Effect of Hardening Rate on the Bendability and Fracture Response of AA6082 Aluminum Extrusions in the VDA238-100 Tight Radius Bend Test

Abstract

1. Introduction

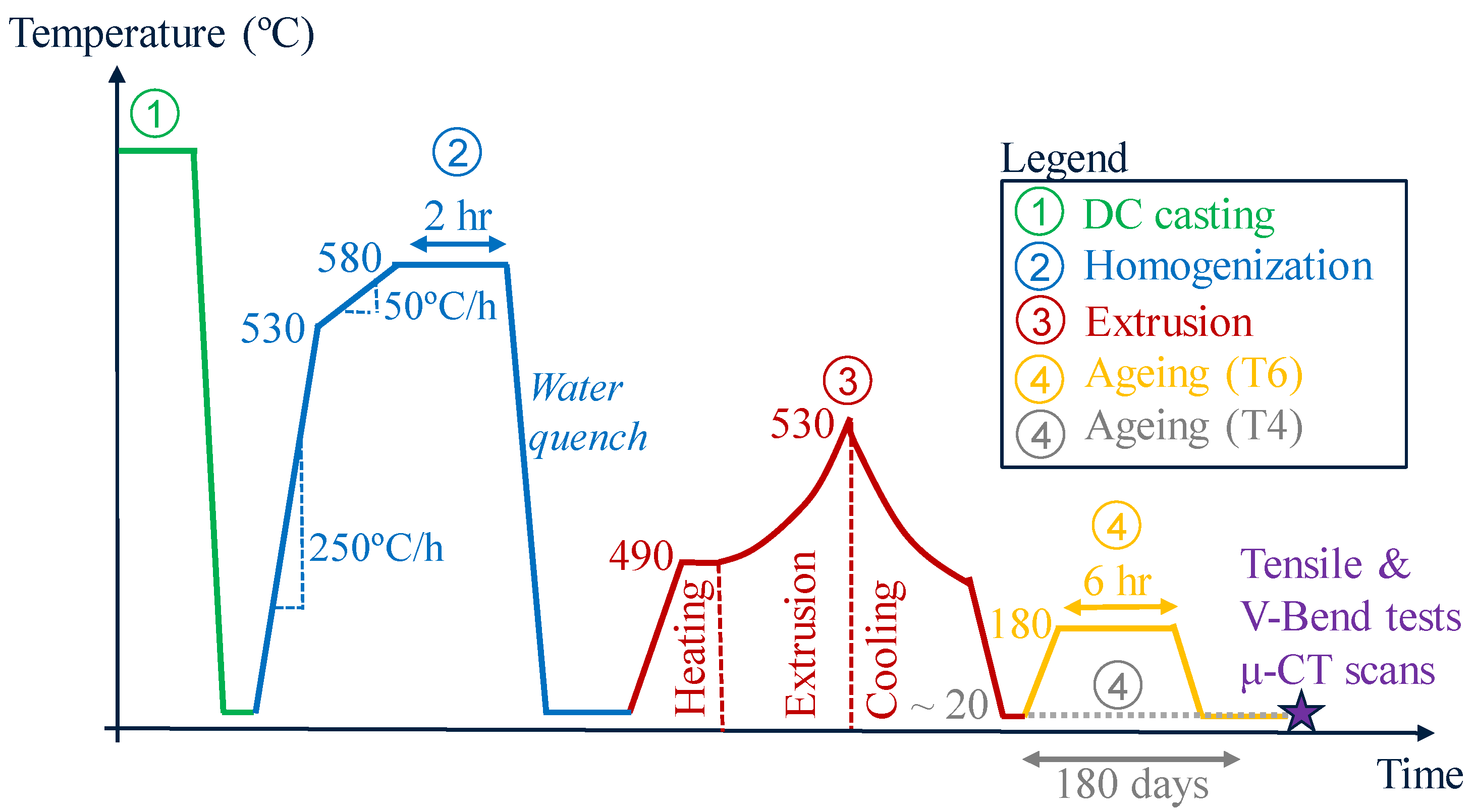

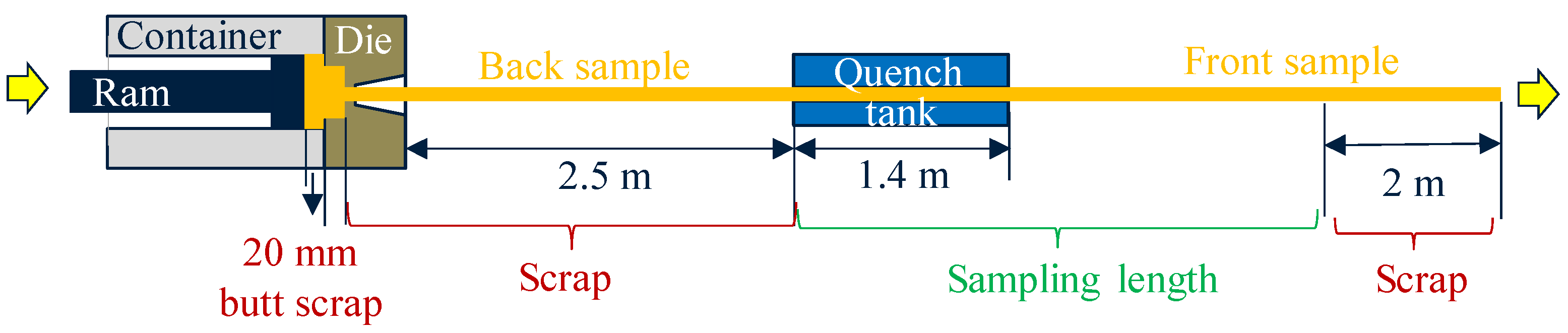

2. Material Selection and Processing History

3. Experimental Methodology

