Study on the Microstructure and Properties of TC4 Alloy Based on Water-Jet-Guided Laser Technology

Abstract

1. Introduction

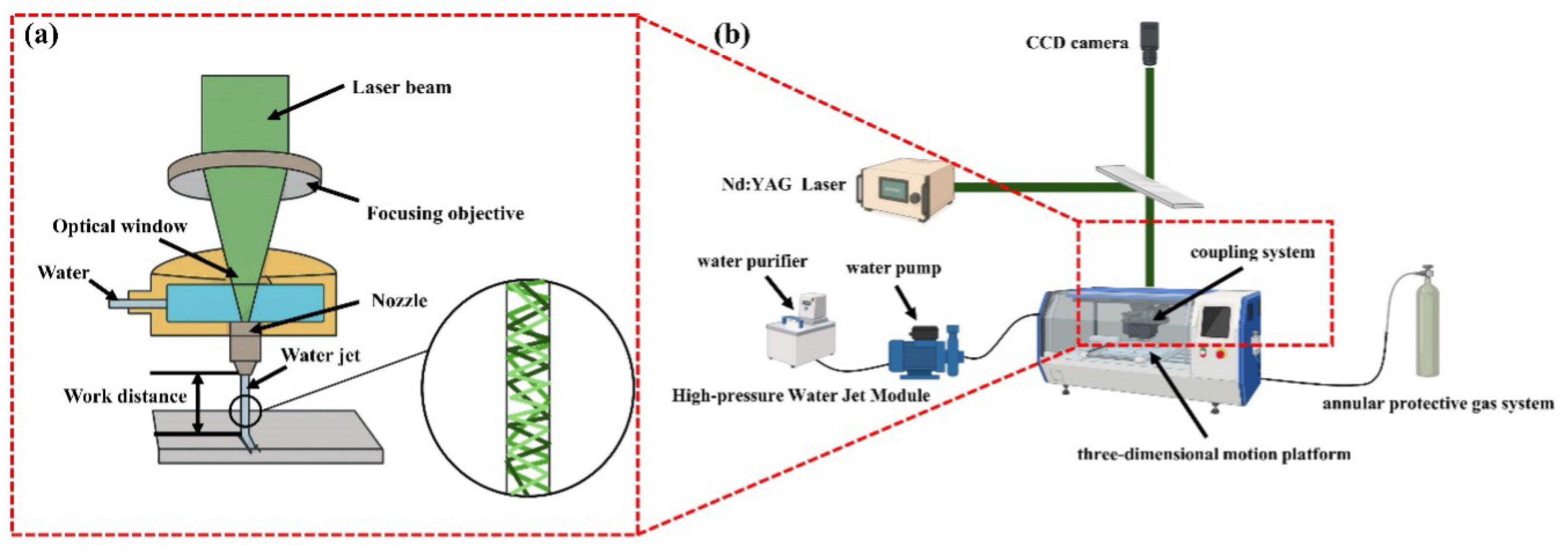

2. Materials and Methods

2.1. Material

2.2. Experimental Details

2.3. Microstructural Characterization

3. Result and Discussion

3.1. Metallographic Analysis of Grooves

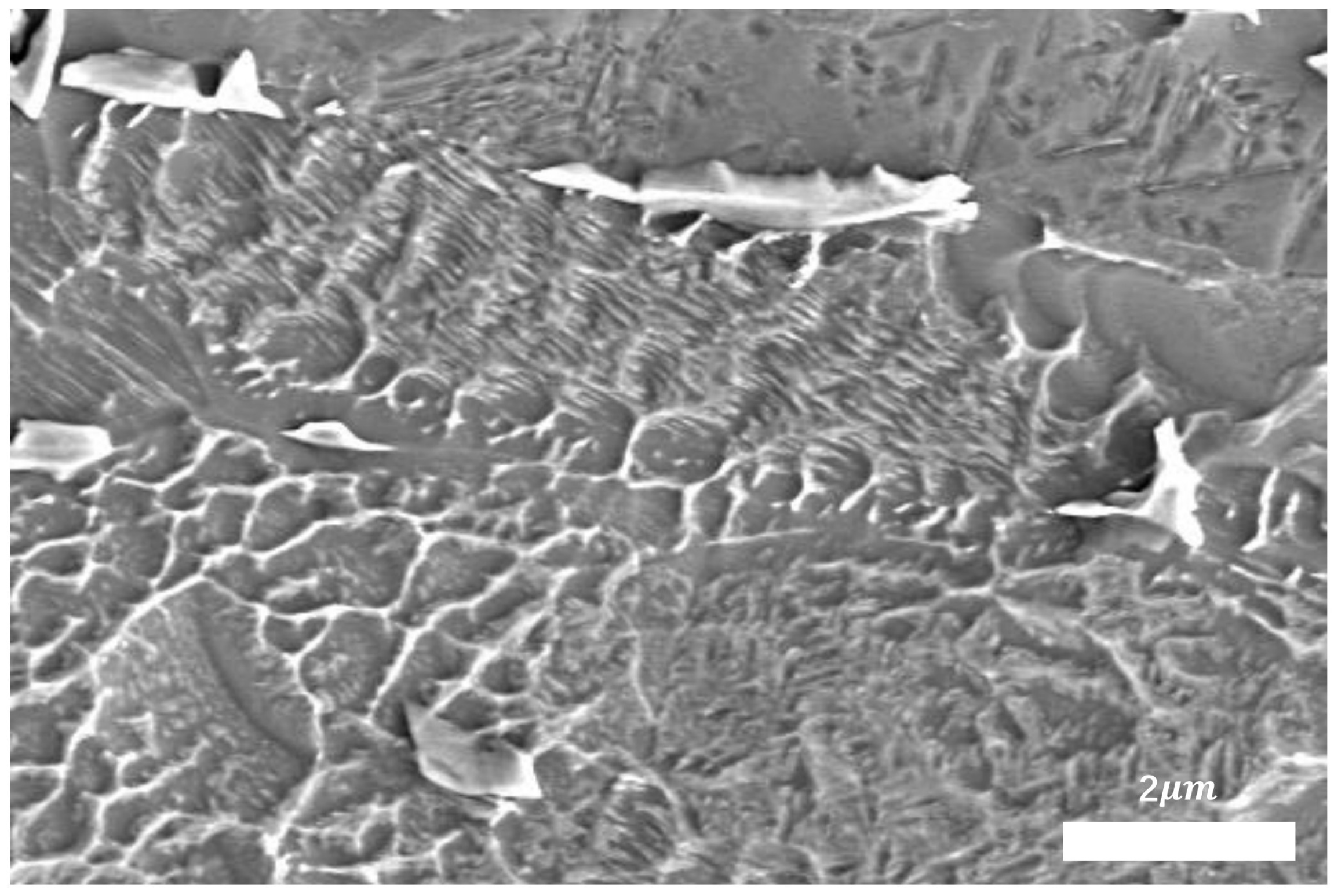

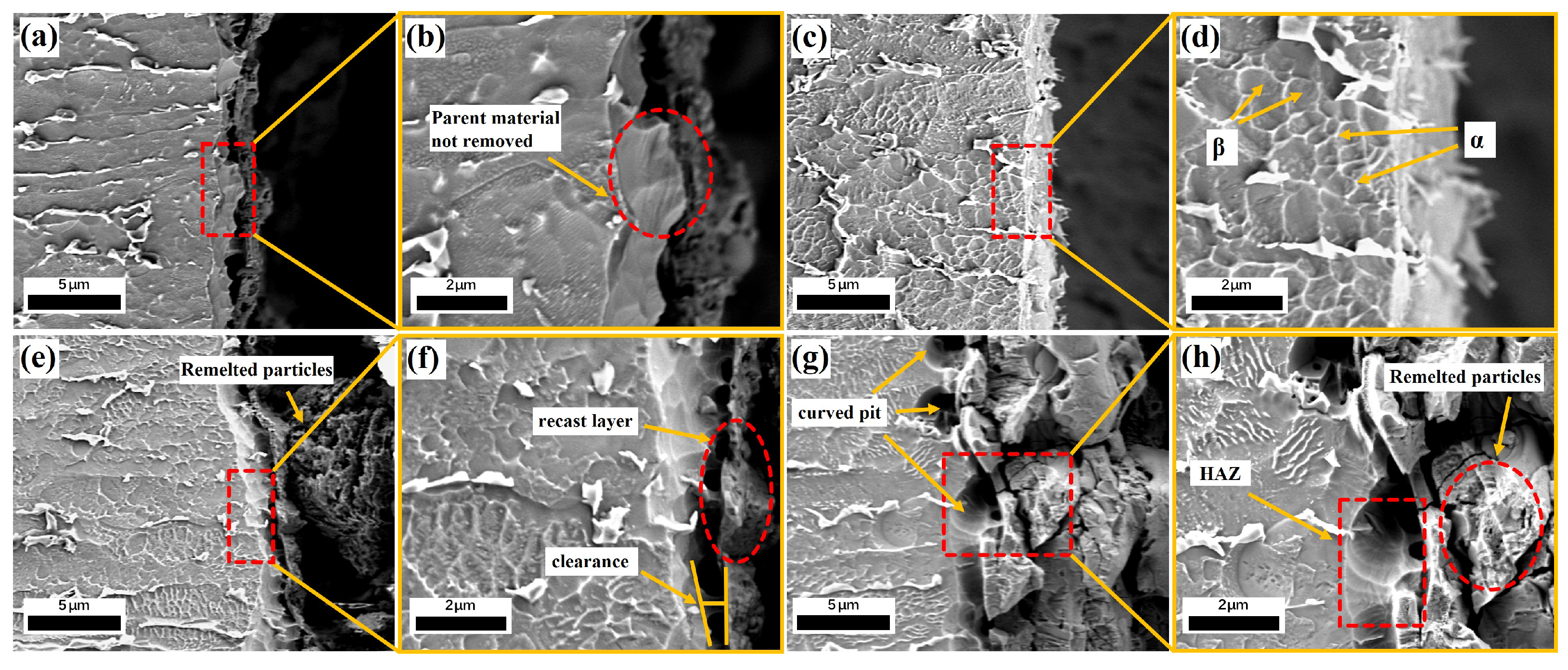

3.2. Micro-Morphology Analysis of Water-Guided-Laser-Cut Grooves

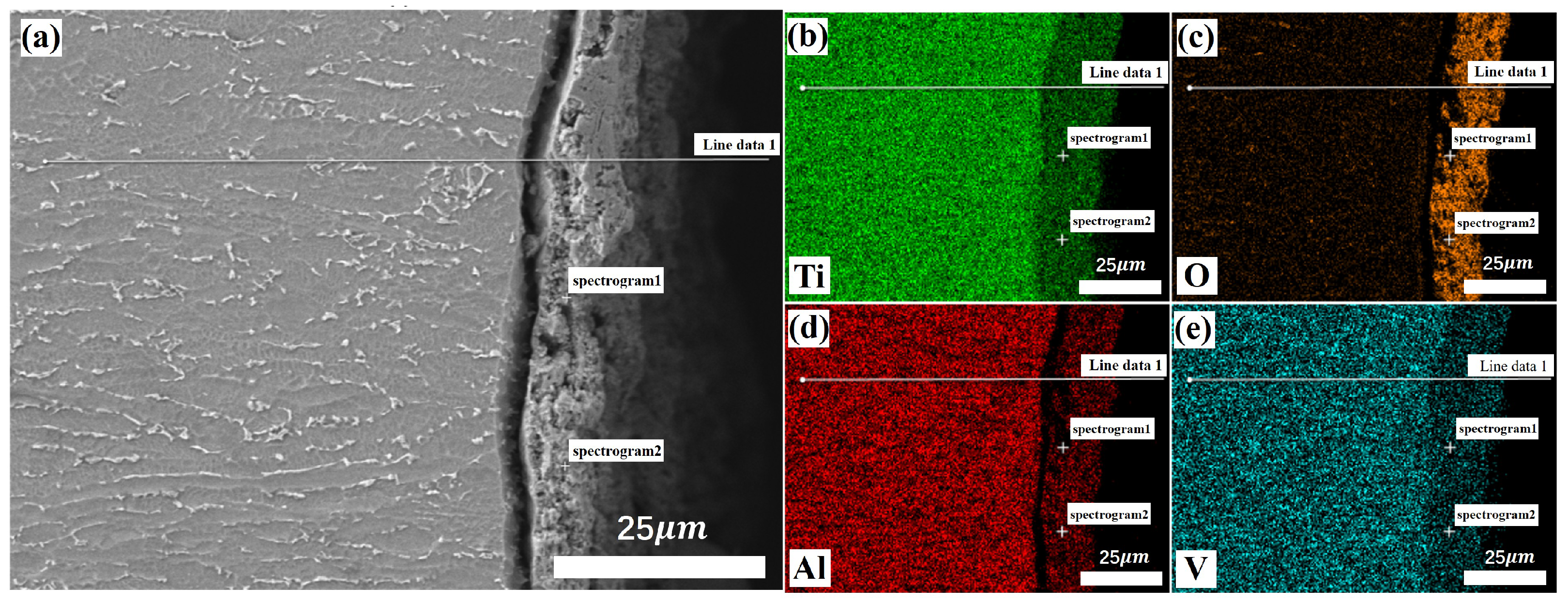

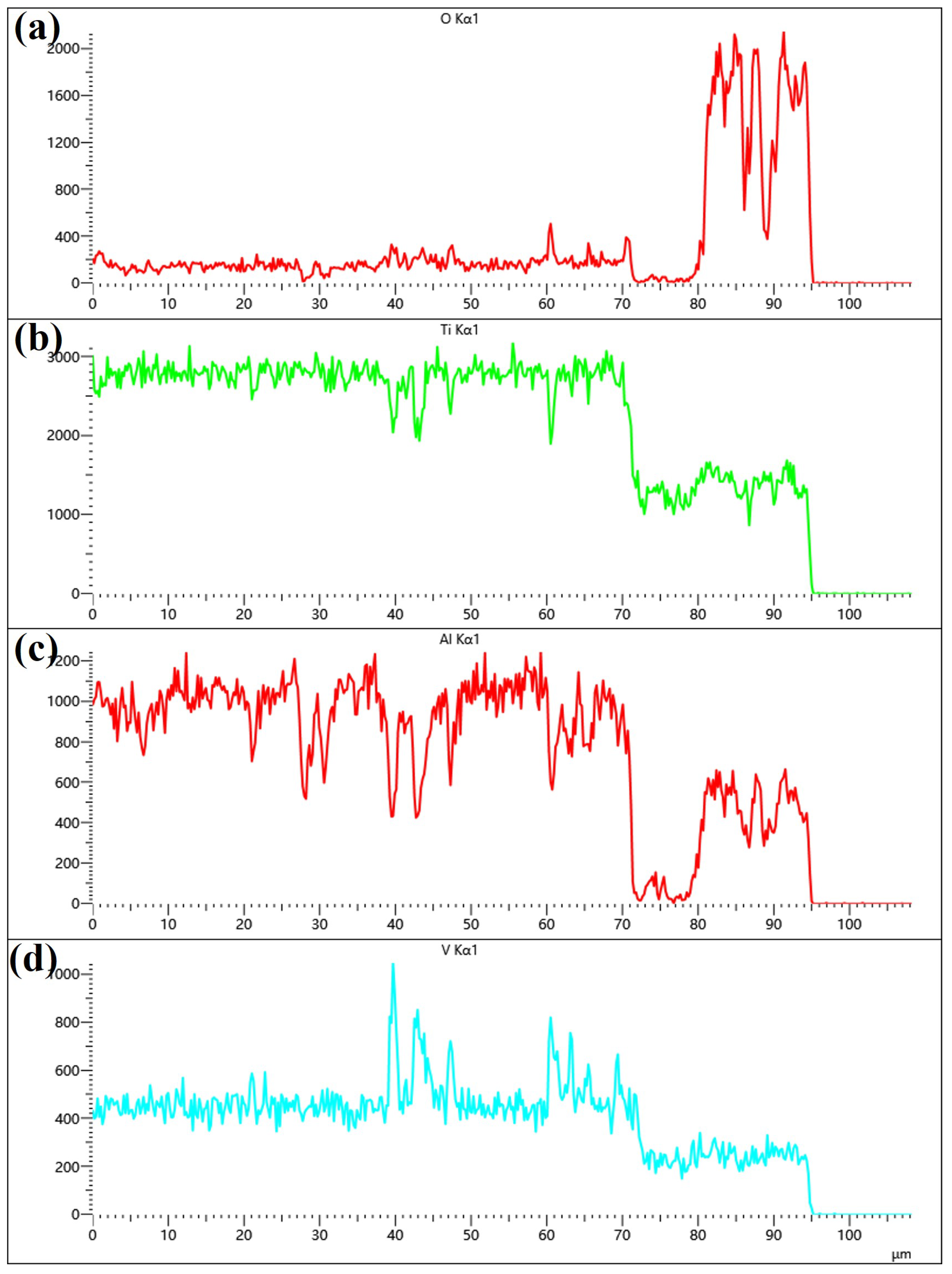

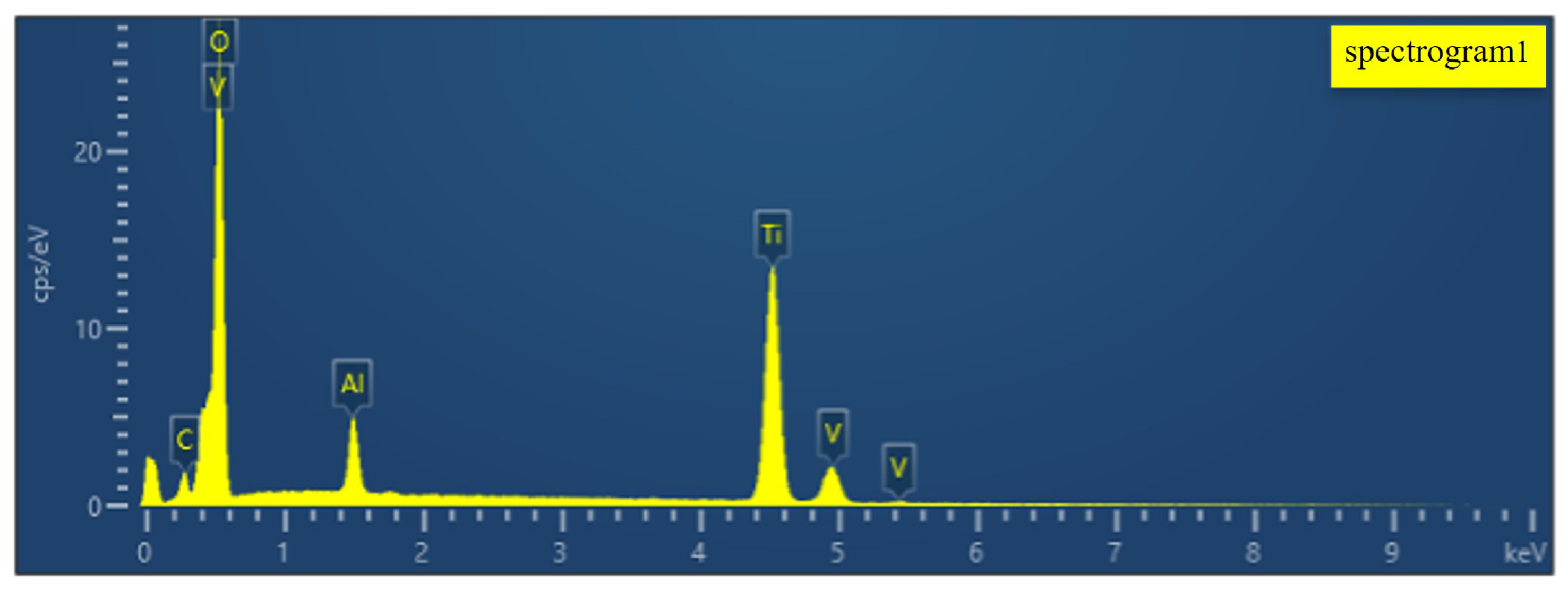

3.3. Trench Edge Elemental Analysis

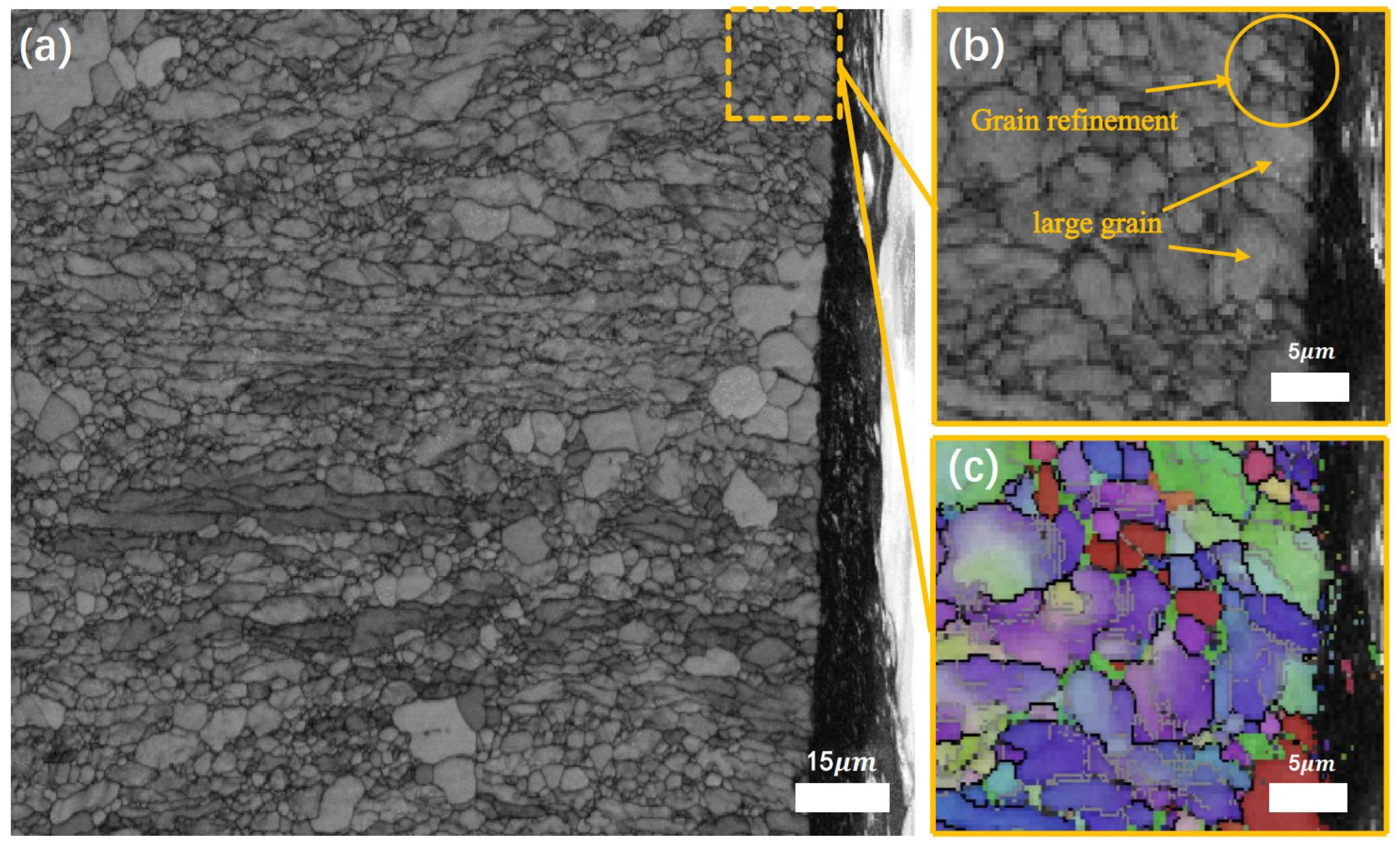

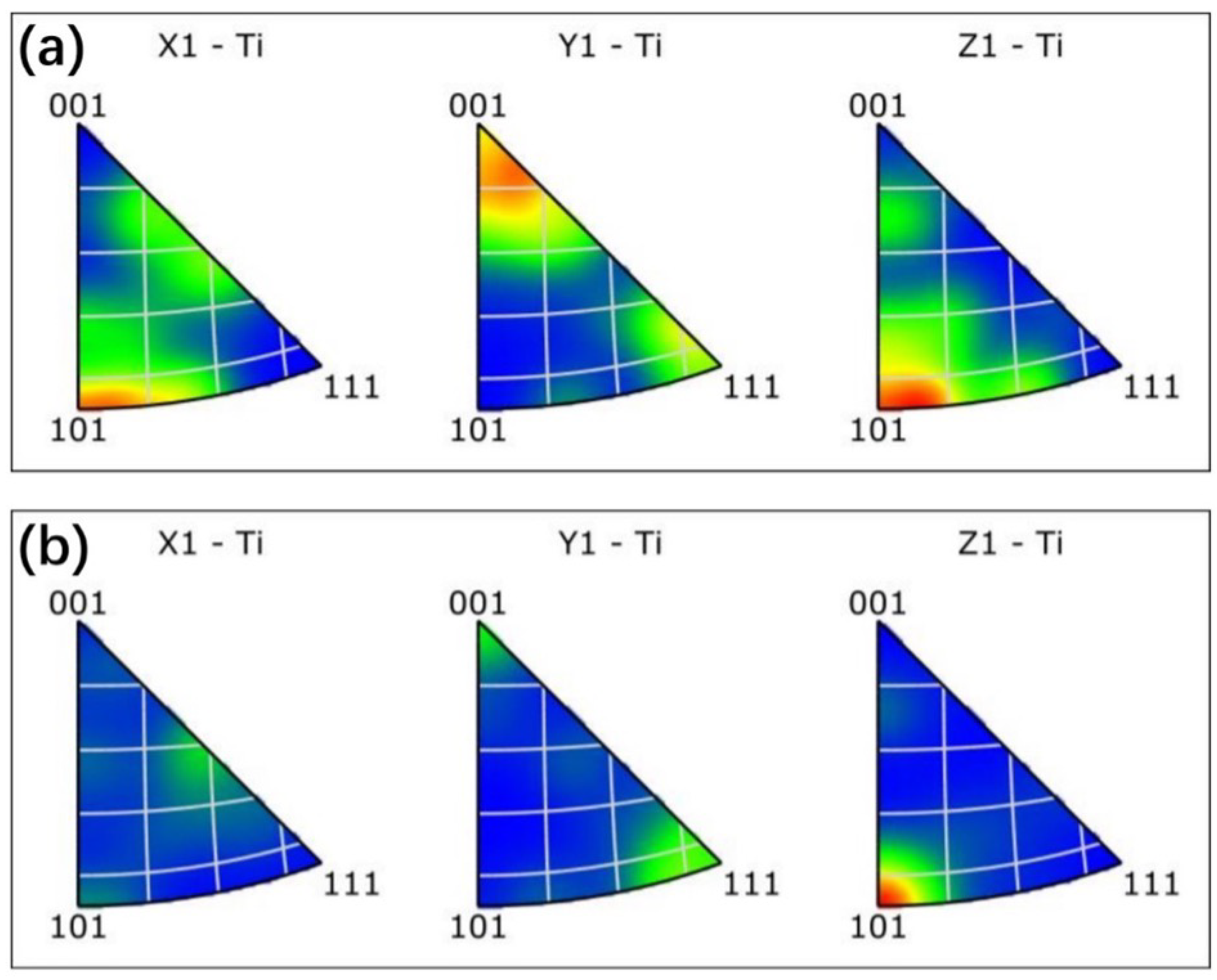

