CAFE Simulation of Solidification Microstructure of Cast WE54 Alloy: Influences of Simulation Parameters and Experimental Verification

Abstract

1. Introduction

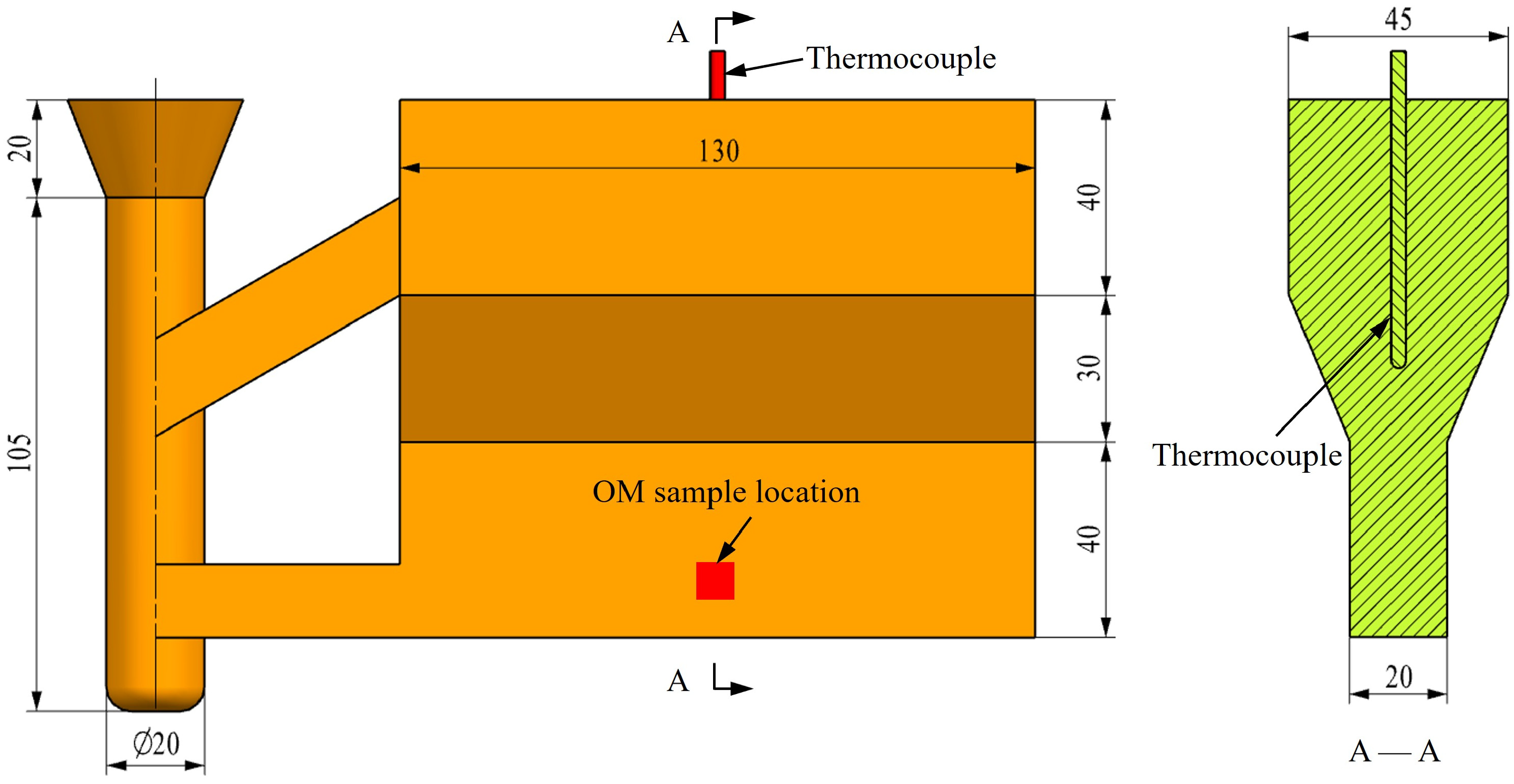

2. Materials and Experiments

3. Numerical Simulation Methods

3.1. Numerical Calculation of Solidification Temperature Field

3.2. Numerical Simulation of Solidification Microstructure

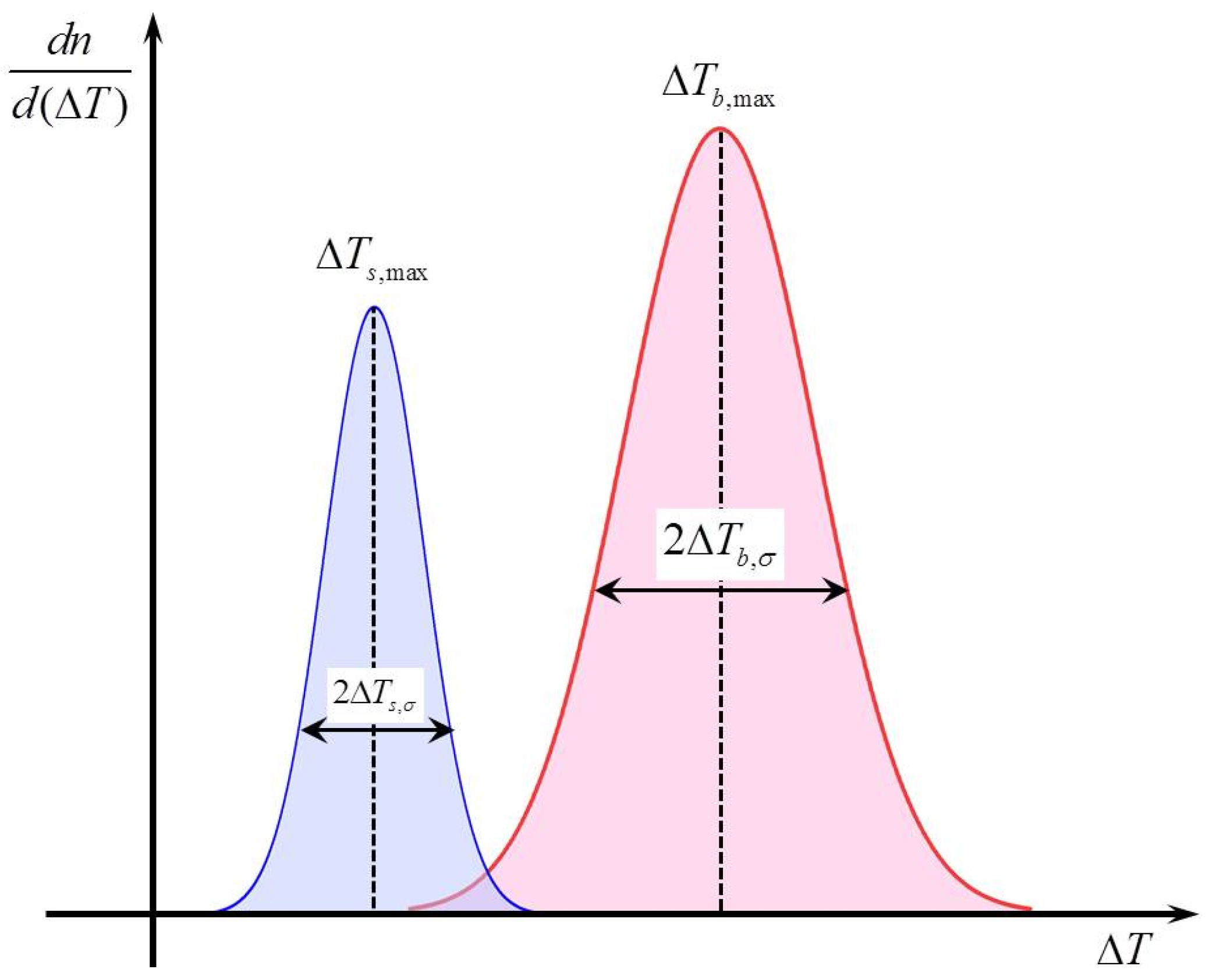

3.2.1. Continuous Nucleation Model

