Advances in the Design and Development of Lightweight Metal Matrix Composites: Processing, Properties, and Applications

Abstract

1. Introduction

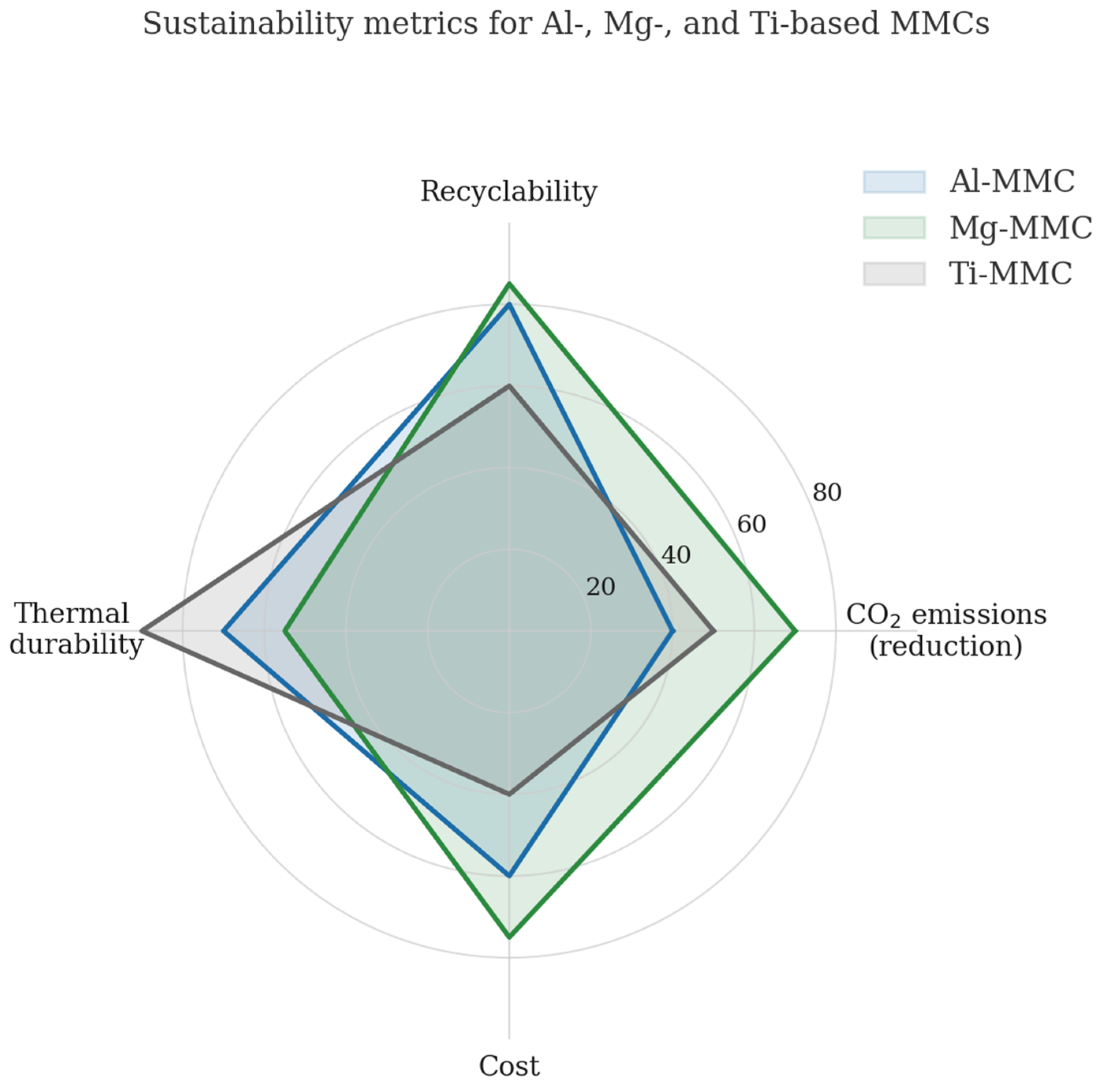

2. Matrices and Reinforcements for Lightweight MMCs

2.1. Metallic Matrices

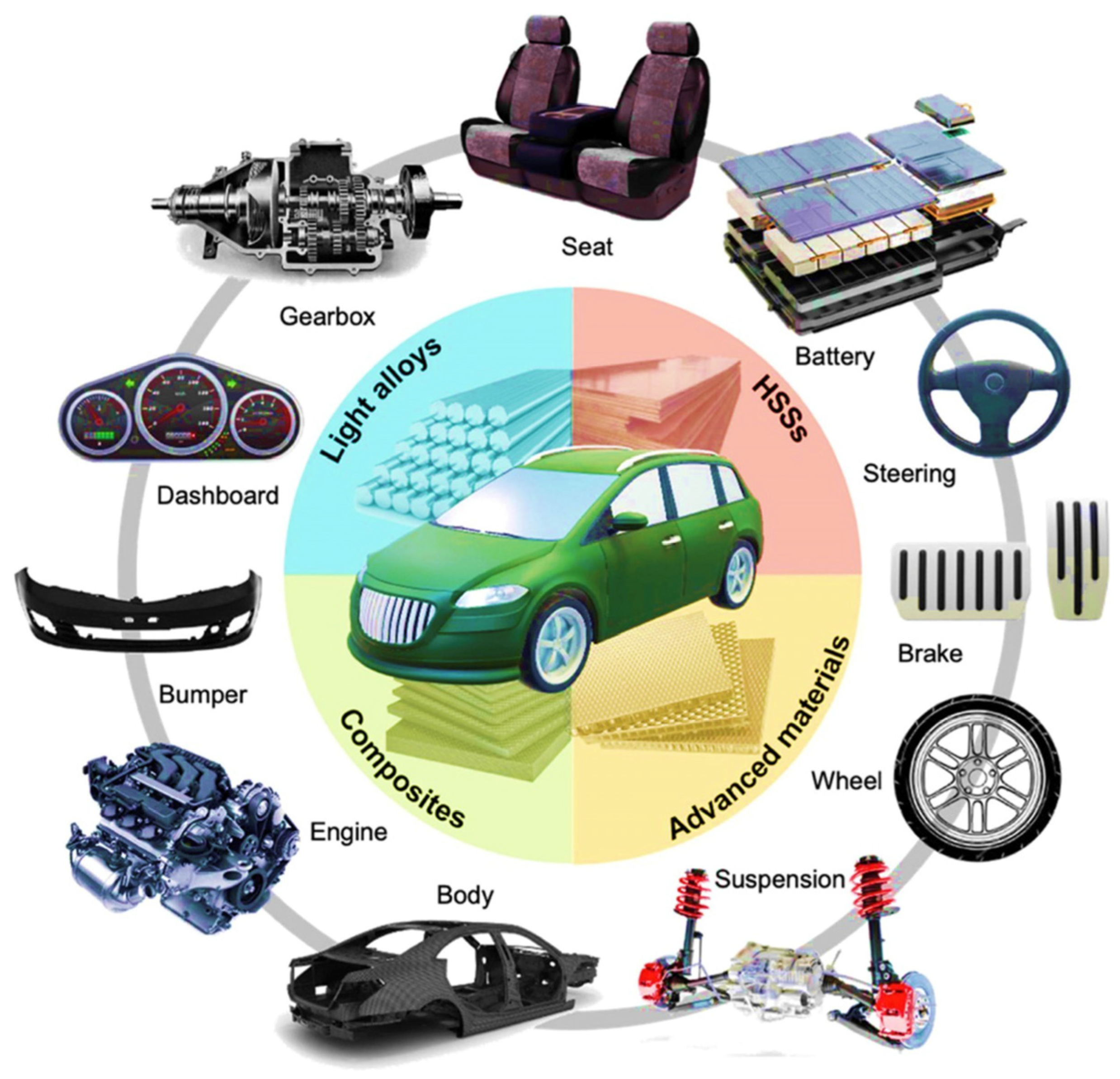

2.1.1. Aluminum Alloys

2.1.2. Magnesium Alloys

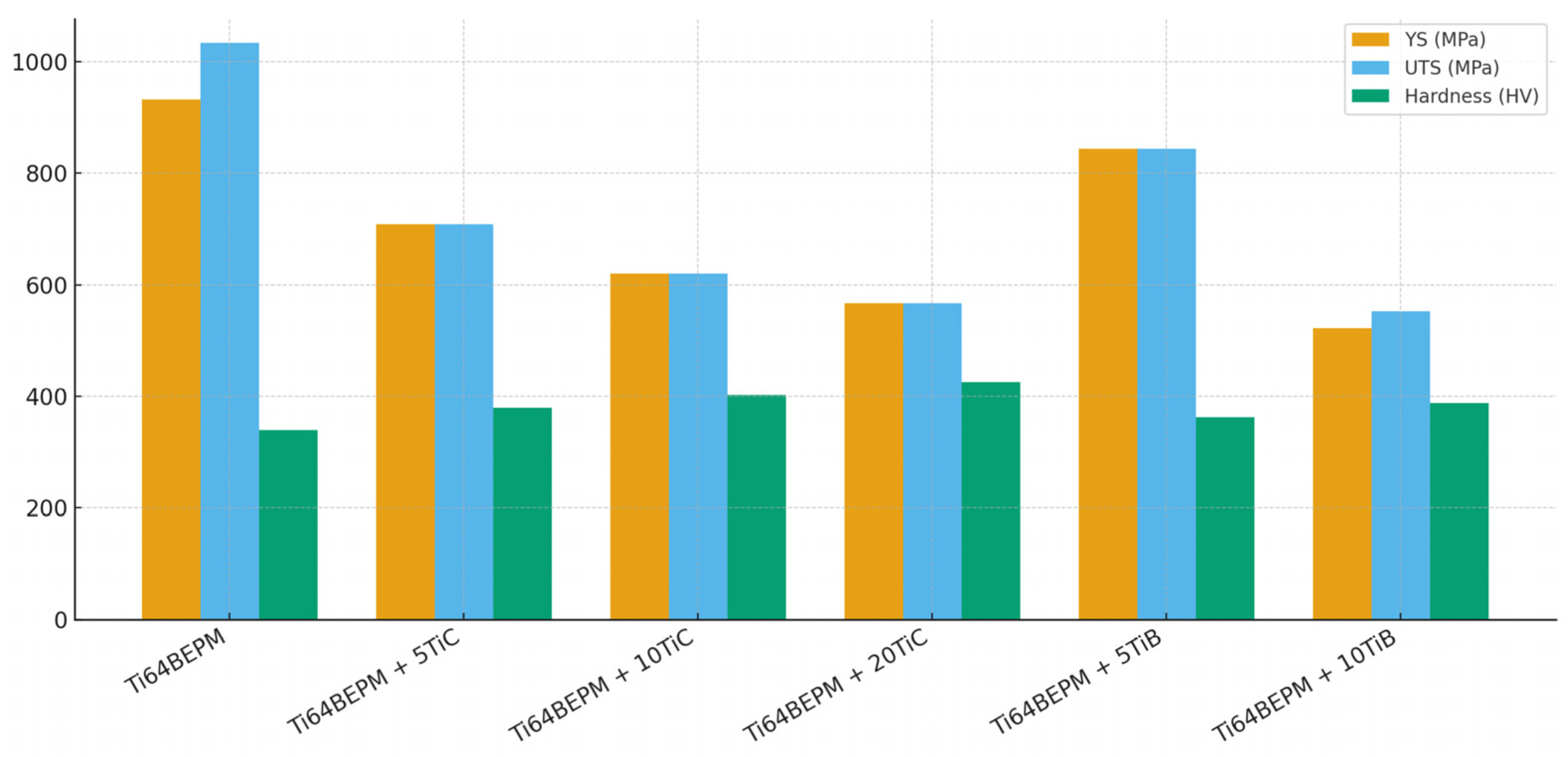

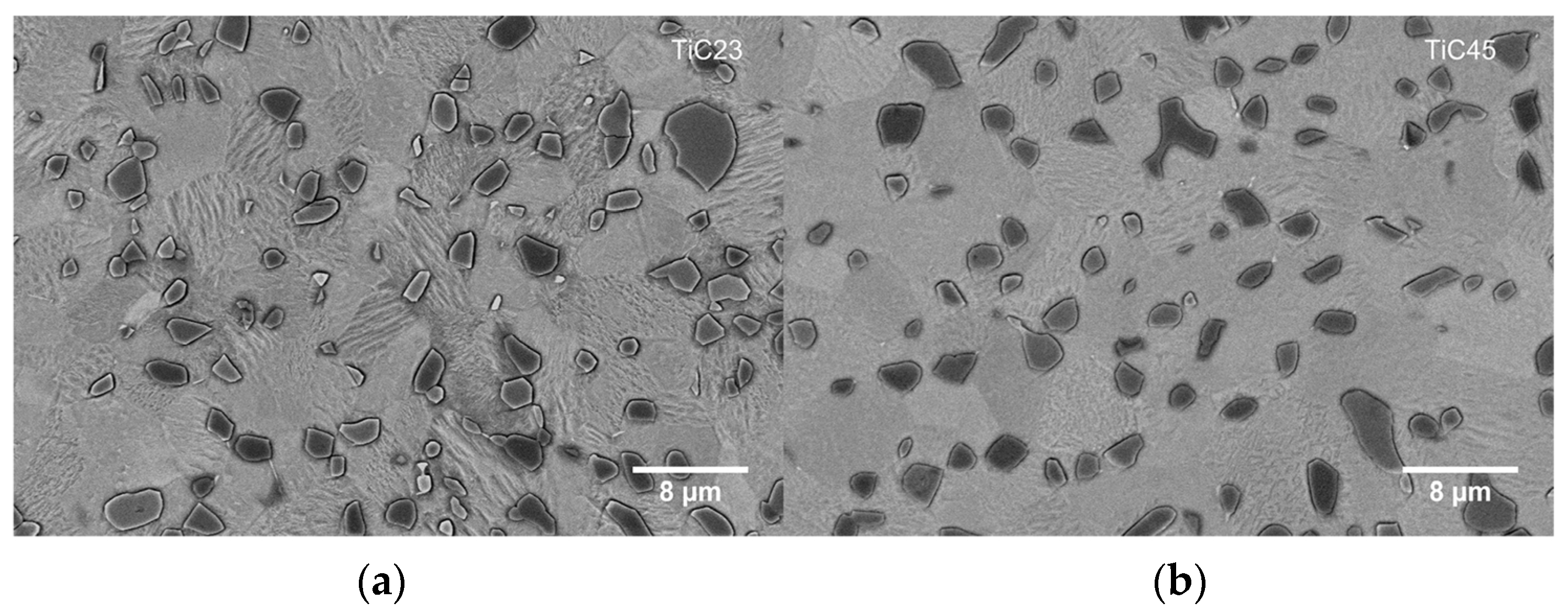

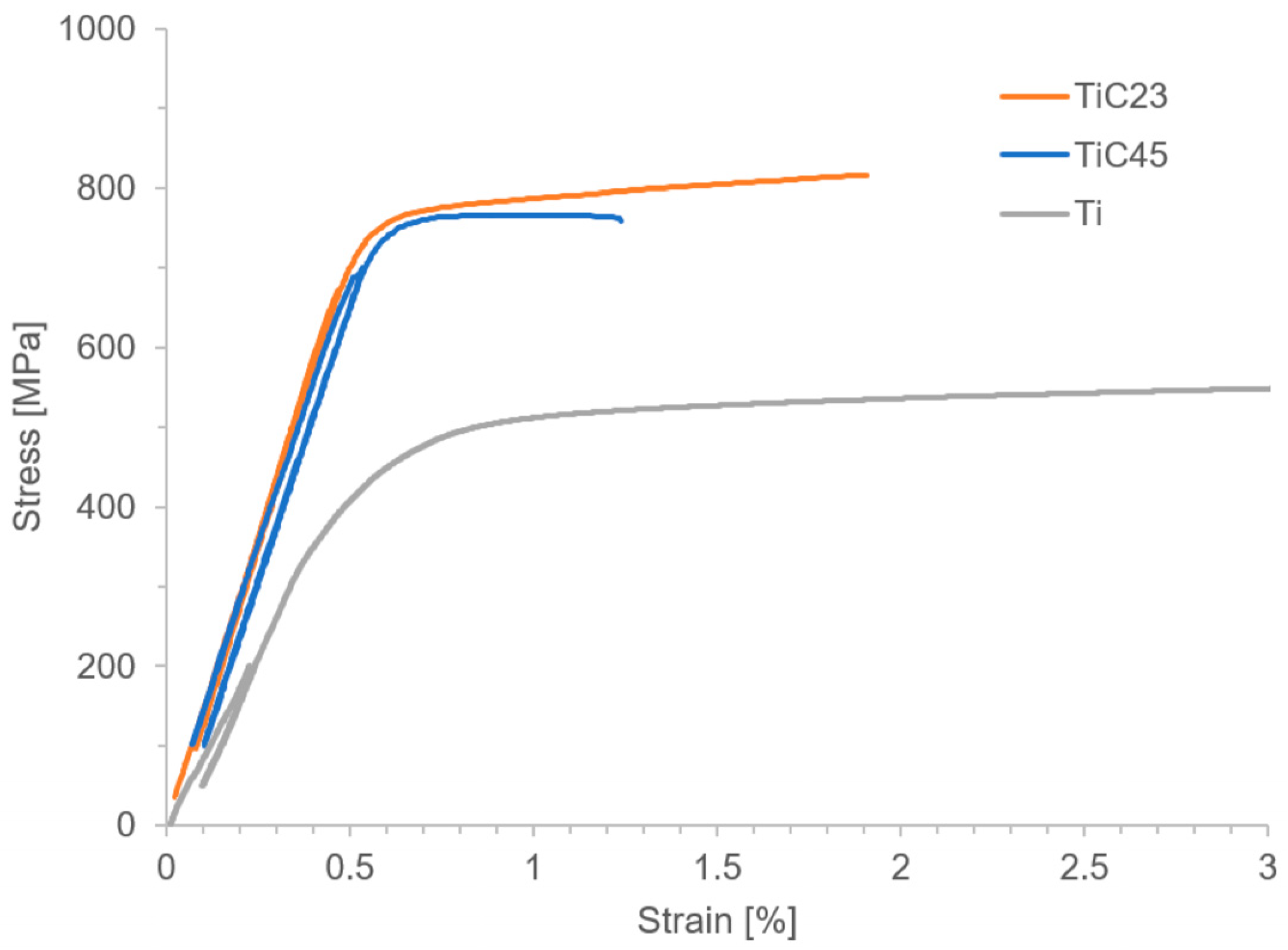

2.1.3. Titanium Alloys

2.1.4. Lightweight Composites Metal Foams

2.1.5. Lightweight Functionally Graded MMCs

2.2. Reinforcement Materials

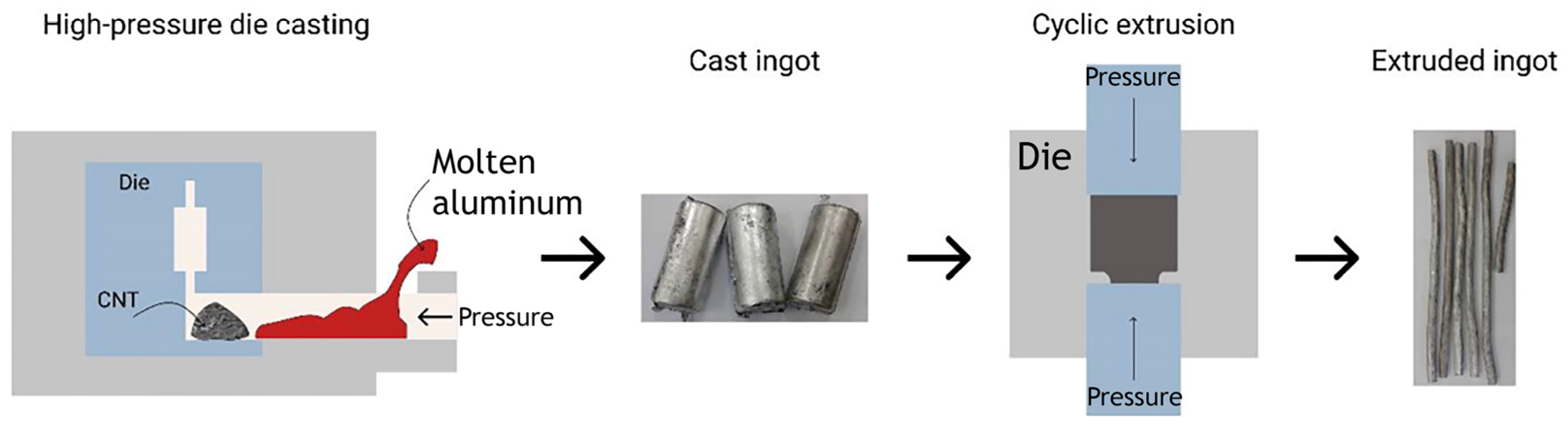

3. Advanced Processing Techniques

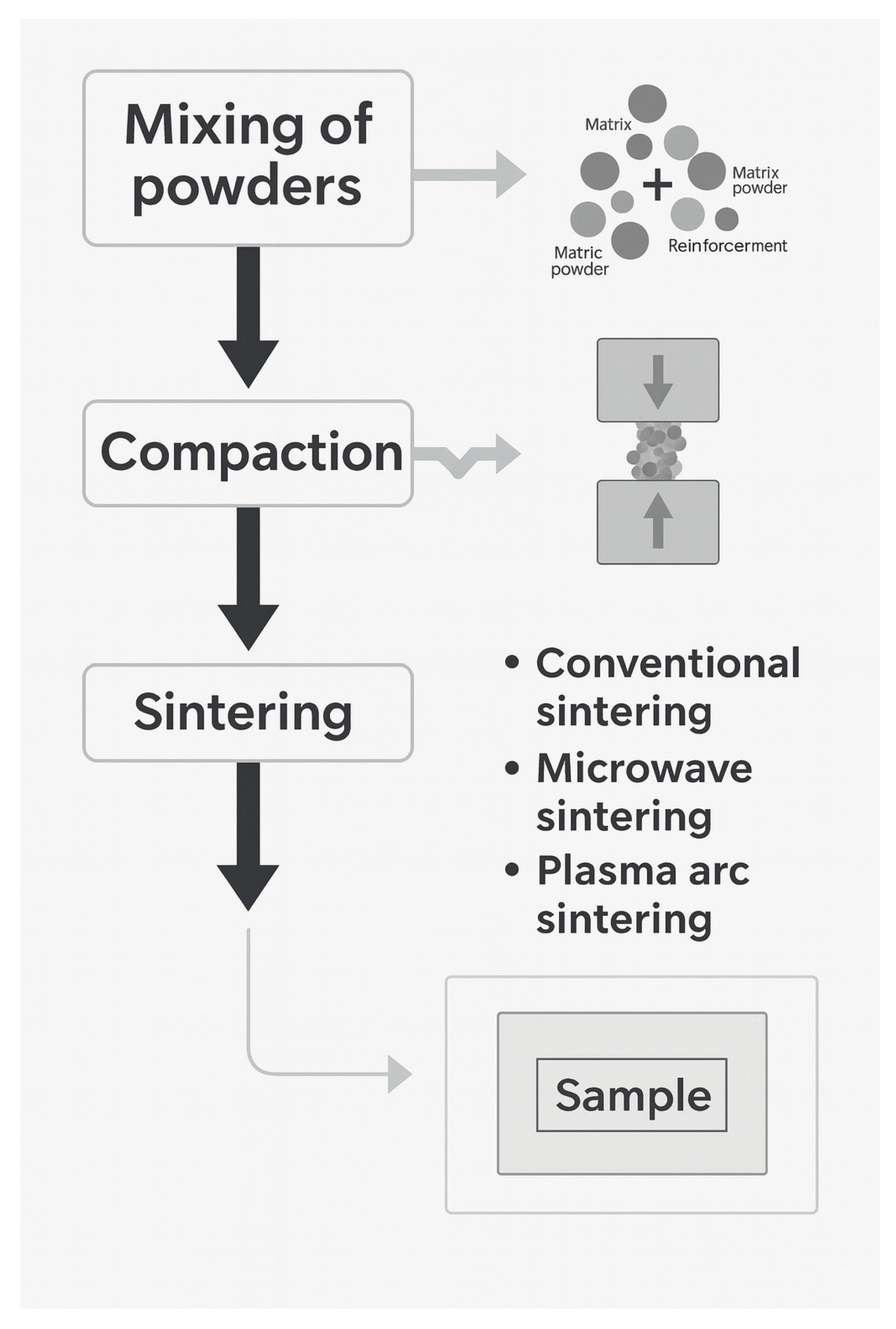

3.1. Powder Metallurgy (PM)

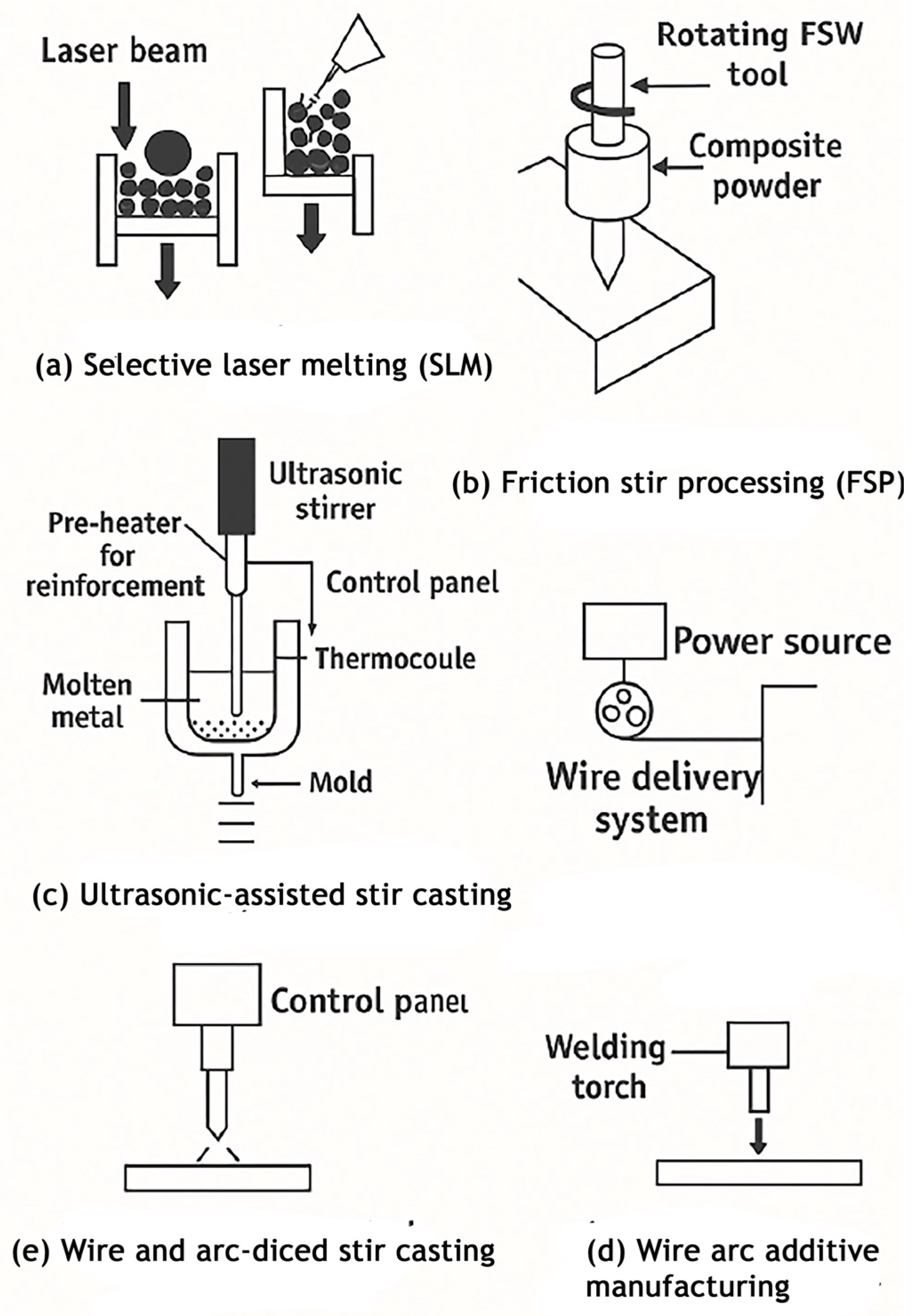

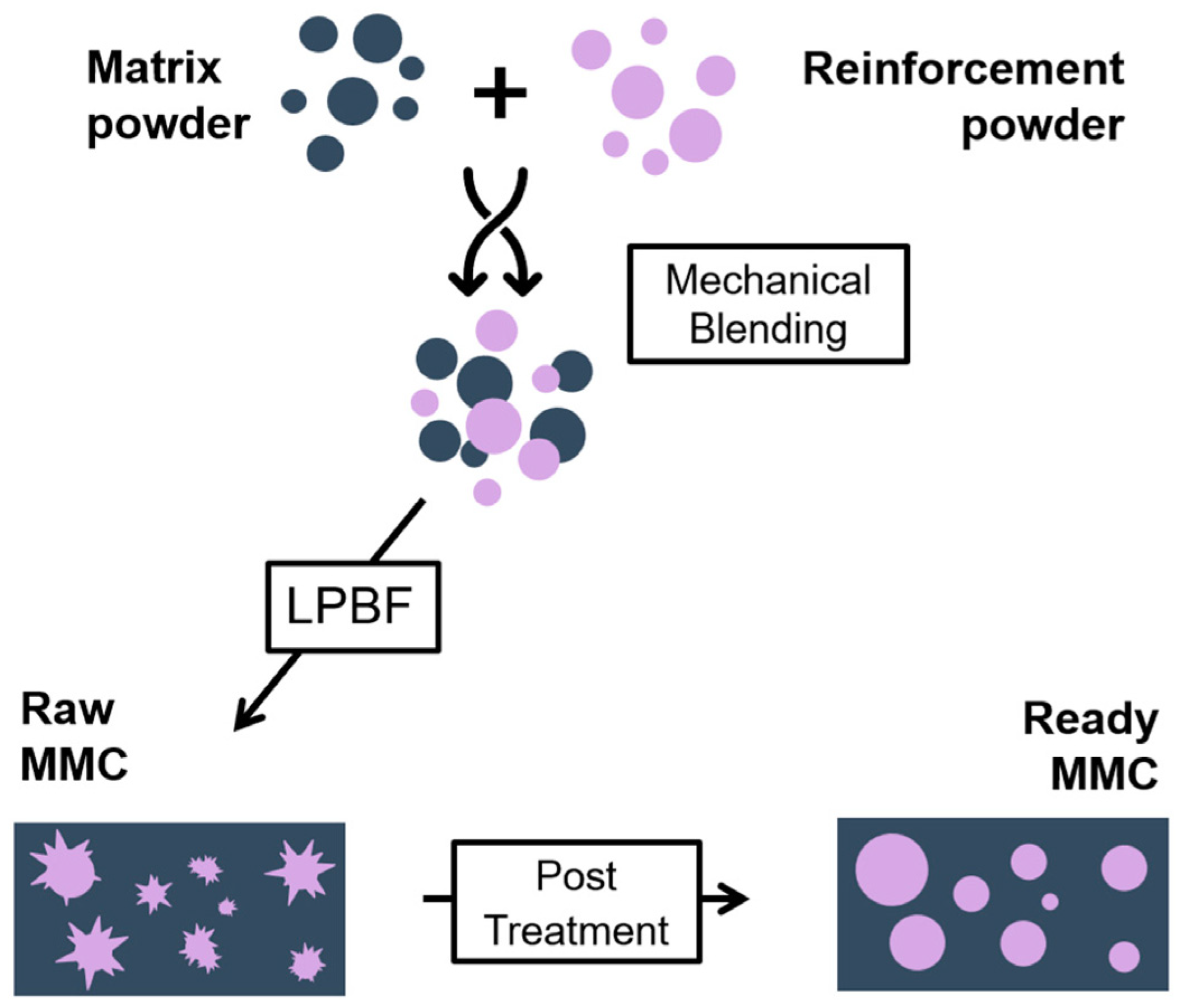

3.2. Additive Manufacturing (AM) of MMCs

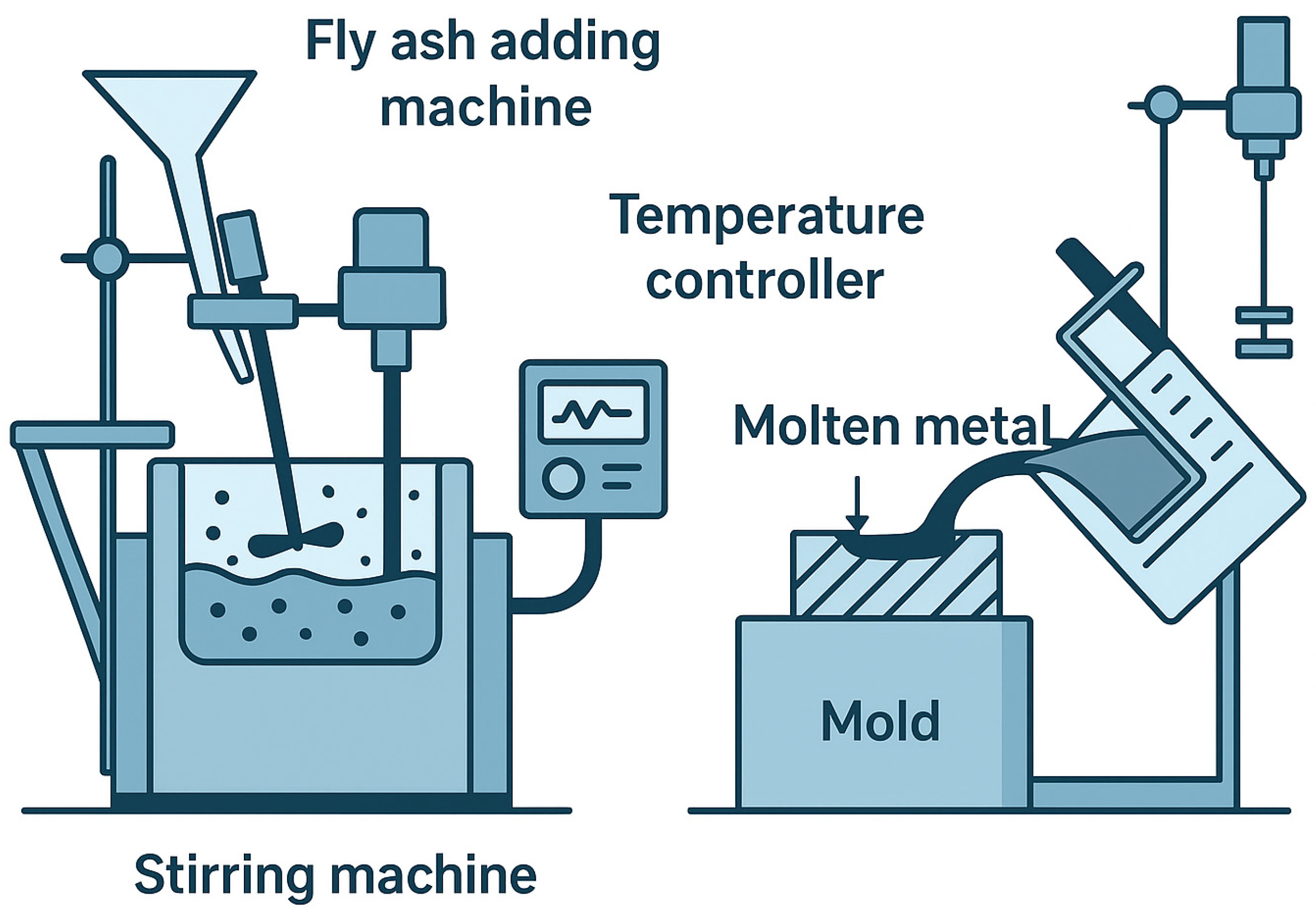

3.3. Stir Casting of MMCs

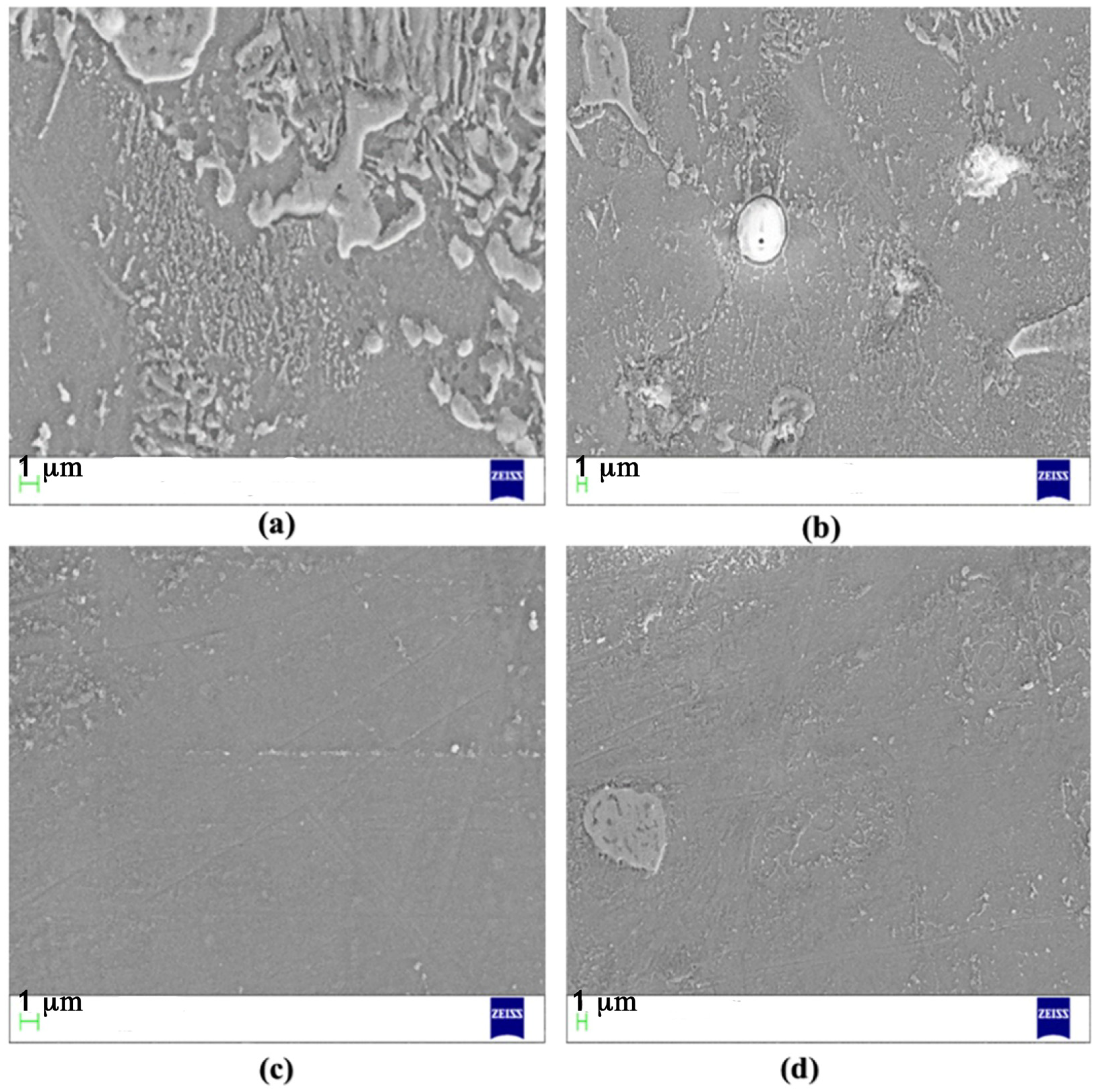

4. Microstructural Design and Property Enhancement

4.1. Principles of Microstructural Design

4.2. Integrated Property Enhancements

4.3. Emerging Trends and Future Directions

5. Applications of Lightweight MMCs

6. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lajis, M.; Ahmad, A.; Yusuf, N.; Azami, A.; Wagiman, A. Mechanical properties of recycled aluminium chip reinforced with alumina (Al2O3) particle. Materialwiss. Werkstofftech. 2017, 48, 306–310. [Google Scholar] [CrossRef]

- Velishala, M.; Pandiripalli, M.; Chilamban, V. Investigation on corrosion and wear properties of Al-7075/TiC composites fabricated by stir casting route. Metall. Mater. Eng. 2022, 28, 435–452. [Google Scholar] [CrossRef]

- Jabbari, A.; Sedighi, M.; Vallant, R.; Huetter, A.; Sommitsch, C. Effect of pass number, rotational and traverse speed on particle distribution and microstructure of AZ31/SiC composite produced by friction stir processing. Key Eng. Mater. 2015, 651–653, 765–770. [Google Scholar] [CrossRef]

- Mohan, R.; Venkatraman, R.; Raghuraman, S.; Chidambaram, B.; Balakrishnan, S.; Vishnuram, S. An experimental study on the effect of reverse two-step sintering on aluminium-silicon carbide metal matrix composite. Adv. Sci. Technol. 2021, 106, 78–83. [Google Scholar] [CrossRef]

