Effect of B4C Amount on Microstructural and Mechanical Properties of Cu/h-BN/B4C Metal Matrix Composites Fabricated via Spark Plasma Sintering

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Fabrication Process

2.2. Characterization

3. Results

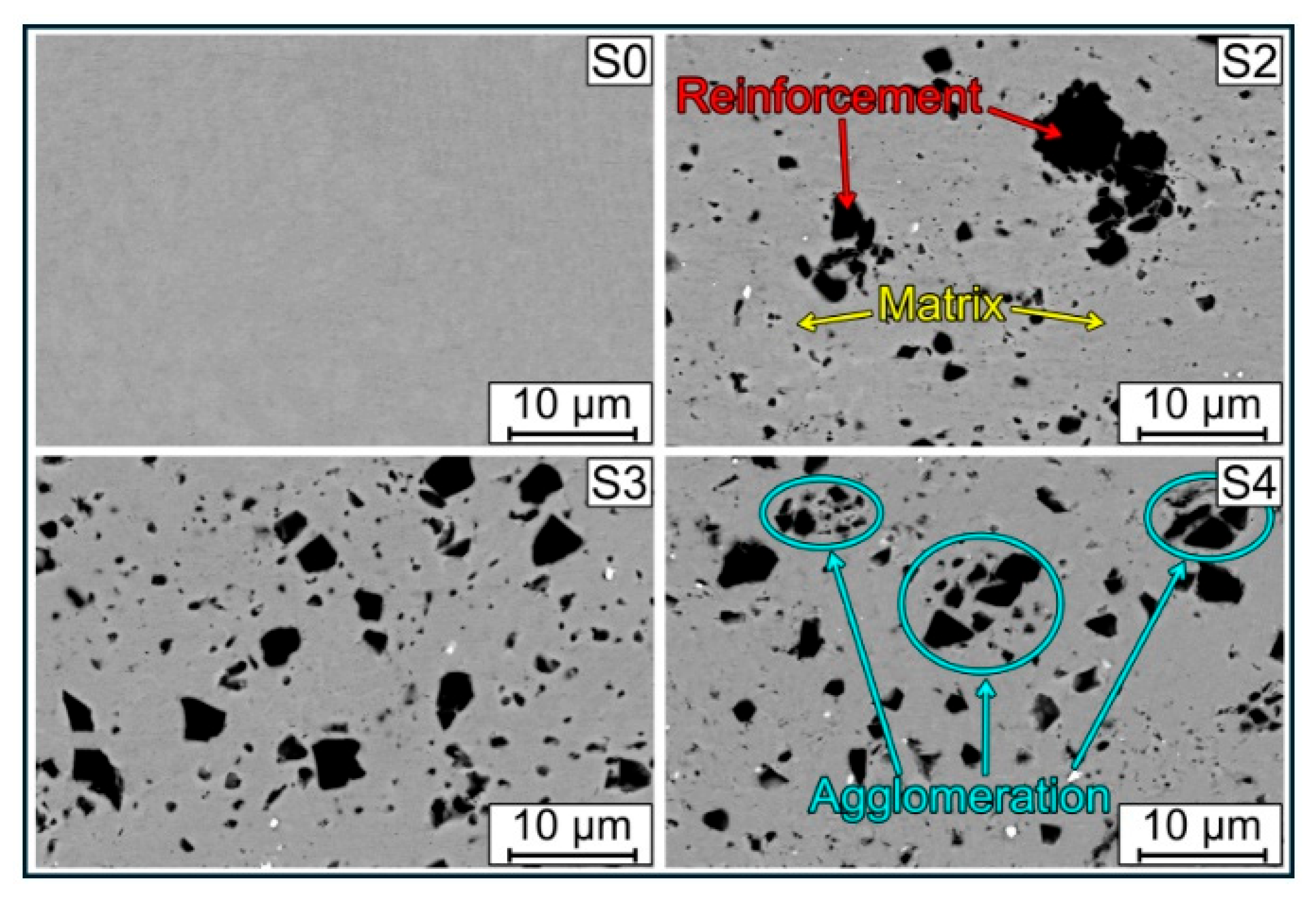

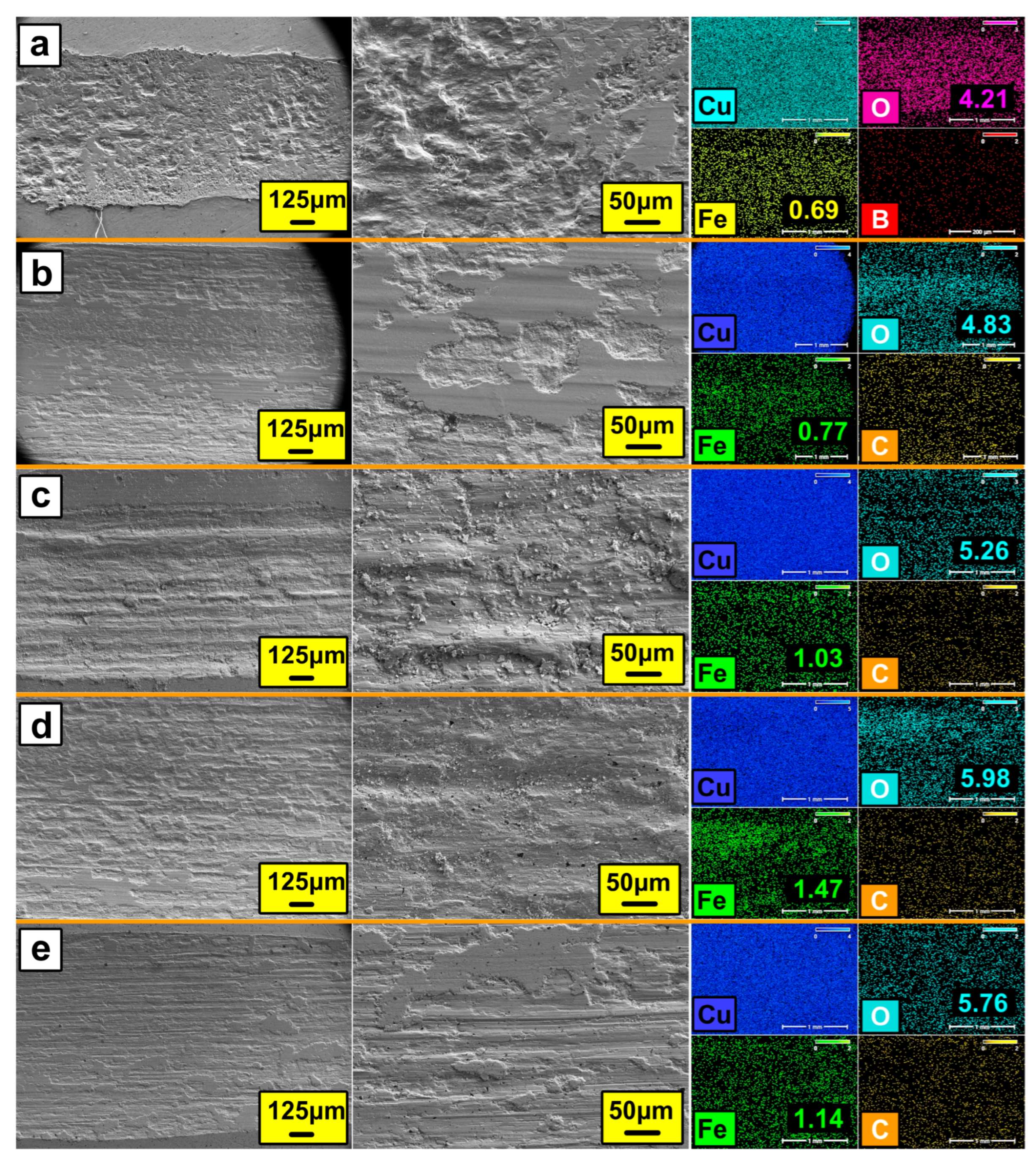

3.1. Microstructure and EDS Analysis

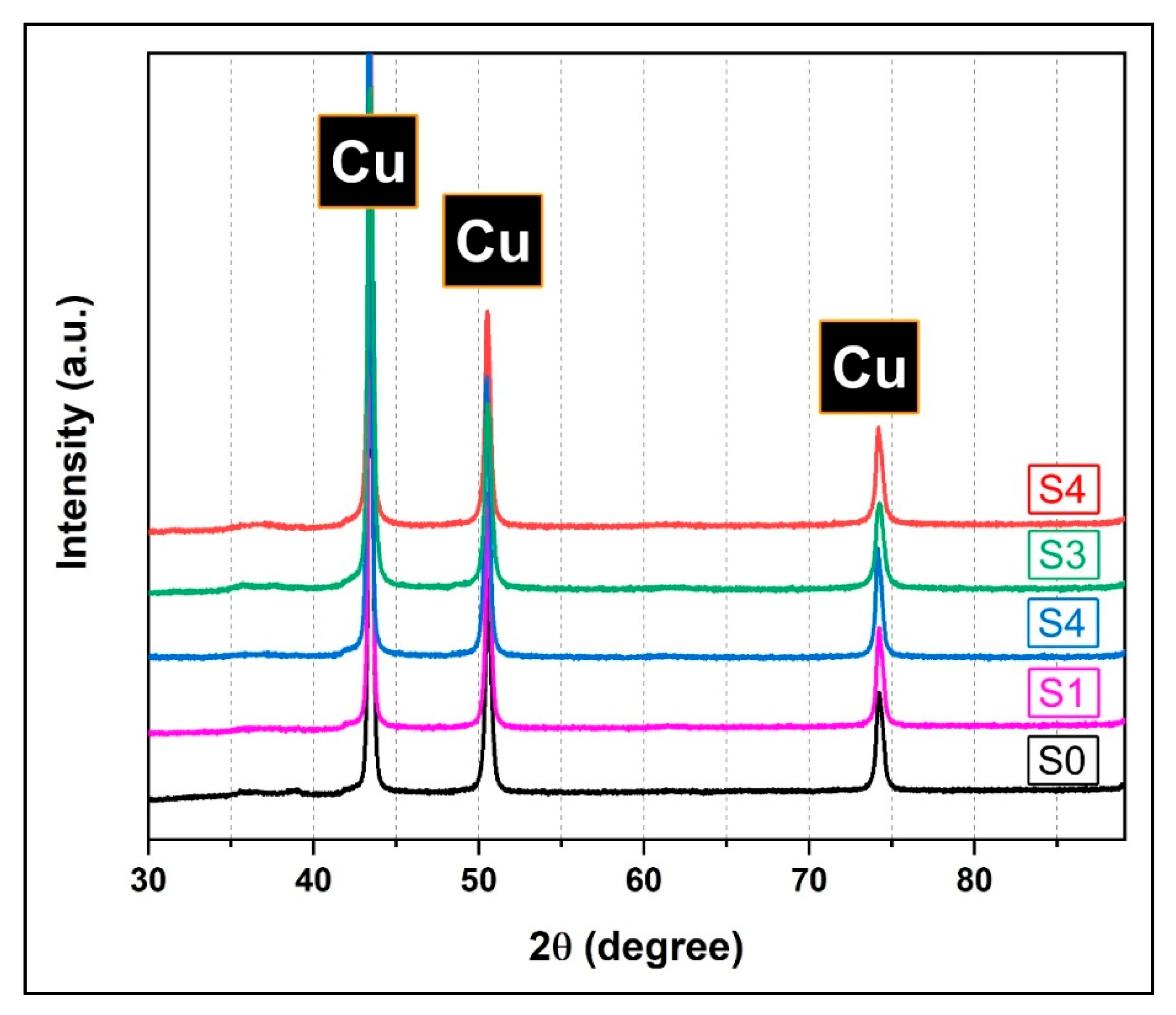

