Investigation on High-Temperature Tensile and Wear Properties in an L-PBF-Fabricated TiB2-Reinforced Austenitic Steel

Abstract

1. Introduction

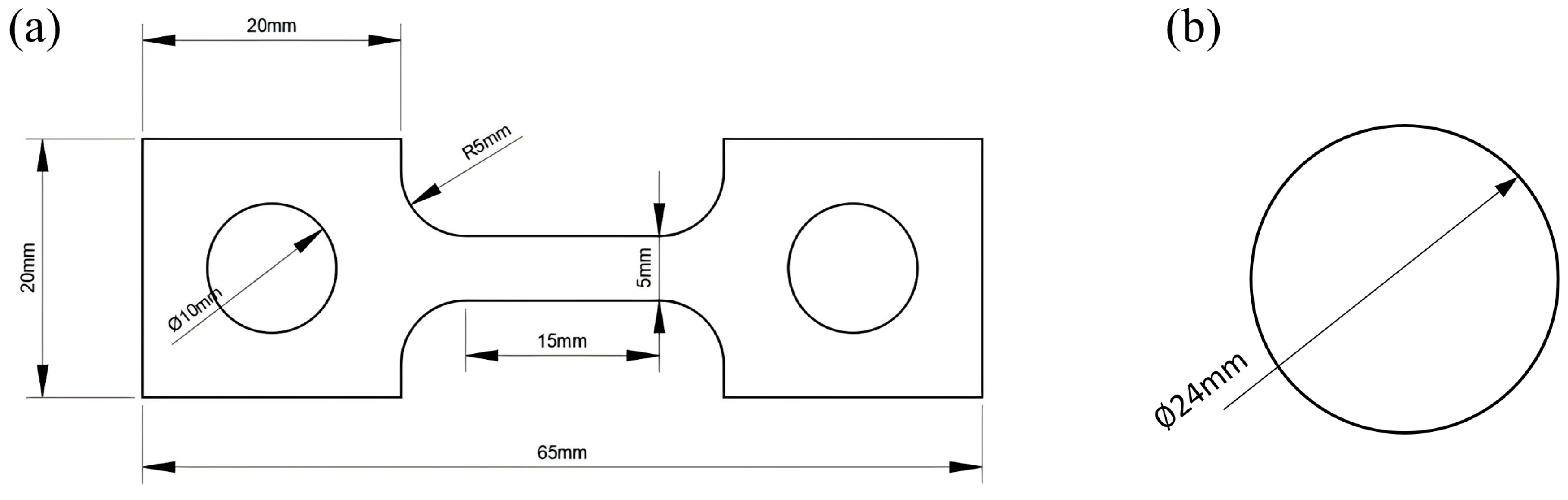

2. Materials and Methods

3. Results and Discussion

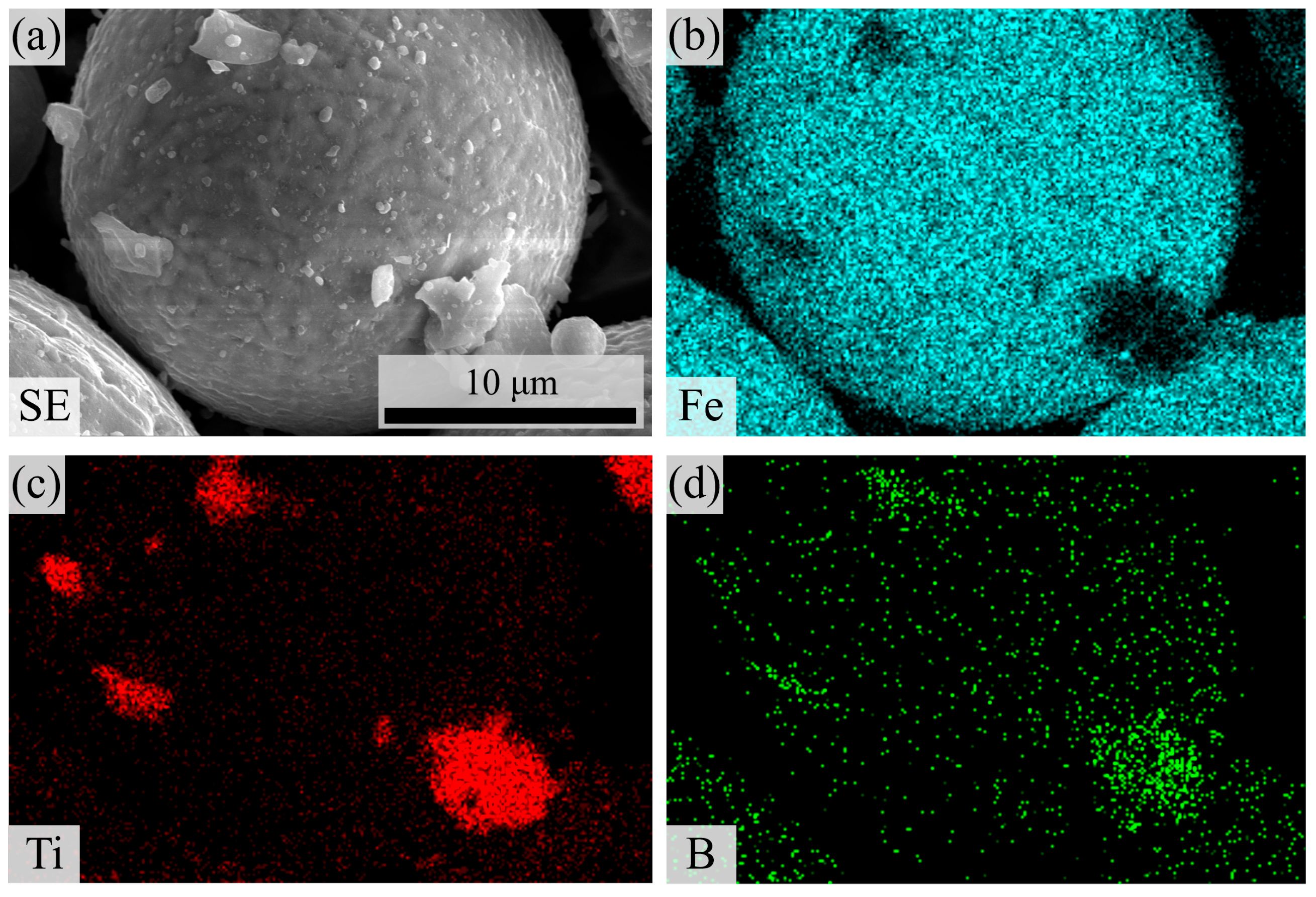

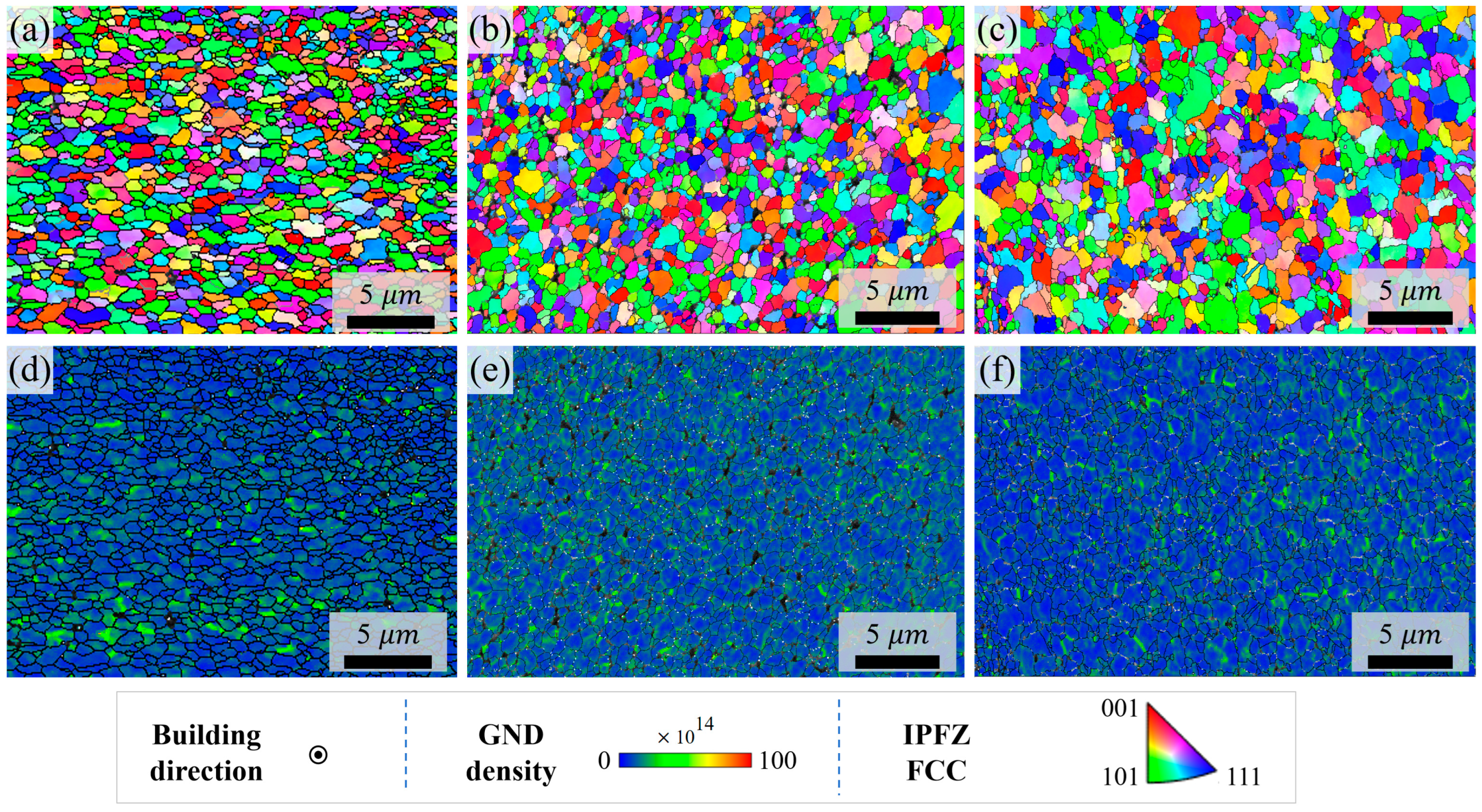

3.1. Composite Powder and L-PBF-Fabricated Samples Characterization

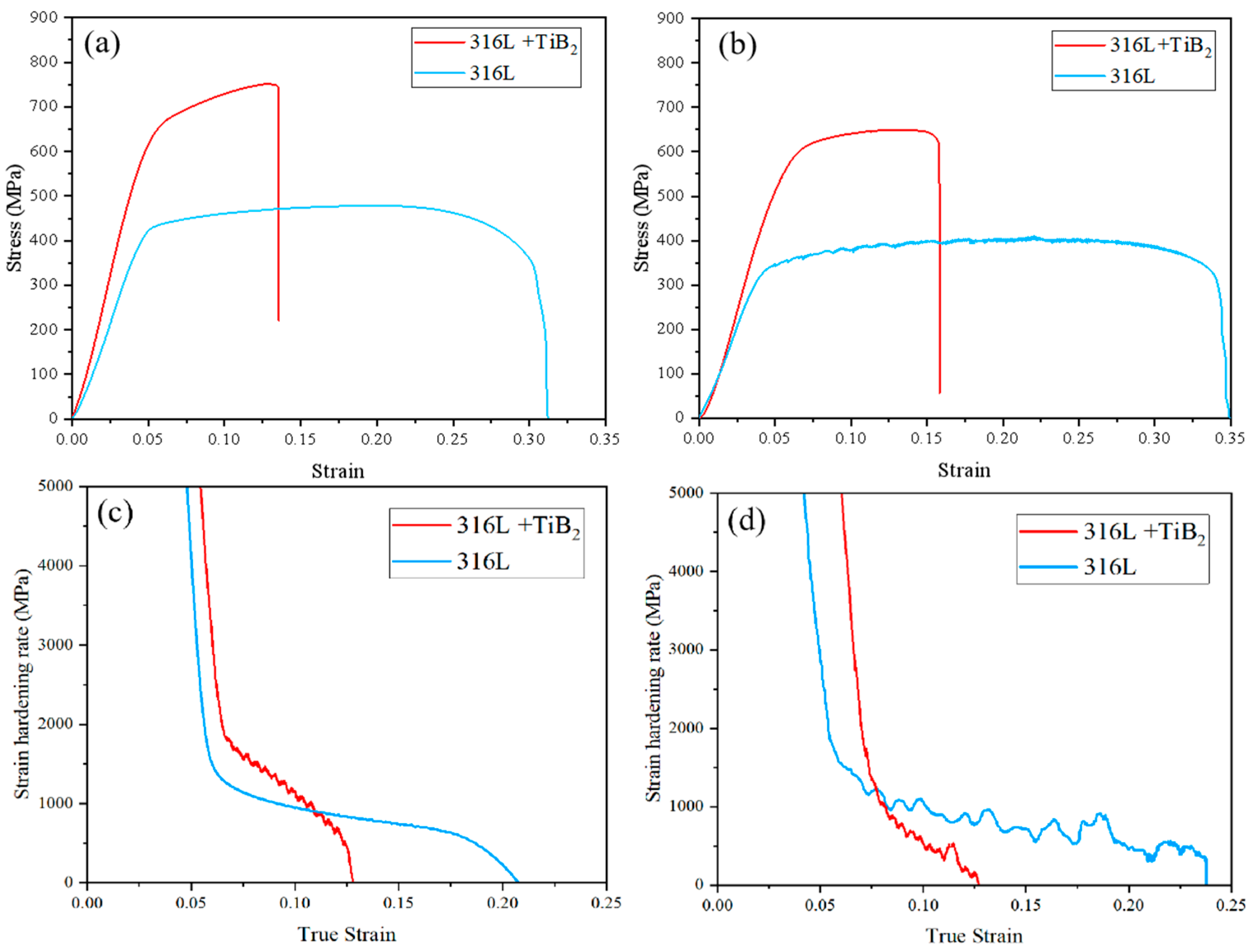

3.2. High-Temperature Tensile Properties and Fracture Behaviour of TiB2-Reinforced 316L Austenitic Steel