3.4. Effects of Water-Guided Laser Processing on Crystal Orientation and Morphology

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| TC4 | Ti–6Al–4V titanium alloy |

| WJGL | Water-jet-guided laser |

| HAZ | Heat-affected zone |

| SEM | Scanning electron microscopy |

| EDS | Energy-dispersive spectroscopy |

| EBSD | Electron backscatter diffraction |

| BCC | Body-centered cubic |

| HCP | Hexagonal close-packed |

| IPF | Inverse pole figure |

| BC | Band contrast |

| GB | Grain boundary |

References

- Hou, J.; Wicks, B.J.; Antoniou, R.A. An investigation of fatigue failures of turbine blades in a gas turbine engine by mechanical analysis. Eng. Fail. Anal. 2002, 9, 201–211. [Google Scholar] [CrossRef]

- Han, J.C.; Ekkad, S. Recent development in turbine blade film cooling. Int. J. Rotating Mach. 2001, 7, 21–40. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, P.; Yang, H.; Yang, W.; Yang, K.; Xu, W. Effect of heat treatment on microstructure and properties of hybrid manufacturing TC4 alloy bonding zone. J. Mater. Res. Technol. 2025, 34, 1108–1119. [Google Scholar] [CrossRef]

- Miao, X.; Hong, H.; Peng, J.; Ping, T.; Fengfeng, B.; Chenyang, J. Study on mixed-mode fracture behavior of TC4 titanium alloy. Theor. Appl. Fract. Mech. 2023, 125, 103911. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, F.; Chen, J.; Jiang, G.; Cui, X.; Yang, X.; Zhu, X. Study on columnar-equiaxed crystal transition of laser deposited TC4 titanium alloy induced by synchronous layer-by-layer ultrasonic impact. Mater. Sci. Eng. A 2025, 931, 148240. [Google Scholar] [CrossRef]