3.2. XRD Analysis

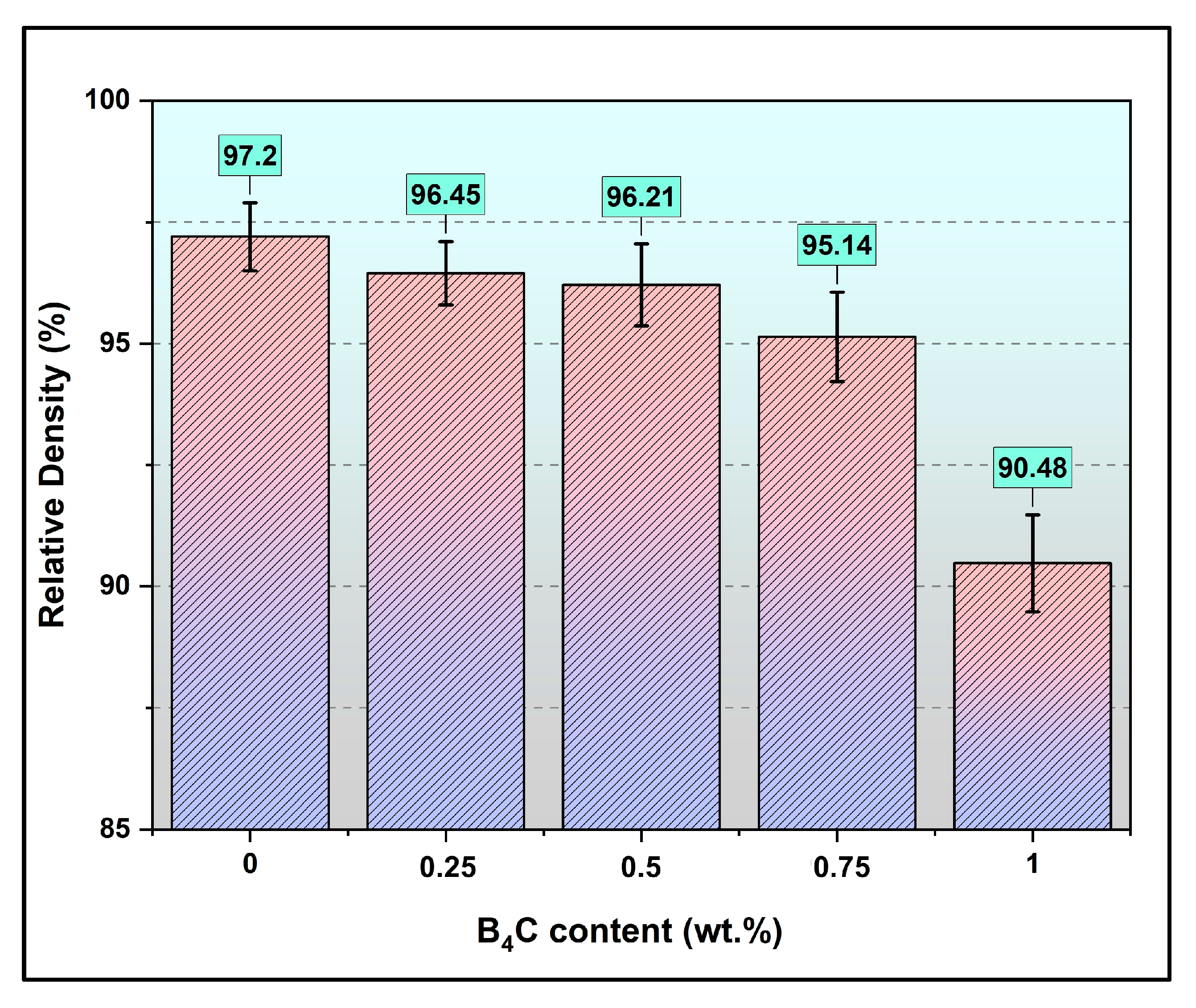

3.3. Relative Density

3.4. Hardness

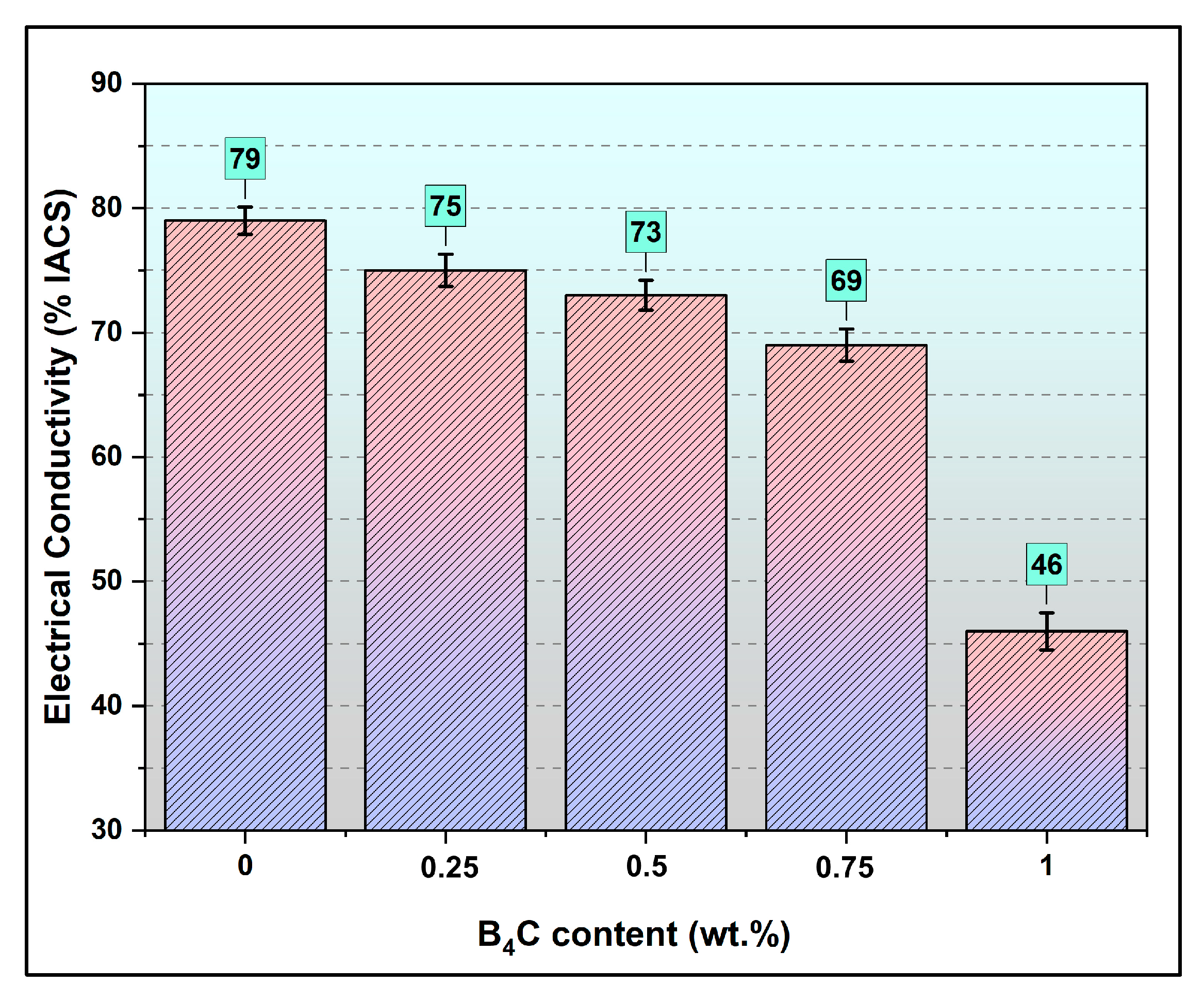

3.5. Electrical Conductivity

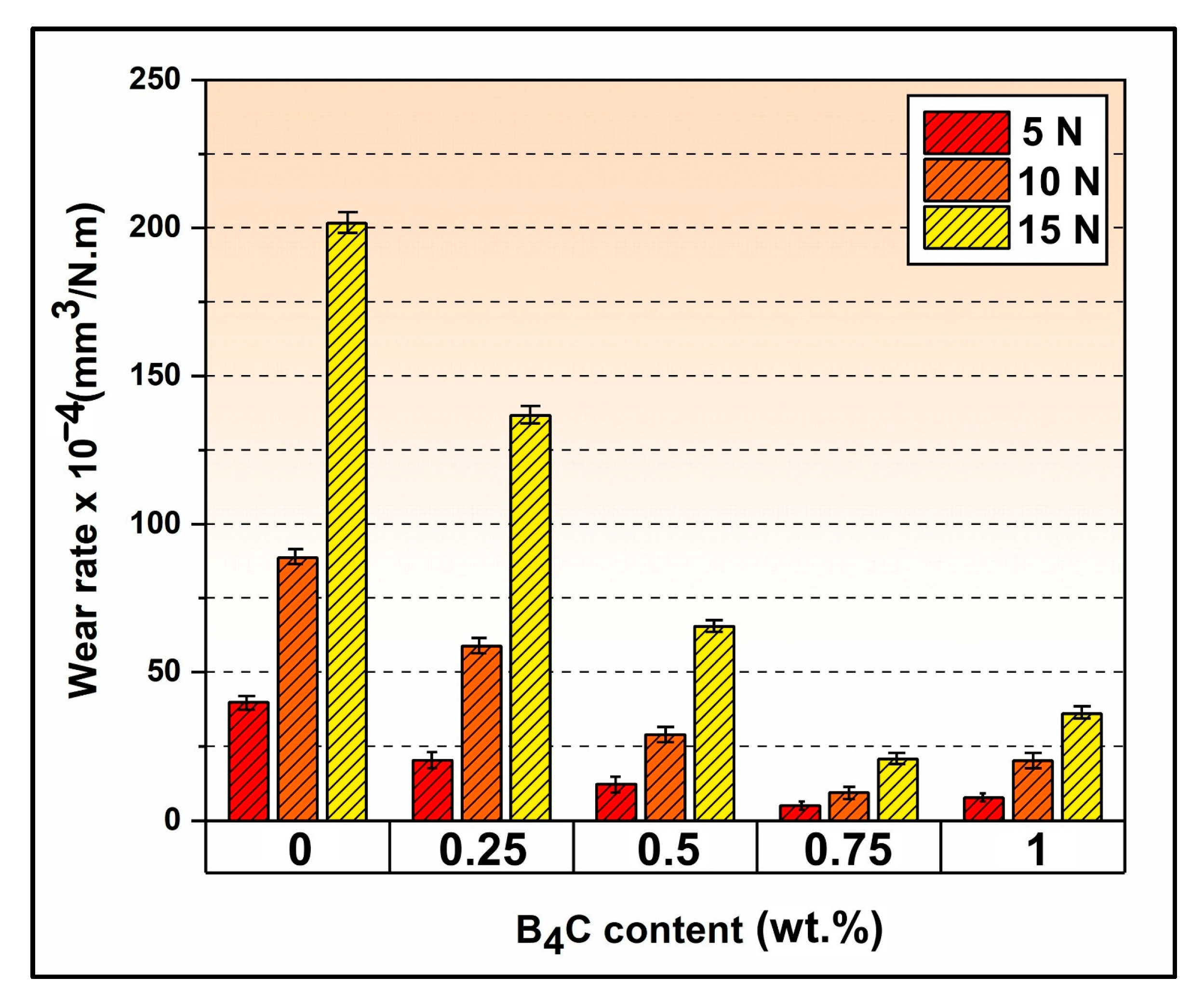

