Numerical Simulation of the Differential Influence of Work Roll and Intermediate Roll Profiles on Strip Shape

Abstract

1. Introduction

2. Strip Profile Evaluation

3. Establishment of the Integrated Finite Element Model for Rolls and Strip

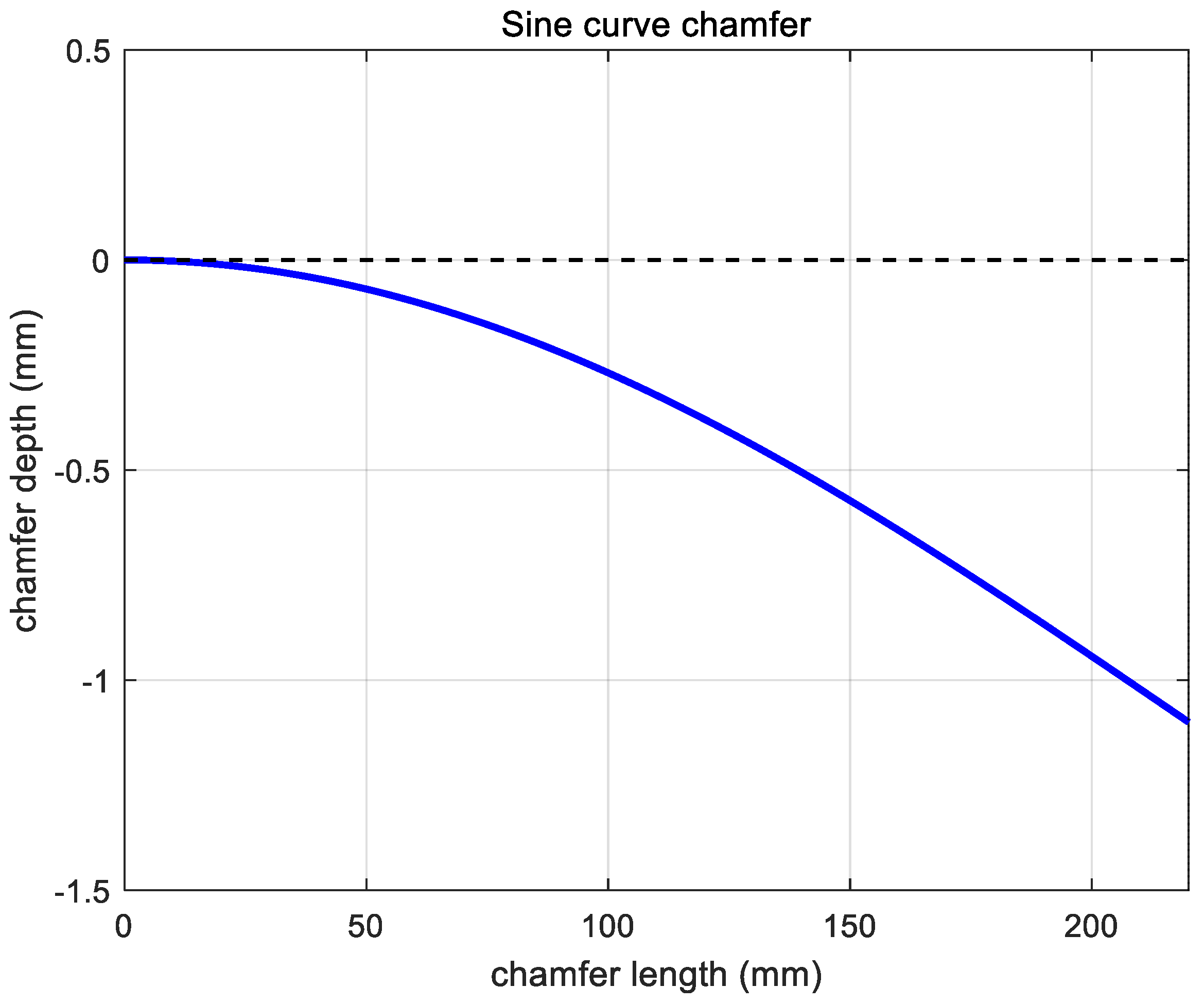

3.1. Roll Profile Curve

3.2. Modeling Parameters

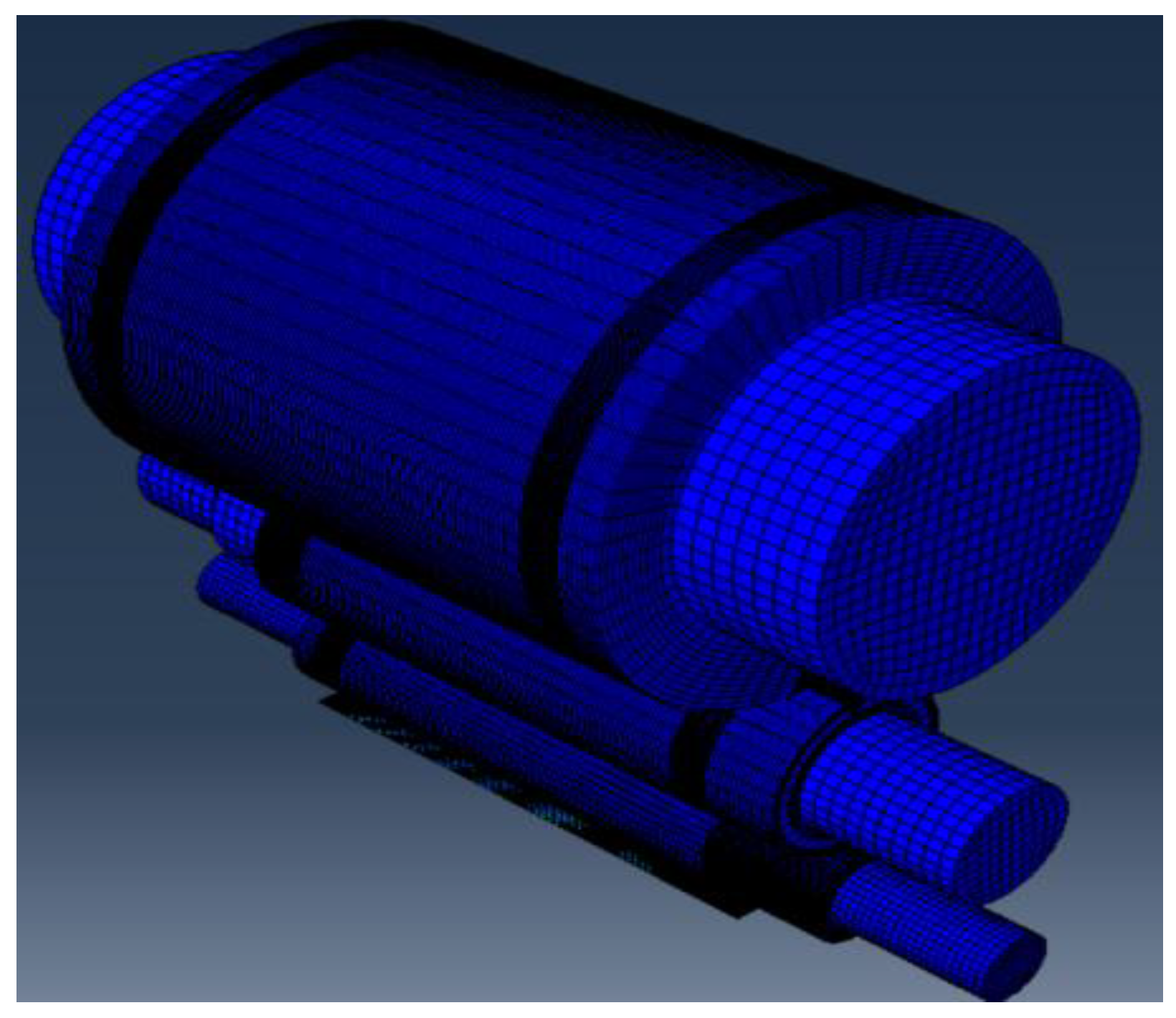

