Abstract

Harsh working environments and excessive usage frequency cause wear, fatigue, and corrosion failure in metallic components in high-end agricultural machinery and equipment. Overall replacements of valuable metallic components could result in high overhaul costs and material waste. Therefore, remanufacturing these local areas is an effective way to put damaged components back into service, thus maximizing the value of the remaining materials. Laser cladding (LC) technology utilizes high-energy, high-density laser beams to create cladding layers with specialized properties such as wear and corrosion resistance on the surfaces of damaged metallic components. This work provides a comprehensive analysis of pre-processing, processing, and post-processing in relation to laser cladding remanufacturing (LCR) of metallic components. The review examines the LC process, including material systems (Fe-, Ni-, and Co-based alloys and composites), process optimization, and path planning. The relationship between material composition, process parameters, microstructure evolution, and resultant properties (wear, corrosion, and fatigue) is emphasized. Finally, challenges and future trends faced in this process are introduced in detail. The discussed topics provide some important insights on high-quality and efficient remanufacturing of metallic components in high-end agricultural machinery and equipment.

1. Introduction

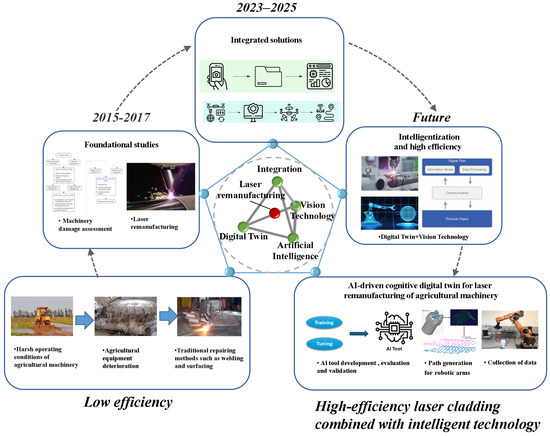

Agricultural machinery and equipment serve as an indispensable material foundation for modern agriculture, playing a pivotal role in ensuring stable grain production, improving fruit quality and yield, and enhancing agricultural productivity. In recent years, increasing attention has been devoted to the strategic significance of agricultural equipment innovation, with explicit emphasis on advancing key technologies in agricultural machinery and promoting high-quality agricultural mechanization. Supported by policy initiatives, the agricultural machinery sector has experienced rapid development, transitioning from conventional tillage and harvesting systems to intelligent, precision-based agricultural technologies [1,2,3].

The key components of agricultural machinery and equipment, such as engines, gearboxes, and other critical parts, are typically fabricated from metal alloys, which inevitably face threats of damage and failure. The operating environment for agricultural machinery is particularly harsh, and widespread use has led to increasingly severe degradation of components. During operations such as plowing, harvesting, and transportation, agricultural equipment is exposed to abrasive soil particles, corrosive agrochemicals, and dynamic mechanical loads, all of which drive metallic components toward their fatigue life limits. These factors contribute to frequent failures and deterioration, including surface wear, crack propagation, corrosion, and fatigue-induced structural degradation in critical components such as tractor engine cylinders, transmission gears, and cutting blades [4,5]. In high-performance machinery—such as intelligent combine harvesters and precision agricultural robotic arms—such degradation not only incurs substantial maintenance costs but also disrupts scheduled farming operations, resulting in significant economic losses [6].

Remanufacturing, as an advanced circular economy model, offers a sustainable solution for addressing wear and damage in agricultural machinery. In contrast to traditional repair or recycling methods, remanufacturing leverages surface engineering technologies to restore degraded components to their original specifications or even enhance their performance. Compared with the production of new parts, remanufacturing can achieve material utilization exceeding 90% and reduce energy consumption by more than 60% [7]. This approach supports efficient resource utilization and environmental protection, positioning it as a key enabler of sustainable agricultural development. However, conventional remanufacturing techniques present notable limitations in the context of agricultural machinery: brush plating yields thin coatings and raises environmental concerns; cold spraying results in limited microstructural refinement; plasma-sprayed coatings primarily form mechanical bonds with the substrate and are susceptible to defects; and plasma-transferred arc welding (PTAW) is associated with a large heat-affected zone and reduced dimensional precision [8,9,10]. By contrast, laser cladding (LC), as a representative laser additive manufacturing (LAM) technology, offers significant advantages, including minimal thermal distortion, low dilution rates, high precision, the formation of strong metallurgical bonds, a wide range of achievable coating thicknesses, and excellent compatibility with diverse materials. These characteristics make LC particularly suitable for modern agricultural machinery remanufacturing and highly aligned with environmentally responsible manufacturing practices and sustainability objectives [11].

Laser-based remanufacturing is an integrated process comprising multiple interrelated sub-processes. At its core lies the laser cladding remanufacturing (LCR) process, which is inherently complex due to the multitude of influencing parameters, rendering the optimization of processing conditions and control of material systems particularly challenging [12,13]. Effective LCR implementation requires comprehensive consideration of substrate properties and the synergistic effects of auxiliary energy fields. Without such considerations, even successful geometric restoration may result in substantial performance degradation. The primary objective of this work is to present a timely and focused review of the end-to-end remanufacturing process for agricultural machinery and equipment, encompassing damage assessment methodologies, inspection techniques, material selection criteria, remanufacturing procedures, and post-processing validation. This critical review aims to provide researchers and practitioners with comprehensive, state-of-the-art insights into LCR, facilitating the identification of current strengths and limitations when applied to agricultural machinery. Furthermore, it seeks to accelerate the maturation and enhancement of technology readiness levels, thereby promoting the transition of LCR technologies from laboratory-scale research to industrial-scale applications.

2. Damage Types of Metallic Components and Conventional Remanufacturing Methods

The operational lifespan of agricultural machinery is fundamentally limited by progressive material degradation occurring under complex field conditions. This section provides a systematic examination of the primary failure modes—wear, corrosion, and fatigue—that are predominant in equipment deterioration. Importantly, it establishes a comparative framework that contrasts conventional repair methods with emerging laser cladding technology, assessing their respective effectiveness in restoring both structural integrity and functional performance. The analysis offers critical insights for the development of precision restoration strategies specifically tailored to agricultural applications.

2.1. The Main Failure Mechanisms of Metallic Components

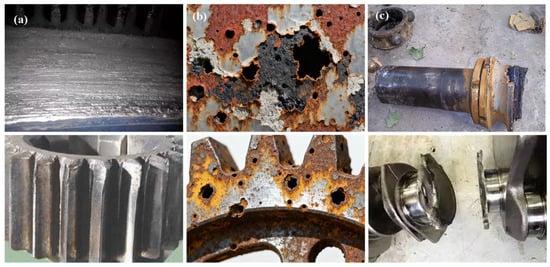

Agricultural machinery components are continuously exposed to erosive conditions in their operating environments, resulting in predictable degradation patterns. The three most prevalent and significant damage mechanisms—friction-induced wear, metal corrosion, and metal fatigue—are shown in Figure 1, which presents classic schematic representations of these failure modes.

Figure 1.

Typical damage types of metallic components. (a) Friction and wear, (b) corrosion, (c) fatigue fracture.

