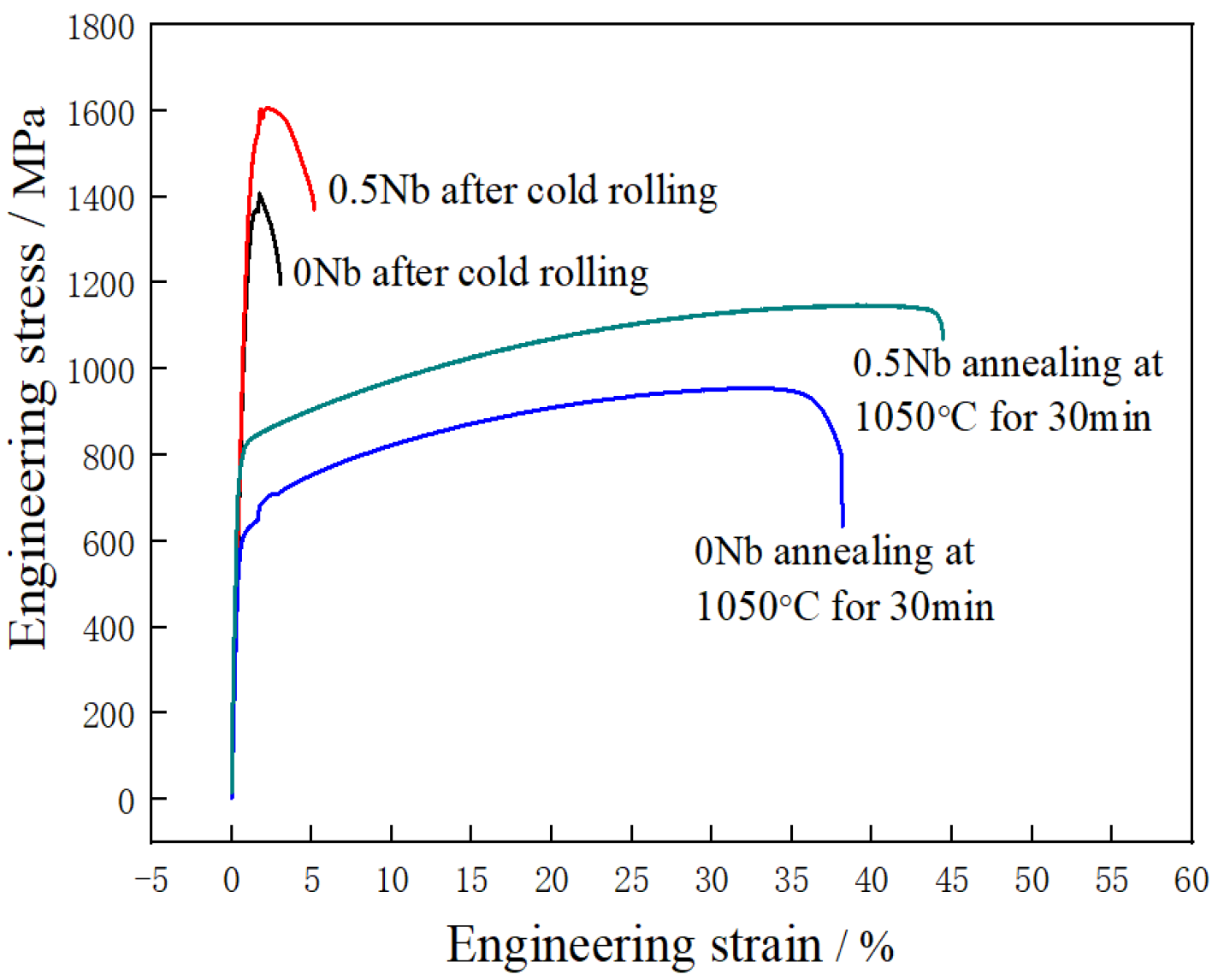

3.4. Effect of Nb Alloying and Solution Treatment on the Mechanical Properties and Fracture Mechanism of Cold-Rolled Test Steels

- (1)

- Influence of Nb Alloying and Solution Treatment on the Mechanical Properties

- (2)