3.2.1. Geometric Model and Boundary Conditions

3.2.2. Material Properties

3.2.3. Contact and Friction Modeling

3.2.4. Meshing and Independence Study

3.2.5. Simulation Procedure

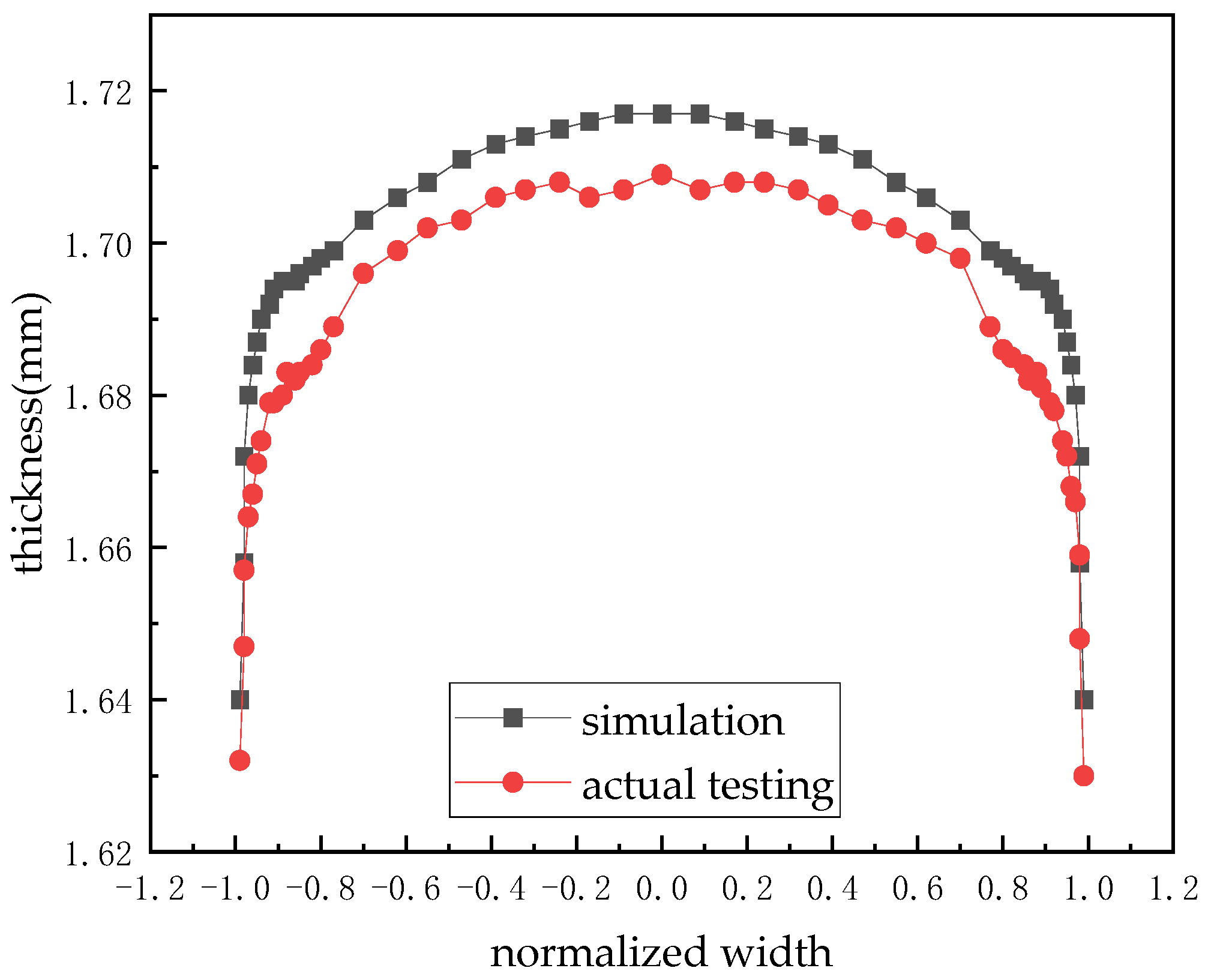

3.3. Finite Element Model Accuracy Verification

3.4. Model Robustness and Generality Analysis

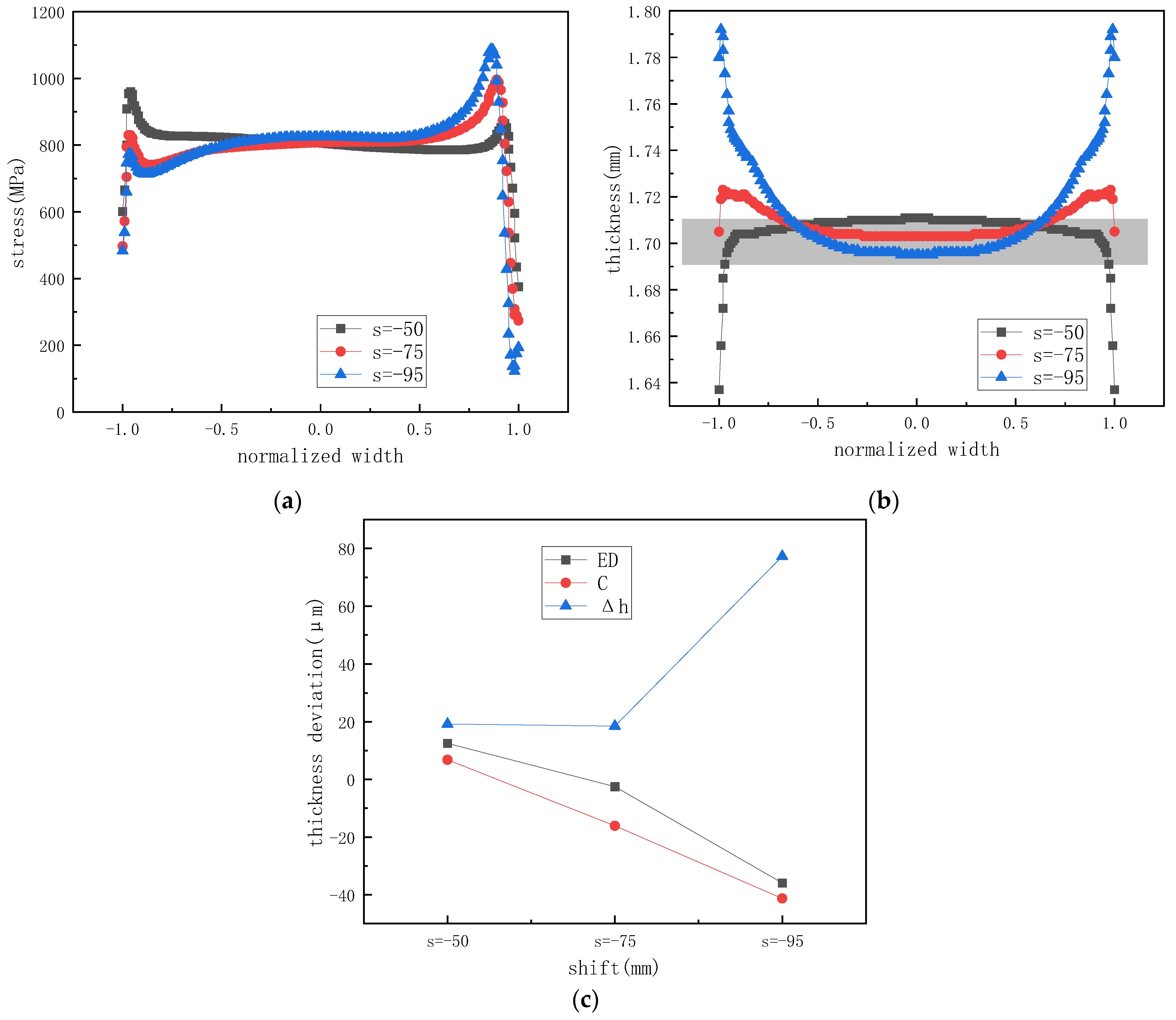

4. Analysis of the Influence of Single-Taper Roll Profile

