Effect of AlCoCrFeNi2.1 High-Entropy Alloy Reinforcement on the Densification, Microstructure, and Hot-Cracking Behavior of LPBF-Processed AA7075

Abstract

1. Introduction

2. Materials and Methods

2.1. Powder Preparation

2.2. LPBF Processing

2.3. Microstructure and Densification Analysis

2.4. Microhardness Testing

2.5. Tensile Testing

3. Results and Discussion

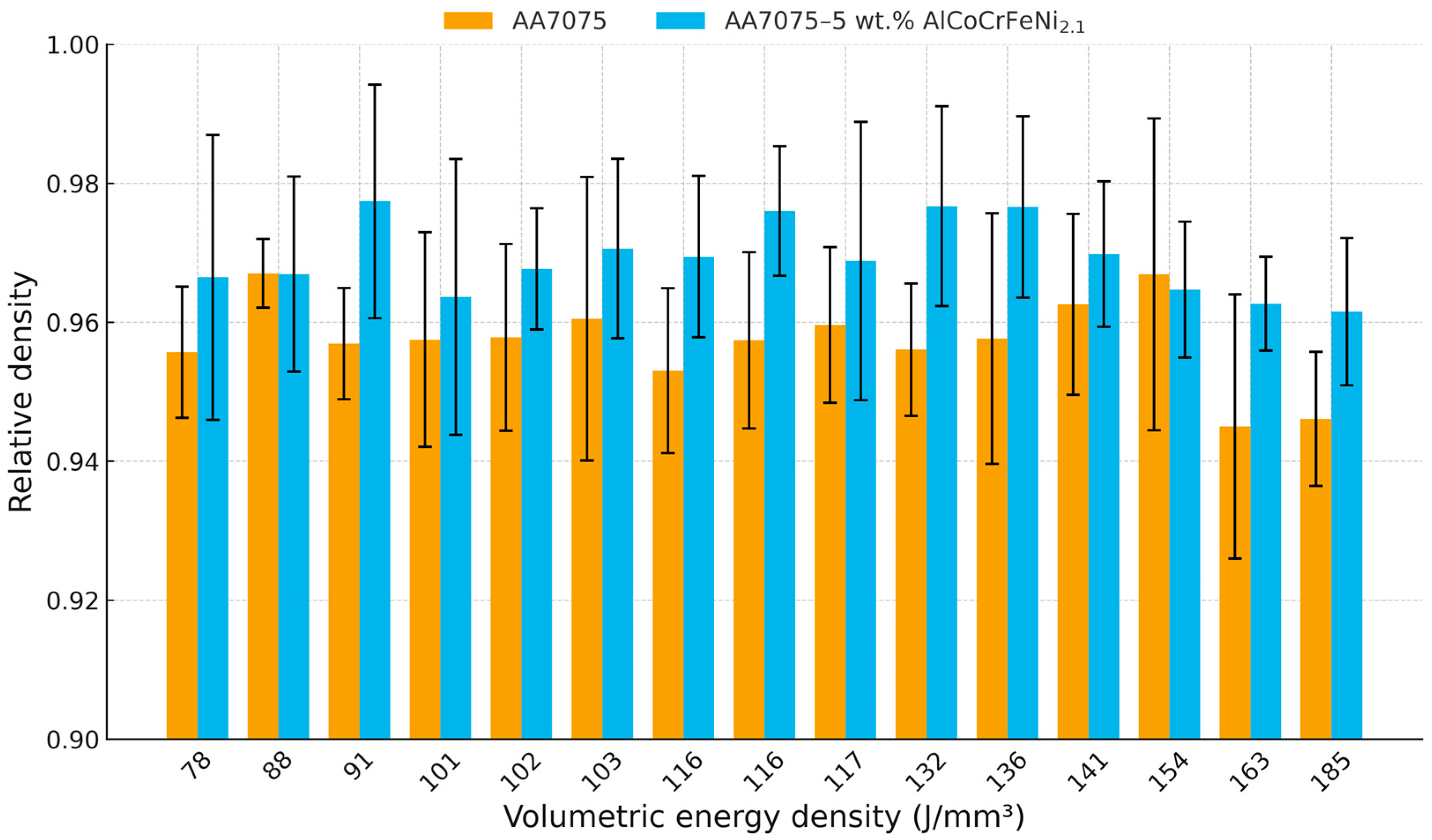

3.1. Densification Behavior

3.2. Microstructural Analysis

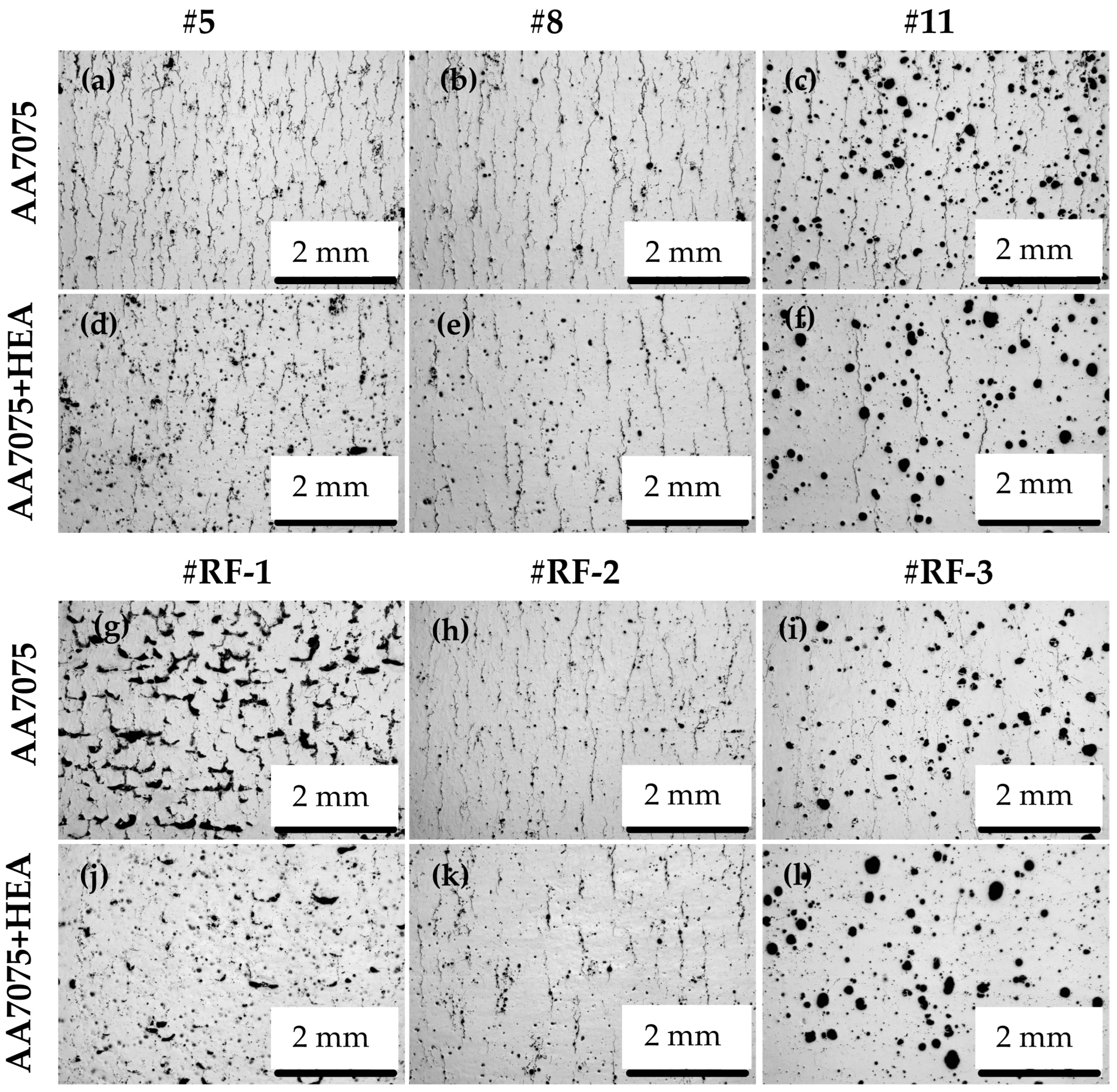

3.2.1. Optical Microscopy

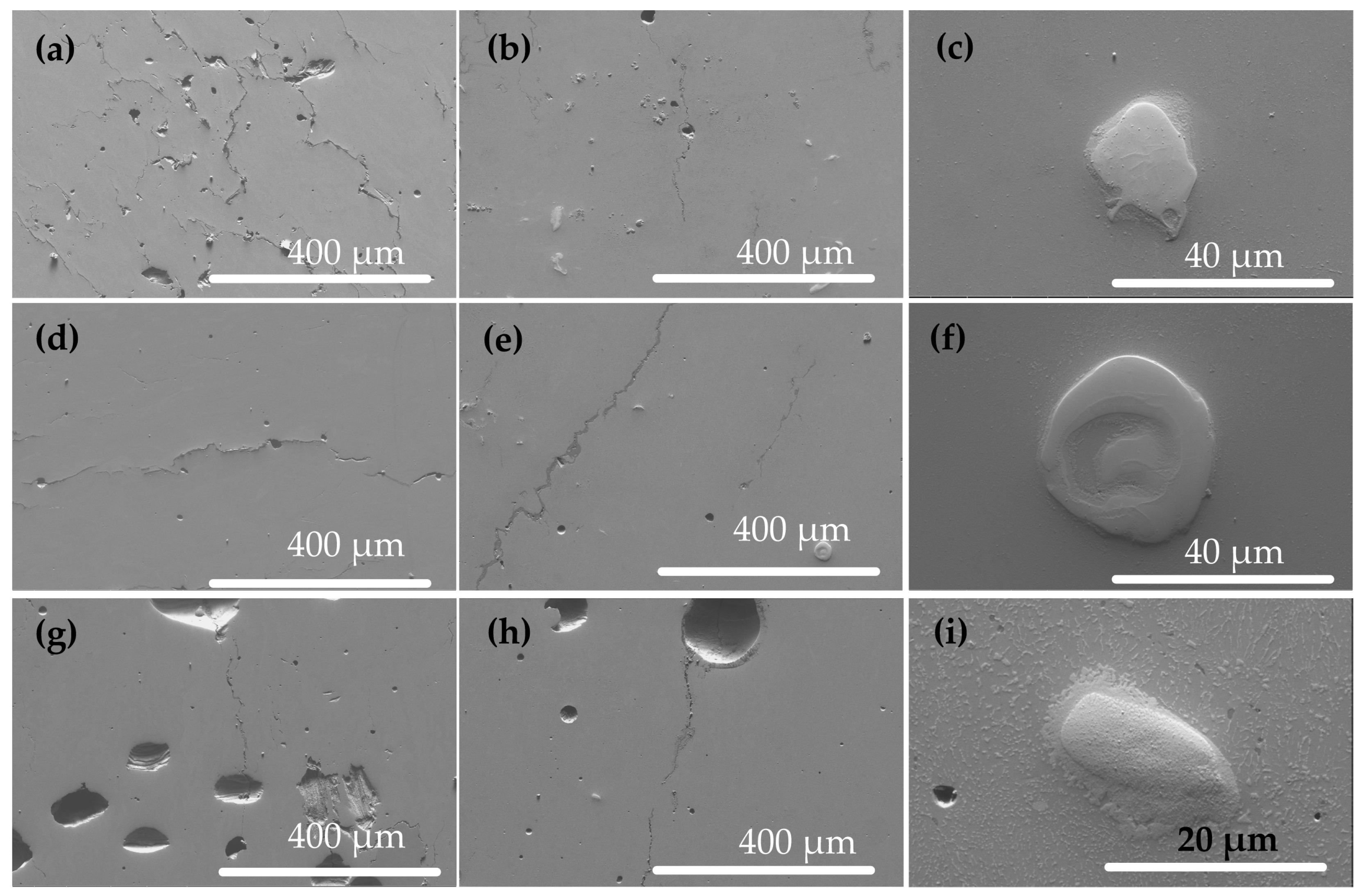

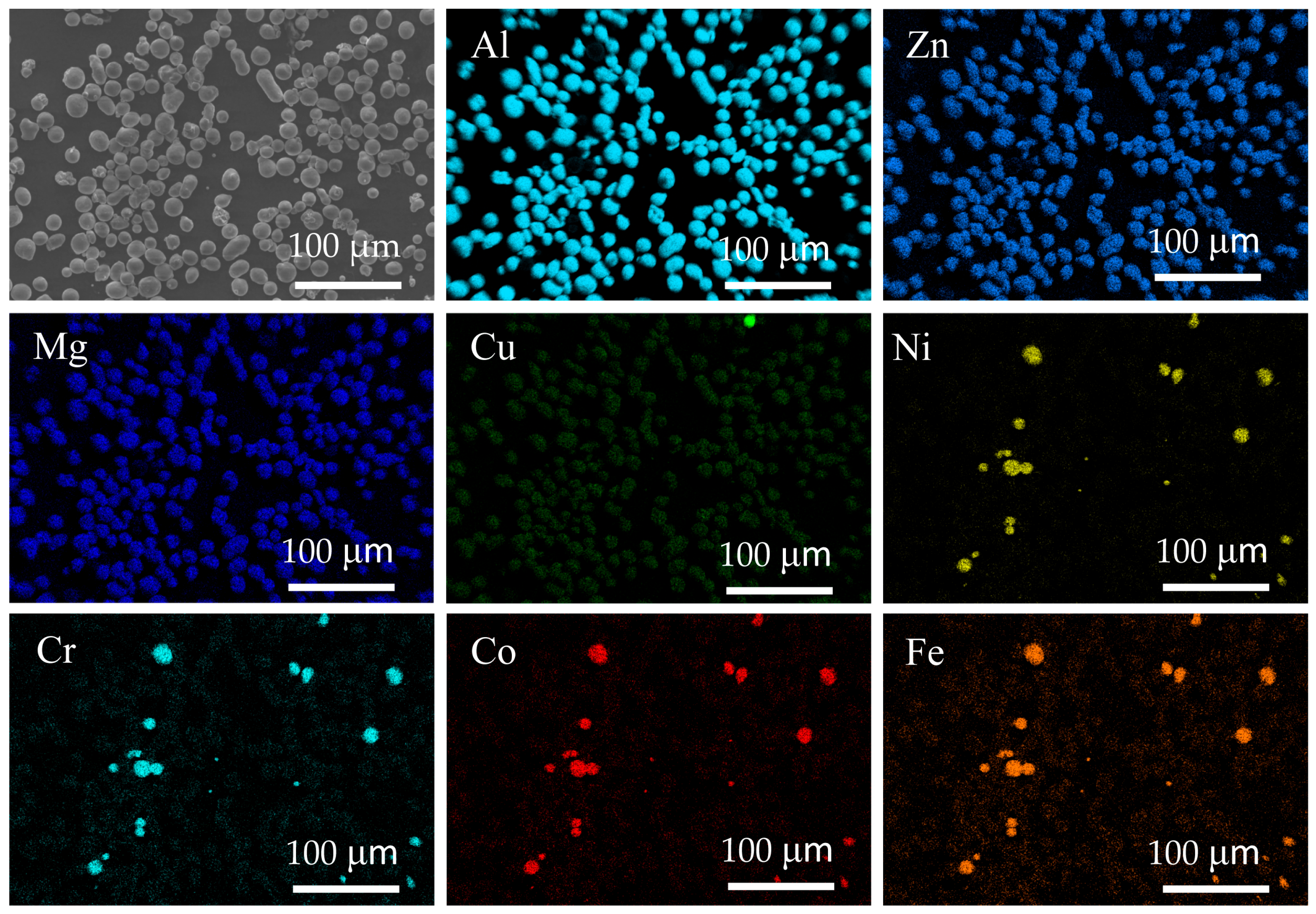

3.2.2. SEM and EDS Analysis

