Quasi-Static Compression and Tensile Behavior of Additively Manufactured Al-Mg-Sc-Zr Alloy Lattices: The Role of Cell Topology

Abstract

1. Introduction

1.1. Progress in Numerical Simulation Research on Metal Lattice Structures

1.2. Research Progress of Mechanical Properties of Lattice Structures

1.3. Purpose of This Study

2. Materials and Methods

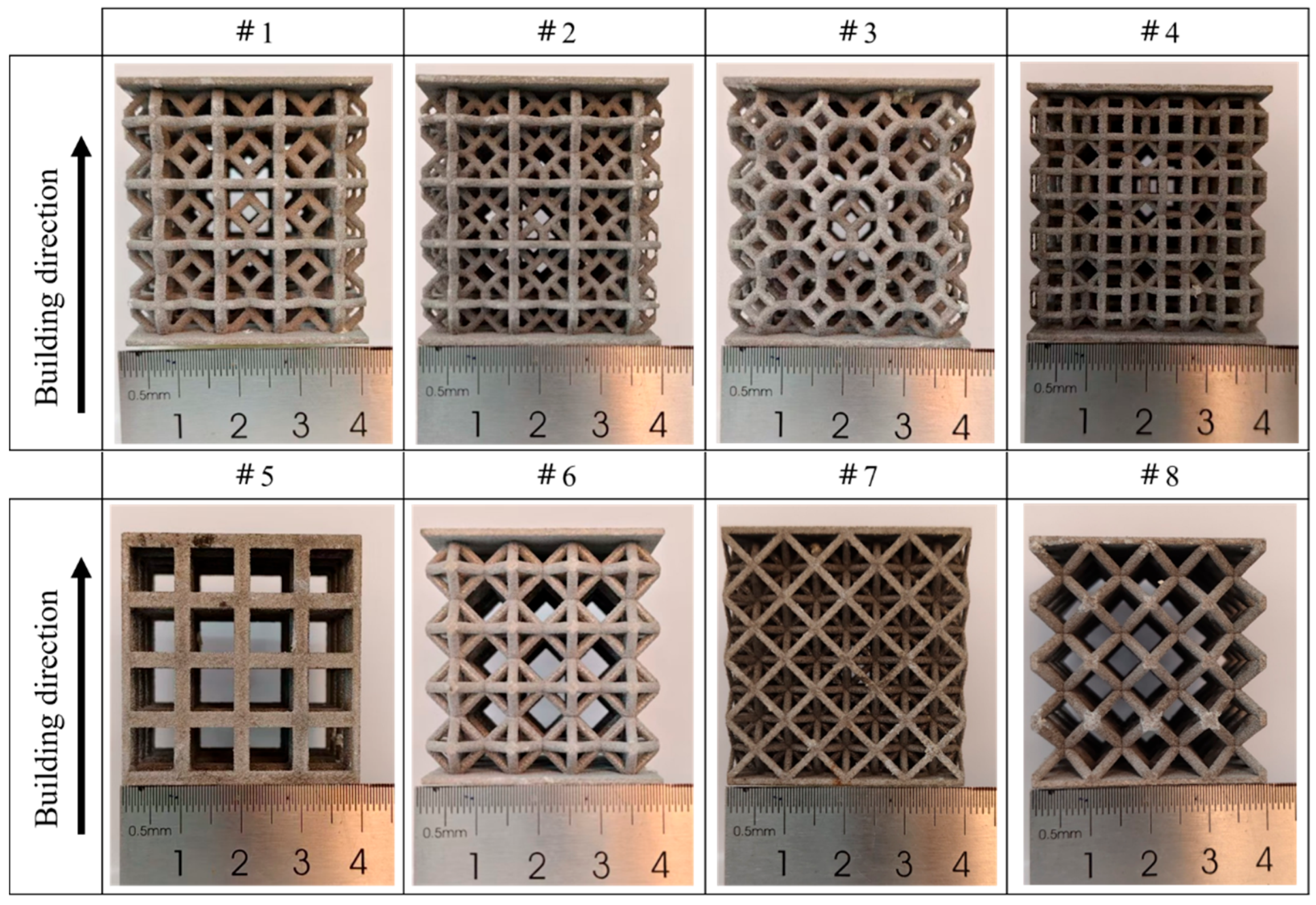

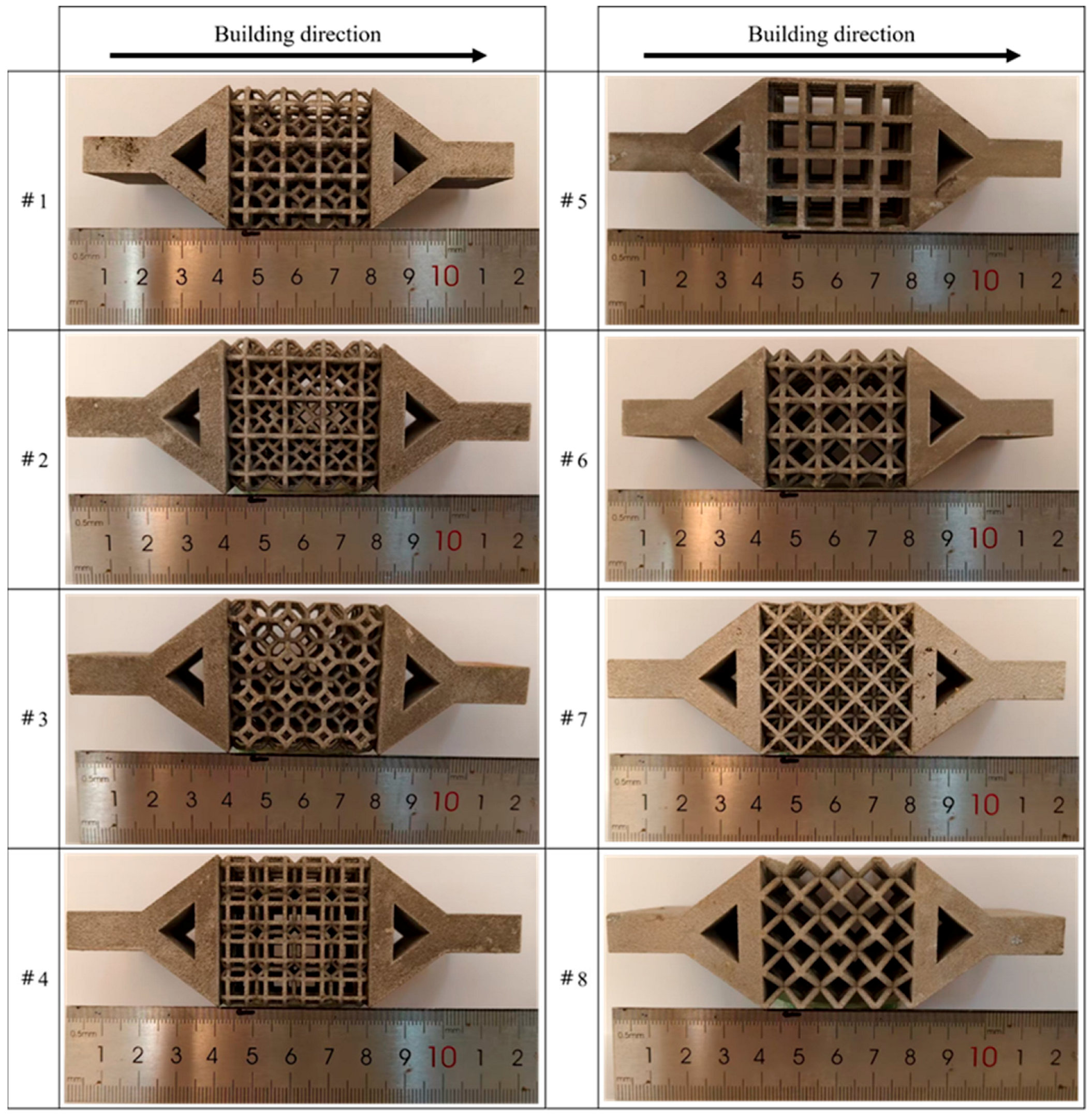

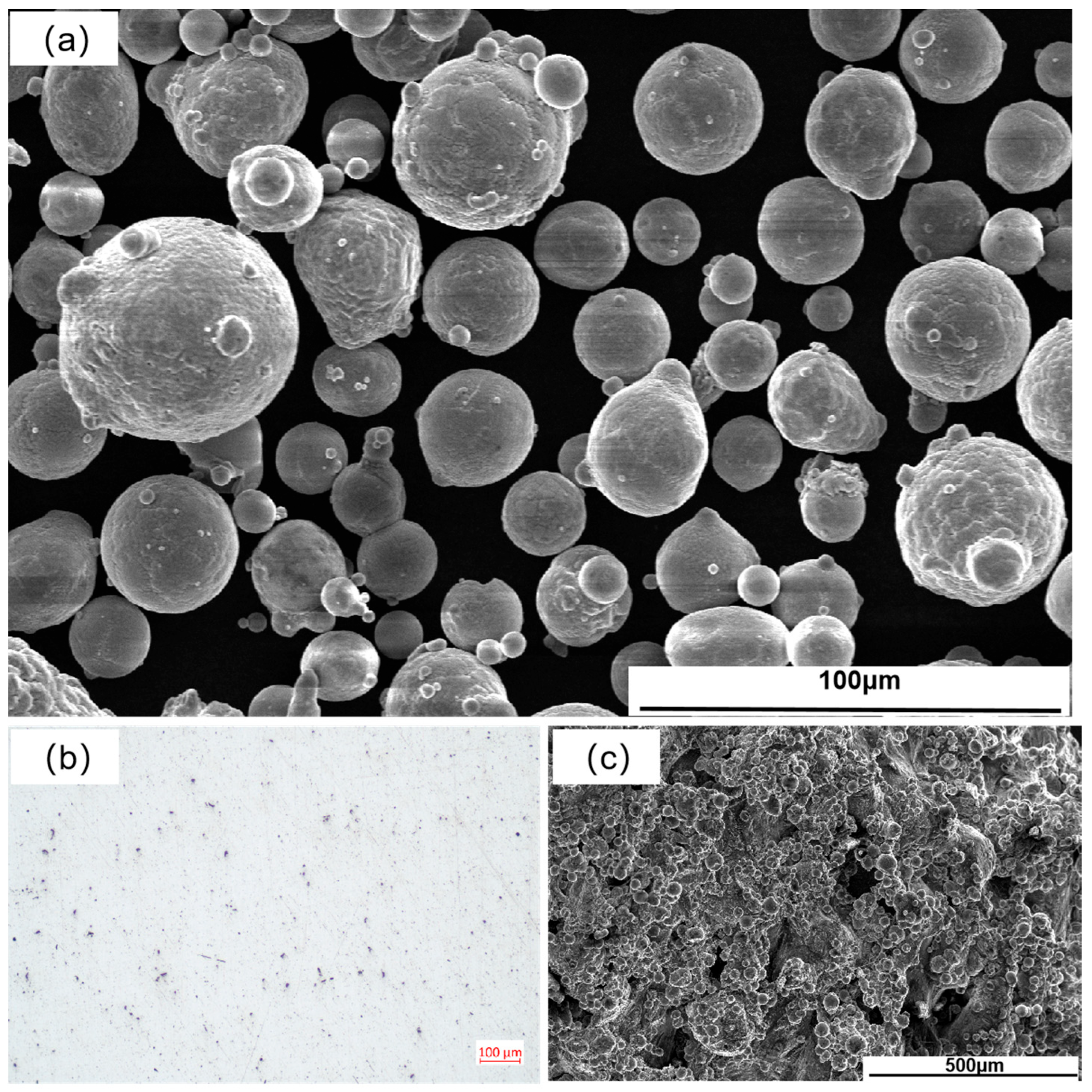

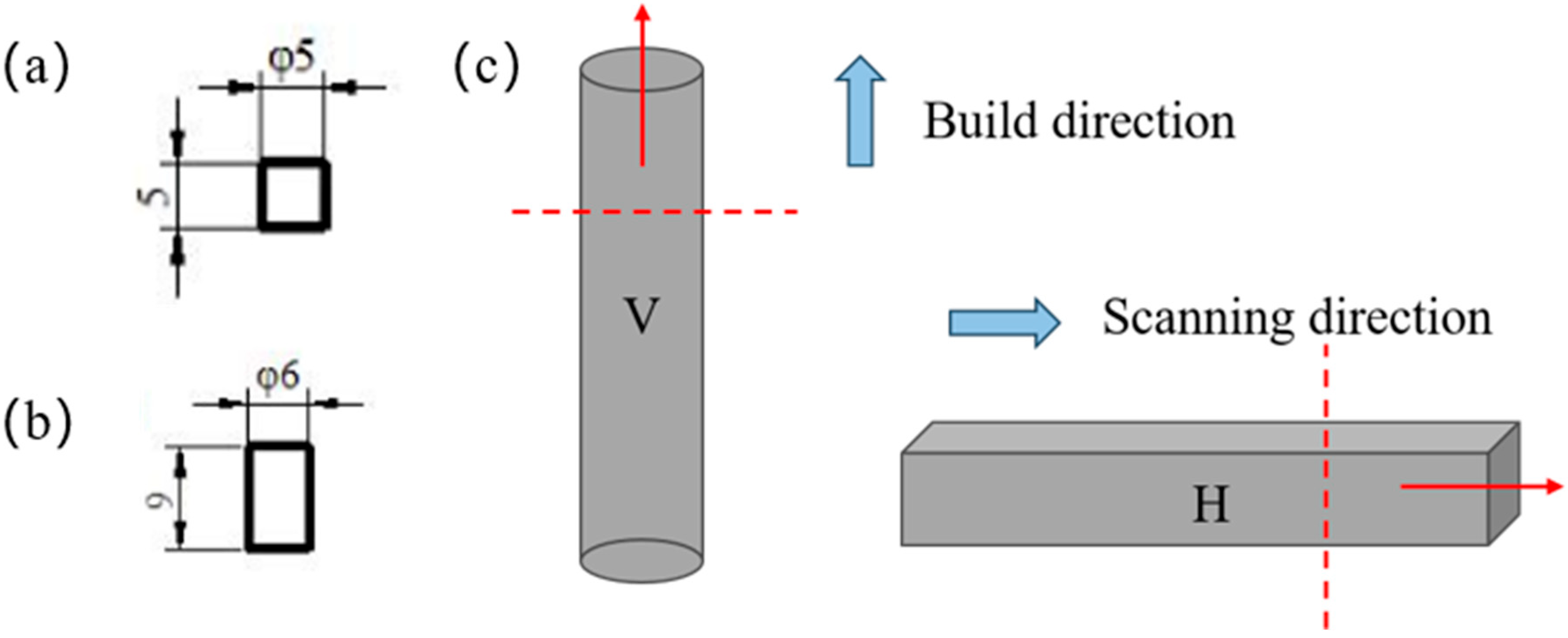

2.1. Material Design and Manufacturing

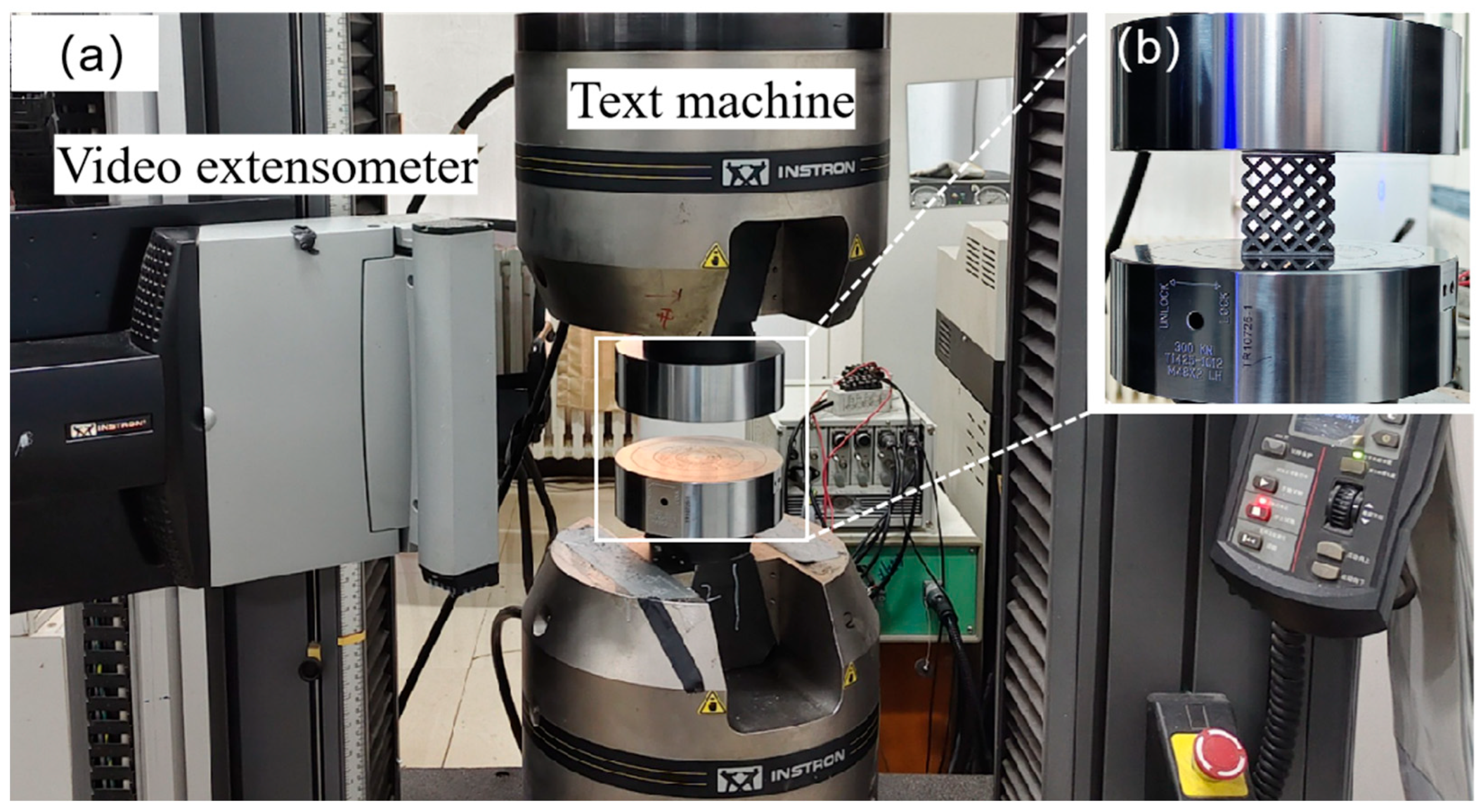

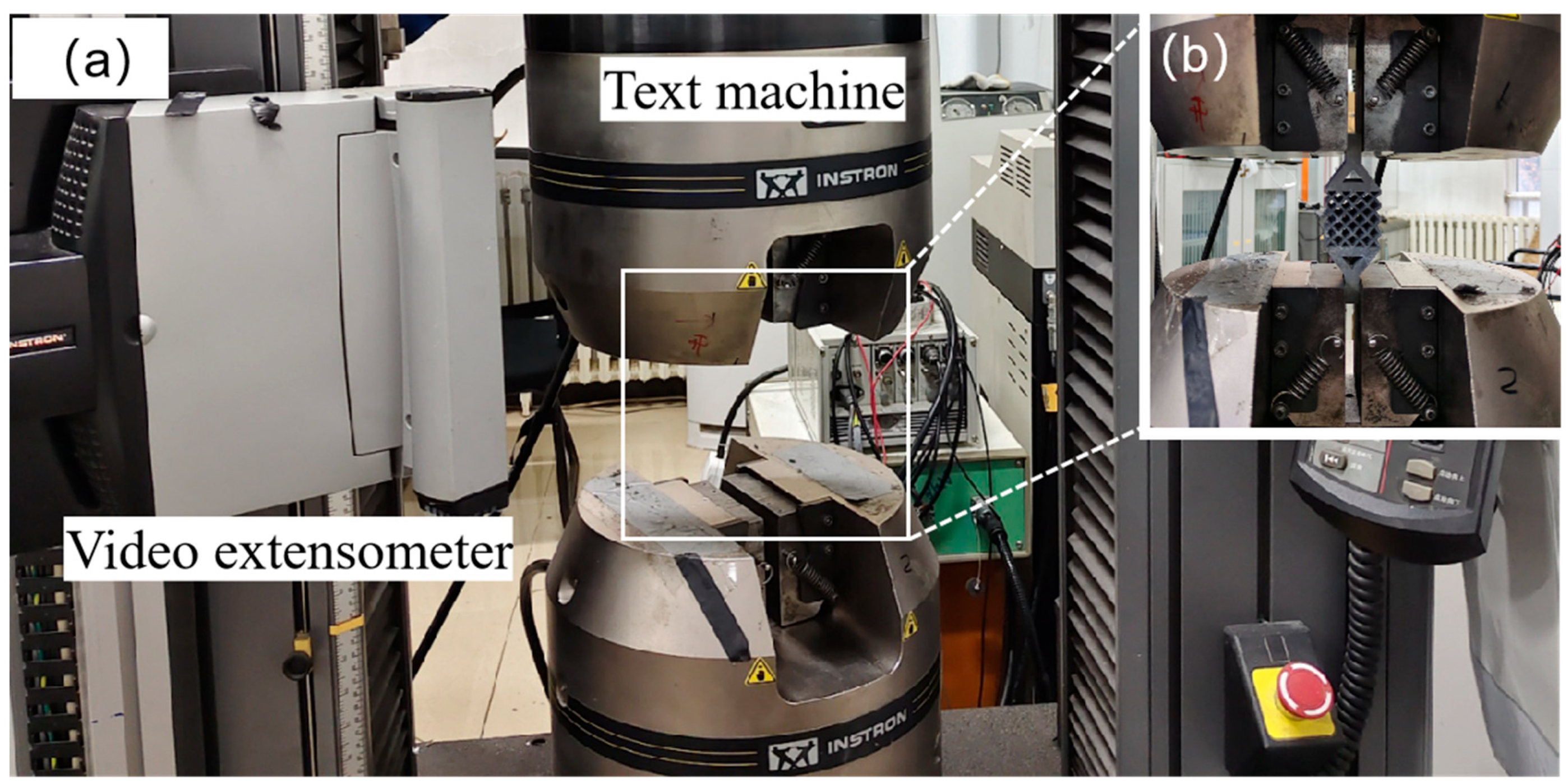

2.2. Test Method

2.3. Numerical Simulation Method

3. Results and Discussion

