Laser Cladding Remanufacturing of Metallic Components in High-End Agricultural Machinery and Equipment: Material Design, Processing, and Properties

Abstract

1. Introduction

2. Damage Types of Metallic Components and Conventional Remanufacturing Methods

2.1. The Main Failure Mechanisms of Metallic Components

2.1.1. Wear

2.1.2. Corrosion

2.1.3. Fatigue

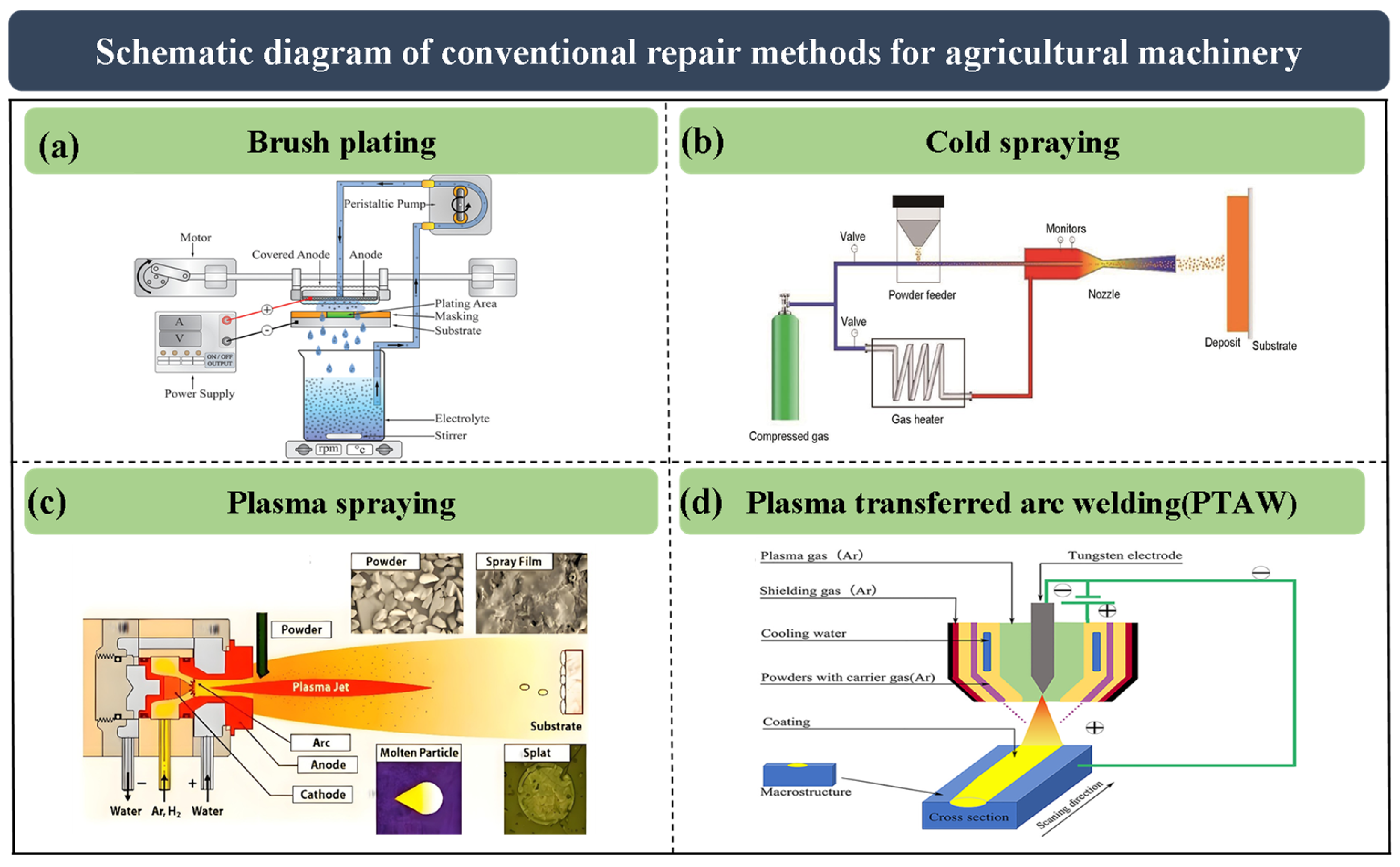

2.2. Conventional Remanufacturing Methods for Damaged Metallic Components

2.2.1. Electroplating and Brush Plating

2.2.2. Cold Spray

2.2.3. Plasma Spraying (PS)

2.2.4. Plasma Transferred Arc Welding (PTAW)

2.3. Characteristics and Advantages of Laser Cladding Technology

2.4. Remanufacturing Demand of Agricultural Machinery

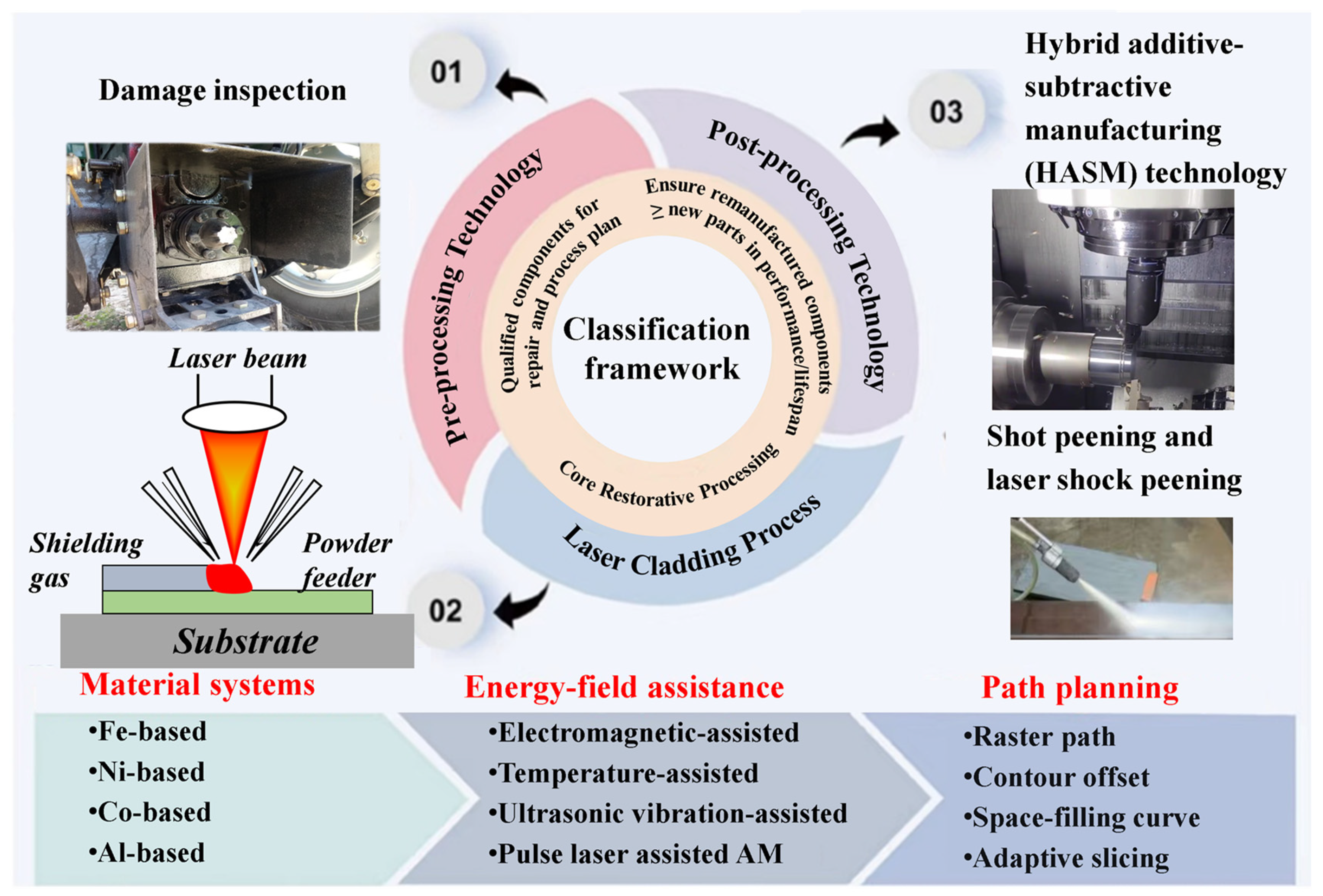

3. Laser Additive Remanufacturing of Metallic Components in Agricultural Machinery

3.1. Pre-Processing: Remanufacturing Assessment of Metallic Components

3.1.1. Candidate Metallic Components

3.1.2. Fundamental Criteria for Remanufacturability

3.1.3. Evaluation Standards of Laser Additive Remanufacturing Technology

3.2. Laser Caldding Process: Materials Systems, Process Optimization, and Path Planning

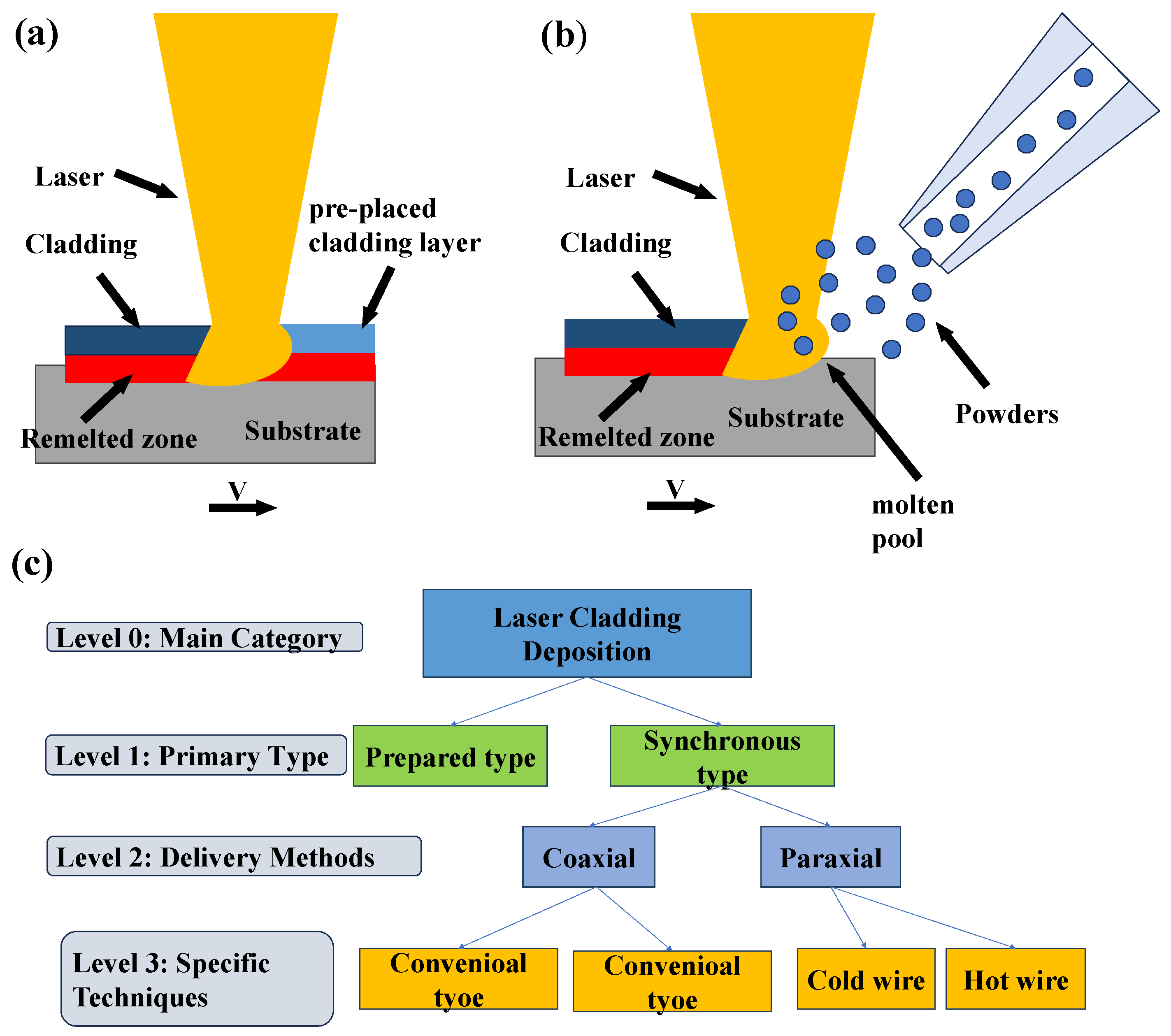

3.2.1. The Principle of Laser Cladding Technology

3.2.2. Material System of Laser Cladding for Damaged Metallic Components

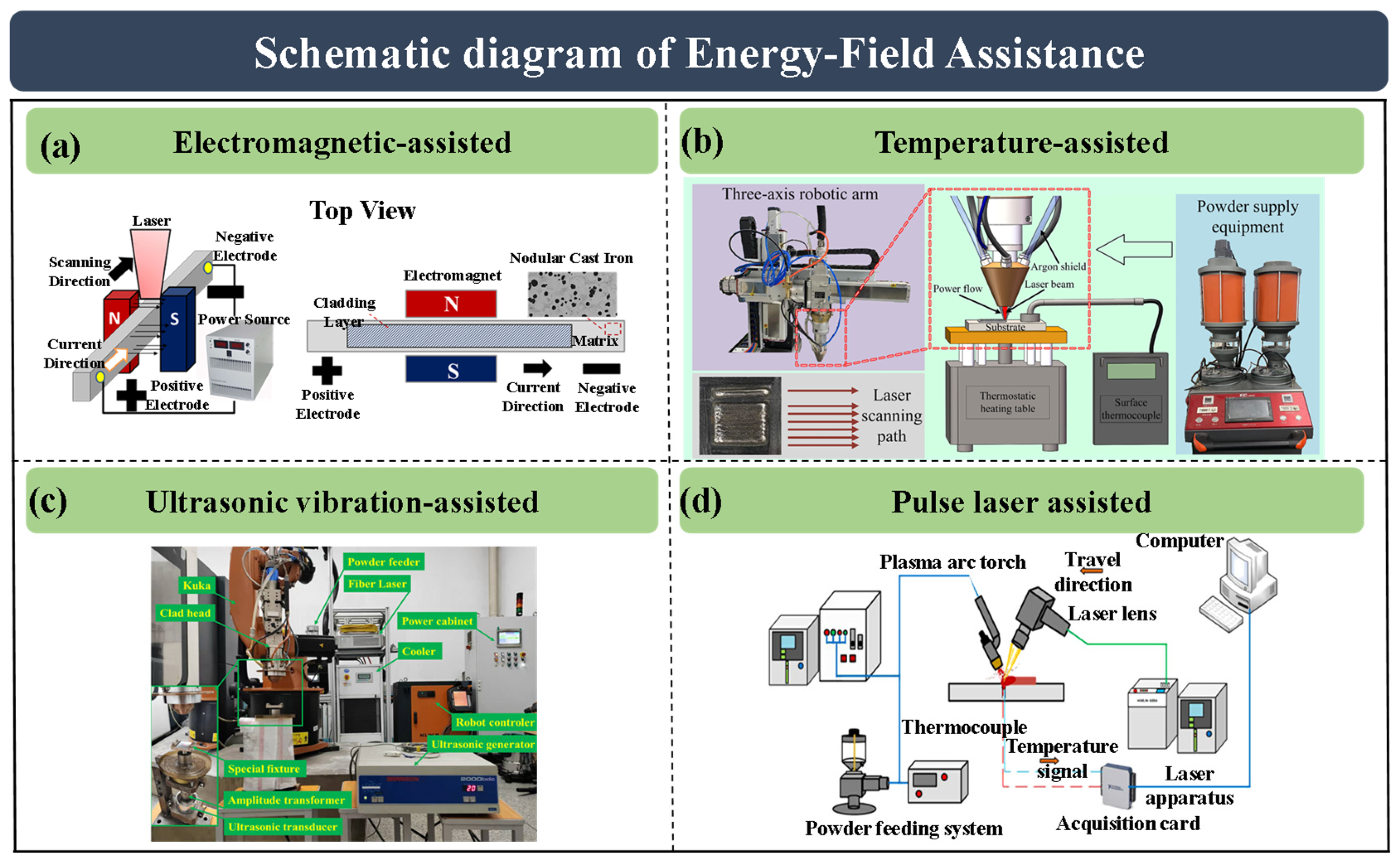

3.2.3. Energy-Field-Assisted Laser Cladding for Microstructure Control and Property Improvement

