Investigation of Weld Quality Grades for Aluminum Alloys Based on Fatigue Life

Abstract

1. Introduction

2. Materials and Methods

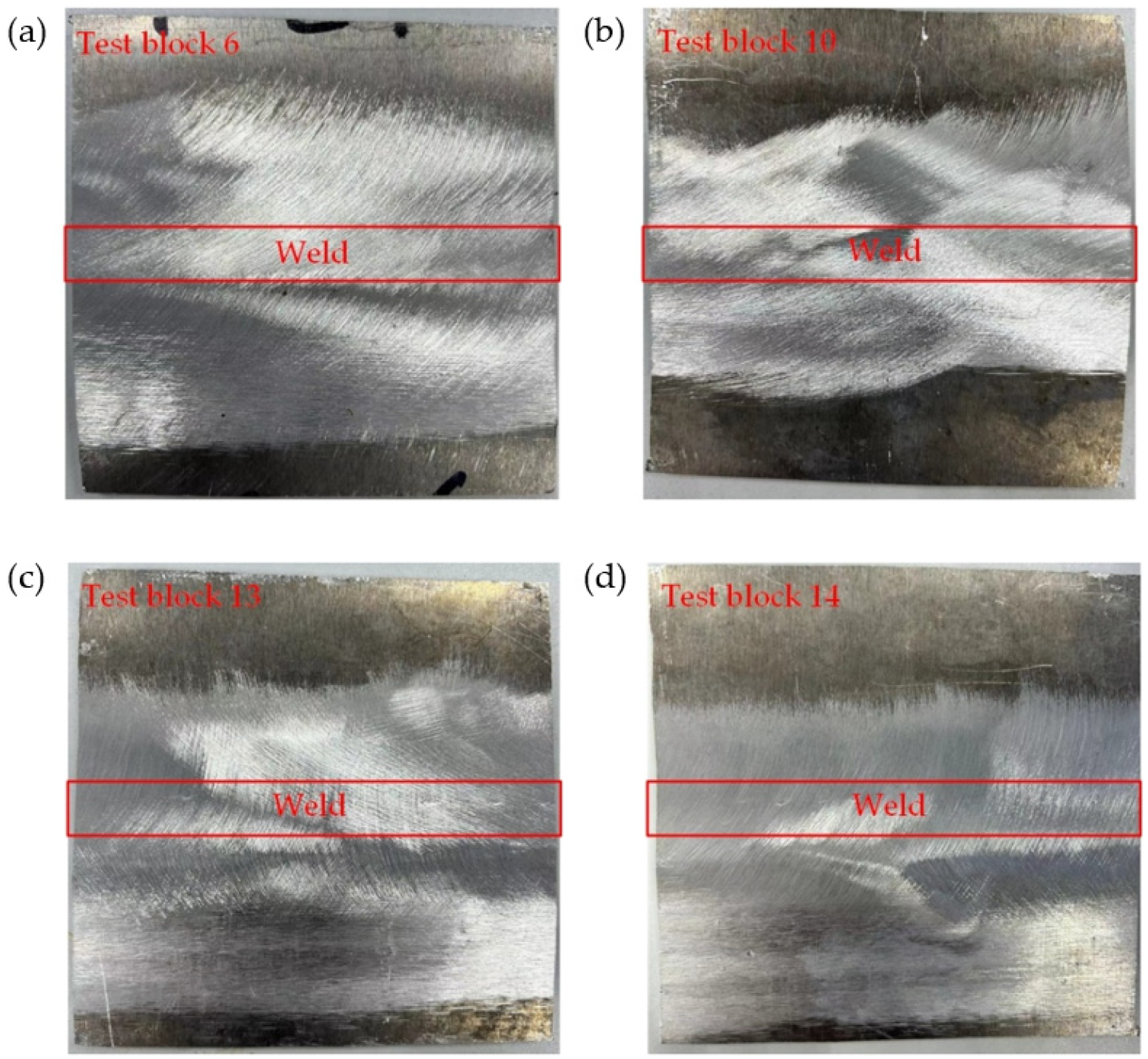

2.1. Welding Process

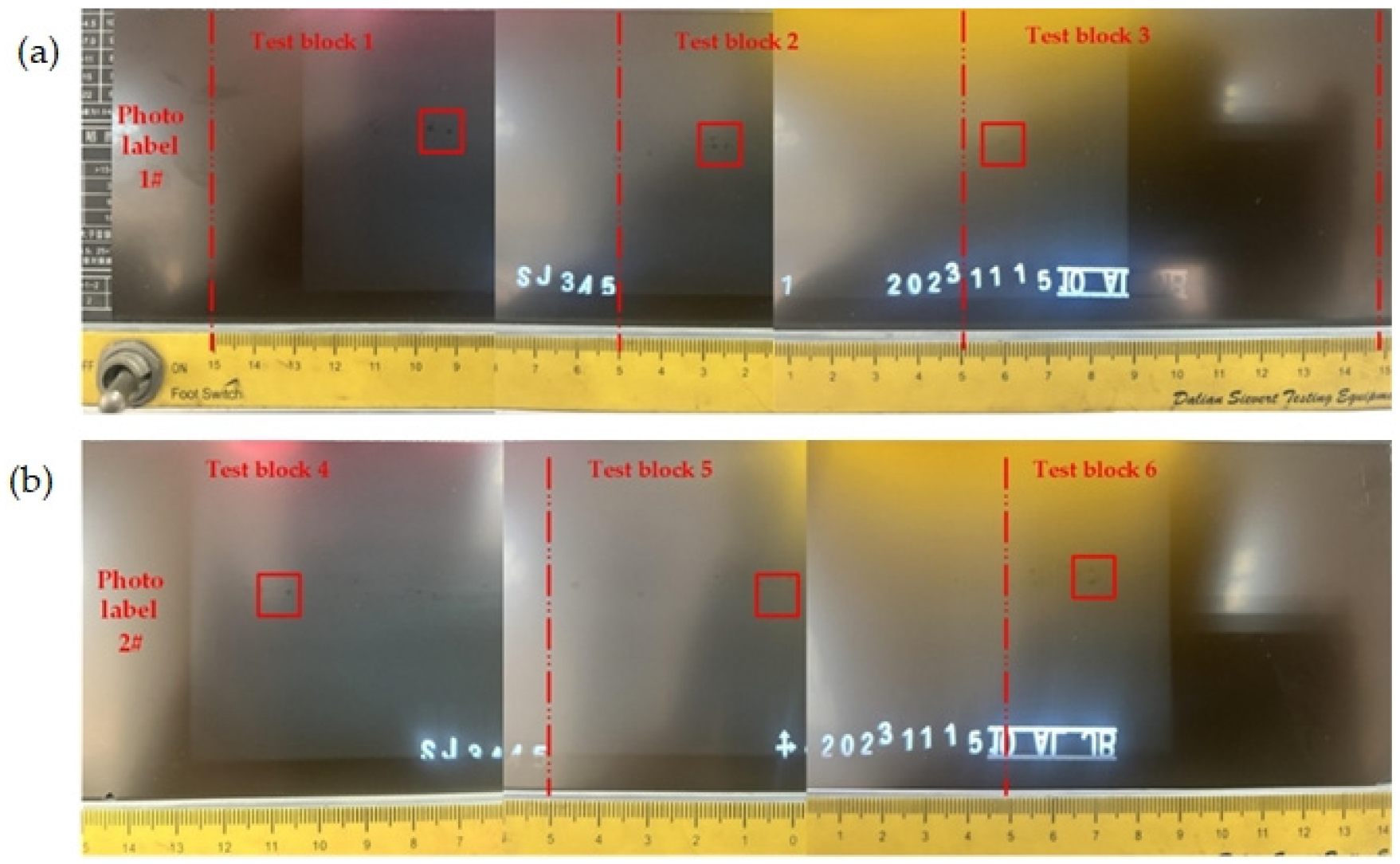