2.1.1. Wear

Metal wear is a predominant failure mode in agricultural machinery and tools characterized by the gradual loss of material from contacting surfaces of friction pairs under operational loads. Based on the underlying mechanisms and the evolution of surface morphology, abrasive metal wear typically progresses through three distinct stages: the initial running-in stage, the steady-state wear stage, and the severe wear stage. During the running-in stage, surface asperities resulting from manufacturing processes are gradually removed. The subsequent steady-state wear stage is marked by relatively constant wear rate and extended duration, during which components generally operate stably—representing normal service conditions. In contrast, the severe wear stage is associated with pronounced surface irregularities, leading to rapid deterioration in geometric dimensions, dimensional accuracy, and surface quality of metallic agricultural components, potentially compromising equipment safety and functionality. The severe wear stage remains the primary concern in current wear-related agricultural machinery issues [14,15,16].

As exemplified by an experimental study on the wear behavior of metal components induced by plant-derived abrasives in agricultural environments, C.J. Yang et al. [17] conducted comparative wear tests on 45 steel under the influence of alfalfa, corn, and wheat abrasives using a rubber wheel abrasive wear tester. Scanning electron microscopy (SEM) analysis of the worn surfaces revealed distinct wear mechanisms: wheat abrasives primarily caused abrasive polishing, whereas corn abrasives led to a combination of abrasive polishing and adhesive wear. Due to their sharp edges, alfalfa abrasives induced significant micro-cutting and intense adhesive wear. The severity of wear followed the following order: alfalfa > corn > wheat.

Consequently, wear failure in soil-engaging components is particularly severe. To predict the service life of components based on wear models, a widely accepted analytical tool—the Archard wear model—can be employed. The model is expressed as V = K × (FN × L)/H, where V denotes the wear volume, FN the normal load, L the sliding distance, H the material hardness, and K the dimensionless wear coefficient.

Building upon this theoretical framework, Z.P. Su et al. [18] investigated the wear and fracture mechanisms of curved nail teeth used in film recovery machines. Through simulated soil abrasion tests combined with scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS), they evaluated three materials: 45 steel, 60Si2Mn, and 40Cr. The results demonstrated that 60Si2Mn spring steel exhibited superior wear resistance, characterized by the lowest surface roughness and wear depth, with fracture surfaces displaying a typical dimple morphology indicative of ductile fracture. Furthermore, research by X.B. Zheng et al. [19] showed that a WC-Ni brazed coating containing 50 wt% WC significantly enhanced the durability of soil-engaging components. This optimized coating achieves synergistic improvements in hardness (1206 HV20), toughness, and corrosion resistance, reducing the wear rate by more than 90% compared to 65Mn steel.

In summary, agricultural machinery operates under extremely harsh conditions, where friction-induced wear readily leads to component degradation, making it a critical factor influencing equipment reliability and service life.

2.1.2. Corrosion

Corrosion of metallic materials in agricultural machinery is a progressive degradation process driven by chemical or electrochemical reactions with environmental media. This phenomenon not only alters the physicochemical properties of materials but also leads to performance deterioration and structural failure. Common forms of corrosion include chemical corrosion, electrochemical corrosion, and microbiologically influenced corrosion (MIC), among which electrochemical corrosion is the most prevalent. During this process, localized regions of metal undergo gradual erosion through electrochemical reactions, thereby compromising material strength. Prolonged exposure may result in functional degradation of metallic components or entire structures, potentially culminating in catastrophic failure—posing significant risks to operational safety.

The severity of corrosion is particularly pronounced in harsh agricultural environments, significantly reducing equipment service life and compromising safety. J. Tan et al. [4] systematically investigated the microstructure, mechanical properties, corrosion behavior, and lightweight application potential of Cu- and Ce-strengthened Mg2Zn alloys. Their analysis revealed distinct morphological evolution of Ce/Cu-containing phases in as-cast and extruded states. The extruded alloy containing 0.8 wt% Ce and 0.5 wt% Cu exhibited optimal mechanical performance, with a yield strength of 289 MPa, tensile strength of 336 MPa, and elongation of 15.8%. This improvement is attributed to synergistic grain boundary strengthening and precipitation hardening mechanisms. After four-month soil burial tests, localized pitting corrosion and crack initiation were observed, indicating preferential anodic dissolution at Ce/Cu-rich phases. Corrosion rates showed strong dependence on environmental conditions, with values of 2.029, 2.293, 2.133, and 1.986 mg·cm−2·day−1 recorded in paddy, vegetable, orchard, and cornfield soils, respectively.

In response to the widespread and severe corrosion challenges in agricultural environments, the development and application of high-performance protective coatings [20,21,22] have become essential for extending the service life and ensuring the operational safety of agricultural machinery. Coatings serve as critical barriers, either physically isolating the metallic substrate from aggressive environmental agents—such as soil, moisture, agrochemicals, and microorganisms—or electrochemically modifying the corrosion processes. The demanding operational conditions—characterized by abrasion from soil and crop residues, impact loading, chemical exposure to fertilizers and pesticides, and significant thermal cycling—require coatings that provide not only excellent corrosion resistance but also robust adhesion, wear resistance, toughness, and, in some cases, advanced functionalities such as hydrophobicity or self-healing capability.

W. Yang et al. [23] used agricultural fertilizers as corrosive media to investigate failure mechanisms in nickel coatings through electrochemical characterization. Corrosion rates in high-concentration fertilizer solutions were substantially higher than those in 3.5% NaCl environments. The accumulation of primary corrosion products (NiO, NiS, and Ni(OH)2) increased with rising fertilizer concentration. Notably, flocculent layers formed via adsorption of fertilizer components accelerated coating degradation, providing valuable theoretical insights for the design of corrosion-resistant coatings. M.L. Skryabin et al. [24] examined corrosion protection in agricultural vehicles, identifying vulnerable areas—such as fenders, sill beams, chassis, and wheel arches—due to seasonal usage patterns. They emphasized the critical importance of corrosion resistance for body panels and compared the performance of cathodic electrodeposition (cataphoresis) and anodic electrodeposition (anaphoresis) coatings in AVTOVAZ vehicle models, offering practical guidance for optimizing anti-corrosion technologies.

2.1.3. Fatigue

Fatigue failure in metallic materials represents a complex, progressive process of damage accumulation under cyclic loading, ultimately leading to fracture. Foundational work by the German engineer August Wöhler led to the development of the first fatigue testing apparatus and introduced seminal concepts such as the S-N curve and the fatigue limit (σ−1), where S denotes the applied stress amplitude and N represents the number of cycles to failure. The fatigue limit (σ−1) corresponds to the asymptotic stress threshold at which the S-N curve stabilizes with increasing cycle counts. Fatigue mechanisms evolve through four distinct regimes defined by cyclic ranges and associated damage modes: low-cycle fatigue (LCF, <104 cycles), dominated by macroscopic plastic deformation; high-cycle fatigue (HCF, 104–106 cycles), governed by quasi-elastic behavior; very-high-cycle fatigue (VHCF, >106 cycles), driven by micro-defect nucleation and propagation; and finally, the crack propagation phase preceding macroscopic fracture. These regimes involve multiscale damage evolution, including dislocation slip [25,26], microvoid nucleation [27,28], and crack initiation [29,30].