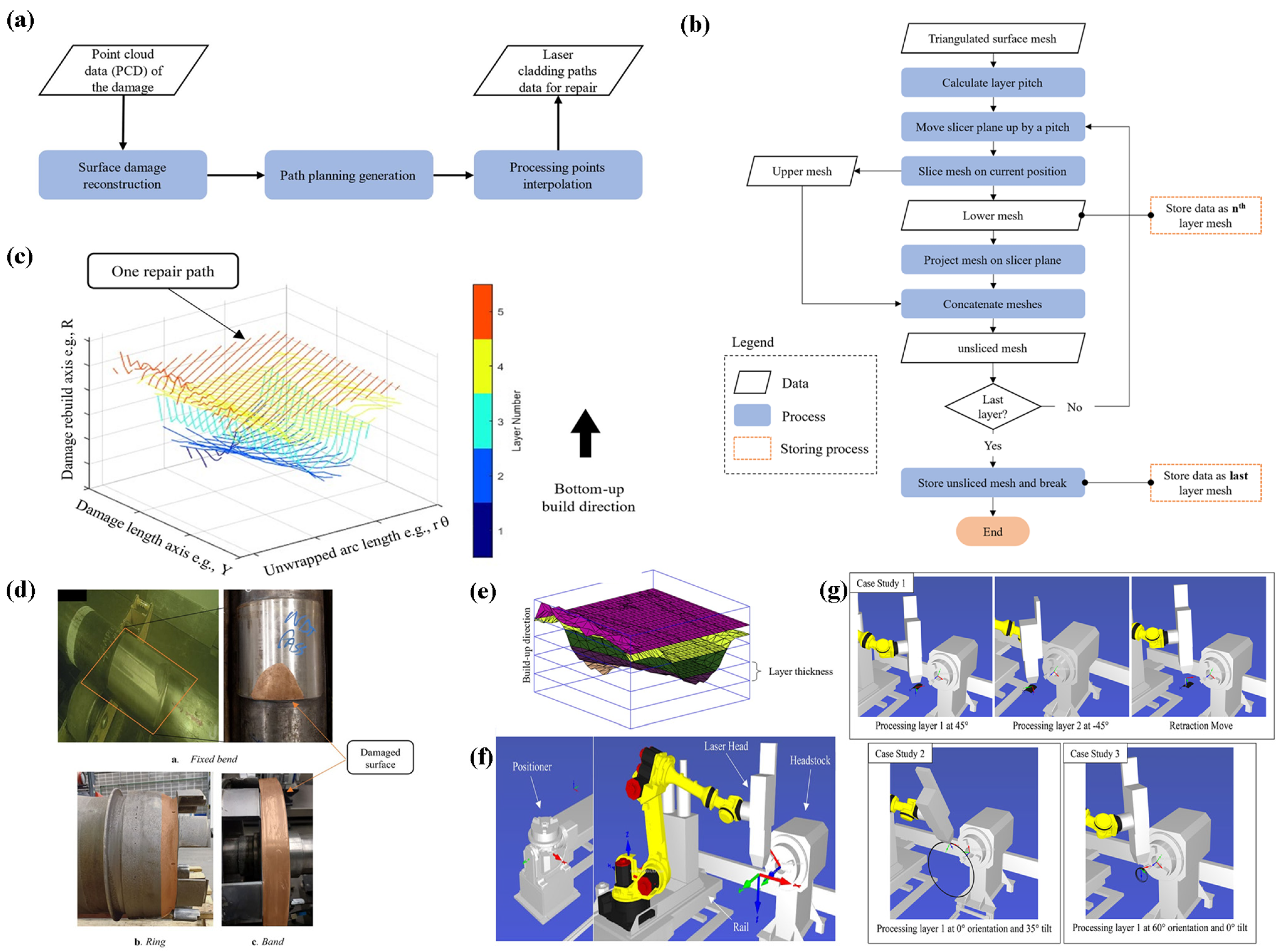

3.2.4. Path Planning for Geometrical Accuracy and Microstructural Homogeneity

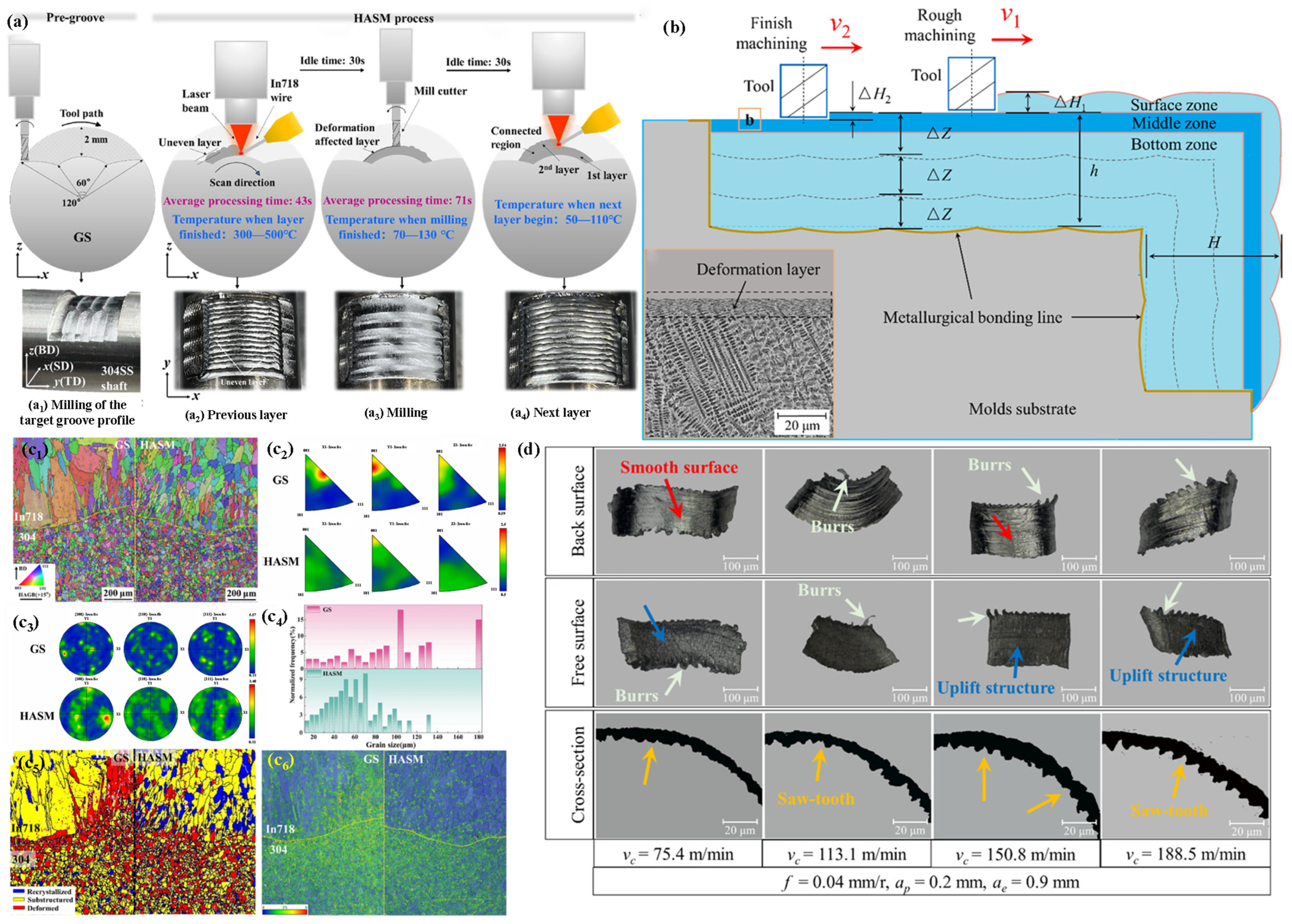

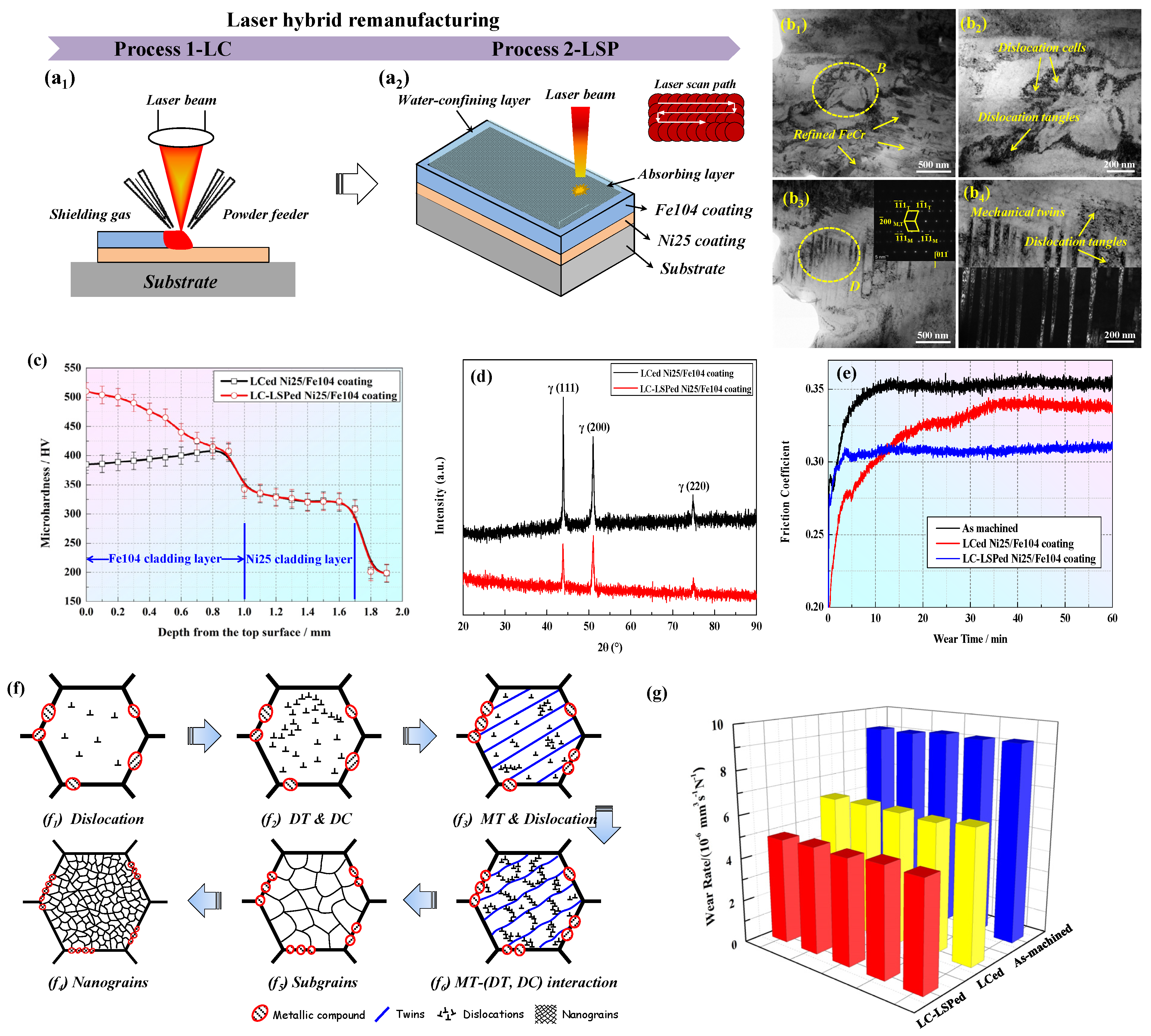

3.3. Post-Processing Technologies

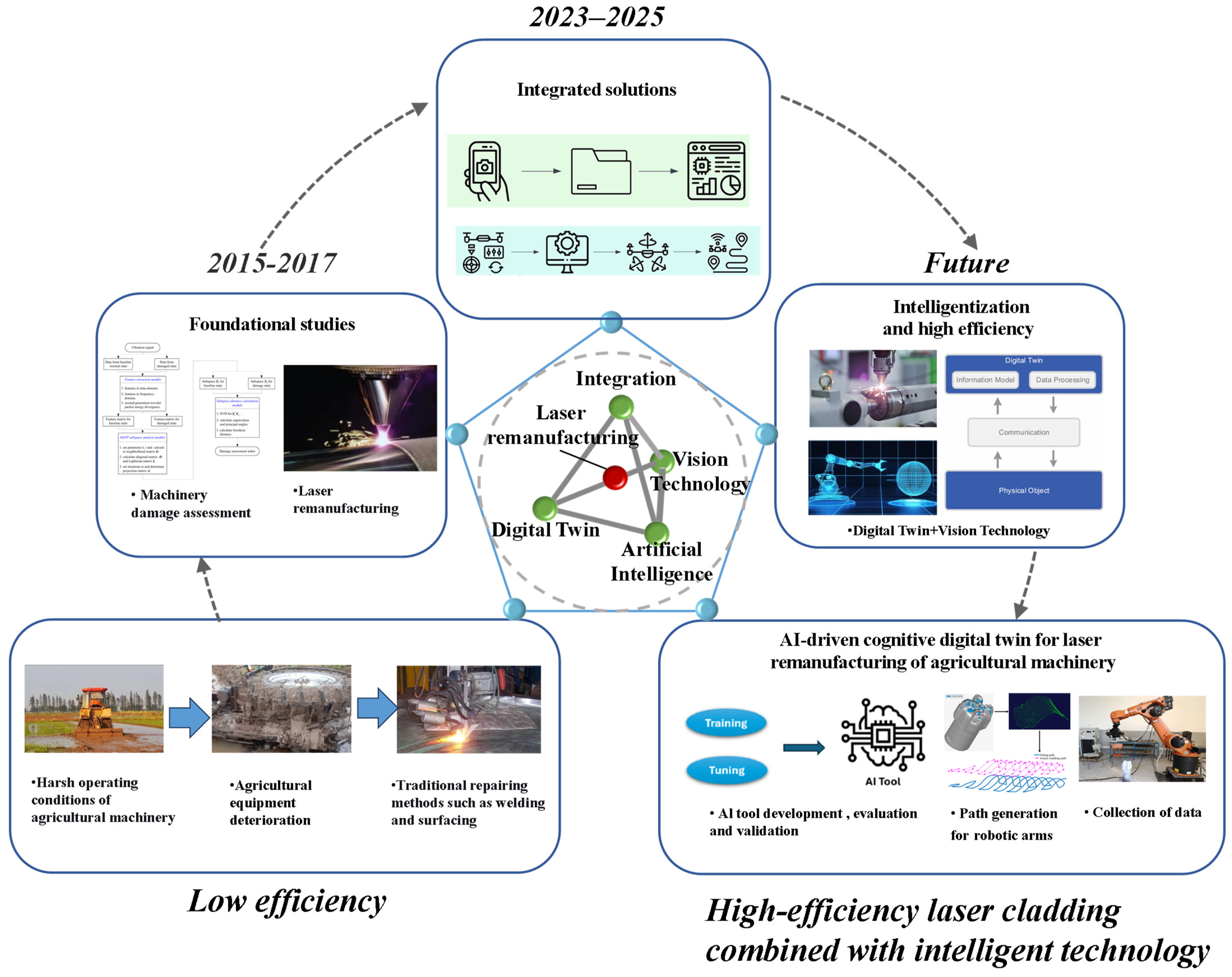

4. Development of Laser Cladding Remanufacturing Technology for Agricultural Machinery

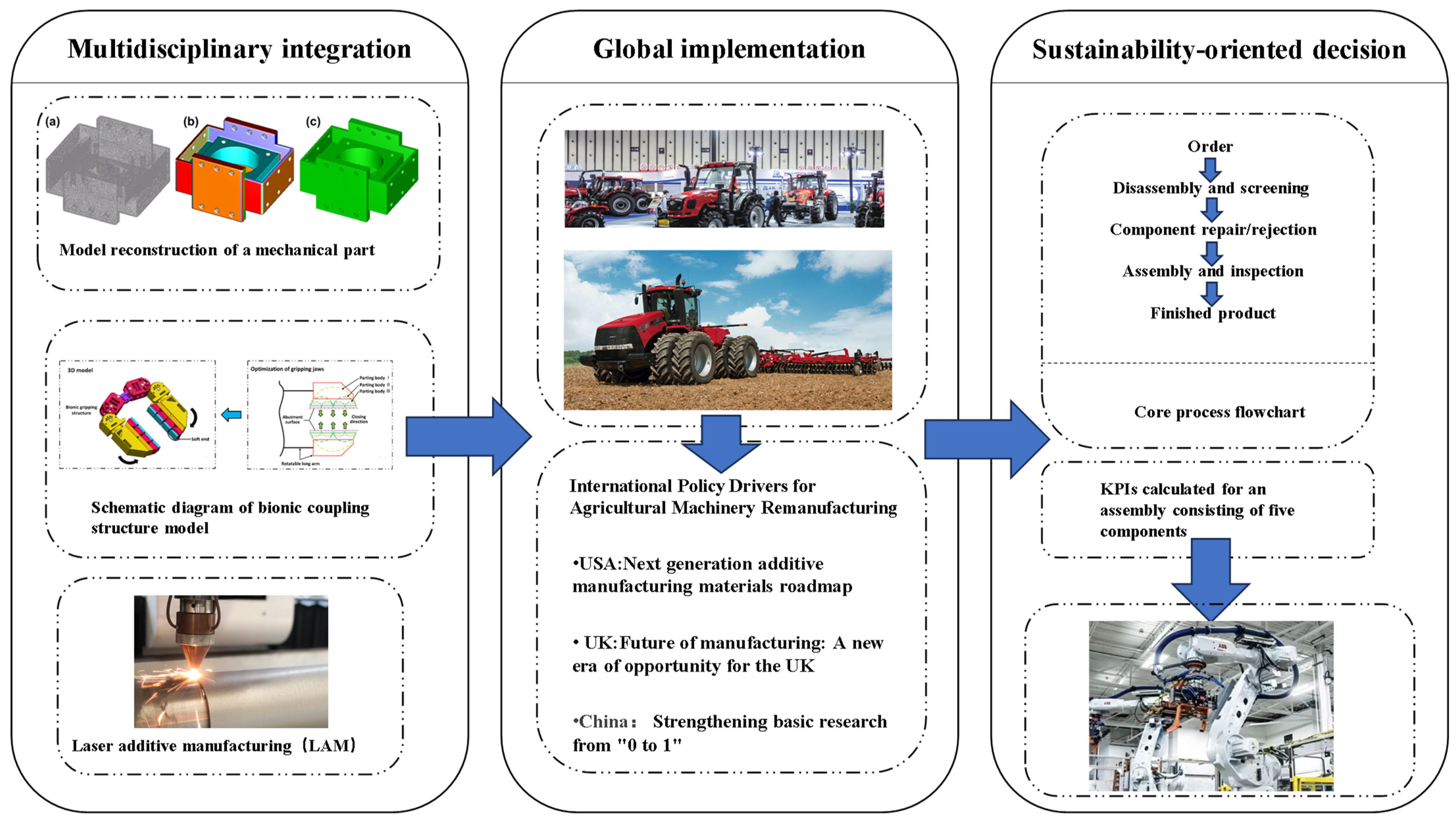

4.1. Multidisciplinary Integration and System Architecture

4.2. Key Advancements in Material Performance and Process Optimization

5. Challenges and Future Perspectives of Laser Cladding Remanufacturing Technology for Metallic Components in Agricultural Machinery

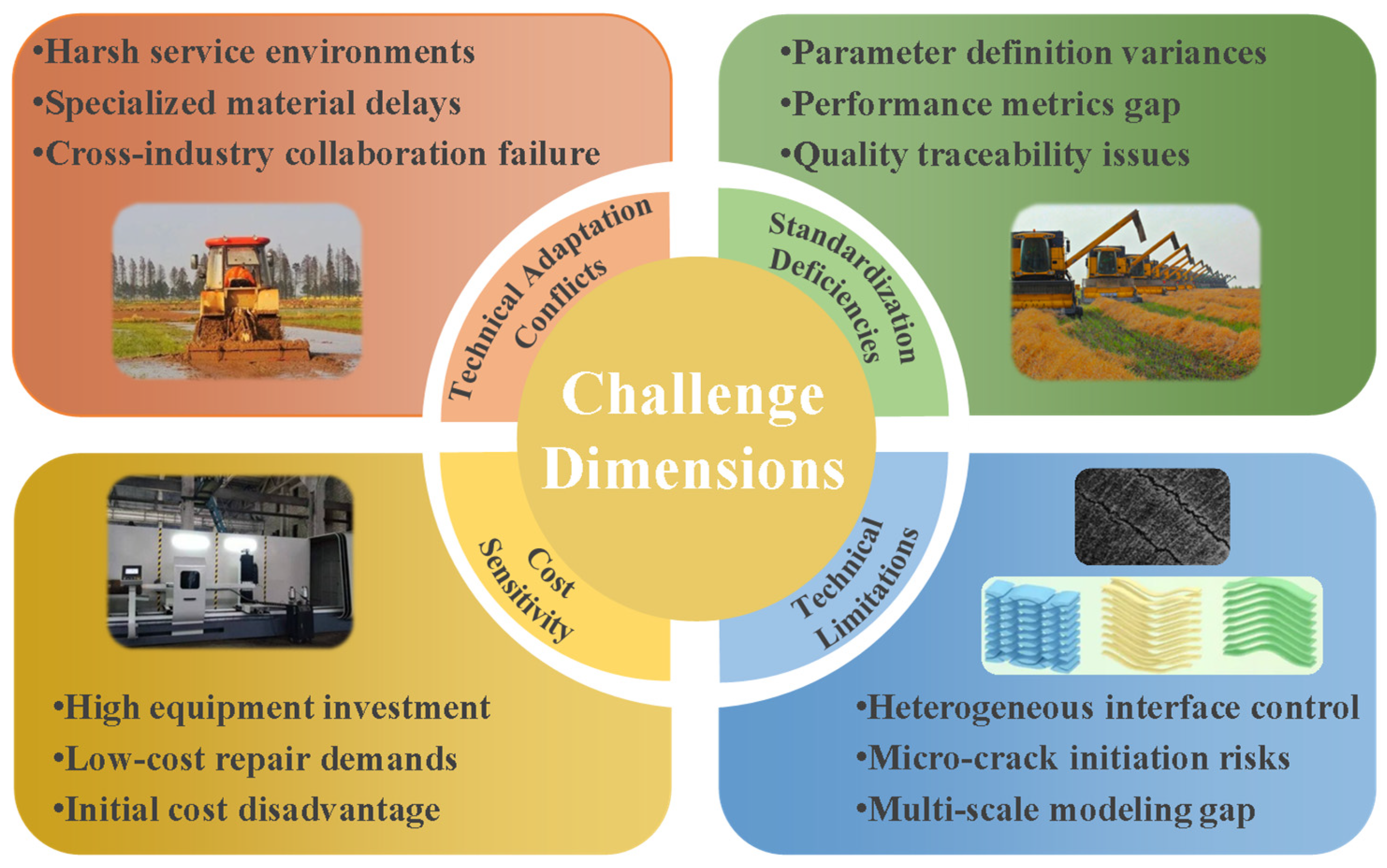

5.1. Current Challenges in Material and Process Application

5.2. Future Perspectives: Advanced Materials, Integrated Processing, and Intelligent Systems

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| LC | Laser Cladding |

| LCR | Laser Cladding Remanufacturing |

| LAM | Laser Additive Manufacturing |

| LMD | Laser Metal Deposition |

| LDED | Laser Directed Energy Deposition |

| PTAW | Plasma Transferred Arc Welding |

| PS | Plasma Spraying |

| CS | Cold Spray |

| HASM | Hybrid Additive-Subtractive Manufacturing |

| LSP | Laser Shock Peening |

| ECF | Electromagnetic Compound Field |

| PBF | Powder Bed Fusion |

| SILD | Synchronous Induction-assisted Laser Deposition |

| OAFW-LDED | Off-Axis Filament Wire Laser Directed Energy Deposition |