3.1. Effect of Cell Topology on the Compressive Mechanical Properties of Lattice Structures

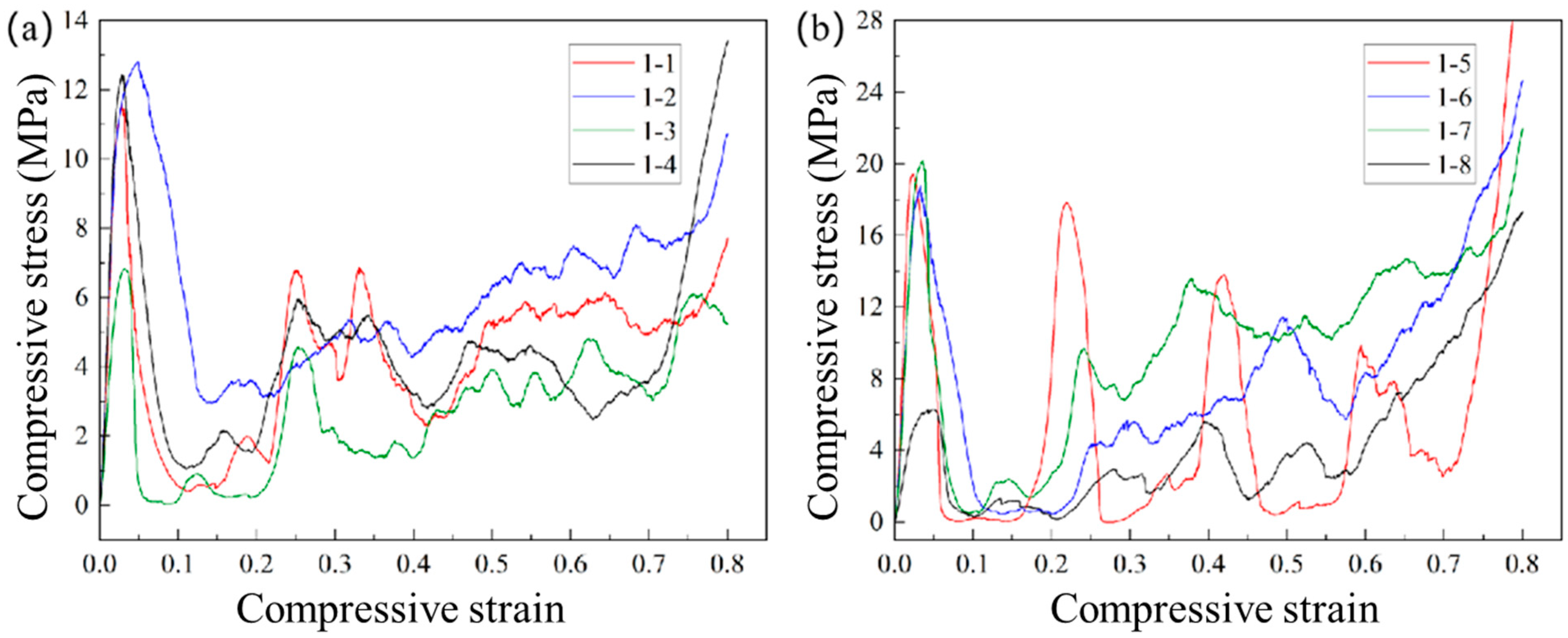

3.1.1. Compression Test Results and Simulation Results

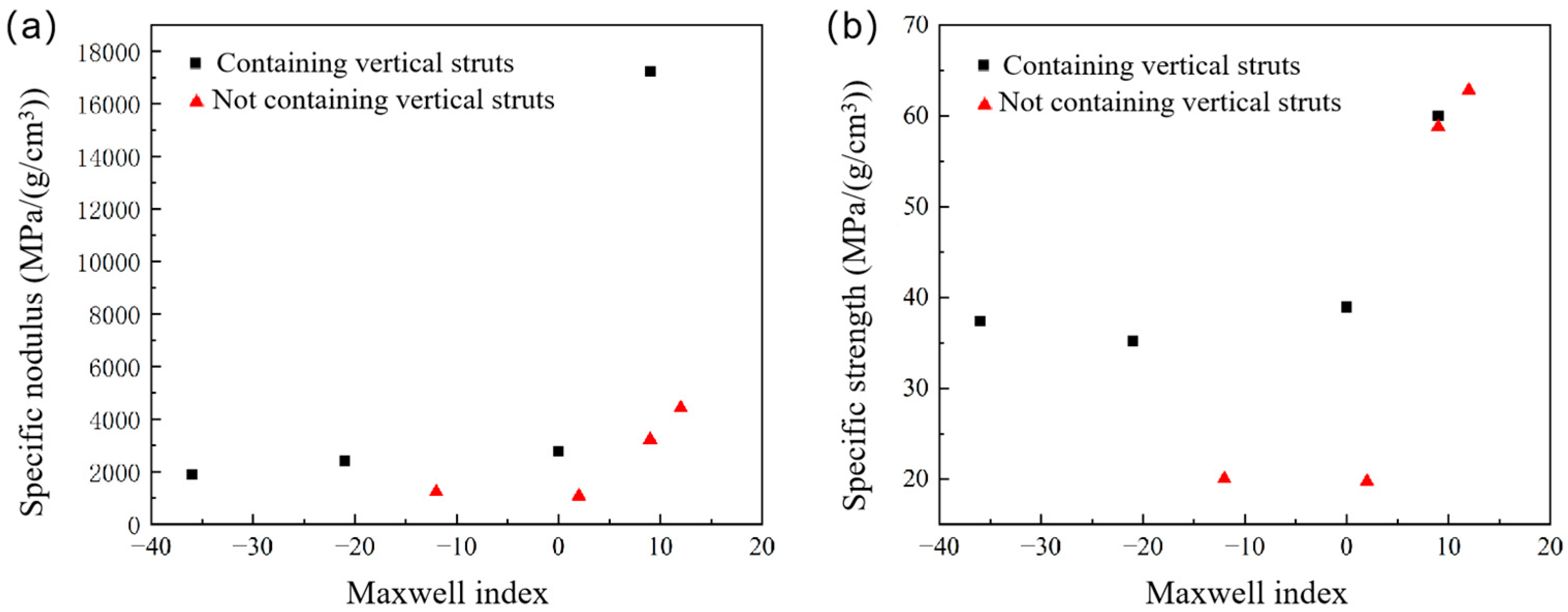

3.1.2. Analysis Based on the Maxwell Index

3.2. Effect of Cellular Element Topology on Tensile Mechanical Properties of Lattice Structures