- Liewald, M.; Riedmüller, K. Material property modification of continuous fibre-reinforced aluminium matrices produced by semi-solid forming strategies. KMUTNB Int. J. Appl. Sci. Technol. 2014, 7, 21–28. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Pakdel, A.; Zhi, C.; Bando, Y.; Tang, D.; Faerstein, K.; Shtansky, D.; Golberg, D. Utilization of multiwalled boron nitride nanotubes for the reinforcement of lightweight aluminum ribbons. Nanoscale Res. Lett. 2013, 8, 3. [Google Scholar] [CrossRef]

- Hynes, N.; Raja, S.; Tharmaraj, R.; Pruncu, C.; Dışpınar, D. Mechanical and tribological characteristics of boron carbide reinforcement of AA6061 matrix composite. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 155. [Google Scholar] [CrossRef]

- Kumar, R.; Bhowmick, H.; Gupta, D.; Bansal, S. Development and characterization of multiwalled carbon nanotube-reinforced microwave sintered hybrid aluminum metal matrix composites: An experimental investigation on mechanical and tribological performances. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 235, 2310–2323. [Google Scholar] [CrossRef]

- Bakshi, S.; Lahiri, D.; Agarwal, A. Carbon nanotube reinforced metal matrix composites—A review. Int. Mater. Rev. 2010, 55, 41–64. [Google Scholar] [CrossRef]

- Malaki, M.; Tehrani, A.; Niroumand, B.; Gupta, M. Wettability in metal matrix composites. Metals 2021, 11, 1034. [Google Scholar] [CrossRef]

- Natrayan, L.; Kumar, M. Mechanical, microstructure and wear behaviour of LM25/SiC/MICA metal matrix composite fabricated by squeeze casting technique. Appl. Eng. Lett. 2019, 4, 72–77. [Google Scholar] [CrossRef]

- Dash, K.; Sukumaran, S.; Ray, B. The behaviour of aluminium matrix composites under thermal stresses. Sci. Eng. Compos. Mater. 2014, 23, 1–20. [Google Scholar] [CrossRef]

- Pruncu, C.; Vlădescu, A.; Hynes, N.; Sankaranarayanan, R. Surface investigation of physella acuta snail shell particle reinforced aluminium matrix composites. Coatings 2022, 12, 794. [Google Scholar] [CrossRef]

- Zhang, Z.; Xu, Z.; Salinas, B. In-situ disintegrating completion tools by means of controlled microgalvanic cells. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–2 October 2013. [Google Scholar] [CrossRef]

- Mishra, A.; Dixit, D.; Al-Sabur, R. Development of specially reinforced magnesium composites prepared by squeeze casting process. Res. Eng. Struct. Mater. 2021, 7, 635–646. [Google Scholar] [CrossRef]