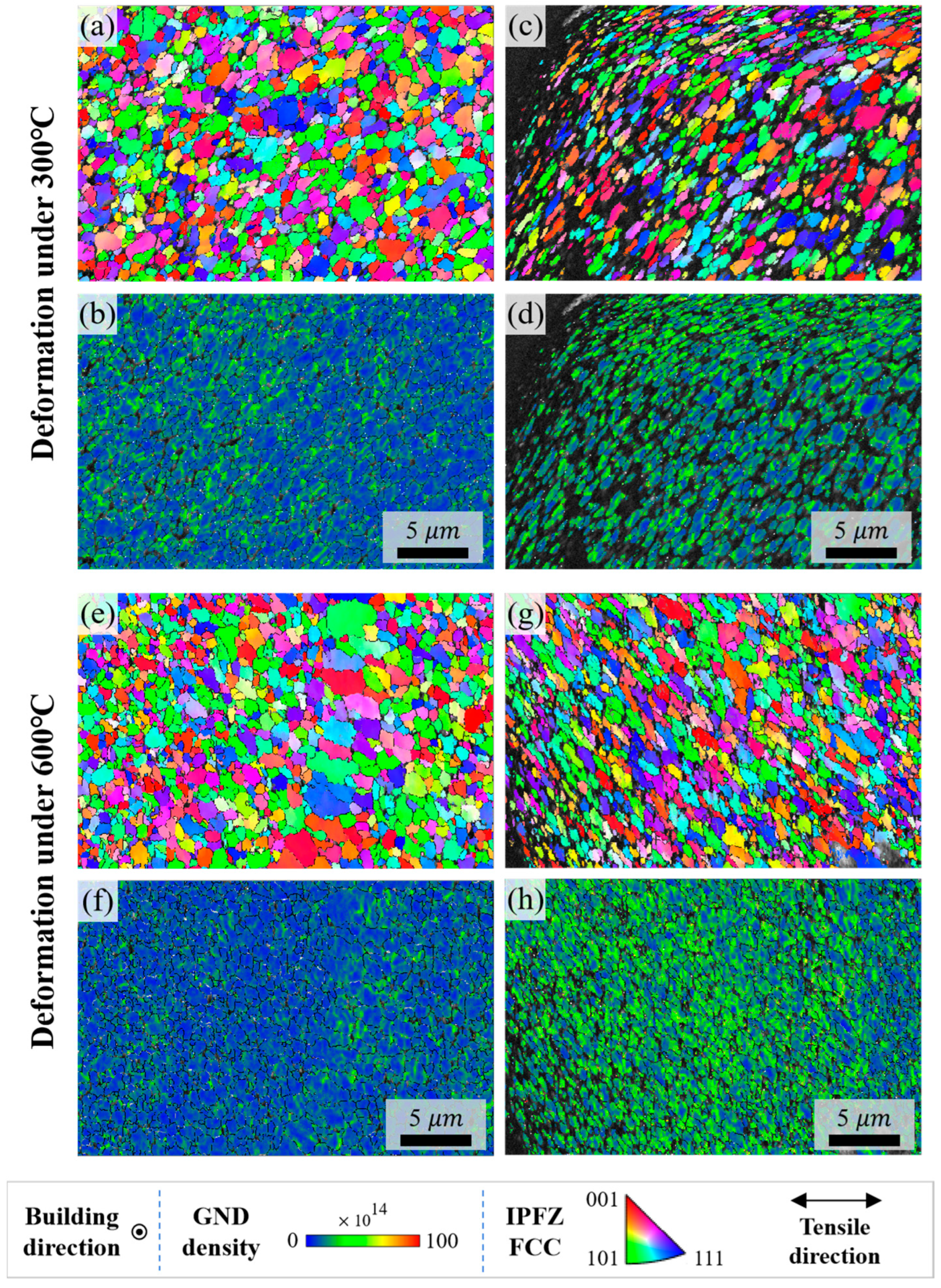

3.3. Microstructure Evolution Under High-Temperature Tensile Test

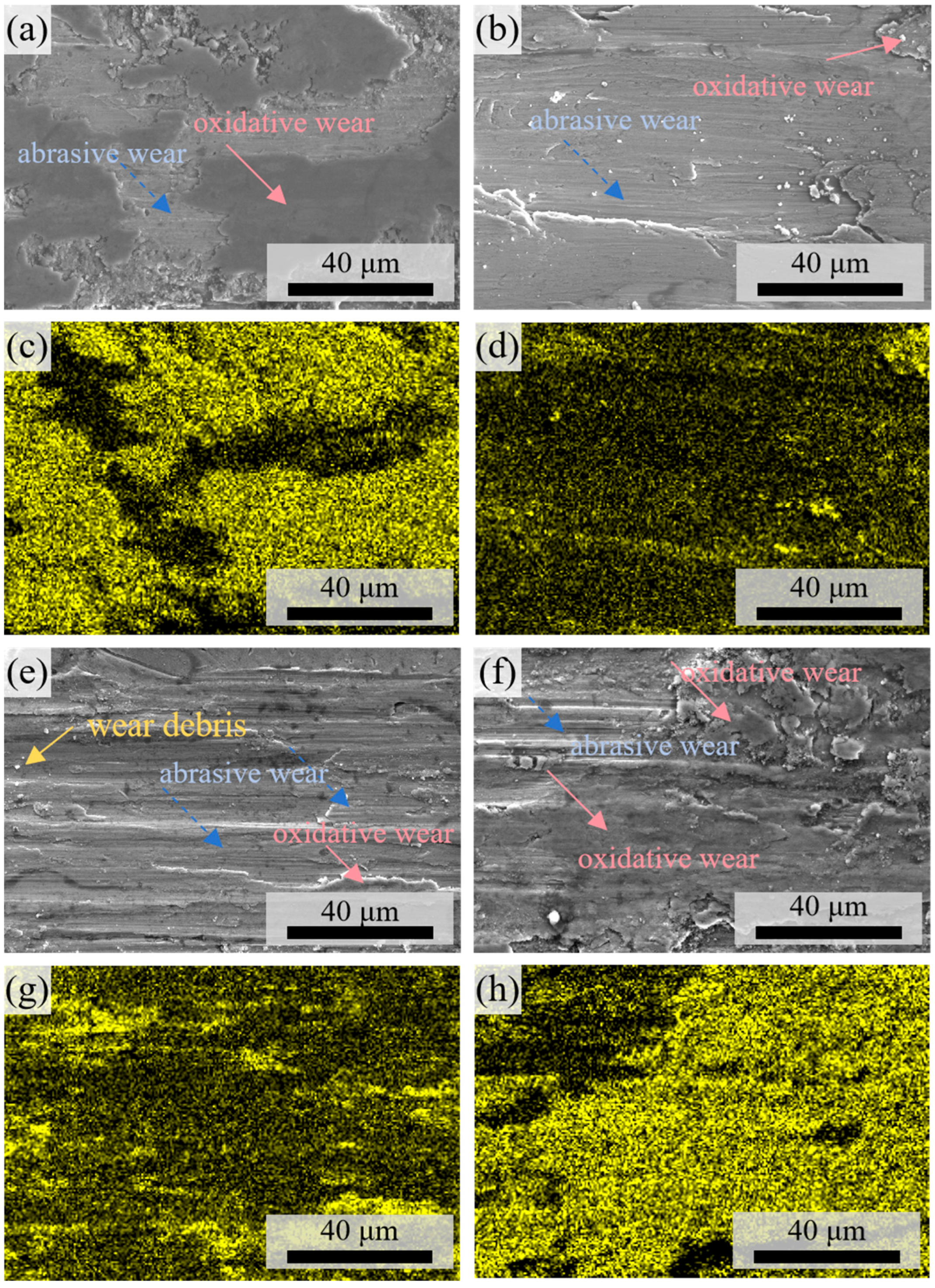

3.4. Wear Properties and Morphology

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mannan, M.S.; Jang, C. High temperature corrosion of wrought and wire arc additively manufactured 316L stainless steel in a simulated boiler environment. J. Mater. Res. Technol. 2024, 32, 4278–4292. [Google Scholar] [CrossRef]