Traditional fatigue theories exhibit significant limitations in predicting VHCF behavior, and modeling complexity increases considerably under multiaxial loading conditions combined with harsh service environments—such as exposure to corrosive media, elevated temperatures, and impact loads—posing substantial challenges for accurate fatigue life assessment. In the context of agricultural machinery reliability, I.S. Hwang et al. [5] conducted quantitative evaluations of electric multi-functional tractors using in situ strain field measurements during off-road operations. Their integrated methodology, combining von Mises stress simulations, rainflow counting [31], and Palmgren–Miner rule analysis, revealed structural safety factors exceeding 1.5 and minimum fatigue lives of 124,176 service years (calculated based on 29.7 annual operating hours and a 5-year design life) for critical components such as chassis connectors and drive shafts under plowing and rotary tillage conditions. These results confirm exceptional long-term operational reliability and establish a quantitative basis for structural optimization through load spectrum–stress-field–life chain analysis.

To address inherent limitations in assessing complex loading modes such as compression–shear coupling, W. Jing et al. [32] developed a novel fatigue testing methodology for rotating machinery based on impact load mechanics. Their approach establishes dynamic correlations between impact-induced yield torque and damage progression, validated through multiaxial testing of Q235 steel specimens. Experimental results showed a 23.7% reduction in 3D surface topography height, an increase in surface roughness (Sₐ) from 0.82 μm to 2.15 μm, and a 2.8-fold rise in dislocation density within damaged zones after cyclic loading. This method enables high-reliability steel life prediction with less than 8% error, representing a significant improvement in accuracy for complex multiaxial fatigue conditions compared to existing empirical approaches. It thus provides a transformative pathway for evaluating multiaxial fatigue performance in rotating components.

2.2. Conventional Remanufacturing Methods for Damaged Metallic Components

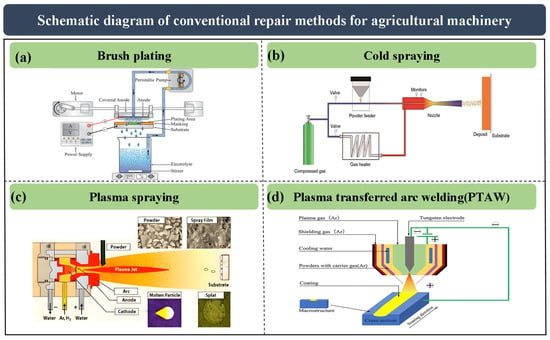

Established surface engineering techniques for repairing damaged agricultural machinery include electroplating/brush plating, cold spray, plasma spraying (PS), and plasma-transferred arc welding (PTAW). These methods offer distinct advantages in addressing wear, corrosion, and fatigue failures, with detailed descriptions provided in the following subsections. Corresponding schematic illustrations are presented in Figure 2.

2.2.1. Electroplating and Brush Plating

Electroplating techniques [33], primarily involving the deposition of chromium and steel, produce metallic coatings under electrolytic conditions (15–105 °C). These processes effectively preserve substrate properties while achieving interfacial bonding strengths exceeding 200 MPa. However, a significant reduction in ductility—by 15–30% per 10 μm thickness increment—occurs due to progressive internal stress accumulation during deposition.

Brush plating (also known as contact plating) [34,35,36], a versatile and portable electroplating method, operates at ambient to moderately elevated temperatures (10–70 °C). This technique enables precise deposition of metallic coatings (e.g., nickel, cobalt, and their composites) onto localized areas without requiring component disassembly. It achieves high interfacial bonding strengths ranging from 150 to 300 MPa and is widely recognized for its rapid deposition rates, often an order of magnitude faster than conventional tank plating. However, the inherently high current densities and mass transfer limitations can result in coarse grain structures and elevated internal stresses. Consequently, a ductility reduction of 20–35% per 10 μm thickness increment is commonly observed, which may restrict its applicability in scenarios requiring thick, crack-resistant coatings.

Technological advancement has been demonstrated by emerging hybrid processes: laser-textured copper plating enhances the strength of brazed joints in 304 stainless steel by 40% [37]. For titanium porous transport layers (Ti-PTLs) in proton exchange membrane electrolyzers, a sequential process involving electrochemical etching (removing 3.2 μm of TiO2 barrier layer), pulse electrodeposition of gold underlayers, and dynamic gold plating at 50 rpm enables complete penetration throughout Au/Ti felt substrates. This integrated approach reduces the operational voltage by 124 mV at 2.0 A·cm−2 compared to conventional static deposition [38], with degradation mechanisms analyzed using custom flow cells incorporating 3D-printed bipolar plates.

2.2.2. Cold Spray

Cold spray technology [39,40,41] utilizes a high-pressure gas stream to accelerate powdered metallic or ceramic feedstock materials to supersonic velocities. Upon impact with the target substrate, these solid particles undergo severe plastic deformation and form a dense coating primarily through mechanical interlocking. This mechanism enables the restoration of components degraded by wear or corrosion. Crucially, particle temperatures remain significantly below the material’s melting point during deposition. This characteristic minimizes thermally induced detrimental effects such as phase transformations, oxidation, and residual stresses, thereby preserving the intrinsic properties of the base material.

As a solid-state deposition process, cold spray technology offers distinct advantages for structural repair applications. Unlike thermal spray techniques, deposition occurs through the high-velocity impact (500–1200 m/s) of solid particles without bulk melting. This eliminates substrate heat-affected zones (HAZ) and associated phase transformations, making the technique particularly suitable for thermally sensitive components. Bond strengths in repaired regions typically reach 300–400 MPa. However, broader industrial adoption remains limited by three primary factors: high equipment costs—particularly those related to high-pressure gas supply systems—moderate deposition rates (5–20 kg/h), and insufficiently developed adaptive processing strategies for components with complex curved geometries [42].

To improve deposition efficiency, A. Astarita et al. [43] developed an innovative magnet-assisted cold spray variant optimized for the deposition of ferromagnetic particles. Concurrently, R. Jones et al. [44] established critical durability assessment criteria for cold-spray-repaired military aircraft components made from 7075 and 6061 aluminum alloys. Their methodology requires quantitative evaluation of both inherent microcrack propagation at the coating–substrate interface and crack evolution near coating termination zones. This dual-path assessment provides a foundation for developing a comprehensive multi-site cooperative damage evolution model.

2.2.3. Plasma Spraying (PS)

Plasma arc is an advanced heat source characterized by ultra-high temperatures (>10,000 °C), high energy density, minimal heat-affected zone, and exceptional stability. Its controllable parameters—such as temperature, arc length, diameter, and impact force—enable precise process modulation [45,46,47]. In plasma spraying (PS), a non-transferred arc is initiated, typically through high-frequency current, between the cathode (rear electrode) and the anode (nozzle). The injected gas (e.g., Ar/N2 mixture) absorbs energy and ionizes to form plasma. Subsequent recombination of ions and electrons releases intense thermal energy, melting refractory metal or ceramic powders into fine molten droplets that are accelerated to high velocities (300–600 m/s). Upon impingement onto a pre-roughened substrate, these particles undergo severe plastic deformation, forming a thin functional coating primarily through mechanical interlocking, supplemented by physical bonding. The resulting coating exhibits moderate adhesion strength (30–70 MPa), low porosity (<5%), and broad material adaptability, making it suitable for aerospace thermal barrier coatings and wear protection in agricultural machinery [48,49].