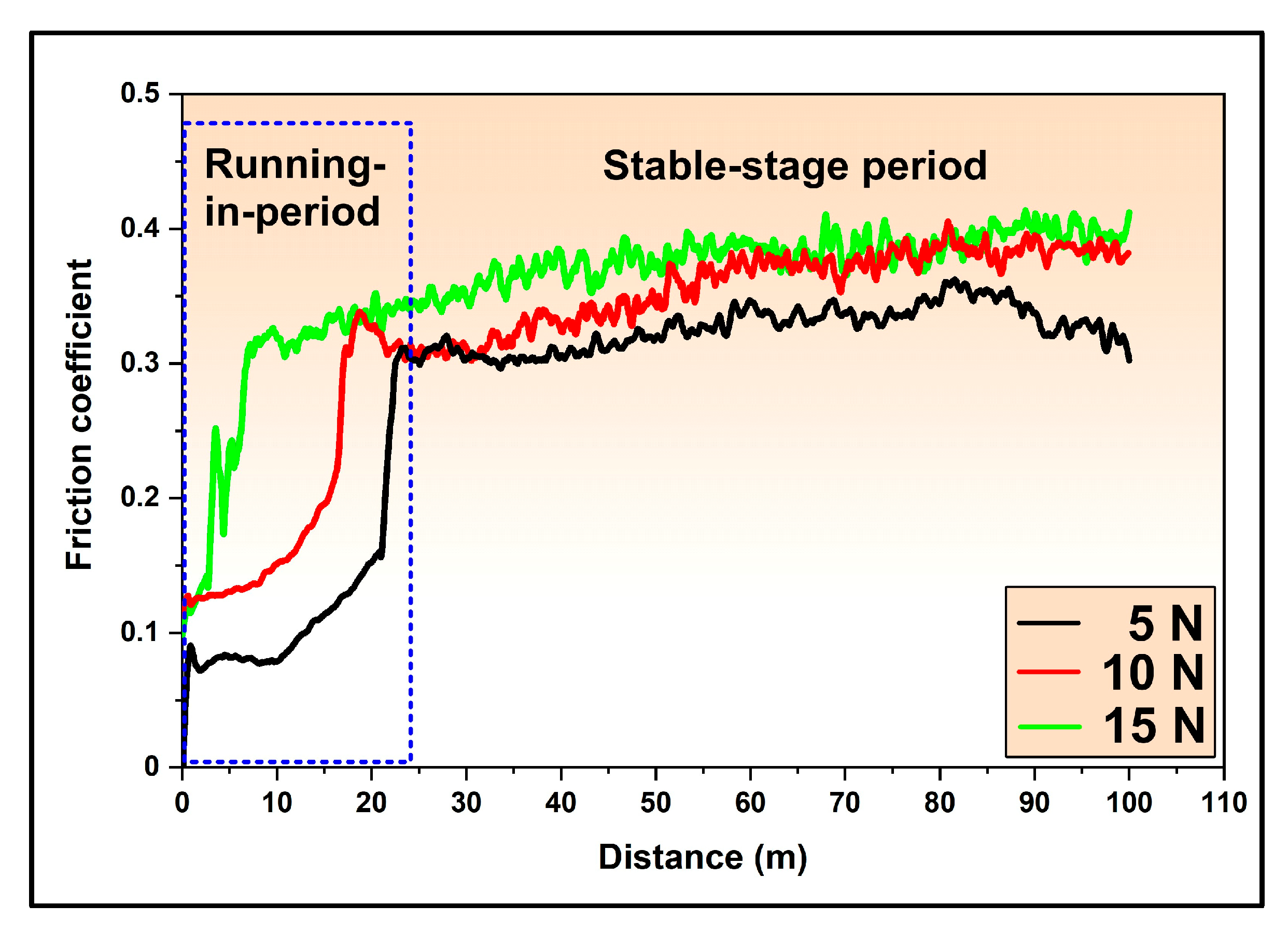

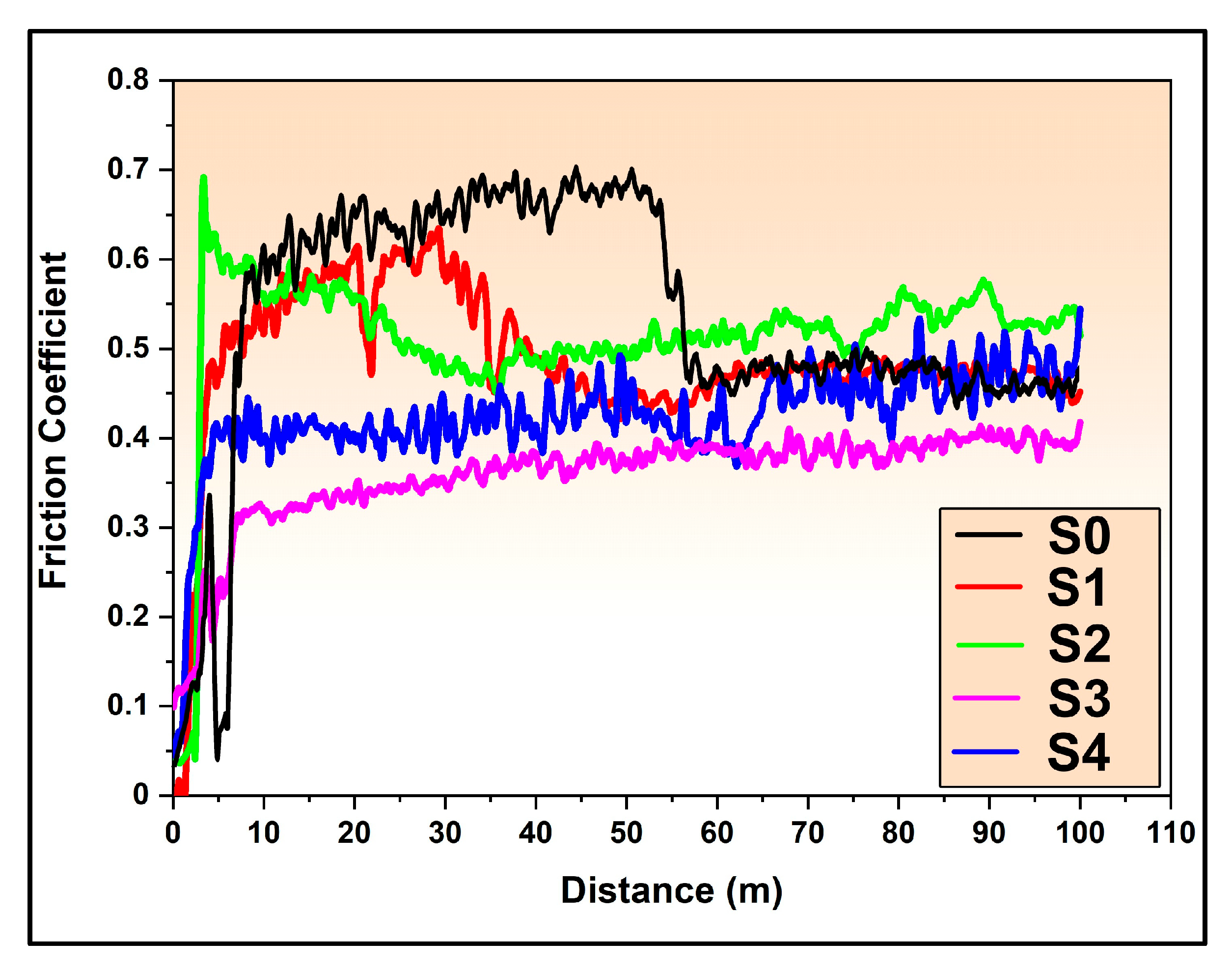

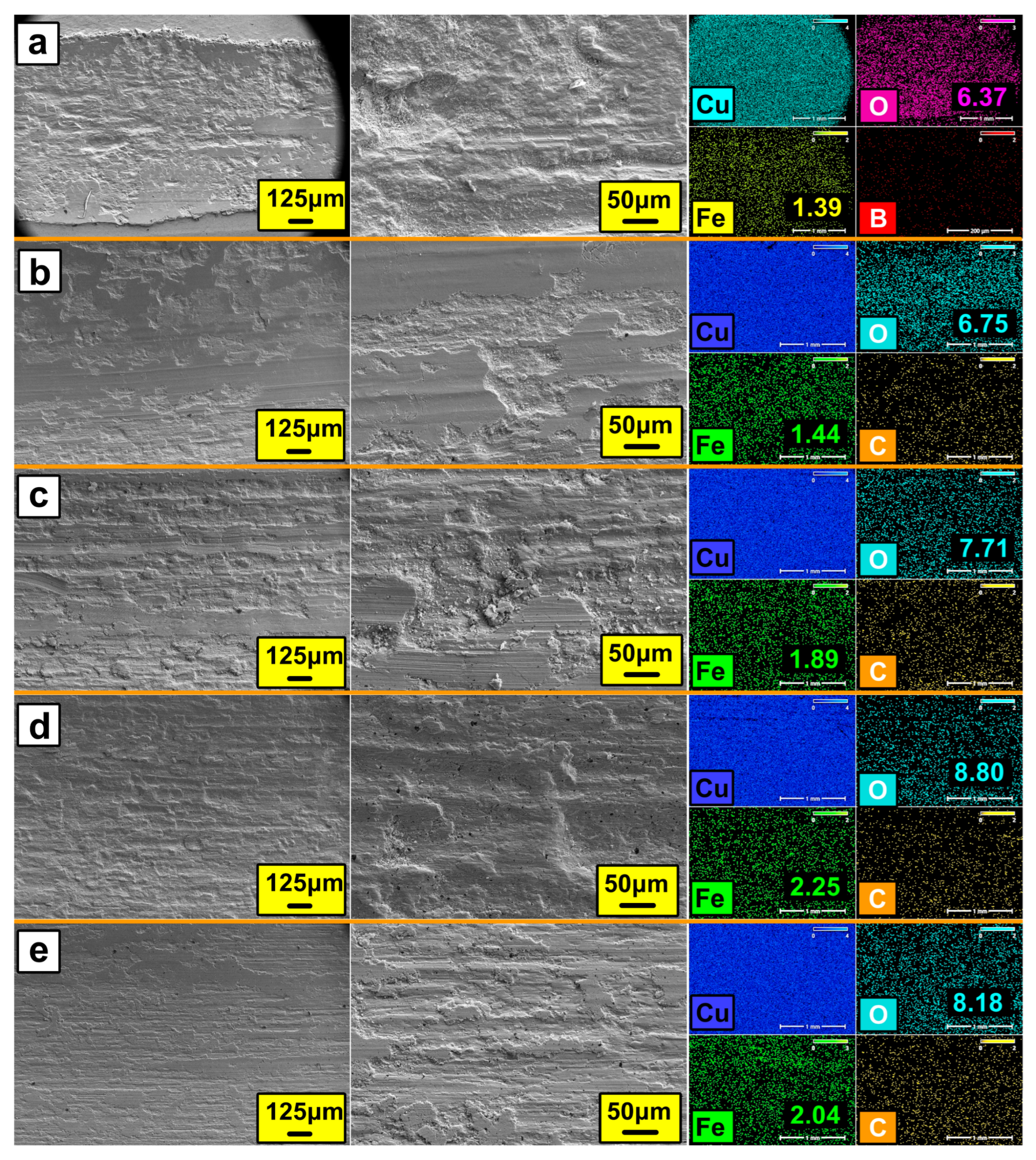

3.6. Tribological Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ho, V.; Ladani, L.; Razmi, J.; Gruber, S.; Murphy, A.B.; Chen, C.; East, D.; Lopez, E. Powder Bed Fabrication of Copper: A Comprehensive Literature Review. Metals 2025, 15, 1114. [Google Scholar] [CrossRef]