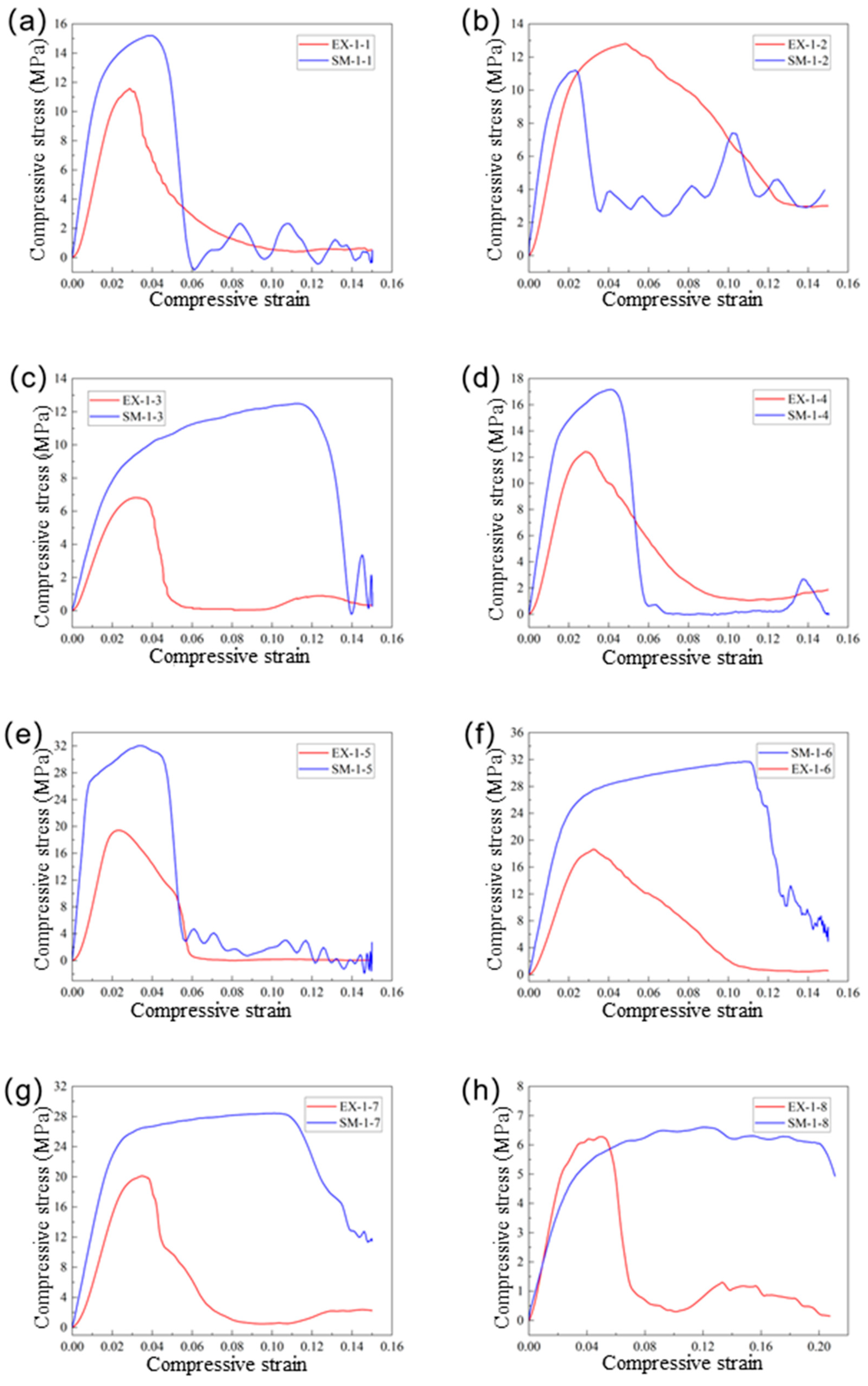

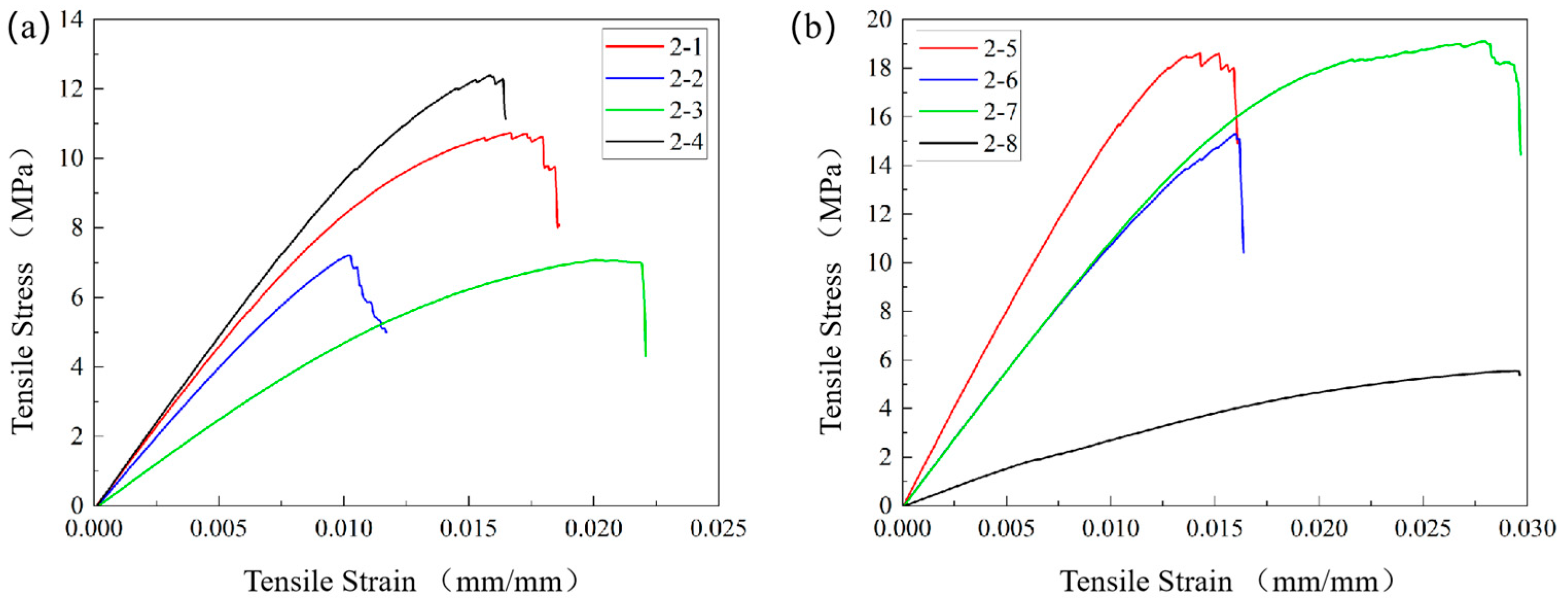

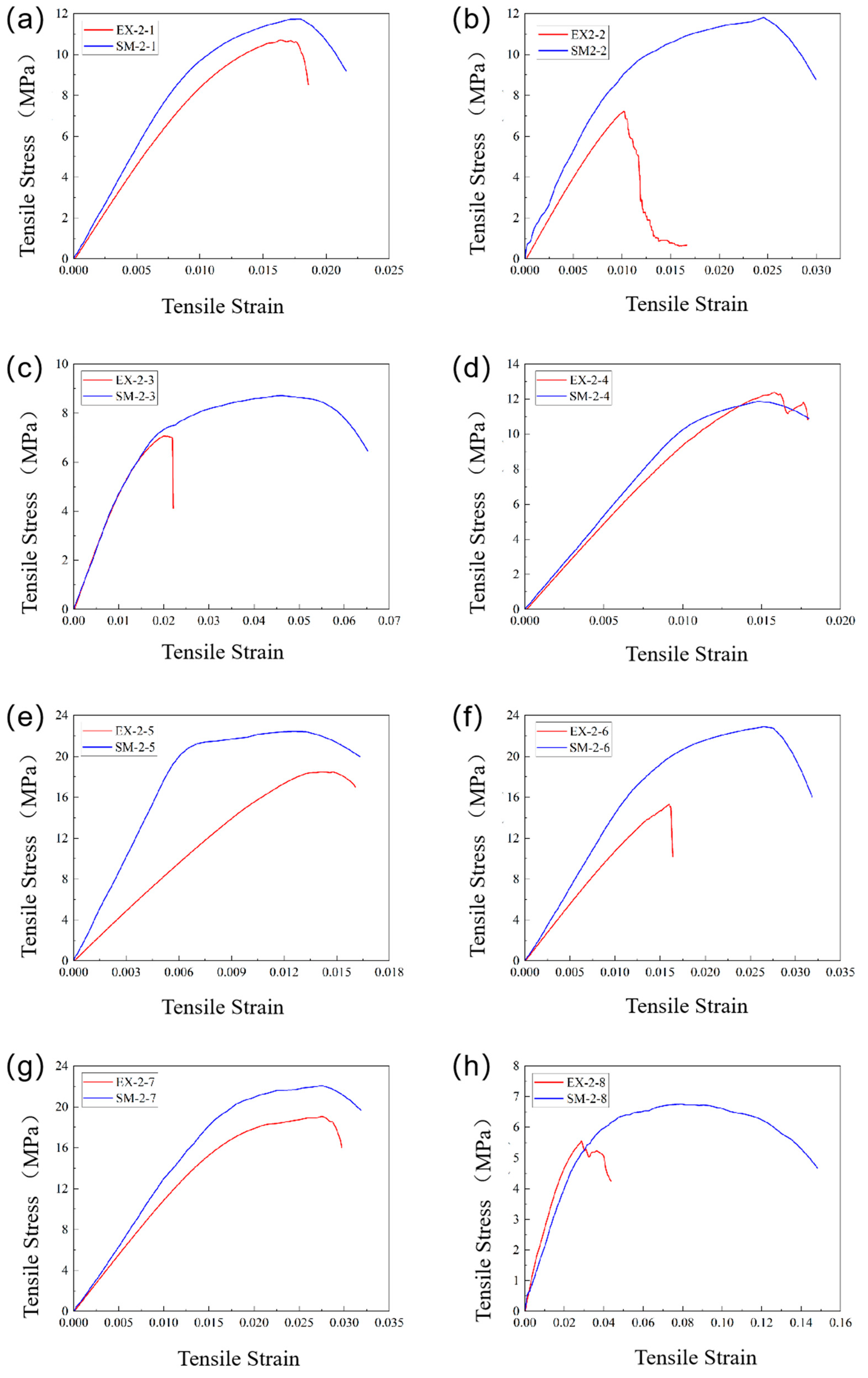

3.2.1. Tensile Test Results and Simulation Results

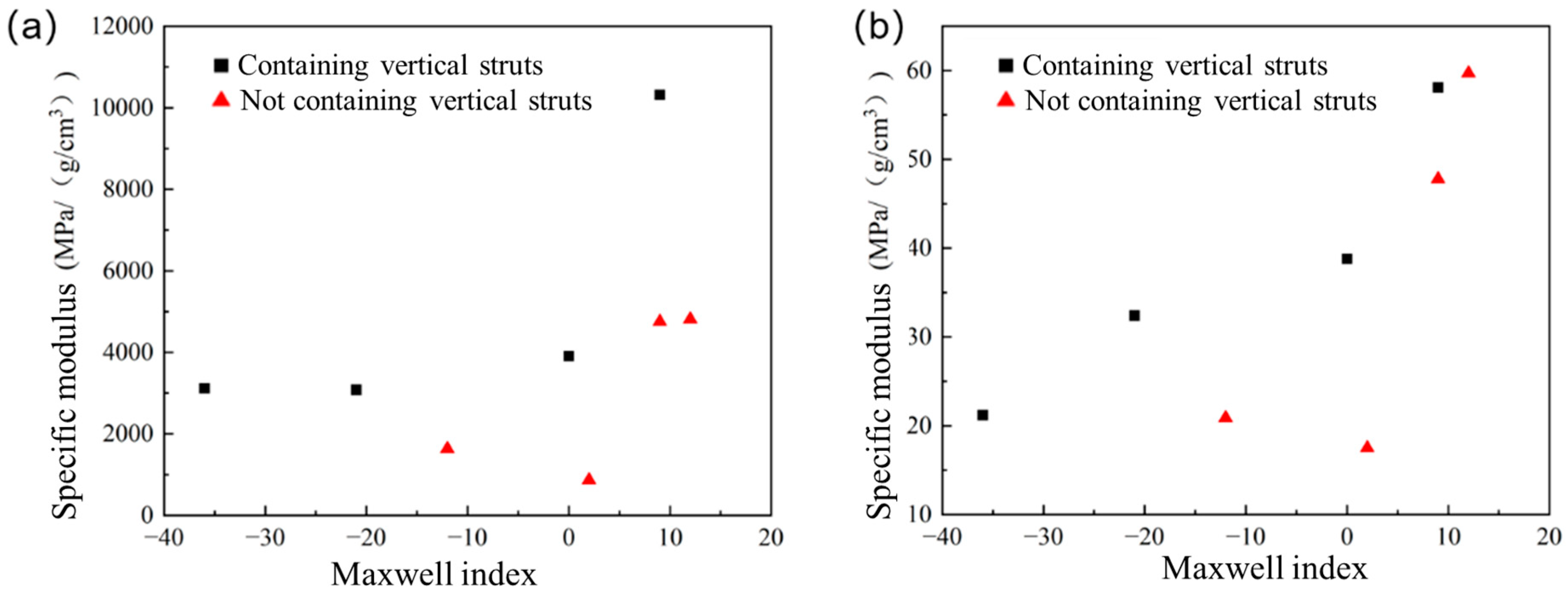

3.2.2. Analysis Based on the Maxwell Index

4. Conclusions

- (1)

- Under quasi-static compression loading, lattice structures exhibit failure through layer-by-layer collapse followed by densification. Under quasi-static tensile loading, however, the structures display higher brittleness characteristics, with failure strains generally below 5%. Failure originates from rapid successive fractures of rod phases at stress concentration points, causing stress–strain curves to exhibit abrupt drops after reaching peak values.