S. Karoonboonyanan et al. [48] evaluated thermal spray coatings for rotary tiller blades operating in sandy soil conditions. HVOF-sprayed WC/Co coatings reduced the wear rate to 0.02 cm3/ha, compared to 0.86 cm3/ha for uncoated blades, demonstrating a 43-fold improvement in wear resistance. In contrast, plasma-sprayed Al2O3-TiO2/NiAl coatings exhibited higher wear (0.90 cm3/ha) due to spallation, confirming the superior performance of WC/Co. For a 50-hectare seasonal cultivation cycle, blade replacements decreased from 58 to 1.3 instances, significantly reducing maintenance costs. W. Zhu et al. [49] deposited FeNiCrAl-B4C and FeNiCrAl-B4C-TiB2 coatings onto Q235 steel using high-velocity arc spraying (HVAS). Orthogonal optimization results showed that TiB2 addition reduced porosity to 3.27%, increased hardness by approximately 70%, and enhanced wear resistance by a factor of 1.8 relative to the B4C-free coating. The dominant wear mechanism was brittle fracture, further verifying the reinforcing effect of TiB2.

2.2.4. Plasma Transferred Arc Welding (PTAW)

Plasma transferred arc welding (PTAW) [50,51,52] utilizes a transferred argon plasma arc (up to 15,000 °C) to melt alloy powders, forming a metallurgically bonded coating. Unlike plasma-sprayed (PS) coatings that rely on mechanical interlocking, PTAW achieves full fusion: powders are heated to molten or semi-molten states within the arc column and subsequently deposited into a molten pool on the substrate. This process produces dense, shallow-penetration cladding layers with exceptional adhesion strength (200–400 MPa), making them highly resistant to spallation under high stress. The technique is particularly suitable for wear and corrosion protection of agricultural machinery components—such as cutters and gears—that require robust interfacial bonding.

X.Z. Li et al. [53] addressed the short service life of crop shredder blades by applying flame spray welding of NiWC alloy onto 45# steel. Orthogonal experiments combined with ANOVA identified optimal processing parameters: 65% Ni60 + 35% WC, preheating at 450 °C, acetylene (C2H2) flow rate of 1000 L/h, and spray distance of 40 mm. H.F. Wang et al. [54] fabricated Ni60-SiC functionally graded coatings on W6Mo5Cr4V2 forging dies using PTAW. The composite containing 30% SiC and 70% Ni60 exhibited optimal performance: microhardness reached 1100 HV (three times higher than the substrate), along with significantly improved thermal conductivity and thermal fatigue resistance. Comparative analysis confirmed the superiority of PTAW over conventional spraying-remelting processes, achieving metallurgical bonding, low interfacial porosity (<3%), and coating thicknesses of 0.5–1.2 mm suitable for high-impact applications.

Figure 2.

Conventional remanufacturing methods for agricultural machinery. (a) Brush plating schematic. Reprinted from Ref. [55], (b) cold spraying schematic. Reprinted from Ref. [56], (c) plasma spraying schematic. Reprinted from Ref. [57], (d) lasma transferred arc welding (PTAW) schematic. Reprinted with permission from ref. [58].

2.3. Characteristics and Advantages of Laser Cladding Technology

Laser cladding (LC) technology is an advanced surface modification technique in which a high-energy-density laser beam melts the deposited material and a thin layer of the substrate, resulting in a metallurgically bonded coating through rapid solidification. This process significantly improves the substrate’s wear resistance, corrosion resistance, thermal stability, and oxidation resistance. In recent years, global adoption of laser cladding has expanded considerably, with market demand projected to grow at a compound annual growth rate (CAGR) of 8.7% from 2020 to 2025. Compared to conventional methods—such as hard chromium plating, thermal spraying, and weld overlaying—laser cladding offers superior processing efficiency (with deposition rates up to 1.2 kg/h) and enhanced environmental compatibility, including zero emissions of hexavalent chromium [59].

As summarized in Table 1, the technical evaluation of additive manufacturing (AM) technologies for agricultural machinery repair identifies laser cladding (LC) as the most versatile solution, combining precision engineering with superior mechanical performance. While electroplating and brush plating offer nanometer-scale surface finishes (Ra 1–20 μm), their limited coating thickness (≤0.3 mm) and low adhesion strength restrict applications to non-structural corrosion protection [60,61]. Cold spray enables thicker coatings (0.1–5.0 mm) without thermal distortion but suffers from high porosity (>5% void content) and moderate bonding strength (<80 MPa) [62,63]. Plasma spraying achieves moderate coating thicknesses (0.05–0.5 mm) with acceptable wear resistance, though it requires energy-intensive post-machining due to inherent surface roughness (Ra 20–100 μm) [45,64]. Plasma-transferred arc welding (PTAW) allows for high-deposition-rate restoration of thick layers (1–10 mm) but at the expense of severe thermal deformation (>10% dimensional change) and coarse microstructures in heat-affected zones (HAZ > 500 μm) [65,66]. In contrast, LC uniquely balances controlled deposition thickness (0.1–5.0 mm), minimal thermal distortion (<2% dimensional deviation), and tunable dilution rates (1–40%) through precise modulation of laser parameters. Its metallurgical bonding (350–700 MPa) and fine-grained microstructure (HAZ: 20–150 μm) surpass the mechanical or intermittent bonding mechanisms of alternative techniques, while achieving functional surface finishes (Ra 10–50 μm) that often eliminate the need for post-processing. These attributes render LC particularly suitable for high-value agricultural components such as precision gear teeth—requiring <30 μm runout tolerance—and combine harvester knife edges—demanding >50 HRC hardness with impact toughness—where competing technologies fail to meet simultaneous requirements for geometric accuracy, wear resistance, and fatigue life extension.

Table 1.

Critical process parameters of restoration techniques.

2.4. Remanufacturing Demand of Agricultural Machinery

Amid global resource constraints and escalating environmental challenges [67,68,69], agricultural machinery remanufacturing aligns with international and national policies promoting resource recycling, component remanufacturing, and end-of-life equipment recovery. High-quality remanufactured machinery extends service life and enhances functionality through the application of green technologies, thereby fulfilling both policy objectives and societal demands. As a circular economy model [70,71,72], agricultural equipment remanufacturing delivers significant economic benefits. Given the cost sensitivity of agricultural producers, this market possesses substantial growth potential. Compared to new equipment manufacturing, remanufacturing significantly reduces resource waste and environmental pollution, effectively mitigating the excessive consumption of metals, coal, and other energy resources.

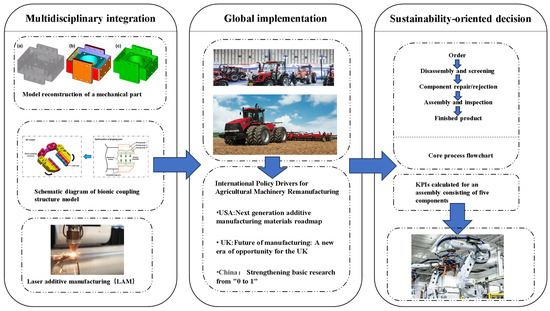

3. Laser Additive Remanufacturing of Metallic Components in Agricultural Machinery

Laser additive manufacturing (LAM), also known as Laser Metal Deposition (LMD) [73,74,75,76], originated from Laser Engineered Net Shaping (LENS™), a technology developed at Sandia National Laboratories in the Albuquerque, NM, USA [77]. Despite variations in nomenclature, the underlying principle remains consistent: LMD encompasses a set of technical methods for repairing locally damaged metal components based on laser cladding methodologies. Recent policy initiatives have elevated LMD to a prominent position within advanced materials processing. Strategic frameworks adopted by major nations are summarized in Table 2.

Table 2.

National/regional strategies and policies on laser remanufacturing technologies and industries.