- Zhang, K.; Li, B.; Liu, C.; Liu, W.; Wang, W.; Wang, H.; Bian, H. Influences of multi-dimensional energy density on multi-scale characteristics of TC4 alloy by Laser Powder Bed Fusion. J. Manuf. Process. 2025, 136, 83–122. [Google Scholar] [CrossRef]

- Teng, J.; Jiang, P.; Cong, Q.; Cui, X.; Nie, M.; Li, X.; Zhang, Z. A comparison on microstructure features, compression property and wear performance of TC4 and TC11 alloys fabricated by multi-wire arc additive manufacturing. J. Mater. Res. Technol. 2024, 29, 2175–2187. [Google Scholar] [CrossRef]

- Wang, C.; Wang, H.; Chu, X.; Lu, Y.; He, H. Study on Forming Mechanism of the Recast Layer on the Workpiece Surface during Micro EDM. Materials 2024, 17, 1073. [Google Scholar] [CrossRef]

- Su, H.; Liu, T.; Kang, J.; Li, L.; Su, R.; Lv, B.; Zheng, C. Competition mechanism of dynamic recrystallization and recovery and microstructure evolution of TC4 alloy during warm deformation. J. Mater. Res. Technol. 2025, 36, 5837–5860. [Google Scholar] [CrossRef]

- Zhao, H.J.; Liu, C.; Hu, J.X.; Yin, S.; Yang, C.W.; Liu, C.S.; Zhan, Y. Residual stress and mechanical properties analysis of TC4 alloy fabricated by laser additive manufacturing. J. Cent. South Univ. 2024, 31, 3983–3995. [Google Scholar] [CrossRef]

- Qi, C.; Du, Y.; Yang, P.; Liu, Z.; Lyu, H.; Zhao, K.; Guo, L. Influence of heat treatment on microstructure and mechanical properties of TC4 fabricated by laser melting deposition. Met. Mater. Int. 2022, 28, 3068–3079. [Google Scholar] [CrossRef]

- Pramanik, D.; Kuar, A.; Sarkar, S.; Mitra, S. Optimisation of edge quality on stainless steel 316L using low power fibre laser beam machining. Adv. Mater. Process. Technol. 2021, 7, 42–53. [Google Scholar] [CrossRef]

- Stráskỳ, J.; Janeček, M.; Harcuba, P.; Bukovina, M.; Wagner, L. The effect of microstructure on fatigue performance of Ti–6Al–4V alloy after EDM surface treatment for application in orthopaedics. J. Mech. Behav. Biomed. Mater. 2011, 4, 1955–1962. [Google Scholar] [CrossRef]

- Yang, J.; Sun, S.; Brandt, M.; Yan, W. Experimental investigation and 3D finite element prediction of the heat affected zone during laser assisted machining of Ti6Al4V alloy. J. Mater. Process. Technol. 2010, 210, 2215–2222. [Google Scholar] [CrossRef]

