Low-Cost Application Strategies of Marine Titanium Alloys: Titanium/Steel Dissimilar Materials

Abstract

1. Introduction

2. Preparation Strategies for Ti/Fe Dissimilar Materials

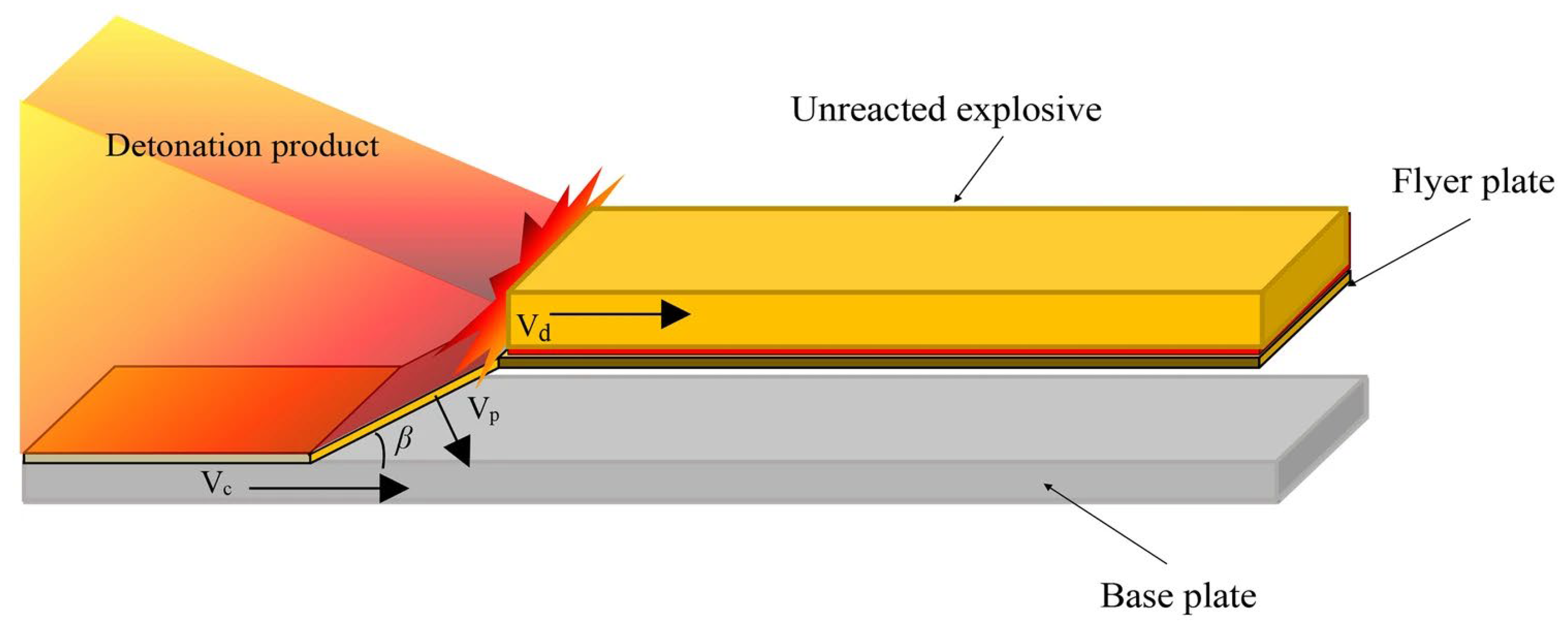

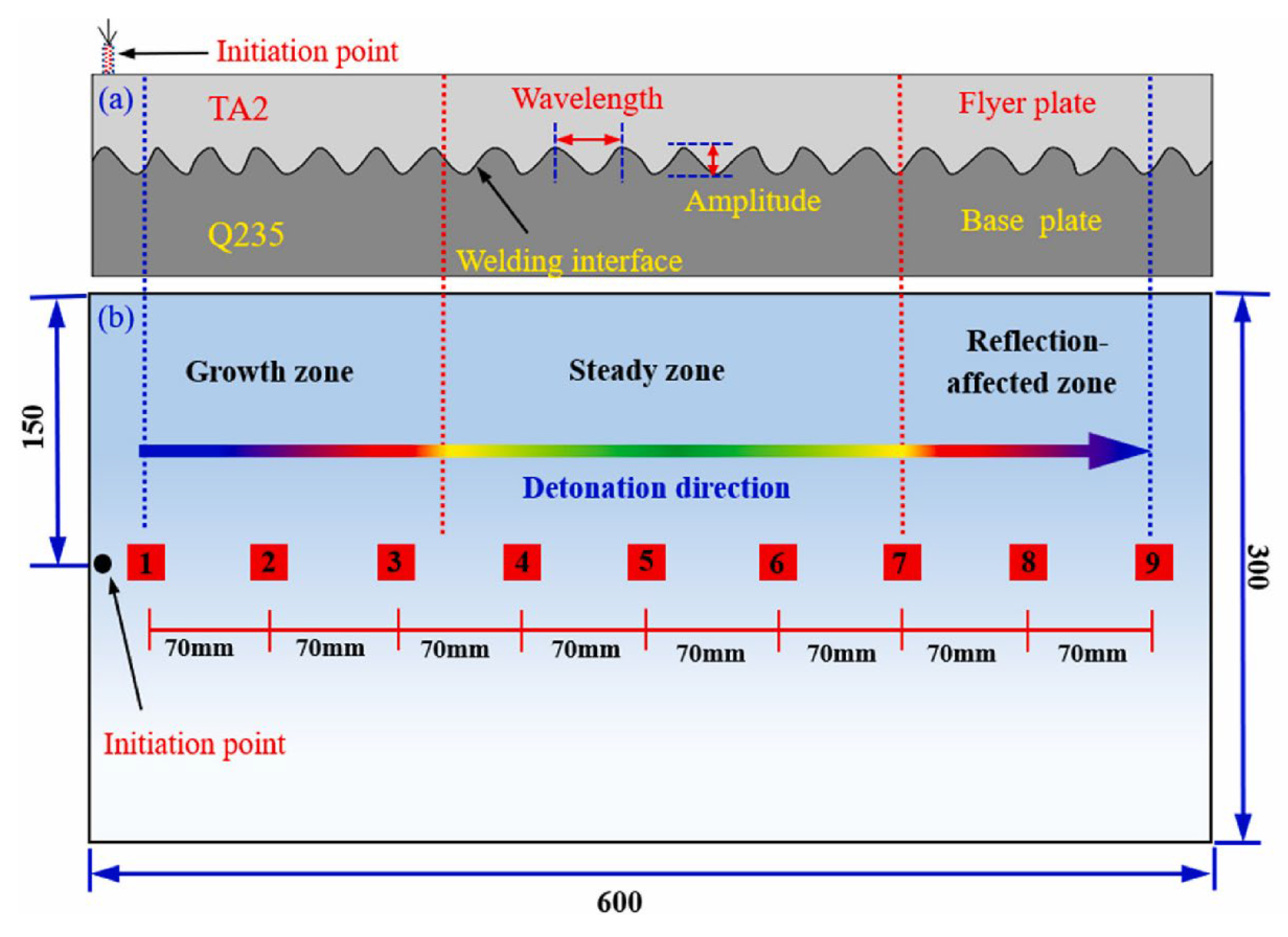

2.1. Explosive Welding

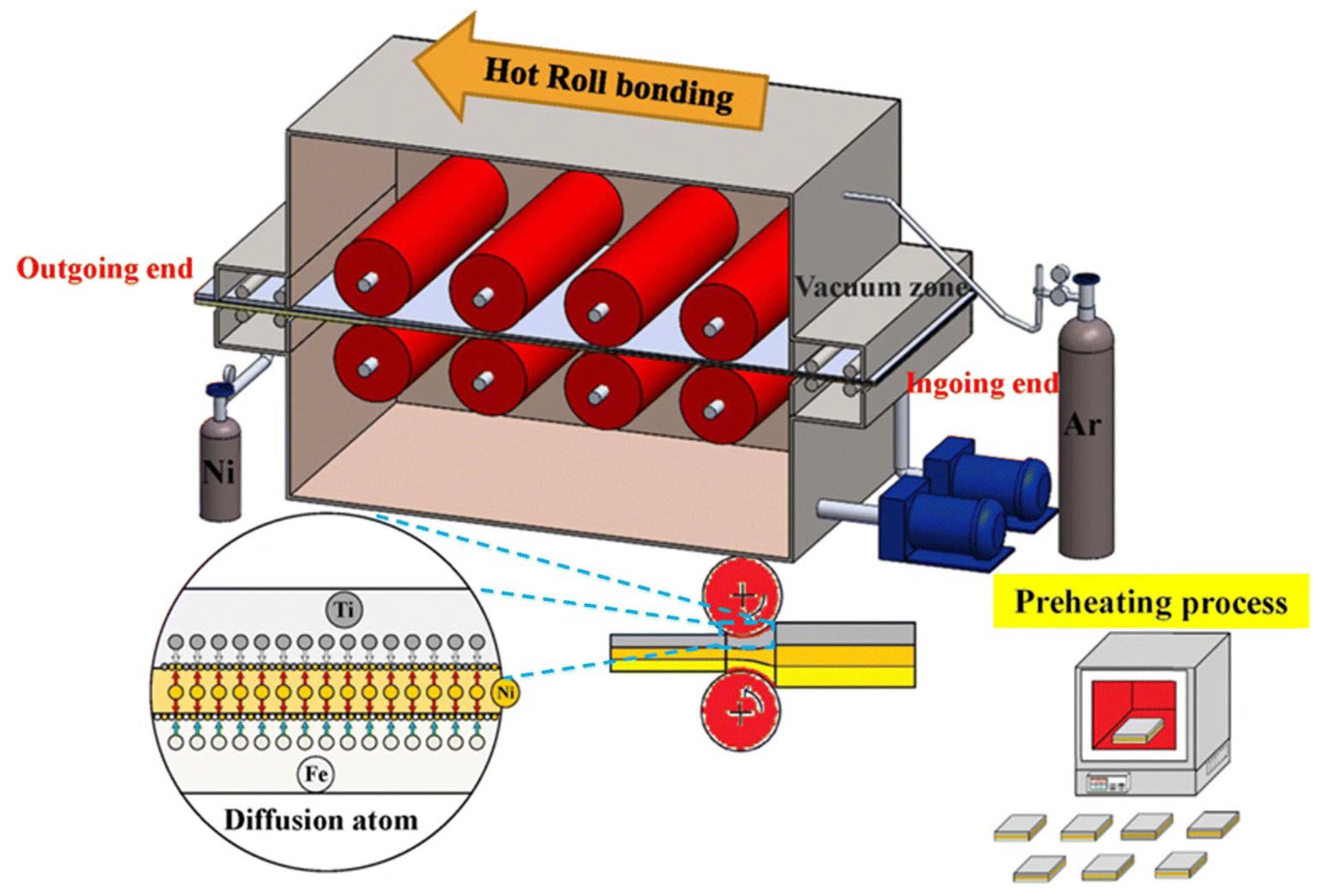

2.2. Rolling

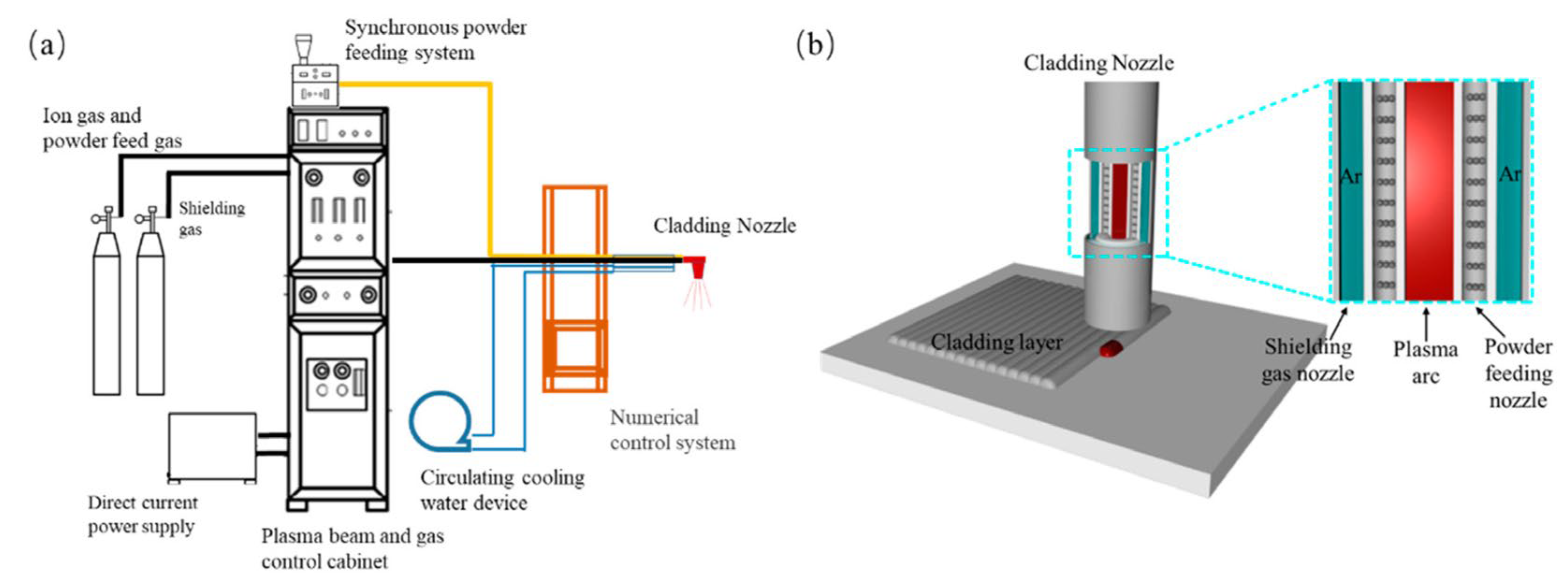

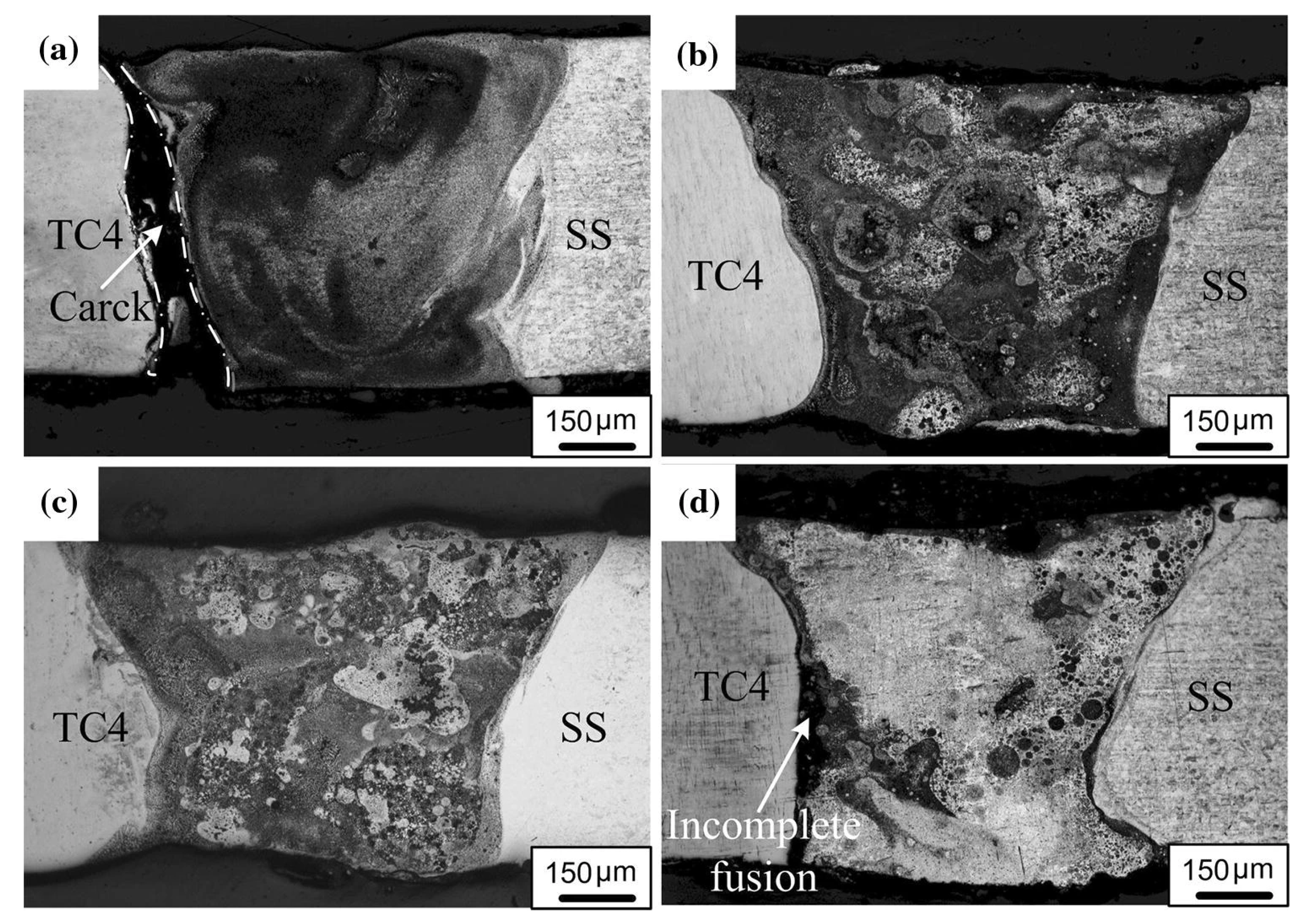

2.3. High-Energy Beam Cladding

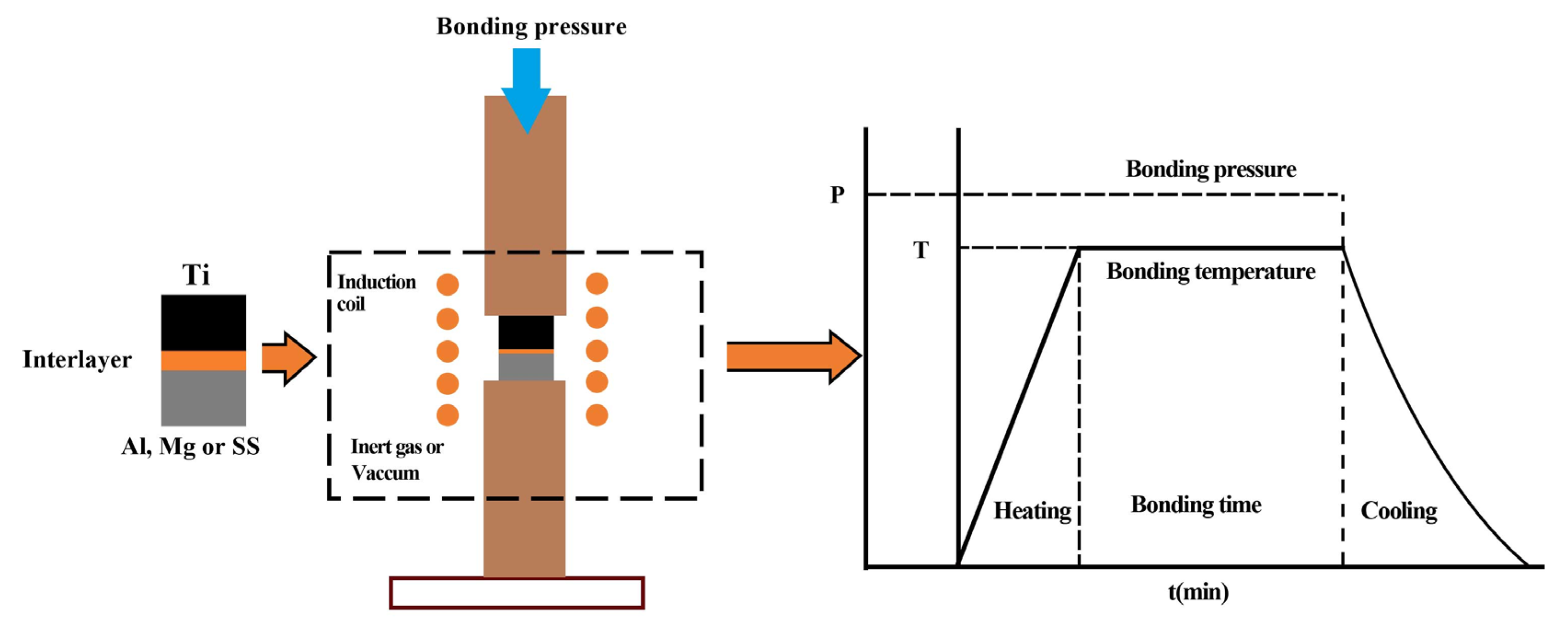

2.4. Diffusion Bonding

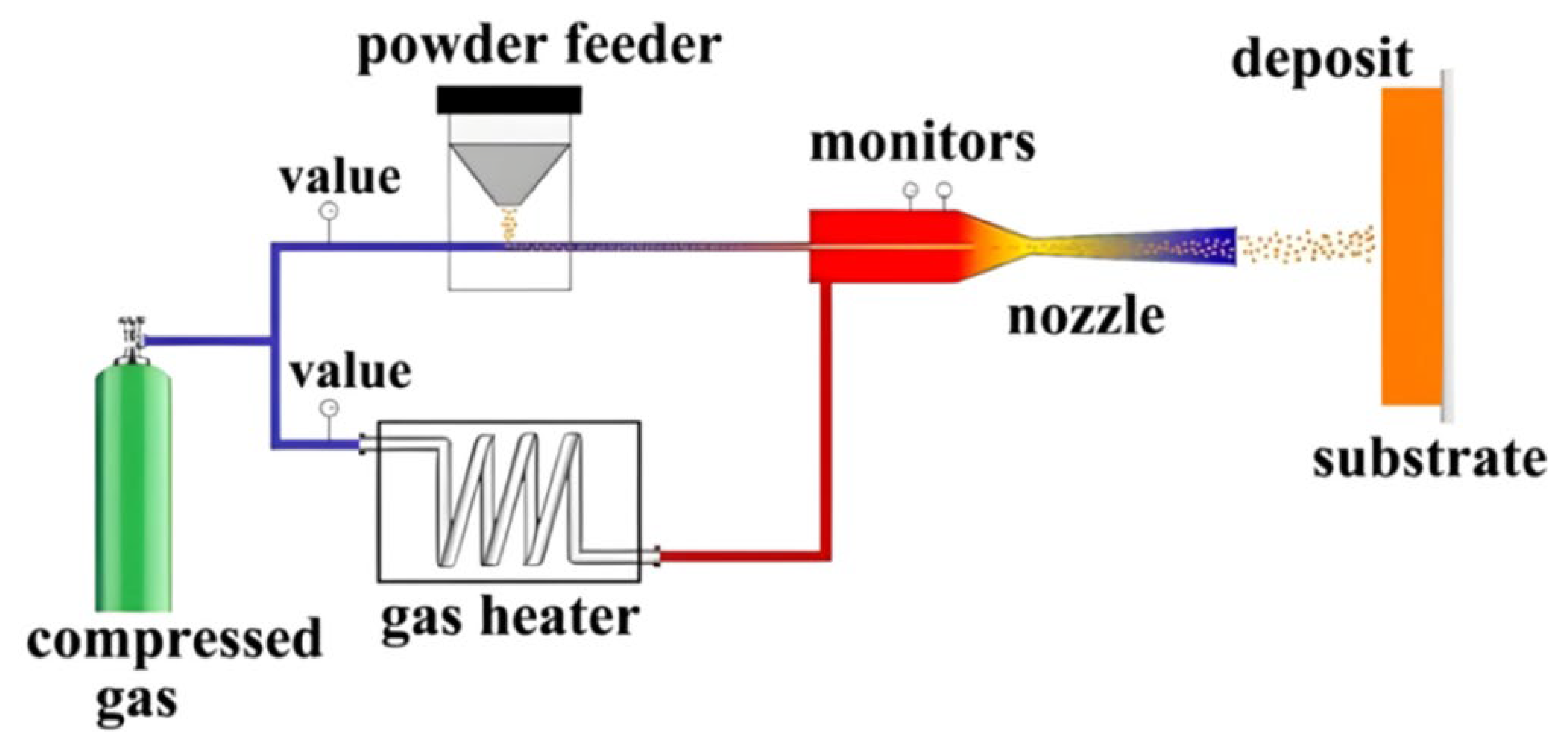

2.5. Cold Spray

2.6. Other Preparation Strategies

3. Interlayer Optimization Strategies

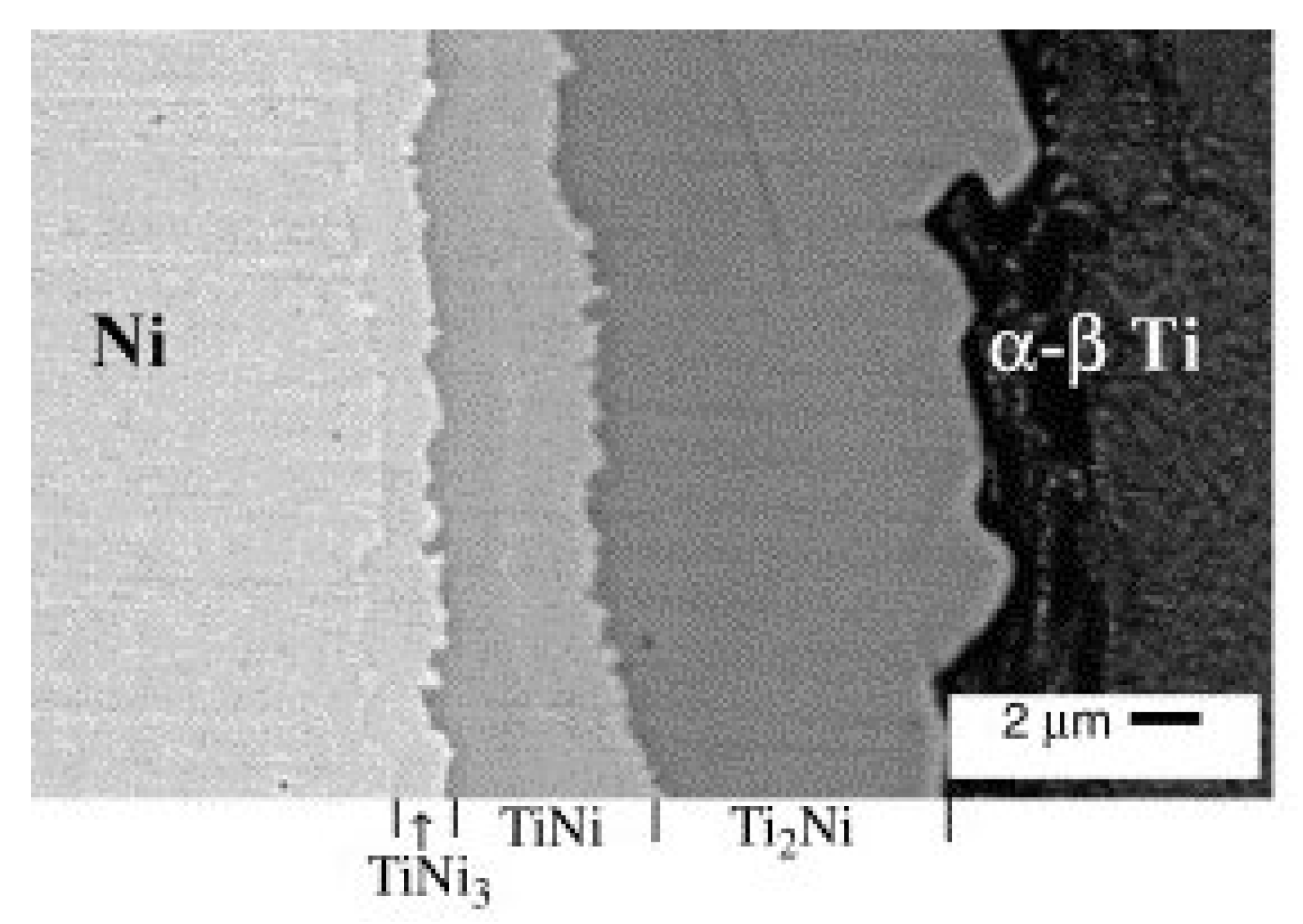

3.1. Ni Interlayer

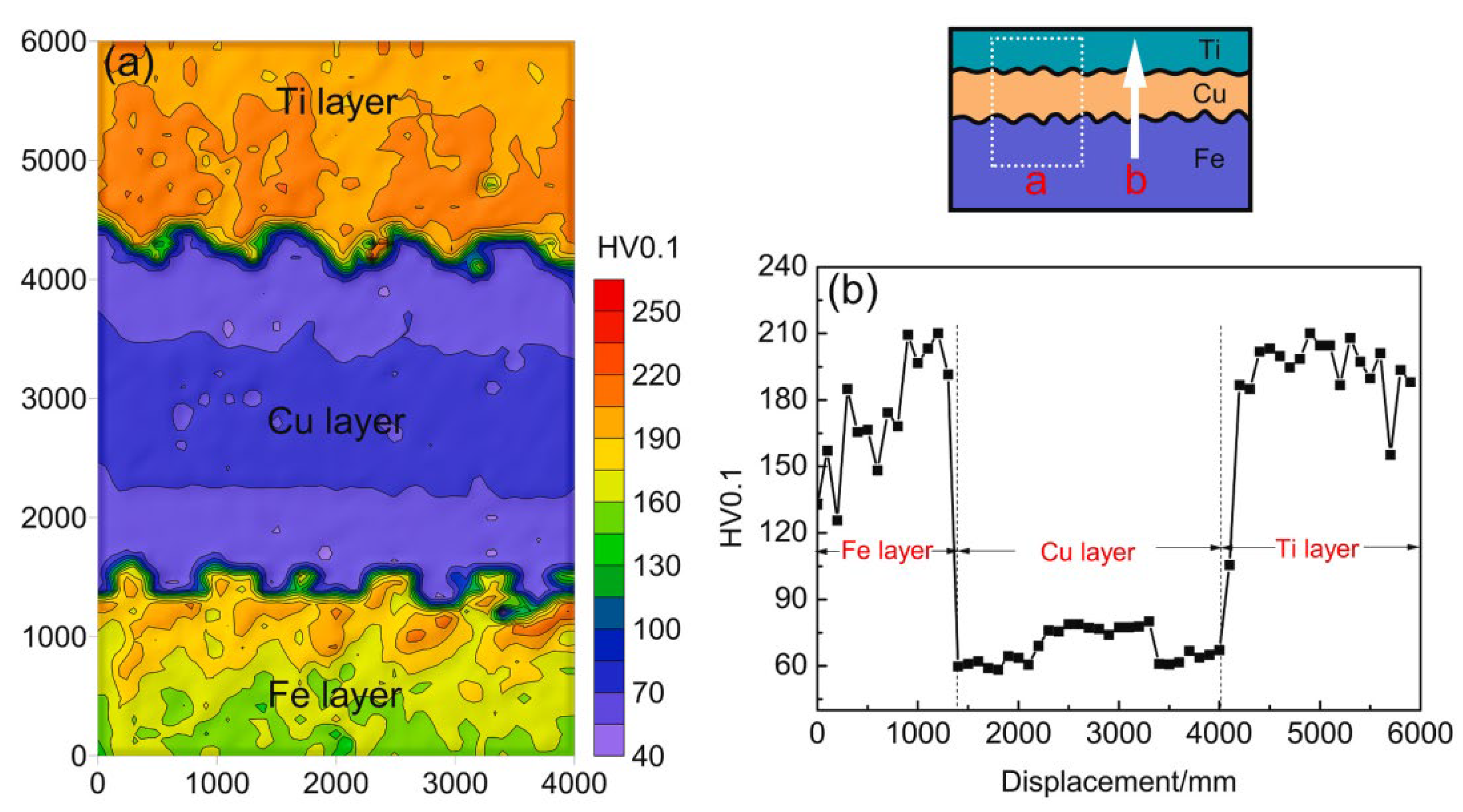

3.2. Cu Interlayer

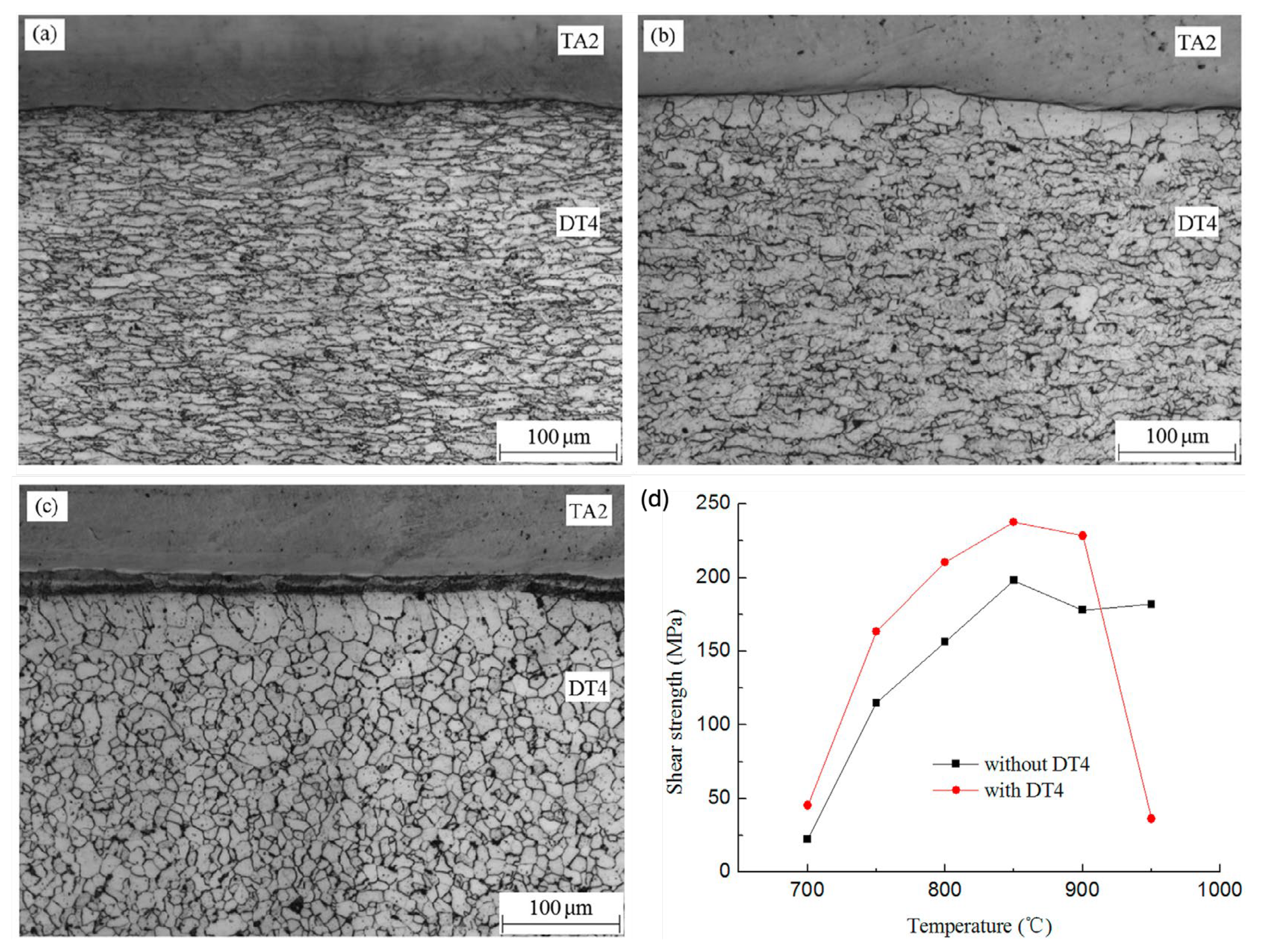

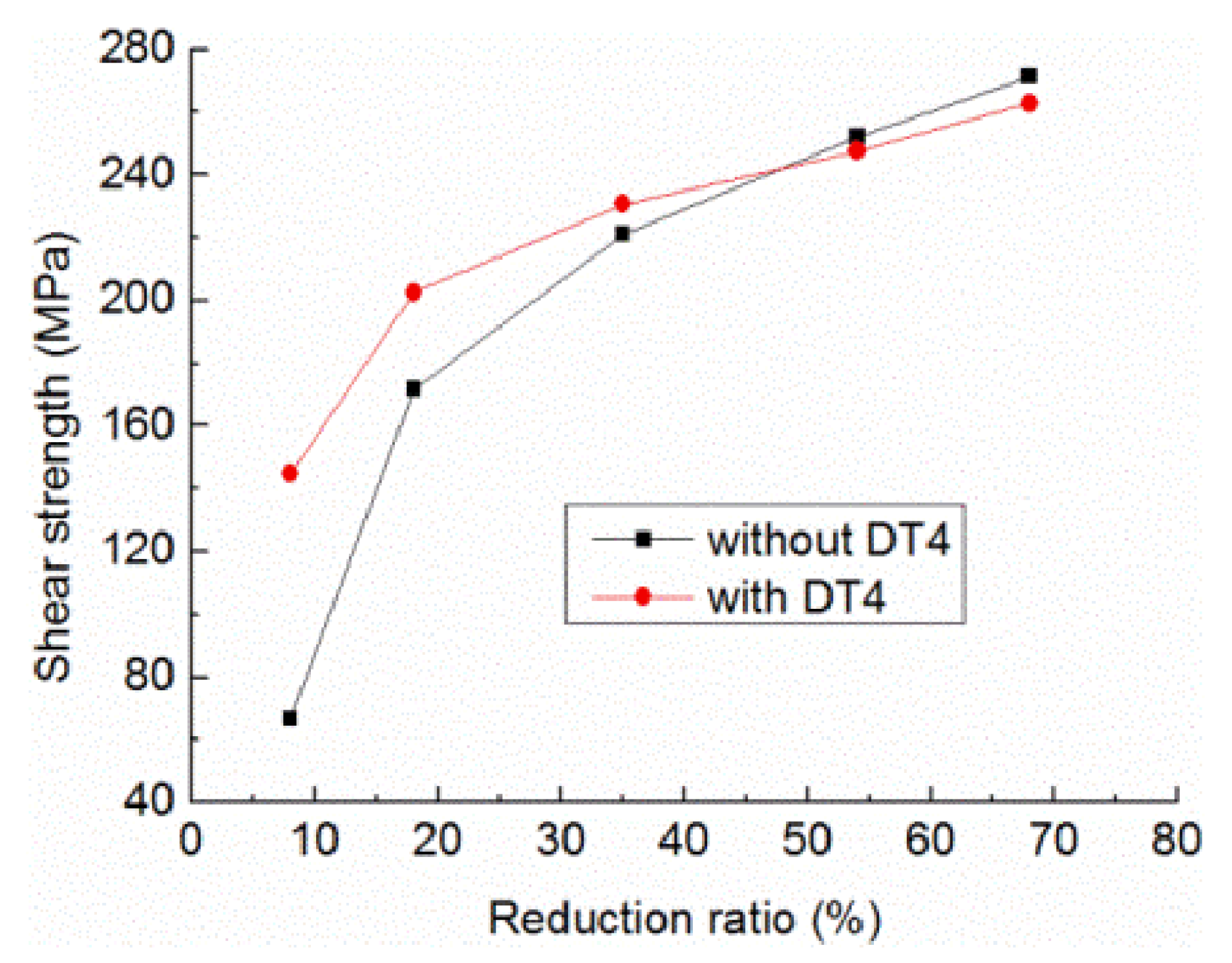

3.3. Fe Interlayer

3.4. Al Interlayer

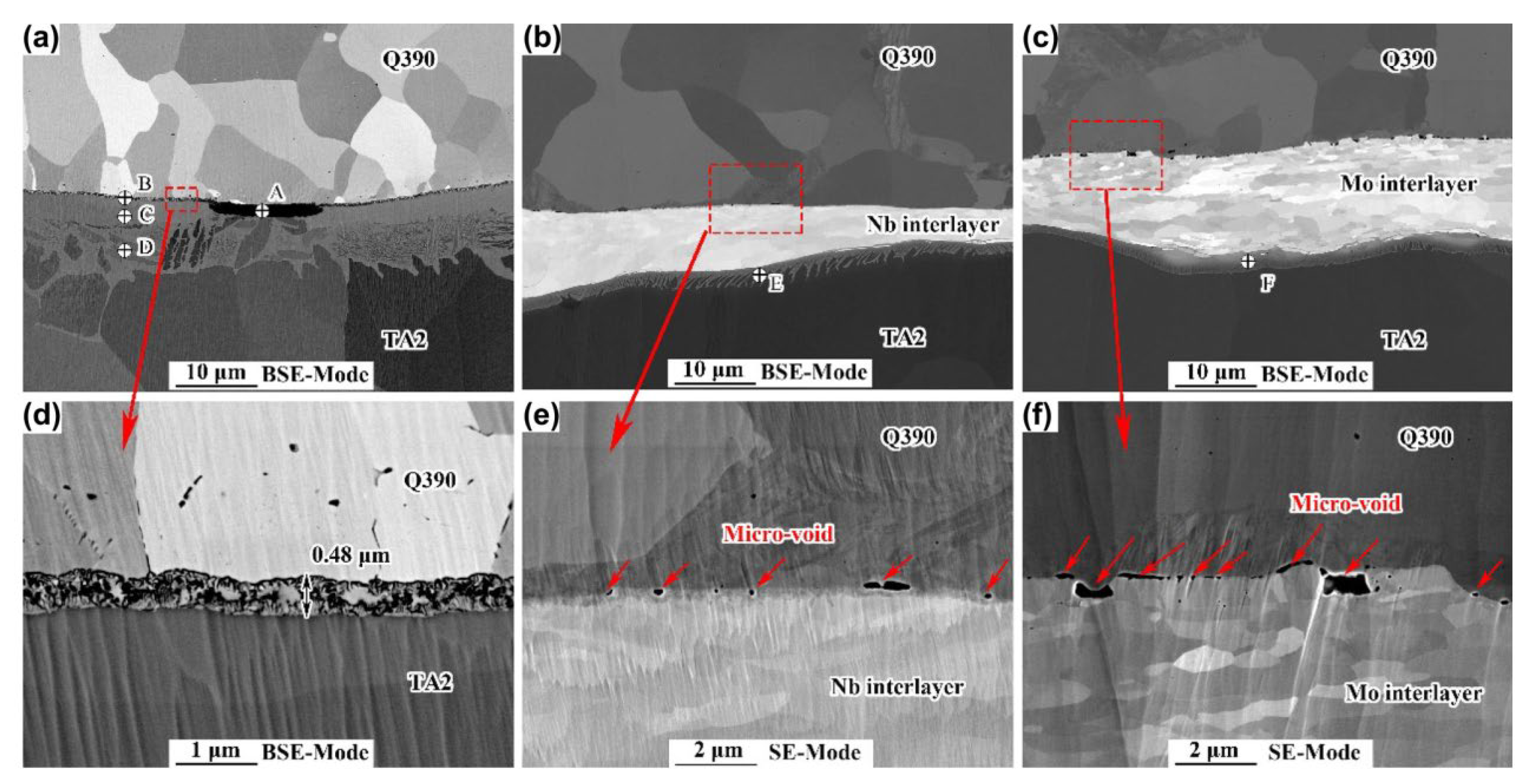

3.5. Other Single Interlayers

3.6. Composite Interlayers

4. Properties of Ti/Fe Dissimilar Materials

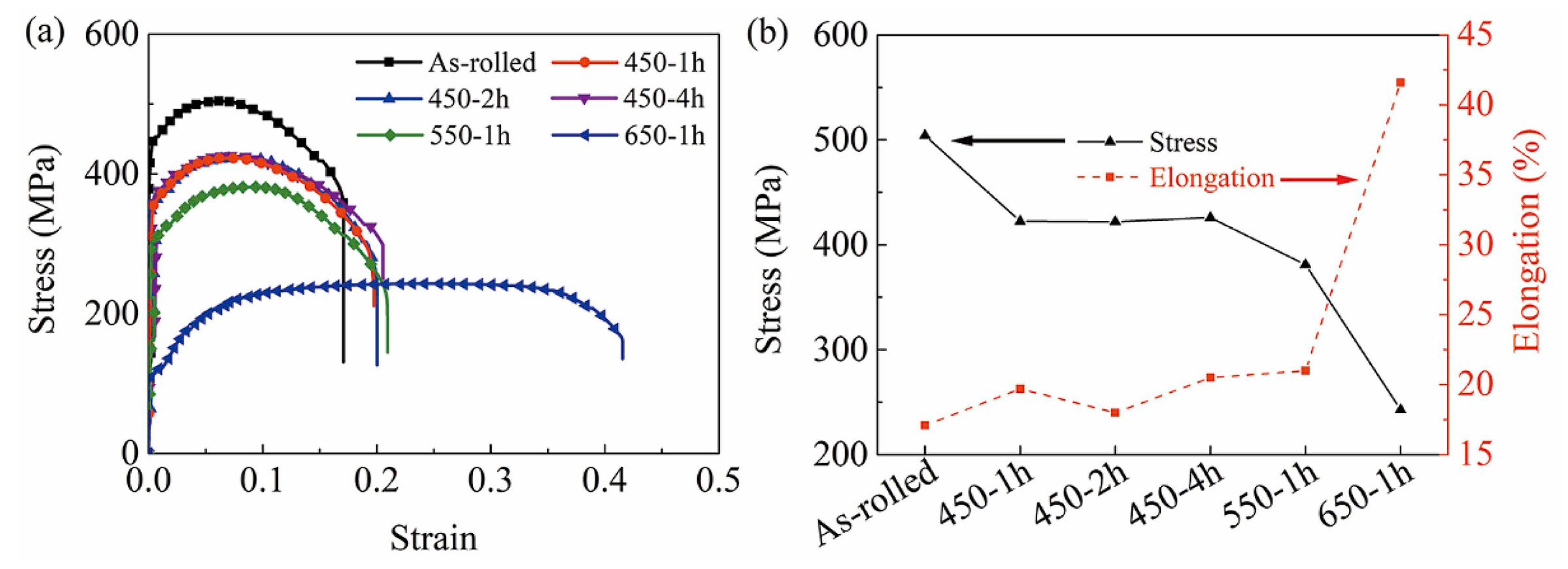

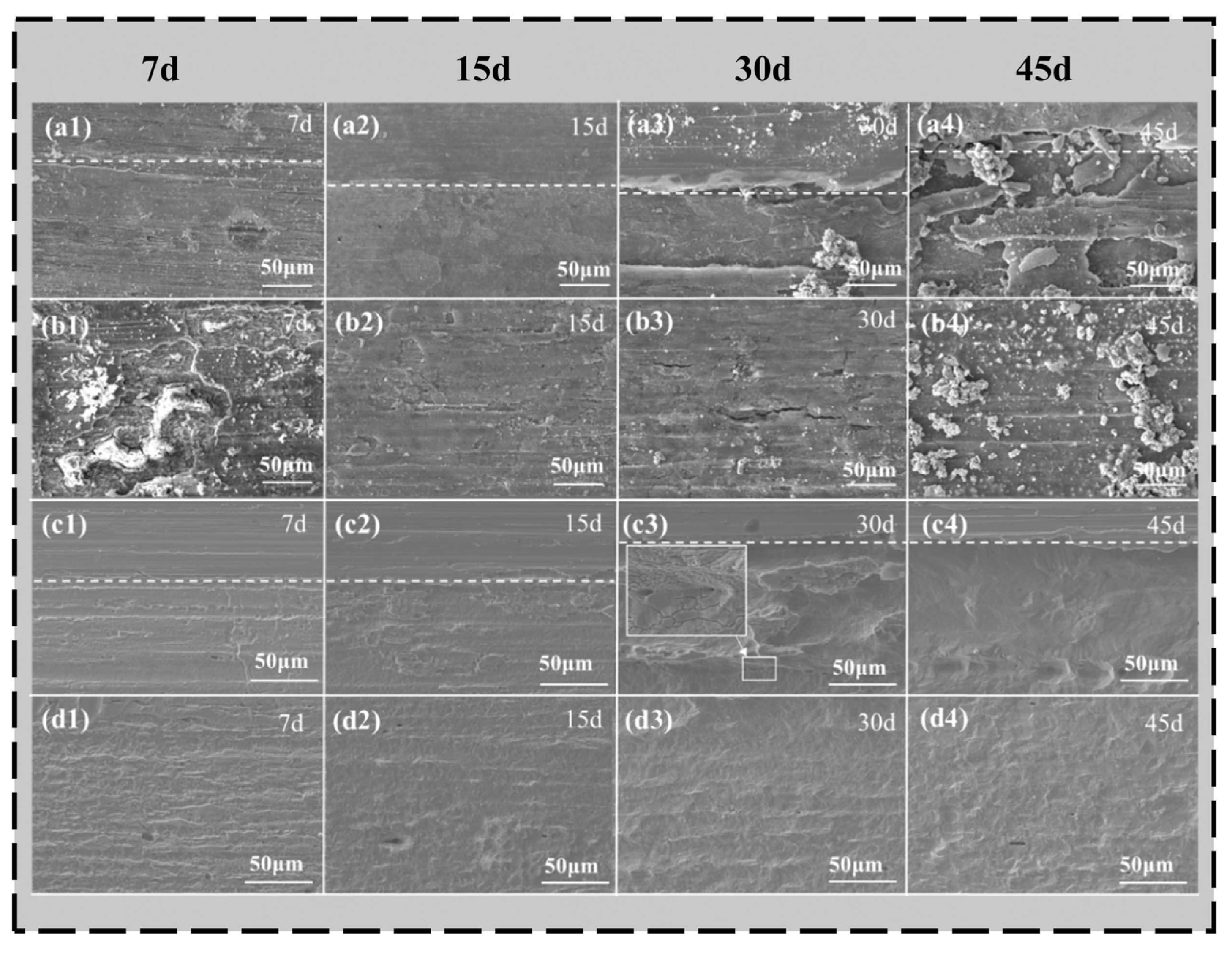

4.1. Mechanical Properties

4.2. Corrosion Resistance

5. Summary and Prospect

- (1)

- Strengthen research on additive manufacturing: Additive manufacturing provides a feasible path for the short-process preparation of Ti/Fe dissimilar materials. In-depth investigations should be conducted on additive manufacturing strategies (including laser cladding, plasma cladding, and ultrasonic additive manufacturing) to meet the short-process requirements of marine engineering components. The balance among process parameters, mechanical properties, and corrosion resistance should be explored.

- (2)

- Improving preparation processes: Machine learning should be used to assist in process design to predict the interface stability of Ti/Fe dissimilar materials by data models, especially in large-scale manufacturing. A systematic relationship between processing parameters, technical routes, and material properties should be established to guide practical production.