- (2)

- Finite element simulations effectively predict the mechanical response of lattice structures. The trends in stress–strain curves from simulations and experiments are generally consistent, though differences exist in the plastic stage and failure strain. Simulated curves typically exhibit longer yield plateaus and larger failure strains, while experimental curves show earlier fracture due to defects like voids and unfused regions introduced during SLM fabrication.

- (3)

- The mechanical properties of lattice structures are fundamentally governed by their cell topology, as explained by the load-bearing mechanisms characterized by the Maxwell index. Stretching-dominated topologies (M ≥ 0), which utilize efficient axial loading of struts, exhibit superior specific modulus and strength, whereas bending-dominated topologies (M < 0) fail through less efficient bending moments. Moreover, an increase in the Maxwell index generally enhances both specific modulus and strength. It is also noteworthy that for topologies with similar Maxwell indices, the incorporation of vertical struts significantly improves structural stability, leading to higher specific modulus and strength under both compression and tension.

- (4)

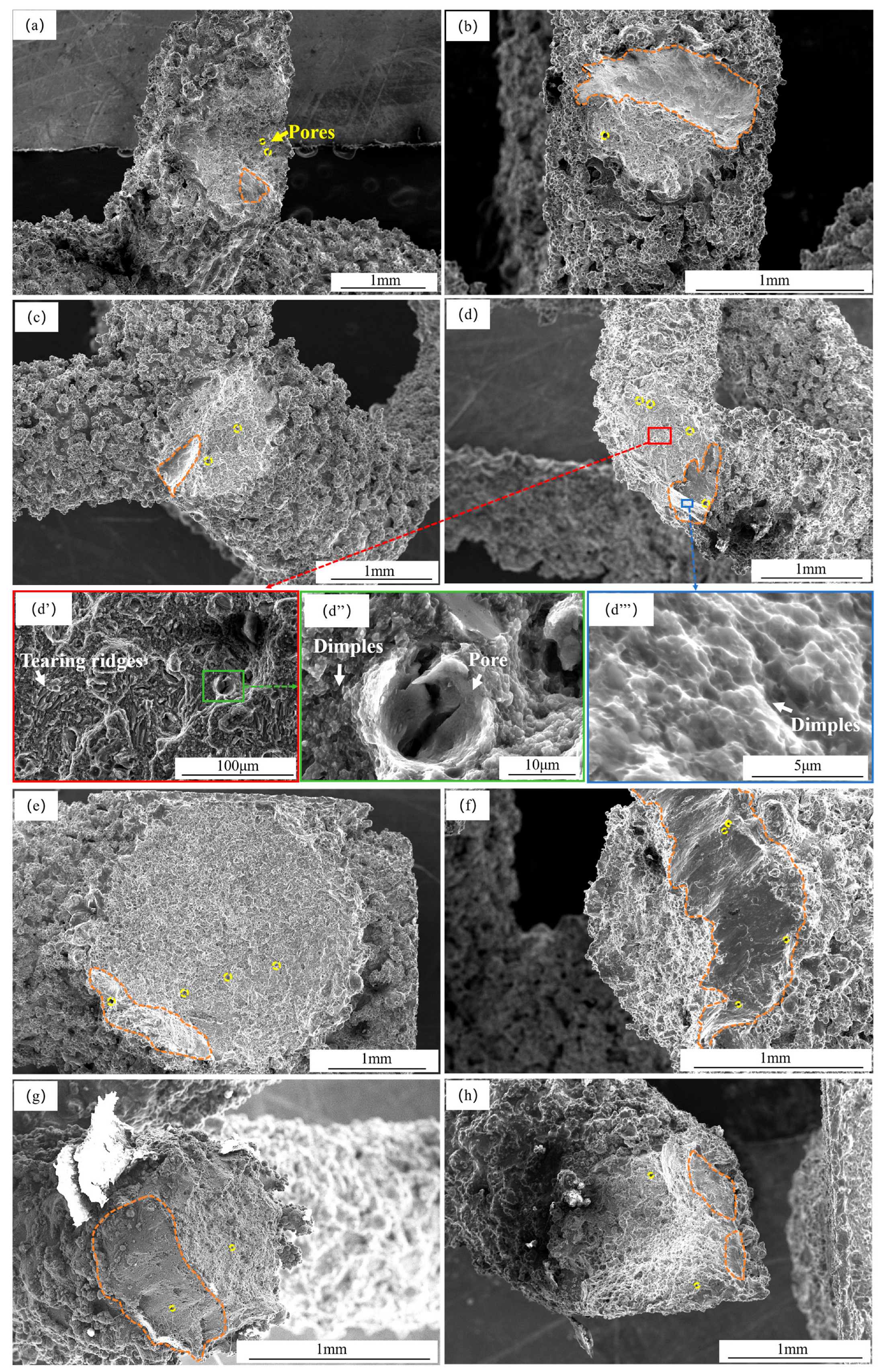

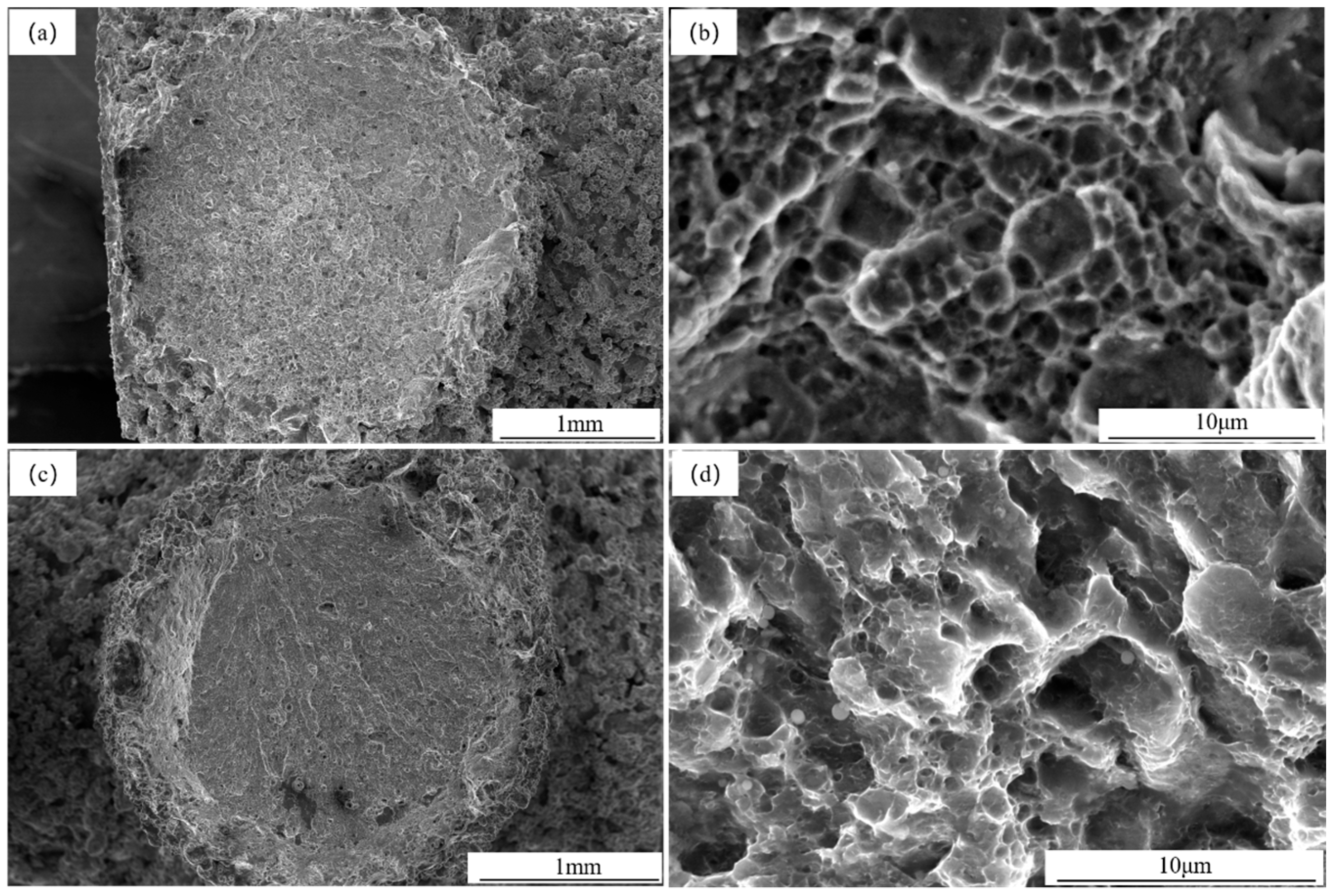

- Fracture analysis indicates that lattice structures exhibit ductile fracture behavior under both compressive and tensile loading. Compressive fractures feature larger and more widespread ductile dimples, demonstrating superior plasticity. Under tensile loading, defects such as pores inherent to the SLM process readily act as crack initiation sites, leading to fracture at relatively low strains. Consequently, despite the presence of dimpled features characteristic of plastic fracture on the fracture surface, the material exhibits a pronounced tendency for macroscopically brittle failure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Evans, A.G.; Hutchinson, J.W.; Fleck, N.A.; Ashby, M.F.; Wadley, H.N.G. The topological design of multifunctional cellular metals. Prog. Mater. Sci. 2001, 46, 309–327. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Fleck, N.A.; Ashby, M.F. Effective properties of the octet-truss lattice material. J. Mech. Phys. Solids 2001, 49, 1747–1769. [Google Scholar] [CrossRef]

- Ekaputra, C.N.; Weiss, D.; Mogonye, J.-E.; Dunand, D.C. Eutectic, precipitation-strengthened alloy via laser fusion of blends of Al-7Ce-10Mg (wt.%), Zr, and Sc powders. Acta Mater. 2023, 246, 118676. [Google Scholar] [CrossRef]

- Kendig, K.L.; Miracle, D.B. Strengthening mechanisms of an Al-Mg-Sc-Zr alloy. Acta Mater. 2002, 50, 4165–4175. [Google Scholar] [CrossRef]

- Panwisawas, C.; Tang, Y.T.; Reed, R.C. Metal 3D printing as a disruptive technology for superalloys. Nat. Commun. 2020, 11, 2327. [Google Scholar] [CrossRef]

- Wang, M.; Yan, H.; Zhang, P. Particulate-reinforced Al-based metal matrix composites fabricated by selective laser melting: A comprehension review. Opt. Laser Technol. 2024, 176, 110918. [Google Scholar] [CrossRef]

- Wang, X.; Lu, Q.; Zhang, P. A review on the simulation of selective laser melting AlSi10Mg. Opt. Laser Technol. 2024, 174, 110500. [Google Scholar] [CrossRef]

- Wang, T.S.; Hua, Z.M.; Yang, Y. Macro-/micro-structures and mechanical properties of magnesium alloys based on additive manufacturing: A review. J. Mater. Sci. 2024, 59, 9908–9940. [Google Scholar] [CrossRef]

- Soni, N.; Renna, G.; Leo, P. Advancements in Metal Processing Additive Technologies: Selective Laser Melting (SLM). Metals 2024, 14, 1081. [Google Scholar] [CrossRef]

- Capasso, I.; Andreacola, F.R.; Brando, G. Additive Manufacturing of Metal Materials for Construction Engineering: An Overview on Technologies and Applications. Metals 2024, 14, 1033. [Google Scholar] [CrossRef]