3.2.2. Grain Growth Model

4. Influences of Simulation Parameters

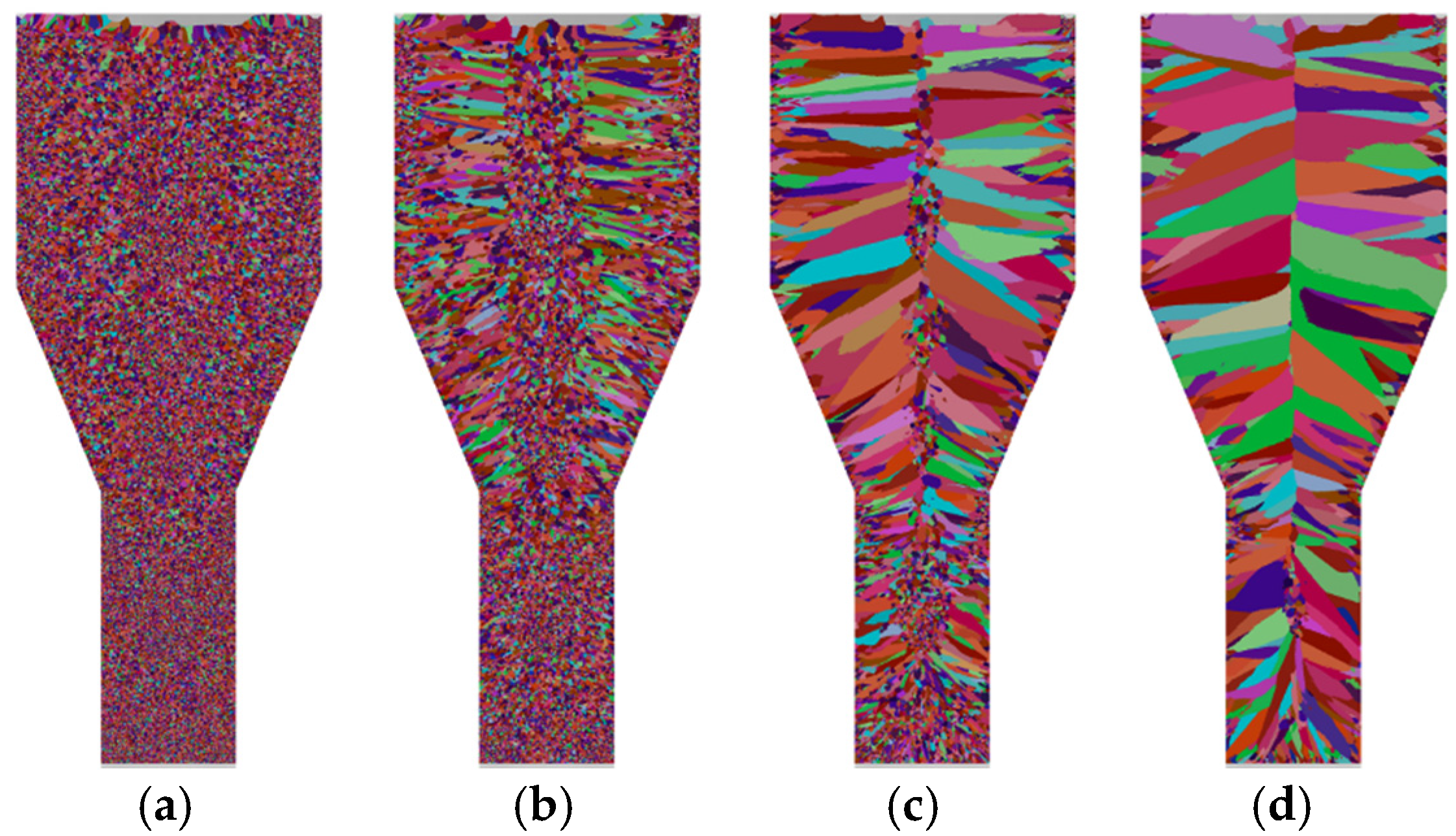

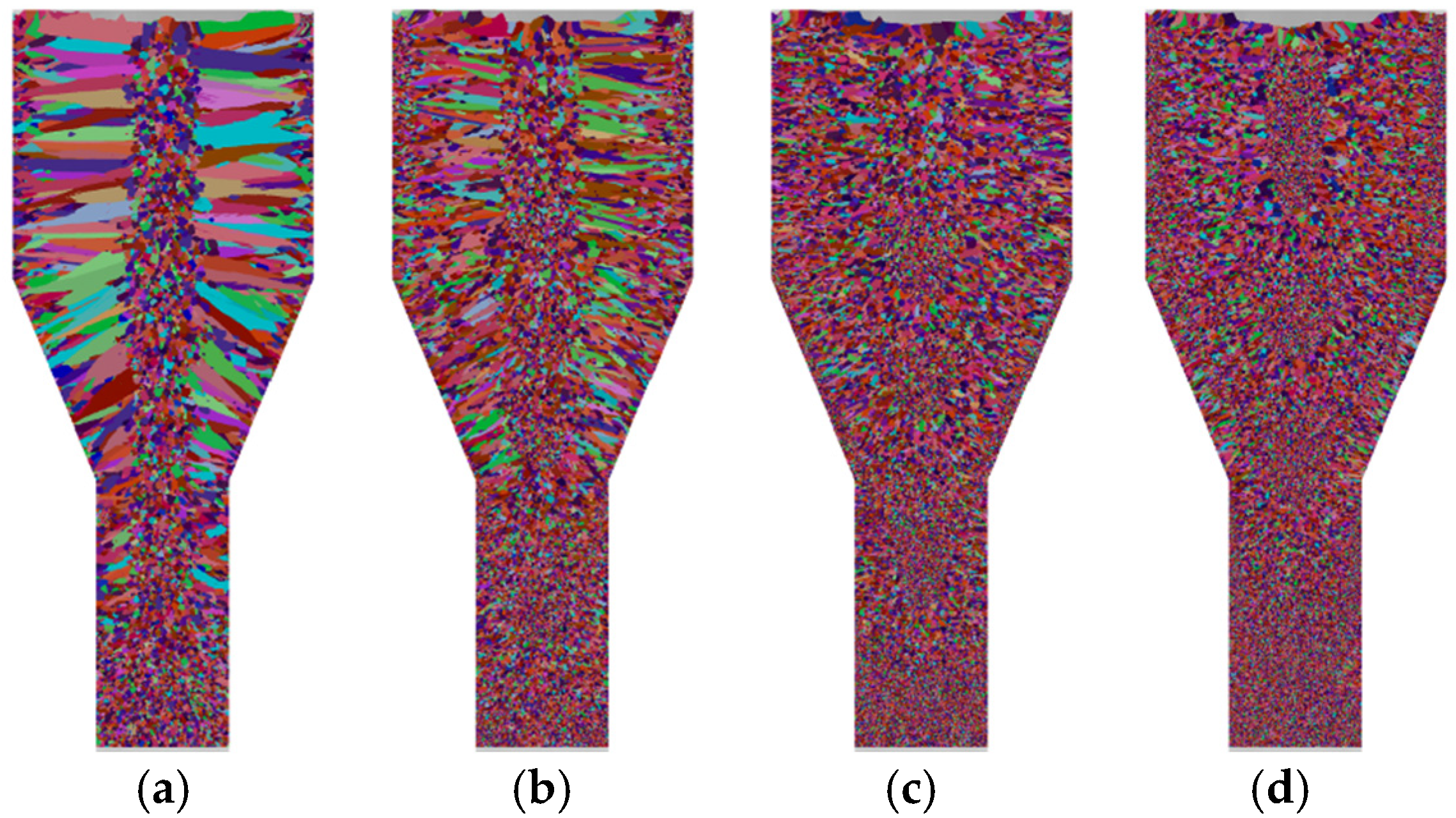

4.1. Influences of Nucleation Parameters

4.2. Influences of Dendrite Tip Growth Kinetic Parameters

4.3. Influences of Solidification Conditions

5. Experimental Verification

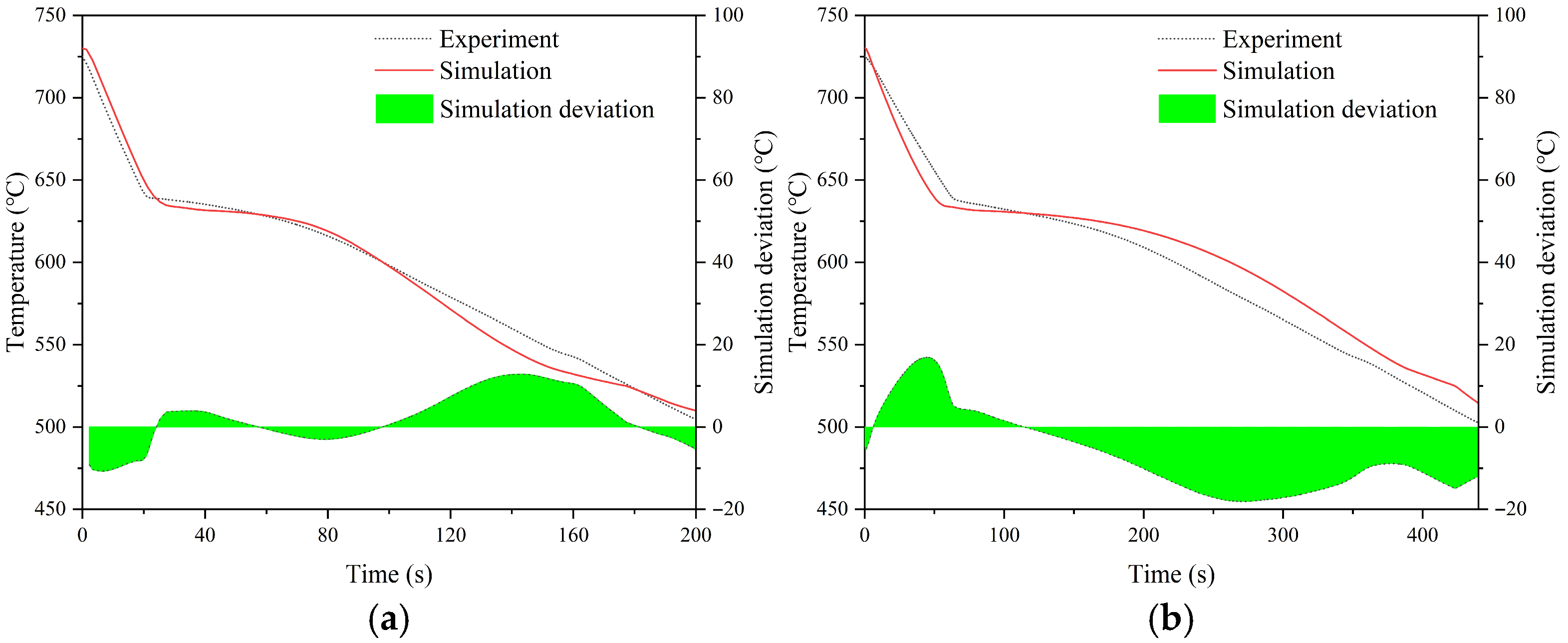

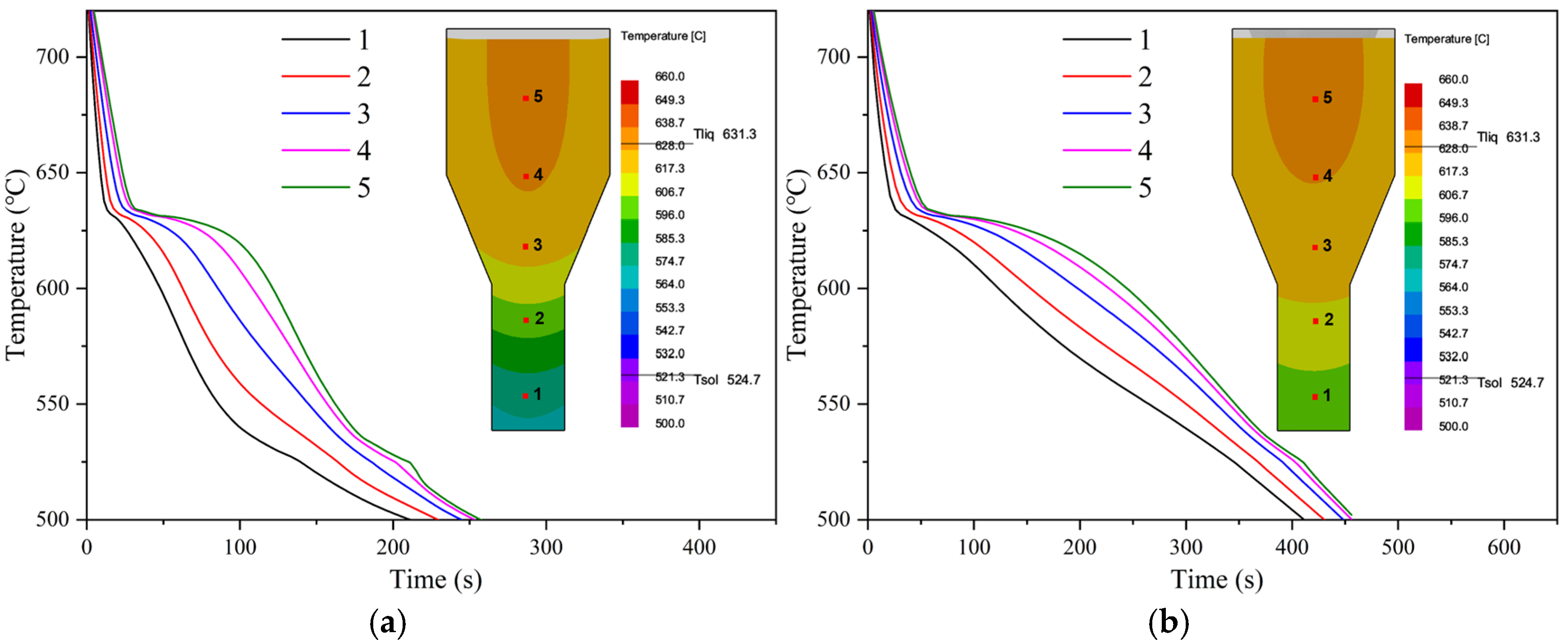