- (3)

- In-depth study of interfacial mechanisms: Further studies are required to clarify the evolution of interfacial microstructures and the precipitation behavior of brittle phases, thereby forming a comprehensive theoretical framework for understanding how microstructures regulate the performance of Ti/Fe dissimilar materials.

- (4)

- Optimization and development of interlayer materials: As interlayers significantly improve the performance of Ti/Fe dissimilar materials, exploring more efficient interlayer systems is essential for enhancing the reliability of Ti/Fe dissimilar materials in harsh marine environments. Further research should establish the relationship between interlayer composition, structure, and performance by simulation and machine learning; conduct high-speed screening of the interlayer design space; and achieve the target performance of Ti/Fe dissimilar materials.

- (5)

- Addressing industrialization challenges: Through process optimization, theoretical innovation, and technological breakthroughs, key issues of improving production efficiency and reducing production costs in industrial applications should be resolved. Welding research should be conducted on Ti/Fe dissimilar materials to meet the needs of large-scale structures. Long-term marine exposure and immersion tests should be conducted to evaluate the damage and corrosion risks of the Ti/Fe dissimilar materials and their welding joint, especially the service safety of these materials in extreme marine environments.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, H.Q.; Zhang, Q.; Li, Y.M.; Liu, G.; Huang, Y. Effects of mechanical stress on protective properties of a marine coating on mild steel substrate. Corros. Sci. 2020, 177, 108986. [Google Scholar] [CrossRef]