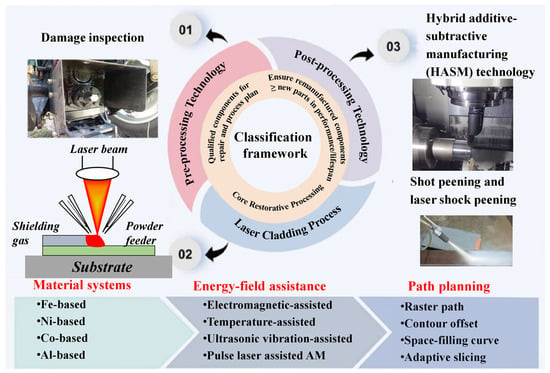

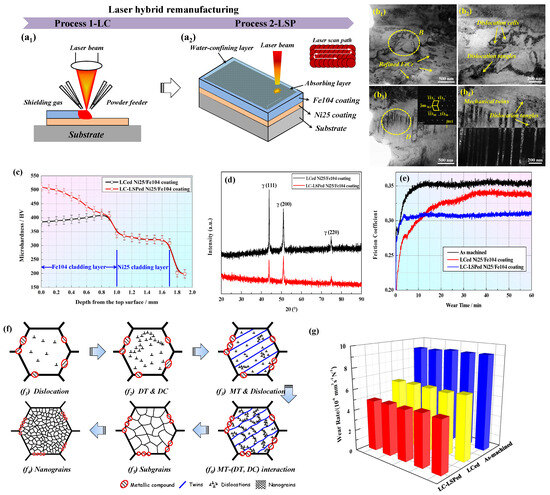

Laser additive remanufacturing constitutes a critical technology for the restoration and reengineering of mechanical components. The process is systematically divided into three sequential stages. The pre-processing phase focuses on comprehensive damage assessment to determine component repairability and suitability for subsequent laser-based repair operations. Following qualification, the core restorative processing stage is dominated by laser cladding technology. This technique employs focused laser energy to precisely deposit clad material onto the substrate through fusion, enabling dimensional restoration of worn or corroded surfaces while simultaneously enhancing their performance characteristics. Finally, post-processing technologies are applied to optimize the surface integrity and functional properties of the restored component. This stage typically involves laser shock peening, which generates beneficial residual compressive stresses via laser-induced shock waves, thereby significantly improving fatigue resistance and surface hardness, as well as laser polishing to selectively remove micro-asperities and reduce surface roughness, enhancing both aesthetic and functional quality. This integrated classification framework for laser remanufacturing is illustrated in Figure 3.

Figure 3.

Classification framework for laser remanufacturing. Reprinted with permission from refs. [78,79,80,81].

3.1. Pre-Processing: Remanufacturing Assessment of Metallic Components

Remanufacturability assessment [82,83,84,85,86] constitutes a pivotal link in the agricultural machinery remanufacturing value chain. This process critically evaluates the capability of end-of-life components to meet required performance standards under specified technical, economic, and environmental constraints, using advanced remanufacturing technologies to determine their inherent remanufacturing value. To address the industrial need for a standardized methodology, we propose an integrated assessment framework based on a weighted scoring model. The framework decomposes the evaluation into three core dimensions, with weights reflecting their relative importance in industrial decision-making: technical feasibility (50%), economic viability (30%), and environmental impact (20%).

Technical feasibility assesses the physical condition and restorability of core components. Key quantifiable indicators include remaining service life estimated through wear models or non-destructive testing, damage severity scored according to the extent of cracks, corrosion, or deformation, and geometric precision loss measured against Original Equipment Manufacturer (OEM) tolerances. Economic viability evaluates the profitability potential of remanufacturing operations by calculating the cost–benefit ratio between total remanufacturing cost and the market value of the remanufactured part, while also considering return on investment, including payback period and profit margin. The environmental impact dimension quantifies ecological benefits by comparing carbon emissions from remanufacturing and new manufacturing processes to assess emission reductions, and by calculating the percentage of raw materials saved through core reuse to measure material conservation.

The overall remanufacturability score (R) is calculated using the formula R = (TS × 0.5) + (ES1 × 0.3) + (ES2 × 0.2), where TS is the technical score, ES1 is the economic score, and ES2 is the environmental score.

Based on the final score, components are classified into distinct decision categories: Priority Remanufacturing (R ≥ 80), Conditionally Feasible (60 ≤ R < 80), or Not Recommended (R < 60). This standardized methodology provides remanufacturers with a clear, data-driven decision-making tool, enabling efficient resource allocation and robust justification for remanufacturing investments.

3.1.1. Candidate Metallic Components

As the remanufacturing industry evolves, the range of mechanical equipment involved continues to expand, encompassing various electromechanical products such as machine tools, agricultural engineering machinery, turbine engine impellers, and crankshafts. The inherent characteristics of agricultural machinery equipment (AM equipment in China Agricultural University, Beijing, China) significantly influence its remanufacturability. Key factors include service conditions, damage characteristics, failure mechanisms, and performance assessment methods, as detailed in Table 3.

Table 3.

Characteristics and implications of remanufacturability for agricultural machinery and equipment.

3.1.2. Fundamental Criteria for Remanufacturability

Fundamental remanufacturability criteria constitute the essential conditions that determine whether an item can be remanufactured. Analysis of extensive remanufacturing case studies reveals that end-of-life electromechanical products must meet specific requirements to be viable candidates for remanufacturing. These criteria are summarized in Table 4.

Table 4.

Condition criteria and their implications for agricultural machinery remanufacturability.

3.1.3. Evaluation Standards of Laser Additive Remanufacturing Technology

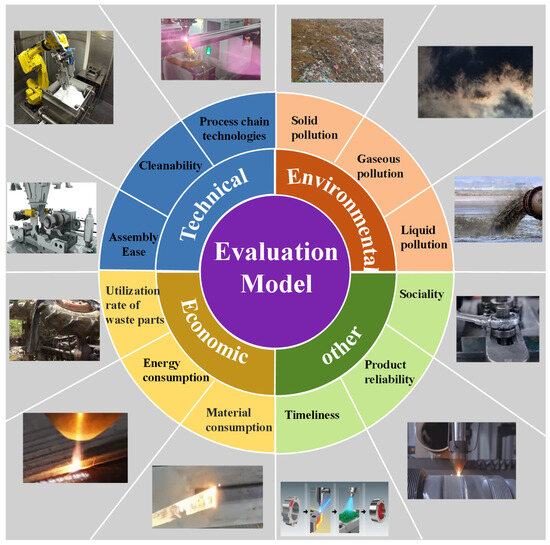

Assessment of remanufacturability during the remanufacturing process [87,88,89] is not an isolated activity, but rather a complex, multidisciplinary challenge. It integrates multiple objectives across different levels and dimensions, involving fields such as mechanical engineering, materials science, economics, and environmental science. Numerous factors influence the remanufacturability of equipment, among which technical feasibility, eco-nomic viability, and environmental impact are the most critical dimensions, as illustrated in Figure 4.

Figure 4.

Factors influencing the remanufacturability of agricultural machinery.

Technical feasibility primarily concerns the difficulty, efficiency, and viability of process chain technologies such as disassembly, cleaning, reprocessing (e.g., laser-based restoration), and reassembly. Economic viability encompasses the cost–benefit relationship within the remanufacturing process, involving factors such as the profit margin of remanufactured products, energy and material consumption, utilization rate of end-of-life core components, processing costs, product profitability, operational and administrative expenses, and pollution control or abatement costs. Environmental impact (green performance) is assessed through metrics related to resource conservation (energy and materials) and the quantification of pollution levels generated throughout the entire life cycle of remanufacturing. Additional considerations include social factors, product reliability, and timeliness.