5.1. Calculation of Solidification Temperature Field

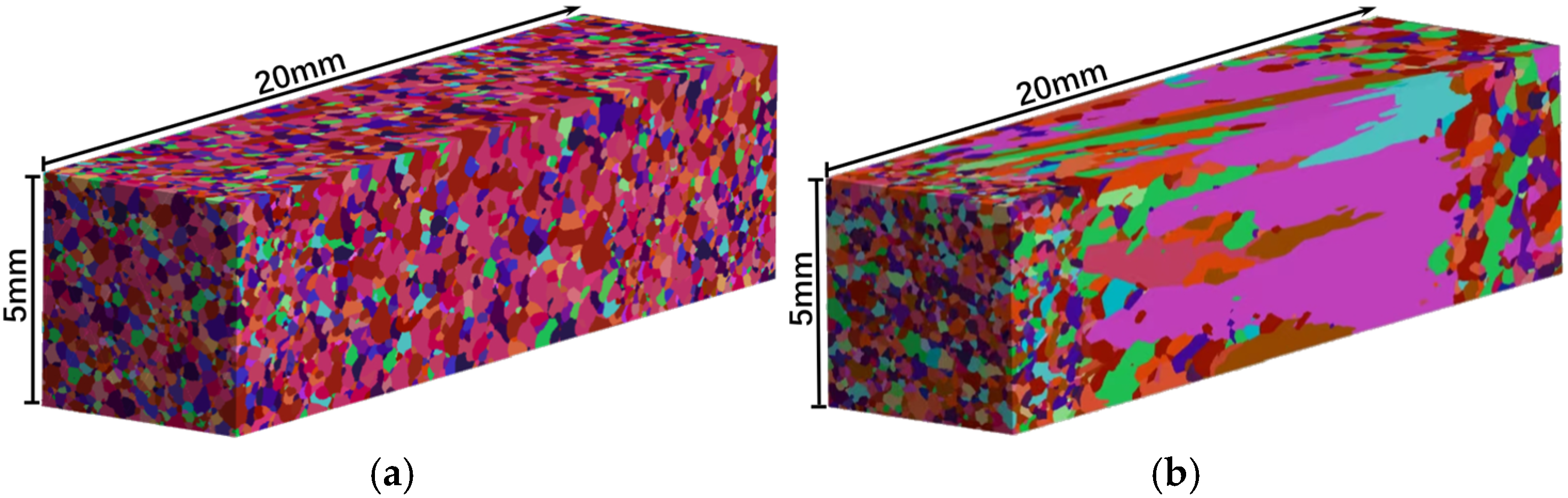

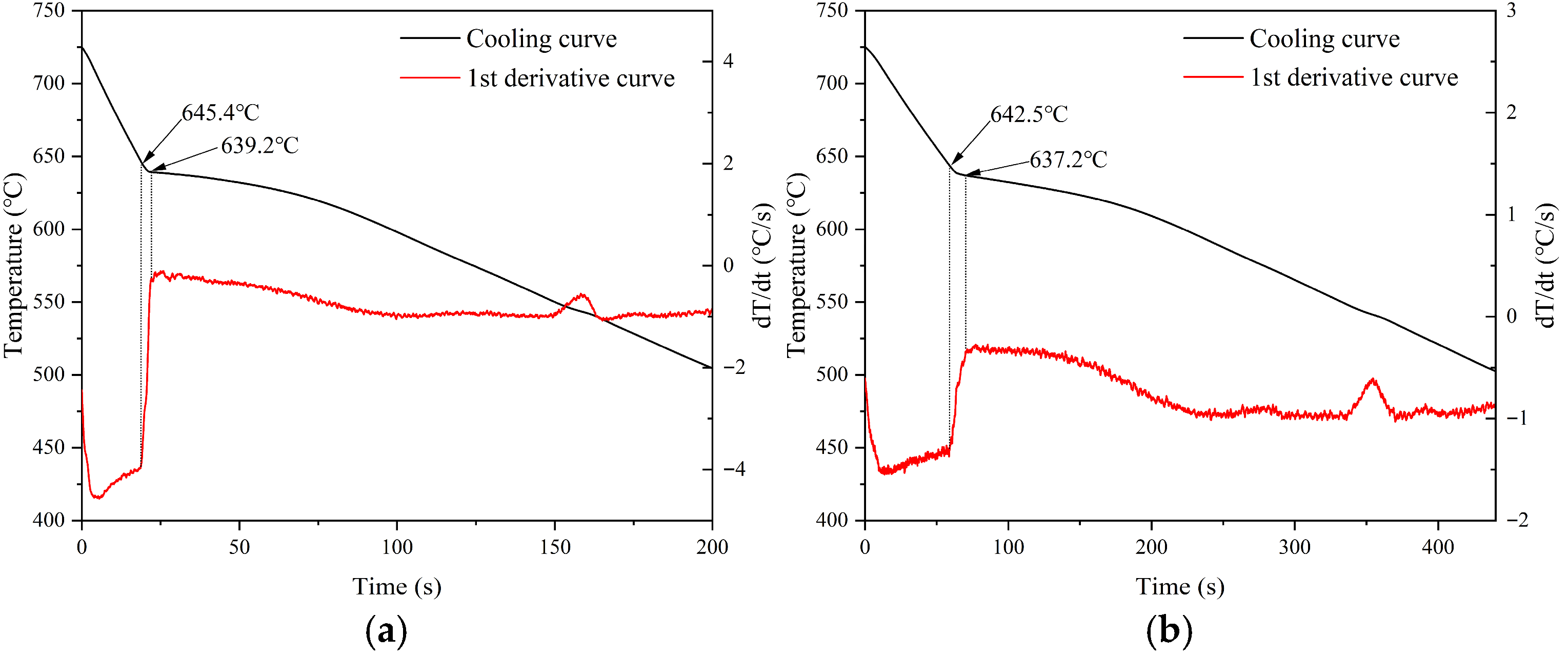

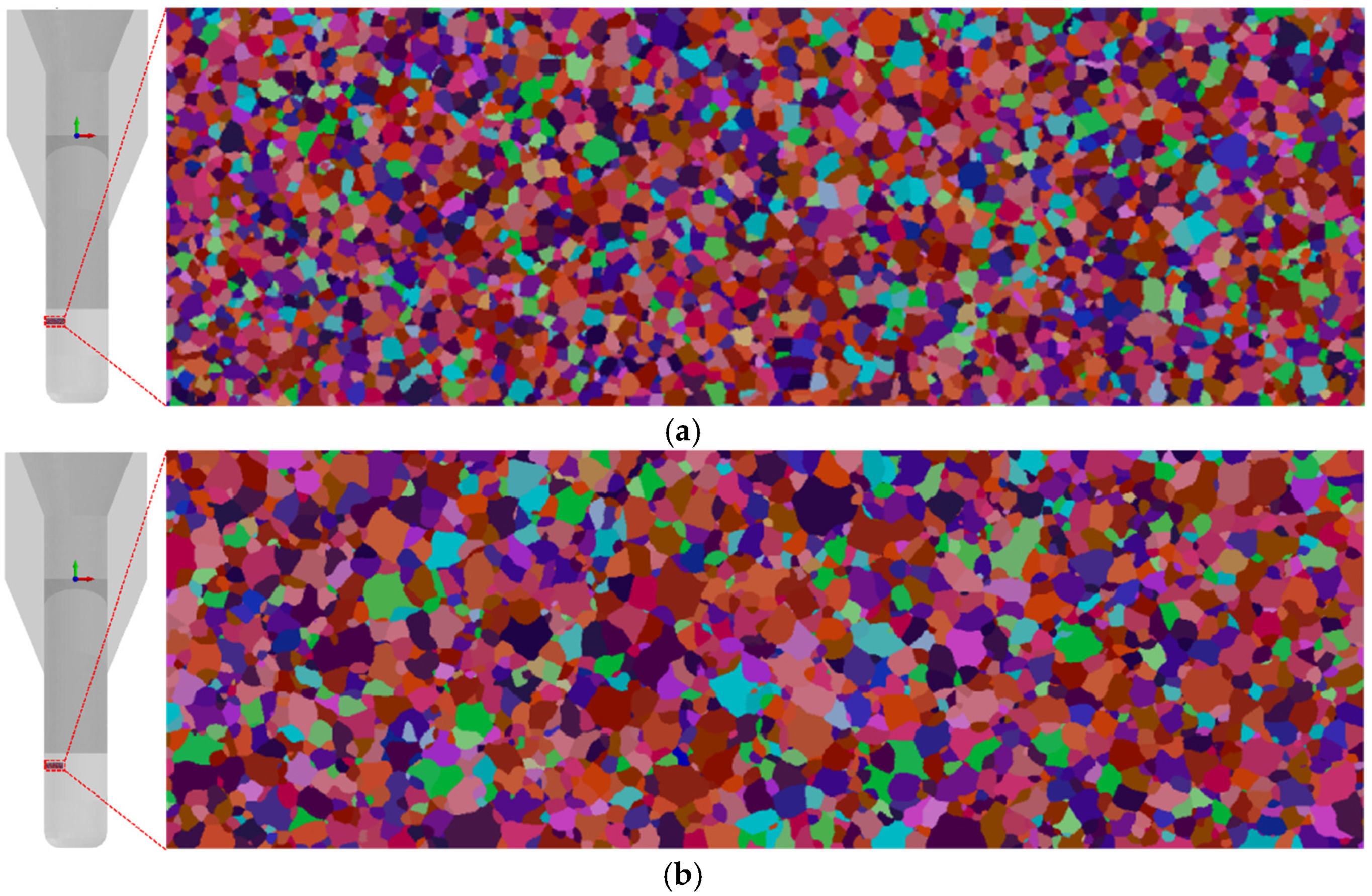

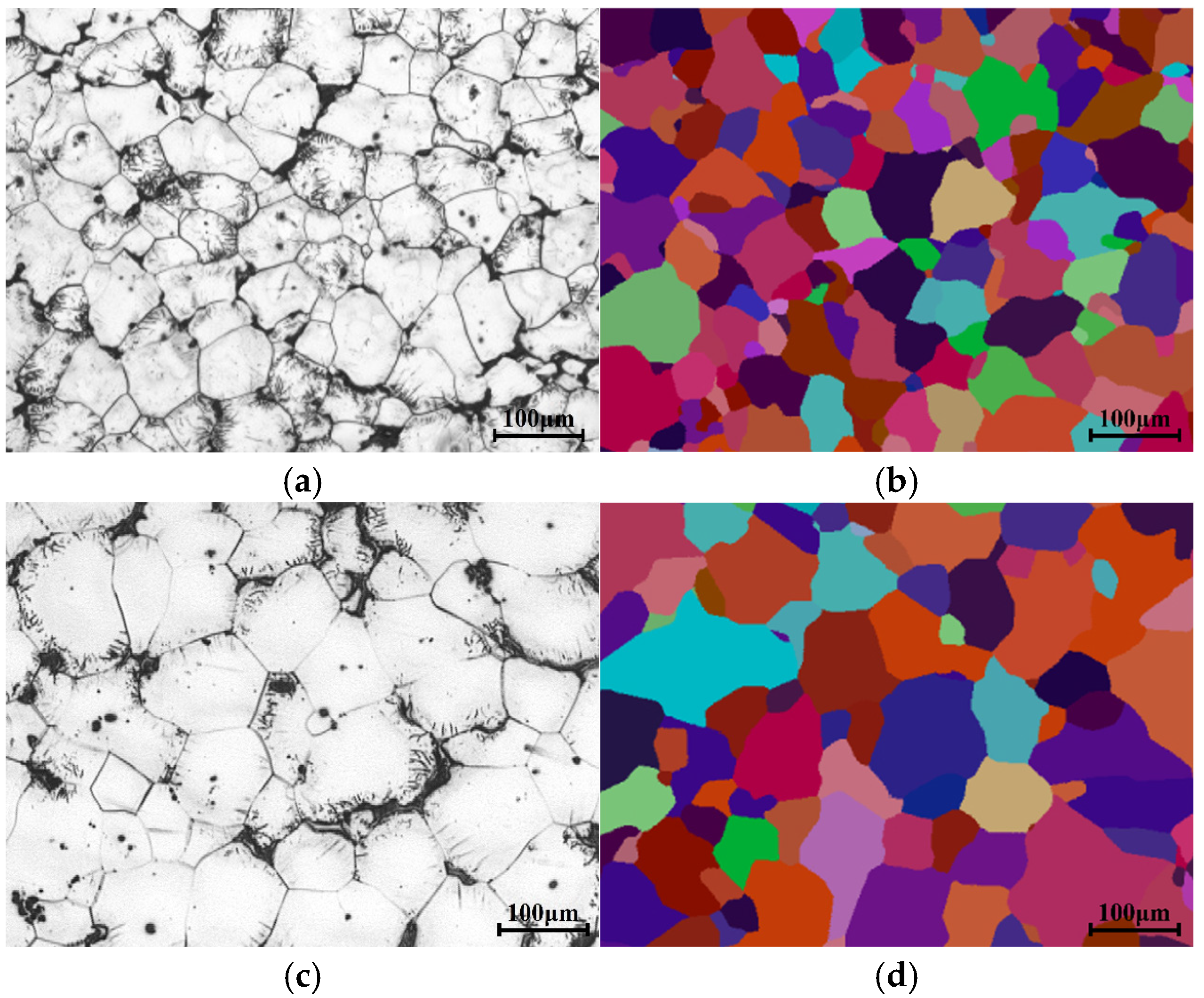

5.2. Solidification Microstructure Simulation

6. Conclusions

- (1)

- The effects of nucleation undercooling and dendrite tip growth kinetic parameters on the CAFE simulation results of the solidification microstructure were investigated. When the surface nucleation undercooling is kept constant, increasing the volume nucleation undercooling significantly increases the proportion of columnar grains in the ingot. Under constant nucleation parameters, increasing the dendrite tip growth rate also expands the columnar grain region.

- (2)

- The influence of cooling rate on simulation results was investigated. As the cooling rate increases, the solidified microstructure becomes markedly refined, indicating that the CAFE model can reasonably capture the effects of cooling conditions and other process parameters on the solidification structure of cast alloys. The CAFE method effectively simulates the solidification microstructure of alloys under different cooling conditions.

- (3)

- Based on experimentally measured cooling curves, inverse heat-transfer analysis was performed to determine the interfacial heat-transfer coefficients for MMC and SMC processes, which were found to be 500 W·m−2·K−1 and 250 W·m−2·K−1, respectively. Using these values, numerical simulations were carried out to obtain the corresponding cooling curves, which showed a high degree of agreement with the experimental results, with a maximum deviation of less than 10 °C. The calculated temperature fields indicate that the average cooling rates of the MMC and SMC WE54 alloys are approximately 1 °C/s and 0.3 °C/s, respectively.