- Yang, H.Q.; Zhang, Q.; Li, Y.M.; Liu, G.; Huang, Y. Effects of mechanical stress and cathodic protection on the performance of a marine organic coating on mild steel. Mater. Chem. Phys. 2021, 261, 124233. [Google Scholar] [CrossRef]

- Hasan, M.; Khan, M.I.; Jamaludin, S.; Hasan, I.; Bin, M.F.; Mohamad, A.F.; Norsani, W.M.; Russtam, M.I.; Ridwan, M.F.; Afrizal, N.B.; et al. A critical analysis of machine learning in ship, offshore, and oil & gas corrosion research, part I: Corrosion detection and classification. Ocean Eng. 2024, 313, 119600. [Google Scholar]

- Song, D.; Liu, S.; Wang, R.; Cui, Z.; Yi, F.; Zheng, Y.; Zhang, B. Corrosion behavior and mechanical property degradation of Al-Zn-Mg-Cu alloy in tropical marine atmosphere. Ocean Eng. 2025, 34, 1122615. [Google Scholar] [CrossRef]

- Qian, R.; Li, Q.; Fu, C.; Zhang, Y.; Wang, Y.; Jin, X. Atmospheric chloride-induced corrosion of steel-reinforced concrete beam exposed to real marine-environment for 7 years. Ocean Eng. 2023, 286, 115675. [Google Scholar] [CrossRef]

- Chen, Q.; Xu, Y.; Ma, A.; Zhang, L.; Zheng, Y. Study of the passivation and repassivation behavior of pure titanium in 3.5 wt% NaCl solution and 6 M HNO3 solution. Corros. Sci. 2023, 224, 111538. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, Z.; Zhang, X.; Su, Z.; Liu, J.; Yu, R.; Wu, K. Mechanistic insight into pre-strain influenced stress corrosion cracking of advanced high-strength steels in marine environment. Corros. Sci. 2025, 255, 113057. [Google Scholar] [CrossRef]

- Xing, C.; Guo, J.; Liu, Y.; Guo, Q.; Cao, S.; Wu, L.; Wang, Z.; Wang, C.; Cao, G. Corrosion failure of copper alloys in sheltered atmospheric environments: A cross-scale analysis combining multiscale characterization and density functional theory. Corros. Sci. 2025, 256, 113255. [Google Scholar] [CrossRef]

- Tian, H.; Cui, Z.; Zhang, B.; Yang, W.; Yang, Y.; Cui, H. Atmospheric corrosion and mechanical property degradation of 2524-T3 aluminum alloy in marine environments. Corros. Sci. 2024, 239, 112398. [Google Scholar] [CrossRef]