3.2. Laser Caldding Process: Materials Systems, Process Optimization, and Path Planning

Laser remanufacturing technology, as a key component of modern advanced manufacturing, demonstrates unique advantages and substantial application potential in the field of remanufacturing. Components inevitably experience damage such as wear and corrosion during prolonged service. This technology employs a high-energy-density laser beam to perform precision repair and enhance the performance of damaged components, thereby extending equipment service life and reducing production costs—developments that are of significant importance for promoting sustainable development in the mechanical industry.

The remanufacturing process is achieved by melting specific materials under the action of a laser beam, forming a sound metallurgical bond with the substrate material to accomplish component repair and remanufacturing. In practical applications, this technology not only restores the dimensional accuracy of agricultural machinery components but also significantly enhances their surface properties, such as wear resistance and corrosion resistance, effectively addressing challenges that are difficult to resolve using conventional remanufacturing techniques.

The following sections will first present the system classifications and process types of laser cladding technology. Subsequently, the core aspects of laser remanufacturing technology will be discussed from three key perspectives: material system research, energy-field assistance, and emerging intelligent technologies.

3.2.1. The Principle of Laser Cladding Technology

Based on material delivery mechanisms, laser additive remanufacturing processes are categorized into pre-placed and synchronous methods. Pre-placed cladding (also known as two-step laser deposition) involves positioning the material onto the repair zone prior to laser scanning, resulting in a metallurgically bonded structure. Synchronous cladding, which is more commonly employed, comprises powder-fed and wire-fed subtypes. Powder-fed systems are further classified into coaxial or off-axis delivery configurations, with coaxial systems subdivided into inside-beam and conventional designs. Wire-fed systems include cold-wire and hot-wire variants, as illustrated in Figure 5.

Figure 5.

(a) Pre-placed coating method, (b) synchronous powder-feeding method, (c) detailed classification of deposition techniques.

Pre-placed laser deposition technology involves depositing preprocessed powder onto the substrate surface, which is subsequently melted by laser scanning to achieve metallurgical bonding. The process includes substrate surface preparation, powder pre-placement, pre-heating, laser scanning, and post-process heat treatment. W.G. Jiru et al. [90] conducted CO2 laser surface alloying of pre-placed Cu/Mn/Mg powders on industrial-purity aluminum. Through parameter optimization (laser power, scan speed, and spot diameter), they achieved a significant increase in microhardness from 30 HV0.5 in the base material to 430 HV0.5 in the alloyed zone, compared to 60 HV0.5 in the heat-affected zone. While the treatment enhanced corrosion resistance, it resulted in slight reductions in tensile strength and elongation. Metallographic analysis revealed dense microstructures, validating this approach for lightweight metal surface enhancement, although the observed trade-offs between hardness and mechanical properties require careful balancing. Separately, Y. Yong et al. [91] integrated molten pool vision monitoring with ANSYS (https://www.ansys.com/, accessed on 18 September 2017) Parametric Design Language (APDL) thermal modeling. Their study showed that clad tracks exhibited crescent-shaped cross-sections, with visual measurements closely matching thermal simulations—demonstrating less than 8% error in pool dimensions. They established quantitative correlations showing that increased scan speed reduced pool area, width, length, and dilution rate by 15–30%, while increased laser power raised these parameters by 20–40%. Additionally, increasing powder thickness enlarged pool dimensions but decreased dilution by approximately 12% per 0.2 mm increment, providing valuable guidelines for process optimization.

Powder-fed synchronous deposition utilizes a high-energy laser beam to form a molten pool while simultaneously delivering powder via carrier gas through a nozzle. The relative motion between the nozzle and substrate generates the clad layer, with common configurations including coaxial powder feeding (featuring concentric material-laser alignment) and off-axis powder feeding (employing angular material delivery). This method offers distinct advantages, including high automation potential, precise control, and improved laser energy utilization. When combined with coaxial shielding gas, it effectively prevents oxidation of the melt pool and produces superior surface morphology, making synchronous powder deposition the predominant choice for industrial applications. W. Fan et al. [92] demonstrated that synchronous induction-assisted laser deposition (SILD), with alternating heating modes, significantly reduced cooling rates at the β-transus of Ti-6Al-4V from 82 °C/s to 23 °C/s.

The quality and uniformity of the powder deposition process constitute a fundamental challenge across powder-based additive manufacturing technologies. This is critically evident in powder bed fusion (PBF), where the quality of the spread powder layer directly determines part density. S.Z. Ajabshir et al. [93] provided a quantitative analysis of this phenomenon, employing a Discrete Element Method (DEM) model to elucidate the interplay between spreading parameters and powder layer quality. Their findings demonstrate that elevated spreading speeds exacerbate particle inertia and shear stress, culminating in particle ejection and a reduced packing fraction, while increased temperature intensifies inter-particle cohesion, promoting aggregate formation. These insights, though derived from the PBF process, have significant implications for laser cladding. The dynamics of high-speed powder spreading are analogous to the challenges of achieving a stable melt pool at high powder feed rates in laser cladding, where excessive momentum can lead to spatter and defects. Furthermore, temperature-dependent cohesivity underscores the complexity of powder flow dynamics in scenarios involving substrate preheating. This comparative analysis enhances the understanding of powder behavior, highlighting that while laser cladding—as a directed energy deposition technique—offers superior adaptability for large-scale component repair, PBF provides distinct advantages in fabricating components with intricate internal architectures.

3.2.2. Material System of Laser Cladding for Damaged Metallic Components

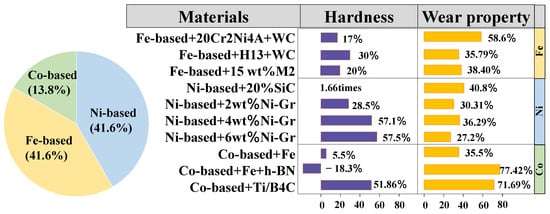

The selection of laser cladding materials serves as the primary determinant of both the microstructure and properties of the cladding layer. Iron-based, nickel-based, and cobalt-based self-fluxing alloys, representing the most prevalent types of alloy materials, find extensive application in this field. The performance optimization of these fundamental alloy systems primarily revolves around two core strategies. The first involves the incorporation of high-hardness reinforcing particles, such as tungsten carbide (WC) and titanium carbide (TiC), which aim to significantly enhance the hardness, wear resistance, and corrosion resistance of the clad layer. The second strategy employs powder mixing technology to introduce additional alloying elements or compounds. This approach modifies the metallurgical reactions and solidification behavior within the melt pool, thereby refining the microstructure of the clad layer, reducing crack susceptibility, and achieving a synergistic improvement in both strength and toughness. As shown in Figure 6, this section summarizes several major materials and their performance improvement data.

Figure 6.

The reconstruction in tensile properties of different material systems. Adapted from Refs. [94,95]. Reprinted with permission from [96,97,98].