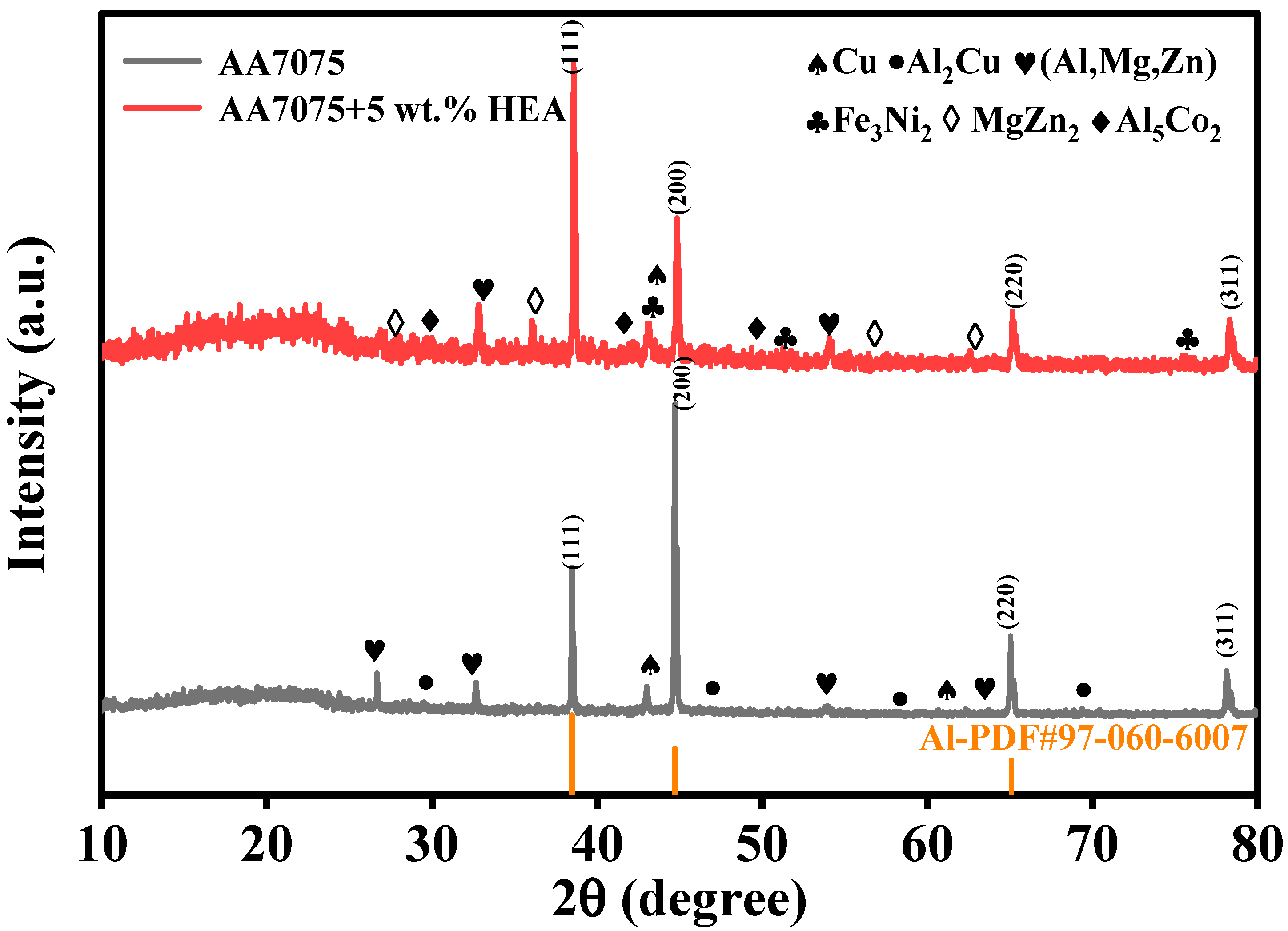

3.2.3. Phase Identification (XRD Analysis)

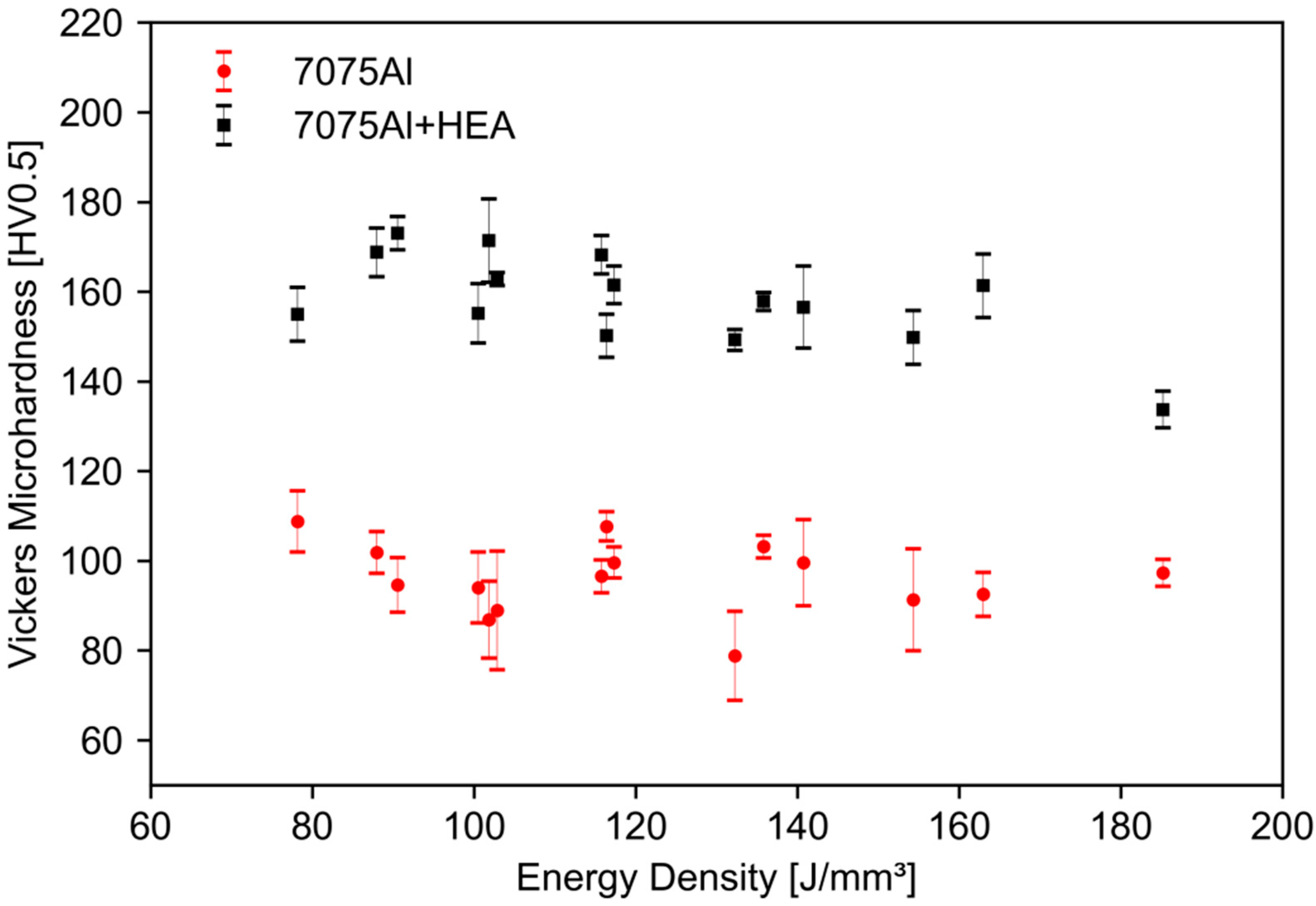

3.3. Microhardness as a Function of Processing Parameters

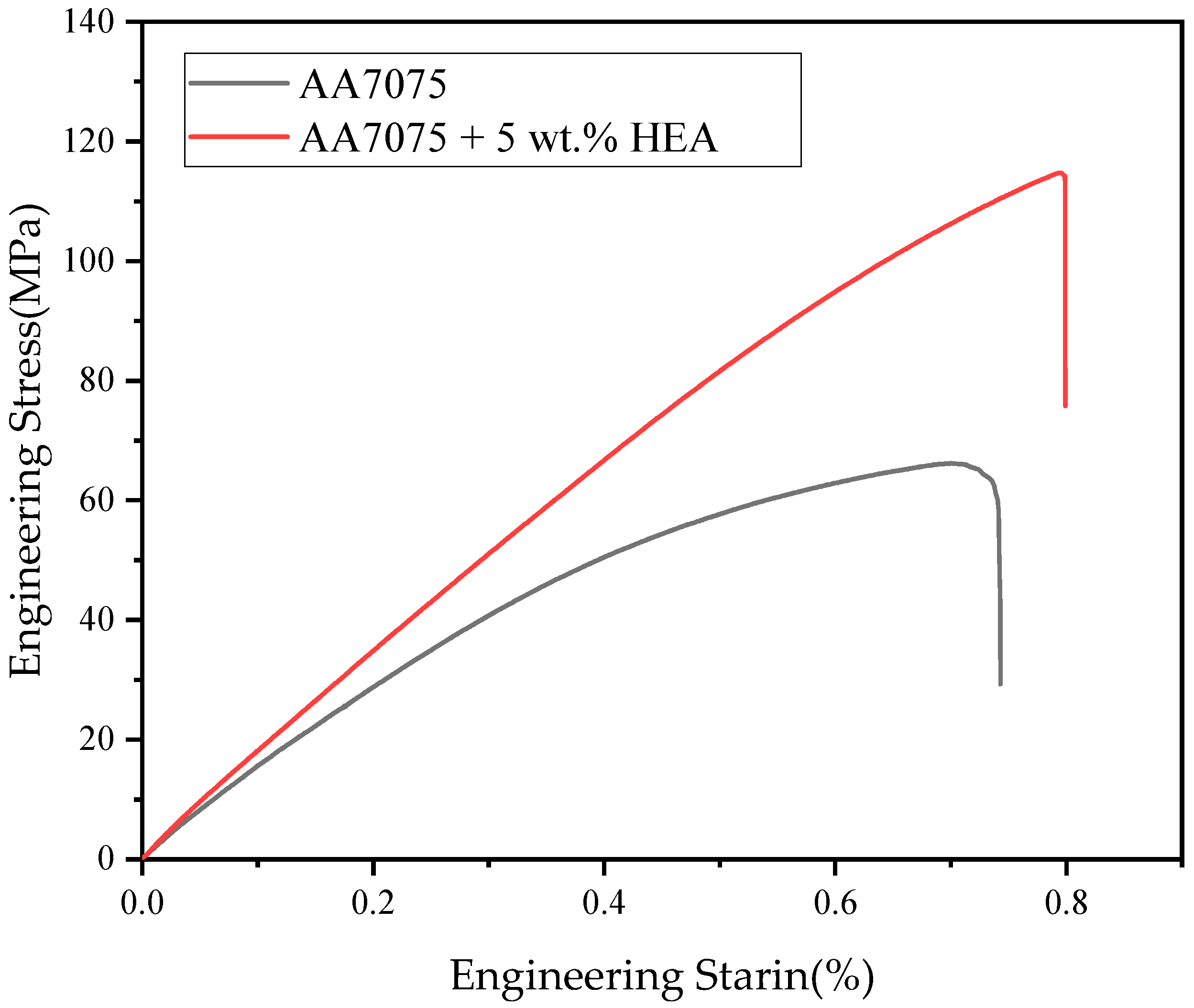

3.4. Validation of Mechanical Performance Enhancement

3.5. Discussion

3.5.1. Densification and Process Window

3.5.2. Crack Behavior and Solute Segregation

3.5.3. Interfacial Phase Formation and Microstructural Control

3.5.4. Mechanical Response and Strengthening Balance

4. Conclusions

- (1)

- Densification. With the addition of HEA, the measured relative density increased by about 0.5–1.5% (absolute) over the same parameter sets, increasing from 94.50 to 96.70% (unreinforced) to 96.15–97.74% (HEA-reinforced). The highest values were obtained near the lower-to-medium VED range (e.g., 97.74% at 220 W/900 mm·s−1, VED = 90.53 J·mm−3 for the composite, and 96.70% at 190 W/800 mm·s−1, VED = 87.96 J·mm−3 for the base alloy). Porosity was not eliminated.