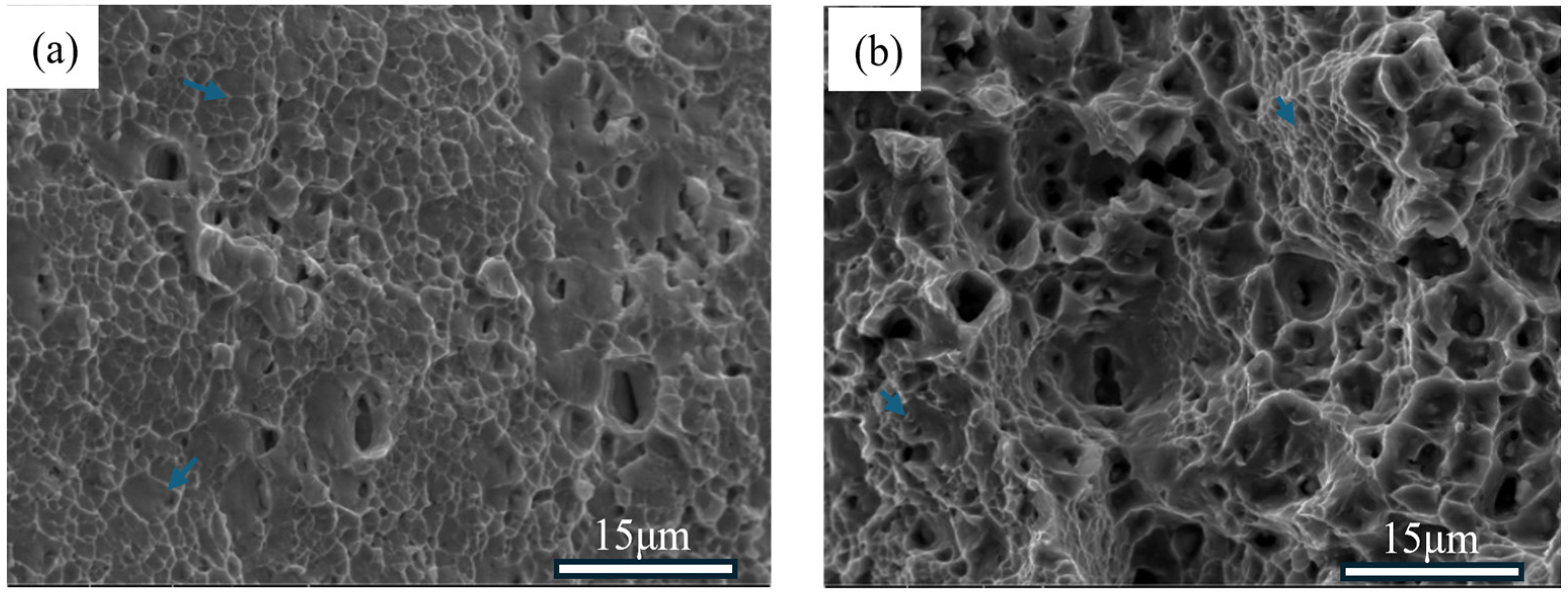

- Tensile Fracture Morphology of Solution-Treated, Low-Density Steel: Effect of Nb Alloying