- (4)

- By analyzing the alloy cooling curves and their first-derivative curves, the nucleation undercooling of WE54 alloy was determined. Under MMC and SMC conditions, the maximum nucleation undercooling is approximately 6 °C and 5 °C, respectively. The dendrite tip growth kinetic parameters were determined using software calculations. Based on these parameters, the simulated solidification microstructures of MMC and SMC WE54 alloys consist entirely of equiaxed grains, consistent with experimental observations. The numerically predicted grain sizes for MMC and SMC WE54 alloys are 86 μm and 143 μm, respectively, whereas the experimentally measured grain sizes are 92 μm and 150 μm. These results demonstrate that the numerical simulation can accurately predict the grain size and thereby provide a reliable basis for predicting the alloy’s mechanical properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, L.; Zheng, J.; He, Q.; Li, T.; Shou, H.; Yin, D.; Bai, S.; Jiang, B.; Pan, F. Achieving superior strength and ductility synergy of WE54 alloy via combined dislocation introduction and twinning. J. Mater. Sci. Technol. 2025, 227, 174–191. [Google Scholar] [CrossRef]

- Saravanan, S.; Hattimare, A.R.; Mahadik, A.B.; Singh, A.; Kumar, U.N.; Annamalai, A.R. Effect of Heat Treatment on High-Temperature Tribological Behavior of WE54 Alloy: An Experimental Study. J. Manuf. Mater. Process. 2025, 9, 304. [Google Scholar] [CrossRef]

- Song, J.; She, J.; Chen, D.; Pan, F. Latest research advances on magnesium and magnesium alloys worldwide. J. Magnes. Alloys 2020, 8, 1–41. [Google Scholar] [CrossRef]

- Yang, Y.; Xiong, X.; Chen, J.; Peng, X.; Chen, D.; Pan, F. Research advances of magnesium and magnesium alloys worldwide in 2022. J. Magnes. Alloys 2023, 11, 2611–2654. [Google Scholar] [CrossRef]

- Bai, J.; Yang, Y.; Wen, C.; Chen, J.; Zhou, G.; Jiang, B.; Peng, X.; Pan, F. Applications of magnesium alloys for aerospace: A review. J. Magnes. Alloys 2023, 11, 3609–3619. [Google Scholar] [CrossRef]

- Meng, X.; Cui, L.; Zhu, M. Research progress of cellular automaton simulation on microstructure evolution of steel solidification. J. Cent. South Univ. 2022, 53, 387–397. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Xu, D.; Yang, R. Recent progress in the simulation of microstructure evolution in titanium alloys. Prog. Nat. Sci. 2019, 29, 295–304. [Google Scholar] [CrossRef]

- Wu, M.W.; Xiong, S.M. Microstructure simulation of high pressure die cast magnesium alloy based on modified CA method. Acta Metall. Sin. 2010, 46, 1534–1542. [Google Scholar]

- Teferra, K.; Rowenhorst, D.J. Optimizing the cellular automata finite element model for additive manufacturing to simulate large microstructures. Acta Mater. 2021, 213, 116930. [Google Scholar] [CrossRef]

- Rappaz, M.; Gandin, C.A. Probabilistic modelling of microstructure formation in solidification processes. Acta Metall. Mater. 1993, 41, 345–360. [Google Scholar] [CrossRef]

- Gandin, C.A.; Desbiolles, J.L.; Rappaz, M.; Thévoz, P. A three-dimensional cellular automaton-finite element model for the prediction of solidification grain structures. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 1999, 30, 3153–3165. [Google Scholar] [CrossRef]

- Gandin, C.-A.; Rappaz, M. A coupled finite element-cellular automaton model for the prediction of dendritic grain structures in solidification processes. Acta Metall. Mater. 1994, 42, 2233–2246. [Google Scholar] [CrossRef]

- Pan, Q.; Jin, W.; Huang, S.; Guo, Y.; Jiang, M.; Li, X. Simulation and Study of Influencing Factors on the Solidification Microstructure of Hazelett Continuous Casting Slabs Using CAFE Model. Materials 2024, 17, 1869. [Google Scholar] [CrossRef]

- Yang, W.; Sa, S.; Hao, W.; Qin, J.; Zhang, J.; Liu, L. Temperature Field and Microstructure Simulation of Directional Solidification Process of Single Crystal Blade Prepared Efficiently with Different Module Structures. Rare Metal Mat. Eng. 2023, 52, 3847–3856. [Google Scholar]

- Sui, D.; Zhou, D.; Liu, Y.; Shan, Y.; Dong, A. Microstructure evolution of K439B Ni-based superalloy casting with varying cross-sections by experiments and simulations. Trans. Nonferr. Met. Soc. China 2025, 35, 1182–1196. [Google Scholar] [CrossRef]

- Peng, B.; Li, X.; Wang, X.; Mo, J.; Luo, L. Simulation study on temperature field and microstructure of Ti-6Al-4V alloy round ingot during EBCHM. Mater. Res. Express 2021, 8, 046505. [Google Scholar] [CrossRef]

- Khosroaghayani, M.; Khorasanian, M.; Zaree, S.R.A.; Eskandari, M. Investigation of Microstructure and Mechanical Properties of AZ91 Magnesium Alloy Produced by Directional Solidification Method in Different Angles Using CAFE Simulation. Int. J. Met. 2023, 17, 195–209. [Google Scholar] [CrossRef]

- Wang, X.Y.; Wang, F.F.; Wu, K.Y.; Wang, X.F.; Xiao, L.; Li, Z.Q.; Han, Z.Q. Experimental study and cellular automaton simulation on solidification microstructure of Mg-Gd-Y-Zr alloy. Rare Metals 2021, 40, 128–136. [Google Scholar] [CrossRef]

- Shi, H.; Chen, Q.P.; Li, K.Y.; Shen, H.F. Numerical Simulation of Grain Structure and Macrosegregation of Electroslag Remelting Process Based on Cellular Automaton-Finite Element Method. Metall. Mater. Trans. B-Proc. Metall. Mater. Proc. Sci. 2022, 53, 107–120. [Google Scholar] [CrossRef]