- (2)

- Hardness. The average Vickers microhardness (HV0.5) increased from 96.41 ± 9.81 to 158.46 ± 11.33 (≈64%). The gain agreed with the observed presence of fine HEA-derived phases/particles in the microstructure and associated grain/particle strengthening.

- (3)

- Cracks and Voids. OM comparisons at 25× (Figure 4) confirmed that adding 5 wt.% HEA modified the failure mode, transforming the long, continuous cracks typical of AA7075 into shorter, deflected ones. Porosity, however, was not eliminated; characteristic lack-of-fusion (LOF) defects persisted at low VEDs, while vaporization-induced near-spherical pores dominated at high VED values.

- (4)

- Phase evolution and refinement: XRD identified the formation of Fe3Ni2 and Al5Co2 intermetallics together with peak features consistent with grain refinement/lattice distortion. These microstructural changes were the primary contributors to the observed increase in hardness.

- (5)

- Elemental redistribution and mechanism insight: EDS mapping showed HEA particles enriched in Fe/Co/Ni/Cr, containing a marked depletion in Zn. In contrast, Zn was segregated linearly along crack paths in the matrix. This redistribution indicated that HEA reinforcement altered the solidification path and solute partitioning, interfering with the metallurgical mechanism underpinning hot cracking in 7xxx alloys.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bouzekova-Penkova, A.; Miteva, A. Some Aerospace Applications of 7075 (B95) Aluminium Alloy. Aerosp. Res. Bulg. 2022, 34, 165–179. [Google Scholar] [CrossRef]

- Kvvssn, V.; Butt, M.M.; Laieghi, H.; Uddin, Z.; Salamci, E.; Kim, D.B.; Kizil, H. Recent Progress in Additive Manufacturing of 7XXX Aluminum Alloys. Int. J. Adv. Manuf. Technol. 2025, 137, 4353–4399. [Google Scholar] [CrossRef]

- Wimmer, A.; Panzer, H.; Zoeller, C.; Adami, S.; Adams, N.A.; Zaeh, M.F. Experimental and Numerical Investigations of the Hot Cracking Susceptibility during the Powder Bed Fusion of AA 7075 Using a Laser Beam. Prog. Addit. Manuf. 2024, 9, 1589–1603. [Google Scholar] [CrossRef]

- Paul, S. Finite Element Analysis in Fused Deposition Modeling Research: A Literature Review. Measurement 2021, 178, 109320. [Google Scholar] [CrossRef]

- Liu, J.; Wen, P. Metal Vaporization and Its Influence during Laser Powder Bed Fusion Process. Mater. Des. 2022, 215, 110505. [Google Scholar] [CrossRef]

- Shi, G.; Zhang, R.; Cao, Y.; Yang, G. A Review of the Vaporization Behavior of Some Metal Elements in the LPBF Process. Micromachines 2024, 15, 846. [Google Scholar] [CrossRef]

- Zhao, C.; Parab, N.D.; Li, X.; Fezzaa, K.; Tan, W.; Rollett, A.D.; Sun, T. Critical Instability at Moving Keyhole Tip Generates Porosity in Laser Melting. Science 2020, 370, 1080–1086. [Google Scholar] [CrossRef] [PubMed]

- Cunningham, R.; Zhao, C.; Parab, N.; Kantzos, C.; Pauza, J.; Fezzaa, K.; Sun, T.; Rollett, A.D. Keyhole Threshold and Morphology in Laser Melting Revealed by Ultrahigh-Speed X-Ray Imaging. Science 2019, 363, 849–852. [Google Scholar] [CrossRef] [PubMed]

- Martin, A.A.; Calta, N.P.; Khairallah, S.A.; Wang, J.; Depond, P.J.; Fong, A.Y.; Thampy, V.; Guss, G.M.; Kiss, A.M.; Stone, K.H.; et al. Dynamics of Pore Formation during Laser Powder Bed Fusion Additive Manufacturing. Nat. Commun. 2019, 10, 1987. [Google Scholar] [CrossRef] [PubMed]

- Matthews, M.J.; Guss, G.; Khairallah, S.A.; Rubenchik, A.M.; Depond, P.J.; King, W.E. Denudation of Metal Powder Layers in Laser Powder Bed Fusion Processes. Acta Mater. 2016, 114, 33–42. [Google Scholar] [CrossRef]

- Gordon, J.V.; Narra, S.P.; Cunningham, R.W.; Liu, H.; Chen, H.; Suter, R.M.; Beuth, J.L.; Rollett, A.D. Defect Structure Process Maps for Laser Powder Bed Fusion Additive Manufacturing. Addit. Manuf. 2020, 36, 101552. [Google Scholar] [CrossRef]

- Kareem, S.A.; Anaele, J.U.; Aikulola, E.O.; Anamu, U.S.; Koko, A.; Bodunrin, M.O.; Alaneme, K.K. Aluminium Matrix Composites Reinforced with High Entropy Alloys: A Comprehensive Review on Interfacial Reactions, Mechanical, Corrosion, and Tribological Characteristics. J. Mater. Res. Technol. 2024, 30, 8161–8186. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, W.; Chiumenti, M.; Cervera, M.; Gillham, B.; Yu, P.; Yin, S.; Lin, X.; Babu, R.P.; Lupoi, R. Crack-Free Laser Powder Bed Fusion by Substrate Design. Addit. Manuf. 2022, 59, 103149. [Google Scholar] [CrossRef]

- Xiao, J.; Yao, C.; Zhang, B.; Xiao, Z.; Zheng, H.; Qi, D.; Cao, W.; Sun, D.; Yu, W. In-Situ High-Speed X-Ray Imaging of Crack Formation and Elimination Mechanisms in AA7075 Alloy during Laser Remelting. Opt. Laser Technol. 2025, 186, 112716. [Google Scholar] [CrossRef]