- Zhang, W.; Huang, L.; Mi, X.; Xie, H.; Feng, X.; Ahn, J.H. Researches for Higher Electrical Conductivity Copper—Based Materials. CMat 2024, 1, e13. [Google Scholar] [CrossRef]

- Özorak, C.; Islak, S. Microstructure, Wear and Corrosion Properties of Cu–SiC/WCCo Composite Coatings on the Cu Substrate Surface by Plasma Spray Method. Mater. Chem. Phys. 2024, 314, 128903. [Google Scholar] [CrossRef]

- Meng, F.; Zhou, Y.; Zhang, H.; Wang, Z.; Liu, D.; Cao, S.; Cui, X.; Nong, Z.; Man, T.; Liu, T. Development and Research Status of Wear-Resistant Coatings on Copper and Its Alloys: Review. Crystals 2025, 15, 204. [Google Scholar] [CrossRef]

- Hvizdoš, P.; Besterci, M.; Kulu, P.; Kvačkaj, T. Tribological Characteristics of Copper Based Composites with Al2O3 Particles at Various Temperatures. High Temp. Mater. Process. 2013, 32, 437–442. [Google Scholar] [CrossRef]

- Fathy, A.; Elkady, O.; Abu-Oqail, A. Microstructure, Mechanical and Wear Properties of Cu–ZrO2 Nanocomposites. Mater. Sci. Technol. 2017, 33, 2138–2146. [Google Scholar] [CrossRef]

- Zhu, W.; Liu, W.; Tan, H.; Yang, J. Fabrication of Ti3AlC2/Cu Composites via Vacuum Infiltration and Their Tribological Properties. Vacuum 2025, 242, 114772. [Google Scholar] [CrossRef]

- Ahmadian, H.; Fouly, A.; Zhou, T.; Kumar, A.S.; Fathy, A.; Weijia, G. Investigating the Valence Balance of Adding Nano SiC and MWCNTs on the Improvement Properties of Copper Composite Using Mechanical Alloying and SPS Techniques. Diam. Relat. Mater. 2024, 145, 111113. [Google Scholar] [CrossRef]

- Karabacak, A.H.; Çanakçı, A.; Özkaya, S.; Tunç, S.A.; Güler, O.; Çelebi, M. Effect of AlCrCuFeNi High Entropy Alloy Reinforcements with and without B4C on Powder Characteristic, Mechanical and Wear Properties of AA5083 Metal-Metal Composites. J. Alloys Compd. 2024, 1008, 176627. [Google Scholar] [CrossRef]

- Varol, T.; Canakci, A.; Ozkaya, S.; Erdemir, F. Determining the Effect of Flake Matrix Size and Al2O3 Content on Microstructure and Mechanical Properties of Al2O3 Nanoparticle Reinforced Al Matrix Composites. Part. Sci. Technol. 2018, 36, 312–323. [Google Scholar] [CrossRef]

- Canakci, A.; Erdemir, F.; Varol, T.; Ozkaya, S. Effect of Process Parameters on the Formation of Fe-Al Intermetallic Coating Fabricated by Mechanical Alloying. Indian. J. Eng. Mater. Sci. 2014, 21, 595–600. [Google Scholar]

- Huang, C.-W.; Aoh, J.-N. Friction Stir Processing of Copper-Coated SiC Particulate-Reinforced Aluminum Matrix Composite. Materials 2018, 11, 599. [Google Scholar] [CrossRef]

- Arif, S.; Samad, A.; Hadidi, H.; Shaikh, M.B.N.; Ansari, S. Dry Sliding Wear Investigation of Graphene Reinforced Copper-Silica Sand Composite by Response Surface Methodology. Mater. Today Commun. 2022, 33, 104857. [Google Scholar] [CrossRef]

- Li, B.; Liu, Y.; Li, J.; Cao, H.; He, L. Effect of Sintering Process on the Microstructures and Properties of in Situ TiB2–TiC Reinforced Steel Matrix Composites Produced by Spark Plasma Sintering. J. Mater. Process Technol. 2010, 210, 91–95. [Google Scholar] [CrossRef]

- Salifu, S.; Olubambi, P.A. Microstructural and Nanoindentation Study of Spark Plasma Sintered High Entropy Alloy Reinforced Aluminium Matrix Composites. J. Alloys Compd. 2024, 999, 175021. [Google Scholar] [CrossRef]

- Singh, K.; Khanna, V.; Sonu; Singh, S.; Bansal, S.A.; Chaudhary, V.; Khosla, A. Paradigm of State-of-the-Art CNT Reinforced Copper Metal Matrix Composites: Processing, Characterizations, and Applications. J. Mater. Res. Technol. 2023, 24, 8572–8605. [Google Scholar] [CrossRef]

- Yilmaz, N.; Baltaci, E.; Baygin, O.; Tüzüner, T.; Ozkaya, S.; Canakci, A. Effect of the Usage of Er,Cr:YSGG Laser with and without Different Remineralization Agents on the Enamel Erosion of Primary Teeth. Lasers Med. Sci. 2020, 35, 1607–1620. [Google Scholar] [CrossRef]

- Stuer, M.; Bowen, P.; Zhao, Z. Spark Plasma Sintering of Ceramics: From Modeling to Practice. Ceramics 2020, 3, 476–493. [Google Scholar] [CrossRef]

- Lee, H.; Kim, K.I.; Kim, J.; Pin, M.-W.; Oh, K.H.; Kim, K.T. Electron Microscopy Characterization of the Tribolayer Formation Mechanism in Sintered Cu-Based Composites under Dry Sliding. Mater. Today Commun. 2022, 30, 103154. [Google Scholar] [CrossRef]

- Tjong, S.C.; Lau, K.C. Tribological Behaviour of SiC Particle-Reinforced Copper Matrix Composites. Mater. Lett. 2000, 43, 274–280. [Google Scholar] [CrossRef]