- Reck, A.; Zeuner, A.T.; Zimmermann, M. Fatigue behavior of non-optimized laser-cut medical grade Ti-6Al-4V-ELI sheets and the effects of mechanical post-processing. Metals 2019, 9, 843. [Google Scholar] [CrossRef]

- Yang, Z.; Stossel, M.; Wang, J. Microstructural evolution and surface strengthening of pulse-laser treated Ti/Ni multilayer thin films. Extrem. Mech. Lett. 2015, 4, 45–51. [Google Scholar] [CrossRef]

- Yu, Z.; Hu, J.; Li, K. Investigating the multiple-pulse drilling on titanium alloy in picosecond laser. J. Mater. Process. Technol. 2019, 268, 10–17. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; Zhang, G.; Wang, B.; Zhang, W. Study on immersion waterjet assisted laser micromachining process. J. Mater. Process. Technol. 2018, 262, 290–298. [Google Scholar] [CrossRef]

- Ren, J.; Kelly, M.; Hesselink, L. Laser ablation of silicon in water with nanosecond and femtosecond pulses. Opt. Lett. 2005, 30, 1740–1742. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Wang, Y.; Huang, X.; Song, G.; Wang, Y. A New Prediction Model for Cutting Depth of Hard Rock Using High-Pressure Water Jets. Rock Mech. Rock Eng. 2024, 57, 7293–7311. [Google Scholar] [CrossRef]

- Cai, C.; Cao, W.; Yang, X.; Zhang, P.; Zeng, L.; Zhou, S. Study on composite rock-breaking mechanism of ultrahigh-pressure water jet–PDC cutter. SPE J. 2024, 29, 3892–3904. [Google Scholar] [CrossRef]

- Liu, Y.; Wei, M.; Zhang, T.; Qiao, H.; Li, H. Overview on the development and critical issues of water jet guided laser machining technology. Opt. Laser Technol. 2021, 137, 106820. [Google Scholar] [CrossRef]

- Liang, J.; Qiao, H.; Zhao, J.; Cao, Z.; Wang, S.; Zhang, Y. Study on water jet stability and processing morphology of groove cutting using water jet guided laser. Opt. Laser Technol. 2024, 174, 110670. [Google Scholar] [CrossRef]

- Li, D.; Xing, F.; Jia, X.; Suo, H.; Li, E.; Wu, F. Analysis of remelted layers of DD6 single-crystal superalloys by water jet-guided laser processing. J. Alloys Compd. 2025, 1010, 177637. [Google Scholar] [CrossRef]

- Hu, H.; Liu, C.; Su, Z.; Ye, F.; Qian, B.; Dai, Y.; Sun, S.; Liu, B.; Qiu, J. Crystallization-resistant water-jet guided laser processing of Cu46Zr46Al8 amorphous alloy via thermally suppressed strategy. Intermetallics 2025, 182, 108789. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiao, H.; Zhao, J.; Cao, Z.; Liang, J.; Kang, F.; Wang, S. Research on the influence of the jet flow regime in the kerf on the cutting surface accuracy in WJGL. Mater. Today Commun. 2023, 35, 105503. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiao, H.; Zhao, J.; Cao, Z. Research on water jet-guided laser micro-hole machining of 6061 aluminum alloy. Int. J. Adv. Manuf. Technol. 2022, 118, 1–13. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Hu, J.; Zhong, L.; Su, Z.; Qian, B.; Liu, X.; Dai, Y.; Song, J.; Sun, S.; et al. Rapid high-precision machining of LTCC utilizing water-jet guided laser technology: Expanding the horizons of functional ceramic processing. Mater. Today Commun. 2024, 41, 111013. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiao, H.; Zhao, J.; Cao, Z.; Liang, J.; Zhang, Q. Numerical and experimental study on the stability of water-beam fiber in double coaxial gas-assisted water jet guided laser machining. Opt. Laser Technol. 2025, 190, 113221. [Google Scholar] [CrossRef]

- Liang, J.; Qiao, H.; Zhao, J.; Cao, Z.; Zhang, Y.; Zhang, Q. Simulation and experimental study on double staggered-axis air-assisted water jet-guided laser film cooling hole machining. Opt. Laser Technol. 2025, 181, 112057. [Google Scholar] [CrossRef]

- Zhao, C.; Zhao, Y.; Zhao, D.; Meng, S.; Zhang, G.; Cao, C.; Zhang, H.; Meng, J. Annular gas-assisted water-jet guided laser manufacturing groove structure of Inconel 718 alloy. Int. J. Adv. Manuf. Technol. 2023, 128, 3969–3982. [Google Scholar] [CrossRef]

- Marla, D.; Bhandarkar, U.V.; Joshi, S.S. A model of laser ablation with temperature-dependent material properties, vaporization, phase explosion and plasma shielding. Appl. Phys. A 2014, 116, 273–285. [Google Scholar] [CrossRef]

- Marimuthu, S.; Smith, B. Water-jet guided laser drilling of thermal barrier coated aerospace alloy. Int. J. Adv. Manuf. Technol. 2021, 113, 177–191. [Google Scholar] [CrossRef]

- Williams, J.C.; Boyer, R.R. Opportunities and issues in the application of titanium alloys for aerospace components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, Y.; Xue, Y.; Sui, X.; Yuan, B.; Wang, Y.; Liang, W. Functional surfaces with reversibly switchable wettability: Fundamentals, progresses, applications and challenges. Prog. Org. Coatings 2024, 188, 108167. [Google Scholar] [CrossRef]