- Zhu, J.; Zhou, H.; Wang, C.; Zhou, L.; Yuan, S.; Zhang, W. A review of topology optimization for additive manufacturing: Status and challenges. Chin. J. Aeronaut. 2021, 34, 91–110. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Senthil, K.; Iqbal, M.A.; Chandel, P.S.; Gupta, N.K. Study of the constitutive behavior of 7075-T651 aluminum alloy. Int. J. Impact Eng. 2017, 108, 171–190. [Google Scholar] [CrossRef]

- Nahshon, K.; Pontin, M.G.; Evans, A.G.; Hutchinson, J.W.; Zok, F.W. Dynamic shear rupture of steel plates. J. Mech. Mater. Struct. 2007, 2, 2049–2066. [Google Scholar] [CrossRef]

- Dey, S.; Børvik, T.; Hopperstad, O.S.; Leinum, J.R.; Langseth, M. The effect of target strength on the perforation of steel plates using three different projectile nose shapes. Int. J. Impact Eng. 2004, 30, 1005–1038. [Google Scholar] [CrossRef]

- Iqbal, M.A.; Senthil, K.; Sharma, P.; Gupta, N.K. An investigation of the constitutive behavior of Armox 500T steel and armor piercing incendiary projectile material. Int. J. Impact Eng. 2016, 96, 146–164. [Google Scholar] [CrossRef]

- Seo, S.; Min, O.; Yang, H. Constitutive equation for Ti–6Al–4V at high temperatures measured using the SHPB technique. Int. J. Impact Eng. 2005, 31, 735–754. [Google Scholar] [CrossRef]

- Ostos, J.B.; Rinaldi, R.G.; Hammetter, C.M.; Stucky, G.D.; Zok, F.W.; Jacobsen, A.J. Deformation stabilization of lattice structures via foam addition. Acta Mater. 2012, 60, 6476–6485. [Google Scholar] [CrossRef]

- Li, P.; Wang, Z.; Petrinic, N.; Siviour, C.R. Deformation behaviour of stainless steel microlattice structures by selective laser melting. Mater. Sci. Eng. A 2014, 614, 116–121. [Google Scholar] [CrossRef]

- Li, D.; Zhang, X.; Qin, R.; Xu, J.; Yue, D.; Chen, B. Influence of processing parameters on AlSi10Mg lattice structure during selective laser melting: Manufacturing defects, thermal behavior and compression properties. Opt. Laser Technol. 2023, 161, 109182. [Google Scholar] [CrossRef]

- Leo, P.; Antonio, D.P.; Teresa, P.; Michele, N. Al-Si10-Mg Manufactured by Selective Laser Melting: Microstructure Sensitivity to Close Values of the Heat Input. Metals 2023, 13, 590. [Google Scholar] [CrossRef]

- Tong, M.; Zhang, H.; Chen, C.; Hao, J.; Chen, Z.; Wang, F. Influence of laser power and scanning speed on microstructure evolutions and mechanical properties of the SLM fabricated Al–Mg–Mn–Sc–Zr alloy. J. Mater. Res. Technol. 2024, 33, 5018–5029. [Google Scholar] [CrossRef]

- Sghaier, T.A.M.; Sahlaoui, H.; Sallem, H.; Rech, J. Selective Laser Melting of Stainless-Steel: A Review of Process, Microstructure, Mechanical Properties and Post-Processing treatments. Int. J. Mater. Form. 2023, 16, 41. [Google Scholar] [CrossRef]

- Huang, M.; Yang, B.; Zhou, Y.; Guan, X.; Wang, Y.; Liao, Z. Effect of Processing Parameters on Tensile Properties and Microstructure of Selective Laser Melted AlSi10Mg Alloy. J. Mater. Eng. Perform. 2024, 34, 6001–6014. [Google Scholar] [CrossRef]

- Sara, G.; Susana, M.P.; Joaquín, B. Impact of the laser scanning strategy on the quality of 17-4PH stainless steel parts manufactured by selective laser melting. J. Mater. Res. Technol. 2022, 20, 2734–2747. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, Y.; Wang, D.; Xiao, Z.; Song, C.; Weng, C. Effect of heat treatment on the microstructure and mechanical properties of Ti6Al4V gradient structures manufactured by selective laser melting. Mater. Sci. Eng. A 2018, 736, 288–297. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Ayatollahi, M.R.; Reinicke, T. Effects of post-processing techniques on the mechanical characterization of additively manufactured parts. J. Manuf. Process. 2023, 107, 98–114. [Google Scholar] [CrossRef]

- Gautam, P.; Nag, A.; Hajnyš, J.; Měsíček, J.; Petrů, J. Investigating the impact of post-processing techniques on surface morphology and wettability of Inconel 718 components fabricated via selective laser melting. Eng. Sci. Technol. Int. J. 2025, 68, 102105. [Google Scholar] [CrossRef]