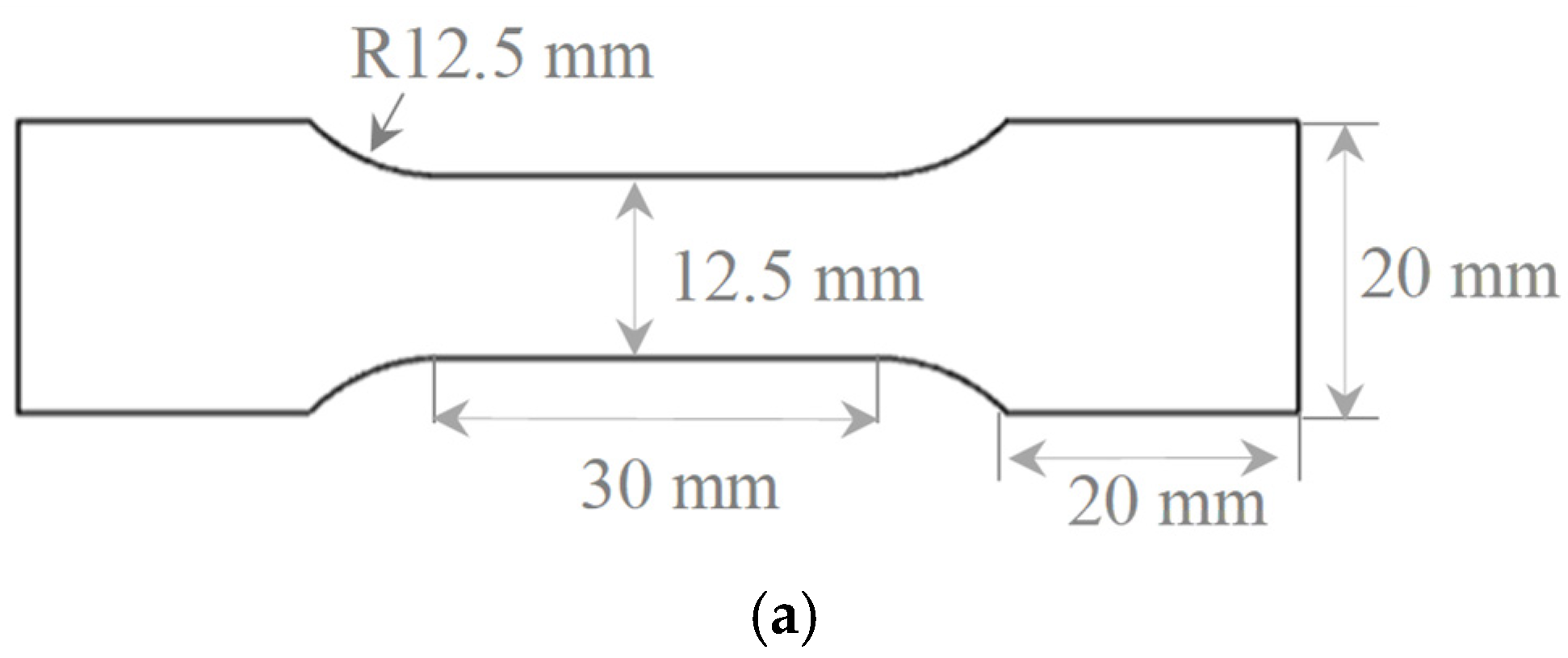

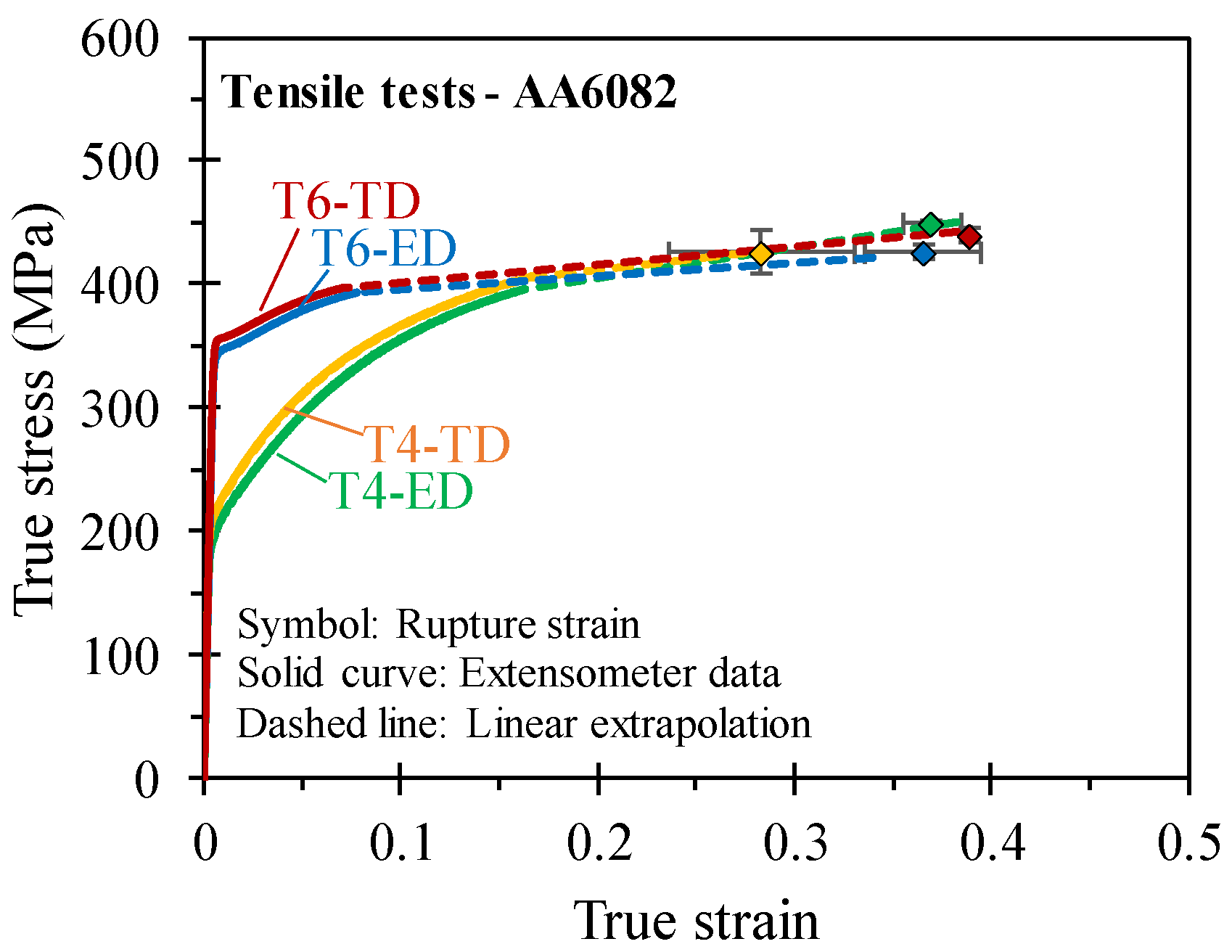

3.1. Tensile Tests

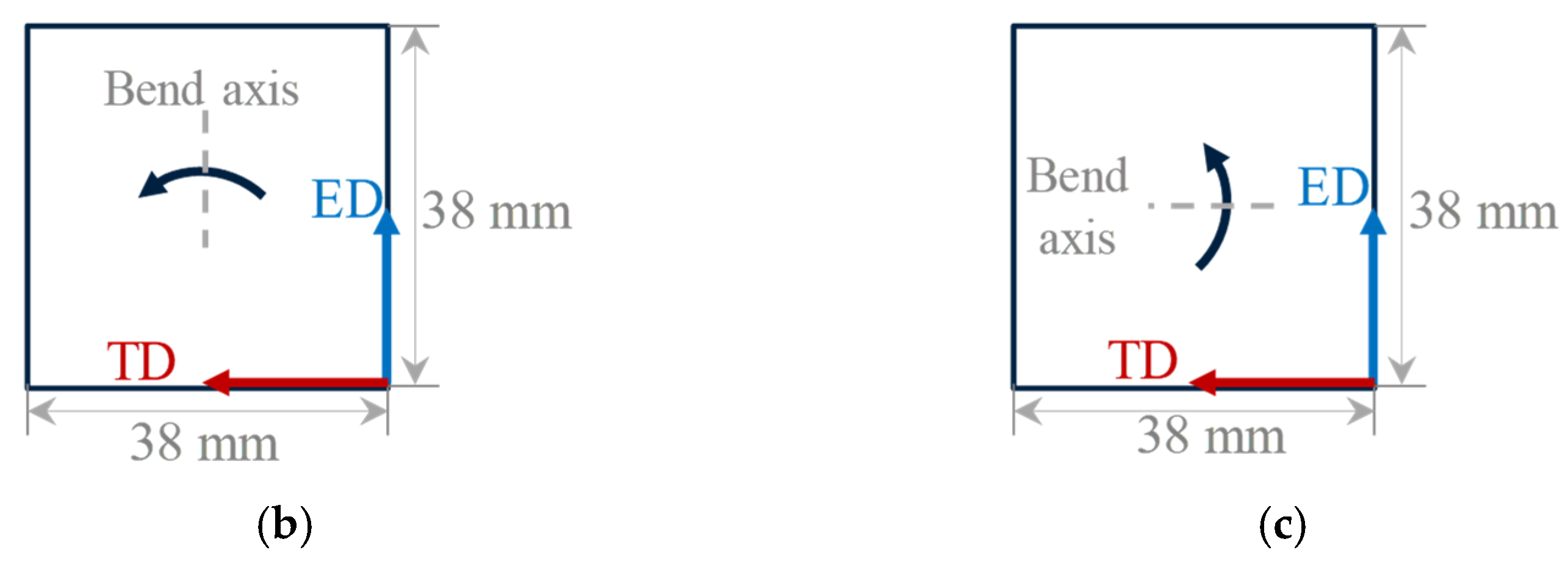

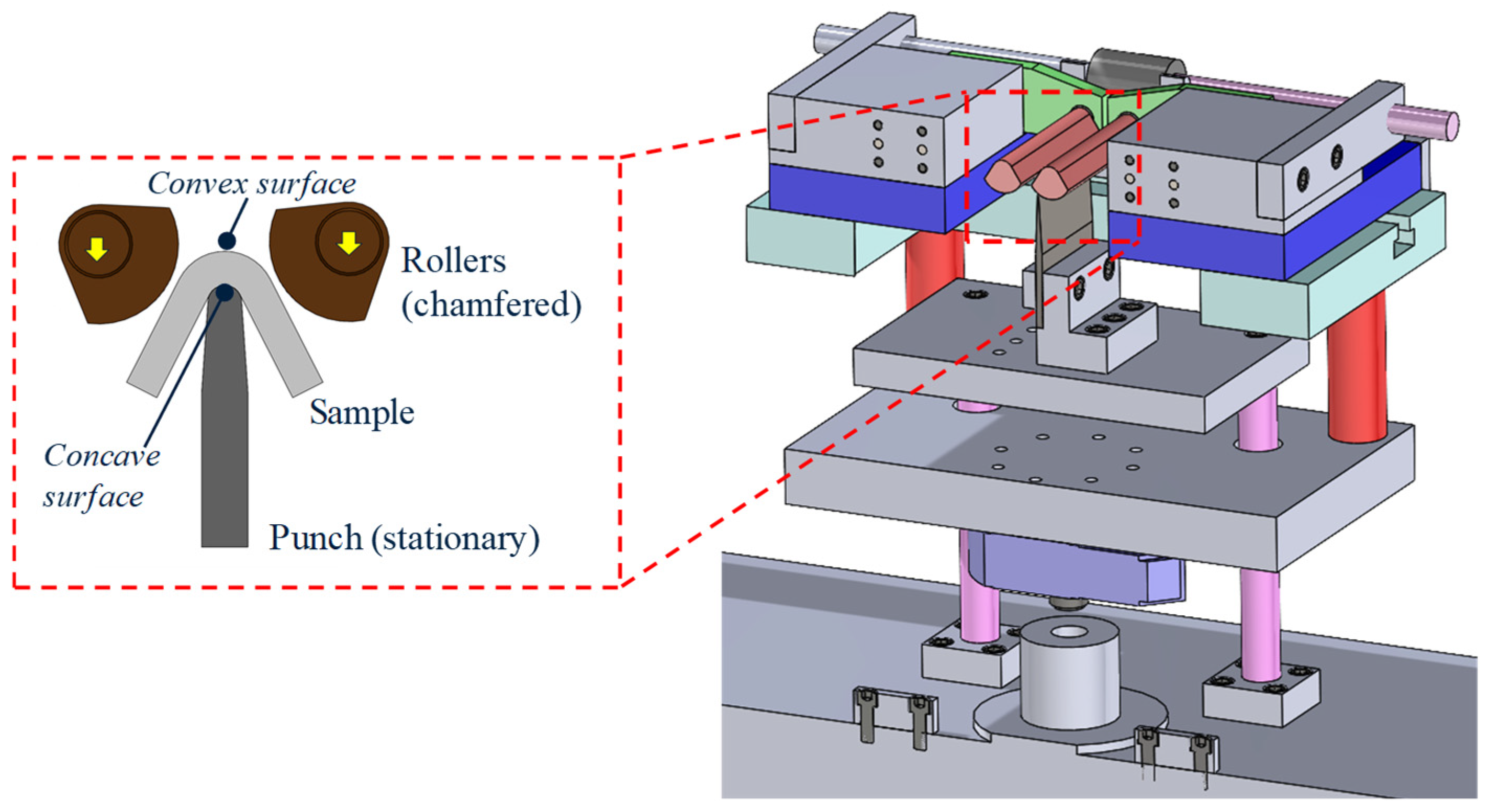

3.2. VDA238-100 Tight Radius Bend Test

3.3. Tomographic Analysis

4. Results and Discussion

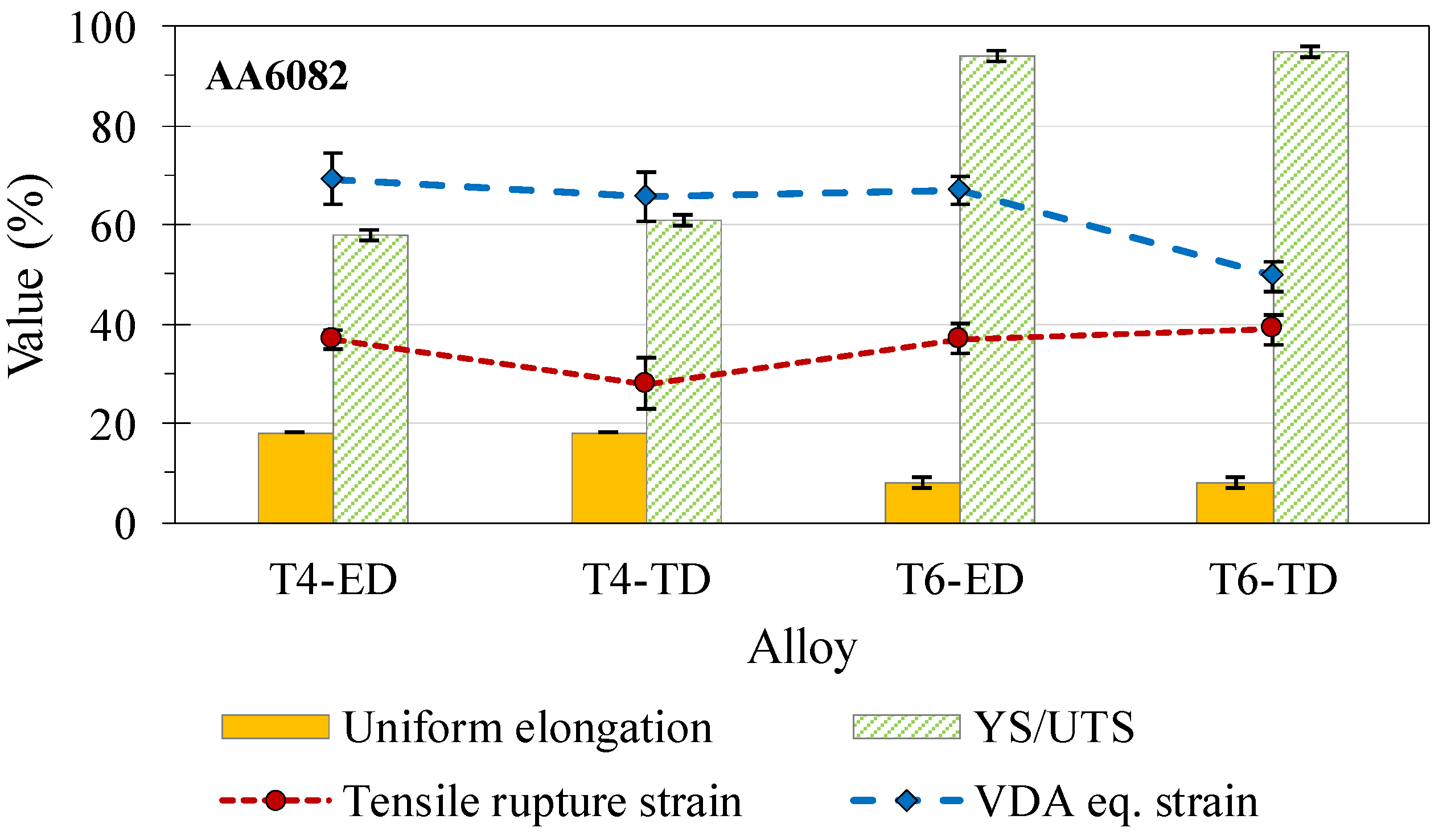