2.2. Radiographic Inspection

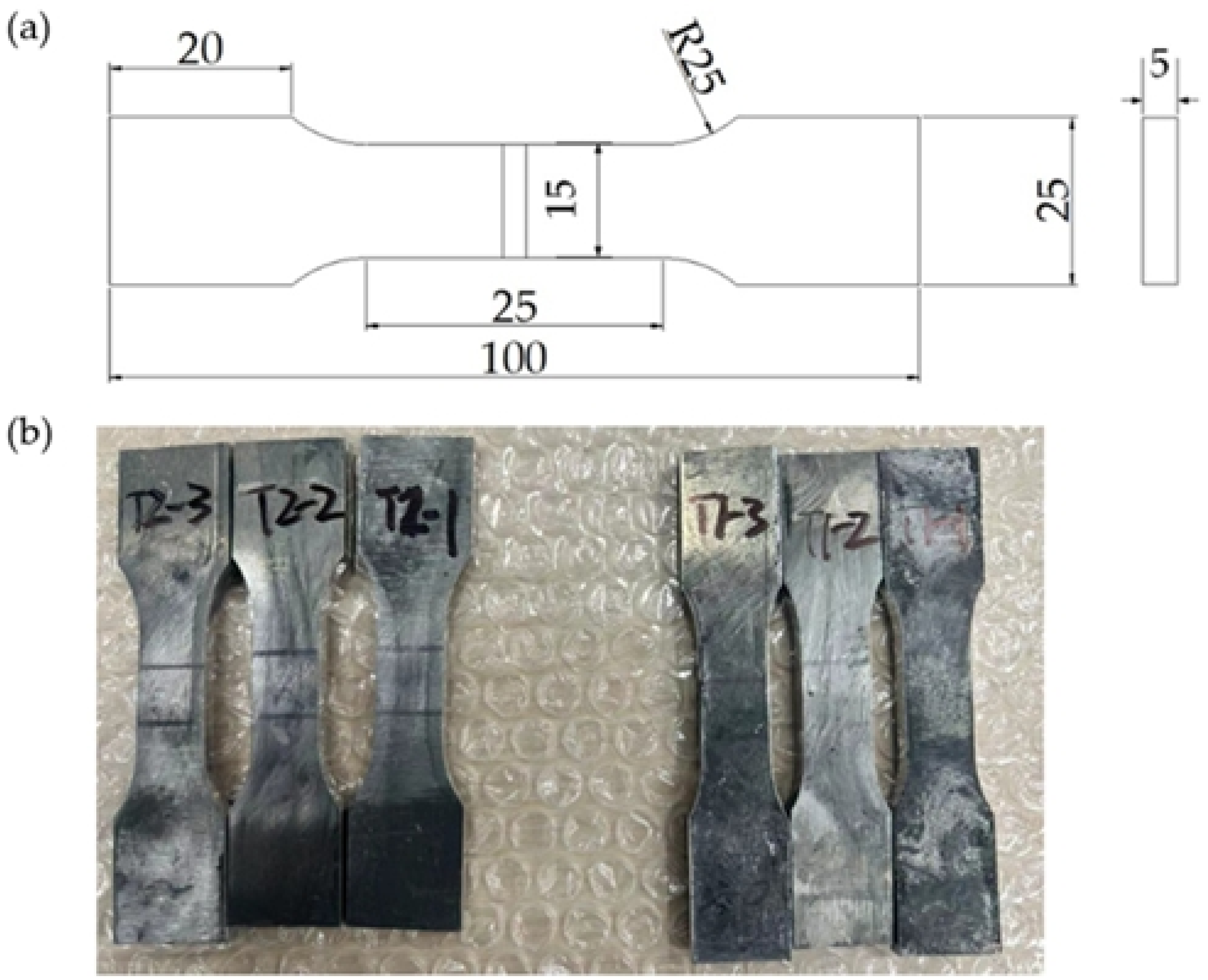

2.3. Experimental Material

2.4. Design of the Fatigue Test

3. Results

3.1. Fatigue Test Results

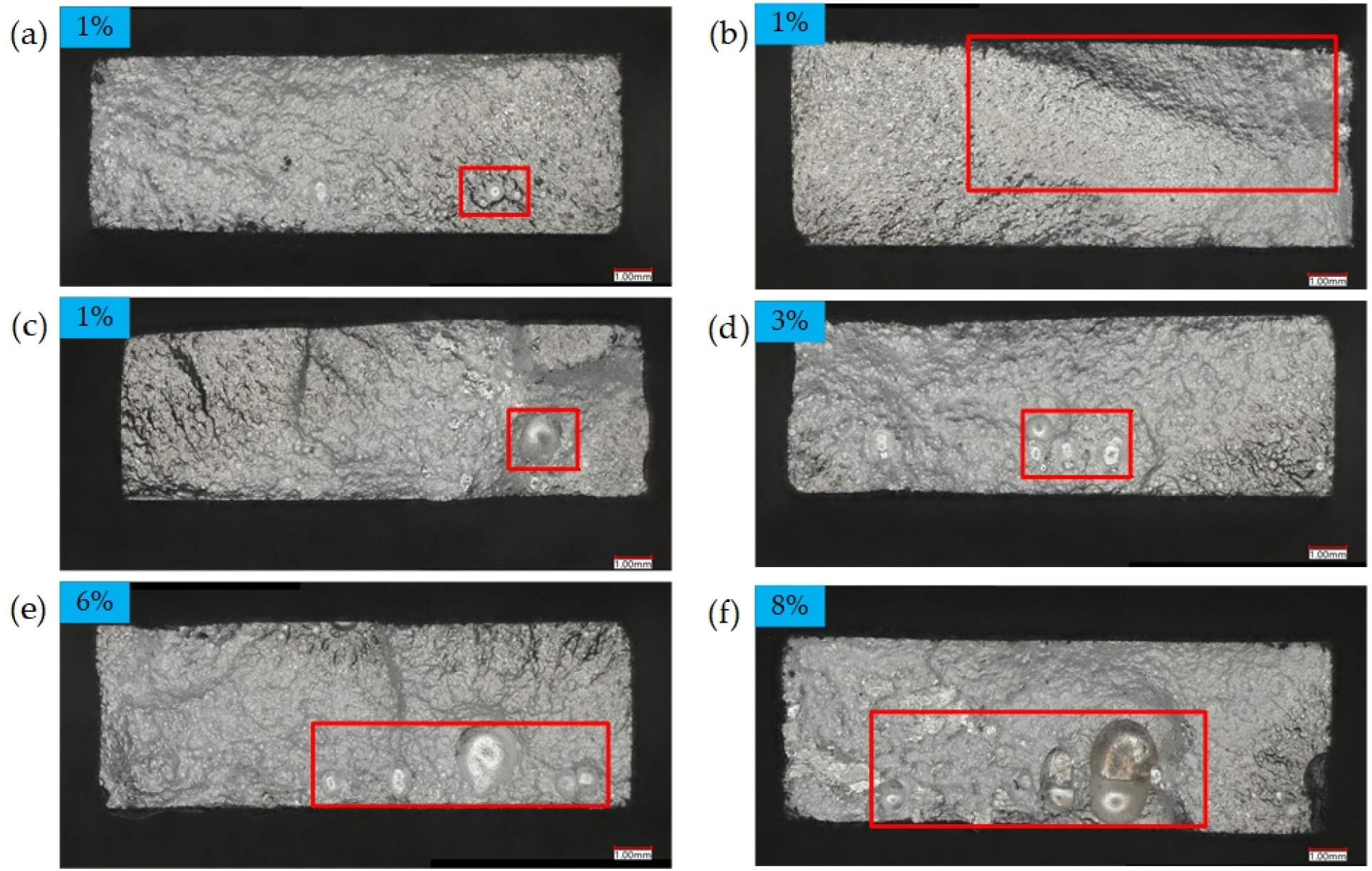

3.2. Fractography Analysis

4. Discussion

4.1. Comparison with ISO FAT

4.2. Effect of Defect Area on Fatigue Life

4.3. Thickness Correction

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sivaraman, P.; Prabhu, M.K.; Nithyanandhan, T.; Razzaq, M.M.; Kousik, K.; Abraham, D.D. Development of aluminum based AA 2014 and AA 7075 dissimilar metals for aerospace applications. Mater. Today Proc. 2021, 37, 522–526. [Google Scholar] [CrossRef]