| WC | Tungsten Carbide |

| TiC | Titanium Carbide |

| VC | Vanadium Carbide |

| Laves | A topologically close-packed phase (e.g., in Ni-based superalloys) |

| HEA | High-Entropy Alloy |

| SEM | Scanning Electron Microscopy |

| XRD | X-Ray Diffraction |

| EDS | Energy Dispersive Spectroscopy |

| TEM | Transmission Electron Microscopy |

| OM | Optical Microscopy |

| EPMA | Electron Probe Microanalysis |

| DEM | Discrete Element Method |

| APDL | ANSYS Parametric Design Language |

| EBSD | Electron Backscatter Diffraction |

| IPF | Inverse Pole Figure |

| VHCF | Very-High-Cycle Fatigue |

| HCF | High-Cycle Fatigue |

| LCF | Low-Cycle Fatigue |

| USS | Ultimate Shear Strength |

| HAZ | Heat-Affected Zone |

| HV | Vickers Hardness (e.g., HV0.5, HV20) |

| HRC | Rockwell Hardness C-Scale |

| Sₐ | Arithmetical Mean Height (Surface Roughness Parameter) |

| Ra | Arithmetic Average Surface Roughness |

| CAGR | Compound Annual Growth Rate |

| OEM | Original Equipment Manufacturer |

| KPIs | Key Performance Indicators |

| R | Remanufacturability Score |

| CRS | Compressive Residual Stress |

| DMs | Dissimilar Materials |

| MIC | Microbiologically Influenced Corrosion |

| AM | Additive Manufacturing |

References

- Guo, Z.W.; Fu, H.; Wu, J.H.; Han, W.K.; Huang, W.L.; Zheng, W.G.; Li, T. Dynamic task planning for multi-arm apple-harvesting robots using lstm-ppo reinforcement learning algorithm. Agriculture 2025, 15, 588. [Google Scholar] [CrossRef]