- Wang, D.; Li, K.; Yao, J.; Geng, X.; Du, B. Effect of Layer-Wise Femtosecond Laser Shock Peening on Cracking Growth in Laser Powder Bed Fused AA 7075. Addit. Manuf. 2024, 95, 104525. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, D.; O’Toole, P.; Qiu, D.; Seibold, M.; Schricker, K.; Bergmann, J.-P.; Rack, A.; Easton, M. In Situ Observation and Reduction of Hot-Cracks in Laser Additive Manufacturing. Commun. Mater. 2024, 5, 84. [Google Scholar] [CrossRef]

- Tan, Q.; Fan, Z.; Tang, X.; Yin, Y.; Li, G.; Huang, D.; Zhang, J.; Liu, Y.; Wang, F.; Wu, T.; et al. A Novel Strategy to Additively Manufacture 7075 Aluminium Alloy with Selective Laser Melting. Mater. Sci. Eng. A 2021, 821, 141638. [Google Scholar] [CrossRef]

- Zheng, T.; Pan, S.; Murali, N.; Li, B.; Li, X. Selective Laser Melting of Novel 7075 Aluminum Powders with Internally Dispersed TiC Nanoparticles. Mater. Lett. 2022, 319, 132268. [Google Scholar] [CrossRef]

- Wu, W.; Gao, C.; Liu, Z.; Wong, K.; Xiao, Z. Laser Powder Bed Fusion of Crack-Free TiN/Al7075 Composites with Enhanced Mechanical Properties. Mater. Lett. 2021, 282, 128625. [Google Scholar] [CrossRef]

- Nothomb, N.; Rodriguez-Barber, I.; Avettand-Fénoël, M.-N.; Pérez Prado, M.T.; Marinova, M.; Simar, A. Understanding the Effect of Tailored Heat Treatment on Zr-Modified Al7075 Fabricated by Laser Powder Bed Fusion. Mater. Des. 2025, 258, 114553. [Google Scholar] [CrossRef]

- Zhou, S.Y.; Su, Y.; Wang, H.; Enz, J.; Ebel, T.; Yan, M. Selective Laser Melting Additive Manufacturing of 7xxx Series Al-Zn-Mg-Cu Alloy: Cracking Elimination by Co-Incorporation of Si and TiB2. Addit. Manuf. 2020, 36, 101458. [Google Scholar] [CrossRef]

- Choi, G.; Chae, H.; Kim, Y.S.; Hong, S.-K.; Shin, E.; Lee, S.Y. Additive Manufacturing of Si-Added 7075 Aluminum Alloys: Microstructural, Mechanical, and Electrochemical Properties via Heat Treatment. Materials 2025, 18, 1544. [Google Scholar] [CrossRef]

- Ron, T.; Shirizly, A.; Aghion, E. Additive Manufacturing Technologies of High Entropy Alloys (HEA): Review and Prospects. Materials 2023, 16, 2454. [Google Scholar] [CrossRef]

- Chen, X.; Kong, J.; Li, J.; Feng, S.; Li, H.; Wang, Q.; Liang, Y.; Dong, K.; Yang, Y. High-Strength AlCoCrFeNi2.1 Eutectic High Entropy Alloy with Ultrafine Lamella Structure via Additive Manufacturing. Mater. Sci. Eng. A 2022, 854, 143816. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, H.; Zhu, Z.; Xue, P.; Wu, L.; Liu, F.; Ni, D.; Xiao, B.; Ma, Z. Dual-Phase Synergistic Deformation Characteristics and Strengthening Mechanism of AlCoCrFeNi2.1 Eutectic High Entropy Alloy Fabricated by Laser Powder Bed Fusion. J. Mater. Sci. Technol. 2023, 150, 75–85. [Google Scholar] [CrossRef]

- Talluri, G.; Maurya, R.S.; Murty, B.S. Composition Design of Eutectic High-Entropy Alloys: A Review. J. Mater. Sci. 2025, 60, 1156–1186. [Google Scholar] [CrossRef]

- He, L.; Wu, S.; Dong, A.; Tang, H.; Du, D.; Zhu, G.; Sun, B.; Yan, W. Selective Laser Melting of Dense and Crack-Free AlCoCrFeNi2.1 Eutectic High Entropy Alloy: Synergizing Strength and Ductility. J. Mater. Sci. Technol. 2022, 117, 133–145. [Google Scholar] [CrossRef]

- Huang, L.; Sun, Y.; Zhao, X.; Wu, C.; Dong, P.; Yang, Q.; Meng, A.; Li, J. Preparation of Ultrahigh-Strength and Ductile Nano-Lamellar Eutectic High-Entropy Alloy via Laser Powder Bed Fusion. Intermetallics 2024, 165, 108165. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Q.; Pan, X.; Chen, X.; Eckert, J.; Qiu, C. On the Microstructural Evolution and Mechanical Property Development of Additively Manufactured AlCoCrFeNi2.1 Eutectic High-Entropy Alloy with Aging Temperature. Mater. Sci. Eng. A 2024, 913, 147060. [Google Scholar] [CrossRef]

- Katagiri, K.; Irvine, S.J.; Hari, A.; Kodama, R.; Ozaki, N.; Sano, T.; Ren, J.; Yang, W.; Chen, W.; Clay, M.P.; et al. Static and Shock Compression Studies of Eutectic High-Entropy Alloy AlCoCrFeNi2.1 to Ultrahigh Pressures. J. Appl. Phys. 2024, 135, 095902. [Google Scholar] [CrossRef]