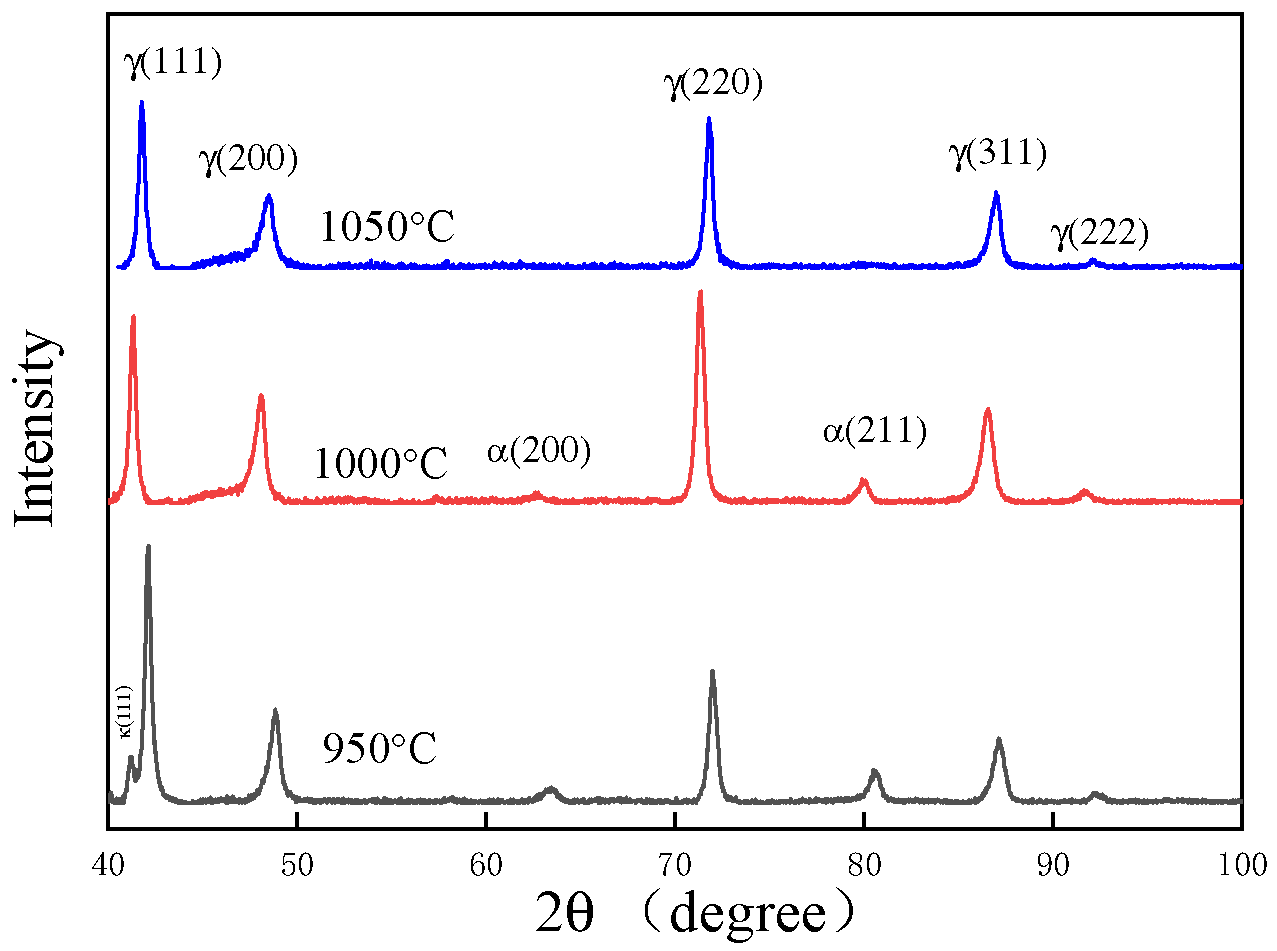

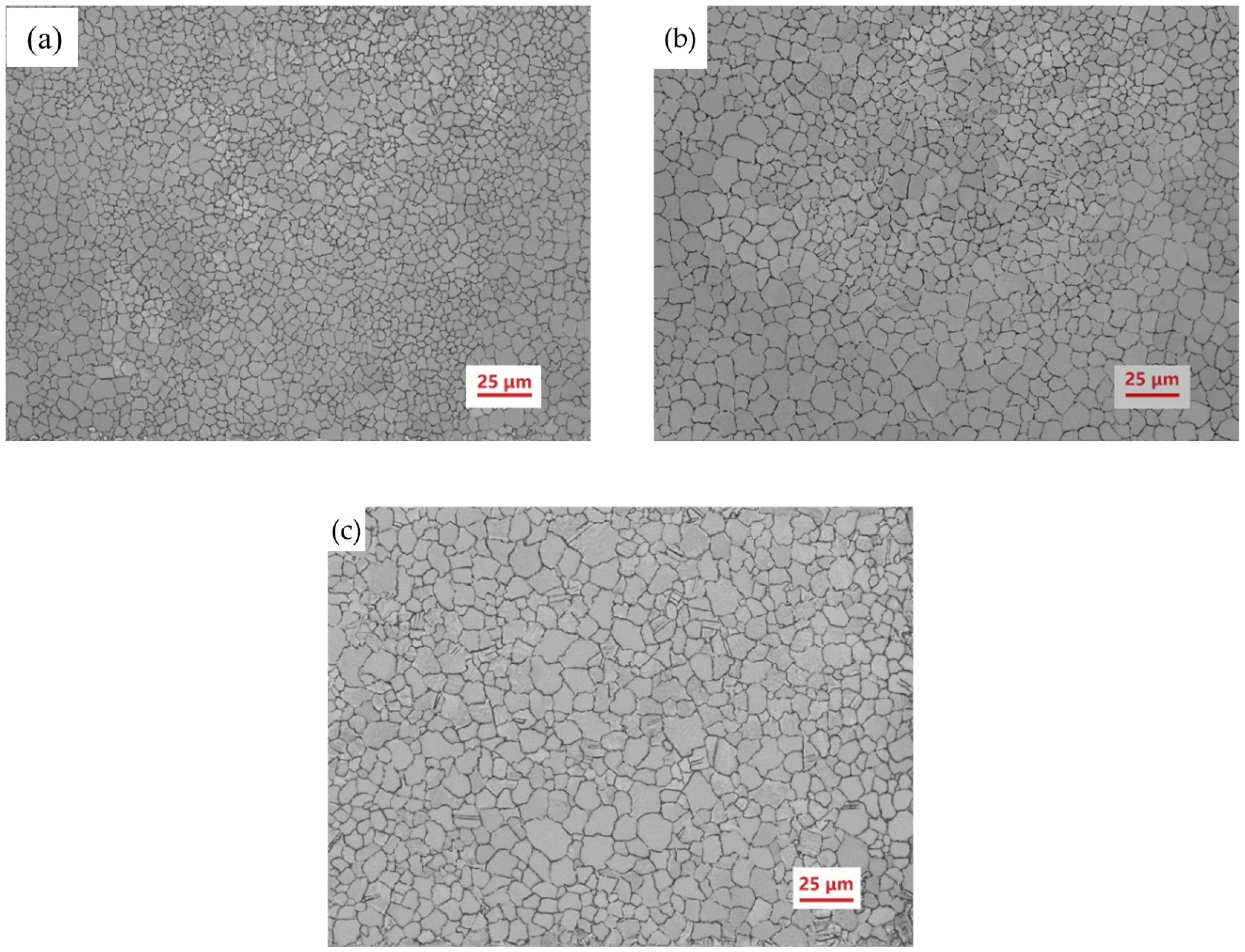

3.5. Effect of Solution Treatment Temperature on the Microstructure and Mechanical Properties of 0.5Nb-Containing Test Steel

- (1)

