Impact Butt Joining of Copper C1100 and Aluminum Alloy A6061-T6 Plates and Rolling of Joined Plate

Abstract

1. Introduction

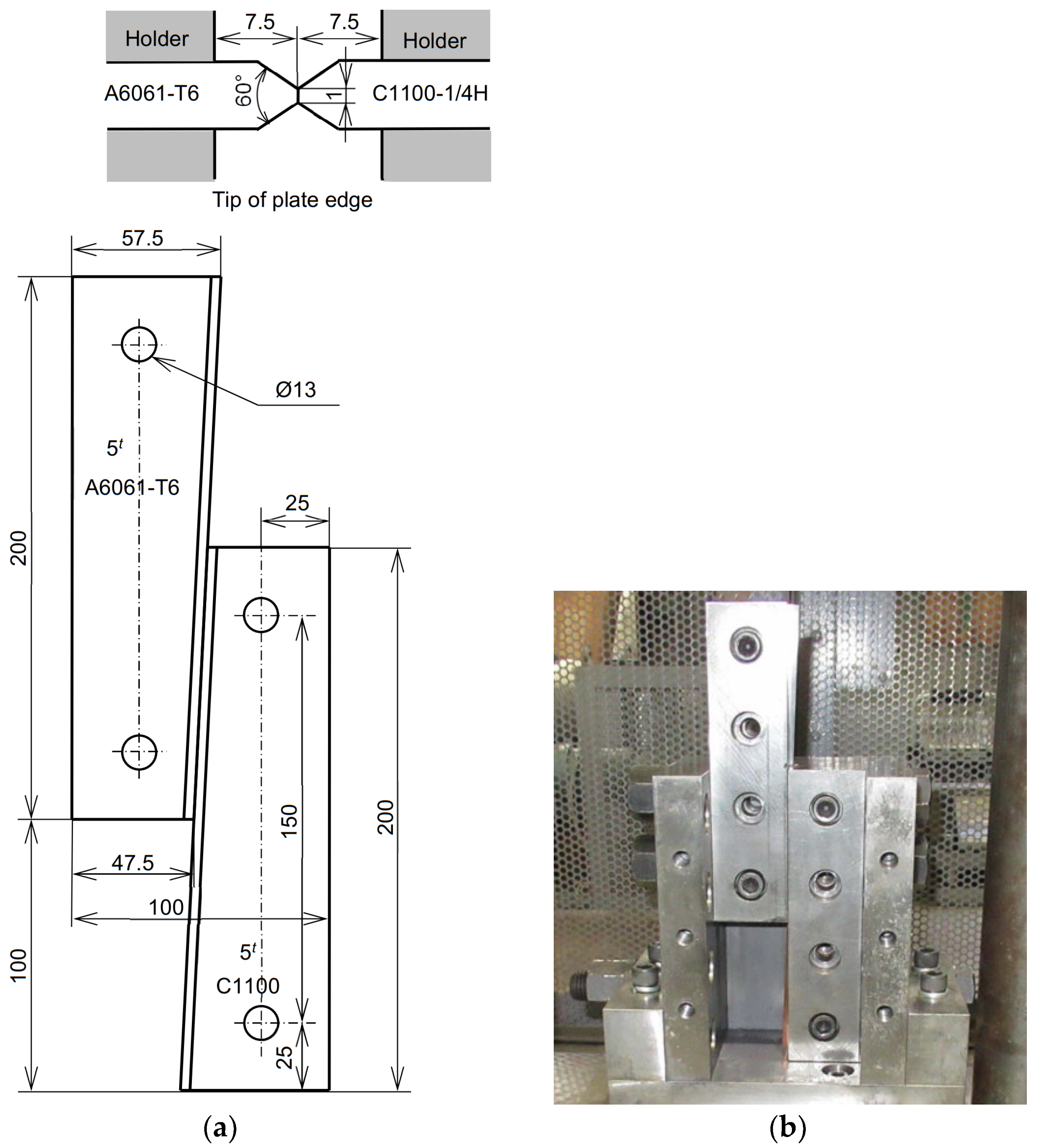

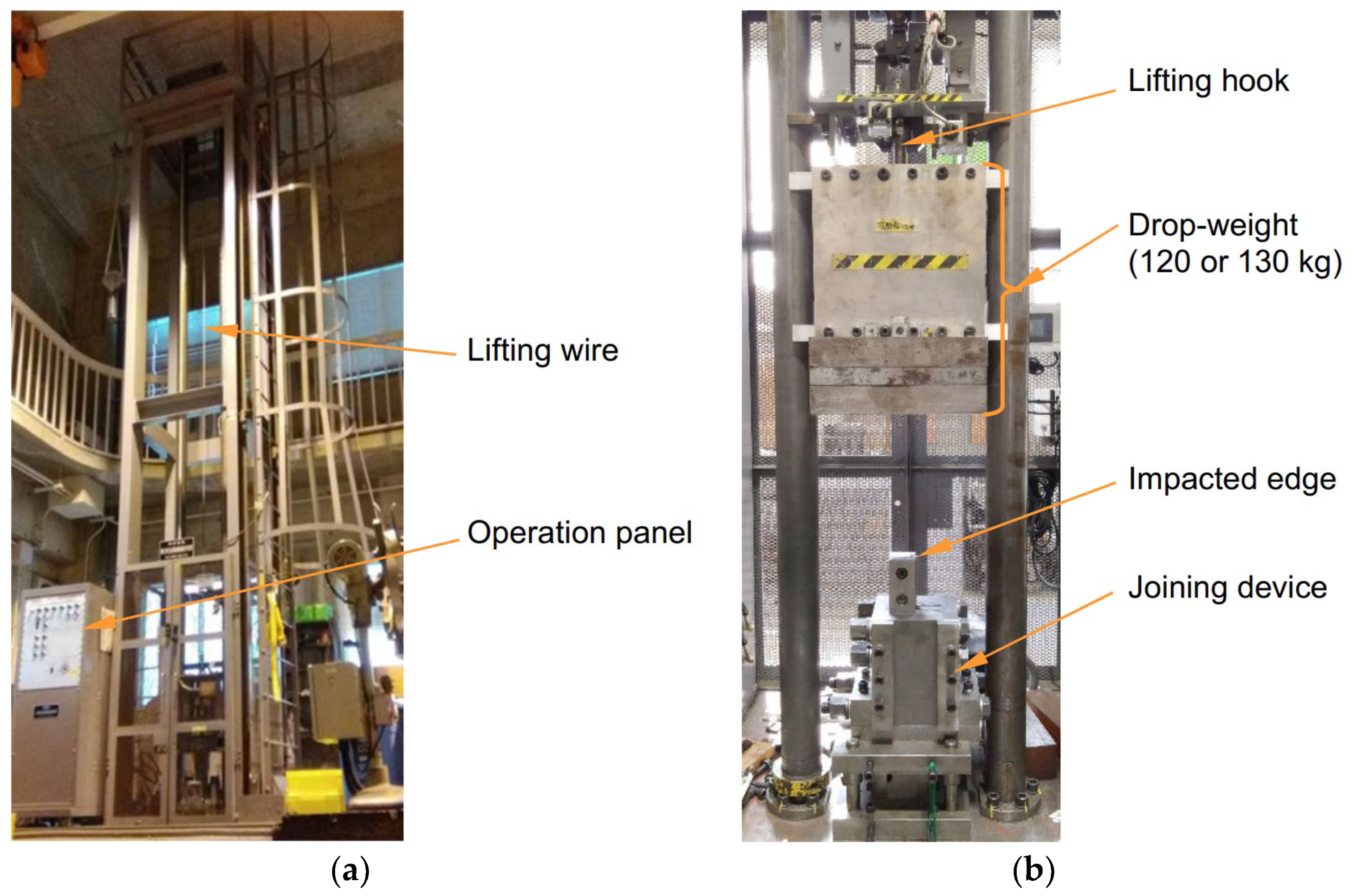

2. Impact Joining Device and Experimental Conditions

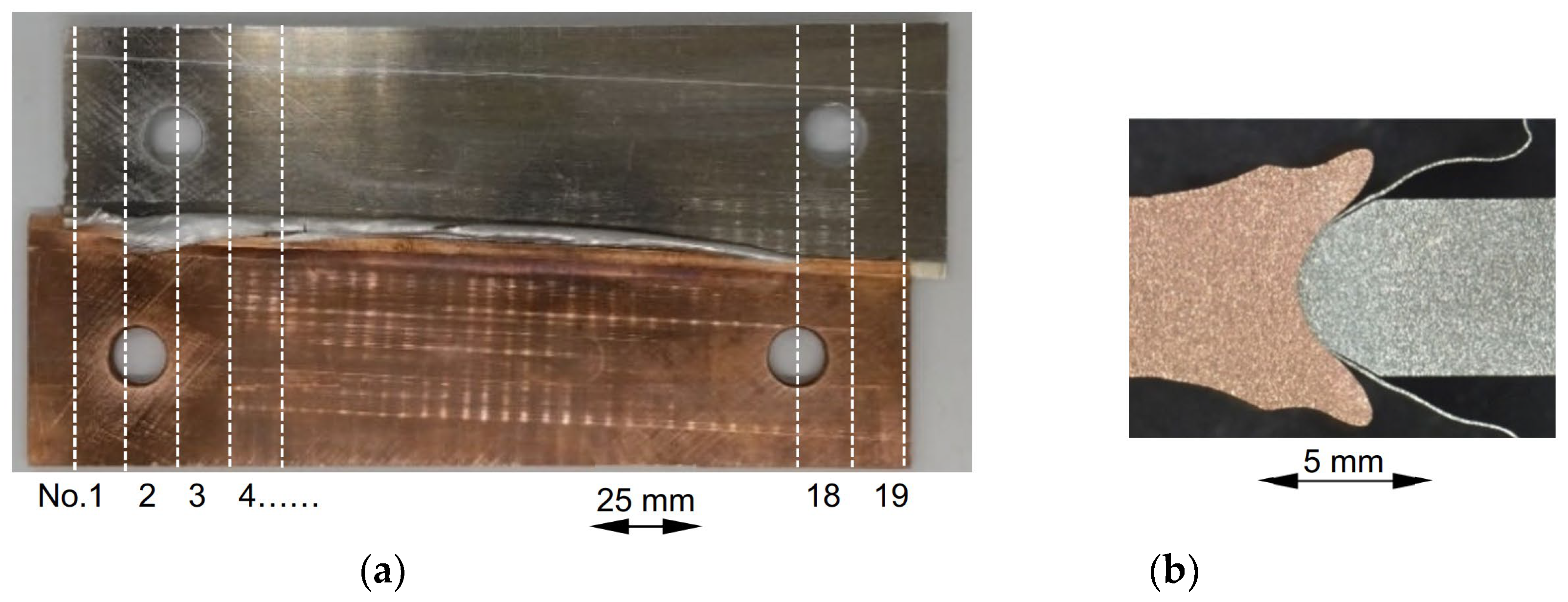

3. Evaluation of Joining Performance

4. Results and Discussion