- Leo, P.; Riccardo, N.; Joaquin, B.; Sonia, B.; Claudio, M. Precipitation hardening stainless steel samples processed by additive manufacturing: Process parameters and thermo mechanical treatments effects on microstructure and corrosion resistance. Opt. Laser Technol. 2022, 156, 108547. [Google Scholar] [CrossRef]

- Tian, C.; Li, X.; Zhang, S.; Guo, G.; Ziegler, S.; Schleifenbaum, J.H.; Wang, L.; Rong, Y. Porous structure design and fabrication of metal-bonded diamond grinding wheel based on selective laser melting (SLM). Int. J. Adv. Manuf. Technol. 2019, 100, 1451–1462. [Google Scholar] [CrossRef]

- Maskery, I.; Aremu, A.O.; Parry, L.; Wildman, R.D.; Tuck, C.J.; Ashcroft, I.A. Effective design and simulation of surface-based lattice structures featuring volume fraction and cell type grading. Mater. Des. 2018, 155, 220–232. [Google Scholar] [CrossRef]

- Habib, F.N.; Iovenitti, P.; Masood, S.H.; Nikzad, M. Fabrication of polymeric lattice structures for optimum energy absorption using Multi Jet Fusion technology. Mater. Des. 2018, 155, 86–98. [Google Scholar] [CrossRef]

- Ahmadi, S.M.; Yavari, S.A.; Wauthle, R.; Pouran, B.; Schrooten, J.; Weinans, H.; Zadpoor, A.A. Additively Manufactured Open-Cell Porous Biomaterials Made from Six Different Space-Filling Unit Cells: The Mechanical and Morphological Properties. Materials 2015, 8, 1871–1896. [Google Scholar] [CrossRef]

- Płatek, P.; Sienkiewicz, J.; Janiszewski, J.; Jiang, F. Investigations on Mechanical Properties of Lattice Structures with Different Values of Relative Density Made from 316L by Selective Laser Melting (SLM). Materials 2020, 13, 2204. [Google Scholar] [CrossRef] [PubMed]

- Crupi, V.; Kara, E.; Epasto, G.; Guglielmino, E.; Aykul, H. Static behavior of lattice structures produced via direct metal laser sintering technology. Mater. Des. 2017, 135, 246–256. [Google Scholar] [CrossRef]

- Lei, H.; Li, C.; Meng, J.; Zhou, H.; Liu, Y.; Zhang, X.; Wang, P.; Fang, D. Evaluation of compressive properties of SLM-fabricated multi-layer lattice structures by experimental test and μ-CT-based finite element analysis. Mater. Des. 2019, 169, 107685. [Google Scholar] [CrossRef]

- Liu, L.; Kamm, P.; García-Moreno, F.; Banhart, J.; Pasini, D. Elastic and failure response of imperfect three-dimensional metallic lattices: The role of geometric defects induced by Selective Laser Melting. J. Mech. Phys. Solids 2017, 107, 160–184. [Google Scholar] [CrossRef]

- GB/T 7314-2017; Metallic Materials—Compression Test Method at Room Temperature. Standards Press of China: Beijing, China, 2017.

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standards Press of China: Beijing, China, 2021.

| Cell Number | Rod Diameter (mm) | Apparent Density (g/cm3) | Relative Density |

|---|---|---|---|

| #1 | 1.30 | 0.33 | 0.123 |

| #2 | 1.04 | 0.34 | 0.125 |

| #3 | 1.20 | 0.34 | 0.125 |

| #4 | 0.92 | 0.32 | 0.119 |

| #5 | 2.43 | 0.32 | 0.120 |

| #6 | 1.44 | 0.32 | 0.120 |

| #7 | 1.04 | 0.32 | 0.118 |

| #8 | 1.60 | 0.32 | 0.119 |

| Elements | Al | Mg | Sc | Mn | Zr | Fe | Ti | Si |

|---|---|---|---|---|---|---|---|---|

| Mass Fractions (%) | 92.91 | 4.83 | 0.65 | 0.36 | 0.26 | 0.06 | 0.05 | 0.04 |

| A (MPa) | B (MPa) | n | C | m |

|---|---|---|---|---|

| 448.2 | 1495.2 | 0.78 | −0.02119 | 0.20346 |

| Specimen | Tensile Modulus (MPa) | Yield Strength (MPa) | Tensile Strength (MPa) | Fracture Strain |

|---|---|---|---|---|

| V | 67,536.4 | 500.2 | 588.5 | 0.10 |

| H | 64,952.4 | 505.5 | 601.2 | 0.11 |

| Number | Relative Density | Young’s Modulus (MPa) | Compressive Strength (MPa) |

|---|---|---|---|

| 1-1 | 0.123 | 797.6 | 11.6 |

| 1-2 | 0.125 | 648.5 | 12.7 |

| 1-3 | 0.125 | 418.0 | 6.8 |

| 1-4 | 0.119 | 890.3 | 12.45 |

| 1-5 | 0.120 | 5511.0 | 19.2 |

| 1-6 | 0.120 | 1031.7 | 18.8 |

| 1-7 | 0.118 | 1437.4 | 20.1 |

| 1-8 | 0.119 | 341.3 | 6.3 |

| Number | Vertical Strut Existence | Maxwell Index | Specific Modulus (MPa/(g/cm3)) | Specific Strength (MPa/(g/cm3)) |

|---|---|---|---|---|

| 1-1 | Yes | −21 | 2416.97 | 35.15 |

| 1-2 | Yes | −36 | 1907.35 | 37.35 |

| 1-3 | No | −12 | 1229.41 | 20.00 |

| 1-4 | Yes | 0 | 2782.19 | 38.91 |

| 1-5 | Yes | 9 | 17,221.88 | 60.00 |

| 1-6 | No | 9 | 3224.06 | 58.75 |

| 1-7 | No | 12 | 4419.88 | 62.81 |

| 1-8 | no | 2 | 1066.56 | 19.69 |

| Number | Relative Density | Young’s Modulus (MPa) | Tensile Strength (MPa) |

|---|---|---|---|

| 2-1 | 0.123 | 1016.1 | 10.7 |

| 2-2 | 0.125 | 1060.1 | 7.2 |

| 2-3 | 0.125 | 555.0 | 7.1 |

| 2-4 | 0.119 | 1248.4 | 12.4 |

| 2-5 | 0.120 | 3301.8 | 18.6 |

| 2-6 | 0.120 | 1521.6 | 15.3 |

| 2-7 | 0.118 | 1540.9 | 19.1 |

| 2-8 | 0.119 | 276.7 | 5.6 |

| Number | Vertical Strut Existence | Maxwell Index | Specific Modulus (MPa/(g/cm3)) | Specific Strength (MPa/(g/cm3)) |

|---|---|---|---|---|

| 2-1 | Yes | −21 | 3079.1 | 32.4 |

| 2-2 | Yes | −36 | 3117.9 | 21.2 |

| 2-3 | No | −12 | 1632.4 | 20.9 |

| 2-4 | Yes | 0 | 3901.3 | 38.8 |

| 2-5 | Yes | 9 | 10,318.1 | 58.1 |

| 2-6 | No | 9 | 4755.0 | 47.8 |

| 2-7 | No | 12 | 4815.3 | 59.7 |

| 2-8 | no | 2 | 864.7 | 17.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Luo, Z.; Guo, Y.; Yan, Z.; Wang, Y. Quasi-Static Compression and Tensile Behavior of Additively Manufactured Al-Mg-Sc-Zr Alloy Lattices: The Role of Cell Topology. Metals 2025, 15, 1255. https://doi.org/10.3390/met15111255

Li J, Luo Z, Guo Y, Yan Z, Wang Y. Quasi-Static Compression and Tensile Behavior of Additively Manufactured Al-Mg-Sc-Zr Alloy Lattices: The Role of Cell Topology. Metals. 2025; 15(11):1255. https://doi.org/10.3390/met15111255

Chicago/Turabian StyleLi, Jingwen, Zhiwei Luo, Yanwu Guo, Zhenyu Yan, and Yangwei Wang. 2025. "Quasi-Static Compression and Tensile Behavior of Additively Manufactured Al-Mg-Sc-Zr Alloy Lattices: The Role of Cell Topology" Metals 15, no. 11: 1255. https://doi.org/10.3390/met15111255

APA StyleLi, J., Luo, Z., Guo, Y., Yan, Z., & Wang, Y. (2025). Quasi-Static Compression and Tensile Behavior of Additively Manufactured Al-Mg-Sc-Zr Alloy Lattices: The Role of Cell Topology. Metals, 15(11), 1255. https://doi.org/10.3390/met15111255