4.1. Tensile Results

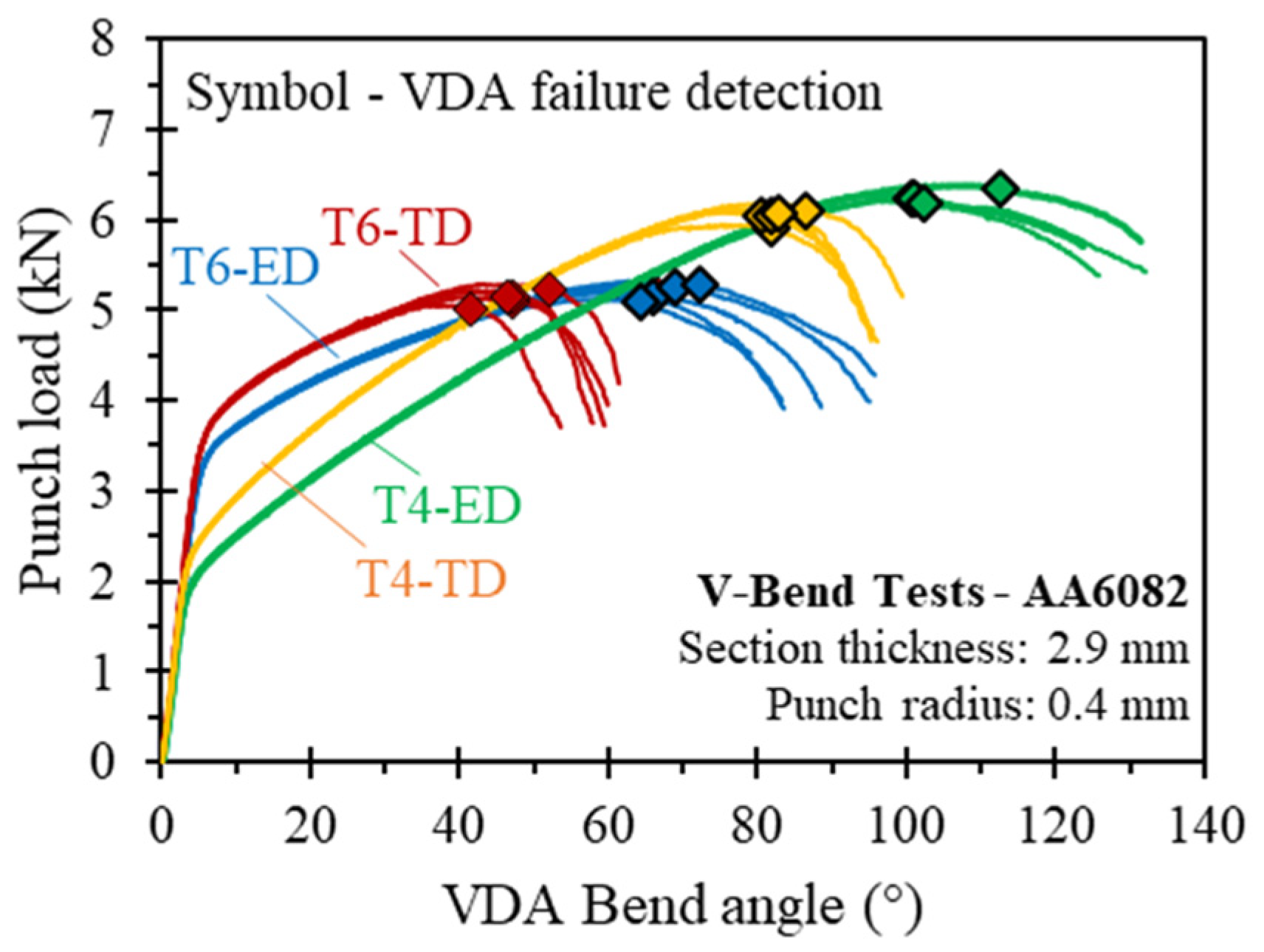

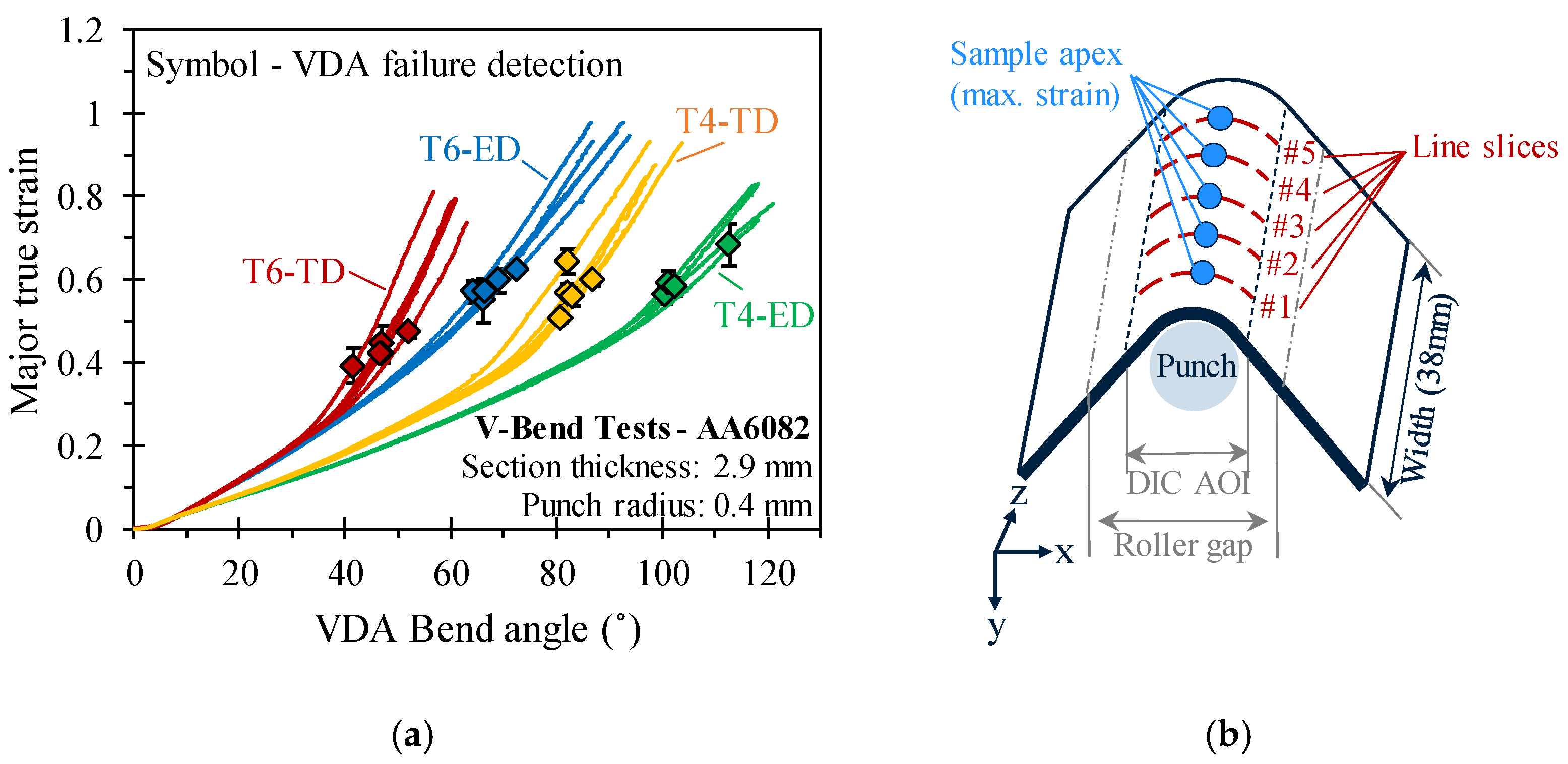

4.2. Bending Results

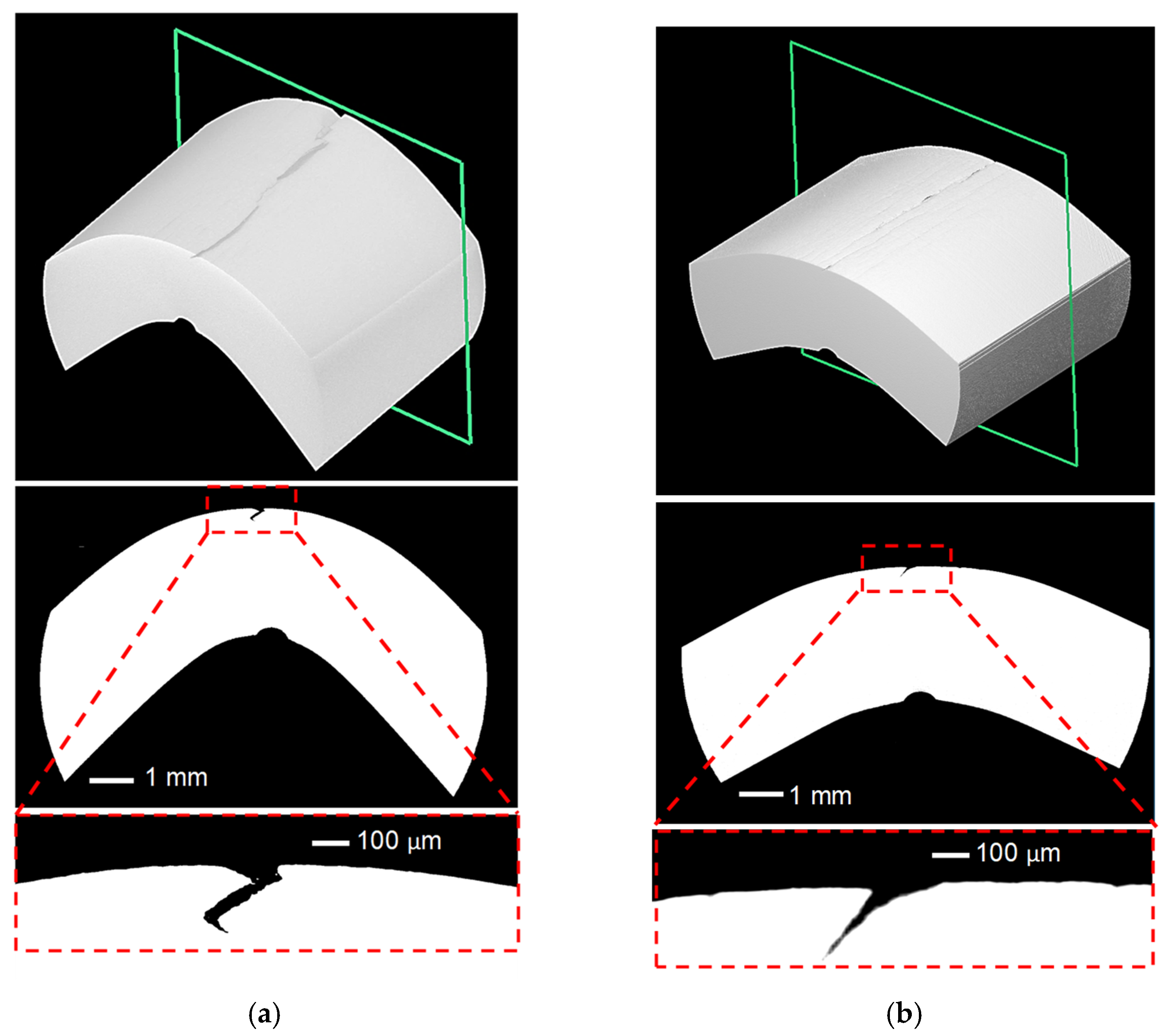

4.3. Microcomputed Tomography (μ-CT) Results

4.4. Correlation Between Tensile and Bending Performance

5. Conclusions

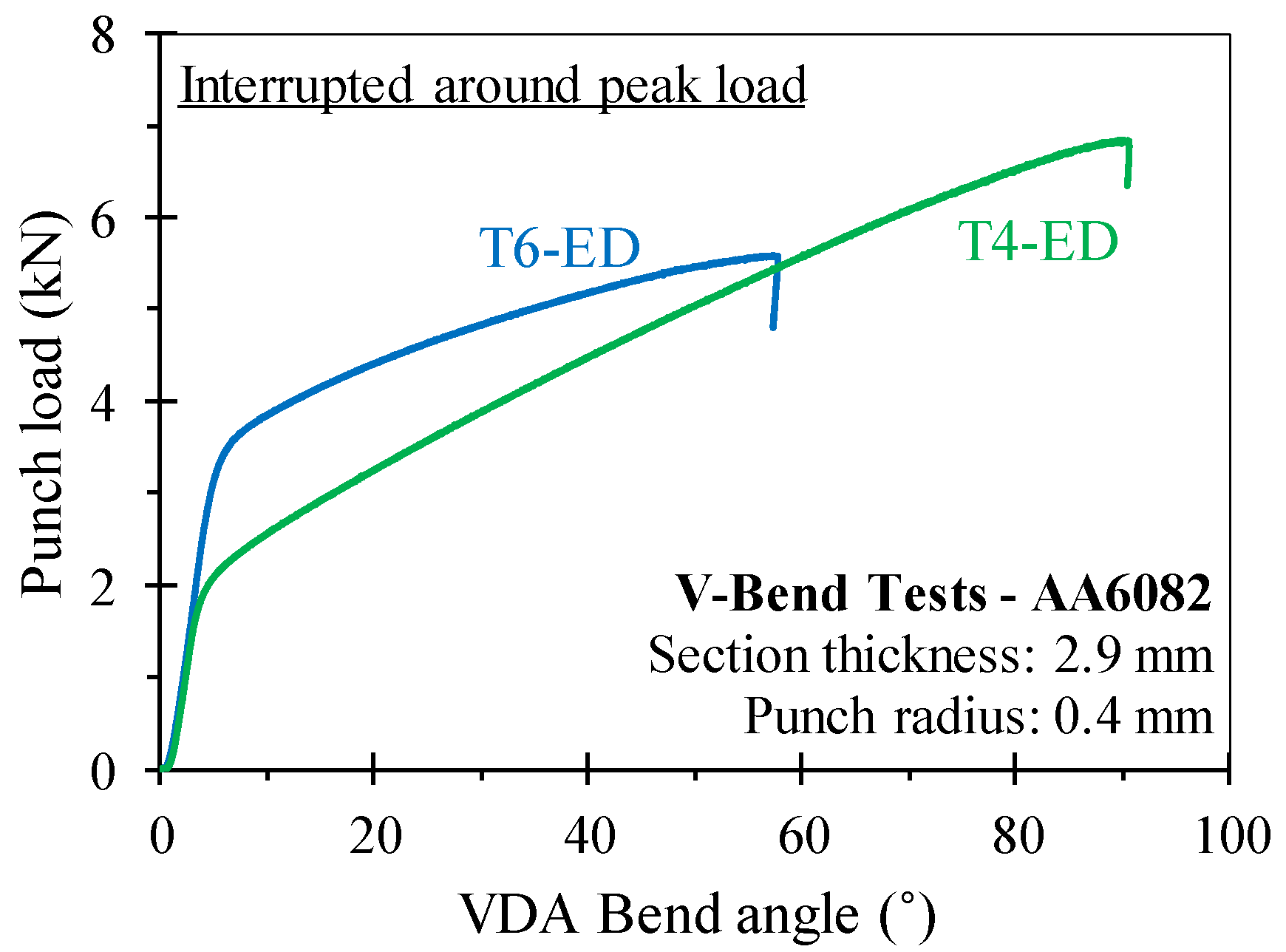

- The bend angle as a unique metric for performance ranking is insufficient for materials with significantly different hardening rates despite similar bend severities. Bend angle analysis should be supplemented with DIC strain measurements. For the studied alloys, a larger bend angle did not correlate with a higher surface strain in plane strain tension. For example, in the T4 condition, bending along the extrusion direction (ED) sustained a much larger VDA bend angle relative to the T6 sample (104° ± 6° versus 68° ± 3°, five repeats), but fracture strains were similar (0.60 ± 0.05 versus 0.58 ± 0.03, five repeats).