- Qin, W.C.; Qiu, B.J.; Xue, X.Y.; Chen, C.; Xu, Z.F.; Zhou, Q.Q. Droplet deposition and control effect of insecticides sprayed with an unmanned aerial vehicle against plant hoppers. Crop Prot. 2016, 85, 79–88. [Google Scholar] [CrossRef]

- Liu, J.Z.; Abbas, I.; Noor, R.S. Development of deep learning-based variable rate agrochemical spraying system for targeted weeds control in strawberry crop. Agronomy 2021, 11, 1480. [Google Scholar] [CrossRef]

- Tan, J.; Liu, L.Z.; Wang, H. Microstructure characterization and corrosion resistance in soil of Mg-2Zn-xCe-yCu alloy for light agricultural machinery. J. Alloys Compd. 2024, 1001, 175127. [Google Scholar] [CrossRef]

- Hwang, I.S.; Kim, J.H.; Im, W.T.; Jeung, H.H.; Nam, J.S.; Shin, C.S. Analyzing safety factors and predicting fatigue life of weak points in an electrically driven, multi-purpose cultivation tractor. Agriculture 2024, 14, 416. [Google Scholar] [CrossRef]

- Li, H.B.; Chen, L.W.; Zhang, Z.Y. A study on the utilization rate and influencing factors of small agricultural machinery: Evidence from 10 hilly and mountainous provinces in china. Agriculture 2022, 13, 51. [Google Scholar] [CrossRef]

- Peng, S.T.; Yang, Y.; Li, T.; Smith, T.M.; Tan, G.Z.; Zhang, H.C. Environmental benefits of engine remanufacture in china’s circular economy development. Environ. Sci. Technol. 2019, 53, 11294–11301. [Google Scholar] [CrossRef]

- Guo, D.W.; Jiang, Z.G. Study on architecture and implement strategy of green remanufacturing management. Key Eng. Mater. 2011, 1104, 1639–1644. [Google Scholar] [CrossRef]

- Yang, J.R.; Liu, Q.Y. Design method research on green modular that oriented remanufacturing engineering. Appl. Mech. Mater. 2013, 2555, 545–548. [Google Scholar] [CrossRef]

- Zhou, Y.; Lin, X.T.; Fan, Z.P.; Wong, K.H. Remanufacturing strategy choice of a closed-loop supply chain network considering carbon emission trading, green innovation, and green consumers. Int. J. Environ. Res. Public Health 2022, 19, 6782. [Google Scholar] [CrossRef]

- Zhang, M. Evaluate the effectiveness of the agricultural machinery purchase subsidy policy for poverty alleviation in guizhou, china. J. Appl. Econ. Policy Stud. 2024, 11, 41–48. [Google Scholar] [CrossRef]

- Zeng, S.J.; Liu, Z.F.; Jiang, J.B. Research on remanufacturability index system and evaluation method of electromechanical products. Adv. Mater. Res. 2012, 1671, 2639–2644. [Google Scholar] [CrossRef]

- James, A.T.; Kumar, G.; Arora, A.; Padhi, S. Development of a design based remanufacturability index for automobile systems. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2021, 235, 3138–3156. [Google Scholar] [CrossRef]

- Saghafian, H.; Hamdi, M.; Shabestari, S.G.; Rahbari, N. The wear behavior of a cast al-20wt mg2si composite thixoformed via sima. Iran. J. Mater. Sci. Eng. 2020, 17, 49–59. [Google Scholar] [CrossRef]

- An, J.; Zhao, W.; Feng, C.Q. Elevated-temperature wear characteristics and mild-severe wear transition in the mg–10.1gd–1.4y–0.4zr alloy. J. Tribol. 2019, 141, 121601. [Google Scholar] [CrossRef]

- Zambrano, O.A.; García, D.S.; Rodríguez, S.A.; Coronado, J.J. The mild-severe wear transition in erosion wear. Tribol. Lett. 2018, 66, 95. [Google Scholar] [CrossRef]

- Yang, C.J.; Huang, X.P.; Wu, J.F.; Wan, F.X. Friction and wear behavior of 45# steel with different plant abrasive. Adv. Mater. Res. 2013, 712–715, 74–77. [Google Scholar] [CrossRef]

- Su, Z.P.; Li, J.B.; Zhang, Z.Y.; Ren, S.X.; Shi, Y.M.; Wang, X.F. Analysis of the mechanical properties and wear characteristics of nail teeth based on sowing layer residual film recovery machine. Eng. Fail. Anal. 2023, 143, 106869. [Google Scholar] [CrossRef]

- Zheng, X.B.; Sun, B.G.; Gao, G.; Wang, H.G.; Qi, Y.; Zhao, G.R.; Ren, J.F.; Zhang, Y. Tribological performance and failure mechanisms of soil-engaging components with brazed WC-Ni coatings. Tribol. Int. 2026, 214, 111139. [Google Scholar] [CrossRef]

- Wang, H.; Yan, L.W. Recent advances in single-atom catalysts for high-performance carbon dioxide electroreduction: Synthetic strategies and electrochemical frontiers. Int. J. Electrochem. Sci. 2025, 20, 101131. [Google Scholar] [CrossRef]

- Wang, X.H.; Wang, Y.; Zhu, H.L.; Chen, S.; Xue, J.Y.; Shen, C.L.; Xiao, Z.L.; Luo, Y.C. Emerging strategies for food preservation: Recent advances and challenges in nanotechnology for edible coatings. Agric. Prod. Process. Storage 2025, 1, 13. [Google Scholar] [CrossRef]

- Yao, Y.; Zhang, Z.; Zheng, Y.Q.; Zhang, Y.; Wang, Z.L.; Liu, X. Recent advances in coating strategies for lithium-rich manganese-based layered oxide cathodes. J. Energy Storage 2025, 134, 118132. [Google Scholar] [CrossRef]

- Yang, W.W.; Liang, Z.H.; Yang, D.T.; Chen, D.X.; Luo, X.C.; Luo, X.L.; Gong, C.Q. Corrosion of electrodeposited ni coatings of agricultural machinery by farming fertilizers. J. Mater. Eng. Perform. 2021, 30, 7275–7282. [Google Scholar] [CrossRef]

- Skryabin, M.L. The main technologies of protection against corrosion of the body and welds of lada vesta and lada largus cars used in agricultural production. IOP Conf. Ser. Earth Environ. Sci. 2020, 548, 062086. [Google Scholar] [CrossRef]

- He, Z.H.; Zhang, Y.X.; Liang, J.; Li, Y.B. Quantitative investigation on the individual contribution of twinning and dislocation slip to creep in dilute Mg-Y alloys with various grain sizes. J. Alloys Compd. 2024, 990, 174473. [Google Scholar] [CrossRef]

- Kang, H.H.; Zhang, Y.X.; Nagaumi, H.; Yang, X.Y. Roles of dislocation slip and twinning in the creep performance of a wrought Mg-Zn-Mn alloy sheet. J. Alloys Compd. 2023, 967, 171631. [Google Scholar] [CrossRef]

- Chen, H.W.; Zeng, W.D.; Luo, H.Y.; Wang, B.N.; Jia, R.C.; Xu, B.; Xu, J.W. The texture evolution near the shear band and corresponding impact on the microvoid nucleation and crack propagation of Ti6242s alloys under high strain rates. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2024, 915, 147243. [Google Scholar] [CrossRef]

- Xie, Z.C.; Chen, Y.; Wang, H.Y.; Dai, L.H. Atomic-level mechanism of spallation microvoid nucleation in medium entropy alloys under shock loading. Sci. China-Technol. Sci. 2021, 64, 1360–1370. [Google Scholar] [CrossRef]

- Du, L.M.; Pan, X.N.; Hong, Y.S. New insights into microstructure refinement in crack initiation region of very-high-cycle fatigue for SLM Ti-6Al-4V via precession electron diffraction. Materialia 2024, 33, 102008. [Google Scholar] [CrossRef]

- Mo, B.; Li, T.; Shi, F.F.; Deng, L.H.; Liu, W.W. Crack initiation and propagation within nickel-based high-temperature alloys during laser-based directed energy deposition: A review. Opt. Laser Technol. 2024, 179, 111327. [Google Scholar] [CrossRef]

- Chen, Z.; Long, K.; Zhang, C.W.; Yang, X.Y.; Lu, F.Y.; Wang, R.X.; Zhu, B.L.; Zhang, X.M. A fatigue-resistance topology optimization formulation for continua subject to general loads using rainflow counting. Struct. Multidiscip. Optim. 2023, 66, 210. [Google Scholar] [CrossRef]

- Jing, W.; Wang, P.; Zhang, N.C. Study on damage fatigue test method of metal materials for rotating machinery. Int. J. Mater. Prod. Technol. 2023, 66, 17–30. [Google Scholar] [CrossRef]

- Huang, J.T.; Jia, J.; Tie, K.L. Study on the wear-resisting property of wood Cu/Ni electroplate coating. Adv. Mater. Res. 2010, 123–125, 1055–1058. [Google Scholar] [CrossRef]

- Chen, X.L.; Jiang, N.; Zhan, Y.; Luo, Y.D.; Ye, N.; Tang, J.C.; Zhuo, H.O. Preparation and tribological performance of Ni-SiC composite coating on 304 stainless steel through brush plating. Surf. Coat. Technol. 2024, 494, 131491. [Google Scholar] [CrossRef]

- Feng, Y.D.; Li, X.Y.; Dong, H.S. The development of novel cu/go nano-composite coatings by brush plating with high wear resistance for potential brass sliding bearing application. Materials 2024, 17, 112623. [Google Scholar] [CrossRef]

- Krella, A.K.; Grzes, J.; Erbe, A.; Folstad, M. Behaviour of nickel coatings made by brush plating technology in conditions of cavitation erosion and corrosion. Wear 2023, 530, 204998. [Google Scholar] [CrossRef]

- Singh, A.; De, B.S.; Singh, S.; Thota, S.P.; Khalid, M.; Shahgaldi, S. Exploring the engineered electroplating process for coating of gold on the inner structure of porous transport layer (PTL): Performance evaluation of coating in simulated PEM electrolyzer. Int. J. Hydrog. Energy 2025, 106, 1029–1040. [Google Scholar] [CrossRef]

- Wang, L.L.; Li, N.; Wang, J.; Wei, X.L.; Ling, X.; Su, X.P.; Wang, Y.C. Improving mechanical strength of vacuum brazed joints via laser texturing combined with electroplating. Mater. Today Commun. 2025, 44, 111871. [Google Scholar] [CrossRef]

- Kumar, A.; Rathor, S.; Vostrak, M.; Houdkova, S.; Kant, R.; Singh, H. Exploring potential of cold spray technology for medical devices: Current and future scenario. Mater. Today Commun. 2024, 40, 109534. [Google Scholar] [CrossRef]

- Mehta, A.; Vasudev, H.; Thakur, L. Application of cold spray technology in design and manufacturing of complex geometries. Int. J. Interact. Des. Manuf.-IJIDeM 2024, 18, 5407–5425. [Google Scholar] [CrossRef]

- Yin, S.; Fan, N.S.; Huang, C.J.; Xie, Y.C.; Zhang, C.; Lupoi, R.; Li, W.Y. Towards high-strength cold spray additive manufactured metals: Methods, mechanisms, and properties. J. Mater. Sci. Technol. 2024, 170, 47–64. [Google Scholar] [CrossRef]

- Champagne, V.; Helfritch, D. Critical assessment 11: Structural repairs by cold spray. Mater. Sci. Technol. 2015, 31, 627–634. [Google Scholar] [CrossRef]