- Zou, Y.; Tan, C.; Qiu, Z.; Ma, W.; Kuang, M.; Zeng, D. Additively manufactured SiC-reinforced stainless steel with excellent strength and wear resistance. Addit. Manuf. 2021, 41, 101971. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, R.; Qin, X.; Ouyang, W.; Wang, Z.; Wang, R. Investigations of the hybrid laser polishing and high-temperature tribological properties of the 316L stainless steel formed by selective laser melting. Tribol. Int. 2024, 200, 110152. [Google Scholar] [CrossRef]

- Wang, Y.; Li, T.; Gu, Z.; Yan, Z.; Di, R.; Lei, J. Effect of directional energy deposition of dual-scale WC particles on the anti-wear properties of 316L. Appl. Surf. Sci. 2025, 688, 162441. [Google Scholar] [CrossRef]

- Tjong, S.C.; Lau, K.C. Sliding wear of stainless steel matrix composite reinforced with TiB2 particles. Mater. Lett. 1999, 41, 153–158. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, D.; Jia, Y.; Wang, G.; Prashanth, K.G. Microstructure evolution and tensile property of high entropy alloy particle reinforced 316 L stainless steel matrix composites fabricated by laser powder bed fusion. J. Alloys Compd. 2023, 965, 171430. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, M.; Zhang, D.; Wang, E. Effect of rare-earth elements on microstructure and mechanical properties of in-situ Fe-TiB2 composites. Mater. Today Commun. 2021, 29, 102860. [Google Scholar] [CrossRef]

- Saxena, A.; Saxena, K.K.; Jain, V.K.; Rajput, S.K.; Pathak, B.N. A review of reinforcements and process parameters for powder metallurgy-processed metal matrix composites. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Zhang, H.; Springer, H.; Aparicio-Fernández, R.; Raabe, D. Improving the mechanical properties of Fe—TiB2 high modulus steels through controlled solidification processes. Acta Mater. 2016, 118, 187–195. [Google Scholar] [CrossRef]

- Wang, X.; Leng, H.; Han, B.; Wang, X.; Hu, B.; Luo, H. Solidified microstructures and elastic modulus of hypo-eutectic and hyper-eutectic TiB2-reinforced high-modulus steel. Acta Mater. 2019, 176, 84–95. [Google Scholar] [CrossRef]