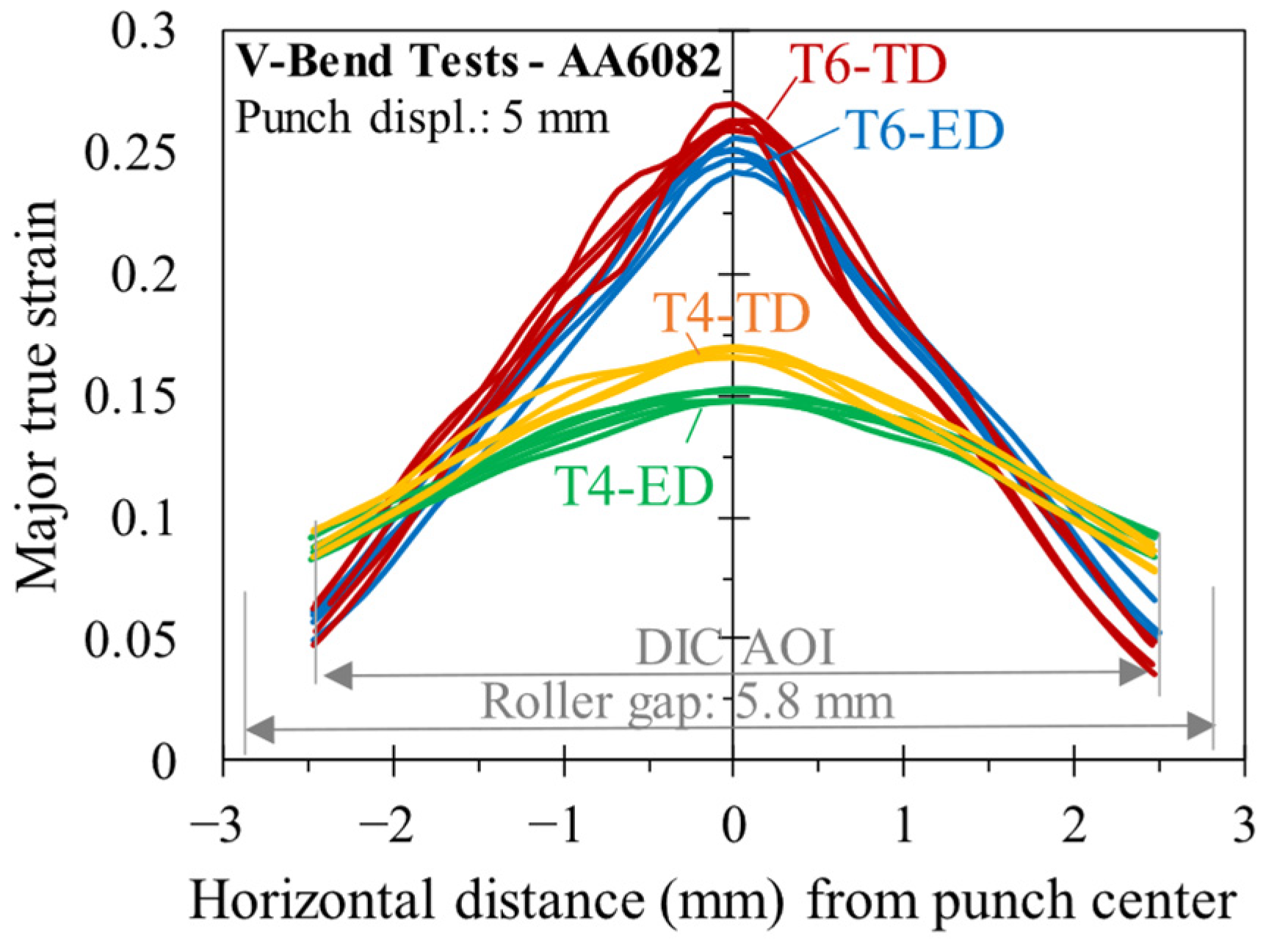

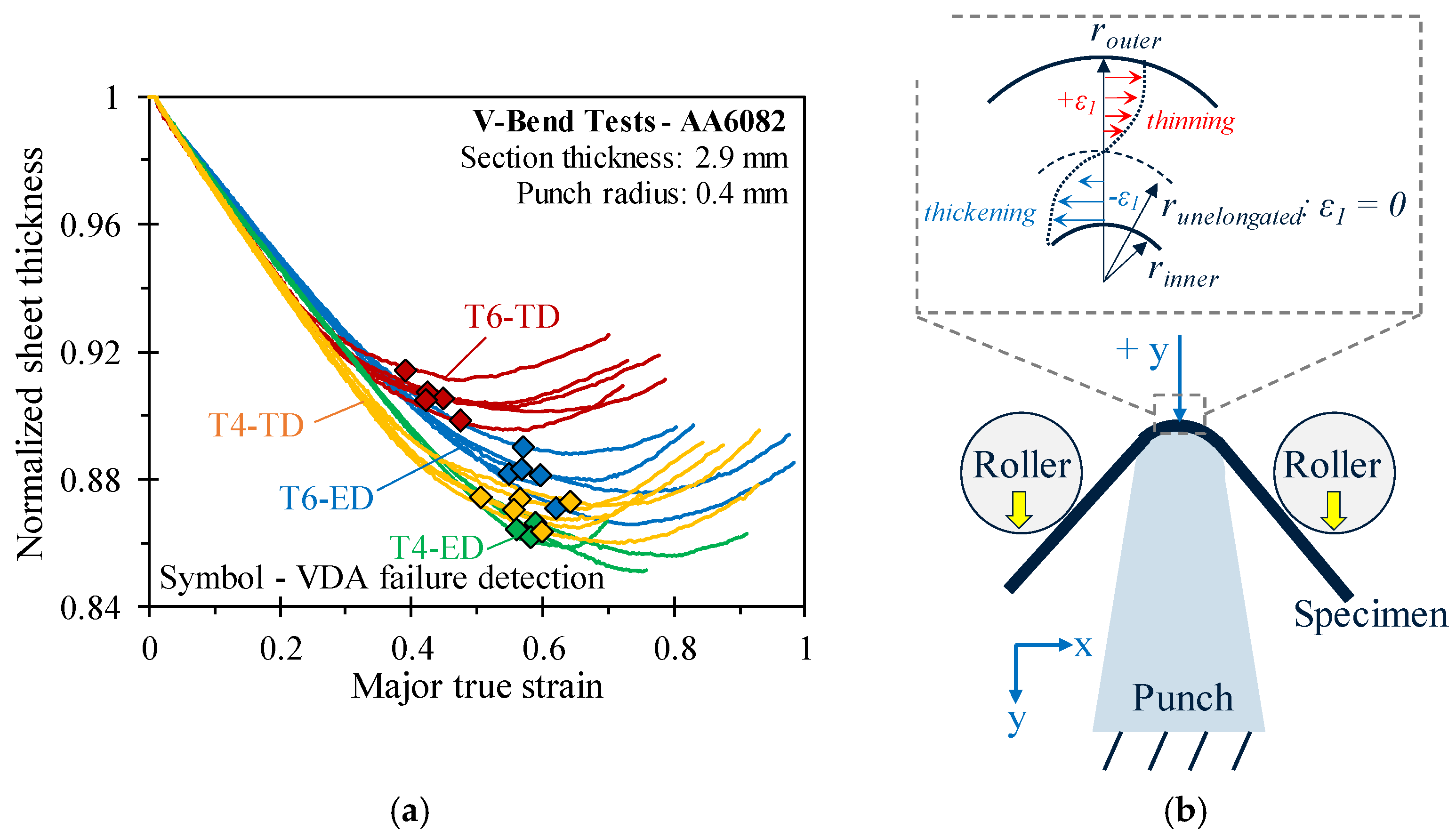

- It is suggested that the material hardening rate governs the strain distribution on the convex surface of the bend sample. The higher hardening rate in the T4 sample better distributes deformation in the bend zone and delays fracture to larger bend angles since the major strain during bending increases at a slower rate relative to the T6 samples. In contrast, deformation in the T6 condition was restricted to a narrow band around the sample apex, since major strain was accumulated faster relative to the T4 temper. For example, at a VDA bend angle of 37°, peak major strains ranged from approximately 0.14 in the T4 condition to 0.25 in the T6 temper.

- The vastly different work hardening rates in the T4 and T6 tempers were manifest in sheet thinning of the material cross-section and are relevant in forming operations with appreciable bending, such as hemming operations. For the same surface strain, more sheet thinning, approximated by tracking the out-of-plane displacement in DIC, occurred in the T4 condition. The higher hardening rate in the T4 temper is believed to accelerate the transition of the unelongated layer towards the inner bend surface, leading to a larger net tensile state of the cross-section, promoting thinning.