- Alam, M.; Ya, H.; Azeem, M.; Mustapha, M.; Yusuf, M.; Masood, F.; Marode, R.; Sapuan, S.; Ansari, A. Advancements in aluminum matrix composites reinforced with carbides and graphene: A comprehensive review. Nanotechnol. Rev. 2023, 12, 20230111. [Google Scholar] [CrossRef]

- Senthilvelan, T.; Gopalakannan, S.; Vishnuvarthan, S.; Keerthivaran, K. Fabrication and characterization of SiC, Al2O3, and B4C reinforced Al-Zn-Mg-Cu alloy (AA 7075) metal matrix composites: A study. Adv. Mater. Res. 2012, 622–623, 1295–1299. [Google Scholar] [CrossRef]

- Krishna, M.; Xavior, M. An investigation on the mechanical properties of hybrid metal matrix composites. Procedia Eng. 2014, 97, 918–924. [Google Scholar] [CrossRef]

- Thayumanavan, M.; Kumar, K. Fabrication and mechanical behaviour investigation on aluminium 7075 boron carbide and Inconel alloy 625 metal matrix composite using ultra sonic stir casting method. Ann. Chim.-Sci. Mat. 2022, 46, 333–338. [Google Scholar] [CrossRef]

- Karthikeyan, A.; Nallusamy, S. Experimental analysis on sliding wear behaviour of aluminium-6063 with SiC particulate composites. Int. J. Eng. Res. Afr. 2017, 31, 36–43. [Google Scholar] [CrossRef]

- Monikandan, V.; Prasanth, P.; Dhas, E. Investigation on casting anomalies of liquid metallurgy—Processed aa 6061-B4C composites. Int. J. Sci. Res. Eng. Manag. 2024, 08, 1–14. [Google Scholar] [CrossRef]

- Bodunrin, M.; Alaneme, K.; Chown, L. Aluminium matrix hybrid composites: A review of reinforcement philosophies; mechanical, corrosion and tribological characteristics. J. Mater. Res. Technol. 2015, 4, 434–445. [Google Scholar] [CrossRef]

- Dolata-Grosz, A.; Dyzia, M.; Walke, W. Influence of particles type and shape on the corrosion resistance of aluminium hybrid composites. Solid State Phenom. 2012, 191, 81–87. [Google Scholar] [CrossRef]

- Uvaraja, V.; Natarajan, N. Optimization of friction and wear behaviour in hybrid metal matrix composites using taguchi technique. J. Miner. Mater. Charact. Eng. 2012, 11, 757–768. [Google Scholar] [CrossRef]

- Popov, V.; Pismenny, A.; Larianovsky, N.; Лaптeвa, A.; Safranchik, D. Corrosion resistance of Al–CNT metal matrix composites. Materials 2021, 14, 3530. [Google Scholar] [CrossRef]

- Simões, S.; Viana, F.; Reis, M.A.L.; Vieira, M.F. Aluminum and Nickel Matrix Composites Reinforced by CNTs: Dispersion/Mixture by Ultrasonication. Metals 2017, 7, 279. [Google Scholar] [CrossRef]