- Influence of Solution Treatment Temperature on the Microstructure of 0.5Nb-Containing Test Steel

- (2)

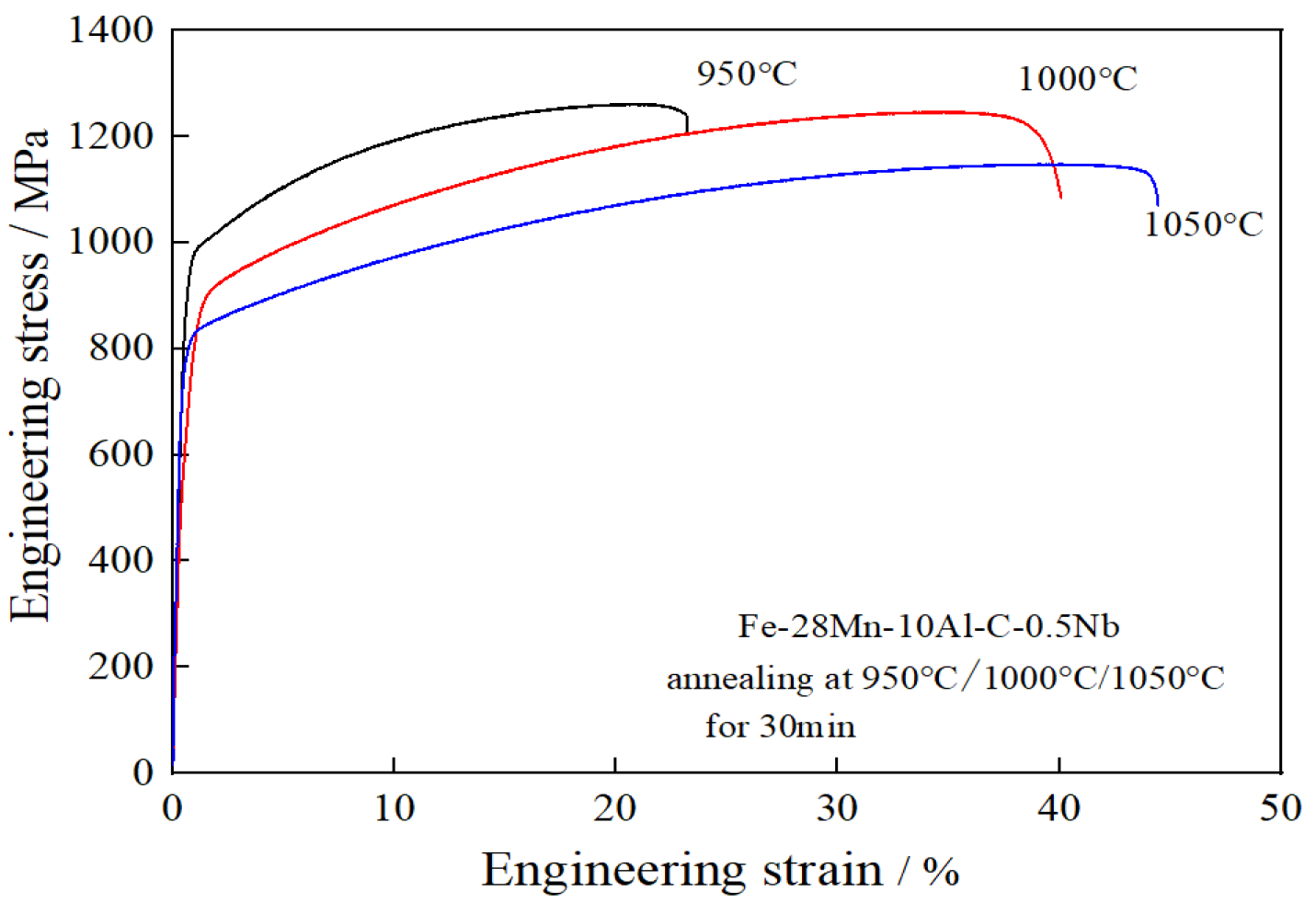

- Mechanical Properties and Work-Hardening Behaviors of 0.5Nb Test Steels at Various Solution Treatment Temperatures