- Gajević, S.; Miladinović, S.; Güler, O.; Özkaya, S.; Stojanović, B. Optimization of Dry Sliding Wear in Hot-Pressed Al/B4C Metal Matrix Composites Using Taguchi Method and ANN. Materials 2024, 17, 4056. [Google Scholar] [CrossRef]

- Karabacak, A.H.; Çanakçı, A.; Erdemir, F.; Özkaya, S.; Çelebi, M. Corrosion and Mechanical Properties of Novel AA2024 Matrix Hybrid Nanocomposites Reinforced with B4C and SiC Particles. Silicon 2022, 14, 8567–8579. [Google Scholar] [CrossRef]

- Akkaş, M.; Islak, S. Microstructure, Wear and Corrosion Properties of NiB-TiC Composite Materials Produced by Powder Metallurgy Method. Sci. Sinter. 2019, 51, 327–338. [Google Scholar] [CrossRef]

- Yan, Y.-F.; Kou, S.-Q.; Yang, H.-Y.; Shu, S.-L.; Qiu, F.; Jiang, Q.-C.; Zhang, L.-C. Ceramic Particles Reinforced Copper Matrix Composites Manufactured by Advanced Powder Metallurgy: Preparation, Performance, and Mechanisms. Int. J. Extrem. Manuf. 2023, 5, 032006. [Google Scholar] [CrossRef]

- Shu, D.; Li, X.; Yang, Q. Effect on Microstructure and Performance of B4C Content in B4C/Cu Composite. Metals 2021, 11, 1250. [Google Scholar] [CrossRef]

- Carreño-Gallardo, C.; Mendoza-Duarte, J.M.; López-Meléndez, C.; Estrada-Guel, I.; Reyes-Ronquillo, J.L.; Uriza-Vega, E.; Martínez-Sánchez, R. Effect of B4C Particles Addition on the Microstructure and Mechanical Performance of Some Aluminum-Based Composites. Microsc. Microanal. 2016, 22, 1888–1889. [Google Scholar] [CrossRef]

- Zhang, M.; Ma, D.; Wang, J.; Dai, S.; Xue, Y.; Zhu, L. Enhancing Interfacial Bonding in Metal Matrix Composites: Challenges, Methods, and Future Prospects. Crit. Rev. Solid State Mater. Sci. 2025, 324, 1–54. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, J.; Pan, W.; Wang, W.; Tang, C. A Review on the Preparation and Application of BN Composite Coatings. Ceram. Int. 2023, 49, 24–39. [Google Scholar] [CrossRef]

- Islak, S.; Çelik, E.; Houssain, H.; Danacı, H.C. Effect of Boron on Microstructure, Thermal, and Mechanical Properties of Ni B Matrix Diamond Cutting Tools. Int. J. Refract. Met. Hard Mater. 2024, 123, 106758. [Google Scholar] [CrossRef]

- Yalçın, E.D.; Çanakçı, A.; Çuvalcı, H.; Varol, T.V.; Karabacak, A.H. The Effect of Boron Nitride (h-BN) and Silicon Carbide (SiC) on the Microstructure and Wear Behavior of ZA40/SiC/h-BN Hybrid Composites Processed by Hot Pressing. Kov. Mater.-Met. Mater. 2023, 61, 257–266. [Google Scholar] [CrossRef]

- Sathishkumar, A.; Soundararajan, R.; Ramesh, A.; Muthu Vel, T.J.; Richie Ronaldo, A.; Sai Deepesh, J. Experimental Investigations on Mechanical and Tribological Behaviour of A356 with x Wt% Boron Carbide and Fly Ash Hybrid Composites. IOP Conf. Ser. Mater. Sci. Eng. 2020, 988, 012023. [Google Scholar] [CrossRef]

- Çanakçı, A.; Çelebi, M. Determination of Nano-Graphene Content for Improved Mechanical and Tribological Performance of Zn-Based Alloy Matrix Hybrid Nanocomposites. J. Alloys Compd. 2024, 1001, 175152. [Google Scholar] [CrossRef]

- Dearnley, P.A.; Bell, T. Engineering the Surface with Boron Based Materials. Surf. Eng. 1985, 1, 203–217. [Google Scholar] [CrossRef]

- Hussain, Z.; Yang, H.-W.; Choi, B.-S. Synthesis of Three-Dimensionally Interconnected Hexagonal Boron Nitride Networked Cu-Ni Composite. Korean J. Met. Mater. 2021, 59, 505–513. [Google Scholar] [CrossRef]

- Kostecki, M.; Cygan, T.; Petrus, M.; Jaroszewicz, J. Thermal Properties of Multilayer Graphene and HBN Reinforced Copper Matrix Composites. J. Therm. Anal. Calorim. 2019, 138, 3873–3883. [Google Scholar] [CrossRef]

- Djouider, F.; Alhawsawi, A.; Elmoujarkach, E.; Banoqitah, E.; Alammari, O.A.; Moustafa, E.B. The Effect of Hybrid B4C and Si3N4 Nanoparticles on the Mechanical and Physical Properties of Copper Nanocomposites. Metals 2023, 13, 1504. [Google Scholar] [CrossRef]

- Balalan, Z.; Gulan, F. Microstructure and Mechanical Properties of Cu-B4C and CuAl-B4C Composites Produced by Hot Pressing. Rare Met. 2019, 38, 1169–1177. [Google Scholar] [CrossRef]

- Kuş, H. Influence of B4C Addition on the Tribological Properties of Bronze Matrix Brake Pad Materials. Open Chem. 2025, 23, 20240126. [Google Scholar] [CrossRef]

- Pellizzari, M.; Cipolloni, G. Spark Plasma Sintering of Copper Matrix Composites Reinforced with TiB2 Particles. Materials 2020, 13, 2602. [Google Scholar] [CrossRef] [PubMed]

- El-Tantawy, A.; Daoush, W.M.; El-Nikhaily, A.E. Microstructure and Properties of BN/Ni-Cu Composites Fabricated by Powder Technology. J. Exp. Nanosci. 2018, 13, 174–187. [Google Scholar] [CrossRef]

- Bobrynina, E.; Koltsova, T.; Larionova, T. Investigation of Copper–Carbon Composite Microstructure and Properties. Metals 2023, 13, 1052. [Google Scholar] [CrossRef]

- Zhang, H.; Niu, D.; Yang, J.; Zhang, X.; Zhu, J.; Li, W. β-Ga2O3 Thin Films via an Inorganic Sol–Gel Spin Coating: Preparation and Characterization. Nanomaterials 2025, 15, 277. [Google Scholar] [CrossRef] [PubMed]

- Vukkum, V.B.; Darwish, A.A.; Choudhari, A.; Yang, Z.; Storck, S.M.; Borkar, T.; Gupta, R.K. Effect of Nitride Addition on Microstructure, Hardness, and Wear Resistance of Additively Manufactured Stainless Steel. J. Mater. Eng. Perform. 2025, 34, 15991–16007. [Google Scholar] [CrossRef]