- Carneiro, Í.; Simões, S. Investigation of Mechanical Properties of Al/CNT Nanocomposites Produced by Powder Metallurgy. Appl. Sci. 2023, 13, 54. [Google Scholar] [CrossRef]

- Pomorska, M.; Kaczmar, J.; Morgiel, J.; Naplocha, K. TEM investigation of interfaces formed between SaffilTM fibers and AA6061 and En Ac 44200 aluminium alloys. Solid State Phenom. 2012, 186, 327–330. [Google Scholar] [CrossRef]

- Hossain, M.; Ali, M.; Amin, M.; Kibria, M.; Ferdous, M. Fabrication and performance test of aluminium alloy-rice husk ash hybrid metal matrix composite as industrial and construction material. Int. J. Eng. Mater. Manuf. 2017, 2, 94–102. [Google Scholar] [CrossRef]

- Kartal, Y.; Er, A. Investigation the machinability of aluminium (Al1070) matrix silicium carbide (SiC) and boron carbide (B4C) hybrid reinforced composite materials. Int. J. Eng. Res. 2024, 16, 47–55. [Google Scholar] [CrossRef]

- Blanco, D.; Rubio, E.; Lorente-Pedreille, R.; Nuño, M. Sustainable processes in aluminium, magnesium, and titanium alloys applied to the transport sector: A review. Metals 2021, 12, 9. [Google Scholar] [CrossRef]

- Szczepanik, S.; Nikiel, P.; Bednarczyk, P. Influence of cold working on mechanical properties of Al-SiC composites. Mater. Sci. Forum 2017, 892, 53–58. [Google Scholar] [CrossRef]

- Jayasathyakawin, S.; Ravichandran, M.; Mohanavel, V.; Sathish, T.; Kumar, S.; Rajkumar, S.; Subbiah, R. A review on exploration of magnesium matrix composites. Mater. Sci. Forum 2022, 1068, 63–70. [Google Scholar] [CrossRef]

- Abbas, A.; Rajagopal, V.; Huang, S. Magnesium metal matrix composites and their applications. In Magnesium Alloys Structure and Properties Edited by Tomasz Tański and Paweł Jarka; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Balakrishnan, M.; Dinaharan, I.; Palanivel, R.; Sivaprakasam, R. Synthesize of AZ31/TiC magnesium matrix composites using friction stir processing. J. Magnes. Alloys 2015, 3, 76–78. [Google Scholar] [CrossRef]

- Gotagunaki, S.; Mudakappanavar, V.; Suresh, R. Investigation on microstructure and tensile fractography of re oxides (CeO2/Y2O3) reinforced AZ91D magnesium matrix composites. Frat. Integrità Strut. 2022, 17, 100–109. [Google Scholar] [CrossRef]

- Matta, A.; Koka, N.; Devarakonda, S. Recent studies on particulate reinforced AZ91 magnesium composites fabricated by stir casting—A review. J. Mech. Energy Eng. 2020, 4, 115–126. [Google Scholar] [CrossRef]