- Liu, F.; Zheng, J.X.; Chen, X.; Xu, X.S.; Chen, B. Study on corrosion resistance of artificially aged 7075 aluminium alloy by using Cs-corrected STEM. Trans. Nonferrous Met. Soc. China 2022, 32, 2828–2837. [Google Scholar] [CrossRef]

- Sinha, A.K.; Pramanik, S.; Yagati, K.P. Effect of interlayer time interval on GTAW based wire arc additive manufacturing of 2319 aluminium alloy. Sadhana 2023, 48, 122. [Google Scholar] [CrossRef]

- Li, C.; Goekelma, M.; Dang, T.; Huang, J.; Huang, C.; Li, J.; Friedrich, B. Assessment of melt cleanliness of secondary 5000 aluminum alloy via non-metallic inclusions characterization. Met. Mater Trans. B 2023, 54, 578–592. [Google Scholar] [CrossRef]

- Liu, F.; Wang, H.; Meng, X.; Tan, C.; Chen, B.; Song, X. Effect of magnetic field orientation on suppressing porosity in steady-magnetic-field-assisted aluminum alloy deep-penetration laser welding. J. Mater. Process. Technol. 2022, 304, 117569. [Google Scholar] [CrossRef]

- ISO 6520-1:2019; Welding and Allied Processes—Classification of Geometric Imperfections in Metallic Materials—Part 1: Fusion welding. International Organization for Standardization: Geneva, Switzerland, 2019.

- European Welding Federation. Quality Management in Welded Fabrication; Woodhead Publishing: Cambridge, UK, 2023. [Google Scholar]

- ISO 5817:2014; Welding—Fusion-Welded Joints in Steel, Nickel, Titanium and Their Alloys (Beam Welding Excluded)—Quality Levels for Imperfections. International Organization for Standardization: Geneva, Switzerland, 2014.

- ISO 10042:2018; Welding—Arc-Welded Joints in Aluminium and Its Alloys—Quality Levels for Imperfections. ISO: Geneva, Switzerland, 2018.

- International Institute of Welding (IIW). IIW Guidelines on Weld Quality in Relationship to Fatigue Strength; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Hobbacher, A.F. Recommendations for Fatigue Design of Welded Joints and Components, 2nd ed.; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Lin, S.; Deng, Y.-L.; Tang, J.-G.; Deng, S.-H.; Lin, H.-Q.; Ye, L.-Y.; Zhang, X.-M. Microstructures and fatigue behavior of metal-inert-gas-welded joints for extruded Al-Mg-Si alloy. Mater. Sci. Eng. A 2019, 745, 63–73. [Google Scholar] [CrossRef]

- Osmond, P.; Le, V.-D.; Morel, F.; Bellett, D.; Saintier, N. Effect of porosity on the fatigue strength of cast aluminium alloys: From the specimen to the structure. Procedia Eng. 2018, 213, 630–643. [Google Scholar] [CrossRef]

- Lattanzi, L.; Fabrizi, A.; Fortini, A.; Merlin, M.; Timelli, G. Effects of microstructure and casting defects on the fatigue behavior of the high-pressure die-cast AlSi9Cu3(Fe)alloy. Procedia Struct. Integr. 2017, 7, 505–512. [Google Scholar] [CrossRef]

- Wang, B.B.; Xue, P.; Xiao, B.L.; Wang, W.G.; Liu, Y.D.; Ma, Z.Y. Achieving equal fatigue strength to base material in a friction stir welded 5083-H19 aluminium alloy joint. Sci. Technol. Weld. Join. 2020, 25, 81–88. [Google Scholar] [CrossRef]

- Ammar, H.R.; Samuel, A.M.; Samuel, F.H. Effect of casting imperfections on the fatigue life of 319-F and A356-T6 Al–Si casting alloys. Mater. Sci. Eng. A 2008, 473, 65–75. [Google Scholar] [CrossRef]

- Duckworth, W.; Ineson, E. The effects of externally introduced alumina particles on the fatigue life of En24 steel, clean steel. Iron Steel Inst. Spec. Rep. 1963, 77, 87–103. [Google Scholar]