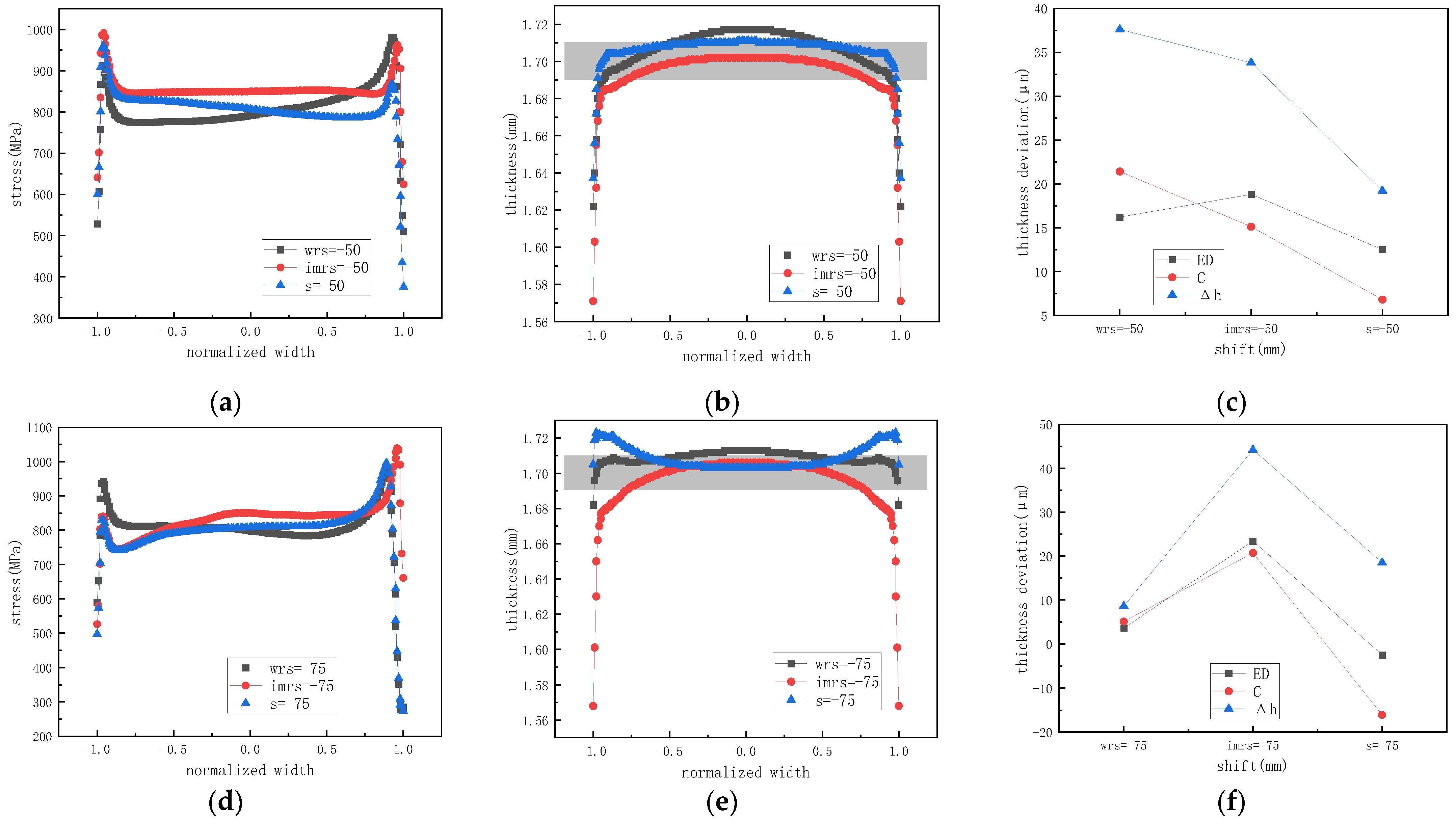

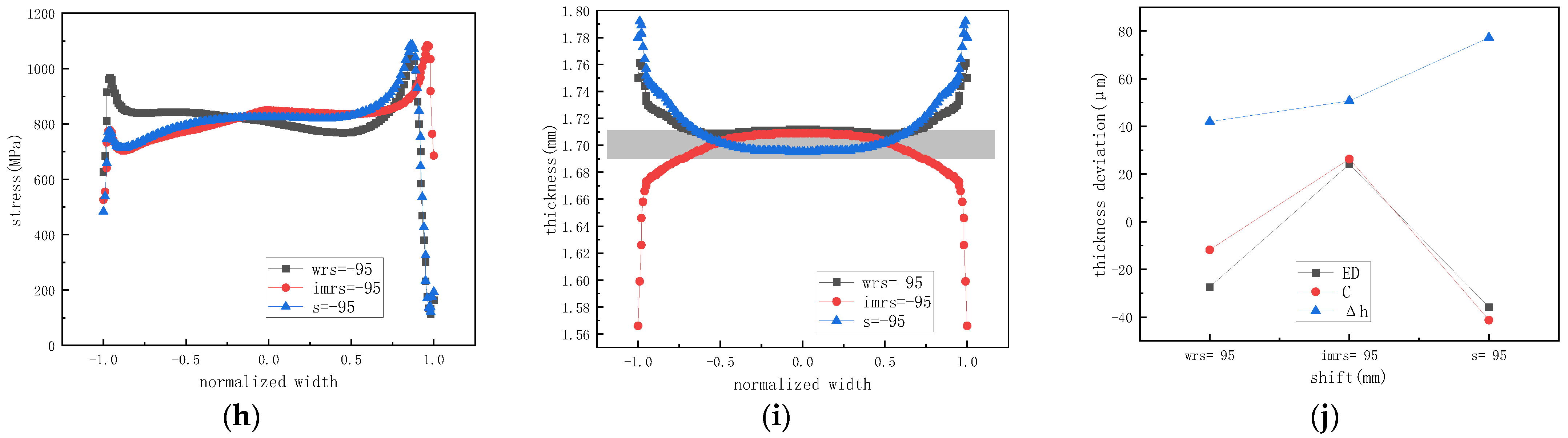

4.1. Influence of Work Roll Profile

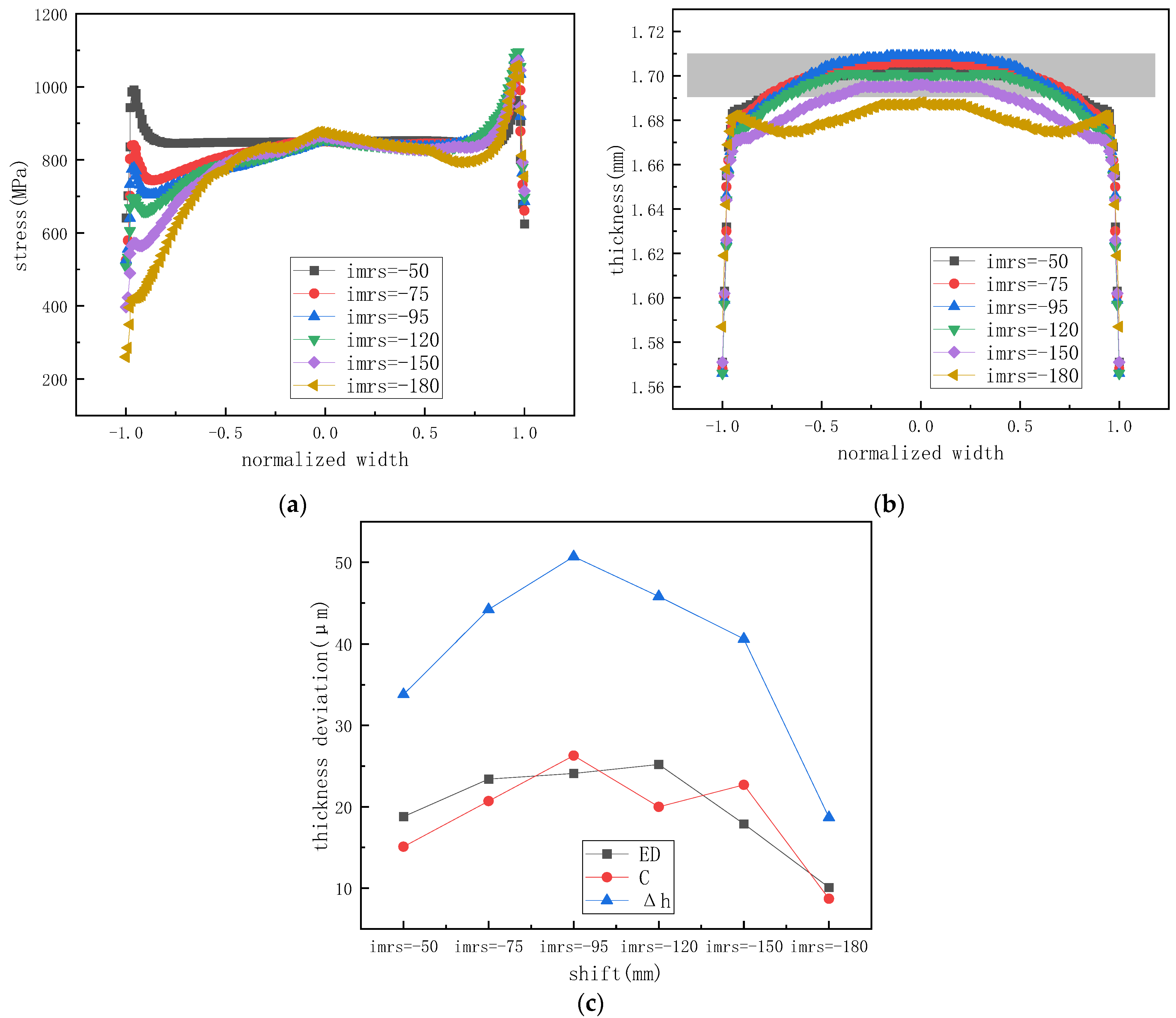

4.2. Influence of Intermediate Roll Profile

4.3. Influence of Combined Work Roll and Intermediate Roll Profiles

4.4. Comparison of Roll Profile Configurations

5. Conclusions

5.1. Summary of Findings

5.2. Engineering Guidance