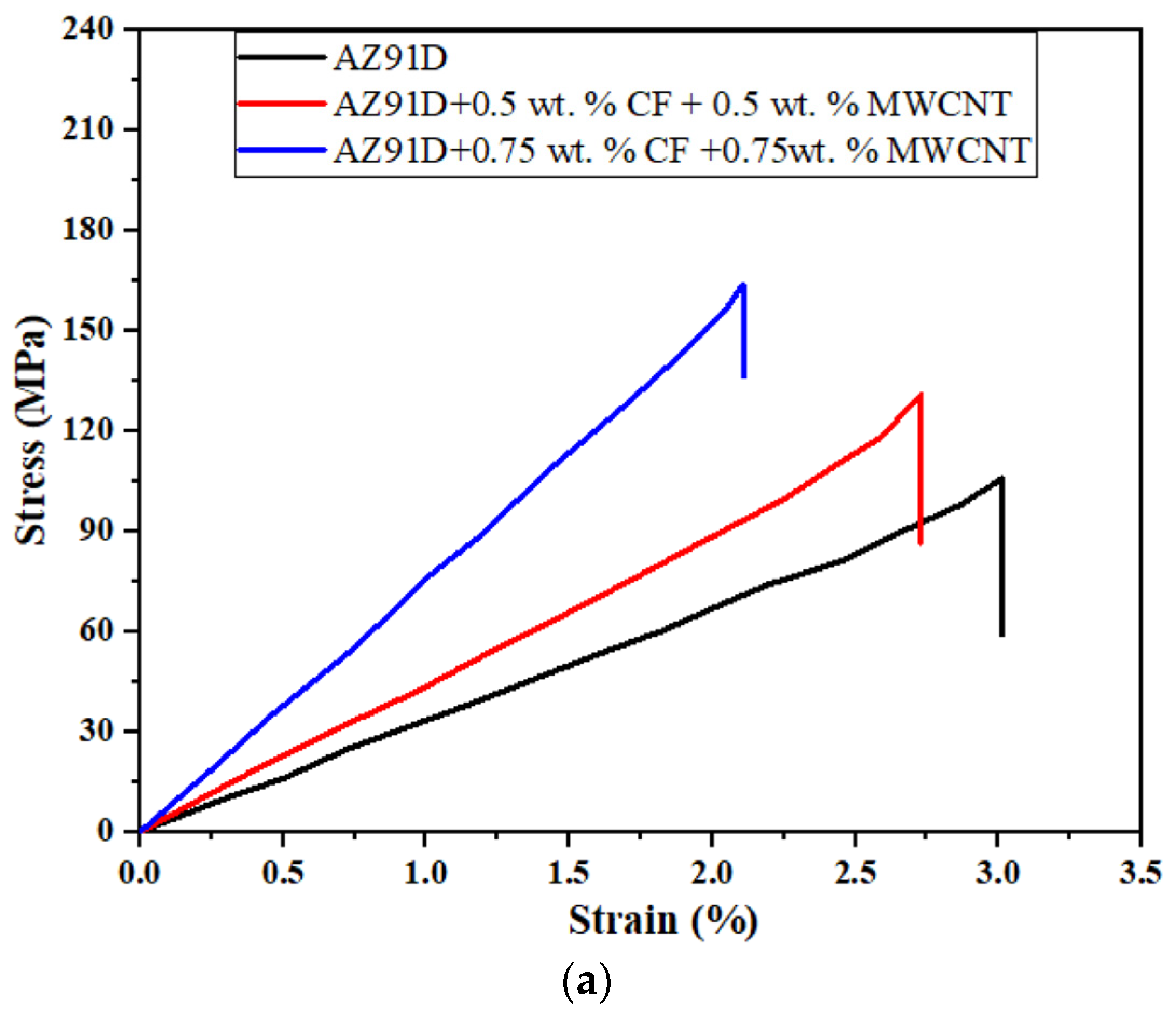

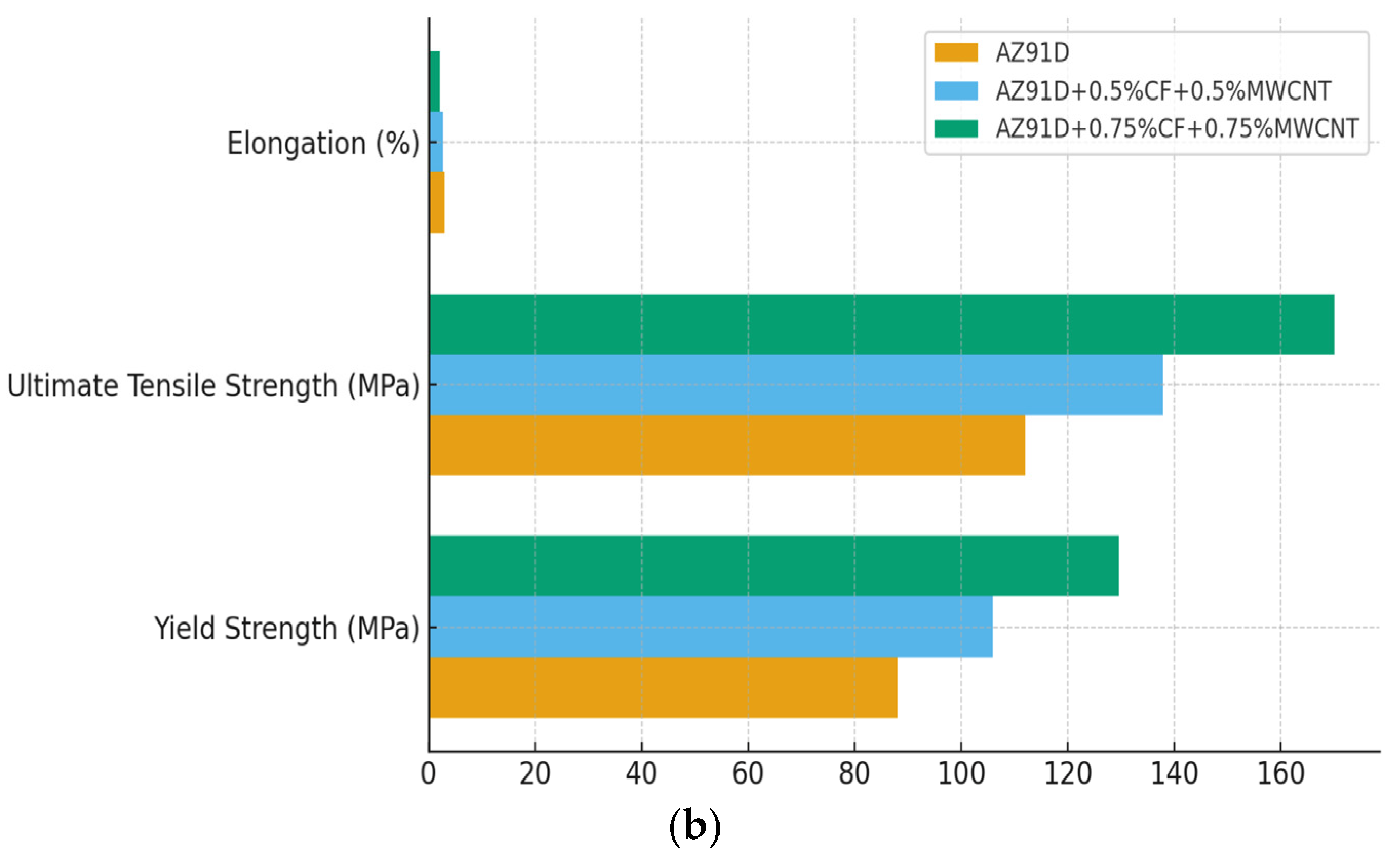

- Raju, G.; Meti, V.; Banapurmath, N.; Khan, T.; Siddhalingeshwar, I.; Vaikunte, V.; Vadlamudi, C.; Krishnappa, S.; Patil, A. Effect of multi-walled carbon nanotubes and carbon fiber reinforcements on the mechanical and tribological behavior of hybrid Mg-AZ91D nanocomposites. Materials 2022, 15, 6181. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, Y.; Zi, X. Study on mechanical property of SiC particulate reinforced magnesium matrix composites prepared by powder metallurgy. Appl. Mech. Mater. 2012, 246–247, 1106–1110. [Google Scholar] [CrossRef]

- Yan, H.; Huang, X.; Hu, Q. Damping capacity of SiCp/AZ61 composites. Adv. Mater. Res. 2010, 123–125, 35–38. [Google Scholar] [CrossRef]

- Deng, K.; Wu, K.; Wu, Y.; Nie, K.; Zheng, M. Effect of submicron size SiC particulates on microstructure and mechanical properties of AZ91 magnesium matrix composites. J. Alloys Compd. 2010, 504, 542–547. [Google Scholar] [CrossRef]

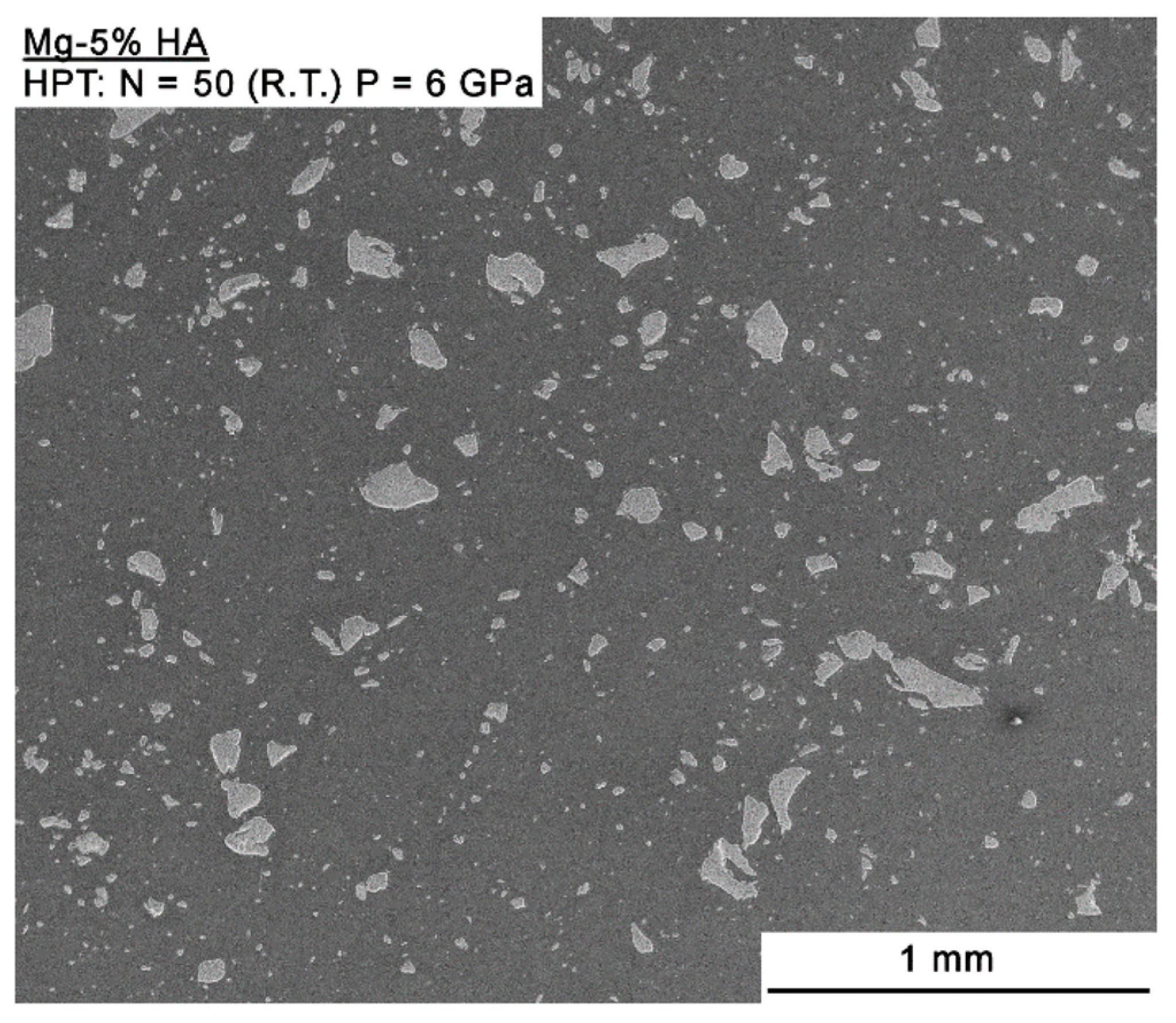

- Castro, M.; Lopes, D.; Soares, R.; Santos, D.; Nunes, E.; Lins, V.; Pereira, H.; Isaac, A.; Langdon, T.G.; Figueiredo, R. Magnesium-based bioactive composites processed at room temperature. Materials 2019, 12, 2609. [Google Scholar] [CrossRef]

- Zhou, J.; Qi, L.; Ouyang, H.; Li, H. Mechanical properties of Csf/AZ91D composites fabricated by extrusion forming process directly following the vacuum infiltration. Adv. Mater. Res. 2010, 89–91, 692–696. [Google Scholar] [CrossRef]

- Liu, S. Mechanical and wear behavior of self-lubricating hybrid metal matrix composite (MMC). Highl. Sci. Eng. Technol. 2024, 116, 226–236. [Google Scholar] [CrossRef]