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ding, H.; Liu, D.; Cai, M.; Zhang, Y. Austenite-Based Fe-Mn-Al-C Lightweight Steels: Research and Prospective. Metals 2022, 12, 1572. [Google Scholar] [CrossRef]

- Wu, Z.; Liu, S.; Hasan, M.; Li, E.; An, X. The hot deformation behavior in austenite-ferrite heterostructured low density Fe-Mn-Al-C steel. Mater. Today Commun. 2023, 37, 107184. [Google Scholar] [CrossRef]

- Ren, J.; Zhang, L.; Li, Z.; Chen, J.; Zhang, W.; Wu, S.; Liu, Z. Fe-Mn-Al-C high-entropy steels with superior mechanical properties at 4.2 K. Mater. Des. 2023, 228, 111840. [Google Scholar] [CrossRef]

- Kang, J.; Li, Y.; Wang, X.; Wang, H.; Yuan, G.; Misra, R.D.K.; Wang, G. Design of a low density Fe-Mn-Al-C steel with high strength-high ductility combination involving TRIP effect and dynamic carbon partitioning. J. Mater. Sci. Eng. A 2018, 742, 464–477. [Google Scholar] [CrossRef]

- Chen, P.; Chen, R.; Li, X. Tensile deformation behavior related with strain-induced martensitic transformation in a duplex Fe-Mn-Al-C low-density steel. Mater. Charact. 2022, 189, 111954. [Google Scholar] [CrossRef]

- Riaz, T.; Das, S.R.; Sahu, P. Influence of Al Variation on the Mechanical Properties and Critical Shear Stress of Twinning in Fe-Mn-Al-C Steels. J. Mater. Eng. Perform. 2022, 32, 1636–1644. [Google Scholar] [CrossRef]

- Rodríguez, J.S.; Duran, J.F.; Aguilar, Y.; Alcazar, G.A.; Perez, T.; Zambrano, O.A. Effect of Al content on the low-stress abrasive wear behaviour of Fe-18Mn-xAl-0.7C alloys. J. Tribol. Int. 2023, 180, 108286. [Google Scholar] [CrossRef]

- Howell, R.A.; Van Aken, D.C. A literature review of age hardening Fe-Mn-Al-C alloys. Iron Steel Technol. 2009, 6, 193–212. [Google Scholar]

- Chen, Z.; Liu, M.; Zhang, J.; Yang, L.; Zhang, Y.; Song, C.; Zhai, Q.; Kang, J. Effect of annealing treatment on microstructures and properties of austenite-based Fe-28Mn-9Al-0.8C lightweight steel with addition of Cu. China Foundry 2021, 18, 207–216. [Google Scholar] [CrossRef]

- Xie, Z.; Hui, W.; Bai, S.; Zhang, Y.; Zhao, X.; Li, B. Effects of annealing temperature and V addition on microstructure and mechanical properties of Fe-Mn-Al-C austenitic low-density steel. Mater. Today Commun. 2023, 35, 106328. [Google Scholar] [CrossRef]

- Pang, J.; Zhou, Z.; Zhao, Z.; Tang, D.; Liang, J.; He, Q. Tensile Behavior and Deformation Mechanism of Fe-Mn-Al-C Low Density Steel with High Strength and High Plasticity. Metals 2019, 9, 897. [Google Scholar] [CrossRef]

- Liu, D.; Ding, H.; Cai, M.; Han, D. Mechanical behaviors of a lower-Mn-added Fe-11Mn-10Al-1.25C lightweight steel with distinguished microstructural features. Mater. Lett. 2019, 242, 131. [Google Scholar] [CrossRef]

- Zhou, N.; Song, R.; Yang, F.; Li, X.; Li, J. Influence of Annealing Temperature on Microstructure and Three-Stage Strain Hardening Behavior in Cold-Rolled Fe-Mn-Al-C Steel. JOM 2019, 71, 4105–4113. [Google Scholar]

- Zheng, C.; Liu, Q.; Zheng, S.; Chong, X.; Jiang, Y.; Feng, J. Effect of solution treatment on mechanical properties and microstructure of welded joints of Fe-29Mn-9Al-0.9C low-density steel. J. Micromechanics Mol. Phys. 2020, 5, 2050006. [Google Scholar]

- Mykhailo, V.; Anastasiia, S.; Volodymyr, S. Microstructure, mechanical and high temperature properties of cast high Mn low-density steels alloying by small Lanthanum additions. Mater. Lett. 2024, 355, 135421. [Google Scholar]