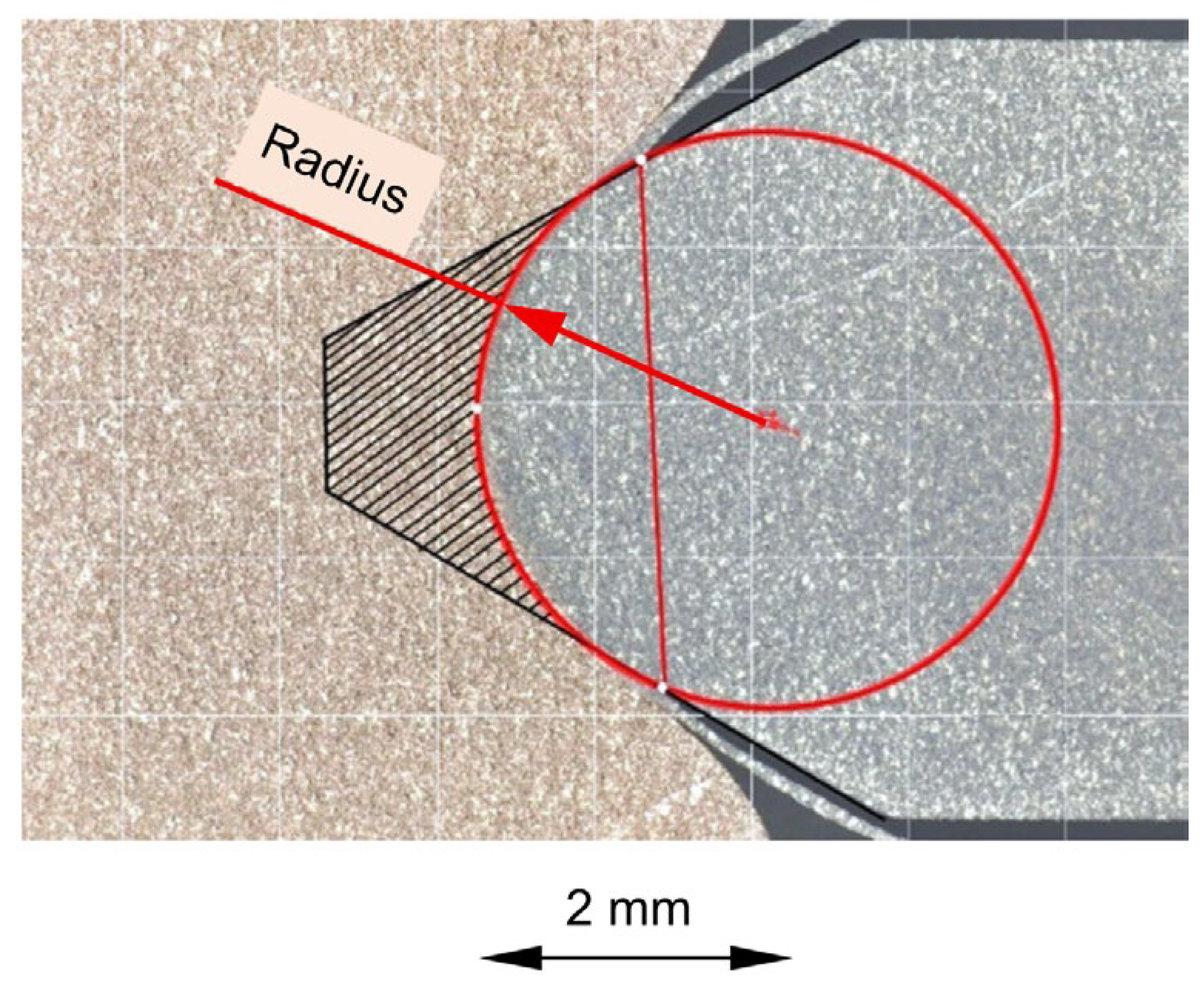

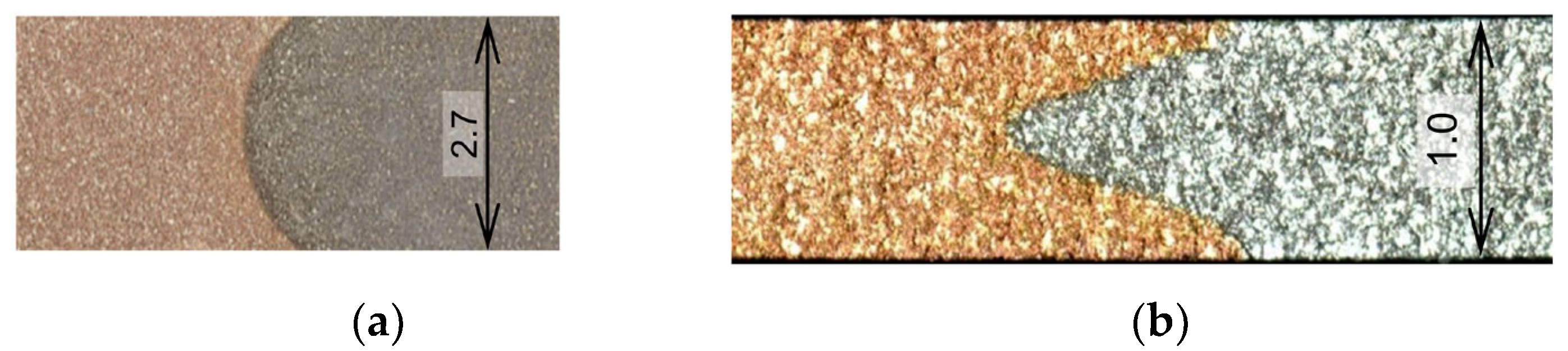

4.1. Effect of Wedge Dimensions of Test Plate on Joining Performance

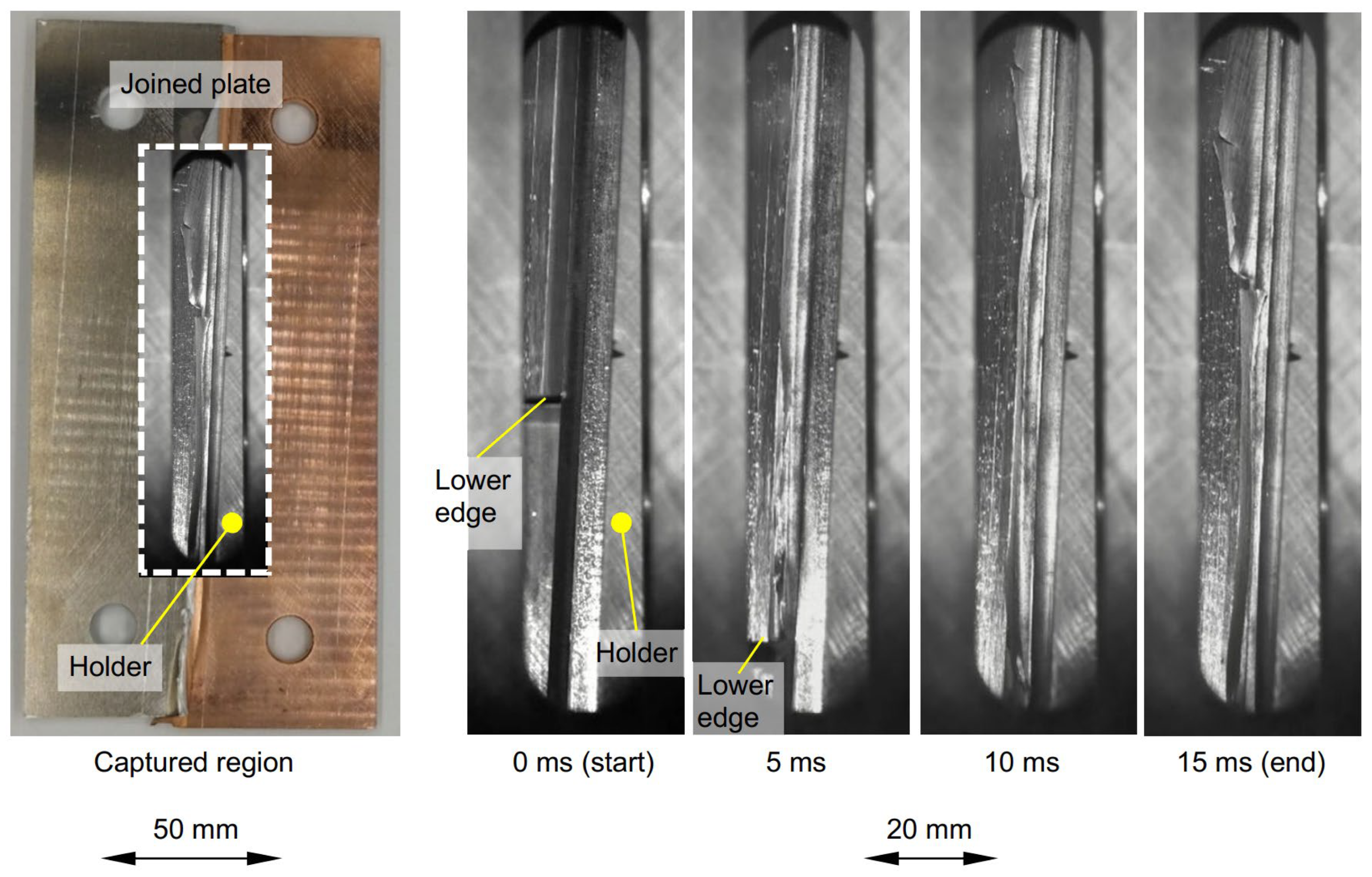

4.2. Effect of Sliding Distance or Mass of Drop-Weight and Observation of Joining Process

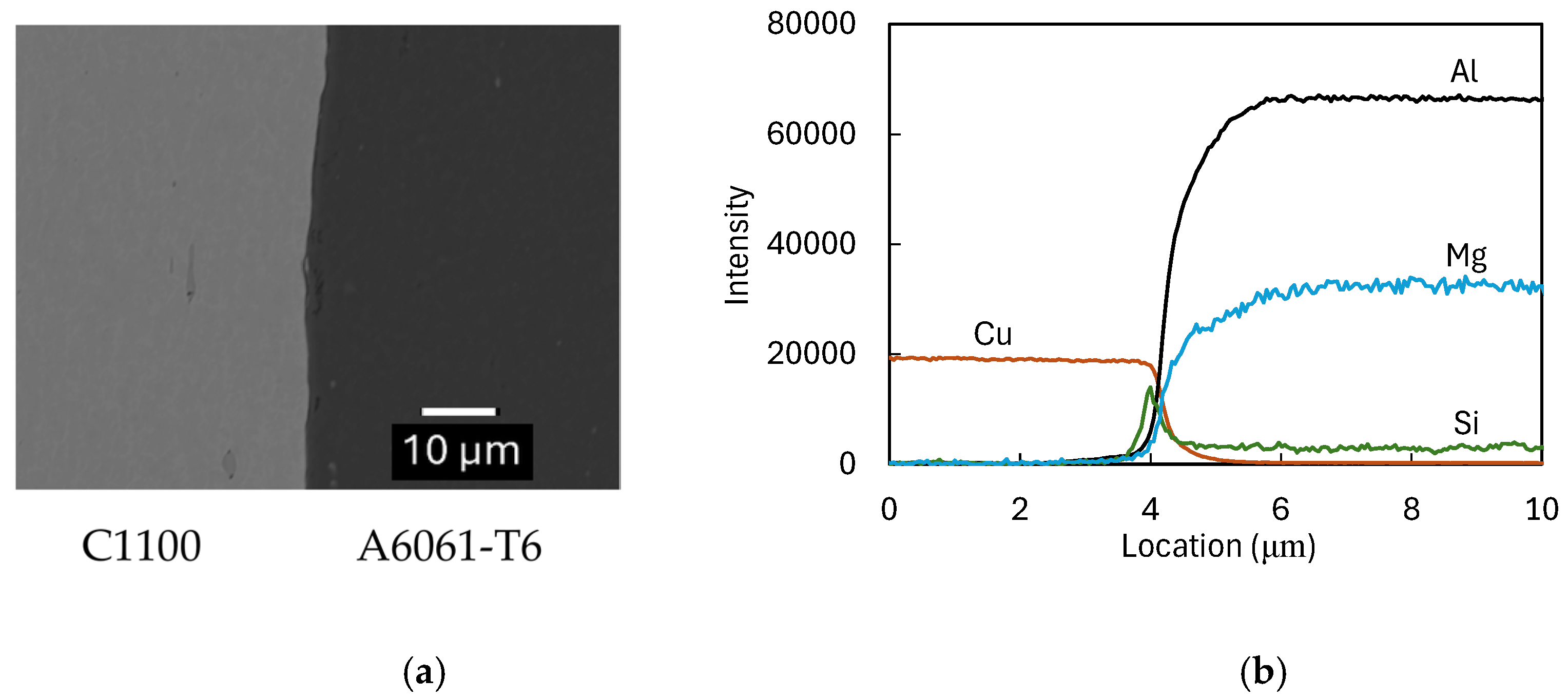

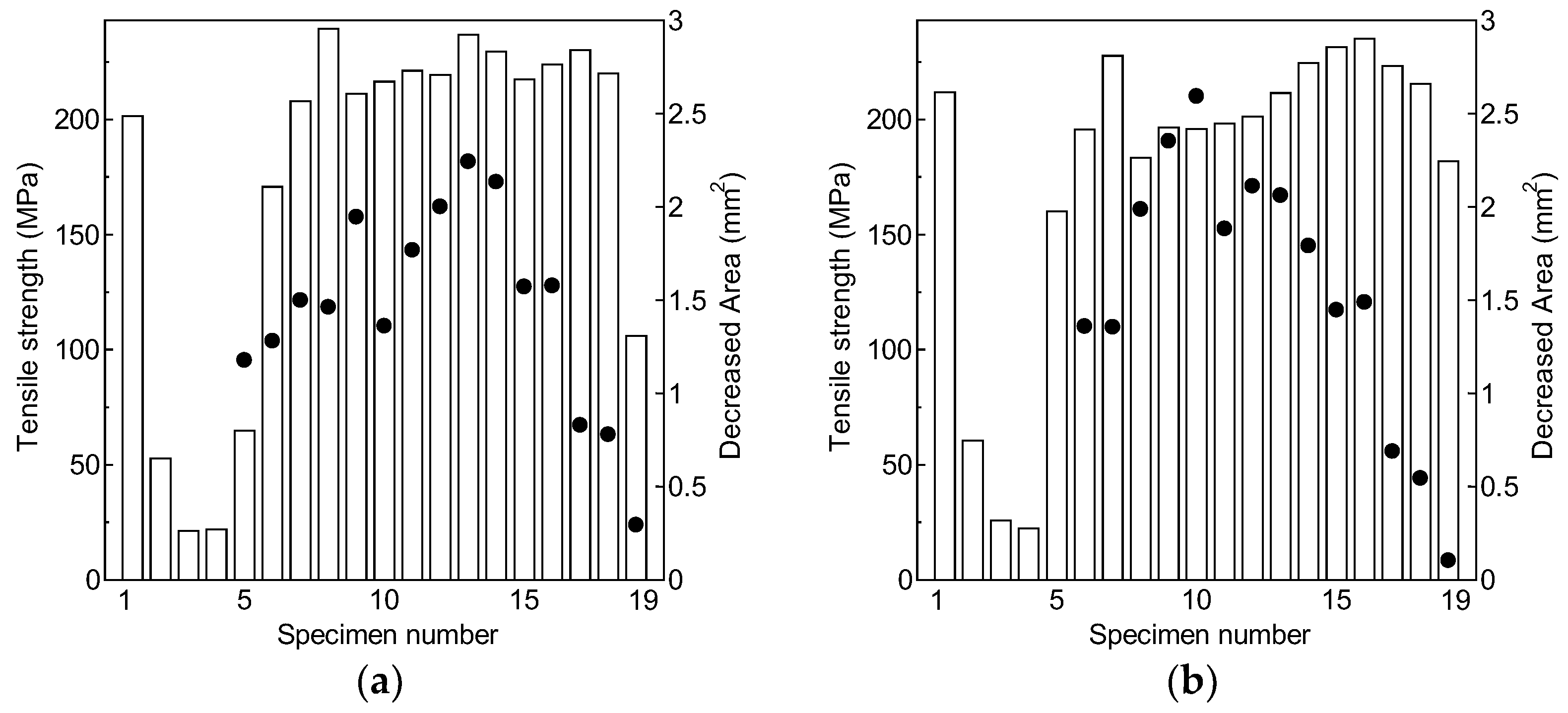