5.3. Limitations and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wei, Z.; Wang, G.Q.; Sun, J.; Peng, W.; Zhang, D.H. Development of Cold-Rolling Edge-Drop Control Technology for Electrical Steel: A Review. Steel Res. Int. 2023, 94, 2200919. [Google Scholar] [CrossRef]

- Li, H.B.; Zhao, Z.W.; Dong, D.W.; Han, G.M.; Zhang, J.; Liu, H.C.; You, X.C. Edge-Drop Control Behavior for Silicon Strip Cold Rolling with a Sendzimir Mill. Metals 2018, 8, 783. [Google Scholar] [CrossRef]

- Wang, X.C.; Yang, Q.; Sun, Y.Z. Rectangular Section Control Technology for Silicon Steel Rolling. J. Iron Steel Res. Int. 2015, 22, 185–191. [Google Scholar] [CrossRef]

- He, H.N.; Dai, Z.H.; Wang, X.C.; Yang, Q.; Shao, J.; Li, J.D.; Zhang, Z.H. Whole Process Prediction Model of Silicon Steel Strip on Transverse Thickness Difference Based on Takagi-Sugeno Fuzzy Network. J. Iron Steel Res. Int. 2023, 30, 2448–2458. [Google Scholar] [CrossRef]

- Cao, J.G.; Chai, X.T.; Li, Y.L.; Kong, N.; Jia, S.H.; Zeng, W. Integrated Design of Roll Contours for Strip Edge Drop and Crown Control in Tandem Cold Rolling Mills. J. Mater. Process. Technol. 2018, 252, 432–439. [Google Scholar] [CrossRef]