- Ding, F.; Guo, Q.; Hu, B.; Xu, Y.; Lai, W.; Zhang, C.; Jin, X.; Luo, H. Influences of Cu alloying on precipitation, austenitic reversion and mechanical properties of NiAl-strengthened medium-Mn steels. Acta Mater. 2025, 284, 120623. [Google Scholar]

- Sha, Q.; Sun, Z. Grain growth behavior of coarse-grained austeniteinaNb-V-Ti micro alloyed steel. Mater. Sci. Eng. A 2009, 523, 77. [Google Scholar]

- Ma, T.; Li, H.; Gao, J.; Wang, X.; Song, H.; Li, Y. Progress on Strengthening Mechanism and Tensile Properties of Fe-Mn-Al-C Low Density Steel and Prospect of Nb Microalloying. Mater. Rep. 2020, 34, 23154–23164. [Google Scholar]

- Zhang, D.; Liu, G.; Zhang, K.; Sun, X.; Liang, X.; Yong, Q. Effect of Nb microalloying on microstructure evolution and mechanical properties in low carbon medium manganese steel. Mater. Sci. Eng. A 2021, 824, 141813. [Google Scholar] [CrossRef]

- Cui, D.; Chen, P.; Wang, P.; Li, X. On the Factors Influencing the High Stretch–Flangeability of a Low-Density 1180 MPa Fe–Mn–Al–C–Nb δ-QP Steel. Acta Metall. Sin. Engl. Lett. 2024, 37, 1291–1300. [Google Scholar]

- Ramos-Fabián, N.I.; Mejía, I.; García-Domínguez, M.; Bedolla-Jacuinde, A. Metallographic, structural and mechanical characterization of a low-density austenitic Fe–Mn–Al–C steel microalloyed with Nb in hot-rolling condition. MRS Adv. 2023, 8, 1291–1295. [Google Scholar] [CrossRef]

- Huo, W.; Song, R.; Zhang, Z.; Wang, Y.; Zhou, N.; Zhao, S.; Zhang, Y.; Sun, J. Effect of Nb contents on microstructure characteristics and yielding behavior of Fe–4Mn–2Al-0.2C steel. Mater. Sci. Eng. A 2021, 819, 141457. [Google Scholar] [CrossRef]

- Zhao, T.; Chen, C.; Wang, Y.; Wang, T.; Sheng, G.; He, Y. Effect of NbeV microalloying on low-cycle fatigue property of Fe-Mn-Al-C austenitic steel. J. Mater. Res. Technol. 2023, 23, 3711–3725. [Google Scholar]

- Zhuang, L.; Wang, Y.; Cheng, X.; Li, Z.; Du, J.; Li, S. The effect of Ti–Mo–Nb on the microstructures and tensile properties of a Fe–Mn–Al–C austenitic steel. Mater. Sci. Eng. A 2020, 780, 139220. [Google Scholar]

- Lee, J.; Park, S.; Kim, H.; Park, S.J.; Lee, K.; Kim, M.Y.; Madakashira, P.P.; Han, H.N. Simulation of κ-Carbide Precipitation Kinetics in Aged Low-Density Fe–Mn–Al–C Steels and Its Effects on Strengthening. Met. Mater. Int. 2018, 24, 702–710. [Google Scholar] [CrossRef]

- Gao, Z.; Kang, Q.; An, X.; Wang, H.; Wang, C.; Cao, W. Enhanced mechanical properties of a Fe-Mn-Al-C austenitic low-density steel by increasing hot-rolling reduction. Mater. Charact. 2023, 204, 113237. [Google Scholar] [CrossRef]

- Park, S.W.; Park, J.Y.; Cho, K.M.; Jang, J.H.; Park, S.J.; Moon, J.; Lee, T.H.; Shin, J.H. Effect of Mn and C on age hardening of Fe-Mn-Al-C lightweight steels. Met. Mater. Int. 2019, 25, 683. [Google Scholar]

- Liu, P.C.; Xu, X.Y.; Liu, Q.N.; Li, J.Z.; Liu, D.; Yan, Z.P.; Sun, M.Y.; Wang, X.M. Solid solution precipitation behavior of Nb in high alumina ferritic steel. J. Eng. Sci. 2019, 41, 882–888. [Google Scholar]

- Yong, Q.L.; Zheng, L.; Sun, Z.B. Preliminary study on ordered NbC in Nb-containing microalloyed steels. J. Met. 1986, 6, 81–83. [Google Scholar]

- Ma, T.; Gao, J.; Li, H.; Meng, X.; Li, Y. Effect of Nb on the Microstructure and Mechanical Properties of Fe-28Mn-10Al-C Low Density Steel. Rare Met. Mater. Eng. 2021, 50, 0860–0866. [Google Scholar]

- Song, W.; Ingendahl, T.; Bleck, W. Control of strain hardening behavior in high-Mn austenitic steels. Acta Metall. Sin. 2014, 27, 546–556. [Google Scholar] [CrossRef]