- Mohr, M.; Wunderlich, R.; Novaković, R.; Ricci, E.; Fecht, H. Precise measurements of thermophysical properties of liquid Ti–6Al–4V (Ti64) alloy on board the international space station. Adv. Eng. Mater. 2020, 22, 2000169. [Google Scholar] [CrossRef]

- Hughes, J.; Sharman, A.; Ridgway, K. The effect of tool edge preparation on tool life and workpiece surface integrity. Proc. Inst. Mech. Eng. Pt. B J. Eng. Manufact. 2004, 218, 1113–1123. [Google Scholar] [CrossRef]

- Huang, Z.; Lu, D.; Zhang, Y.; Jiang, Y.; Lu, Y.; Guo, Y. Mechanical performance and failure modes of self-piercing riveted joints between AA6061 and solution-treated TC4 alloy. Mater. Res. Express 2023, 10, 056510. [Google Scholar] [CrossRef]

- Safavi, M.; Balazinski, M.; Mehmanparast, H.; Niknam, S. Experimental characterization of tool wear morphology and cutting force profile in dry and wet turning of titanium metal matrix composites (Ti-MMCs). Metals 2020, 10, 1459. [Google Scholar] [CrossRef]

- Gardiola, B.; Andrieux, J.; Viala, J.; Dezellus, O. Synthesis of Ti matrix composites reinforced with tic particles: Thermodynamic equilibrium and change in microstructure. J. Mater. Sci. 2016, 52, 4129–4141. [Google Scholar] [CrossRef]

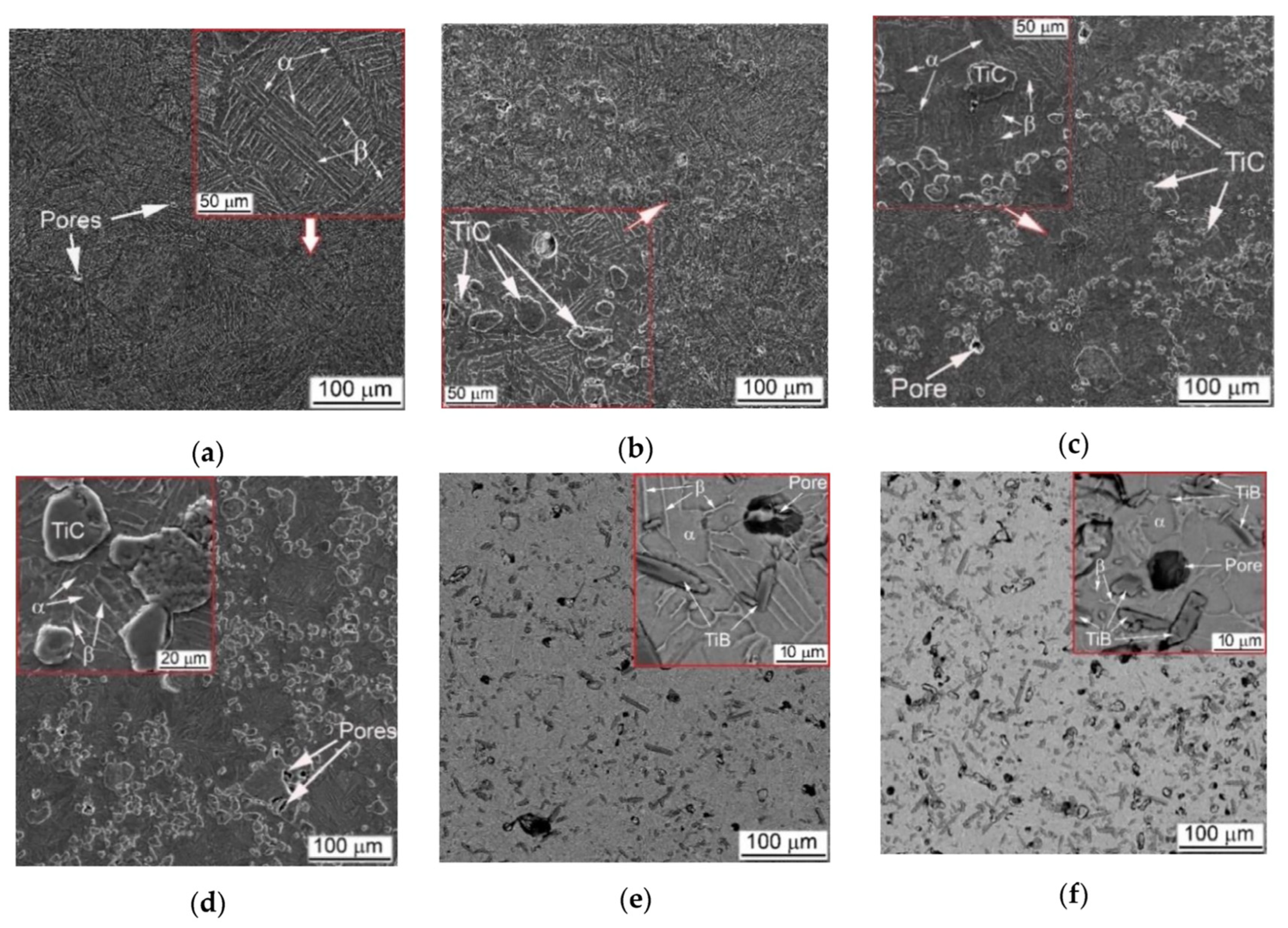

- Markovsky, P.; Janiszewski, J.; Stasyuk, O.; Bondarchuk, V.; Savvakin, D.; Cieplak, K.; Goran, D.; Soni, P.; Prikhodko, S. Mechanical behavior of titanium based metal matrix composites reinforced with TiC or TiB particles under quasi-static and high strain-rate compression. Materials 2021, 14, 6837. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Q.; Ho, M.; Pook, S.; Chandra, M.; Yong, M. Microstructural investigation of particulate reinforced Ti-Sn metal matrix composites. Solid State Phenom. 2006, 111, 35–38. [Google Scholar] [CrossRef]

- Devesa, F.; Rial, S.; Amigó, V. Processing and characterization of β-Ti alloys by means of powder metallurgy processing and blender elemental. Mater. Sci. Forum 2012, 727–728, 61–66. [Google Scholar] [CrossRef]

- Das, D.; Mishra, P.; Singh, S.; Pattanaik, S. Fabrication and heat treatment of ceramic-reinforced aluminium matrix composites—A review. Int. J. Mech. Mater. Eng. 2014, 9, 6. [Google Scholar] [CrossRef]

- Moser, N.; Staufer, E.; Klein, T.; Horky, J.; Schmitz-Niederau, M.; Neubauer, E.; Trunova, L.; Edtmaier, C. Preparation and characterization of Ti-6-4 and Ti-8-1-1 metal matrix composites with high specific stiffness using powder hot extrusion and arc remelting. Adv. Eng. Mater. 2024, 26, 2400514. [Google Scholar] [CrossRef]

- Rabiei, A.; O’Neill, A. A study on processing of a composite metal foam via casting. Mater. Sci. Eng. A 2005, 404, 159–164. [Google Scholar] [CrossRef]

- Sharma, S.; Rajpoot, Y. Development of aluminum metal foam using blowing agent. IOP Conf. Ser. Mat. Scien. Engin. 2018, 377, 012150. [Google Scholar] [CrossRef]

- Gandhapu, S.; Mahajan, A.; Sasikumar, S. Cell structure improvement in melt processed pure aluminium foams by pre-treatment of foaming mixture. IOP Conf. Ser. Mat. Scien. Engin 2022, 1248, 012038. [Google Scholar] [CrossRef]

- Husain, F.; Siddiquee, A.; Khan, Z. Fabrication routes of aluminium metal foams: A review. In Proceedings of the 2022 2nd Indian International Conference on Industrial Engineering and Operations Management, Warangal, India, 16–18 August 2022. [Google Scholar] [CrossRef]

- Rabiei, A.; Karimpour, K.; Janssens, M.; Basu, D. Simulated pool fire testing and modeling of a composite metal foam. Fire Mater. 2020, 45, 379–386. [Google Scholar] [CrossRef]

- Rabiei, A.; Cance, J.; Chacko, Z. A study on welding of porous metals and metallic foams. Adv. Eng. Mater. 2023, 26, 2301430. [Google Scholar] [CrossRef]

- Szovák, B.; Kemény, A.; Orbulov, I. Unidirectional steel wire reinforced metal matrix syntactic foams. IOP Conf. Ser. Mater. Sci. Eng. 2024, 1319, 012007. [Google Scholar] [CrossRef]

- Zheng, J.; Wang, T.; Chen, T.; Yu, Y. Effect of pore distribution on melting behavior of paraffin in fractal metal foam. Commun. Theor. Phys. 2018, 70, 501. [Google Scholar] [CrossRef]

- Feng, B.; Li, D.; Rong, Y.; Gao, J.; Zhou, J.; Luo, G. Experimental transient performance of heat sink with phase change material and movable metal foams insert. J. Phys. Conf. Ser. 2023, 2598, 012011. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, W.; Chu, X.; Liu, S.; Hui, K. Feasibility investigation of direct laser cutting process of metal foam with high pore density. Int. J. Adv. Manuf. Technol. 2018, 96, 2803–2814. [Google Scholar] [CrossRef]

- Cui, C.; Sun, J. Optimizing the design of bio-inspired functionally graded material (FGM) layer in all-ceramic dental restorations. Dent. Mater. J. 2014, 33, 173–178. [Google Scholar] [CrossRef]

- Singh, R.; Singh, R. Property investigation of functionally graded materials leaf spring plate fabricated through stir casting process by using new gradient evaluation method. Materialwiss. Werkstofftech. 2024, 55, 1297–1309. [Google Scholar] [CrossRef]

- Chmielewski, M.; Pietrzak, K. Metal-ceramic functionally graded materials—Manufacturing, characterization, application. Bull. Pol. Acad. Sci. Tech. Sci. 2016, 64, 151–160. [Google Scholar] [CrossRef]

- Shareef, M.; Al-Khazraji, A.; Amin, S. Bending properties of a functionally graded polymeric composite reinforced with a hybrid nanomaterial. Iraqi J. Mech. Mater. Eng. 2021, 21, 302–319. [Google Scholar] [CrossRef]

- Jabbar, N.; Hussain, I.; Abdullah, O.; Mohammed, M. An experimental investigation and numerical analysis of the thermal behavior of a clutch system using the frictional facing of functionally graded materials. Designs 2023, 7, 125. [Google Scholar] [CrossRef]

- Arsha, A.; Jayakumar, E.; Rajan, T.; Pai, B. Processing and characterization of functionally graded In Situ aluminum composite. Mater. Sci. Forum 2015, 830–831, 485–488. [Google Scholar] [CrossRef]

- Genc, S.; Taskin, N. New processing route for the production of functionally graded 7075 Al/SiCp composites via a combination of semisolid stirring and sequential squeeze casting. Crystals 2024, 14, 297. [Google Scholar] [CrossRef]

- Wu, D.; Liang, X.; Li, Q.; Jiang, L. Laser rapid manufacturing of stainless steel 316L/Inconel718 functionally graded materials: Microstructure evolution and mechanical properties. Int. J. Opt. 2010, 2010, 1–5. [Google Scholar] [CrossRef]

- Mohandas, A.; Radhika, N. Studies on mechanical behaviour of aluminium/nickel coated silicon carbide reinforced functionally graded composite. Tribol. Ind. 2017, 39, 145–151. [Google Scholar] [CrossRef]

- Surya, M.; Prasanthi, G. Tribological behaviour of aluminum silicon carbide functionally graded material. Tribol. Ind. 2018, 40, 247–253. [Google Scholar] [CrossRef]

- Niu, X.; Rahbar, N.; Farias, S.; Soboyejo, W. Bio-inspired design of dental multilayers: Experiments and model. J. Mech. Behav. Biomed. Mater. 2009, 2, 596–602. [Google Scholar] [CrossRef]

- Mohn, W.; Vukobratovich, D. Engineered metal matrix composites for precision optical systems., Proceedings Volume 0817, Optomechanical Systems Engineering. In Proceedings of the 31st Annual Technical Symposium on Optical and Optoelectronic Applied Sciences and Engineering, San Diego, CA, USA, 17–21 August 1987; Volume 817, p. 181. [Google Scholar] [CrossRef]

- Bhoi, N.; Singh, H.; Pratap, S. Developments in the aluminum metal matrix composites reinforced by micro/nano particles—A review. J. Compos. Mater. 2019, 54, 813–833. [Google Scholar] [CrossRef]