- Wang, B.G.; Wang, G.D.; Misra, R.D.K.; Yi, H.L. Increased hot-formability and grain-refinement by dynamic recrystallization of ferrite in an in situ TiB2 reinforced steel matrix composite. Mater. Sci. Eng. A 2021, 812, 141100. [Google Scholar] [CrossRef]

- Nartu, M.S.K.K.Y.; Agrawal, P. Additive manufacturing of metal matrix composites. Mater. Des. 2025, 252, 113609. [Google Scholar] [CrossRef]

- Wang, Q.Z.; Lin, X.; Kang, N.; Wen, X.L.; Cao, Y.; Lu, J.L.; Peng, D.J.; Bai, J.; Zhou, Y.X.; El Mansori, M.; et al. Effect of laser additive manufacturing on the microstructure and mechanical properties of TiB2 reinforced Al-Cu matrix composite. Mater. Sci. Eng. A 2022, 840, 142950. [Google Scholar] [CrossRef]

- Al Mahmoud, Z.; Safaei, B.; Asmael, M.; Kenevisi, M.S.; Sahmani, S.; Karimzadeh, S.; Jen, T.-C.; Hui, D. Impact of process parameters on mechanical and microstructure properties of aluminum alloys and aluminum matrix composites processed by powder-based additive manufacturing. J. Manuf. Process. 2025, 146, 79–158. [Google Scholar] [CrossRef]

- AlMangour, B.; Baek, M.-S.; Grzesiak, D.; Lee, K.-A. Strengthening of stainless steel by titanium carbide addition and grain refinement during selective laser melting. Mater. Sci. Eng. A 2018, 712, 812–818. [Google Scholar] [CrossRef]

- Zhai, W.; Zhou, W.; Nai, S.M.L. In-situ formation of TiC nanoparticles in selective laser melting of 316L with addition of micronsized TiC particles. Mater. Sci. Eng. A 2022, 829, 142179. [Google Scholar] [CrossRef]

- Zhai, W.; Zhou, W.; Yu, Y.; Nai, S.M.L. Direct evidence of melting and decomposition of TiC particles in laser powder bed fusion processed 316L-TiC composite. J. Mater. Sci. Technol. 2024, 198, 166–175. [Google Scholar] [CrossRef]

- AlMangour, B.; Kim, Y.-K.; Grzesiak, D.; Lee, K.-A. Novel TiB2-reinforced 316 L stainless steel nanocomposites with excellent room- and high-temperature yield strength developed by additive manufacturing. Compos. Part B Eng. 2019, 156, 51–63. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Jenn, M. Selective laser melting of TiC reinforced 316 L stainless steel matrix nanocomposites: Influence of starting TiC particle size and volume content. Mater. Des. 2016, 104, 141–151. [Google Scholar] [CrossRef]

- Gain, A.K.; Cui, Y.; Zhang, L. Wear mechanism and subsurface structure of ultra-fine-grained stainless steel-titanium boride nanocomposites fabricated via selective laser melting. Wear 2025, 571, 205788. [Google Scholar] [CrossRef]

- Karan, B.; Tan, Q.; Moheimani, K.; Wang, F.; Bhowmik, A.; Zhang, M. Enhancement of tribological properties by reinforcing 316L stainless steel with nano ceramics fabricated by laser powder bed fusion. Wear 2025, 582–583, 206334. [Google Scholar] [CrossRef]

- ASTM E21-20; Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM G99-23; Standard Test Method for Wear and Friction Testing with a Pin-on-Disk or Ball-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2023.

- Gain, A.K.; Cui, Y.; Zhang, L.; Li, Z. Mechanical properties of additively manufactured ultrafine grain stainless steel-titanium boride (SS–TiB2) nanocomposites. Mater. Sci. Eng. A 2024, 911, 146961. [Google Scholar] [CrossRef]

- Zhang, K.; Gao, Y.; Zhang, A.; Chen, Z.; Zhao, J.; Song, Y.; He, W.; Dong, Z.; Yang, Y.; Song, J.; et al. Excellent high temperature mechanical properties of Mg-5Y-0.6La composites reinforced by Al2Y-TiB2 particles. J. Alloys Compd. 2025, 1038, 182683. [Google Scholar] [CrossRef]