- Yoo, J.D.; Park, K.T. Microband-induced plasticity in a high Mn–Al–C light steel. Mater. Sci. Eng. A 2008, 496, 417–424. [Google Scholar] [CrossRef]

- Ma, T.; Gao, J.; Li, H.; Li, C.; Zhang, H.; Li, Y. Microband-Induced Plasticity in a Nb Content Fe–28Mn–10Al–C Low Density Steel. Metals 2021, 11, 345. [Google Scholar] [CrossRef]

- Wu, Z.Q. Research on Organizational Properties and Deformation Mechanism of High Strength and High Plasticity Low Density Steel. Ph.D. Thesis, Northeastern University, Shenyang, China, 2015. [Google Scholar]

- She, Y.; Zhang, Z.; Ju, J.; Jin, B. Phase Transformation Behavior of Niobium Containing Microalloyed Steel with Predeformation and Continuous Cooling. Mater. Sci. Forum 2014, 804, 281–284. [Google Scholar] [CrossRef]

- Wang, J.; Liu, D.; Yan, D. Austenite Growth Behavior and Prediction Modeling of Ti Microalloyed Steel. Materials 2024, 17, 3236. [Google Scholar] [CrossRef] [PubMed]

- Liao, W.; Mazánová, V.; Heczko, M.; Hou, W.; Procario, J.; Mills, M.; Liu, X. Underlying mechanisms for the effect of Nb micro-alloying on the elemental distribution and precipitation behavior in the X70 weld metal. Materialia 2024, 38, 102264. [Google Scholar] [CrossRef]

- Duan, F.; Lin, Y.; Pan, J.; Zhao, L.; Guo, Q.; Zhang, D.; Li, Y. Ultra-strong nano twinned pure nickel with extremely fine twin thickness. Sci. Adv. 2021, 27, 5113. [Google Scholar] [CrossRef]

- Bai, S.; Chen, Y.; Liu, X.; Lu, H.-H.; Bai, P.-K.; Li, D.; Huang, Z.; Li, J. Research status and development prospect of Fe-Mn-C-Al system low-density steels. J. Mater. Res. Technol. 2023, 25, 1537–1559. [Google Scholar] [CrossRef]

- Zhang, J.; Raabe, D.; Tasan, C.C. Designing duplex, ultrafine-grained Fe-Mn-Al-C steels by tuning phase transformation and recrystallization kinetics. Acta Mater. 2017, 141, 374–387. [Google Scholar] [CrossRef]

- Xie, Z.; Hui, W.; Zhang, Y.; Zhao, X. Effect of Cu and solid solution temperature on microstructure and mechanical properties of Fe-Mn-Al-C low-density steels. J. Mater. Res. Technol. 2022, 18, 1307–1321. [Google Scholar] [CrossRef]

- Wang, H.; Liang, Y.; Hao, S.; Wang, J.; Shi, H. Heterogeneous Fe-Mn-Al-C lightweight steel breaking the strength-ductility trade-off via high-temperature warm rolling process. Mater. Charact. 2024, 218, 114571. [Google Scholar] [CrossRef]

- Moon, J.; Park, S.J.; Jang, J.H. Investigations of the microstructure evolution and tensile deformation behavior of austenite Fe-Mn-Al-C lightweight steels and the effect of Mo addition. Acta Mater. 2018, 147, 226. [Google Scholar] [CrossRef]

- Ren, P.; Chen, X.; Yang, M.; Liu, S.; Cao, W. Effect of early stage of k-carbides precipitation on tensile properties and deformation mechanism in high Mn-Al-C austenitic lowdensity steel. Mater. Sci. Eng. A 2022, 857, 144132. [Google Scholar] [CrossRef]

- Haase, C.; Barrales-Mora, L.A.; Molodov, D.A.; Gottstein, G. Application of texture analysis for optimizing thermo-mechanical treatment of a high Mn TWIP steel. Adv. Mater. Res. 2014, 922, 213–218. [Google Scholar] [CrossRef]

- Wu, D.; Meng, C.; Mao, W.; Ou, X.; Song, M. Microstructural Evolution and Tensile Performance of a Commercial Fe–Mn–Al–C High-Manganese Steel. Steel Res. Int. 2023, 94, 2200877. [Google Scholar] [CrossRef]

- Powell, D.J.; Pilkington, R.; Miller, D.A. The precipitation characteristics of 20% Cr/25% Ni-Nb stabilised stainless steel. Acta Metall. 1988, 36, 713–724. [Google Scholar] [CrossRef]