- Varol, T.; Canakci, A.; Ozsahin, S.; Erdemir, F.; Ozkaya, S. Artificial Neural Network-Based Prediction Technique for Coating Thickness in Fe-Al Coatings Fabricated by Mechanical Milling. Part. Sci. Technol. 2018, 36, 742–750. [Google Scholar] [CrossRef]

- Digole, S.; Bohara, S.; Kothapalli, C.R.; Bajaj, B.; Borkar, T. Effect of Hexagonal Boron Nitride (HBN) Addition on Microstructure, Mechanical, and Biocompatible Properties of Spark Plasma Sintered Titanium (Ti) Matrix Composites. J. Mech. Behav. Biomed. Mater. 2025, 168, 107030. [Google Scholar] [CrossRef]

- Kumar, R.; Bakshi, S.; Joardar, J.; Parida, S.; Raja, V.; Singh Raman, R. Structural Evolution during Milling, Annealing, and Rapid Consolidation of Nanocrystalline Fe–10Cr–3Al Powder. Materials 2017, 10, 272. [Google Scholar] [CrossRef]

- Suzuki, T.S.; Uchikoshi, T.; Sakka, Y. Densification of SiC by Colloidal Processing and SPS without Sintering Additives. Adv. Appl. Ceram. 2014, 113, 85–88. [Google Scholar] [CrossRef]

- Ghafuri, F.; Ahmadian, M.; Emadi, R.; Zakeri, M. Effects of SPS Parameters on the Densification and Mechanical Properties of TiB2-SiC Composite. Ceram. Int. 2019, 45, 10550–10557. [Google Scholar] [CrossRef]

- Babu, N.; Soundararajan, R.; Santhosh, V.J.; Kamaraj, M. Effect of Processing Route on the Mechanical and Tribological Behaviour of AA8011 Hybrid Composites. J. Inst. Eng. Ser. D 2023, 104, 561–567. [Google Scholar] [CrossRef]

- Tasci, U. Microstructure, Mechanical Strength, and Tribological Behavior of B4C/WS2-Hybrid-Reinforced B319 Aluminum Matrix Composites. Lubricants 2025, 13, 247. [Google Scholar] [CrossRef]

- Somasundaram, M.; Uttamchand, N.K.; Annamalai, A.R.; Jen, C.-P. Insights on Spark Plasma Sintering of Magnesium Composites: A Review. Nanomaterials 2022, 12, 2178. [Google Scholar] [CrossRef]

- Boldin, M.S.; Popov, A.A.; Lantsev, E.A.; Nokhrin, A.V.; Chuvil’deev, V.N. Investigation of the Densification Behavior of Alumina during Spark Plasma Sintering. Materials 2022, 15, 2167. [Google Scholar] [CrossRef] [PubMed]

- Hajagos, S.; Kovács, J.G.; Suplicz, A.; Széplaki, P.; Zink, B. An Experimental and Theoretical Study on the Electrical Conductivity of Polymer Composites. J. Mater. Res. Technol. 2025, 39, 6300–6309. [Google Scholar] [CrossRef]

- Şap, S.; Uzun, M.; Usca, Ü.A.; Pimenov, D.Y.; Giasin, K.; Wojciechowski, S. Investigation on Microstructure, Mechanical, and Tribological Performance of Cu Base Hybrid Composite Materials. J. Mater. Res. Technol. 2021, 15, 6990–7003. [Google Scholar] [CrossRef]

- Harichandran, R.; Selvakumar, N. Microstructure and Mechanical Characterization of (B4C+ h-BN)/Al Hybrid Nanocomposites Processed by Ultrasound Assisted Casting. Int. J. Mech. Sci. 2018, 144, 814–826. [Google Scholar] [CrossRef]

- Ayyanar, S.; Gnanavelbabu, A.; Rajkumar, K.; Loganathan, P. Studies on High Temperature Wear and Friction Behaviour of AA6061/B4C/HBN Hybrid Composites. Met. Mater. Int. 2021, 27, 3040–3057. [Google Scholar] [CrossRef]

- Jin, H.; Jiang, G.-Y. Synergistic Effect of B4C/h-BN Addition on the Tribological and Corrosion Behavior of Laser Prepared Ni60AA Composite Coating. Surf. Coat. Technol. 2025, 517, 132781. [Google Scholar] [CrossRef]

- Igual Munoz, A.; Espallargas, N.; Mischler, S. Tribocorrosion; Springer International Publishing: Cham, Germany, 2020; ISBN 978-3-030-48106-3. [Google Scholar]

- Yunus, M.; Alfattani, R. Assessment of Mechanical and Tribological Behavior of AA6061 Reinforced with B4C and Gr Hybrid Metal Matrix Composites. Coatings 2023, 13, 1653. [Google Scholar] [CrossRef]

| Sample Code | Milling Time (h) | Reinforcement Content | Milling Speed (rpm) | Ball-to-Powder Weight Ratio | |

|---|---|---|---|---|---|

| h-BN (wt.%) | B4C (wt.%) | ||||

| S0 | 2 | 1 | 0 | - | - |

| S1 | 2 | 1 | 0.25 | 400 | 10:1 |

| S2 | 2 | 1 | 0.5 | 400 | 10:1 |

| S3 | 2 | 1 | 0.75 | 400 | 10:1 |

| S4 | 2 | 1 | 1 | 400 | 10:1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Çelebi, M.; Karabacak, A.H.; Özkaya, S.; Çelik, E.; Sekban, D.M.; Çanakçı, A.; Yanar, H. Effect of B4C Amount on Microstructural and Mechanical Properties of Cu/h-BN/B4C Metal Matrix Composites Fabricated via Spark Plasma Sintering. Metals 2025, 15, 1283. https://doi.org/10.3390/met15121283

Çelebi M, Karabacak AH, Özkaya S, Çelik E, Sekban DM, Çanakçı A, Yanar H. Effect of B4C Amount on Microstructural and Mechanical Properties of Cu/h-BN/B4C Metal Matrix Composites Fabricated via Spark Plasma Sintering. Metals. 2025; 15(12):1283. https://doi.org/10.3390/met15121283

Chicago/Turabian StyleÇelebi, Müslim, Abdullah Hasan Karabacak, Serdar Özkaya, Ertuğrul Çelik, Dursun Murat Sekban, Aykut Çanakçı, and Harun Yanar. 2025. "Effect of B4C Amount on Microstructural and Mechanical Properties of Cu/h-BN/B4C Metal Matrix Composites Fabricated via Spark Plasma Sintering" Metals 15, no. 12: 1283. https://doi.org/10.3390/met15121283

APA StyleÇelebi, M., Karabacak, A. H., Özkaya, S., Çelik, E., Sekban, D. M., Çanakçı, A., & Yanar, H. (2025). Effect of B4C Amount on Microstructural and Mechanical Properties of Cu/h-BN/B4C Metal Matrix Composites Fabricated via Spark Plasma Sintering. Metals, 15(12), 1283. https://doi.org/10.3390/met15121283