4.3. Relationship Between Amount of Generated Aluminum Alloy Foil and Joint Efficiency

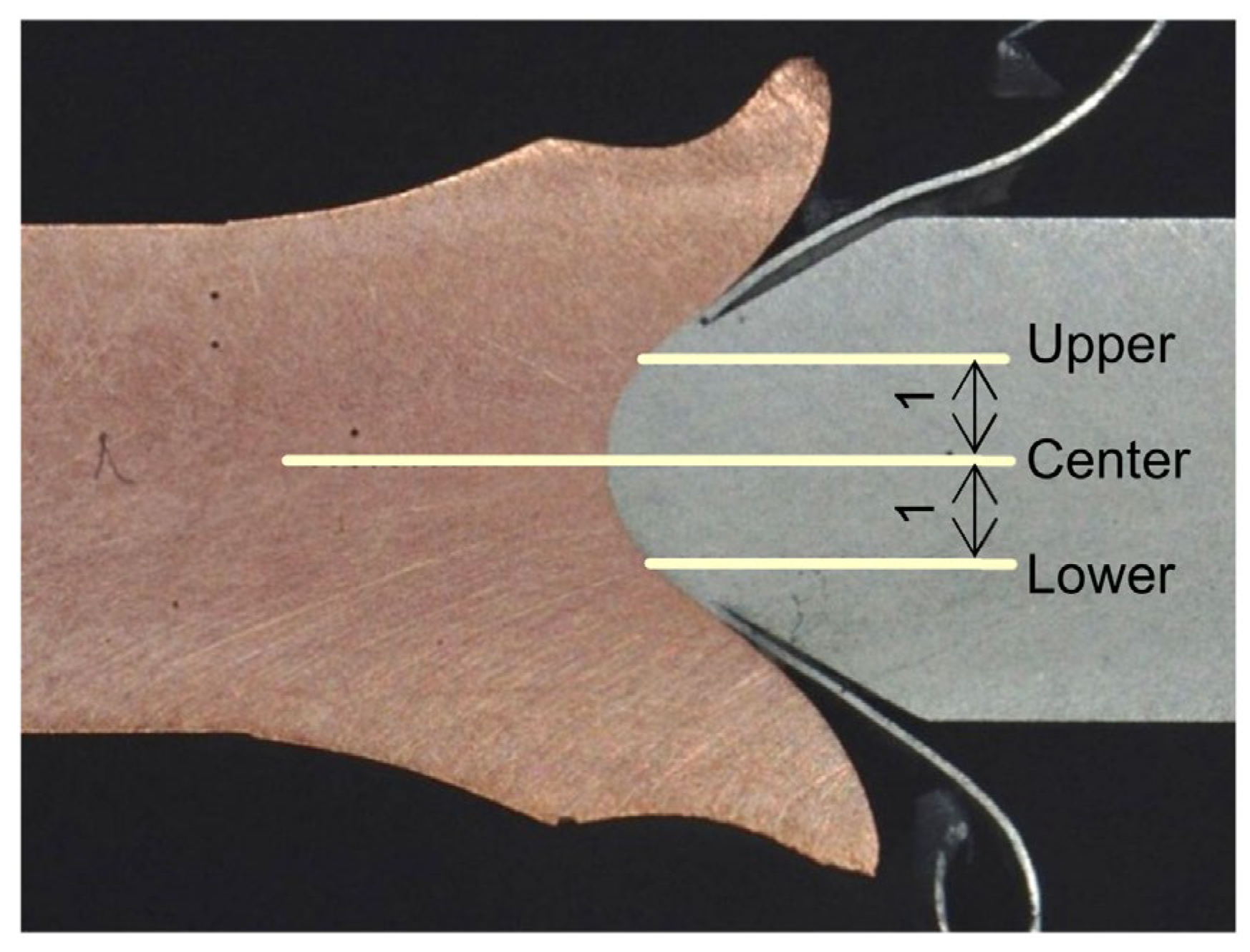

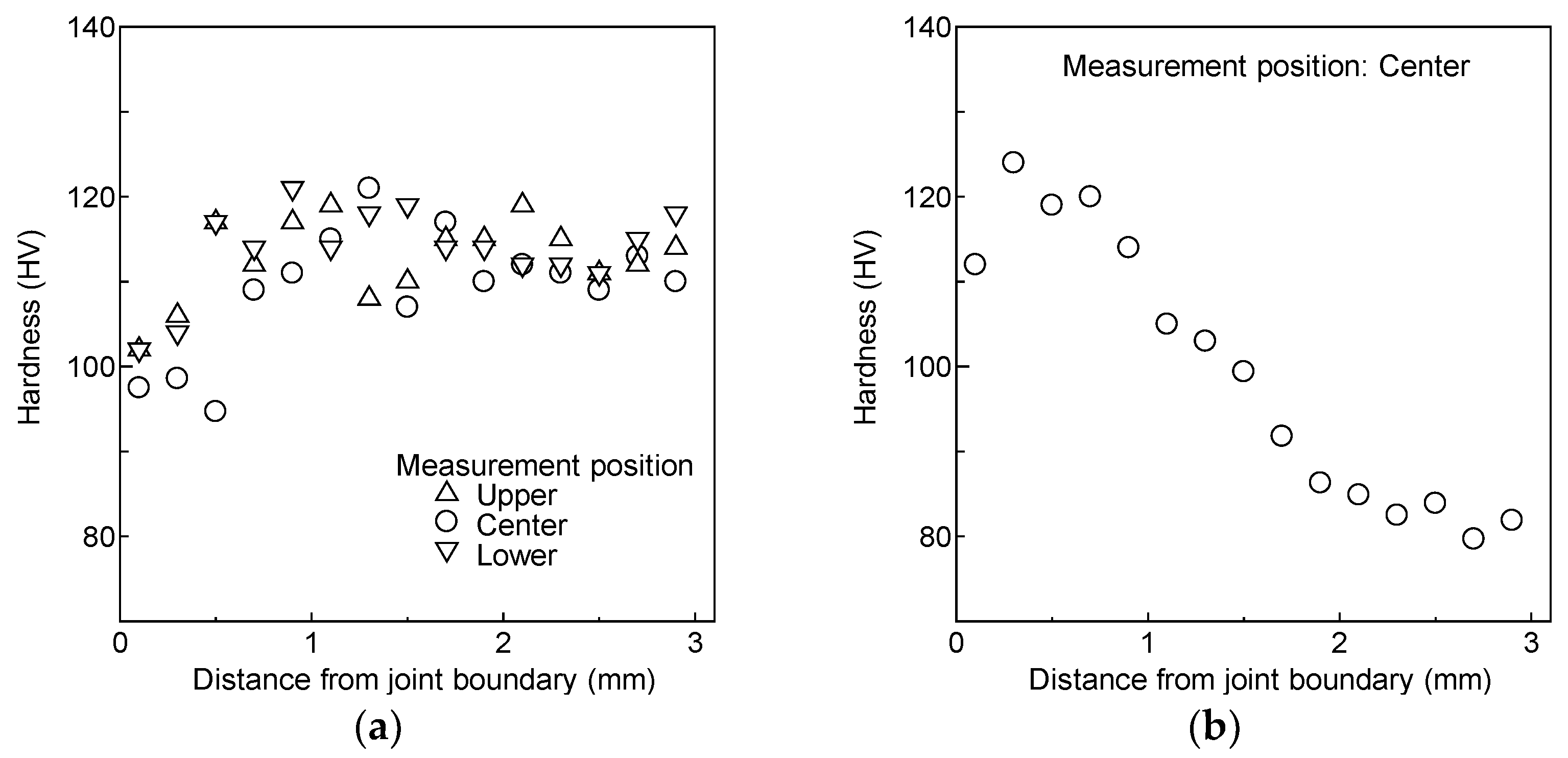

4.4. Hardness Distribution near Joint Boundary

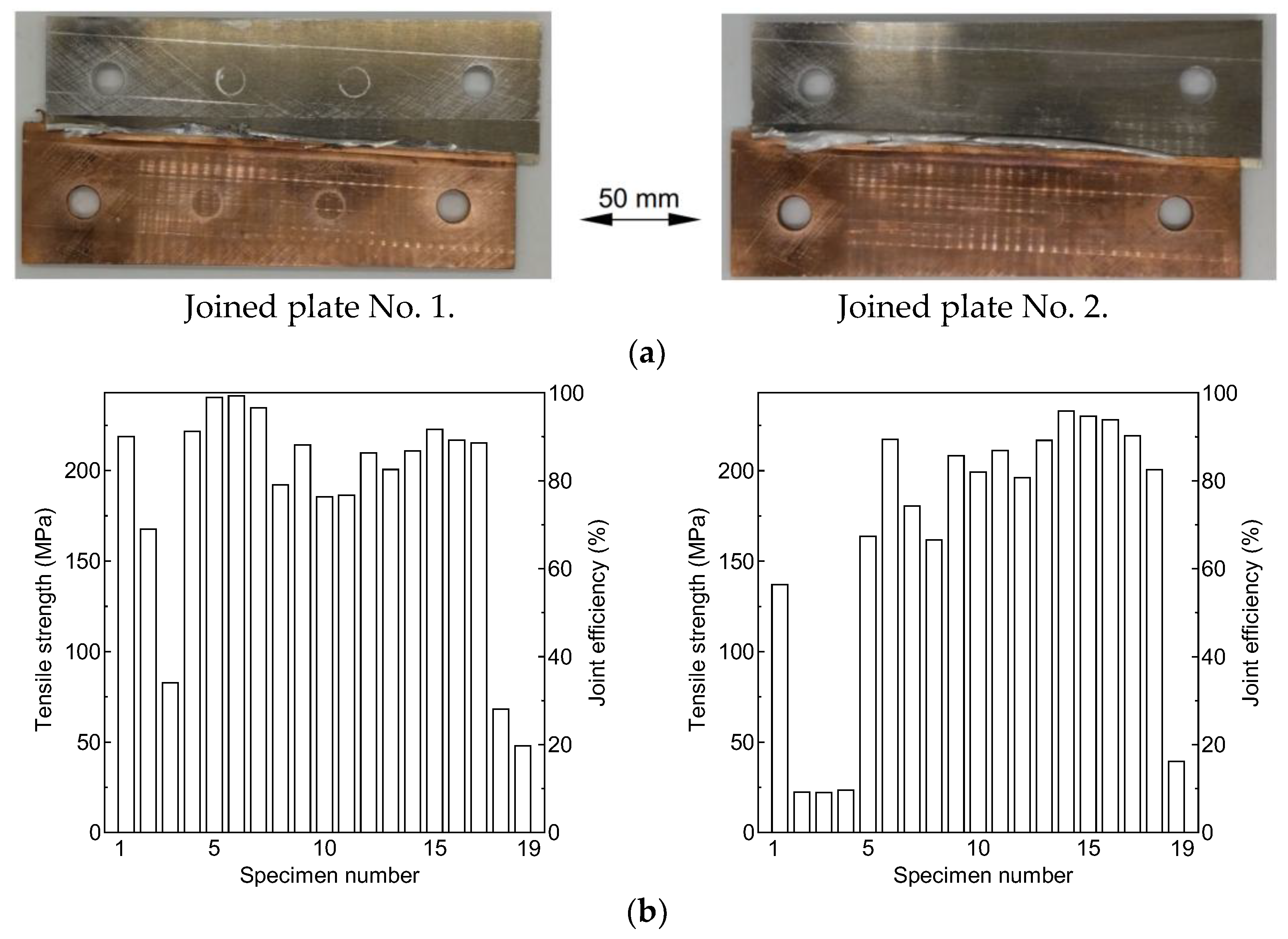

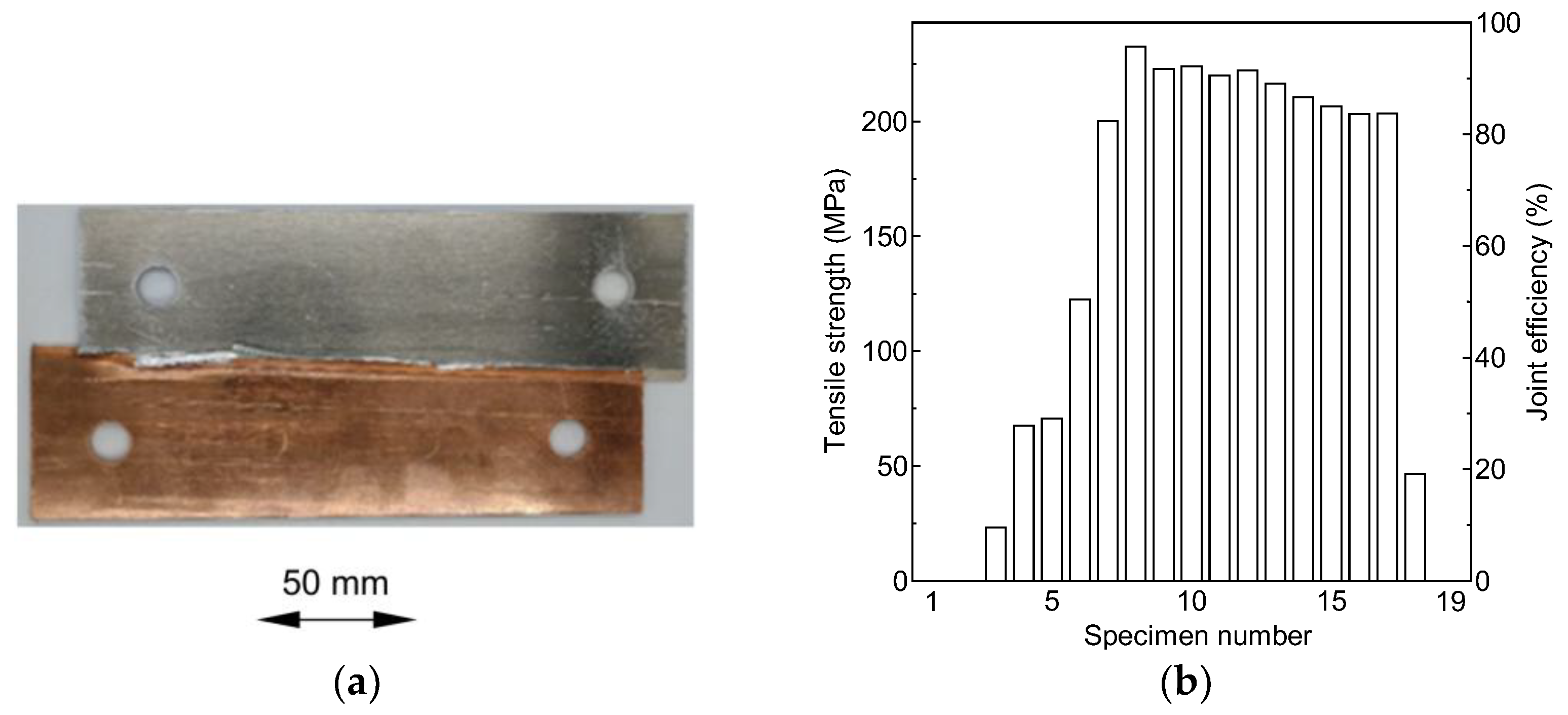

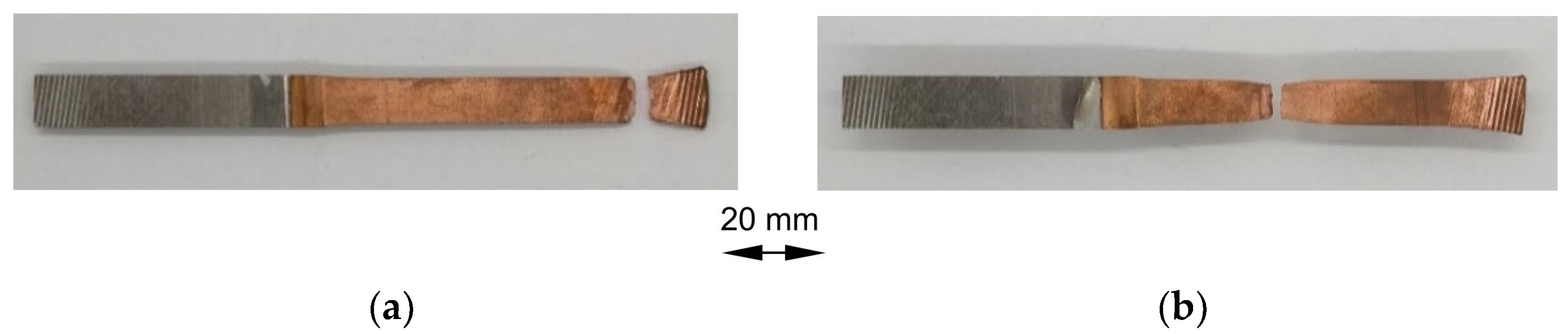