- Najafizadeh, M.; Yazdi, S.; Bozorg, M.; Ghasempour, M.M.; Hosseinzadeh, M.; Zarrabian, M.; Cavaliere, P. Classification and applications of titanium and its alloys: A review. J. Alloys Compd. Commun. 2024, 3, 100019. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, B.; Wang, Q.; Jiang, P. Application of Titanium Alloy Materials for the Pressure-Resistant Structure of Deep Diving Equipment. Chin. J. Eng. Sci. 2019, 21, 18. [Google Scholar] [CrossRef]

- Jia, L.F.; Hao, B. Report on China titanium industry in 2020. Iron Steel Vanadium Titan. 2021, 42, 1–9. [Google Scholar]

- Hai, L.T.; Ban, H.Y.; Huang, C.Y.; Shi, Y.J. Fatigue properties of titanium-clad bimetallic steel butt-welded joints. Thin-Walled Sruct. 2024, 202, 112149. [Google Scholar] [CrossRef]

- Fu, L.; Yu, C.; Donnini, R.; Xiao, H.; Angella, G. Preparation of Ti/Steel composite plates with AA6061 as the intermediate layer based on CRB. Mater. Lett. 2024, 363, 136287. [Google Scholar] [CrossRef]

- Li, X.; Bi, Z.; Wang, Q.; Rong, K.; Xu, M.; Zhang, T.; Qian, J. Influence of copper foil interlayer on microstructure and bonding properties of titanium-steel explosive welded composite plate. Mater. Today Commun. 2023, 34, 105143. [Google Scholar] [CrossRef]

- Prasanthi, T.N.; Sudha, R.C.; Saroja, S. Explosive cladding and post-weld heat treatment of mild steel and titanium. Mater. Des. 2016, 93, 180–193. [Google Scholar] [CrossRef]

- Yu, C.; Fu, L.; Xiao, H.; Lv, Q.; Gao, B. Effect of carbon content on the microstructure and bonding properties of hot-rolling pure titanium clad carbon steel plates. Mater. Sci. Eng. A 2021, 820, 141572. [Google Scholar] [CrossRef]

- Marrocco, T.; Hussain, T.; McCartney, D.G.; Shipway, P.H. Corrosion Performance of Laser Posttreated Cold Sprayed Titanium Coatings. J. Therm. Spray Technol. 2011, 20, 909–917. [Google Scholar] [CrossRef]