- Sambathkumar, M.; Gukendran, R.; Mohanraj, T.; Karupannasamy, D.; Natarajan, N.; Christopher, D. A systematic review on the mechanical, tribological, and corrosion properties of Al 7075 metal matrix composites fabricated through stir casting process. Adv. Mater. Sci. Eng. 2023, 2023, 1–17. [Google Scholar] [CrossRef]

- Liu, Y.; Kumar, S. Polymer/carbon nanotube nano composite fibers–a review. Acs Appl. Mater. Interfaces 2014, 6, 6069–6087. [Google Scholar] [CrossRef]

- Merino, C.; Meza, J.; Ledezma-Sillas, J.; Ramírez, J. Characterization of metal matrix composites reinforced with carbon nanotubes by high resolution transmission electron microscopy. Microsc. Microanal. 2017, 23, 1926–1927. [Google Scholar] [CrossRef]

- Anthymidis, K.; David, C.; Trakali, A.; Agrianidis, P. Characterization of al metal matrix composites produced by the stir-casting method. Key Eng. Mater. 2013, 577–578, 85–88. [Google Scholar] [CrossRef]

- Sougavabar, M.; Niknam, S.; Davoodi, B.; Songmené, V. Milling Al520-MMC reinforced with SiC particles and additive elements Bi and Sn. Materials 2022, 15, 1533. [Google Scholar] [CrossRef] [PubMed]

- Sarmah, P.; Gupta, K. Recent Advancements in Fabrication of Metal Matrix Composites: A Systematic Review. Materials 2024, 17, 4635. [Google Scholar] [CrossRef] [PubMed]

- Aynalem, G. Processing methods and mechanical properties of aluminium matrix composites. Adv. Mater. Sci. Eng. 2020, 2020, 3765791. [Google Scholar] [CrossRef]

- Ali, S.; Bhaskar, K.; Raju, K. A review on distribution of reinforcement and tensile strength of aluminum lithium alloy based nano metal matrix composites fabricated by stir casting. J. Phys. Conf. Ser. 2024, 2765, 012023. [Google Scholar] [CrossRef]

- Gaohong, C.; Yu, M.; Dong, H.; Liu, J. Experimental investigation into the preparation process of graphene-reinforced aluminum matrix composites by friction stirring processing. Materials 2024, 17, 3918. [Google Scholar] [CrossRef]

- Andilab, B.; Emadi, P.; Ravindran, C. Casting and characterization of A319 aluminum alloy reinforced with graphene using hybrid semi-solid stirring and ultrasonic processing. Materials 2022, 15, 7232. [Google Scholar] [CrossRef]

- Ali, S.; Murtaza, Q.; Gupta, P. Evaluation of phase, microstructural and mechanical characteristics in stir casted AA6351-Gr-TiC hybrid metal matrix composites. Proc. Inst. Mech. Eng. Pt. C J. Mechan. Eng. Sci. 2023, 238, 5097–5112. [Google Scholar] [CrossRef]

- Abood, A.; Jayanthi, M.; Anjaneyulu, M.; Thethi, H.; Singh, S.; Chahuan, N. Advancing aluminum-based composite manufacturing: Leveraging WC reinforcement through stir casting technique. E3s Web Conf. 2024, 507, 01040. [Google Scholar] [CrossRef]

- Maji, P.; Ghosh, S.; Nath, R.; Karmakar, R. Microstructural, mechanical and wear characteristics of aluminum matrix composites fabricated by friction stir processing. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 191. [Google Scholar] [CrossRef]

- Mohammad, Q.; Borah, A.R.; Ram, K.R.P.; Nagpal, A.; Chauhan, S.; Meheta, A. Advancements in aluminum-based composite manufacturing: Leveraging ZrO2 reinforcement through friction stir process. E3s Web Conf. 2024, 507, 01020. [Google Scholar] [CrossRef]

- Vij, V.; Agarwal, R.; Garg, M.; Khanna, R.; Gupta, V. Fabrication and mechanical characterization of hybrid composite reinforced with nanoparticles of alumina and zirconia. Polym. Compos. 2022, 43, 7315–7325. [Google Scholar] [CrossRef]

- Ding, W.; Cheng, Y.; Chen, T.; Zhao, X.; Liu, X. Research status and application prospect of aluminum matrix composites. J. Mater. Sci. Res. 2020, 2. [Google Scholar] [CrossRef]

- Dudina, D.; Georgarakis, K.; Olevsky, E. Progress in aluminium and magnesium matrix composites obtained by spark plasma, microwave and induction sintering. Int. Mater. Rev. 2022, 68, 225–246. [Google Scholar] [CrossRef]

- Liang, J.; Wu, C.; Zhao, Z.; Tang, W. Forming process and simulation analysis of helical carbon fiber reinforced aluminum matrix composite. Metals 2021, 11, 2024. [Google Scholar] [CrossRef]

- Ali, A.; Hafez, W. Overcoming challenges in the powder metallurgy process of metal matrix composites. SVU-Int. J. Appl. Eng. Sci. 2023, 5, 13–18. [Google Scholar] [CrossRef]

- Fatchurrohman, N.; Mamat, A.; Yetrina, M.; Muhida, R. Investigation of metal matrix composites aluminium reinforced graphite particles produced using powder metallurgy. J. Teknol. 2022, 12, 76–81. [Google Scholar] [CrossRef]

- Azadi, M.; Zomorodipour, M.; Fereidoon, A. Sensitivity analysis of mechanical properties and ductile/brittle behaviors in aluminum-silicon alloy to loading rate and nano-particles, considering interaction effects. Eng. Rep. 2020, 3, e12341. [Google Scholar] [CrossRef]

- Arma, M.L.; Syahid, M. The Effect of Hot Pressing on the Mechanical Properties of Metal Composites (Al/SiC) Result from Metallurgical Processes with Heating Temperature Variations in Bushing Making. EPI Int. J. Eng. 2023, 6, 24–27. [Google Scholar] [CrossRef]

- Sames, W.; List, F.; Pannala, S.; Dehoff, R.; Babu, S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Gu, D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Bernard, G.; Pejchal, V.; Sereda, O.; Logé, R.E. Tensile Properties of Ex-Situ Ti-TiC Metal Matrix Composites Manufactured by Laser Powder Bed Fusion. Materials 2024, 17, 5613. [Google Scholar] [CrossRef]

- Dhandapani, S.; Rajmohan, T.; Palanikumar, K.; Mugunthan, C. Preparation and characterization of hybrid aluminum matrix composites reinforced with MWCNT using powder metallurgy process. Appl. Mech. Mater. 2015, 813–814, 620–624. [Google Scholar] [CrossRef]

- Mahboob, H.; Sajjadi, S.; Zebarjad, S. Influence of nanosized Al2O3 weight percentage on microstructure and mechanical properties of Al–matrix nanocomposite. Powder Metall. 2011, 54, 148–152. [Google Scholar] [CrossRef]

- Özel, S.; Aslan, K. Investigation of the effect of Cr2O3 particles on Al-Si matrix composites produced by powder metallurgy. Bitlisfen 2023, 12, 387–395. [Google Scholar] [CrossRef]

- Ravichandran, M.; Manikandan, A.; Omkumar, M. Investigations on properties of Al-B4C composites synthesized through powder metallurgy route. Appl. Mech. Mater. 2016, 852, 93–97. [Google Scholar] [CrossRef]

- Plötz, S.; Lohmüller, A.; Singer, R. Influence of Ti and Zn on particle incorporation of Al particles in aluminum using the stir casting process. Key Eng. Mater. 2017, 742, 173–180. [Google Scholar] [CrossRef]

- Juang, S.H.; Li, C.-F. Influence of Different Addition Ratios of Fly Ash on Mechanical Properties of ADC10 Aluminum Matrix Composites. Metals 2022, 12, 653. [Google Scholar] [CrossRef]

- Kumar, B.; Shobha, K.; Singh, M.; Rinawa, M.; Madhavarao, S.; Wadhawa, G.; Alrebdi, T.A.; Christopher, D. Optimization and wear properties for the composites of metal matrix AA8011/boron nitride using taguchi method. J. Nanomater. 2022, 2022, 6957545. [Google Scholar] [CrossRef]

- Kumar, S.; Chaganty, S.; Rajesh, V.; Reddy, K.; Babu, N.; Shnain, A. Review on development, nanoparticle reinforcement and sustainable materials for enhancement of mechanical properties in aluminium hybrid metal matrix composites. E3s Web Conf. 2024, 552, 01068. [Google Scholar] [CrossRef]

- Rajesh, T.; Narayana, B.; Kumar, M.; Natarajan, T. Development and characterization of C355.0 alloy composite for automotive applications—A review. J. Mines Met. Fuels. 2023, 71, 260–273. [Google Scholar] [CrossRef]

- Rathod, N.; Menghani, J. A consequence of reinforcements in aluminum-based metal matrix composites: A literature review. Metall. Mater. Eng. 2019, 25, 195–208. [Google Scholar] [CrossRef]

- Rey, P.; Gonzàlez-Doncel, G. Advances in lightweight metal matrix composites. Metals 2025, 15, 160. [Google Scholar] [CrossRef]

- Arévalo, C.; Montealegre-Meléndez, I.; Ariza, E.; Kitzmantel, M.; Rubio-Escudero, C.; Neubauer, E. Influence of sintering temperature on the microstructure and mechanical properties of in situ reinforced titanium composites by inductive hot pressing. Materials 2016, 9, 919. [Google Scholar] [CrossRef]

- Shahid, R.; Scudino, S. Microstructure and mechanical behavior of Al-Mg composites synthesized by reactive sintering. Metals 2018, 8, 762. [Google Scholar] [CrossRef]

- Reeb, A.; Schulze, V.; Weidenmann, K. Interface characterization of hybrid composite extrusions. Mater. Sci. Forum 2015, 825–826, 134–141. [Google Scholar] [CrossRef]

- Patel, M.; Sahu, S.; Singh, M. Fabrication and investigation of mechanical properties of sic particulate reinforced AA5052 metal matrix composite. J. Mod. Mater. 2020, 7, 26–36. [Google Scholar] [CrossRef]

- Farid, W.; Li, H.; Wang, Z.; Cui, H.; Kong, C.; Yu, H. Integrating experimental and computational analyses for mechanical characterization of titanium carbide/aluminum metal matrix composites. Materials 2024, 17, 2093. [Google Scholar] [CrossRef] [PubMed]

- Cao, F.; Zhang, X.; Dong, G.; Jiang, Y.; Gao, F.; Cai, P.; Cai, P.; Wang, T.; Liang, S. Microstructures and properties of in situ (TiB2p+TiBw)/Cu composites with different Ce content. Adv. Eng. Mater. 2022, 24, 2200251. [Google Scholar] [CrossRef]

- Zhu, D.; Dong, D.; Liu, L.; Wang, X.; Qi, J. Control of the lamellar structure and analysis of tensile properties of TiC/Ti-6Al-3Sn-9Zr-1.5Mo composite produced by in situ casting technique. Metals 2021, 11, 160. [Google Scholar] [CrossRef]

- Kordijazi, A.; Zhao, T.; Zhang, J.; Alrfou, K.; Rohatgi, P. A review of application of machine learning in design, synthesis, and characterization of metal matrix composites: Current status and emerging applications. JOM 2021, 73, 2060–2074. [Google Scholar] [CrossRef]

- Gupta, P.; Gupta, M. Mechanical and microstructural analysis of Al-Al2O3/B4C hybrid composites. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 1503–1514. [Google Scholar] [CrossRef]

- Murmu, S.; Chattopadhayaya, S.; Čep, R.; Kumar, A.; Kumar, A.; Mahato, S.; Kumar, A.; Logesh, K. Exploring tribological properties in the design and manufacturing of metal matrix composites: An investigation into the Al6061-SiC-fly ash alloy fabricated via stir casting process. Front. Mater. 2024, 11, 1415907. [Google Scholar] [CrossRef]

- Alizadeh, A.; Taheri-Nassaj, E.; Baharvandi, H. Preparation and investigation of Al–4 wt % B4C nanocomposite powders using mechanical milling. Bull. Mater. Sci. 2011, 34, 1039–1048. [Google Scholar] [CrossRef]

- Balasubramani, V.; Pandiarajan, R.; Stalin, B.; Kavimani, V. Mechanical and metallurgical characterization of B4C and SiC reinforced stir casted AA6061 hybrid mmc. Phys. Scr. 2023, 98, 105922. [Google Scholar] [CrossRef]

- Xu, Z.; Shi, X.; Zhai, W.; Yao, J.; Song, S.; Zhang, Q. Preparation and tribological properties of TiAl matrix composites reinforced by multilayer graphene. Carbon 2014, 67, 168–177. [Google Scholar] [CrossRef]