- Gao, Y.X.; Yi, J.Z.; Lee, P.D.; Lindley, T.C. The effect of porosity on the fatigue life of cast aluminium-silicon alloys. Fatig. Fract. Eng. Mater. Struct. 2004, 27, 559–570. [Google Scholar] [CrossRef]

- Xie, C.; Wu, S.; Yu, Y.; Zhang, H.; Hu, Y.; Zhang, M.; Wang, G. Defect-correlated fatigue resistance of additively manufactured Al-Mg4.5Mn alloy with in situ micro-rolling. J. Mater. Process. Technol. 2021, 291, 117039. [Google Scholar] [CrossRef]

- He, C.; Wei, J.; Li, Y.; Zhang, Z.; Tian, N.; Qin, G.; Zuo, L. Improvement of microstructure and fatigue performance of wire-arc additive manufactured 4043 aluminum alloy assisted by interlayer friction stir processing. J. Mater. Sci. Technol. 2023, 133, 183–194. [Google Scholar] [CrossRef]

- Muhammad, M.; Nezhadfar, P.D.; Thompson, S.; Saharan, A.; Phan, N.; Shamsaei, N. A comparative investigation on the microstructure and mechanical properties of additively manufactured aluminum alloys. Int. J. Fatigue 2021, 146, 106165. [Google Scholar] [CrossRef]

- Yang, S.; Hu, W.; Li, J.; Meng, Q.; Zhan, Z. Fatigue tests and damage model development on Al-Si-Mg aluminum alloys with low-velocity impact pit. Int. J. Fatigue 2021, 153, 106466. [Google Scholar] [CrossRef]

- Rotella, A.; Nadot, Y.; Piellard, M.; Augustin, R.; Fleuriot, M. Influence of defect morphology and position on the fatigue limit of cast Al alloy: 3D characterization by X-ray microtomography of natural and artificial defects. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2020, 785, 139347. [Google Scholar] [CrossRef]

- Liu, D.; Wu, D.; Wang, R.; Shi, J.; Niu, F.; Ma, G. Formation mechanism of Al-Zn-Mg-Cu alloy fabricated by laser-arc hybrid additive manufacturing: Microstructure evaluation and mechanical properties. Addit. Manuf. 2022, 50, 102554. [Google Scholar] [CrossRef]

- Zhang, Z.; Ma, Z.; He, S.; Song, G.; Liu, L. Effect of laser power on the microstructure and mechanical properties of 2319-Al fabricated by wire-based additive manufacturing. J. Mater. Eng. Perform. 2021, 30, 6640–6649. [Google Scholar] [CrossRef]

- Fang, X.; Chen, G.; Yang, J.; Xie, Y.; Huang, K.; Lu, B. Wire and arc additive manufacturing of high-strength Al-Zn-Mg aluminum alloy. Front. Mater. 2021, 8, 656429. [Google Scholar] [CrossRef]

- Vivek Pamarthi, V.; Sun, T.; Das, A.; Franciosa, P. Tailoring the weld microstructure to prevent solidification cracking in remote laser welding of AA6005 aluminium alloys using adjustable ringmode beam. J. Mater. Res. Technol. 2023, 25, 7154–7168. [Google Scholar] [CrossRef]

- Tian, Z.; Chen, S.; Wang, Y.; Tao, W.; Ye, X.; Ren, W.; Yang, S. Dynamic laser welding hot cracking behavior and mechanism of new structural material Ni e 28W e 6Cr alloy for molten salt reactor. J. Mater. Res. Technol. 2023, 25, 3022–3036. [Google Scholar] [CrossRef]

- Soysal, T.; Kou, S. A simple test for solidification cracking susceptibility and filler metal effect. Weld. J. 2017, 96, 389–401. [Google Scholar]

- Ou, X.; Chen, X.; Xu, X.; Xie, L.; Chen, X.; Hong, Z.; Bai, H.; Liu, X.; Chen, Q.; Li, L.; et al. Recent development in X-ray imaging technology: Future and challenges. Research 2021, 2021, 9892152. [Google Scholar] [CrossRef]

- ASTM E505-22; Standard Reference Radiographs for Inspection of Aluminum and Magnesium Die Castings. ASTM International: West Conshohocken, PA, USA, 2022; pp. 1–3.