- Ginzburg, V.B. Steel-Rolling Technology: Theory and Practice, 1st ed.; CRC Press: Boca Raton, FL, USA, 1989. [Google Scholar]

- Karagiozis, A.; Lenard, J. Temperature distribution in a slab during hot rolling. ASME J. Eng. Mater. Technol. 1988, 110, 17–21. [Google Scholar] [CrossRef]

- He, H.N.; Shao, J.; Wang, X.C.; Yang, Q.; Feng, X.W. Silicon Steel Strip Profile Control Technology for Six-High Cold Rolling Mill with Small Work Roll Radius. Metals 2020, 10, 401. [Google Scholar] [CrossRef]

- He, H.N.; Shao, J.; Wang, X.C.; Yang, Q.; Liu, Y.; Xu, D.; Sun, Y.Z. Research and Application of Approximate Rectangular Section Control Technology in Hot Strip Mills. J. Iron Steel Res. Int. 2021, 28, 279–290. [Google Scholar] [CrossRef]

- Tao, H.; Li, H.B.; Shao, J.; Zhang, J.; Liu, Y.J.; You, X.C. Research on Shape Control Characteristics of Non-Oriented Silicon Steel for UCMW Cold Rolling Mill. Metals 2020, 10, 1066. [Google Scholar] [CrossRef]

- Wang, Q.L.; Sun, J.; Liu, Y.M.; Wang, P.F.; Zhang, D.H. Numerical and Experimental Analysis of Strip Cross-Directional Control and Flatness Prediction for UCM Cold Rolling Mill. Int. J. Adv. Manuf. Technol. 2018, 94, 1371–1389. [Google Scholar] [CrossRef]

- Wang, Q.L.; Sun, J.; Liu, Y.M.; Wang, P.F.; Zhang, D.H. Analysis of Symmetrical Flatness Actuator Efficiencies for UCM Cold Rolling Mill by 3D Elastic-Plastic FEM. Int. J. Adv. Manuf. Technol. 2017, 92, 1371–1389. [Google Scholar] [CrossRef]

- Wang, Q.L.; Sun, J.; Liu, Y.M.; Wang, P.F.; Zhang, D.H. Optimization of Flatness Actuator Efficiency in Cold Rolling Process Based on Finite Element Simulation and Process Data Processing. Steel Res. Int. 2022, 93, 2100314. [Google Scholar] [CrossRef]

- Li, H.B.; Zhao, Z.W.; Zhang, J.; Kong, N.; Bao, R.R.; Jia, S.H.; He, F. Analysis of Flatness Control Capability Based on the Effect Function and Roll Contour Optimization for 6-h CVC Cold Rolling Mill. Int. J. Adv. Manuf. Technol. 2019, 100, 2387–2399. [Google Scholar] [CrossRef]

- Han, G.M.; Li, H.B.; Wang, G.; Liu, Y.J.; Zhang, J.; Hu, Z.Y.; You, X.C.; Xie, Y. Prediction and Control of Profile for Silicon Steel Strip in the Whole Tandem Cold Rolling Based on PSO-BP Algorithm. J. Manuf. Process. 2024, 120, 250–259. [Google Scholar] [CrossRef]

- Song, C.N.; Cao, J.G.; Wang, L.L.; Xiao, J.; Zhao, Q.F. The Prediction of Transverse Thickness Difference for 6-High Tandem Cold Rolling Mills Based on GA-PSO-SVR. Steel Res. Int. 2022, 93, 2200302. [Google Scholar] [CrossRef]

- Song, C.N.; Cao, J.G.; Li, Y.L.; Kong, N.; Jia, S.H.; Zeng, W. Control Strategy of Multi-Stand Work Roll Bending and Shifting on the Crown for UVC Hot Rolling Mill Based on MOGPR Approach. J. Manuf. Process. 2023, 85, 832–843. [Google Scholar] [CrossRef]

- Song, C.N.; Cao, J.G.; Wang, L.L.; Xiao, J.; Zhao, Q.F. Transverse Thickness Profile Control of Electrical Steel in 6-High Cold Rolling Mills Based on the GA-PSO Hybrid Algorithm. Int. J. Adv. Manuf. Technol. 2022, 121, 295–308. [Google Scholar] [CrossRef]

- Wang, Z.; Jin, X.; Li, C.S.; Wang, Y.; Li, X.G.; Guo, T.; Xiang, Y.G. Multi-Objective Optimization of Intermediate Roll Profile for a 6-High Cold Rolling Mill. Metals 2020, 10, 287. [Google Scholar] [CrossRef]

- Wang, Q.L.; Sun, J.; Peng, W.; Zhang, D.H. Edge Drop Control Characteristics of the Taper-Work Roll Contour for Six-High Cold Mill. Steel Res. Int. 2023, 94, 2300077. [Google Scholar]