- Liu, J.K.; Li, Y.Z.; Zhuang, Q.D.; Huang, M.X.; Xu, W. Low-density and high-modulus steel achieved by hypereutectic TiB2 and high Al ferrite phase. J. Mater. Sci. Technol. 2026, 258, 83–99. [Google Scholar] [CrossRef]

- Bae, J.-S.; Lim, K.-H.; Chandra, S.; Tan, X.; Sim, G.-D. Exploring the high-temperature tensile behavior of additively manufactured 316 L stainless steel with fine equiaxed grains. J. Mater. Res. Technol. 2025, 36, 9790–9802. [Google Scholar] [CrossRef]

- Shuai, L.; Huang, T.; Yu, T.; Wu, G.; Hansen, N.; Huang, X. Segregation and precipitation stabilizing an ultrafine lamellar-structured Al-0.3%Cu alloy. Acta Mater. 2021, 206, 116595. [Google Scholar] [CrossRef]

- Huang, M.; Wang, L.; Yuan, S.; Wang, J.; Wang, C.; Mogucheva, A.; Xu, W. Scale-up fabrication of gradient AGS in austenitic stainless steels achieves a simultaneous increase in strength and toughness. Mater. Sci. Eng. A 2022, 853, 143763. [Google Scholar] [CrossRef]

- Huang, M.; Wang, L.; Wang, C.; Li, Y.; Wang, J.; Yuan, J.; Hu, J.; Huang, M.; Xu, W. Optimizing crack initiation energy in austenitic steel via controlled martensitic transformation. J. Mater. Sci. Technol. 2024, 198, 231–242. [Google Scholar] [CrossRef]

- Allain, S.; Chateau, J.P.; Bouaziz, O.; Migot, S.; Guelton, N. Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe–Mn–C alloys. Mater. Sci. Eng. A 2004, 387–389, 158–162. [Google Scholar] [CrossRef]

- Li, S.; Withers, P.J.; Deng, Y.; Yan, K. Deformation microstructures and martensitic transformation pathways in cryogenically deformed 316 L stainless steel. J. Mater. Sci. 2024, 59, 2134–2154. [Google Scholar] [CrossRef]

- Yetim, A.F.; Tekdir, H.; Turalioglu, K.; Taftali, M.; Yetim, T. Tribological behavior of plasma-sprayed Yttria-stabilized zirconia thermal barrier coatings on 316 L stainless steel under high-temperature conditions. Mater. Lett. 2023, 336, 133873. [Google Scholar] [CrossRef]

- Wen, S.; Hu, H.; Zhou, Y.; Chen, Z.; Wei, Q.; Shi, Y. Enhanced hardness and wear property of S136 mould steel with nano-TiB2 composites fabricated by selective laser melting method. Appl. Surf. Sci. 2018, 457, 11–20. [Google Scholar] [CrossRef]

- Zhai, W.; Bai, L.; Zhou, R.; Fan, X.; Kang, G.; Liu, Y.; Zhou, K. Recent Progress on Wear-Resistant Materials: Designs, Properties, and Applications. Adv. Sci. 2021, 8, 2003739. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, M.; Chen, Y. Investigation on High-Temperature Tensile and Wear Properties in an L-PBF-Fabricated TiB2-Reinforced Austenitic Steel. Metals 2025, 15, 1233. https://doi.org/10.3390/met15111233

Huang M, Chen Y. Investigation on High-Temperature Tensile and Wear Properties in an L-PBF-Fabricated TiB2-Reinforced Austenitic Steel. Metals. 2025; 15(11):1233. https://doi.org/10.3390/met15111233

Chicago/Turabian StyleHuang, Minghao, and Yutong Chen. 2025. "Investigation on High-Temperature Tensile and Wear Properties in an L-PBF-Fabricated TiB2-Reinforced Austenitic Steel" Metals 15, no. 11: 1233. https://doi.org/10.3390/met15111233

APA StyleHuang, M., & Chen, Y. (2025). Investigation on High-Temperature Tensile and Wear Properties in an L-PBF-Fabricated TiB2-Reinforced Austenitic Steel. Metals, 15(11), 1233. https://doi.org/10.3390/met15111233