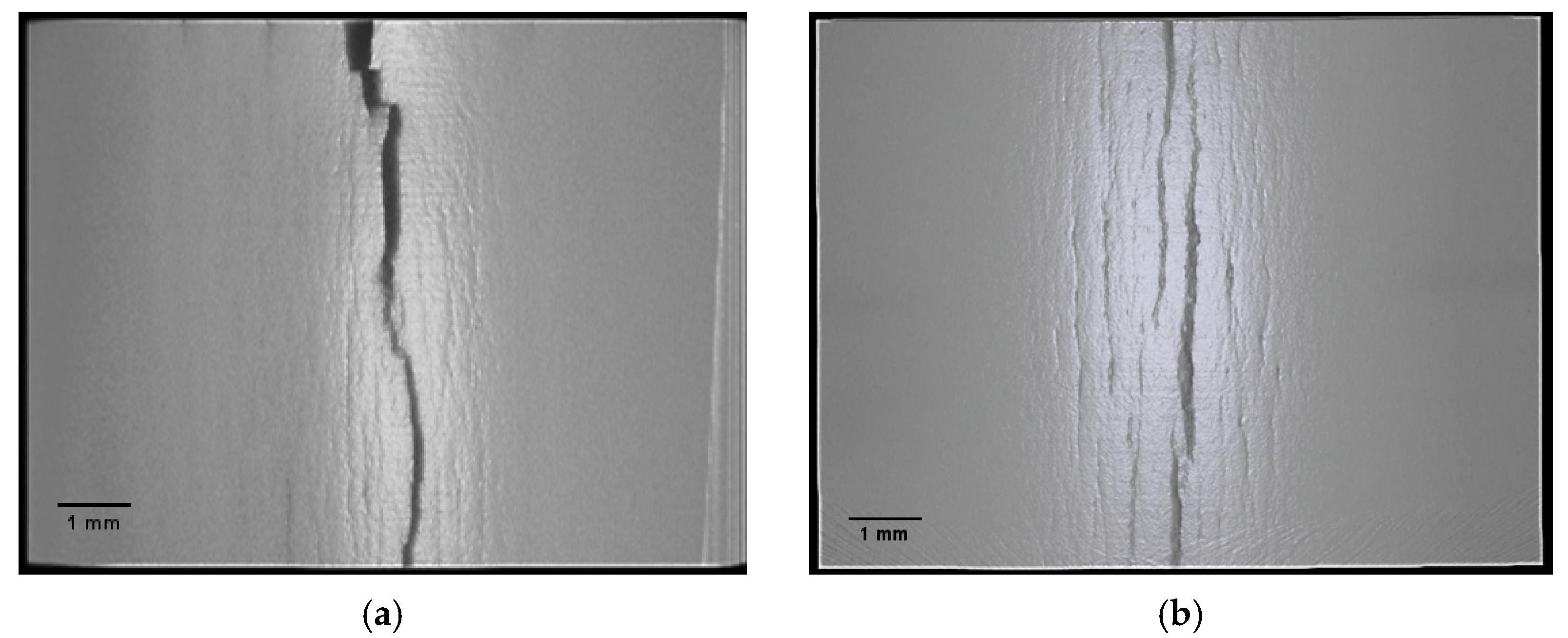

- Distribution and severity of damage in the form of cracks on the outer bend surface of interrupted tests were found to be distinct for the specific alloy temper. Single large cracks in a narrow band developed around the sample apex in the T4 samples compared to many small cracks broadly distributed within the bend zone of the T6 temper. It is suggested that a higher work hardening rate leads to strengthening of the neighboring material to delay crack initiation. Future work should consider μ-CT at a resolution higher than 10 μm to assess void formation across the sample face.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Scamans, G. Treading Lightly with Secondary Aluminum, Light Metal Age. 2023. Available online: https://www.lightmetalage.com/news/industry-news/automotive/treading-lightly-with-secondary-aluminum/ (accessed on 28 January 2025).

- Kan, Y.; Shida, R.; Takahashi, J.; Uzawa, K. Energy saving effect of light-weight electric vehicle using CFRP on transportation sector. In Proceedings of the Japan International SAMPE Symposium, Tokyo, Japan, 27–30 November 2007. [Google Scholar]

- Burd, J.T.J.; Moore, E.A.; Ezzat, H.; Kirchain, R.; Roth, R. Improvements in electric vehicle battery technology influence vehicle lightweighting and material substitution decision. Appl. Energy 2021, 283, 116269. [Google Scholar] [CrossRef]

- Parson, N.; Fourmann, J.; Beland, J. Aluminum Extrusions for Automotive Crash Applications. In Proceedings of the WCXTM 17: SAE World Congress Experience, Detroit, MI, USA, 4–6 April 2017. [Google Scholar]

- Dunand, M.; Maertens, A.P.; Luo, M.; Mohr, D. Experiments and modeling of anisotropic aluminum extrusions under multi-axial loading—Part I: Plasticity. Int. J. Plast. 2012, 36, 34–49. [Google Scholar] [CrossRef]

- Luo, M.; Dunand, M.; Mohr, D. Experiments and modeling of anisotropic aluminum extrusions under multi-axial loading—Part II: Ductile fracture. Int. J. Plast. 2012, 32–33, 36–58. [Google Scholar] [CrossRef]

- Thomesen, S.; Hopperstad, O.S.; Børvik, T. Anisotropic Plasticity and Fracture of Three 6000-Series Aluminum Alloys. Metals 2021, 11, 557. [Google Scholar] [CrossRef]

- VDA 238-100 (2020); Specification: Plate Bending Test for Metallic Materials. VDA: Berlin, Germany, 2020.

- VDA 238-100 (2017); Test Specification: Plate Bending Test for Metallic Materials. VDA: Berlin, Germany, 2017.

- VDA 238-100 (2010); Test Specification: Plate Bending Test for Metallic Materials. VDA: Berlin, Germany, 2010.

- Larour, P.; Hackl, B.; Leomann, F. Sensitivity analysis on the calculated bending angle in the instrumented bending test. In Proceedings of the International Deep Drawing Research Group, Zurich, Switzerland, 2–5 June 2013. [Google Scholar]

- Roth, C.; Mohr, D. Ductile fracture experiments with locally proportional loading histories. Int. J. Plast. 2016, 79, 328–354. [Google Scholar] [CrossRef]

- Cheong, K.; Omer, K.; Butcher, C.; George, R.; Dykeman, J. Evaluation of the VDA 238-100 tight radius bending test using digital image correlation strain measurement. In Proceedings of the International Deep Drawing Research Group, Munich, Germany, 2–6 July 2017. [Google Scholar]

- Boul, I.; Lang, M.; Mees, G.; Sponem, F.; Sturel, T.; Garat, X. Bending test and bendability of ultra high strength steels. In Proceedings of the International Deep Drawing Research Group, Gyor, Hungary, 21–23 May 2007. [Google Scholar]

- Labudde, T.; Bleck, W. Characterisation of Ductility of Ultra-High Strength Steels. In Proceedings of the International Conference on Technology of Plasticity, Aachen, Germany, 25–30 September 2011. [Google Scholar]

- Troive, L. New method for evaluation of bendability based on three-point-bending and the evolution of the cross-section moment. In Proceedings of the International Deep Drawing Research Group, Munich, Germany, 2–6 July 2017. [Google Scholar]

- Noder, J.; Dykeman, J.; Butcher, C. New Methodologies for Fracture Detection of Automotive Steels in Tight Radius Bending: Application to the VDA 238-100 V-Bend Test. Exp. Mech. 2021, 61, 367–394. [Google Scholar] [CrossRef]

- Grolleau, V.; Roth, C.C.; Lafilé, V.; Galpin, B.; Mohr, D. Loading of mini-Nakazima specimens with a dihedral punch: Determining the strain to fracture for plane strain tension through stretch-bending. Int. J. Mech. Sci. 2019, 152, 329–345. [Google Scholar] [CrossRef]

- Davidkov, A.; Petrov, R.H.; De Smet, P.; Schepers, B.; Kestens, L.A.I. Microstructure controlled bending response in AA6016 Al alloys. Mater. Sci. Eng. A 2011, 528, 7068–7076. [Google Scholar] [CrossRef]

- Castany, P.; Diologent, F.; Rossoll, A.; Despois, J.-F.; Bezenon, C.; Mortensen, A. Influence of quench rate and microstructure on bendability of AA6016 aluminum alloys. Mater. Sci. Eng. A 2013, 559, 558–565. [Google Scholar] [CrossRef]

- Sarkar, J.; Kutty, T.R.G.; Conlon, K.T.; Wilkinson, D.S.; Embury, J.D.; Lloyd, D.J. Tensile and bending properties of AA5754 aluminum alloys. Mater. Sci. Eng. A 2001, 316, 52–59. [Google Scholar] [CrossRef]

- Ikawa, S.; Asano, M.; Kuroda, M.; Yoshida, K. Effects of crystal orientation on bendability of aluminum alloy sheet. Mater. Sci. Eng. A 2011, 528, 4050–4054. [Google Scholar] [CrossRef]

- Snilsberg, K.E.; Westermann, I.; Holmedal, B.; Hopperstad, O.S.; Langsrud, Y.; Marthinsen, K. Anisotropy of Bending Properties in Industrial Heat-treatable Extruded Aluminium Alloys. MSF 2010, 638–642, 487–492. [Google Scholar] [CrossRef]

- Kordmir, S. Anisotropy of Strength and Fracture Behavior in Al-Mg-Si-(Mn) Extrusion Alloys. Master’s Thesis, University of British Columbia, Vancouver, BC, Canada, 2023. [Google Scholar]

- Sarkar, J.; Kutty, T.R.G.; Wilkinson, D.S.; Embury, J.D.; Lloyd, D.J. Tensile properties and bendability of T4 treated AA6111 aluminum alloys. Mater. Sci. Eng. A 2004, 369, 258–266. [Google Scholar] [CrossRef]

- Datsko, J.; Yang, C.T. Correlation of Bendability of Materials with their tensile properties. J. Manuf. Sci. Eng. 1960, 82, 309–313. [Google Scholar] [CrossRef]

- Westermann, I.; Snilsberg, K.E.; Sharifi, Z. Three-Point Bending of Heat-Treatable Aluminum Alloys: Influence of Microstructure and Texture on Bendability and Fracture Behavior. Metall. Mater. Trans. 2011, 42, 3386–3398. [Google Scholar] [CrossRef]

- Cheong, K.; Noder, J.; Zhumagulov, A.; Butcher, C. Characterization and Prediction of Plane Strain Bendability in Advanced High Strength Steels. Metals 2023, 13, 1711. [Google Scholar] [CrossRef]

- Durrenberger, L.; Dietsch, P. Bending angle correlation regarding sheet thickness. In Proceedings of the International Deep Drawing Research Group, Waterloo, ON, Canada, 3–7 June 2018. [Google Scholar]

- Parson, N. (Rio Tinto Aluminium, Saguenay, QC, Canada). Private communication, 2025.