- Astarita, A.; Ausanio, G.; Boccarusso, L.; Prisco, U.; Viscusi, A. Deposition of ferromagnetic particles using a magnetic assisted cold spray process. Int. J. Adv. Manuf. Technol. 2019, 103, 29–36. [Google Scholar] [CrossRef]

- Jones, R.; Matthews, N.; Peng, D.; Raman, R.K.S.; Phan, N. Experimental studies into the analysis required for the durability assessment of 7075 and 6061 cold spray repairs to military aircraft. Aerospace 2020, 7, 119. [Google Scholar] [CrossRef]

- Zhu, S.; Xu, B.S.; Yao, J.K. High quality ceramic coatings sprayed by high efficiency hypersonic plasma spraying gun. Mater. Sci. Forum 2005, 475–479, 3981–3984. [Google Scholar] [CrossRef]

- Beauvais, S.; Guipont, V.; Borit, F.; Jeandin, M.; Español, M.; Khor, K.A.; Robisson, A.; Saenger, R. Process-microstructure-property relationships in controlled atmosphere plasma spraying of ceramics. Surf. Coat. Technol. 2004, 183, 204–211. [Google Scholar] [CrossRef]

- Fukumasa, O.; Tagashira, R.; Tachino, K.; Mukunoki, H. Spraying of MgO films with a well-controlled plasma jet. Surf. Coat. Technol. 2003, 169, 579–582. [Google Scholar] [CrossRef]

- Karoonboonyanan, S.; Salokhe, W.M.; Niranatlumpong, P. Wear resistance of thermally sprayed rotary tiller blades. Wear 2007, 263, 604–608. [Google Scholar] [CrossRef]

- Zhu, W.; Kang, M.; Ndumia, J.N.; Lin, J.; Huang, F.; Zhang, Y. Microstructure and Wear Properties of TiB2 Reinforced Fe-Based Composite Coating. J. Mater. Eng. Perform. 2022, 31, 5559–5570. [Google Scholar] [CrossRef]

- Bhoskar, A.; Singh, K.; Kalyankar, V. On the impact of stack patterns on the microstructure and wear performance of colmonoy 6 coatings deposited on ss 304 via ptaw. Results Surf. Interfaces 2025, 18, 100365. [Google Scholar] [CrossRef]

- Chenrayan, V.; Shahapurkar, K.; Manivannan, C.; Rajeshkumar, L.; Sivakumar, N.; Sharma, R.R.; Venkatesan, R. Effect of powder composition, PTAW parameters on dilution, microstructure and hardness of Ni-Cr-Si-B alloy deposition: Experimental investigation and prediction using machine learning technique. Heliyon 2024, 10, 36087. [Google Scholar] [CrossRef]

- Wu, M.; Lu, X.K.; Wan, C.X.; Zhou, L.; Pan, L.; Huang, Y.Y.; Zhao, Y.Y. Effect of pool temperature on microstructure and corrosion resistance of PTAW Ni layer. J. Mater. Res. Technol.-JmrT 2024, 30, 2945–2954. [Google Scholar] [CrossRef]

- Li, X.Z.; Hao, J.J.; Gao, L.; Ma, L.P.; Ma, Y.J. Research on cutter of field straw chopper strengthened with flame spray welding. Appl. Mech. Mater. 2012, 1923, 1317–1320. [Google Scholar] [CrossRef]

- Wang, H.F.; Wang, H.C.; Wang, X. Ni60-sic coating prepared by plasma spraying, plasma re-melting and plasma spray welding on surface of hot forging die. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2011, 26, 715–718. [Google Scholar] [CrossRef]

- Srimaneerat, J.; Kothanam, N.; Moolla, P.; Wintachai, P.; Triroj, N.; Harachai, K.; Jaroenapibal, P. Advancing Ni-W/diamond coatings with pulse-brush plating: Insights into particle incorporation and hardness. Diam. Relat. Mater. 2025, 157, 112472. [Google Scholar] [CrossRef]

- Li, W.Y.; Zhang, Z.M.; Xu, Y.X.; Song, Z.G.; Yin, S. Research progress in cold-sprayed ni and nickel-based composite coatings. Acta Metall. Sin. 2022, 58, 1–16. [Google Scholar]

- Hub, S.L. Plasma Spray Process Diagram. 2014. Available online: https://www.sciencelearn.org.nz/images/250-plasma-spray-process (accessed on 1 September 2025).

- Liu, Z.H.; Liu, G.; Miao, X.L.; Sun, L.Y.; Han, Z.H.; Zhang, G.J. Microstructure and wear-resistance of the CoCrFeNiMo high entropy alloy coatings by modulated arc currents using plasma transferred arc weld. Intermetallics 2024, 175, 108506. [Google Scholar] [CrossRef]

- Liu, M.; Cai, Y.J.; Duan, C.Z.; Li, G.H. Key techniques in parts repair and remanufacturing based on laser cladding: A review. J. Manuf. Process. 2024, 132, 994–1014. [Google Scholar] [CrossRef]

- Isern, L.; Impey, S.; Almond, H.; Clouser, S.J.; Endrino, J.L. PTFE layer formation during brush electroplating of nickel. Sci. Rep. 2024, 14, 24069. [Google Scholar] [CrossRef]

- Singh, R.; Arab, A.; Caceres, A.; Eybel, R.; Medraj, M. Establishing industrial Zn-Ni brush electroplating process without post-plating hydrogen embrittlement relief baking. Surf. Coat. Technol. 2024, 478, 130363. [Google Scholar] [CrossRef]

- Huang, C.; Yin, S.; Li, W.; Guo, X. Cold spray technology and its system: Research status and prospect. Surf. Technol. 2021, 50, 1–23. [Google Scholar] [CrossRef]

- Klinkov, S.V.; Kosarev, V.F.; Rein, M. Cold spray deposition: Significance of particle impact phenomena. Aerosp. Sci. Technol. 2005, 9, 582–591. [Google Scholar] [CrossRef]

- Khafizov, A.A.; Valiev, R.I.; Shakirov, Y.I. Plasma spray coating with ferromagnetic powder by thermoelectric plasma equipment. Int. Sci.-Tech. Conf. Innov. Eng. Technol. Equip. Mater. (ISTC-IETEM) 2016, 240, 012041. [Google Scholar] [CrossRef]

- Mandal, S.; Kumar, S.; Bhargava, P.; Premsingh, C.H.; Paul, C.P.; Kukreja, L.M. An analysis on bead characteristics in material deposition by ptaw process. Appl. Mech. Mater. 2014, 592–594, 33–37. [Google Scholar] [CrossRef]

- Hirpara, K.P.; Valaki, J.B.; Chaudhari, M.D.; Siddhpura, M.A. A comprehensive review on recent developments in materials and technological parameters for plasma transferred arc hardfacing process. Proc. Inst. Mech. Eng. Part E-J. Process Mech. Eng. 2024, 238, 1507–1519. [Google Scholar] [CrossRef]

- Hassan, G.; Shabbir, M.A.; Ahmad, F.; Pasha, I.; Aslam, N.; Ahmad, T.; Rehman, A.; Manzoor, M.F.; Inam-Ur-Raheem, M.; Aadil, R.M. Cereal processing waste, an environmental impact and value addition perspectives: A comprehensive treatise. Food Chem. 2021, 363, 130352. [Google Scholar] [CrossRef]

- Han, Z.X.; Wang, N.; Zhang, H.L.; Yang, X.Y. Heavy metal contamination and risk assessment of human exposure near an e-waste processing site. Acta Agric. Scand. Sect. B—Soil Plant Sci. 2017, 67, 119–125. [Google Scholar] [CrossRef]

- El, S.M.; Li, J.; Kamal, N.; Mahmoud, E.; Omara, A.E.D.; Du, D.l. Assessing and predicting soil quality in heavy metal-contaminated soils: Statistical and ann-based techniques. J. Soil Sci. Plant Nutr. 2023, 23, 6510–6526. [Google Scholar] [CrossRef]

- Filippi, E.; Niero, M.; Corsini, F.; Frey, M. Beyond the life cycle: Assessing business models for the circular economy through life-cycle-based methodologies. Sustain. Prod. Consum. 2025, 60, 18–35. [Google Scholar] [CrossRef]

- Lin, S.W.; Holden, N.M.; Thongdara, R.; Silalertruksa, T.; Gheewala, S.H.; Prapaspongsa, T. Circular economy models of sugarcane biorefinery towards carbon neutrality and environmental sustainability. Sustain. Prod. Consum. 2025, 59, 305–324. [Google Scholar] [CrossRef]

- Otaru, A.J. Circular economy: Kinetic-triplet, thermodynamic, and gradient descent optimisation algorithm of deep learning models for the thermal degradation of walnut shell. Case Stud. Therm. Eng. 2025, 74, 106942. [Google Scholar] [CrossRef]

- Wang, X.; Gong, X.; Chou, K. Review on powder-bed laser additive manufacturing of Inconel 718 parts. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2017, 231, 1890–1903. [Google Scholar] [CrossRef]

- Fan, H.J.; Hu, J.Y.; Wang, Y.; Zhang, H.Q.; Guo, W.; Li, J.S.; Xu, S.B.; Li, H.X.; Liu, P. A review of laser additive manufacturing (LAM) aluminum alloys: Methods microstructures and mechanical properties. Opt. Laser Technol. 2024, 175, 110722. [Google Scholar] [CrossRef]

- Sibisi, T.H.; Shongwe, M.B.; Tshabalala, L.C.; Mathoho, I. LAM additive manufacturing: A fundamental review on mechanical properties, common defects, dominant processing variables, and its applications. Int. J. Adv. Manuf. Technol. 2023, 128, 2847–2861. [Google Scholar] [CrossRef]

- Dar, J.; Ponsot, A.G.; Jolma, C.J.; Lin, D. A review on scan strategies in laser-based metal additive manufacturing. J. Mater. Res. Technol. 2025, 36, 5425–5467. [Google Scholar] [CrossRef]

- Izadi, M.; Farzaneh, A.; Mohammed, M.; Gibson, I.; Rolfe, B. A review of laser engineered net shaping (LENS) build and process parameters of metallic parts. Rapid Prototyp. J. 2020, 26, 1059–1078. [Google Scholar] [CrossRef]

- Zheng, H.; Li, E.; Wang, Y.; Shi, P.; Xu, B.; Yang, S. Environmental life cycle assessment of remanufactured engines with advanced restoring technologies. Robot. Comput.-Integr. Manuf. 2019, 59, 213–221. [Google Scholar] [CrossRef]

- Zhao, S.; Yu, M.; Yan, R.; Zhai, Q.; Liu, J.; Dai, X.; Lei, C.; Wang, D. Surface roughness and microhardness improvement of laser cladding stainless-steel 316 by laser polishing based on multiple remelting. Opt. Laser Technol. 2024, 176, 110903. [Google Scholar] [CrossRef]

- Chen, X.; Li, K.; Lin, Y.; Xu, Z.; Guo, B.; Chen, J.; Jiang, Q.; Zhao, Z. Effect of laser shock peening uniformity on bending fatigue life of 20CrNiMo. Opt. Laser Technol. 2024, 175, 110704. [Google Scholar] [CrossRef]

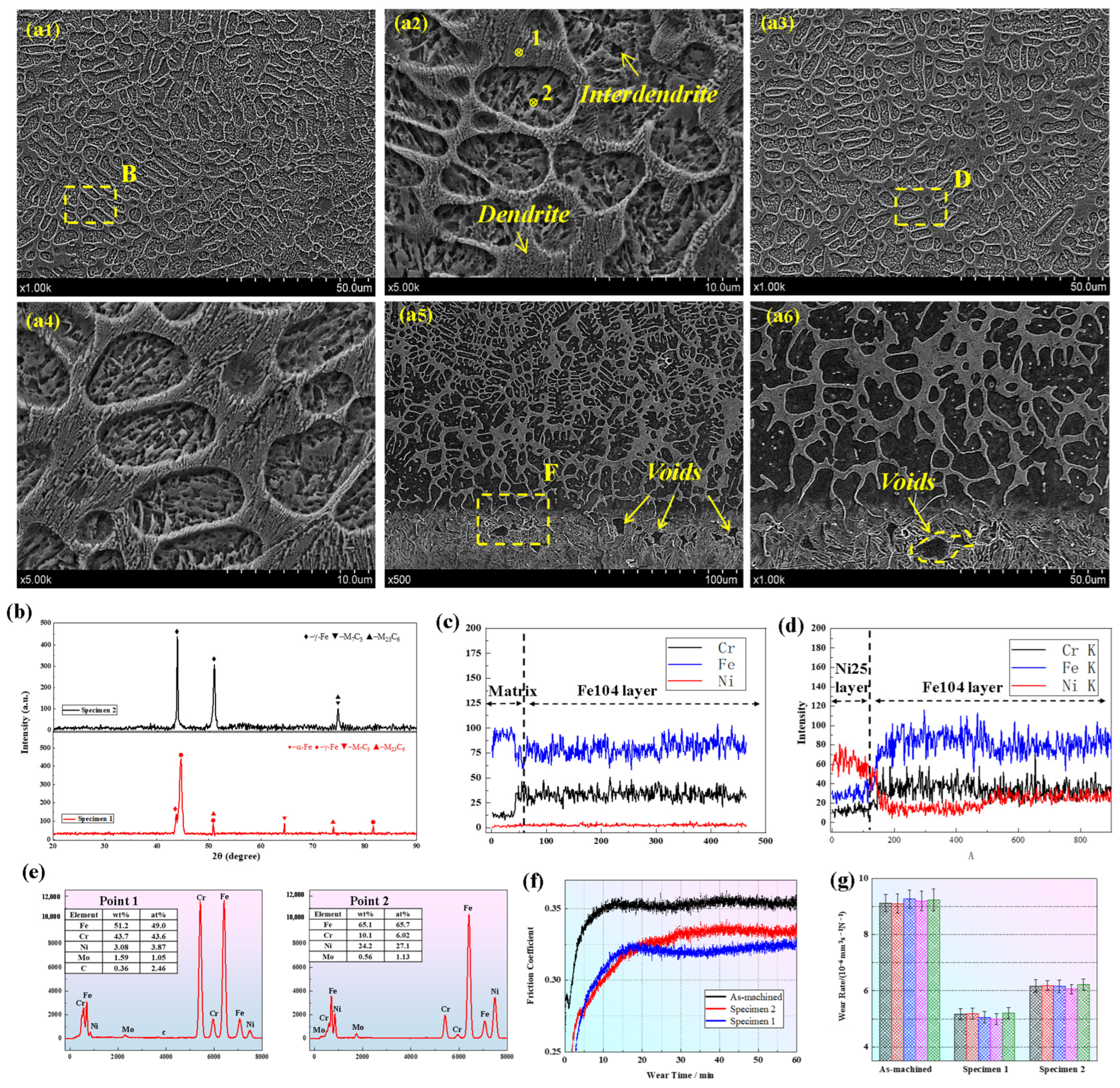

- Lu, H.; Xue, K.; Xu, X.; Luo, K.; Xing, F.; Yao, J.; Lu, J. Effects of laser shock peening on microstructural evolution and wear property of laser hybrid remanufactured Ni25/Fe104 coating on H13 tool steel. J. Mater. Process. Technol. 2021, 291, 117016. [Google Scholar] [CrossRef]