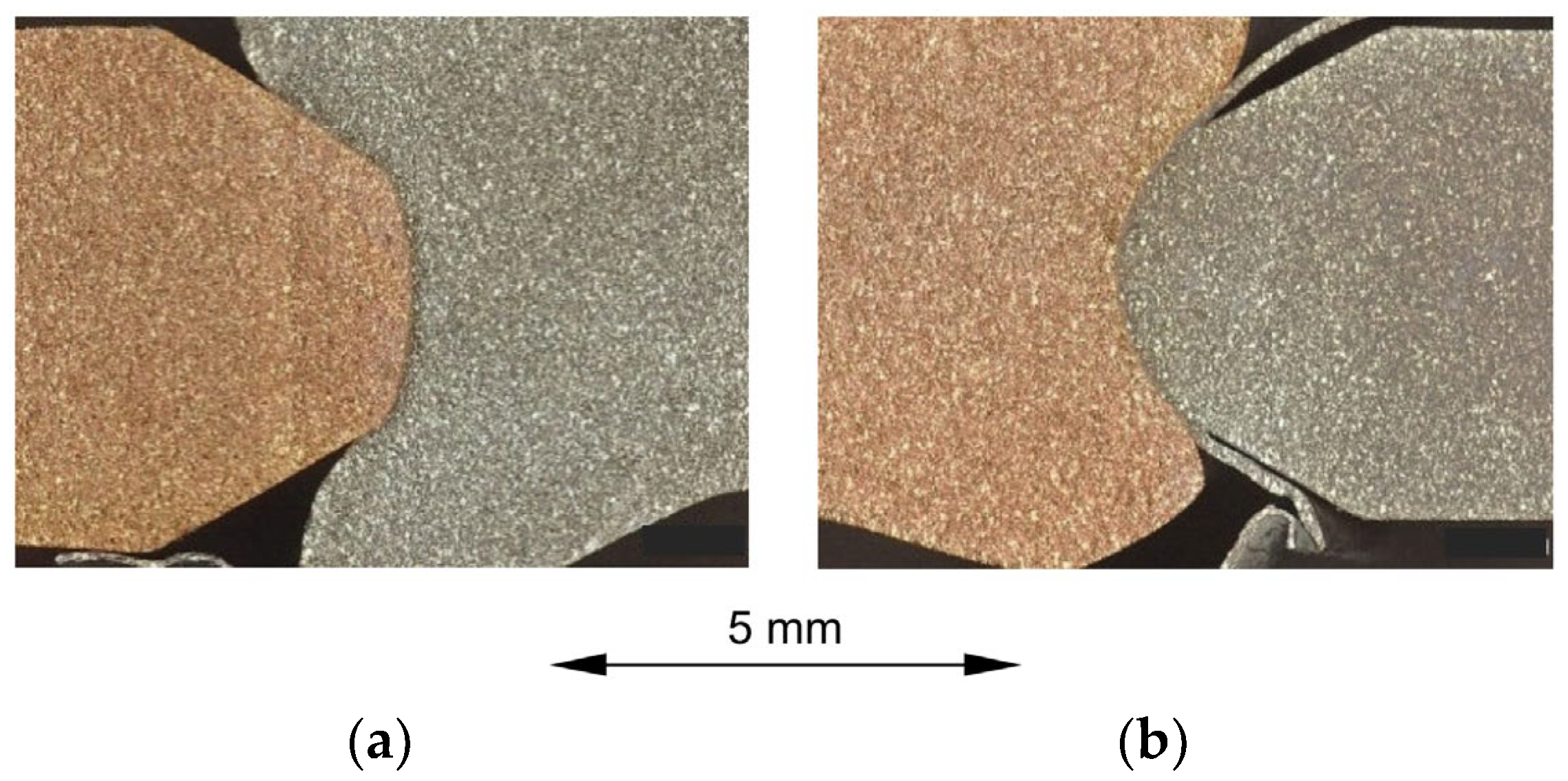

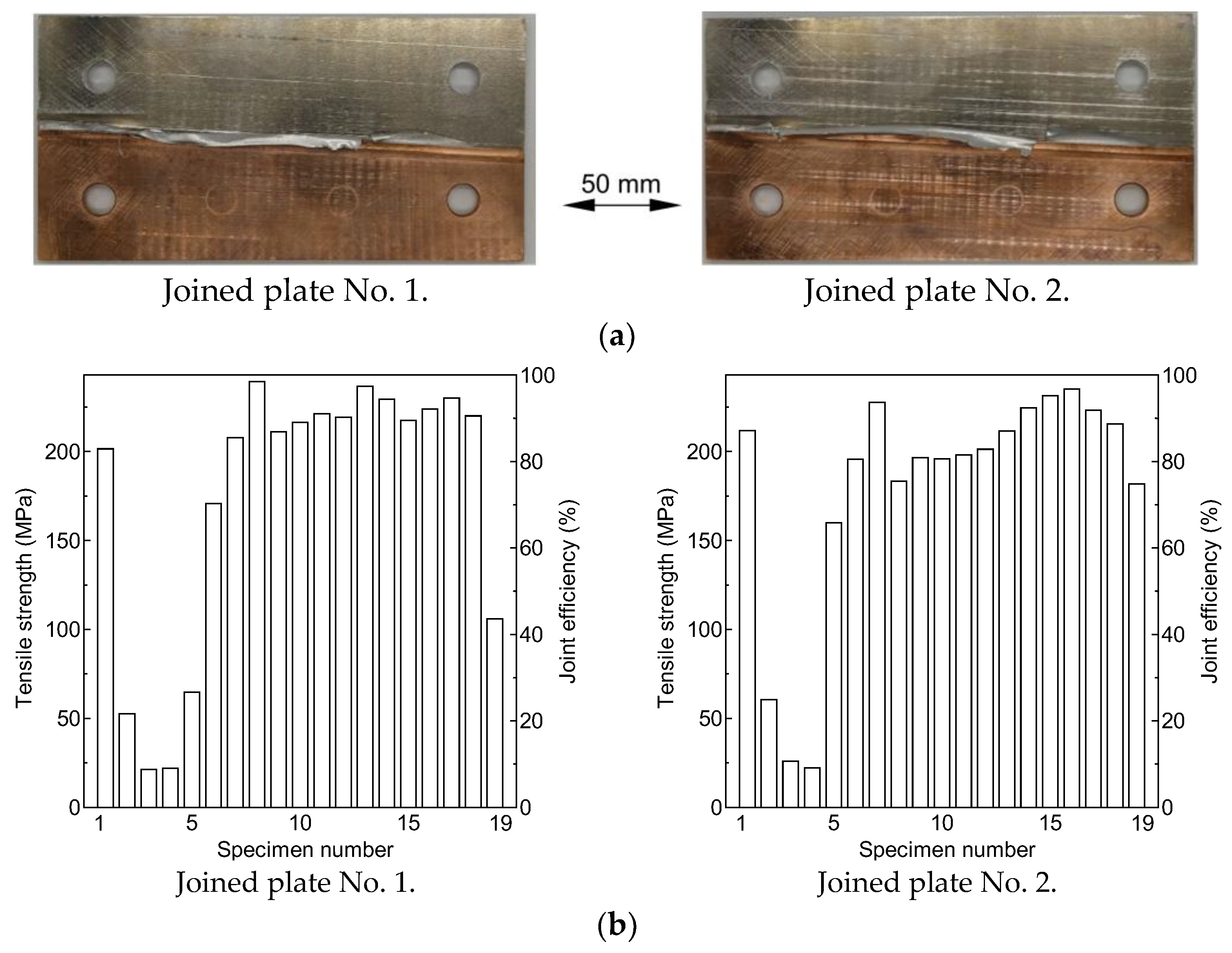

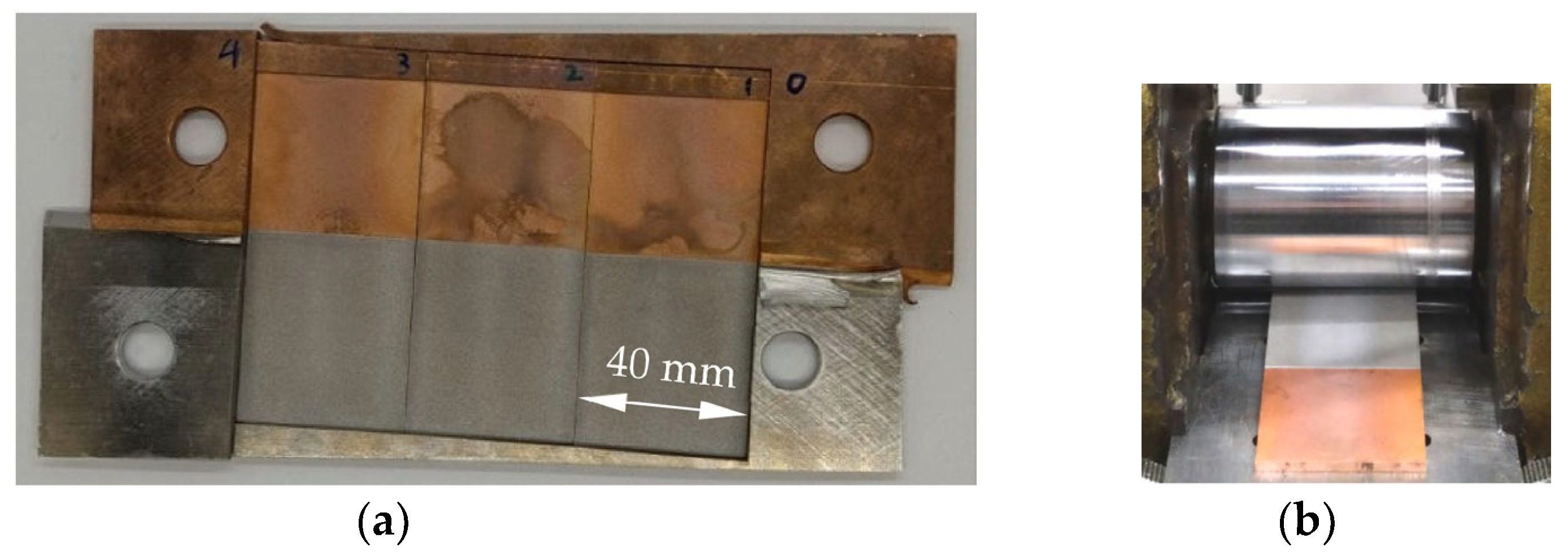

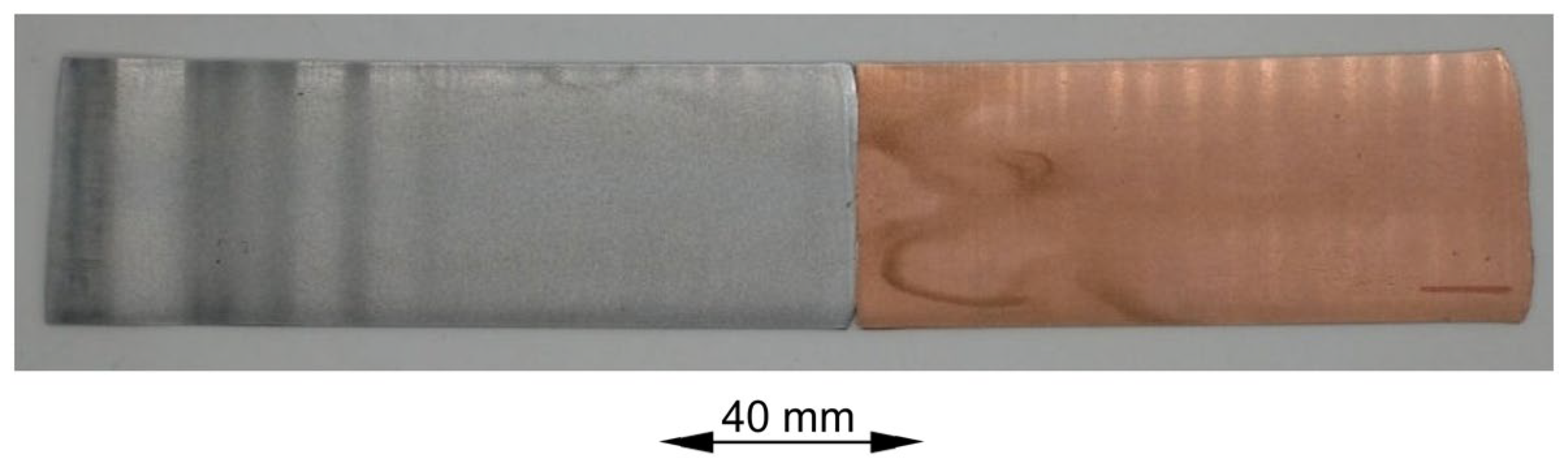

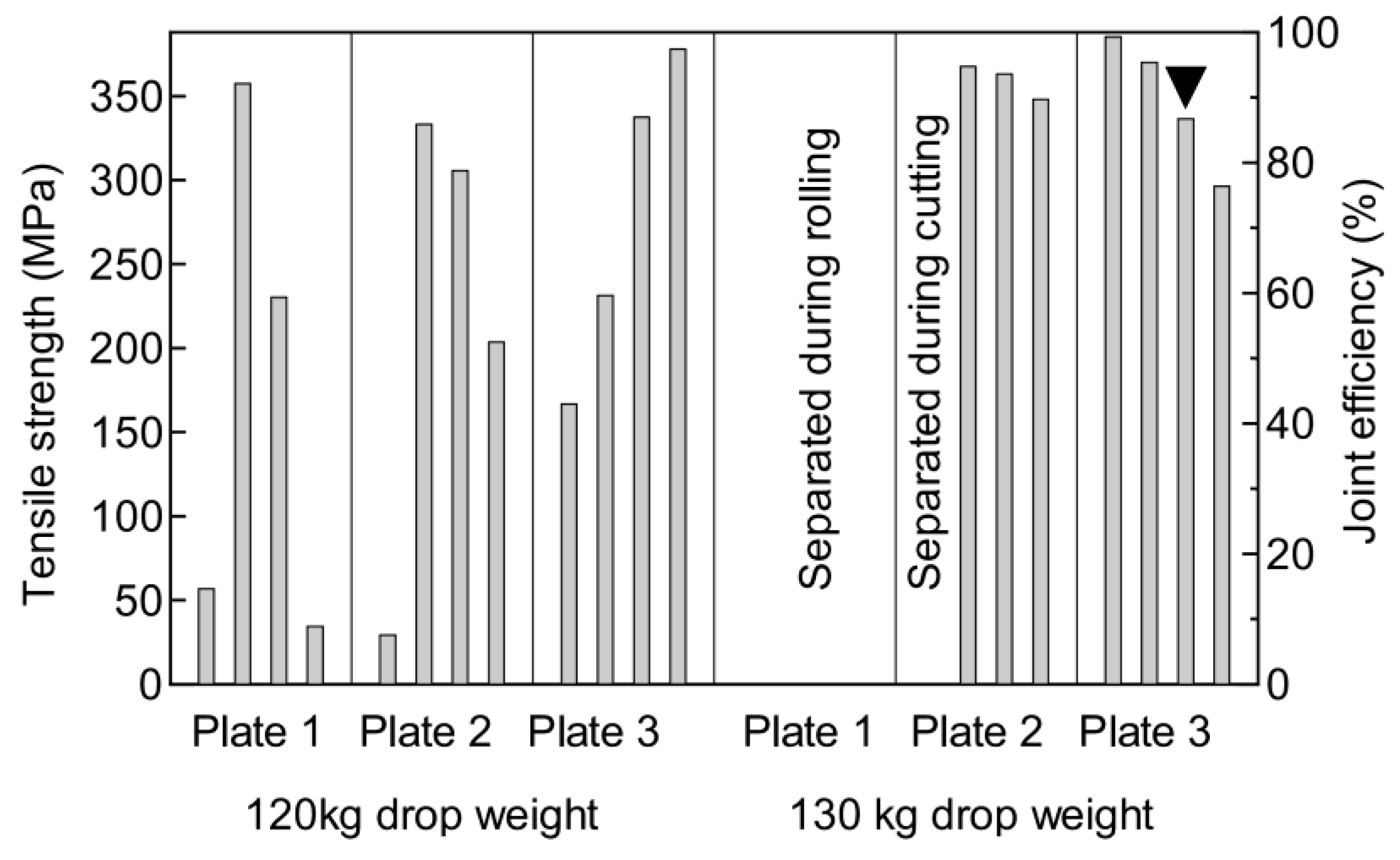

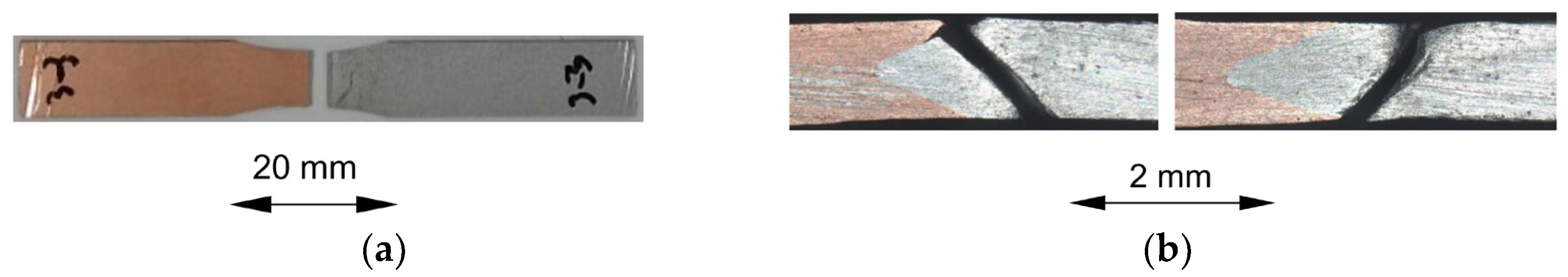

4.5. Rolling of Joined Plate and Tensile Test of Rolled Sheet

5. Conclusions

- The effect of compressive force was examined by changing the wedge shape of the test plate. The use of a steeper wedge-shape improved the joining performance significantly. Some tensile test specimens exhibited a fracture in the C1100 region.

- The joining performance did not improve significantly even though the sliding distance increased from 90 mm to 100 mm. No tensile test specimen fractured in the C1100 region due to the misalignment between the centers of the plates caused by excessive compressive deformation.

- Observation using a high-speed video camera during impact joining confirmed that aluminum alloy foil, the formation of which is essential to the joining process, began to form as early as just 5 ms into the test. The joining process was completed in 15 ms.

- Measurement of Vickers hardness revealed that the hardness of A6061-T6 decreases within a very limited range of only 0.8 mm from the joint boundary. The hardness of C1100 is comparable to or slightly greater than that of A6061-T6 near the joint boundary. The affected region of C1100 is about 2 mm, which is only 40% of the plate’s thickness.