- Fini, S.N. The Effect of PCG Layer Thickness on Bendability of Aluminum Extrusion Alloys. Master’s Thesis, University of British Columbia, Vancouver, BC, Canada, 2023. [Google Scholar]

- Jonsson, S.; Frómeta, D.; Grifé, L.; Larsson, F.; Kajberg, J. Assessment of Rate-Dependency and Adiabatic Heating on the Essential Work of Fracture of Press-Hardening Steels. Metals 2025, 15, 316. [Google Scholar] [CrossRef]

- Larour, P.; Hackl, B.; Leomann, F.; Benedyk, K. Bending angle calculation in the instrumented three-point bending test. In Proceedings of the International Deep Drawing Research Group, Mumbai, India, 25–28 November 2012. [Google Scholar]

- Boerckel, J.D.; Mason, D.E.; McDermott, A.M.; Alsberg, E. Microcomputed tomography: Approaches and applications in bioengineering. Stem Cell Res. Ther. 2014, 5, 144. [Google Scholar] [CrossRef]

- Dumitraschkewitz, P.; Gerstl, S.S.A.; Stephenson, L.T.; Uggowitzer, P.J.; Pogatscher, S. Clustering in Age-Hardenable Aluminum Alloys. Adv. Eng. Mater. 2018, 20, 1800255–1800279. [Google Scholar] [CrossRef]

- Bollmann, C.; Yu, C.; Lalpoor, M.; Miroux, A. Evolution of Work Hardening and Hemming in 6xxx Aluminum Alloys in the Course of Natural Aging Following Continuous Annealing. In Proceedings of the TMS2022, Anaheim, CA, USA, 27 February–3 March 2022. [Google Scholar]

- Miao, W.F.; Laughlin, D.E. Precipitation hardening in aluminum alloy 6022. Scr. Mater. 1999, 40, 873–878. [Google Scholar] [CrossRef]

- Myhr, O.R.; Hopperstad, O.S.; Borvik, T. A Combined Precipitation, Yield Stress, and Work Hardening Model for Al-Mg-Si Alloys Incorporating the Effects of Strain Rate and Temperature. Metall. Mater. Trans. A 2018, 49, 3592–3609. [Google Scholar] [CrossRef]

- Cheng, L.M.; Poole, W.J.; Embury, J.D.; Lloyd, D.J. The influence of precipitation on the work-hardening behavior of the aluminum alloys AA6111 and AA7030. Metall. Mater. Trans. A 2003, 34, 2473–2481. [Google Scholar] [CrossRef]

- Marciniak, Z.; Duncan, J.L.; Hu, S.J. Mechanics of Sheet Metal Forming, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2002; pp. 1–211. [Google Scholar]

- Cheong, K.; Butcher, C.; Dykeman, J. The Influence of the through-thickness strain gradients on the fracture characterization of advanced high-strength steels. SAE Int. J. Mater. Manuf. 2018, 11, 541–552. [Google Scholar] [CrossRef]

- Noder, J. Plastic Instability and Failure of Sheet Metals Subjected to Complex Stress States. Ph.D. Thesis, University of Waterloo, Waterloo, ON, Canada, 2022. [Google Scholar]

- Mattei, L.; Daniel, D.; Guiglionda, G.; Klöcker, H.; Driver, J.H. Strain localization and damage mechanisms during bending of AA6016 sheet. Mater. Sci. Eng. A 2013, 559, 812–821. [Google Scholar] [CrossRef]

- Jin, H.; Lu, W.-Y.; Korellis, J. Experimental Study of Voids in High Strength Aluminum Alloys. In Proceedings of the SEM Annual Conference, Indianapolis, IN, USA, 7–10 June 2010. [Google Scholar]

- Hance, B. Advanced High Strength Steel: Deciphering Local and Global Formability. In Proceedings of the IABC 2106, Chicago, IL, USA, 28–29 September 2016. [Google Scholar]

- Paul, S.K. A critical review on hole expansion ratio. Materialia 2020, 9, 100566–100578. [Google Scholar] [CrossRef]

| Mg | Si | Mn | Cr | Fe |

|---|---|---|---|---|

| 0.70 | 1.04 | 0.49 | 0.15 | 0.18 |

| DIC Analysis Parameters | Details |

|---|---|

| DIC Software | Vic-3D (version 8), Correlated Solutions, Inc. (Columbia, SC, USA) |

| Camera resolution | 0.035 mm/pixel |

| Subset Size and Shape Function | 27 pixels, affine |

| Step size | 4 pixels |

| Filter size | 5 |

| VSG | 1.5 mm |

| Subset Weights | Gaussian |

| Strain Filter Weights | Gaussian—90% center-weighted |

| Interpolation | Optimized 8-tap splines |

| Radial Distortion Correction Model and Parameters | Seidel (Order = 1), k1 = −0.26 and −0.27 (two cameras) |

| Image Center (both Cameras) | 1024 pixels × 1024 pixels |

| Temper | Test Direction | YS (MPa) | UTS (MPa) | YS/UTS | Uniform Elongation | Rupture Strain | R-Value |

|---|---|---|---|---|---|---|---|

| T4 | ED | 194 ± 3 | 336 ± 2 | 0.58 ± 0.01 | 0.18 ± 0.00 | 0.37 ± 0.02 | 0.24 ± 0.02 |

| TD | 211 ± 1 | 344 ± 1 | 0.61 ± 0.01 | 0.18 ± 0.00 | 0.28 ± 0.05 | 1.22 ± 0.09 | |

| T6 | ED | 341 ± 1 | 364 ± 1 | 0.94 ± 0.01 | 0.08 ± 0.01 | 0.37 ± 0.03 | 0.28 ± 0.04 |

| TD | 353 ± 1 | 371 ± 1 | 0.95 ± 0.01 | 0.08 ± 0.00 | 0.39 ± 0.00 | 1.03 ± 0.03 |

| Temper | Loading Direction | Punch Load (kN) | Punch Displ. (mm) | Bend Angle (°) | Major Strain | Minor Strain |

|---|---|---|---|---|---|---|

| T4 | ED | 6.23 ± 0.07 | 11.75 ± 0.51 | 104 ± 6 | 0.60 ± 0.05 | 0.00 ± 0.00 |

| TD | 6.02 ± 0.08 | 9.82 ± 0.21 | 83 ± 2 | 0.57 ± 0.05 | 0.00 ± 0.00 | |

| T6 | ED | 5.18 ± 0.08 | 8.35 ± 0.31 | 68 ± 3 | 0.58 ± 0.03 | 0.00 ± 0.00 |

| TD | 5.12 ± 0.09 | 6.14 ± 0.41 | 47 ± 4 | 0.43 ± 0.03 | 0.00 ± 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noder, J.; Cheong, K.; Butcher, C.; Rometsch, P.; Poole, W.J. Effect of Hardening Rate on the Bendability and Fracture Response of AA6082 Aluminum Extrusions in the VDA238-100 Tight Radius Bend Test. Metals 2025, 15, 1199. https://doi.org/10.3390/met15111199

Noder J, Cheong K, Butcher C, Rometsch P, Poole WJ. Effect of Hardening Rate on the Bendability and Fracture Response of AA6082 Aluminum Extrusions in the VDA238-100 Tight Radius Bend Test. Metals. 2025; 15(11):1199. https://doi.org/10.3390/met15111199

Chicago/Turabian StyleNoder, Jacqueline, Kenneth Cheong, Cliff Butcher, Paul Rometsch, and Warren J. Poole. 2025. "Effect of Hardening Rate on the Bendability and Fracture Response of AA6082 Aluminum Extrusions in the VDA238-100 Tight Radius Bend Test" Metals 15, no. 11: 1199. https://doi.org/10.3390/met15111199

APA StyleNoder, J., Cheong, K., Butcher, C., Rometsch, P., & Poole, W. J. (2025). Effect of Hardening Rate on the Bendability and Fracture Response of AA6082 Aluminum Extrusions in the VDA238-100 Tight Radius Bend Test. Metals, 15(11), 1199. https://doi.org/10.3390/met15111199