- Xuan, Z.; Li, Z.; Zhou, D. Study on manufacturability evaluation of MBD model based on interactive method. Mod. Manuf. Eng. 2021, 8, 70–76. [Google Scholar] [CrossRef]

- Yeo, C.; Cheon, S.; Mun, D. Manufacturability evaluation of parts using descriptor-based machining feature recognition. Int. J. Comput. Integr. Manuf. 2021, 34, 1196–1222. [Google Scholar] [CrossRef]

- Jin, Q.Y.; Xu, J.F.; Huang, X.L.; Liu, X.Q.; Huang, L.; Jiang, K. Remanufacturing scheduling under uncertainty considering remanufacturability assessment with adaptive hybrid optimization algorithm. Swarm Evol. Comput. 2025, 96, 101990. [Google Scholar] [CrossRef]

- Liu, Q.T.; Shang, Z.Y.; Ding, K.; Guo, L.; Zhang, L. Multi-process routes based remanufacturability assessment and associated application on production decision. J. Clean. Prod. 2019, 240, 118114. [Google Scholar] [CrossRef]

- Shi, J.L.; Pan, Y.X.; Yu, Z.H.; Song, X.Q. Multidimensional remanufacturability assessment method for used products based on LCSA. Int. J. Life Cycle Assess. 2024, 29, 1779–1798. [Google Scholar] [CrossRef]

- Ding, M.C.; Zhang, Y.L. All-crack remanufacturability evaluation for blade with surface crack. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 434. [Google Scholar] [CrossRef]

- Wang, J.L.; Yu, J.; Yang, Y.X.; Du, F.M.; Wang, J.S. Study of the remanufacturing critical threshold and remanufacturability evaluation for FV520B-I blade based on fatigue life and FEA. Eng. Fail. Anal. 2020, 112, 104509. [Google Scholar] [CrossRef]

- Zhang, X.G.; Tang, Y.J.; Zhang, H.; Jiang, Z.G.; Cai, W. Remanufacturability evaluation of end-of-life products considering technology, economy and environment: A review. Sci. Total Environ. 2021, 764, 142922. [Google Scholar] [CrossRef]

- Jiru, W.G.; Sankar, M.R.; Dixit, U.S. Laser surface alloying of copper, manganese, and magnesium with pure aluminum substrate. J. Mater. Eng. Perform. 2016, 25, 1172–1181. [Google Scholar] [CrossRef]

- Yong, Y.; Fu, W.; Deng, Q.; Chen, D. A comparative study of vision detection and numerical simulation for laser cladding of nickel-based alloy. J. Manuf. Process. 2017, 28, 364–372. [Google Scholar] [CrossRef]

- Fan, W.; Tan, H.; Lin, X.; Huang, W.D. Thermal analysis of synchronous induction-assisted laser deposition of Ti-6Al-4V using different laser-induction interaction modes. Addit. Manuf. 2020, 35, 101267. [Google Scholar] [CrossRef]

- Ajabshir, S.Z.; Hare, C.; Sofia, D.; Barletta, D.; Poletto, M. Investigating the effect of temperature on powder spreading behaviour in powder bed fusion additive manufacturing process by Discrete Element Method. Powder Technol. 2024, 436, 119468. [Google Scholar] [CrossRef]

- Wang, S.; Chen, L.; Jiang, X. Research progress on damping and mechanical properties of iron-based damping alloy. Heat Treat. Met. 2021, 46, 187–192. [Google Scholar]

- Liang, Q.; Xu, Y.; Xu, B.; Chen, H.; Ma, B. Effect of in-situ synthesis of TiC/TiB2 particles by laser cladding on the microstructure and properties of Co-based coatings. Opt. Laser Technol. 2025, 192, 113620. [Google Scholar] [CrossRef]

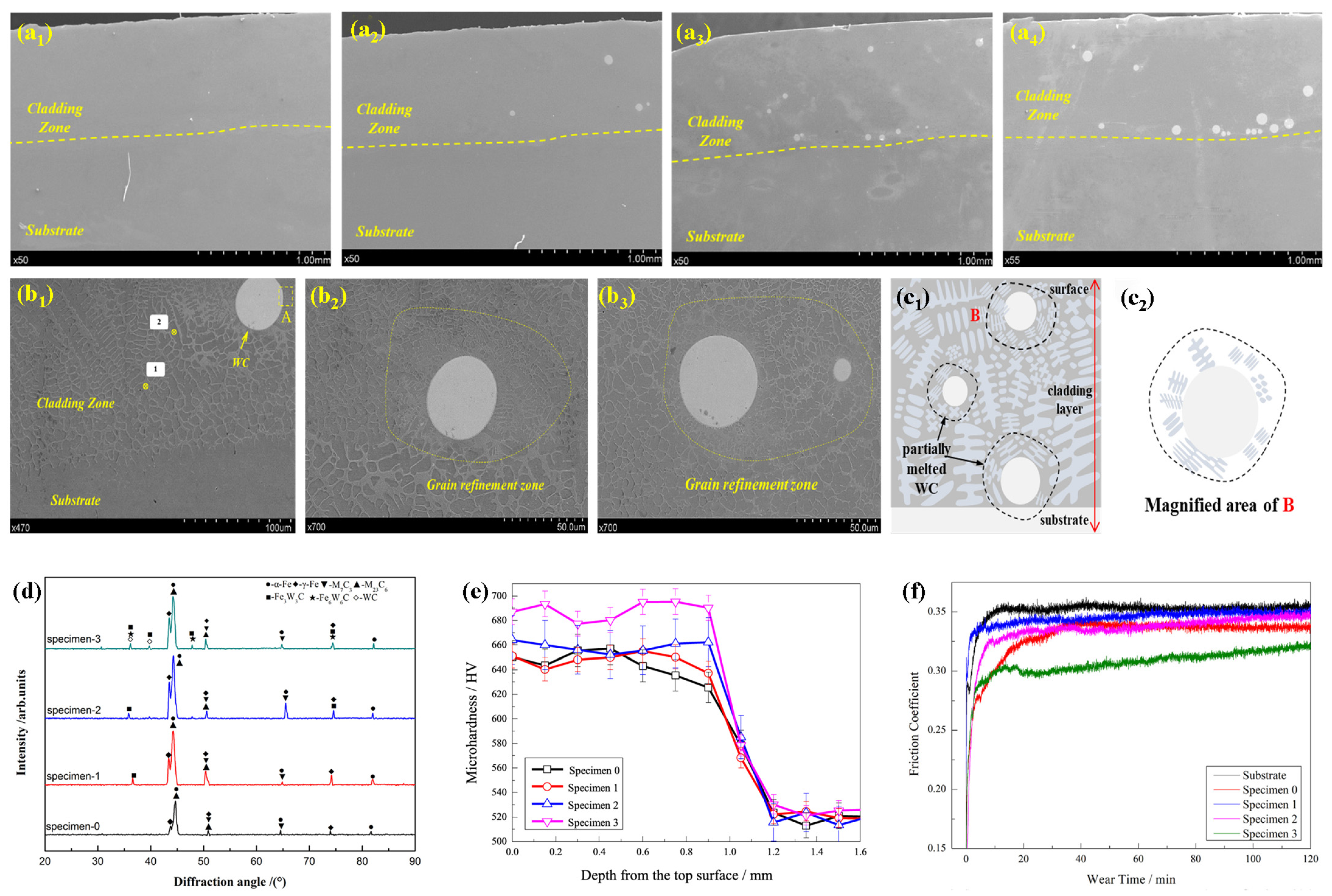

- Lu, J.Z.; Cao, J.; Lu, H.F.; Zhang, L.Y.; Luo, K.Y. Wear properties and microstructural analyses of Fe-based coatings with various WC contents on H13 die steel by laser cladding. Surf. Coat. Technol. 2019, 369, 228–237. [Google Scholar] [CrossRef]

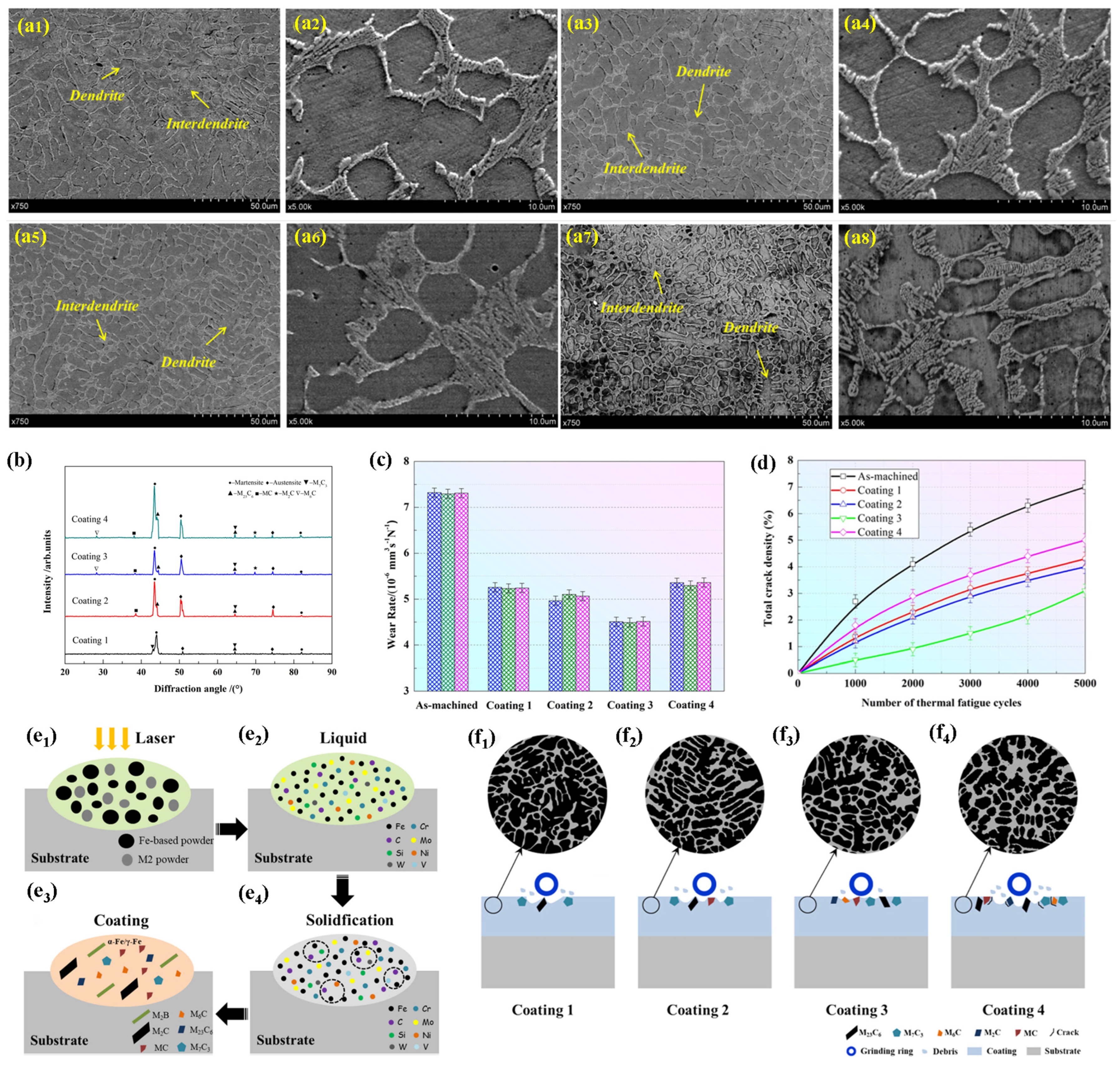

- Lu, H.F.; Cai, J.; Luo, K.Y.; Xing, F.; Zhang, Q.L.; Yao, J.H.; Lu, J.Z. Thermal fatigue life and improvement mechanism of Fe-based coatings on H13 extrusion die by laser additive remanufacturing. Surf. Coat. Technol. 2021, 408, 126808. [Google Scholar] [CrossRef]