- ASTM E2422-17; Standard Digital Reference Images for Inspection of Aluminum Castings. ASTM International: West Conshohocken, PA, USA, 2017; pp. 1–5.

- ASTM. ASTM Compass [WWW Document]. 2021. Available online: https://compass.astm.org/ (accessed on 5 March 2022).

- Ai, Y.; Liu, J.; Ye, C.; Cheng, J. Influence of oscillation parameters on energy distributions and dynamic behaviors during laser welding of aluminum alloy T-joints assisted with solder patch. Int. J. Therm. Sci. 2024, 201, 108953. [Google Scholar] [CrossRef]

- Li, S.; Mi, G.; Wang, C. A study on laser beam oscillating welding characteristics for the 5083 aluminum alloy: Morphology, microstructure and mechanical properties. J. Manuf. Process. 2020, 53, 12–20. [Google Scholar] [CrossRef]

- ASTM A370-19; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM E114/E114M-15(2020); Standard Practice for Ultrasonic Pulse-Echo Straight-Beam Examination by the Contact Method. ASTM International: West Conshohocken, PA, USA, 2020.

| Welding Grade | Welding Speed (mm/s) | Gas Flow (L/min) |

|---|---|---|

| A | 10 | 15 |

| B | 8 | 12 |

| C | 6 | 10 |

| Photo Label | Number of Test Block | Position (mm) | Number of Round Holes | Porosity |

|---|---|---|---|---|

| 1# | 1 | 150–50 left off-center | 3 | 3% |

| 2 | Off-center 50 left to 50 right | 8 | 8% | |

| 3 | 50–150 right off-center | 1 | 1% | |

| 2# | 4 | 150–50 left off-center | 1 | 1% |

| 5 | Off-center 50 left to 50 right | 3 | 3% | |

| 6 | 50–150 right off-center | 3 | 3% | |

| 3# | 7 | 150–50 left off-center | 6 | 6% |

| 8 | 30–130 right off-center | 1 | 1% | |

| 9 | Off-center 90 left to 10 right | 3 | 3% | |

| 4# | 10 | 140–40 left off-center | 0 | 1% |

| 5# | 11 | Off-center 140 left to 40 right | 1 | 1% |

| 12 | 10–110 right off-center | 1 | 1% | |

| 6# | 13 | Off-center 90 left to 10 right | 2 | 2% |

| 14 | 10–110 right off-center | 1 | 1% |

| Porosity | 1% | 3% | 6% | 8% |

| FAT | 50 | 45 | 40 | 36 |

| Quality level | I | II | III | III |

| Thickness (mm) | 1~5 | 5~10 | 10~20 | 20~40 | 40~80 | 80~100 | 100~120 |

|---|---|---|---|---|---|---|---|

| I | 1 | 3 | 4 | 6 | 7 | 9 | 10 |

| II | 3 | 10 | 14 | 21 | 24 | 31 | 35 |

| III | 6 | 21 | 28 | 42 | 49 | 63 | 70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Cai, G.; Ye, Y.; Li, Y. Investigation of Weld Quality Grades for Aluminum Alloys Based on Fatigue Life. Metals 2025, 15, 1266. https://doi.org/10.3390/met15111266

Zhao Z, Cai G, Ye Y, Li Y. Investigation of Weld Quality Grades for Aluminum Alloys Based on Fatigue Life. Metals. 2025; 15(11):1266. https://doi.org/10.3390/met15111266

Chicago/Turabian StyleZhao, Zhibiao, Gangyi Cai, Yufeng Ye, and Yuebing Li. 2025. "Investigation of Weld Quality Grades for Aluminum Alloys Based on Fatigue Life" Metals 15, no. 11: 1266. https://doi.org/10.3390/met15111266

APA StyleZhao, Z., Cai, G., Ye, Y., & Li, Y. (2025). Investigation of Weld Quality Grades for Aluminum Alloys Based on Fatigue Life. Metals, 15(11), 1266. https://doi.org/10.3390/met15111266