Fe-based self-fluxing alloys can be easily processed, exhibit high hardness, and offer the lowest cost, but possess poor corrosion resistance. Regarding reinforcement phases for iron-based alloys, X. Yang et al. [99] developed an in situ autogenous ceramic phase-reinforced laser cladding layer containing vanadium (V) and titanium (Ti) to improve the surface properties of rolls in the iron and steel metallurgy industry. Their study evaluated the effect of V and Ti content on the microstructure, hardness, shear properties, and high-temperature wear behavior of the clad layer. The results indicated that with increasing V and Ti content, the precipitated TiC and VC ceramic phases increased within grains and along grain boundaries, with their morphology transitioning from spherical to polygonal. Concurrently, grain refinement was observed, and the microhardness improved significantly. However, the weak bonding strength between large-sized carbides and the matrix led to a degradation in shear properties. The clad layer with 5% V and Ti content exhibited optimal wear resistance, demonstrating a more than 21-fold improvement and over a 2-fold improvement compared to the layer without V and Ti at room temperature and 600 °C, respectively.

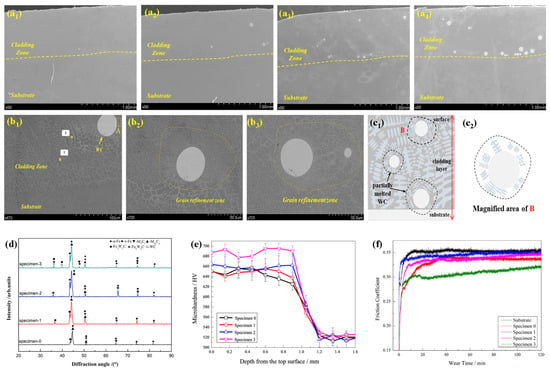

J.Z. Lu et al. [95] systematically modulated the hard phase and alloy elements, validating a toughening design method for iron-based coatings. By utilizing a multi-scale synergistic effect, they introduced tungsten carbide (WC) particles, which significantly enhanced the surface properties of H13 steel. After adding WC, only the periphery of the particles melted, while the unmelted core served as a hard reinforcing phase. As the WC content increased, Fe3W3C and Fe6W6C phases gradually formed in the coating. Compared to the coating containing 3% WC, the wear rate of the coating with 9% WC was reduced by 35.79%. The mechanism by which WC particles influence microstructural evolution is illustrated in Figure 7: WC enhances coating properties through solid solution strengthening, grain refinement strengthening, and dispersion strengthening. Controlling the WC content (e.g., at 9 wt%) enables the preparation of iron-based coatings with high hardness and excellent wear resistance, providing an effective solution for the surface strengthening of H13 die steel.

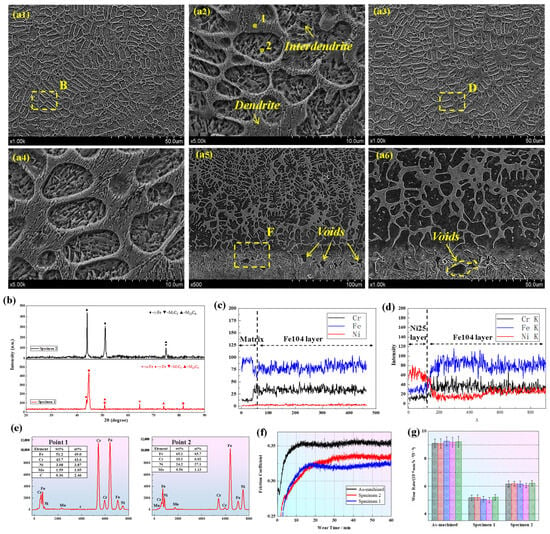

Figure 7.

(a1–a4) Cross-sectional morphologies of Fe-based coatings with different WC content, (b1–b3) typical SEM images of different regions, (c1,c2) influence mechanism of WC particles on the microstructural evolution, (d) XRD spectra for four types of Fe-based coatings, (e) in-depth microhardness distributions, (f) friction coefficient curves. Reprinted with permission from ref. [95].

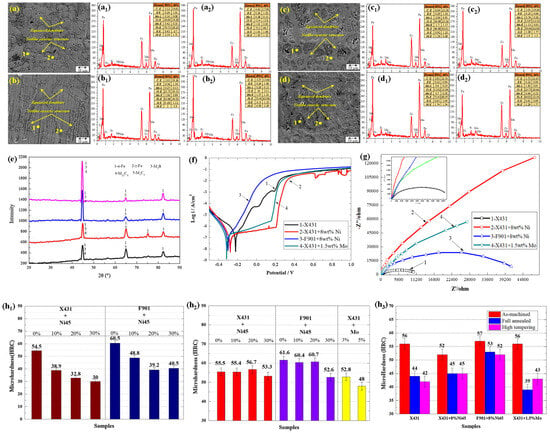

X. Xu et al. [100] fabricated four types of multi-layer iron-based composite coatings on 4Cr5MoSiV1 steel using a 4 kW continuous-wave fiber laser system (YLS-4000, IPG, New York, NY, USA). They systematically investigated the microstructure, mechanical properties, and corrosion resistance through optical microscopy (OM), scanning electron microscopy (SEM), energy dispersive spectroscopy (EDS), X-ray diffraction (XRD), microhardness testing, impact toughness testing, and electrochemical corrosion testing (as shown in Figure 8). They discovered that the coating prepared by adding 8 wt% of Ni45 to X431 powder exhibited a balanced combination of satisfactory hardness (close to that of the substrate), high impact toughness, and excellent corrosion resistance. This provides an effective solution for surface strengthening of 4Cr5MoSiV1 steel.

Figure 8.

Typical SEM images of four Fe-based coatings and EDS results of corresponding elements (a) X431, (b) X431 + 8 wt% Ni45, (c) F901 + 8 wt% Ni45, (d) X431 + 1.5 wt% Mo, (a1–d2): respectively corresponding to (a–d) in (1,2) element energy spectrum (EDS) analysis results. (e) XRD pattern analysis of four Fe-based coatings, (f) potentiodynamic polarization curves of four Fe-based coatings immersed in 3.5 wt. % NaCl solution at room temperature, (g) typical Nyquist plots of four Fe-based coatings immersed in 3.5 wt. % NaCl solution at room temperature, (h1) two Fe-based coatings+Ni45, (h2) two Fe-based coatings +Ni45/Mo, (h3) four Fe-based coatings under different heat treatment conditions. Reprinted with permission from ref. [100].

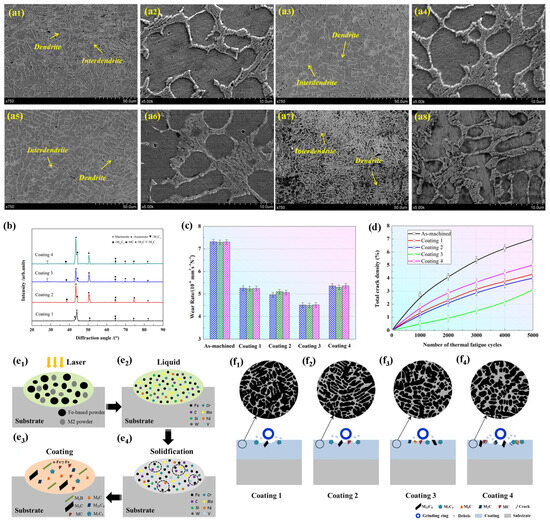

H.F. Lu et al. [96] prepared four types of Fe-based coatings on H13 hot-work die steel (extrusion punches and plate specimens) using an IPG fiber laser system (maximum power 4 kW, wavelength 980 nm). The effects of M2 powder content on the phase composition, microstructure, mechanical properties, wear resistance, and thermal fatigue life of the coatings were systematically studied through XRD, OM, SEM, transmission electron microscopy (TEM), electron probe microanalysis (EPMA), microhardness testing, tensile testing, dry sliding wear testing, and thermal fatigue testing. As shown in Figure 9, the Fe-based coating prepared by adding 15 wt% M2 powder to Fe104 powder exhibited high hardness, excellent wear resistance, and the longest thermal fatigue life for H13 extrusion dies. This provides an optimized formulation and technical support for the laser additive remanufacturing of H13 molds.