- Lu, J.Z.; Xue, K.N.; Lu, H.F.; Xing, F.; Luo, K.Y. Laser shock wave-induced wear property improvement and formation mechanism of laser cladding Ni25 coating on H13 tool steel. J. Mater. Process. Technol. 2021, 296, 117202. [Google Scholar] [CrossRef]

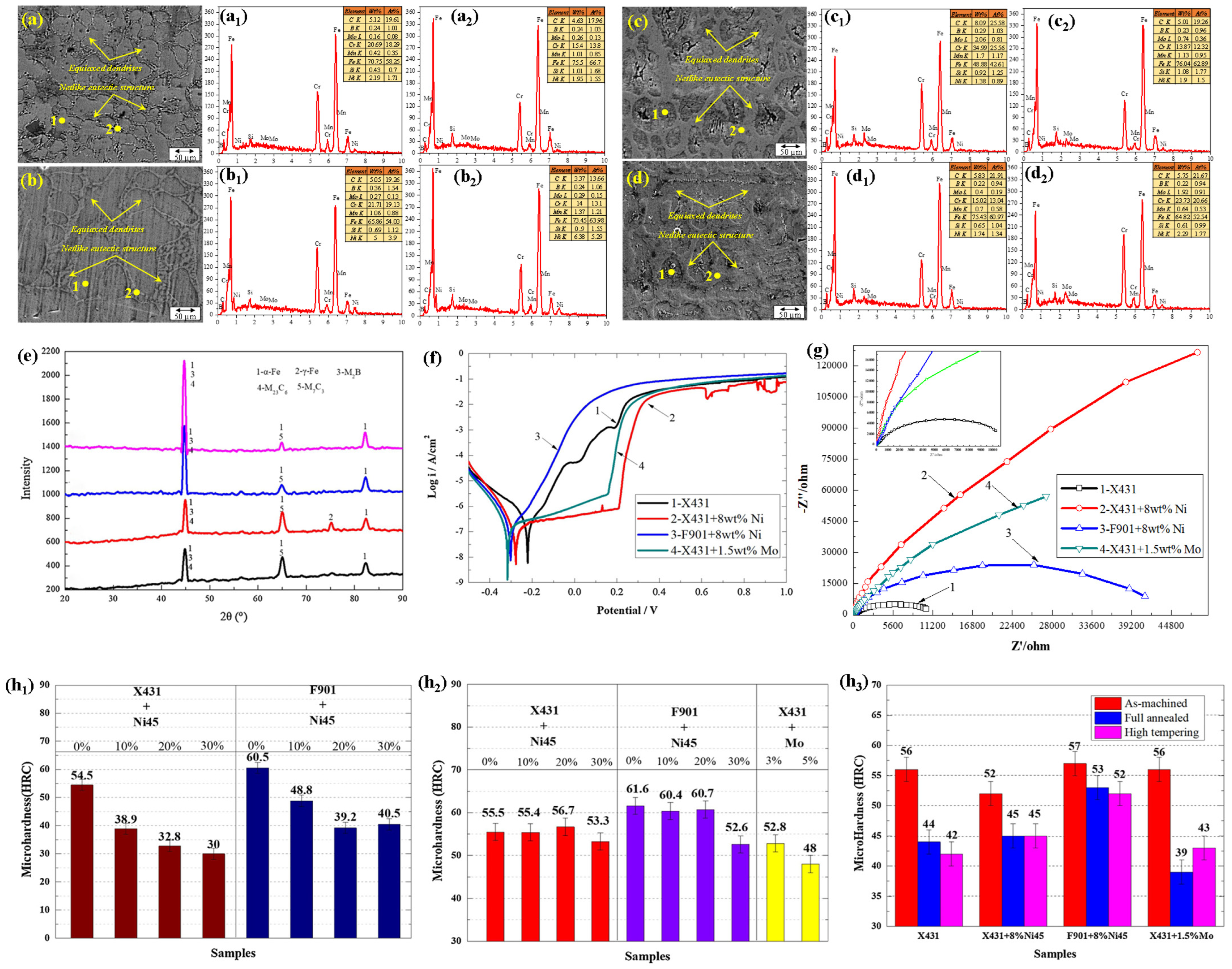

- Yang, X.; Chen, Y.; Zhang, Z.; Liu, Y.; Tao, S.; Li, G.; Chen, H. Study on microstructure and properties of laser-clad Fe-based (Ti, V)C composite coatings. Surf. Coat. Technol. 2023, 464, 129552. [Google Scholar] [CrossRef]

- Xu, X.; Lu, H.F.; Luo, K.Y.; Yao, J.H.; Xu, L.Z.; Lu, J.Z.; Lu, Y.F. Mechanical properties and electrochemical corrosion resistance of multilayer laser cladded Fe-based composite coatings on 4Cr5MoSiV1 steel. J. Mater. Process. Technol. 2020, 284, 116736. [Google Scholar] [CrossRef]

- Zhao, Y.; Shi, W.; Huang, J. Microstructure evolution and performance effect of composite carbide (W,Ti)C enhanced Ni-based coatings fabricated by laser cladding. J. Mater. Res. Technol. 2025, 35, 298–307. [Google Scholar] [CrossRef]

- Cui, W.; Li, Y.; Li, F.; Qi, X.; Sun, X.; Pan, Z.; Niu, J. Wear and corrosion properties of in-situ TiC–TiB2 modified Ni-based composite coatings with different B/C ratios prepared by laser cladding. Ceram. Int. 2024, 50, 2424–2435. [Google Scholar] [CrossRef]

- Li, Z.; Lin, T.; Jing, C.; Tu, Y.; Fu, T.; Liu, N. Influence of Ti element on the microstructure and crack of modulated WC-strengthened Ni-based alloy coatings by laser cladding. Mater. Today Commun. 2024, 41, 110541. [Google Scholar] [CrossRef]

- Xue, K.N.; Lu, H.F.; Luo, K.Y.; Cui, C.Y.; Yao, J.H.; Xing, F.; Lu, J.Z. Effects of Ni25 transitional layer on microstructural evolution and wear property of laser clad composite coating on H13 tool steel. Surf. Coat. Technol. 2020, 402, 126488. [Google Scholar] [CrossRef]

- Yuan, J.J.; Li, X.; Pan, G.H.; Zhang, S.M.; Cui, Y.D.; Zhu, R.X.; Lu, H.T.; Song, Q.R. Effect of SiC-Si4N3 ceramic reinforcement on the microstructure and corrosion resistance to molten aluminum of laser-cladded Co-based coatings. Ceram. Int. 2025, 51, 13493–13506. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, L.; Yao, J.; Xia, H.; Li, J.; Liu, R. Effects of electromagnetic compound field on the escape behavior of pores in molten pool during laser cladding. Surf. Coat. Technol. 2020, 383, 125198. [Google Scholar] [CrossRef]

- Gu, B.; Zhang, H.; Wang, Y.; Xu, G.; Wang, C.; Gao, L.; Chu, J.; Yang, Y. Microstructure and corrosion properties of CrMnFeCoNi high entropy alloy coating by temperature field-assisted laser cladding. Surf. Coat. Technol. 2024, 494, 131473. [Google Scholar] [CrossRef]

- Nunekpeku, X.; Zhang, W.; Gao, J.; Adade, S.Y.-S.S.; Li, H.; Chen, Q. Gel strength prediction in ultrasonicated chicken mince: Fusing near-infrared and Raman spectroscopy coupled with deep learning LSTM algorithm. Food Control 2025, 168, 110916. [Google Scholar] [CrossRef]

- Chen, D.; Cai, Y.; Luo, Y.; Tu, J.; Tang, F. Analysis on the microstructure regulation based on the pulsed laser oscillating molten pool in Laser-PTA additive manufacturing. J. Manuf. Process. 2020, 59, 587–594. [Google Scholar] [CrossRef]

- Wang, Y.H.; Zhou, H.M.; Wang, Z.D.; Xiang, N.X.; Cao, X.Y. Effect of electromagnetic field on microstructure properties of laser cladding nickel-based coatings. Surf. Technol. 2024, 53, 198–207. [Google Scholar]

- Chen, J.; Yao, Z.; Wang, F.; Chi, Y.; Wang, Z.; Tofil, S.; Yao, J. Grain refinement and Laves phase dispersion by high-intensity ultrasonic vibration in laser cladding of Inconel 718. J. Mater. Res. Technol.-JmrT 2024, 30, 8563–8575. [Google Scholar] [CrossRef]

- Fu, B.; Gu, Y.; Lin, J.; Zhou, X.; Gao, T.; Wang, J.; Han, L.; Zhang, Y. Pulsed laser remelting non-resonant vibration assisted grinding Al-Si alloy. Int. J. Mech. Sci. 2025, 293, 110226. [Google Scholar] [CrossRef]

- Hamdan, A.M.; Rafiq, A. A path planning method for surface damage repair using a robot-assisted laser cladding process. Int. J. Adv. Manuf. Technol. 2022, 122, 1259–1279. [Google Scholar] [CrossRef]

- Liu, J.; Ba, Z.; Shu, D. Laser cladding path planning for curved metal parts. Metals 2024, 14, 1055. [Google Scholar] [CrossRef]

- Li, Y.; Wu, J.; Li, M.; Xu, W.; Ye, R.; Wang, Z. Improved Inconel 718 superalloy repaired performance on 304 stainless steel shafts via recrystallization and Laves phase suppression in hybrid additive-subtractive manufacturing. J. Mater. Res. Technol.-JmrT 2025, 37, 3289–3302. [Google Scholar] [CrossRef]

- Liu, M.; Duan, C.; Li, G.; Cai, Y.; Wang, F. Friction property and milling machinability of Ni60 cladding layer in hybrid additive-subtractive manufacturing. J. Manuf. Process. 2023, 93, 162–172. [Google Scholar] [CrossRef]

- Wu, D.; Liang, J.; Wang, H.; Yu, J. Investigative on the remanufacturing process of TC4 blade based on selective laser melting and CNC machining. J. Mater. Res. Technol.-JmrT 2022, 21, 450–464. [Google Scholar] [CrossRef]

- Niu, Z.W.; Li, L.; Zheng, G.M.; Wei, X.T.; Li, Z.Y. Research on the remanufacturing based on ultrasonic mechanical aluminizing and micro arc oxidation. In Proceedings of the 2018 International Conference on Energy Development and Environmental Protection, Nanjing, China, 17–19 August 2018; Volume 174, pp. 434–440. [Google Scholar] [CrossRef]

- Munno, M.; Beneduce, S.; Lamanna, G.; Caputo, F. Selection criteria based on kpis for redesigning of components for remanufacturing purposes in agricultural machinery field. Macromol. Symp. 2023, 413, 2300254. [Google Scholar] [CrossRef]

- Wang, J.; Gu, D.X.; Yu, Z.Y.; Tan, C.B.; Zhou, L.S. A framework for 3D model reconstruction in reverse engineering. Comput. Ind. Eng. 2012, 63, 1189–1200. [Google Scholar] [CrossRef]

- Chen, H.; Jiang, Q.; Zhang, Z.; Wu, S.; Shen, Y.; Xu, F. Structural design and optimization of adaptive soft adhesion bionic climbing robot. Autom. Constr. 2025, 171, 105975. [Google Scholar] [CrossRef]

- Wang, J.S.; Shu, L.S. Laser cladding remanufacturing and repair of agricultural tractor spindle. Laser Optoelectron. Prog. 2020, 57, 071404. [Google Scholar] [CrossRef]

- Wang, Z.W.; Liu, X.B.; Zhou, A.; Zhang, F.Z.; Zhang, S.H. Research progress of surface technology to improve the wear resistance of agricultural and forestry machinery and application. China Surf. Eng. 2024, 37, 102–116. [Google Scholar]

- Yi, Q.; Feng, F. Optimization of laser repair process for agricultural machinery parts based on genetic algorithm. Materials 2025, 18, 775. [Google Scholar] [CrossRef]

- Singh, E.; Pratap, A.; Mehta, U.; Azid, S.I. Smart agriculture drone for crop spraying using image-processing and machine learning techniques: Experimental validation. Iot 2024, 5, 250–270. [Google Scholar] [CrossRef]

- Hananto, A.L.; Tirta, A.; Herawan, S.G.; Idris, M.; Soudagar, M.E.M.; Djamari, D.W.; Veza, I. Digital twin and 3d digital twin: Concepts, applications, and challenges in industry 4.0 for digital twin. Computers 2024, 13, 100. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, Z.; He, Z.; Shen, Z.; Chen, B. Manifold learning-based subspace distance for machinery damage assessment. Mech. Syst. Signal Process. 2016, 70–71, 637–649. [Google Scholar] [CrossRef]

- Márton Virt, M.Z. An AI-based fuel designer tool for sustainable E-fuel development: Methodology, Validation, and Optimization. Energy AI 2025, 21, 100583. [Google Scholar] [CrossRef]

- Zheng, C.; Yang, D.; Hao, W.; Qiao, T.; Tan, Z.; Jin, J. Smooth path generation method of laser cladding bit repair robot based on 3D automatic measurement of wear surface point cloud. J. Phys. Conf. Ser. 2021, 1939, 012117. [Google Scholar] [CrossRef]

- Xin, Z.; Sun, J.; Tian, Y.; Lu, B.; Hang, Y.Y.; Chen, Q.S. Hyperspectral technique combined with deep learning algorithm for detection of compound heavy metals in lettuce. Food Chem. 2020, 321, 126503. [Google Scholar] [CrossRef]