- Sureshkumar, P.; Sasikumar, C.; Rajan, S.; Jagadeesha, T.; Natrayan, L.; Ravichandran, M.; Veeman, D.; Borek, W. Evaluation of mechanical and wear properties of AA6063/(Si3N4)6%–12%/(CuN2O6)2%–4% composite via pm route and optimization through robust design technique. Mater. Res. Express 2022, 9, 076502. [Google Scholar] [CrossRef]

- Shuvho, M.; Chowdhury, M.; Hossain, N.; Roy, B.; Kowser, M.; Islam, A. Tribological study of al-6063-based metal matrix embedded with SiC–Al2O3–TiO2 particles. SN Appl. Sci. 2020, 2, 287. [Google Scholar] [CrossRef]

- Venkatesh, V.; Deoghare, A. Effect of controllable parameters on the tribological behavior of ceramic particulate reinforced aluminium metal matrix composites: A review. J. Phys. Conf. Ser. 2020, 1451, 012025. [Google Scholar] [CrossRef]

- Yan, D.; Dai, K.; Xiang, Z.; Li, Z.; Ji, X.; Zhang, W. Electrical conductivity and major mechanical and thermal properties of carbon nanotube-filled polyurethane foams. J. Appl. Polym. Sci. 2011, 120, 3014–3019. [Google Scholar] [CrossRef]

- Yu, S.; Shin, K. Fabrication of aluminum/aluminum nitride composites by reactive mechanical alloying. Mater. Sci. Forum 2007, 534–536, 181–184. [Google Scholar] [CrossRef]

- Yadav, V.; Harimkar, S. Microstructure and properties of spark plasma sintered carbon nanotube reinforced aluminum matrix composites. Adv. Eng. Mater. 2011, 13, 1128–1134. [Google Scholar] [CrossRef]

- Li, H.; Shuai, L.; Tu, K.; Zeng, M.; Yan, H. Microstructure and mechanical properties of 7075 composites reinforced with tio2-coated carbon nanotubes. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2023, 239, 129–139. [Google Scholar] [CrossRef]

- Shin, S.; Lee, D.; Lee, Y.; Ko, S.; Park, H.; Lee, S.; Kim, Y.; Lee, S.-K.; Jo, I. High temperature mechanical properties and wear performance of B4C/Al7075 metal matrix composites. Metals 2019, 9, 1108. [Google Scholar] [CrossRef]

- Pardo, Á.; Merino, M.; López, M.; Viejo, F.; Carboneras, M.; Merino, S. Influence of reinforcement grade and matrix composition on corrosion resistance of cast aluminium matrix composites (A3xx.x/SiCp) in a humid environment. Mater. Corros. 2003, 54, 311–317. [Google Scholar] [CrossRef]

- Venkatesh, R.; Sakthivel, P.; Vivekanandan, M.; Chidambaram, K.; Krishna, J.; Dhanabalan, S.; Thirugnanasambandham, T.; Majora, M. Synthesis and thermal adsorption characteristics of silver-based hybrid nanocomposites for automotive friction material application. Adsorp. Sci. Technol. 2023, 2023, 1003492. [Google Scholar] [CrossRef]

- Li, B.; Zhou, L.; Wang, B.; Yin, M.; Qian, Y.; Shi, X.; Guo, Z.; Han, Z.; Sun, L. Nanoscale dispersion of carbon nanotubes in a metal matrix to boost thermal and electrical conductivity via facile ball milling techniques. Nanomaterials 2023, 13, 2815. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Xing, W.; Shen, C.; Song, C.; Dickey, M.; Deng, T. Liquid metal composites with enhanced thermal conductivity and stability using molecular thermal linker. Adv. Mater. 2021, 33, 2103104. [Google Scholar] [CrossRef] [PubMed]

- Chawla, N.; Chawla, K. Metal-matrix composites in ground transportation. JOM 2006, 58, 67–70. [Google Scholar] [CrossRef]

- Mahesha, C.; Suprabha, R.; Harne, M.; Galme, S.; Thorat, S.; Nagabhooshanam, N.; Seikh, A.H.; Siddique, M.H.; Markos, M. Nanotitanium oxide particles and jute-hemp fiber hybrid composites: Evaluate the mechanical, water absorptions, and morphological behaviors. J. Nanomater. 2022, 2022, 3057293. [Google Scholar] [CrossRef]

| Matrix/Reinforcement | Tensile Strength (MPa) | Hardness (HV) | Density (g/cm3) | Thermal Conductivity (W/m·K) | |

|---|---|---|---|---|---|

| AA6061 | 310 ± 15 | 105 ± 5 | 2.70 | 167 | [17] |

| AA6061 + 10% SiC | 420 ± 20 | 140 ± 8 | 2.75 | 160 | [22] |

| AA7075 + 5% CNTs | 550 ± 25 | 180 ± 10 | 2.72 | 175 | [25] |

| AA2024 + Hybrid (SiC + CNTs) | 480 ± 18 | 155 ± 7 | 2.73 | 168 | [30] |

| Absorbance | Average | Viability | |

|---|---|---|---|

| Control Group | 2.8065 | 2.817 | 100% |

| 2.9065 | |||

| 2.7375 | |||

| Mg-5% HA | 2.781 | 2.781 | 99% |

| Matrix/Reinforcement | Tensile Strength (MPa) | Hardness (HV) | Density (g/cm3) | Thermal Conductivity (W/m·K) | |

|---|---|---|---|---|---|

| AZ91 | 250 ± 12 | 80 ± 4 | 1.81 | 78 | [33] |

| AZ91 + 10% SiC | 350 ± 18 | 120 ± 6 | 1.85 | 75 | [39] |

| AZ31 + 5% CNTs | 320 ± 15 | 110 ± 5 | 1.83 | 82 | [42] |

| AZ91 + Hybrid (CF + MWCNT) | 380 ± 20 | 135 ± 7 | 1.84 | 80 | [38] |

| Matrix/Reinforcement | Tensile Strength (MPa) | Hardness (HV) | Density (g/cm3) | Thermal Conductivity (W/m·K) | |

|---|---|---|---|---|---|

| Ti64 | 950 ± 40 | 350 ± 15 | 4.43 | 7.1 | [44] |

| Ti64 + 10% TiC | 1200 ± 50 | 450 ± 20 | 4.50 | 6.8 | [49] |

| Ti64 + 5% TiB | 1100 ± 45 | 420 ± 18 | 4.48 | 7.0 | [48] |

| Ti64 + Hybrid (TiC + TiB) | 1300 ± 55 | 480 ± 22 | 4.52 | 6.9 | [47] |

| Matrix/Reinforcement | Compressive Strength (MPa) | Energy Absorption (MJ/m3) | Density (g/cm3) | Thermal Conductivity (W/m·K) | |

|---|---|---|---|---|---|

| Al Foam | 50 ± 5 | 10 ± 2 | 0.5 | 50 | [56] |

| Al + Hollow Spheres | 80 ± 8 | 18 ± 3 | 0.6 | 45 | [59] |

| Al + Steel Wires | 100 ± 10 | 22 ± 4 | 0.7 | 48 | [61] |

| Al syntactic foams | 70 ± 7 | 15 ± 2 | 0.55 | 55 | [62] |

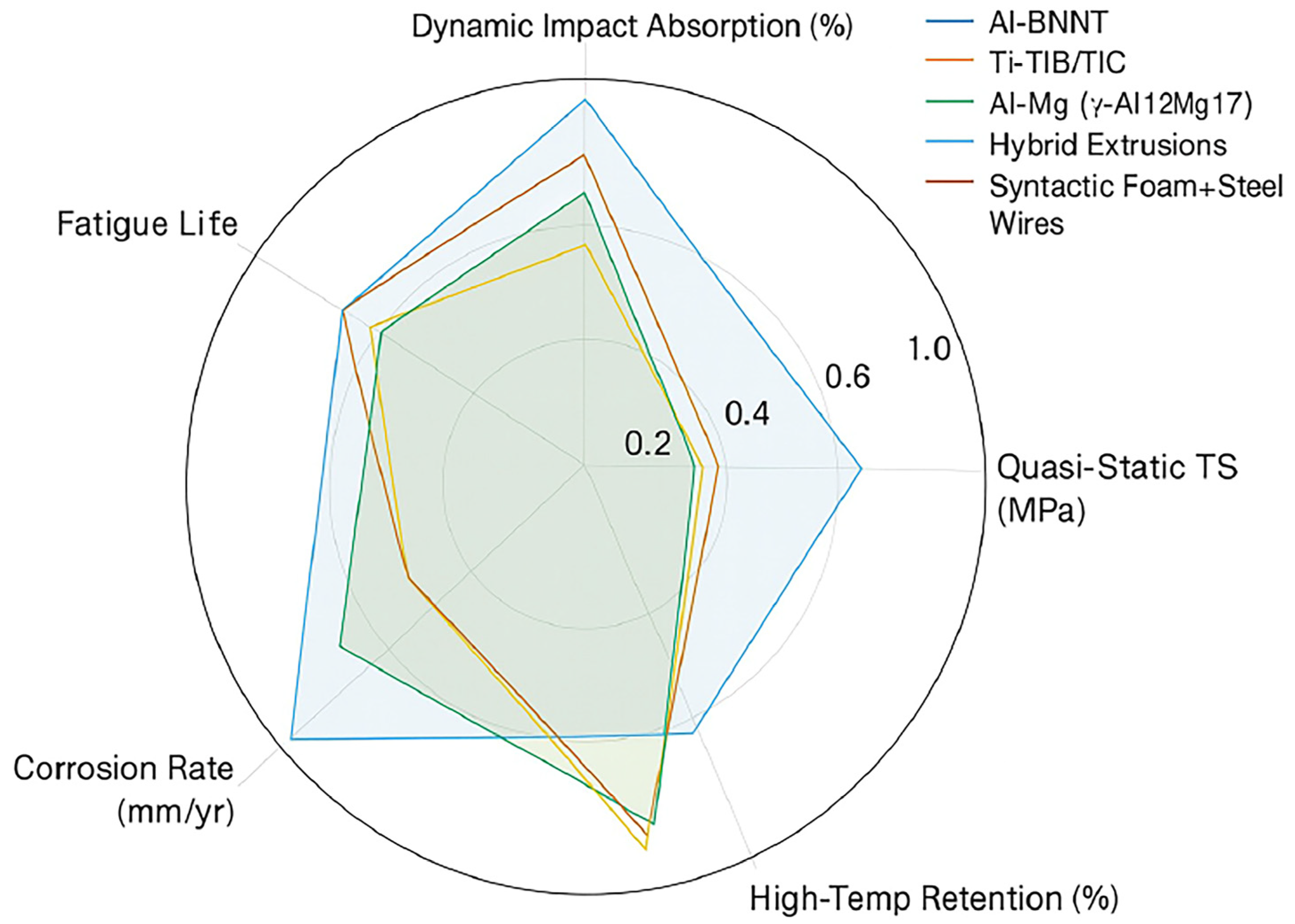

| MMC Type/ Reinforcement | Quasi-Static TS (MPa) | Dynamic Impact Absorption (%) | Fatigue Life (Cycles at 107) | Corrosion Rate (mm/Year) | High-Temp Retention (%) at 300 °C | |

|---|---|---|---|---|---|---|

| Al-BNNT | 455–505 | 35 ± 5 | 1.8 | 0.02 ± 0.005 | 85 ± 5 | [6] |

| Ti-TiB/TiC | 1100–1200 | 50 ± 8 | 2.5 | 0.01 ± 0.003 | 90 ± 3 | [114] |

| Al-Mg (γ-Al12Mg17) | 380–420 | 40 ± 6 | 1.5 | 0.03 ± 0.006 | 80 ± 4 | [115] |

| Hybrid Extrusions | 430–470 | 45 ± 7 | 2.0 | 0.025 ± 0.005 | 88 ± 5 | [116] |

| Syntactic Foam + Steel Wires | 332–368 | 55 ± 10 | 1.7 | 0.04 ± 0.008 | 75 ± 6 | [58] |

| Al-SiC | 400–440 | 42 ± 6 | 1.9 | 0.02 ± 0.004 | 82 ± 4 | [117] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simões, S. Advances in the Design and Development of Lightweight Metal Matrix Composites: Processing, Properties, and Applications. Metals 2025, 15, 1281. https://doi.org/10.3390/met15121281

Simões S. Advances in the Design and Development of Lightweight Metal Matrix Composites: Processing, Properties, and Applications. Metals. 2025; 15(12):1281. https://doi.org/10.3390/met15121281

Chicago/Turabian StyleSimões, Sónia. 2025. "Advances in the Design and Development of Lightweight Metal Matrix Composites: Processing, Properties, and Applications" Metals 15, no. 12: 1281. https://doi.org/10.3390/met15121281

APA StyleSimões, S. (2025). Advances in the Design and Development of Lightweight Metal Matrix Composites: Processing, Properties, and Applications. Metals, 15(12), 1281. https://doi.org/10.3390/met15121281