- Chen, Y.F.; Peng, L.G.; Feng, P.J.; Zhou, Y.L.; Li, C.S. Optimization of Multi-Segment Work Roll Profile for 1340mm HC Tandem Cold-Rolling Mills Based on DBSCAN and NSGA-II Algorithms. Steel Res. Int. 2023, 94, 2300077. [Google Scholar] [CrossRef]

- Wang, X.C.; Yang, Q.; He, H.N.; Sun, Y.Z.; Xu, D.; Liu, Y. Effect of Work Roll Shifting Control on Edge Drop for 6-Hi Tandem Cold Mills Based on Finite Element Method Model. Int. J. Adv. Manuf. Technol. 2020, 107, 2497–2511. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Z.; Chen, S.; Wang, X. Finite Element Analysis of Strip Shape Regulation Ability of Work Roll Shifting. J. Manuf. Process. 2023, 104, 512–523. [Google Scholar]

- Liu, X.; Zhao, T.; Peng, Y.; Zhang, D. Roll Profile and Roll Shifting Strategy for Silicon Steel Edge Drop. J. Manuf. Process. 2024, 107, 586–598. [Google Scholar]

- Wang, R.; Xu, J.; Tang, C.; Zhou, Y. Prediction and Control of Profile for Silicon Steel Strip in Whole Tandem Cold Rolling. J. Manuf. Process. 2024, 106, 409–421. [Google Scholar]

- Li, C.; Sun, Y.; Feng, J.; Yang, Q. A Novel Paradigm of Flatness Prediction and Optimization for Strip Using Machine Learning-Based Models. J. Mater. Process. Technol. 2023, 321, 118016. [Google Scholar]

- Huang, S.; Wu, Y.; Li, M.; Zhou, F. Careful Finite Element Simulations of Cold Rolling with Accurate Through-Thickness Resolution and Prediction of Residual Stress. Steel Res. Int. 2024, 95, 2301004. [Google Scholar]

- Chen, L.; Gao, Y.; Liu, R.; Xu, Q. Industrial IoT-Enabled Real-Time Prediction of Strip Cross-Section Shape for Hot-Rolling Steel. Int. J. Adv. Manuf. Technol. 2023, 128, 4721–4735. [Google Scholar]

- Zhao, W.; Han, B.; Zhang, L.; Chen, J. Modeling and Simulation of Shape Control Based on Digital Twin Technology in Hot Strip Rolling. Sensors 2024, 24, 614. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Work Roll Body × Length (mm) | |

| Work Roll Diameter × Length (mm) | |

| Intermediate Roll Body × Length (mm) | |

| Intermediate Roll Diameter × Length (mm) | |

| Backup Roll Body × Length (mm) | |

| Backup Roll Diameter × Length (mm) | |

| Strip Thickness × Width × Length (mm) | |

| Strip Yield Strength (MPa) | 520 |

| Rolling Force (kN) | 15,500 |

| Front Tension (MPa) | 180 |

| Rear Tension (MPa) | 60 |

| Work Roll Bend Force (kN) | 50 |

| Intermediate Roll Bend Force (kN) | 200 |

| Work Roll Shift Range (mm) | −50~−100 |

| Intermediate Roll Shift Range (mm) | −50~−100 |

| Roll Friction Coefficient | 0.1 |

| Work Roll-Strip Friction Coefficient | 0.05 |

| Case | Strip Width (mm) | Rolling Force (kN) | RMSE (μm) | Crown Error (μm) |

|---|---|---|---|---|

| A | 1200 | 15,500 | 8.2 | +3.8 |

| B | 1320 | 17,000 | 7.1 | −3.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Li, H.; You, X.; Zhao, H. Numerical Simulation of the Differential Influence of Work Roll and Intermediate Roll Profiles on Strip Shape. Metals 2025, 15, 1226. https://doi.org/10.3390/met15111226

Liu Y, Li H, You X, Zhao H. Numerical Simulation of the Differential Influence of Work Roll and Intermediate Roll Profiles on Strip Shape. Metals. 2025; 15(11):1226. https://doi.org/10.3390/met15111226

Chicago/Turabian StyleLiu, Yujin, Hongbo Li, Xuechang You, and Hairui Zhao. 2025. "Numerical Simulation of the Differential Influence of Work Roll and Intermediate Roll Profiles on Strip Shape" Metals 15, no. 11: 1226. https://doi.org/10.3390/met15111226

APA StyleLiu, Y., Li, H., You, X., & Zhao, H. (2025). Numerical Simulation of the Differential Influence of Work Roll and Intermediate Roll Profiles on Strip Shape. Metals, 15(11), 1226. https://doi.org/10.3390/met15111226