- Gao, W.; Wang, S.; Hu, K.; Jiang, X.; Yu, H.; Sun, D. Effect of laser cladding speed on microstructure and properties of tita-nium alloy coating on low carbon steel. Surf. Coat. Technol. 2022, 451, 129029. [Google Scholar] [CrossRef]

- Deng, Y.; Sheng, G.; Xu, C. Evaluation of the microstructure and mechanical properties of diffusion bonded joints of tita-nium to stainless steel with a pure silver interlayer. Mater. Des. 2013, 46, 84–87. [Google Scholar] [CrossRef]

- Atasoy, E.; Kahraman, N. Diffusion bonding of commercially pure titanium to low carbon steel using a silver interlayer. Mater. Charact. 2008, 59, 1481–1490. [Google Scholar] [CrossRef]

- Zhao, D.S.; Yan, J.C.; Liu, Y.J.; Ji, Z.S. Interfacial structure and mechanical properties of hot-roll bonded joints between titanium alloy and stainless steel using niobium interlayer. Trans. Nonferrous Met. Soc. China 2014, 24, 2839–2844. [Google Scholar] [CrossRef]

- Sam, S.; Kundu, S.; Chatterjee, S. Diffusion bonding of titanium alloy to micro-duplex stainless steel using a nickel alloy interlayer: Interface microstructure and strength properties. Mater. Des. 2012, 40, 237–244. [Google Scholar] [CrossRef]

- Lee, M.K.; Lee, J.G.; Choi, Y.H.; Kim, D.W.; Rhee, C.K.; Lee, Y.B.; Hong, S.J. Interlayer engineering for dissimilar bonding of titanium to stainless steel. Mater. Lett. 2010, 64, 1105–1108. [Google Scholar] [CrossRef]

- Wang, J.; Li, X.J.; Dong, S.H.; Wang, H.H.; Yan, H.H.; Wang, X.H. Research on explosive welding interface of titanium-steel under different welding parameters. Int. J. Adv. Manuf. Technol. 2022, 120, 6407–6417. [Google Scholar] [CrossRef]

- Wu, T.; Yang, C. Interfacial evolution of titanium/steel clad plates during pulsed tungsten inert gas welding. Mater. Sci. Technol. 2023, 39, 834–846. [Google Scholar] [CrossRef]

- Chu, Q.; Zhang, M.; Li, J.; Yan, C. Experimental and numerical investigation of microstructure and mechanical behavior of titanium/steel interfaces prepared by explosive welding. Mater. Sci. Eng. A 2017, 689, 323–331. [Google Scholar] [CrossRef]