- Tahir, H.E.; Zou, X.; Shi, J.; Mahunu, G.K.; Zhai, X.; Mariod, A.A. Quality and postharvest-shelf life of cold-stored strawberry fruit as affected by gum arabic (Acacia senegal) edible coating. J. Food Biochem. 2018, 42, e12527. [Google Scholar] [CrossRef]

- Zhang, S.; Qiu, B.; Xue, X.; Sun, T.; Peng, B. Parameters optimization of crop protection UAS based on the first industry standard of China. Int. J. Agric. Biol. Eng. 2020, 13, 29–35. [Google Scholar] [CrossRef]

- Dai, C.X.; Huang, X.Y.; Lv, R.Q.; Zhang, Z.C.; Sun, J.; Aheto, J.H. Analysis of volatile compounds of Tremella aurantialba fermentation via electronic nose and HS-SPME-GC-MS. J. Food Saf. 2018, 38, e12555. [Google Scholar] [CrossRef]

- Wu, X.H.; Zhu, J.; Wu, B.; Zhao, C.; Sun, J.; Dai, C.X. Discrimination of chinese liquors based on electronic nose and fuzzy discriminant principal component analysis. Foods 2019, 8, 38. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.Y.; Pan, S.H.; Sun, Z.Y.; Ye, W.T.; Aheto, J.H. Evaluating quality of tomato during storage using fusion information of computer vision and electronic nose. J. Food Process Eng. 2018, 41, e12832. [Google Scholar] [CrossRef]

- Yue, P.P.; Zhang, M.; Zhao, T.; Liu, P.; Peng, F.; Yang, L.Q. Eco-friendly epoxidized Eucommia ulmoides gum based composite coating with enhanced super-hydrophobicity and corrosion resistance properties. Ind. Crops Prod. 2024, 214, 118523. [Google Scholar] [CrossRef]

- Huang, X.Y.; Lv, R.Q.; Wang, S.; Aheto, J.H.; Dai, C.X. Integration of computer vision and colorimetric sensor array for nondestructive detection of mango quality. J. Food Process Eng. 2018, 41, e12873. [Google Scholar] [CrossRef]

- Abeyrathna, R.M.R.D.; Nakaguchi, V.M.; Liu, Z.; Sampurno, R.M.; Ahamed, T. 3d camera and single-point laser sensor integration for apple localization in spindle-type orchard systems. Sensors 2024, 24, 3753. [Google Scholar] [CrossRef]

- Tang, N.Q.; Sun, J.; Yao, K.S.; Zhou, X.; Tian, Y.; Cao, Y.; Nirere, A. Identification of Lycium barbarum varieties based on hyperspectral imaging technique and competitive adaptive reweighted sampling-whale optimization algorithm-support vector machine. J. Food Process Eng. 2021, 44, e13603. [Google Scholar] [CrossRef]

- Chen, A.H.; Liang, H.X.; Chen, T.M.; Yang, W.J.; Ding, C. Influence of long-term irrigation with treated papermaking wastewater on soil ecosystem of a full-scale managed reed wetland. J. Soils Sediments 2016, 16, 1352–1359. [Google Scholar] [CrossRef]

- Chen, J.; Lian, Y.; Zou, R.; Zhang, S.; Ning, X.; Han, M. Real-time grain breakage sensing for rice combine harvesters using machine vision technology. Int. J. Agric. Biol. Eng. 2020, 13, 194–199. [Google Scholar] [CrossRef]

- Liang, Z.; Xu, L.; De Baerdemaeker, J.; Li, Y.; Saeys, W. Optimisation of a multi-duct cleaning device for rice combine harvesters utilising CFD and experiments. Biosyst. Eng. 2020, 190, 25–40. [Google Scholar] [CrossRef]

- Zhou, M.L.; Shan, Y.Y.; Xue, X.L.; Yin, D.Q. Theoretical analysis and development of a mechanism with punching device for transplanting potted vegetable seedlings. Int. J. Agric. Biol. Eng. 2020, 13, 85–92. [Google Scholar] [CrossRef]

- Song, J.X.; He, D.X.; Wang, J.F.; Mao, H.P. How to diagnose potassium abundance and deficiency in tomato leaves at the early cultivation stage. Horticulturae 2023, 9, 1225. [Google Scholar] [CrossRef]

- Zhu, W.D.; Sun, J.; Wang, S.M.; Shen, J.F.; Yang, K.F.; Zhou, X. Identifying field crop diseases using transformer-embedded convolutional neural network. Agriculture 2022, 12, 1083. [Google Scholar] [CrossRef]

- Ji, W.; Zhai, K.L.; Xu, B.; Wu, J.W. Green apple detection method based on multidimensional feature extraction network model and transformer module. J. Food Prot. 2025, 88, 100397. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.F.; Li, T.Z.; Chen, T.H.; Zhang, X.D.; Taha, M.F.; Yang, N.; Mao, H.P.; Shi, Q. Cucumber downy mildew disease prediction using a cnn-lstm approach. Agriculture 2024, 14, 1155. [Google Scholar] [CrossRef]

- Hu, B.; Li, H.; Jiang, Y.; Tang, P.; Du, L. Review of the interaction mechanism for droplets and foliage under sprinkler irrigation and water-fertilizer integration. Int. J. Agric. Biol. Eng. 2024, 17, 31–43. [Google Scholar] [CrossRef]

- Yang, W.T.; Zhong, W.; Jia, W.D.; Ou, M.X.; Dong, X.; Zhang, T.; Ding, S.M.; Yu, P.P. The effect of oil-in-water emulsion pesticide on the evolution of liquid sheet rim disintegration and the spraying distribution. Crop Prot. 2023, 177, 106547. [Google Scholar] [CrossRef]

- Yang, J.; Peng, D.; Jin, W.; Geng, F.; Cheng, C.; Wang, L.; Zhang, H.; Duan, Y.; Deng, Q. Redesign of air/oil-water interface via physical fields coupled with pH shifting to improve the emulsification, foaming, and digestion properties of plant proteins. Crit. Rev. Food Sci. Nutr. 2025, 65, 1093–1108. [Google Scholar] [CrossRef]

- Guan, C.S.; Fu, J.J.; Cui, Z.C.; Wang, S.L.; Gao, Q.S.; Yang, Y.T. Evaluation of the tribological and anti-adhesive properties of different materials coated rotary tillage blades. Soil Tillage Res. 2021, 209, 104933. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, L.; Li, J.; Li, S.; Qu, W.; Ma, H.; Oladejo, A.O.; Ye, X. In-situ and real-time monitoring of enzymatic process of wheat gluten by miniature fiber NIR spectrometer. Food Res. Int. 2017, 99, 147–154. [Google Scholar] [CrossRef]

- Khulal, U.; Zhao, J.; Hu, W.; Chen, Q. Nondestructive quantifying total volatile basic nitrogen (TVB-N) content in chicken using hyperspectral imaging (HSI) technique combined with different data dimension reduction algorithms. Food Chem. 2016, 197, 1191–1199. [Google Scholar] [CrossRef]

- Li, H.; Kutsanedzie, F.; Zhao, J.; Chen, Q. Quantifying Total Viable Count in Pork Meat Using Combined Hyperspectral Imaging and Artificial Olfaction Techniques. Food Anal. Methods 2016, 9, 3015–3024. [Google Scholar] [CrossRef]

- Zhao, S.G.; Jiao, T.H.; Adade, S.Y.-S.S.; Zhen, W.; Qin, O.Y.; Chen, Q.S. Digital twin for predicting and controlling food fermentation: A case study of kombucha fermentation. J. Food Eng. 2025, 393, 112467. [Google Scholar] [CrossRef]

- Lu, S.; Sun, Z.N.; Huang, M. The impact of digital literacy on farmers’ pro-environmental behavior: An analysis with the Theory of Planned Behavior. Front. Sustain. Food Syst. 2024, 8, 1432184. [Google Scholar] [CrossRef]

- Feng, L.; Wu, J.N.; Cai, L.; Li, M.; Dai, Z.Q.; Li, D.J.; Liu, C.Q.; Zhang, M. Effects of different hydrocolloids on the water migration, rheological and 3D printing characteristics of β-carotene loaded yam starch-based hydrogel. Food Chem. 2022, 393, 133422. [Google Scholar] [CrossRef]

- Zhang, R.X.; Zhu, H.T.; Chang, Q.L.; Mao, Q.R. A comprehensive review of digital twins technology in agriculture. Agriculture 2025, 15, 903. [Google Scholar] [CrossRef]

| Restoration Techniques | Coating Thickness (mm) | Thermal Deformation | Dilution Ratio (%) | Surface Precision (Ra, μm) |

|---|---|---|---|---|

| Electroplating/Brush Plating | 0.001–0.3 | None | 0 | 1–20 |

| Cold Spray | 0.1–5.0 | None | 0 | 50–200 |

| Plasma Spraying (PS) | 0.05–0.5 | Low | 5–30 | 20–100 |

| Plasma Transferred Arc (PTAW) | 1–10 | High | 10–50 | 100–500 |

| Laser Cladding (LC) | 0.1–5.0 | Minimal | 1–40 | 10–50 |

| Country/Region | Year | Strategic Initiatives |

|---|---|---|

| USA | 2012 | National Strategic Plan for Advanced Manufacturing (emphasizing economic/security foundations) Establishment of National Additive Manufacturing Innovation Institute (NAMII) USITC report: Remanufactured Goods: U.S. and Global Industries, Markets, and Trade |

| USA | 2016 | Next Generation Additive Manufacturing Materials Roadmap (NIST-funded) |

| UK | 2011 | High Value Manufacturing Catapult (prioritizing near-net-shape and additive manufacturing) |

| UK | 2013 | Future of Manufacturing: A New Era of Opportunity for the UK (addressing remanufacturing/AM) |

| EU | 2007 | 7th Framework Programme (high-power lasers/laser cladding) |

| EU | 2008 | Micro-Nano Manufacturing Platform (MINAM) |

| EU | 2013 | Photonics 2014–2020 Roadmap (advancing laser AM/cleaning processes) |

| EU | 2014 | Horizon 2020 (AM as Key Enabling Technology) |

| China | 2015 | Made in China 2025 Technology Roadmap (prioritizing AM materials/processes) |

| China | 2016 | 13th Five-Year National S&T Innovation Plan Ultra-fast/high-power laser manufacturing R&D Laser processing equipment development |

| China | 2017 | High-End Intelligent Remanufacturing Action Plan (2018–2020) |

| China | 2020 | Strengthening Basic Research from “0 to 1” (supporting AM/laser manufacturing) |

| Characteristic | Implications |

|---|---|

| Complexity of Service Conditions | Continuous action of fatigue loads; Coupled effects of multiple strong fields (acoustic, optical, electrical, magnetic, thermal). |

| Multi-Scale Nature of Damage | Multiple damage types (fatigue, corrosion, wear, etc.); Damage scales from microscopic cracks to nanoscale lattice distortions; Presence of both surface and internal damage. |

| Uncertainty of Failure Mechanisms | Damage characteristics evolve with changing service conditions; Coupling and competition effects exist between instances of damage across different scales. |

| Diversity of Performance Assessment Methods | Methods for single-source/multi-source damage assessment; Single-field/multi-field strength assessment methods; High-cycle/ultra-high-cycle fatigue assessment methods; Probabilistic/reliability assessment methods. |

| Condition | Implications |

|---|---|

| 1. The object is a durable product. | Must be an electromechanical product designed for long service life (e.g., blades, crankshafts, and cylinder heads). |

| 2. The object has lost its functionality. | It can no longer perform its intended function, or its residual service capability is insufficient for one full service cycle. |

| 3. The original product was manufactured to standardized requirements. | Possesses defined manufacturing standards and processes, ensuring interchangeability. |

| 4. The object has high added value. | The original product is costly and complex to manufacture; remanufacturing offers significant production cost savings. |

| 5. The acquisition cost of the object is low. | The object is widely available. |

| 6. Mature remanufacturing technology exists. | The processes and technologies involved in remanufacturing are stable, with well-defined technical pathways. |

| 7. Consumer awareness of remanufactured products exists. | Remanufactured products enjoy relatively broad market acceptance. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, H.; Yan, H.; Lv, J.; Deng, W.; Liang, Y.; Xu, X.; Cai, J.; Luo, K.; Lu, J. Laser Cladding Remanufacturing of Metallic Components in High-End Agricultural Machinery and Equipment: Material Design, Processing, and Properties. Metals 2025, 15, 1166. https://doi.org/10.3390/met15111166

Lu H, Yan H, Lv J, Deng W, Liang Y, Xu X, Cai J, Luo K, Lu J. Laser Cladding Remanufacturing of Metallic Components in High-End Agricultural Machinery and Equipment: Material Design, Processing, and Properties. Metals. 2025; 15(11):1166. https://doi.org/10.3390/met15111166

Chicago/Turabian StyleLu, Haifei, Hailong Yan, Jiming Lv, Weiwei Deng, Yuchen Liang, Xiang Xu, Jie Cai, Kaiyu Luo, and Jinzhong Lu. 2025. "Laser Cladding Remanufacturing of Metallic Components in High-End Agricultural Machinery and Equipment: Material Design, Processing, and Properties" Metals 15, no. 11: 1166. https://doi.org/10.3390/met15111166

APA StyleLu, H., Yan, H., Lv, J., Deng, W., Liang, Y., Xu, X., Cai, J., Luo, K., & Lu, J. (2025). Laser Cladding Remanufacturing of Metallic Components in High-End Agricultural Machinery and Equipment: Material Design, Processing, and Properties. Metals, 15(11), 1166. https://doi.org/10.3390/met15111166