- Lan, L.; Wang, W.; Cui, Z.; Hao, X.; Qiu, D. Anisotropy Study of the Microstructure and Properties of AlCoCrFeNi2.1 Eutectic High Entropy Alloy Additively Manufactured by Selective Laser Melting. J. Mater. Sci. Technol. 2022, 129, 228–239. [Google Scholar] [CrossRef]

- Fu, Z.; Li, X.; Wu, P.; Liao, L. A Selective Laser Melted AlCoCrFeNi2.1 Eutectic High-Entropy Alloy with Improved Synergy of Strength and Hydrogen Embrittlement Resistance. Opt. Laser Technol. 2025, 183, 112364. [Google Scholar] [CrossRef]

- Akinwande, A.A.; Moskovskikh, D.; Romanovski, V. Enhancing Mechanical and Damping Performance of 3D-Printed Aluminium-7075 with Shape Memory High-Entropy Alloy (SMHEA): Parametric Optimization and Mathematical Modeling. Int. J. Adv. Manuf. Technol. 2024, 130, 369–383. [Google Scholar] [CrossRef]

- Verma, P.K.; Singh, A. Microstructure Evolution and Mechanical Properties of Aluminium Matrix Composites Reinforced with CoMoMnNiV High-Entropy Alloy. Int. J. Met. 2024, 18, 546–563. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Gu, H.; Li, R.; Chen, P.; Kong, C.; Yu, H. Insight of High-Entropy Alloy Particles-Reinforced 2219 Al Matrix Composites via the Ultrasonic Casting Technology. Mater. Charact. 2021, 182, 111548. [Google Scholar] [CrossRef]

- ASTM E8/E8M-24; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

| Powder | D10 (μm) | D50 (μm) | D90 (μm) |

|---|---|---|---|

| AA7075 | 18.284 | 31.687 | 54.776 |

| AlCoCrFeNi2.1 | 18.191 | 33.858 | 57.794 |

| Element | AlCoCrFeNi2.1 | AA7075 |

|---|---|---|

| Al | 8.22 | Bal. |

| Co | 18.34 | — |

| Cr | 16.53 | 0.21 |

| Fe | 17.55 | 0.33 |

| Ni | Bal. | — |

| Si | — | 0.23 |

| Cu | — | 1.45 |

| Mn | — | 0.13 |

| Mg | — | 2.31 |

| Zn | — | 5.15 |

| No. | Power (W) | Speed (mm·s−1) | Layer Thickness (mm) | Hatch Spacing (mm) | VED (J·mm−3) |

|---|---|---|---|---|---|

| RF-1 | 100 | 500 | 0.03 | 0.09 | 74.07 |

| RF-2 | 190 | 500 | 0.03 | 0.09 | 140.74 |

| RF-3 | 300 | 500 | 0.03 | 0.09 | 222.22 |

| 1 | 190 | 500 | 0.03 | 0.09 | 140.74 |

| 2 | 190 | 600 | 0.03 | 0.09 | 117.28 |

| 3 | 190 | 700 | 0.03 | 0.09 | 100.53 |

| 4 | 190 | 800 | 0.03 | 0.09 | 87.96 |

| 5 | 190 | 900 | 0.03 | 0.09 | 78.19 |

| 6 | 220 | 500 | 0.03 | 0.09 | 162.96 |

| 7 | 220 | 600 | 0.03 | 0.09 | 135.8 |

| 8 | 220 | 700 | 0.03 | 0.09 | 116.4 |

| 9 | 220 | 800 | 0.03 | 0.09 | 101.85 |

| 10 | 220 | 900 | 0.03 | 0.09 | 90.53 |

| 11 | 250 | 500 | 0.03 | 0.09 | 185.19 |

| 12 | 250 | 600 | 0.03 | 0.09 | 154.32 |

| 13 | 250 | 700 | 0.03 | 0.09 | 132.28 |

| 14 | 250 | 800 | 0.03 | 0.09 | 115.74 |

| 15 | 250 | 900 | 0.03 | 0.09 | 102.88 |

| Material | Relative Density (%) | Microhardness (HV0.5) | UTS (MPa) | Elongation (%) |

|---|---|---|---|---|

| AA7075 | 95.92 ± 1.11 | 97.46 ± 5.80 | 58.79 ± 7.42 | 0.70 ± 0.09 |

| AA7075 +5 wt.% HEA | 97.09 ± 0.84 | 157.10 ± 7.51 | 120.21 ± 5.79 | 0.81 ± 0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gan, S.; Xu, Q.; Zhang, Y.; Bhathal Singh, B.S. Effect of AlCoCrFeNi2.1 High-Entropy Alloy Reinforcement on the Densification, Microstructure, and Hot-Cracking Behavior of LPBF-Processed AA7075. Metals 2025, 15, 1193. https://doi.org/10.3390/met15111193

Gan S, Xu Q, Zhang Y, Bhathal Singh BS. Effect of AlCoCrFeNi2.1 High-Entropy Alloy Reinforcement on the Densification, Microstructure, and Hot-Cracking Behavior of LPBF-Processed AA7075. Metals. 2025; 15(11):1193. https://doi.org/10.3390/met15111193

Chicago/Turabian StyleGan, Shixi, Qiongqi Xu, Yi Zhang, and Baljit Singh Bhathal Singh. 2025. "Effect of AlCoCrFeNi2.1 High-Entropy Alloy Reinforcement on the Densification, Microstructure, and Hot-Cracking Behavior of LPBF-Processed AA7075" Metals 15, no. 11: 1193. https://doi.org/10.3390/met15111193

APA StyleGan, S., Xu, Q., Zhang, Y., & Bhathal Singh, B. S. (2025). Effect of AlCoCrFeNi2.1 High-Entropy Alloy Reinforcement on the Densification, Microstructure, and Hot-Cracking Behavior of LPBF-Processed AA7075. Metals, 15(11), 1193. https://doi.org/10.3390/met15111193