- Wang, M.; Hu, J.; Li, K.; Luo, N.; Li, X.; Chen, X.; Chen, Z. Study on the relationship between interface morphology and mechanical properties of explosive welded titanium/duplex stainless steel. Int. J. Adv. Manuf. Technol. 2024, 132, 4249–4268. [Google Scholar] [CrossRef]

- Wang, D.; Sun, Y.; Xue, Z.; Zhang, P.; Wu, J.; Fan, K.; Huang, X. Preparation and Properties of Large-Size Titanium-Steel Composite Plates. Rare Met. Mater. Eng. 2023, 52, 3723–3729. [Google Scholar]

- Zhou, Q.; Liu, R.; Zhou, Q.; Ran, C.; Fan, K.; Xie, J.; Chen, P. Effect of microstructure on mechanical properties of titani-um-steel explosive welding interface. Mater. Sci. Eng. A 2022, 830, 142260. [Google Scholar] [CrossRef]

- Zhou, Q.; Liu, R.; Zhou, Q.; Chen, P.; Zhu, L. Microstructure characterization and tensile shear failure mechanism of the bonding interface of explosively welded titanium-steel composite. Mater. Sci. Eng. A 2021, 820, 141559. [Google Scholar] [CrossRef]

- Bi, Z.; Li, X.; Yang, K.; Kai, R.; Wang, Q.; Xu, M.; Zhang, T.; Dai, X.; Qian, J.; Wu, Y. Experimental and numerical studies of titanium foil/steel explosively welded clad plate. Def. Technol. 2023, 25, 192–202. [Google Scholar] [CrossRef]

- Liang, L.; Yong, S.; Jian, C.; Yu, F.; Xiao, X.; Jin, Y. Study on microstructure and properties of TA1-304 stainless steel explosive welding cladding plate. Mater. Res. Express 2020, 7, 026557. [Google Scholar] [CrossRef]

- Kaya, Y.; Eser, G. Production of ship steel-titanium bimetallic composites through explosive cladding. Weld. World 2019, 63, 1547–1560. [Google Scholar] [CrossRef]

- Zhou, Q.; Lu, H.; Zhang, Y.; Guo, Y.; Zhu, L.; Huang, G.; Chen, P. Intermetallic Reaction of the Bonding Interface of TA2/Q235 Explosive Welding Composite. Metals 2023, 13, 571. [Google Scholar] [CrossRef]

- Lin, C.M.; Rizi, M.S.; Chen, C.K. Effects of temperature on interfacial evolution and mechanical properties of pure titanium and carbon steel sheets bonded via new multi-pass continuous hot-roll diffusion with nickel interlayer. Int. J. Adv. Manuf. Technol. 2021, 119, 2811–2823. [Google Scholar] [CrossRef]

- Chen, Y.; Ma, S.; Ju, J.; Chen, K.; Wang, J.; Shen, Z.; Zeng, X. Phase transformation-mediated high-temperature oxidation in an AlCrFeCoNi2.1 EHEA alloy at elevated temperature. Corros. Sci. 2025, 245, 112674. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, K.; Ferreirós, P.A.; Gao, D.; Song, M.; Shen, Z.; Que, Z.; Yu, J.; Zhang, L.; Zeng, X. Printed cellular structure enhancing re-passivation of stress corrosion cracking in high-temperature water. Corros. Sci. 2025, 244, 112636. [Google Scholar] [CrossRef]

- Wang, Z.; Shen, Z.; Liu, Y.; Zhao, Y.; Zhu, Q.; Chen, Y.; Wang, J.; Li, Y.; Lozano, S.; Zeng, X. The effect of LPSO phase on the high-temperature oxidation of a stainless Mg-Y-Al alloy. J. Magnes. Alloy. 2024, 12, 4045–4052. [Google Scholar] [CrossRef]

- Yang, D.H.; Luo, Z.A.; Xie, G.M.; Misra, R.D.K. Effect of interfacial compounds on mechanical properties of titanium–steel vacuum roll-cladding plates. Mater. Sci. Technol. 2018, 34, 1700–1709. [Google Scholar] [CrossRef]

- Chang, S.; Yang, X.; Shi, H.S.; Fang, Z.H.; Sun, Z.R.; Feng, K.; Shao, F. Manufacturing Process and Interface Properties of Vacuum Rolling Large-Area Titanium-Steel Cladding Plate. Russ. J. Non-Ferr. Met. 2019, 60, 152–161. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, G.; Xie, G.; Wang, L.; Zhao, K. Interfacial microstructure and properties of a vacuum hot roll-bonded tita-nium-stainless steel clad plate with a niobium interlayer. Acta Metall. Sin. (Engl. Lett.) 2013, 26, 754–760. [Google Scholar] [CrossRef]

- Yang, D.H.; Luo, Z.A.; Xie, G.M.; Wang, M.K.; Misra, R.D.K. Effect of vacuum level on microstructure and mechanical properties of titanium–steel vacuum roll clad plates. J. Iron. Steel Res. Int. 2018, 25, 72–80. [Google Scholar] [CrossRef]

- Xie, G.; Luo, Z.; Wang, G.; Li, L.; Wang, G. Interface Characteristic and Properties of Stainless Steel/HSLA Steel Clad Plate by Vacuum Rolling Cladding. Mater. Trans. 2011, 52, 1709–1712. [Google Scholar] [CrossRef]

- Zhao, J.X.; Luo, Z.A.; Wang, M.K.; Xie, G.M.; Xv, J.P. Microstructure and mechanical property of titanium steel by vacuum roll-cladding with interlayer. Mater. Sci. Technol. 2022, 38, 824–835. [Google Scholar] [CrossRef]

- Chen, W.; Chen, L.; Pan, X.; Xu, Y.; Xu, S.; Zhang, K.; Li, J.; Zhang, M. Effect of hot rolling thinning temperature on the in-terfacial microstructure and mechanical properties of titanium/steel composite plates. J. Mater. Sci. 2025, 60, 5232–5246. [Google Scholar] [CrossRef]

- Bai, Y.L.; Liu, X.F. Interfacial reaction behavior of titanium/steel composite plate formed by cold-hot rolling. Mater. Charact. 2023, 202, 113030. [Google Scholar] [CrossRef]

- Wang, W.; Tu, Y.; Liu, M.; Liu, X. Effect of inhomogeneous plastic deformation on the interfacial microstructure and properties of titanium/stainless steel. J. Mater. Res. Technol. 2023, 241, 240–251. [Google Scholar] [CrossRef]

- Lu, Y.; Watanabe, M.; Miyata, R.; Nakamura, J.; Yamada, J.; Kato, H.; Yoshimi, K. Microstructures and mechanical properties of TiC particulate reinforced Ti-Mo-Al intermetallic matrix composites. Mater. Sci. Eng. A 2020, 790, 139523. [Google Scholar] [CrossRef]

- Yang, J.; Li, X.; Yao, H.; Guan, Y. Interfacial Features of Stainless Steel/Titanium Alloy Multi-metal Fabricated by Laser Additive Manufacturing. Acta Metall. Sin. (Engl. Lett.) 2022, 35, 1357–1364. [Google Scholar] [CrossRef]

- Karlsson, J.; Snis, A.; Engqvist, H.; Lausmaa, J. Characterization and comparison of materials produced by Electron Beam Melting (EBM) of two different Ti-6Al-4V powder fractions. J. Mater. Process. Technol. 2013, 213, 2109–2118. [Google Scholar] [CrossRef]

- Li, K.; Ma, R.; Qin, Y.; Gong, N.; Wu, J.; Wen, P.; Tan, S.; Zhang, D.Z.; Murr, L.E.; Luo, J. A review of the multi-dimensional application of machine learning to improve the integrated intelligence of laser powder bed fusion. J. Mater. Process. Technol. 2023, 318, 118032. [Google Scholar] [CrossRef]

- Hu, K.; Jiang, X.; Yu, H.; Sun, D. Solidification and corrosion mechanisms: A novel metallurgical bonding Ti-6Al-4V coating on mild steel. Surf. Coat. Technol. 2024, 476, 130258. [Google Scholar] [CrossRef]

- Lang, Z.; Wang, D.; Liu, H.; Gou, X. Mapping the knowledge domains of research on corrosion of petrochemical equipment: An informetrics analysis-based study. Eng. Failure Anal. 2021, 129, 105736. [Google Scholar] [CrossRef]

- Chen, M.; Van, S.; Zou, Z.; Simonelli, M.; Tse, Y.Y.; Chang, C.S.T.; Makowska, M.G.; Ferreira, D.; Moens, H. Microstructural engineering of a dual-phase Ti-Al-V-Fe alloy via in situ alloying during laser powder bed fusion. Addit. Manuf. 2022, 59, 103173. [Google Scholar] [CrossRef]

- Kazantseva, N.; Krakhmalev, P.; Thuvander, M.; Yadroitsev, I.; Vinogradova, N.; Ezhov, I. Martensitic transformations in Ti-6Al-4V (ELI) alloy manufactured by 3D Printing. Mater. Charact. 2018, 146, 101–112. [Google Scholar] [CrossRef]

- Xu, S.; Cai, Q.; Li, G.; Lu, X.; Zhu, X. Effect of scanning speed on microstructure and properties of TiC/Ni60 composite coatings on Ti6Al4V alloy by laser cladding. Opt. Laser Technol. 2022, 154, 108309. [Google Scholar] [CrossRef]

- Yang, Z.; Jian, Y.; Chen, Z.; Qi, H.; Huang, Z.; Huang, G.; Xing, J. Microstructure, hardness and slurry erosion-wear behaviors of high-speed laser cladding Stellite 6 coatings prepared by the inside-beam powder feeding method. J. Mater. Res. Technol. 2022, 19, 2596–2610. [Google Scholar] [CrossRef]

- Muvvala, G.; Patra Karmakar, D.; Nath, A.K. Online assessment of TiC decomposition in laser cladding of metal matrix composite coating. Mater. Des. 2017, 121, 310–320. [Google Scholar] [CrossRef]

- Hu, K.; Tian, Y.; Jiang, X.; Yu, H.; Sun, D. Microstructure regulation and performance of titanium alloy coating with Ni interlayer on the surface of mild steel by laser cladding. Surf. Coat. Technol. 2024, 487, 130939. [Google Scholar] [CrossRef]

- Wang, S.; Gao, W.; Hu, K.; Li, Z.; He, W.; Yu, H.; Sun, D. Effect of Powder Particle Size and Shape on Appearance and Per-formance of Titanium Coatings Prepared on Mild Steel by Plasma Cladding. Coatings 2022, 12, 12081149. [Google Scholar]

- Buytoz, S.; Orhan, A.; Gur, A.K.; Caligulu, U. Microstructural Development of Fe-Cr-C and B4C Powder Alloy Coating on Stainless Steel by Plasma-Transferred Arc Weld Surfacing. Arab. J. Sci. Eng. 2013, 38, 2197–2204. [Google Scholar] [CrossRef]

- Jalali, A.; Atapour, M.; Shamanian, M.; Vahman, M. Transient liquid phase (TLP) bonding of Ti-6Al-4V/UNS 32750 super duplex stainless steel. J. Manuf. Process. 2018, 33, 194–202. [Google Scholar] [CrossRef]

- Mo, D.F.; Song, T.F.; Fang, Y.J.; Jiang, X.S.; Luo, C.Q.; Simpson, M.D.; Luo, Z.P. A Review on Diffusion Bonding between Titanium Alloys and Stainless Steels. Adv. Mater. Sci. Eng. 2018, 2018, 8701890. [Google Scholar] [CrossRef]

- Cooke, K.O.; Atieh, A.M. Current Trends in Dissimilar Diffusion Bonding of Titanium Alloys to Stainless Steels, Alumin-ium and Magnesium. J. Manuf. Mater. Process. 2020, 4, 39. [Google Scholar]

- Gao, D.; Li, C.; Zhang, C.; Yang, B.; Lin, T.; Chen, L.; Si, X.; Qi, J.; Cao, J. Microstructure and wettability of the micro-laminated Ti6Al4V/304 stainless steel composite fabricated by diffusion bonding. J. Mater. Res. Technol. 2023, 273, 788–796. [Google Scholar] [CrossRef]