- Yuan, W.; Zhao, H.; Shen, X.; Zou, C.; Liu, Y.; Xu, Q. Numerical simulation of microstructure and microporosity morphology in directional solidification of aluminum-copper alloys: Effect of copper content and withdrawal rate. China Foundry 2025, 22, 33–44. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, Z.; Zhang, Q.; Wang, X. A modified microscopic cellular automaton model for the simulation of microstructure evolution during solidification/melting of nickel-based superalloys. J. Cryst. Growth 2025, 652, 128052. [Google Scholar] [CrossRef]

- Zhou, R.Y.; Feng, X.H.; Zheng, C.; Huang, Q.Y.; Li, Y.J.; Yang, Y.S. Numerical Simulation of Microstructure Evolution of Directionally Annealed Pure Iron by Cellular Automata. Metals 2023, 13, 2. [Google Scholar] [CrossRef]

- Rappaz, M. Modelling of microstructure formation in solidification processes. Int. Mater. Rev. 1989, 34, 93–124. [Google Scholar] [CrossRef]

- Jia, Y.; Zhao, D.; Li, C.; Bao, L.; Le, Q.; Wang, H.; Wang, X. Study on Solidification Structure Evolution of Direct-Chill Casting High Purity Copper Billet Using Cellular Automaton-Finite Element Method. Metals 2020, 10, 8. [Google Scholar] [CrossRef]

- Perepezko, J.H.; Wilde, G. Melt undercooling and nucleation kinetics. Curr. Opin. Solid State Mat. Sci. 2016, 20, 3–12. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Y.; Zheng, H.; Guo, Z.; Liu, G.; Wang, Z. Investigation and Application of Inverse Determination of Interfacial Heat Transfer Coefficient in Vacuum Investment Casting. Int. J. Met. 2024, 18, 3210–3220. [Google Scholar] [CrossRef]

- Motoyama, Y.; Tokunaga, H.; Matsushita, A.; Sakamoto, T.; Okane, T. A Combined Experimental-Numerical Method for Determining the Heat Transfer Coefficient at a Fluid Flowing Molten Copper-Casting Mold Interface. Int. J. Met. 2023, 17, 158–169. [Google Scholar] [CrossRef]

- Li, J.; Feng, J.; Li, Y.; Dong, F.; Geng, G. Cooling curve thermal analysis, phase constitution, and solidification characteristics of cast Mg-5Gd-2Y-xNd-Zr alloys. J. Therm. Anal. Calorim. 2020, 142, 1429–1435. [Google Scholar] [CrossRef]

- Yu, H.H.; Xin, Y.C.; Wang, M.Y.; Liu, Q. Hall-Petch relationship in Mg alloys: A review. J. Mater. Sci. Technol. 2018, 34, 248–256. [Google Scholar] [CrossRef]

| Y | Gd | Nd | Zr | Mg |

|---|---|---|---|---|

| 4.55 | 2.13 | 2.25 | 0.45 | Bal. |

| Case No. | ΔTs,max (K) | ΔTs,σ (K) | ΔTv,max (K) | ΔTv,σ (K) |

|---|---|---|---|---|

| 01 | 1 | 0.1 | 5 | 0.5 |

| 02 | 1 | 0.1 | 6 | 0.5 |

| 03 | 1 | 0.1 | 6.5 | 0.5 |

| 04 | 1 | 0.1 | 7 | 0.5 |

| 05 | 1 | 0.1 | 7.5 | 0.5 |

| 06 | 1 | 0.1 | 8 | 0.5 |

| Case No. | a2 (m/(s·K2)) | a3 (m/(s·K3)) |

|---|---|---|

| 07 | 0 | 3 × 10−6 |

| 08 | 0 | 6 × 10−6 |

| 09 | 0 | 1.2 × 10−5 |

| 10 | 0 | 2.4 × 10−5 |

| Case No. | Mold Material | HTC (W/(m2·K)) | Cooling Rate (°C/s) |

|---|---|---|---|

| 11 | AISI 1008 | 300 | 0.5 |

| 12 | AISI 1008 | 500 | 1 |

| 13 | AISI 1008 | 750 | 2 |

| 14 | AISI 1008 | 1000 | 3 |

| Casting Process | Cast Alloy | Mold Material 1 | HTC (W/(m2·K)) | Pouring Temperature (°C) |

|---|---|---|---|---|

| MMC | WE54 | AISI 1008 | 500 | 760 |

| SMC | WE54 | Silica sand | 250 | 760 |

| Casting Process | ns,max (m−2) | nv,max (m−3) | ΔTs,max (K) | ΔTs,σ (K) | ΔTv,max (K) | ΔTv,σ (K) | a2 (m/(s·K2)) | a3 (m/(s·K2)) |

|---|---|---|---|---|---|---|---|---|

| MMC | 2 × 109 | 6.5 × 1013 | 1 | 0.1 | 6 | 0.5 | 0 | 1 × 10−7 |

| SMC | 1.5 × 109 | 4 × 1013 | 1 | 0.1 | 5 | 0.5 | 0 | 1 × 10−7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Zhao, R.; Feng, J. CAFE Simulation of Solidification Microstructure of Cast WE54 Alloy: Influences of Simulation Parameters and Experimental Verification. Metals 2025, 15, 1268. https://doi.org/10.3390/met15111268

Li J, Zhao R, Feng J. CAFE Simulation of Solidification Microstructure of Cast WE54 Alloy: Influences of Simulation Parameters and Experimental Verification. Metals. 2025; 15(11):1268. https://doi.org/10.3390/met15111268

Chicago/Turabian StyleLi, Jilin, Ruohan Zhao, and Junning Feng. 2025. "CAFE Simulation of Solidification Microstructure of Cast WE54 Alloy: Influences of Simulation Parameters and Experimental Verification" Metals 15, no. 11: 1268. https://doi.org/10.3390/met15111268

APA StyleLi, J., Zhao, R., & Feng, J. (2025). CAFE Simulation of Solidification Microstructure of Cast WE54 Alloy: Influences of Simulation Parameters and Experimental Verification. Metals, 15(11), 1268. https://doi.org/10.3390/met15111268