- Yong, J.; Chen, F.; Yang, Q.; Hou, X. Femtosecond laser controlled wettability of solid surfaces. Soft Matter 2015, 11, 8897–8906. [Google Scholar] [CrossRef] [PubMed]

- Korobeinikova, E.; Prokhorov, I.; Strelov, V. Development of Methods for Controlling Crystal Growth Using Thermal Effect on Melt. Crystallogr. Rep. 2019, 64, 484–487. [Google Scholar] [CrossRef]

- Hu, X.; Jiang, G.; Fan, P.; Hu, G.; Xu, G.; Wang, W.; Wang, L.; Zhang, H.; Zhong, M. 1000° C High-Temperature Wetting Behaviors of Molten Metals on Laser-Microstructured Metal Surfaces. Langmuir 2023, 39, 17538–17550. [Google Scholar] [CrossRef]

- Qiao, K.; Zhong, S.; Tang, S.; Yang, K.; Yue, H.; Ma, K.; Song, L.; Liang, B. Influence of pore structure on thermal stress distribution inside coal particles during primary fragmentation. Particuology 2024, 85, 49–61. [Google Scholar] [CrossRef]

- Joy, N.; Prakash, S.; Krishnamoorthy, A.; Antony, A. Experimental investigation and analysis of drilling in Grade 5 Titanium alloy (Ti-6Al-4V). Mater. Today Proc. 2020, 21, 335–339. [Google Scholar] [CrossRef]

- Zhao, Z.Y.; Li, L.; Bai, P.K.; Jin, Y.; Wu, L.Y.; Li, J.; Guan, R.G.; Qu, H.Q. The heat treatment influence on the microstructure and hardness of TC4 titanium alloy manufactured via selective laser melting. Materials 2018, 11, 1318. [Google Scholar] [CrossRef]

- Liang, Z.; Tang, B.; Gui, Y.; Zhao, Q. High-temperature oxidation behavior of the Ti-6Al-4V alloy manufactured by selective laser sintering. JOM 2019, 71, 3600–3605. [Google Scholar] [CrossRef]

- Chen, W.; Boehlert, C.; Howe, J.Y.; Payzant, E.A. Elevated-temperature mechanical behavior of as-cast and wrought Ti-6Al-4V-1B. Metall. Mater. Trans. A 2011, 42, 3046–3061. [Google Scholar] [CrossRef]

- Wei, J.; Yuan, S.; Yang, S.; Gao, M.; Fu, Y.; Hu, T.; Li, X.; Fan, X.; Zhang, W. Waterjet-guided laser processing of SiC/SiC ceramic matrix composites to obtain high cleanliness and low oxidation damage characteristics surfaces. Surf. Coatings Technol. 2024, 484, 130791. [Google Scholar] [CrossRef]

- Huang, K.; Logé, R.E. A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Zhang, D.; Qiu, D.; Gibson, M.A.; Zheng, Y.; Fraser, H.L.; StJohn, D.H.; Easton, M.A. Additive manufacturing of ultrafine-grained high-strength titanium alloys. Nature 2019, 576, 91–95. [Google Scholar] [CrossRef]

- Chen, D.; Sixta, M.; Zhang, X.; De Jonghe, L.; Ritchie, R. Role of the grain-boundary phase on the elevated-temperature strength, toughness, fatigue and creep resistance of silicon carbide sintered with Al, B and C. Acta Mater. 2000, 48, 4599–4608. [Google Scholar] [CrossRef]

| Element | Ti | Al | V | Fe | Si | C | N | O |

|---|---|---|---|---|---|---|---|---|

| Mass fraction (%) | Bal. | 6.00 | 4.10 | 0.30 | 0.10 | 0.10 | 0.05 | 0.015 |

| Parameter | Value |

|---|---|

| Wavelength (nm) | 532 |

| Laser power (W) | 0–40 |

| Repetition rate (kHz) | 10 |

| Water pressure (MPa) | 22.2 |

| Feed rate (mm/s) | 0–70 |

| Nozzle inner diameter (m) | 70 |

| Spot diameter (m) | 70 |

| Flow rate of water (mL/s) | 0.6–0.7 |

| Fluence (J/) | 0–2.1 × |

| Intensity (W/) | 0–3.9 × |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Lu, M.; Zhao, J.; Han, C.; Li, D.; Sun, B. Study on the Microstructure and Properties of TC4 Alloy Based on Water-Jet-Guided Laser Technology. Metals 2025, 15, 1204. https://doi.org/10.3390/met15111204

Yang H, Lu M, Zhao J, Han C, Li D, Sun B. Study on the Microstructure and Properties of TC4 Alloy Based on Water-Jet-Guided Laser Technology. Metals. 2025; 15(11):1204. https://doi.org/10.3390/met15111204

Chicago/Turabian StyleYang, Hao, Mingrui Lu, Jibin Zhao, Chongyang Han, Dongming Li, and Boyu Sun. 2025. "Study on the Microstructure and Properties of TC4 Alloy Based on Water-Jet-Guided Laser Technology" Metals 15, no. 11: 1204. https://doi.org/10.3390/met15111204

APA StyleYang, H., Lu, M., Zhao, J., Han, C., Li, D., & Sun, B. (2025). Study on the Microstructure and Properties of TC4 Alloy Based on Water-Jet-Guided Laser Technology. Metals, 15(11), 1204. https://doi.org/10.3390/met15111204