- Kundu, S.; Sam, S.; Mishra, B.; Chatterjee, S. Diffusion Bonding of Microduplex Stainless Steel and Ti Alloy with and without Interlayer: Interface Microstructure and Strength Properties. Metall. Mater. Trans. A 2014, 45, 371–383. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, G.; Lv, K.; Li, J.; Yu, X.; Yu, Y.; Guo, C.; Zhang, J. Research Progress on Preparation, Microstructure, Properties, and Optimization of Ta and Its Compounds’ Coatings. Metals 2025, 15, 416. [Google Scholar] [CrossRef]

- Borchers, C.; Gärtner, F.; Stoltenhoff, T.; Assadi, H.; Kreye, H. Microstructural and macroscopic properties of cold sprayed copper coatings. J. Appl. Phys. 2003, 93, 10064–10070. [Google Scholar] [CrossRef]

- Maev, R.G.; Leshchynsky, V. Air gas dynamic spraying of powder mixtures: Theory and application. J. Therm. Spray Technol. 2006, 15, 198–205. [Google Scholar] [CrossRef]

- Li, Z.; Wang, N.; Li, S.; Wen, L.; Xu, C.; Sun, D. Preparation of Cold Sprayed Titanium TA2 Coating by Irregular Powder and Evaluation of Its Corrosion Resistance. Coatings 2023, 13, 1894. [Google Scholar] [CrossRef]

- Wathanyu, K.; Tuchinda, K.; Daopiset, S.; Sirivisoot, S.; Kondas, J.; Bauer, C. Study of the Properties of Titanium Porous Coating with Different Porosity Gradients on 316L Stainless Steel by a Cold Spray Process. J. Therm. Spray Technol. 2022, 31, 545–558. [Google Scholar] [CrossRef]

- Wathanyu, K.; Tuchinda, K.; Daopiset, S.; Sirivisoot, S. Corrosion resistance and biocompatibility of cold-sprayed titanium on 316L stainless steel. Surf. Coat. Technol. 2022, 445, 128721. [Google Scholar] [CrossRef]

- Morks, M.F.; Zahiri, S.; Chen, X.B.; Gulizia, S.; Cole, I.S. Enhancement of the corrosion properties of cold sprayed Ti–6Al–4V coatings on mild steel via silica sealer. Mater. Corros. 2022, 73, 20–30. [Google Scholar] [CrossRef]

- Zhao, Z.; Tariq, N.U.H.; Tang, J.; Jia, C.; Qiu, X.; Ren, Y.; Liu, H.; Shen, Y.; Du, H.; Cui, X.; et al. Microstructural evolutions and mechanical characteristics of Ti/steel clad plates fabricated through cold spray additive manufacturing fol-lowed by hot-rolling and annealing. Mater. Des. 2020, 185, 108249. [Google Scholar] [CrossRef]

- Zhao, Z.; Tang, J.; Tariq, N.u.H.; Liu, H.; Liu, H.; Ren, Y.; Tong, M.; Yin, L.; Du, H.; Wang, J.; et al. Effect of rolling tem-perature on microstructure and mechanical properties of Ti/steel clad plates fabricated by cold spraying and hot-rolling. Mater. Sci. Eng. A 2020, 795, 139982. [Google Scholar] [CrossRef]

- Yao, Y.; Han, Y.; Zhang, K.; Zhu, H.; Zhang, W.; Qian, H.; Zhou, C.; Zhang, L. The dependence of fracture mode on interfacial microstructure in TA1 pure titanium/AgCuNi/304 stainless steel vacuum brazed joints. Vacuum 2022, 203, 111318. [Google Scholar] [CrossRef]

- Cao, X.; Dong, K.; Zhu, R.; Wang, Q.; Kong, J. A high-strength vacuum brazed TC4/316L joint with a Ti–Zr-based amorphous ribbon as the filler metal. Vacuum 2021, 187, 110070. [Google Scholar] [CrossRef]

- Foumani, M.; Naffakh, M.H. The effect of vacuum brazing time on the microstructure and mechanical properties of Ti-6Al-4 V to 316 L dissimilar joint using BNi-2 filler metal. J. Adv. Join. Process. 2024, 9, 100176. [Google Scholar] [CrossRef]

- Su, Z.; Yin, L.; Jiang, H.; Zhang, L.; Chen, Y.; Zhang, L.; Zhang, H.; Feng, W. Research progress of electromagnetic pulse welding technology: A review. J. Mater. Res. Technol. 2025, 36, 217–235. [Google Scholar] [CrossRef]

- Sharma, S.K.; Chebolu, R.; Kakarla, M.; Rani, R.; Mishra, S.; Aravind, J.M.V.V.S.; Kumar, R.; Kumar, G.K.; Nallu, R.; Sharma, A. Magnetic pulse welding for dissimilar metals and corrosion studies at interface. Weld. Int. 2025, 39, 154–161. [Google Scholar] [CrossRef]

- Chebolu, R.; Kakarla, M.; Nallu, R.; Sharma, S.K.; Kumar, K.; Sharma, A. Experimental investigation on microstructure, hardness and corrosion resistance of an electromagnetic welded titanium-stainless steel dissimilar materials. Eng. Res. Express 2024, 6, 025555. [Google Scholar] [CrossRef]

- Chebolu, R.; Kakarla, M.; Nallu, R.; Sharma, S.K.; Barmavatu, P.; Sharma, A. Effect of interlayer materials on microstructure, hardness and corrosion resistance of an electromagnetic welded titanium–stainless steel interface. Acta Mech. 2024, 235, 3687–3697. [Google Scholar] [CrossRef]

- Guo, C.; Fan, Q.; Wu, Y.; Wang, T.; Jiang, F. A review on composition design and microstructure analysis of interlayers in titanium alloy/steel dissimilar connections. Mater. Today Commun. 2025, 42, 111361. [Google Scholar] [CrossRef]

- Zhu, L.; Xue, P.; Lan, Q.; Meng, G.; Ren, Y.; Yang, Z.; Xu, P.; Liu, Z. Recent research and development status of laser cladding: A review. Opt. Laser Technol. 2021, 138, 106915. [Google Scholar] [CrossRef]

- Chattopadhyay, A.; Muvvala, G.; Sarkar, S.; Racherla, V.; Nath, A.K. Mitigation of cracks in laser welding of titanium and stainless steel by in-situ nickel interlayer deposition. J. Mater. Process. Technol. 2022, 300, 117403. [Google Scholar] [CrossRef]

- Yan, J.C.; Zhao, D.S.; Wang, C.W.; Wang, L.Y.; Wang, Y.; Yang, S.Q. Vacuum hot roll bonding of titanium alloy and stainless steel using nickel interlayer. Mater. Sci. Technol. 2009, 25, 914–918. [Google Scholar] [CrossRef]

- Yang, D.H.; Luo, Z.A.; Xie, G.M.; Jiang, T.; Zhao, S.; Misra, R.D.K. Interfacial microstructure and properties of a vacuum roll-cladding titanium-steel clad plate with a nickel interlayer. Mater. Sci. Eng. A 2019, 75, 349–358. [Google Scholar] [CrossRef]

- Wang, F.L.; Sheng, G.M.; Deng, Y.Q. Impulse pressuring diffusion bonding of titanium to 304 stainless steel using pure Ni interlayer. Rare Met. 2014, 35, 331–336. [Google Scholar] [CrossRef]

- Meng, Y.; Gu, X.; Cui, M.; Gu, X.; Zhao, X. Laser assisted diffusion bonding of TC4 titanium alloy to 301 stainless steel using a Ni interlayer. J. Mater. Res. Technol. 2022, 217, 39–48. [Google Scholar] [CrossRef]

- Yıldız, A.; Kaya, Y.; Kahraman, N. Joint properties and microstructure of diffusion-bonded grade 2 titanium to AISI 430 ferritic stainless steel using pure Ni interlayer. Int. J. Adv. Manuf. Technol. 2016, 86, 1287–1298. [Google Scholar] [CrossRef]

- Kundu, S.; Chatterjee, S. Interfacial microstructure and mechanical properties of diffusion-bonded titanium–stainless steel joints using a nickel interlayer. Mater. Sci. Eng. A 2006, 425, 107–113. [Google Scholar] [CrossRef]

- Lin, C.M.; Rizi, M.S. Microstructural evolution, metallurgical reactions, and the mechanical properties of pure titanium and carbon steel sheets bonded via hot-roll diffusion with a nickel interlayer. Can. Metall. Q. 2022, 61, 377–388. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Liu, Z.F.; Lu, J.F.; Shen, X.B.; Wang, F.C.; Wang, Y.D. The sintering mechanism in spark plasma sintering-Proof of the occurrence of spark discharge. Scr. Mater. 2014, 81, 56–59. [Google Scholar] [CrossRef]

- Elmi Hosseini, S.R.; Feng, K.; Nie, P.; Zhang, K.; Huang, J.; Li, Z.; Kokawa, H.; Guo, B.; Xue, S. Interlayer thickening for de-velopment of laser-welded Ti-SS joint strength. Opt. Laser Technol. 2019, 112, 379–394. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, D.; Gu, X.; Li, H. Characterization of Laser-Welded Ti Alloy and Stainless Steel Joint Using Cu Interlayer. J. Mater. Eng. Perform. 2019, 28, 6092–6101. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, B.G.; Feng, J.C. Influences of different filler metals on electron beam welding of titanium alloy to stainless steel. T. Nonferr. Metal. Soc 2014, 24, 108–114. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, B.-g.; Chen, G.Q.; Feng, J.C.; Tang, Q. Electron beam welding of Ti-15-3 titanium alloy to 304 stainless steel with copper interlayer sheet. T. Nonferr. Metal. Soc 2010, 20, 1829–1834. [Google Scholar] [CrossRef]

- Chu, Q.; Cao, Q.; Zhang, M.; Zheng, J.; Zhao, P.; Yan, F.; Cheng, P.; Yan, C.; Luo, H. Microstructure and mechanical properties investigation of explosively welded titanium/copper/steel trimetallic plate. Mater. Charact. 2022, 192, 112250. [Google Scholar] [CrossRef]

- Elrefaey, A.; Tillmann, W. Solid state diffusion bonding of titanium to steel using a copper base alloy as interlayer. J. Mater. Process. Technol. 2009, 209, 2746–2752. [Google Scholar] [CrossRef]

- Hao, X.; Dong, H.; Li, S.; Xu, X.; Li, P. Lap joining of TC4 titanium alloy to 304 stainless steel with fillet weld by GTAW using copper-based filler wire. J. Mater. Process. Technol. 2018, 257, 88–100. [Google Scholar] [CrossRef]

- Yu, C.; Xiao, H.; Yu, H.; Qi, Z.C.; Xu, C. Mechanical properties and interfacial structure of hot-roll bonding TA2/Q235B plate using DT4 interlayer. Mater. Sci. Eng. A 2017, 695, 120–125. [Google Scholar] [CrossRef]

- Li, B.X.; Chen, Z.J.; He, W.J.; Wang, P.J.; Lin, J.S.; Wang, Y.; Peng, L.; Li, J.; Liu, Q. Effect of interlayer material and rolling temperature on microstructures and mechanical properties of titanium/steel clad plates. Mater. Sci. Eng. A 2019, 749, 241–248. [Google Scholar] [CrossRef]

- Wang, F.R.; Guo, S.; Wang, Y.K.; Xie, G.M. Effect of tempering temperature on the microstructure and mechanical proper-ties of Ti-6Al-4V/EH690 clad plates with stainless steel interlayer by vacuum hot rolling. Mater. Sci. Eng. A 2025, 931, 148232. [Google Scholar] [CrossRef]

- He, P.; Yue, X.; Zhang, J.H. Hot pressing diffusion bonding of a titanium alloy to a stainless steel with an aluminum alloy interlayer. Mater. Sci. Eng. A 2008, 486, 171–176. [Google Scholar] [CrossRef]

- Cheepu, M.; Che, W.S. Friction Welding of Titanium to Stainless Steel Using Al Interlayer. Trans. Indian Inst. Met. 2019, 72, 1563–1568. [Google Scholar] [CrossRef]