- Wang, M.; Sun, H.; Phaniraj, M.P.; Han, H.N.; Jang, J.; Zhou, Z. Evolution of microstructure and tensile properties of Fe-18Ni-12Cr based AFA steel during aging at 700 °C. Mater. Sci. Eng. A 2016, 672, 23–31. [Google Scholar] [CrossRef]

| ωNb/% | ωκ-carbide/% | ωα-ferrite/% |

|---|---|---|

| 0 | 13.87 | 86.28 |

| 0.3 | 13.75 | 85.86 |

| 0.5 | 13.71 | 85.77 |

| Steel | wC/% | wMn/% | wAl/% | wNb/% | wS/% | wN/% | wP/% | wFe/% |

|---|---|---|---|---|---|---|---|---|

| 0Nb | 0.98 | 28.53 | 10.21 | — | ≤0.003 | 0.0056 | ≤0.003 | Bal. |

| 0.5Nb | 1.05 | 29.82 | 10.95 | 0.56 | ≤0.003 | 0.0041 | ≤0.003 | Bal. |

| Parameters | Values and Functions |

|---|---|

| ρ | 2.94 × 10−5 (mol/m2) |

| σ | 9 (mJ/mol) |

| −2243.38 + 4.309T (J/mol) | |

| −1000 + 1.123T (J/mol) | |

| 2800 + 5T (J/mol) | |

| −22,166 (J/mol) | |

| 4046 (J/mol) | |

| 2180 + 532 () (J/mol) | |

| 3339 (J/mol) | |

| 42,500 (J/mol) | |

| 26,910 (J/mol) | |

| 27,403 (J/mol) | |

| 0.7+ 0.62− 0.64 | |

| 0.62 | |

| 580 | |

| 250− 4750− 6.2 | |

When . Where | |

When . Where |

| Steel | State | YS/MPa | UTS/MPa | El/% | PSE/MPa·% |

|---|---|---|---|---|---|

| 0Nb | Cold rolling | 1279 | 1407 | 3.03 | 4.26 |

| 0Nb | Solution treatment | 591 | 955 | 38.14 | 36.42 |

| 0.5Nb | Cold rolling | 1409 | 1605 | 5.13 | 8.23 |

| 0.5Nb | Solution treatment | 795 | 1146 | 44.45 | 50.94 |

| Composition (wt.%) | TE (%) | UTS (MPa) | PSE/MPa·% | Thermal/Mechanical Processes |

|---|---|---|---|---|

| Fe-28Mn-10Al-C-0.5Nb | 44.45 | 1146 | 50.94 | Cold rolling/solution |

| Fe-23Mn-1.5Al-0.3C [40] | 98.9 | 840 | 83.08 | Hot rolling/solution |

| Fe-25Mn-10Al-1.1C [41] | 62 | 913 | 56.6 | Solution/water quenching |

| Fe-11Mn-10Al-1.2C [42] | 35.4 | 1183 | 41.88 | Solution/water quenching |

| Fe-30Mn-11Al-1.2C [43] | 17.8 | 1218 | 21.68 | Solution/aging |

| Fe-21Mn-10Al-C-5Ni [44] | 80 | 775 | 62.00 | Solution/water quenching |

| Fe-29Mn-9.4Al-0.3C [45] | 30 | 757 | 22.71 | Cold rolling/annealing |

| Fe-13.6Mn-1.2Al-0.6C [46] | 74 | 1120 | 82 | Solution/water quenching |

| Steel | YS/MPa | UTS/MPa | El/% | PSE/MPa·% |

|---|---|---|---|---|

| 950 °C | 975 | 1260 | 23.25 | 29.3 |

| 1000 °C | 889 | 1244 | 40.07 | 49.85 |

| 1050 °C | 795 | 1146 | 44.45 | 50.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huo, L.; Gao, J.; Li, Y.; Xu, P.; Wei, X.; Ma, T. Effect of Nb Alloying and Solution Treatment on the Mechanical Properties of Cold-Rolled Fe-Mn-Al-C Low-Density Steel. Metals 2025, 15, 102. https://doi.org/10.3390/met15020102

Huo L, Gao J, Li Y, Xu P, Wei X, Ma T. Effect of Nb Alloying and Solution Treatment on the Mechanical Properties of Cold-Rolled Fe-Mn-Al-C Low-Density Steel. Metals. 2025; 15(2):102. https://doi.org/10.3390/met15020102

Chicago/Turabian StyleHuo, Litu, Jianxin Gao, Yungang Li, Pengfei Xu, Xiangyu Wei, and Tao Ma. 2025. "Effect of Nb Alloying and Solution Treatment on the Mechanical Properties of Cold-Rolled Fe-Mn-Al-C Low-Density Steel" Metals 15, no. 2: 102. https://doi.org/10.3390/met15020102

APA StyleHuo, L., Gao, J., Li, Y., Xu, P., Wei, X., & Ma, T. (2025). Effect of Nb Alloying and Solution Treatment on the Mechanical Properties of Cold-Rolled Fe-Mn-Al-C Low-Density Steel. Metals, 15(2), 102. https://doi.org/10.3390/met15020102