- The joined plate was rolled until the true strain in the plate thickness reached about −1.0. A maximum joint efficiency of 99% was obtained, though statistical verification is necessary to confirm the reliability of the joint interface. When the joint efficiency was over 80%, the fracturing took place mainly in the A6061-T6 alloy.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Groche, P.; Wohletz, S.; Erbe, A.; Altin, A. Effect of the primary heat treatment on the bond formation in cold welding of aluminum and steel by cold forging. J. Mater. Process. Technol. 2014, 214, 2040–2048. [Google Scholar] [CrossRef]

- Krishna, B.V.; Venugopal, P.; Rao, K.P. Solid state joining of dissimilar sintered P/M preform tubes by simultaneous cold extrusion. Mater. Sci. Eng. A 2004, 386, 301–317. [Google Scholar] [CrossRef]

- Lilleby, A.; Grong, Ø.; Hemmer, H. Cold pressure welding of severely plastically deformed aluminum by divergent extrusion. Mater. Sci. Eng. A 2010, 527, 1351–1360. [Google Scholar] [CrossRef]

- Groche, P.; Wohletz, S.; Mann, A.; Krech, M.; Monnerjahn, V. Conjoint forming—Technologies for simultaneous forming and joining. Mater. Sci. Eng. 2016, 119, 012025. [Google Scholar] [CrossRef]

- Yan, H.; Lenard, J.G. A study of warm and cold roll-bonding of an aluminum alloy. Mater. Sci. Eng. A 2004, 385, 419–428. [Google Scholar] [CrossRef]

- Pragana, J.P.M.; Sapage, M.S.T.; Sampaio, R.F.V.; Braganca, I.M.F.; Ribeiro, I.; Silva, C.M.A.; Martins, P.A.F. Joining of hybrid busbars for E-Mobility: An economic and environmental study. J. Adv. Join. Process. 2023, 8, 100159. [Google Scholar] [CrossRef]

- Kaya, Y. Investigation of copper-aluminum composite materials produced by explosive welding. Metals 2018, 8, 780. [Google Scholar] [CrossRef]

- Seibold, M.; Schricker, K.; Bergmann, J.P. Systematic adjustment of the joining time in pulsed laser beam welding of aluminum-copper joints by means of a closed-loop control. J. Adv. Join. Process. 2022, 5, 100104. [Google Scholar] [CrossRef]

- Mathivanan, K.; Plapper, P. Laser welding of dissimilar copper and aluminum sheets by shaping the laser pulses. Procedia Manuf. 2019, 36, 154–162. [Google Scholar] [CrossRef]

- Dimatteo, V.; Ascari, A.; Liverani, E.; Fortunato, A. Experimental investigation on the effect of spot diameter on continuous-wave laser welding of copper and aluminum thin sheets for battery manufacturing. Opt. Laser Technol. 2022, 145, 107495. [Google Scholar] [CrossRef]

- Das, A.; Barai, A.; Masters, I.; Williams, D. Comparison of tab-to-busbar ultrasonic joints for electric vehicle Li-ion battery applications. World Electr. Veh. J. 2019, 10, 55. [Google Scholar] [CrossRef]

- Yang, J.; Cao, B. Investigation of resistance heat assisted ultrasonic welding of 6061 aluminum alloys to pure copper. Mater. Des. 2015, 74, 19–24. [Google Scholar] [CrossRef]

- Das, A.; Barai, A.; Masters, I.; Williams, D. Process robustness and strength analysis of multi-layered dissimilar joints using ultrasonic metal welding. Int. J. Adv. Manuf. Technol. 2019, 101, 881–900. [Google Scholar] [CrossRef]

- Hamed, A.A.; Yamagata, T.; Katoh, M.; Nishio, K.; Yamaguchi, T. Joining of A1050/A5052 and A1050/Cu by ultrasonic bonding and their materials evaluation. Q. J. Jpn. Weld. Soc. 2003, 21, 493–500. [Google Scholar] [CrossRef]

- Pawlicki, M.; Drenger, T.; Pieszak, M.; Borowski, J. Cold upset forging joining of ultra-fine-grained aluminum and copper. J. Mater. Process. Technol. 2015, 223, 193–202. [Google Scholar] [CrossRef]

- Eivani, A.R.; Mirzakoochakshirazi, H.R.; Jafarian, H.R. Investigation of joint interface and cracking mechanism of thick cladding of copper on aluminum by equal channel angular pressing (ECAP). J. Mater. Res. Technol. 2020, 9, 3394–3405. [Google Scholar] [CrossRef]

- Medvedev, A.E.; Lapovok, R.; Koch, E.; Höppel, H.B.; Göken, M. Optimization of interface formation by shear inclination: Example of aluminum-copper hybrid produced by ECAP with back-pressure. Mater. Des. 2018, 146, 142–151. [Google Scholar] [CrossRef]

- Matsumoto, R.; Hashimoto, K.; Utsunomiya, H. Improvement in bonding strength by applying circumferential sliding in cold copper/aluminum forge-bonding. J. Mater. Process. Technol. 2022, 307, 117685. [Google Scholar] [CrossRef]

- Yamagishi, H. Cu/Al dissimilar cold spot forge welding: Effects of bonding temperature and reduction ratio on joint strength and reaction layer growth. Metall. Mater. Trans. 2023, 54A, 3519–3536. [Google Scholar] [CrossRef]

- Habba, M.I.A.; Ahmed, M.M.Z. Friction stir welding of dissimilar aluminum and copper alloys: A review of strategies for enhancing joint quality. J. Adv. Join. Process. 2025, 11, 100293. [Google Scholar] [CrossRef]

- Celik, S.; Cakir, R. Effect of friction stir welding parameters on the mechanical and microstructure properties of the Al-Cu butt joint. Metals 2016, 6, 133. [Google Scholar] [CrossRef]

- Yamashita, M.; Shibuya, T.; Nikawa, M. Impact joining of metallic sheets and evaluation of its performance. Mater. Res. Proc. 2019, 13, 91–96. [Google Scholar] [CrossRef]

- Yamashita, M.; Iwatsuka, T.; Taguchi, H.; Nikawa, M. Impact joining of pure copper C1100 and aluminum alloy A6061-T6 plates at edges. Metals 2022, 12, 1565. [Google Scholar] [CrossRef]

- Yamashita, M.; Imayoshi, A.; Nikawa, M. Joining of metal plates at edges by high-speed sliding with compression. In Proceedings of the 14th International Conference on the Technology of Plasticity—Current Trends in the Technology of Plasticity, Mandelieu-La Napoule, France, 24–29 September 2023; pp. 19–26. [Google Scholar] [CrossRef]

- Yamashita, M.; Nishimura, Y.; Imayoshi, A.; Nikawa, M. Joining of copper and aluminum alloy A6061 plates at edges by high-speed sliding with compression. Metals 2024, 14, 878. [Google Scholar] [CrossRef]

- Scapin, M.; Manes, A. Behavior of Al6061-T6 alloy at different temperatures and strain-rates: Experimental characterization and material modelling. Mater. Sci. Eng. A 2018, 734, 318–328. [Google Scholar] [CrossRef]

- Ogar, P.; Ugryumov, E.; Koryakyn, I. The Influence of the mechanical properties of copper at elevated temperatures on the tightness of the sealing joint. Mater. Today Proc. 2021, 38, 1764–1768. [Google Scholar] [CrossRef]

- Roh, Y.; Byon, M.; Lee, Y. Numerical analysis of edge cracking in high-silicon steel during cold rolling with 3D fracture locus. Appl. Sci. 2021, 11, 8408. [Google Scholar] [CrossRef]

- Pan, L.; Li, P.; Hao, X.; Zhou, J.; Dong, H. Inhomogeneity of microstructure and mechanical properties in radial direction of aluminum/copper friction welded joints. J. Mater. Process. Technol. 2018, 255, 308–318. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Al |

|---|---|---|---|---|---|---|---|

| 0.40~0.8 | Max. 0.70 | 0.15~0.40 | Max. 0.15 | 0.8~1.2 | 0.04~0.35 | Max. 0.25 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yamashita, M.; Nishimura, Y.; Nikawa, M. Impact Butt Joining of Copper C1100 and Aluminum Alloy A6061-T6 Plates and Rolling of Joined Plate. Metals 2025, 15, 1207. https://doi.org/10.3390/met15111207

Yamashita M, Nishimura Y, Nikawa M. Impact Butt Joining of Copper C1100 and Aluminum Alloy A6061-T6 Plates and Rolling of Joined Plate. Metals. 2025; 15(11):1207. https://doi.org/10.3390/met15111207

Chicago/Turabian StyleYamashita, Minoru, Yuya Nishimura, and Makoto Nikawa. 2025. "Impact Butt Joining of Copper C1100 and Aluminum Alloy A6061-T6 Plates and Rolling of Joined Plate" Metals 15, no. 11: 1207. https://doi.org/10.3390/met15111207

APA StyleYamashita, M., Nishimura, Y., & Nikawa, M. (2025). Impact Butt Joining of Copper C1100 and Aluminum Alloy A6061-T6 Plates and Rolling of Joined Plate. Metals, 15(11), 1207. https://doi.org/10.3390/met15111207