- Kundu, S.; Chatterjee, S. Interface microstructure and strength properties of diffusion bonded joints of titanium-Al interlayer-18Cr-8Ni stainless steel. Mater. Sci. Eng. A 2010, 527, 2714–2719. [Google Scholar] [CrossRef]

- Chai, X.; Pan, T.; Chai, F.; Luo, X.; Su, H.; Yang, Z.; Yang, C. Interlayer engineering for titanium clad steel by hot roll bonding. J. Iron. Steel Res. Int. 2018, 25, 739–745. [Google Scholar] [CrossRef]

- Kundu, S.; Thirunavukarasu, G. Diffusion Welding of Ti6Al4V and 17-4 Stainless Steel Using Cu/Ni Microlayers. J. Mater. Eng. Perform. 2023, 32, 735–751. [Google Scholar] [CrossRef]

- Song, T.F.; Jiang, X.S.; Shao, Z.Y.; Fang, Y.J.; Mo, D.F.; Zhu, D.G.; Zhu, M.H. Microstructure and mechanical properties of vacuum diffusion bonded joints between Ti-6Al-4V titanium alloy and AISI316L stainless steel using Cu/Nb multi-interlayer. Vacuum 2017, 145, 68–76. [Google Scholar] [CrossRef]

- Fang, Y.; Jiang, X.; Song, T.; Mo, D.; Luo, Z. Pulsed laser welding of Ti-6Al-4V titanium alloy to AISI 316L stainless steel using Cu/Nb bilayer. Mater. Lett. 2019, 244, 163–166. [Google Scholar] [CrossRef]

- Safari, M.; Yaghooti, H.; Joudaki, J. Laser welding of titanium and stainless steel sheets using Ag-Cu interlayers: Micro-structure and mechanical characterization. Int. J. Adv. Manuf. Technol. 2021, 117, 3063–3073. [Google Scholar] [CrossRef]

- Zhao, B.; Ren, Z.; Chang, H.; Zhou, Z.; Ding, Y. Role of Cr addition in Ni-based interlayer on strengthening titanium and steel dissimilar bimetallic structures enabled by directed energy deposition with laser beam. J. Mater. Sci. Technol. 2025, 209, 27–42. [Google Scholar] [CrossRef]

- Chu, Q.; Tong, X.; Xu, S.; Zhang, M.; Yan, F.; Cheng, P.; Yan, C. The formation of intermetallics in Ti/steel dissimilar joints welded by Cu-Nb composite filler. J. Alloys Compd. 2020, 828, 154389. [Google Scholar] [CrossRef]

- Gao, W.; Wang, S.C.; Si, J.; Hu, K.K.; Yu, H.Y.; Sun, D.B. Laser Cladding of Titanium Alloy Coating on Low Carbon Steel via Cu Interlayer. Mater. Sci. Forum 2022, 1071, 80–90. [Google Scholar] [CrossRef]

- Zhang, Y.; Bi, Y.; Zhou, J.; Sun, D.; Li, H. Microstructure and mechanical property improvement of Ti alloy and stainless steel joint based on a hybrid connection mechanism. Mater. Lett. 2020, 274, 128012. [Google Scholar] [CrossRef]

- Zhao, B.; Zhou, H.; Ding, Y.; Chang, H. Wavy microstructure for improvement of bonding strength in titanium to carbon steel brazed joints. J. Mater. Process. Technol. 2022, 305, 117572. [Google Scholar] [CrossRef]

- Xie, M.X.; Zhang, L.J.; Zhang, G.F.; Zhang, J.X.; Bi, Z.Y.; Li, P.C. Microstructure and mechanical properties of CP-Ti/X65 bimetallic sheets fabricated by explosive welding and hot rolling. Mater. Des. 2015, 87, 181–197. [Google Scholar] [CrossRef]

- Yu, X.H.; Li, N.; Qi, Z.C.; Ren, Z.K. Effect of DT4 Interlayer on Properties of Hot-roll Bonding TA2/Q235B Plate. IOP Publ. 2017, 229, 012017. [Google Scholar] [CrossRef]

- Li, B.X.; He, W.J.; Chen, Z.J.; Mo, T.Q.; Peng, L.; Li, J.; Liu, Q. Influence of annealing on the microstructure, interfacial compounds and mechanical properties of hot rolling bonded Ti/steel clad plate with bimetallic interlayered steel and vana-dium. Mater. Sci. Eng. A 2019, 764, 138227. [Google Scholar] [CrossRef]

- Si, J.; Gao, W.; Xu, X.; Wang, S.; Yu, H.; Sun, D. Preparation, microstructure evolution and performance of laser-cladded titanium alloy coating on mild steel. Mater. Today Commun. 2022, 33, 104779. [Google Scholar] [CrossRef]

- Huang, C.; Hai, L.; Jiang, J.; Ban, H. High-cycle fatigue properties of explosion bonded titanium-clad bimetallic steel. Int. J. Fatigue 2023, 169, 107499. [Google Scholar] [CrossRef]

- Hai, L.; Ban, H.; Yang, X.; Shi, Y. Low-cycle fatigue behaviour of hot-rolled titanium-clad bimetallic steel. Int. J. Mech. Sci. 2023, 254, 108443. [Google Scholar] [CrossRef]

- Ban, H.; Huang, C.; Shi, Y.; Hai, L. High-cycle fatigue properties of hot-rolled bonding titanium-clad bimetallic steel. Int. J. Fatigue 2025, 195, 108865. [Google Scholar] [CrossRef]

- Procopio, L. The role of biofilms in the corrosion of steel in marine environments. World J. Microbiol. Biotechnol. 2019, 35, 73. [Google Scholar] [CrossRef]

- Madrid, F.M.G.; Soliz, A.; Caceres, L.; Salazar, A.S.; Guzman, D.; Galvez, E. Corrosion of Reinforced A630-420H Steel in Direct Contact with NaCl Solution. Materials 2023, 16, 6017. [Google Scholar] [CrossRef]

- Vera, R.; Bagnara, M.; Henriquez, R.; Munoz, L.; Rojas, P.; Diaz, G.A. Performance of Anticorrosive Paint Systems for Carbon Steel in the Antarctic Marine Environment. Materials 2023, 16, 5713. [Google Scholar] [CrossRef]

- Qiu, L.; Zhao, D.; Zheng, S.; Gong, A.; Liu, Z.; Su, Y.; Liu, Z. Inhibition Effect of Pseudomonas stutzeri on the Corrosion of X70 Pipeline Steel Caused by Sulfate-Reducing Bacteria. Materials 2023, 16, 2896. [Google Scholar] [CrossRef]

- Gao, W.; Wang, S.; Tian, Y.; Lu, H.; Liu, H.; Wang, Q.; Yu, H.; Sun, D. Effect of the powder feeding rate on the microstructure and properties of the laser-cladded titanium coating. J. Mater. Res. Technol. 2025, 38, 4676–4687. [Google Scholar] [CrossRef]

- Li, N.; Wang, B.; Liu, T.; Liu, C.; Che, Z.; Chen, T.; Li, Q.; Li, Z.; Wang, L.; Cheng, X.; et al. Revealing the coupling of multiple corrosion behaviors in the corrosion process of titanium-steel composites in marine environment. Corros. Sci. 2024, 233, 112107. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, Z.; Xu, L.; Xu, Z.; Yin, F.; Zheng, K. Unraveling the interfacial structure of TA2 titanium-A36 steel composite plate and its corrosion behavior in marine environment. Corros. Sci. 2024, 230, 111923. [Google Scholar] [CrossRef]

- Jiang, J.; Li, N.; Wang, B.; Liu, F.; Liu, C.; Cheng, X. A Study on the Influence of Different Defect Types on the Corrosion Behavior of Q235/TA2 Composite Plates in a Marine Environment. Metals 2024, 14, 652. [Google Scholar] [CrossRef]

- Hu, J.; Huang, H.; Deng, P.; Wang, G.; Wu, M.; Liu, W. Galvanic corrosion behavior of titanium-clad steel plate in the marine environment. Mater. Corros. 2022, 73, 887–896. [Google Scholar] [CrossRef]

| Preparation Strategy | Advantages | Disadvantages |

|---|---|---|

| Explosive welding | High connection efficiency over large areas, high bonding strength | Environmentally unfriendly, not supporting thin Ti layer, uneven interface |

| Rolling | High production efficiency, low cost, minimal pollution | Unbound areas are likely to appear |

| High-energy beam cladding | Controllable microstructure, high precision, adjustable thickness | Prone to residual stress and brittle phase |

| Diffusion bonding | Solid solution zone enhances strength, homogeneous structure | Time-consuming, high temperature, low efficiency |

| Cold spray | Low-temperature preparation and a simple process | High porosity, low bonding strength |

| Base Materials | Interlayer Material | Preparation Strategy | IMCs | Bonding Strength [MPa] | References |

|---|---|---|---|---|---|

| Ti/304 SS | Ni | Diffusion bonding | TiNi3, TiNi, Ti2Ni, TiC (Ni/Ti interface) | 219 | [92] |

| Ti/Carbon steel | Rolling | 343 | [93] | ||

| Ti/Fe | Diffusion bonding | 187 | [45] | ||

| Ti/Fe | Cu | High-energy beam cladding | CuTi2, Cu4Ti3, CuTi, Cu4Ti (Cu/Ti interface) | 95 | [115] |

| TA15/304 SS | High-energy beam welding | 234 | [97] | ||

| Ti/Fe | Diffusion bonding | 105 | [100] | ||

| TA2/Q235 | Fe | Diffusion bonding | TiC, Fe2Ti, FeTi (Fe/Ti interface) | 238 | [102] |

| TC4/EH690 | Rolling | 256 | [104] | ||

| TC4/SS | Al | Diffusion bonding | FeAl6, Fe3Al, FeAl2, AlTi, Al3Ti (Fe/Al and Al/Ti interface) | 183 | [105] |

| Ti/SS | Diffusion bonding | 267 | [107] | ||

| TA2/Q390 | Nb | Rolling | / | 290 | [108] |

| Ti/304 SS | Ag | Diffusion bonding | AgTi(not the weak phase) | 414 | [20] |

| Ti/Carbon steel | V | Rolling | / | 220 | [103] |

| TC4/SS | Cu-Ni dual-layer | Diffusion bonding | Ni-Ti IMCs, Cu-Ti IMCs (interlayer/Ti interface and inside interlayer) | 660 | [109] |

| TC4/316L SS | Cu/Nb dual-layer | Diffusion bonding | / | 489 | [110] |

| Ti/Fe | Cu/Nb composite interlayers | Explosive welding | Fe2Ti, Fe2Nb, Cu-Ti IMCs (interlayer/Ti interface and interlayer/Fe) | 334 | [114] |

| Ti/316L SS | Ag-Cu dual-layer | High-energy beam welding | Ti-Cu IMCs (interlayer/Ti interface) | 230 | [112] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, W.; Wang, S.; Zhang, H.; Wang, Q.; Liu, H.; Yu, H.; Sun, D. Low-Cost Application Strategies of Marine Titanium Alloys: Titanium/Steel Dissimilar Materials. Metals 2025, 15, 1205. https://doi.org/10.3390/met15111205

Gao W, Wang S, Zhang H, Wang Q, Liu H, Yu H, Sun D. Low-Cost Application Strategies of Marine Titanium Alloys: Titanium/Steel Dissimilar Materials. Metals. 2025; 15(11):1205. https://doi.org/10.3390/met15111205

Chicago/Turabian StyleGao, Wei, Shicheng Wang, Han Zhang, Qi Wang, Hao Liu, Hongying Yu, and Dongbai Sun. 2025. "Low-Cost Application Strategies of Marine Titanium Alloys: Titanium/Steel Dissimilar Materials" Metals 15, no. 11: 1205. https://doi.org/10.3390/met15111205

APA StyleGao, W., Wang, S., Zhang, H., Wang, Q., Liu, H., Yu, H., & Sun, D. (2025). Low-Cost Application Strategies of Marine Titanium Alloys: Titanium/Steel Dissimilar Materials. Metals, 15(11), 1205. https://doi.org/10.3390/met15111205