Figure 9.

(a1–a8) Typical SEM images of Fe-based coatings with different M2 content, (b) XRD results for four types of Fe-based coatings, (c) wear rate comparisons, (d) crack density as a function of thermal fatigue cycle, (e1–e4) diagram illustration for LC process of Fe-based coatings, (f1–f4) action mechanism of different M2 contents on wear performance of Fe-based coatings. Reprinted with permission from ref. [96].

Nickel-based alloys exhibit excellent self-fluxing properties and high toughness, demonstrating superior overall performance. Consequently, they are commonly employed for aero-engine blade repair and corrosion protection in marine equipment. In the study of reinforcement phases for Ni-based materials, Y. Zhao et al. [101] investigated (W,Ti)C-reinforced Ni-based coatings fabricated by laser cladding on 316L steel. It was found that the decomposition of (W,Ti)C promoted the formation of dense MC and M23C6 carbides, leading to microstructural refinement and a transition in grain morphology. Consequently, wear resistance was significantly enhanced with increasing (W,Ti)C content, as evidenced by a reduced friction coefficient and lower wear loss. However, electrochemical tests revealed a trade-off: corrosion resistance in a sulfur-containing chloride environment deteriorated, whereas it initially decreased and then improved in a pure chloride solution. W. Cui et al. [102] developed a modified nickel-based composite coating via laser cladding, utilizing in situ synthesized TiC–TiB2 ceramic phases from TA0, B4C, and Ni-coated graphite. The study found that increasing the content of Ni-coated graphite raised the C/Ti ratio, which reduced the nucleation rate and ultimately led to larger ceramic phase sizes. The coating with 3 wt% B4C and 8 wt% Ni-coated graphite exhibited optimal performance, showing a 26.47% reduction in wear volume due to a change in wear mechanism. Furthermore, the best-performing coating demonstrated a 39% increase in corrosion potential and a reduction in corrosion current density by over an order of magnitude, which was attributed to ceramic particles blocking corrosion channels. This work provides theoretical guidance for fabricating high-performance Ni-based coatings. Z. Li et al. [103] introduced the alloying element Ti as a crack mitigation strategy. It was found that with a 3 wt% Ti addition, cracks were effectively eliminated, resulting in optimal coating morphology and properties. The improvement was attributed to the in situ formation of TiC/TiWC2 phases, which dispersed localized stresses and refined the microstructure by reducing the area of brittle secondary phases. However, the trade-off was an increased dilution rate and reduced coating strength. The research demonstrates that adjusting Ti content can effectively control microstructure and mitigate macroscopic defects.

Regarding the study of Fe-Ni composite coatings, K.N. Xue et al. [104] prepared two types of coatings on H13 tool steel using an IPG YLS-4000 ytterbium fiber laser system (maximum power: 4 kW, wavelength: 980 nm). The influence of a Ni25 transition layer on the phase composition, microstructure, hardness, and wear resistance of the Fe104 layer was systematically investigated through XRD, OM, SEM, TEM, EDS, microhardness testing, and dry sliding wear tests. As shown in Figure 10, the results indicated that no significant defects were observed at the interface between the Fe104 and Ni25 layers. The average hardness of both the Fe104 layer and the Ni25 transition layer was higher than that of the substrate (198 HV0.2). In terms of wear resistance, the wear rate was reduced. The mechanism of the Ni25 transition layer lies in its excellent wettability and fluidity. Although this led to a slight decrease in mechanical properties, the composite coating still met industrial application standards, offering a surface restoration solution for H13 tool steel that balances bonding quality and wear resistance.

Figure 10.

(a1–a6) Typical cross-sectional SEM images of Fe104 coatings, (b) XRD results for two coatings (Fe104, Ni25+Fe104), (c,d) line scanning result of the interdendrites, (e) EDS analysis of the interdendrites, (f) friction coefficient curves, (g) wear rate comparisons. Reprinted with permission from ref. [104].

Cobalt-based alloys demonstrate optimal high-temperature performance along with superior wear and corrosion resistance. Nevertheless, they incur significantly higher costs and pose substantial machining challenges. J.J. Yuan et al. [105] developed SiC-Si3N4-reinforced Co-based composite coatings on carbon steel using laser cladding. When tested in molten 6061 aluminum at 760 °C, the coatings exhibited exceptional resistance, which can be attributed to the dense carbon-based framework and the inherent erosion resistance of the ceramics, which underwent a beneficial structural transformation under high-temperature catalysis. The optimal coating with 4 wt% SiC-Si3N4 demonstrated a remarkable 14.3-fold improvement in corrosion resistance compared to uncoated 45# steel, presenting an effective solution for protecting industrial components.

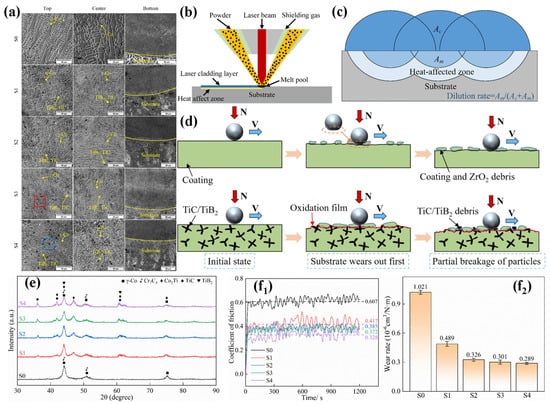

Q. Liang et al. [98] investigated in situ synthesized TiC/TiB2 composite coatings on D2 steel via laser cladding with varying Ti/B4C powder contents. The results demonstrated that the in situ particles significantly refined the grain size and enhanced the microhardness, which peaked at 711.0 HV1.0 with 12% additive content. Wear resistance showed a positive correlation with Ti/B4C content, achieving a maximum reduction in wear rate of 71.69% (as illustrated in Figure 11). While ultimate tensile strength and elongation improved, impact toughness decreased. This work provides a valuable reference for the industrial application of in situ synthesis to enhance the mechanical properties of coatings.

Figure 11.

(a) Microstructure of 0%, 3%, 6%, 9%, 12% Ti/B4C powder added to Co06 powder, among them, the red box and the blue box parts underwent line scan analysis (b) schematic diagram of synchronized powder feeding laser cladding experiment, (c) Dilution rate measurement method, (d) schematic diagram of the coating wear process without and with TiC/TiB2, (e) XRD patterns, (f1) coefficient of friction, (f2) wear rate. Reprinted with permission from ref. [98].

From a practical application standpoint, the selection between Fe-, Ni-, and Co-based alloy systems involves a critical trade-off between performance and cost. Fe-based alloys, as the most economical option, provide a compelling solution for a wide range of applications requiring high hardness and wear resistance, particularly when enhanced with cost-effective reinforcements such as WC or in situ carbides. Their primary limitation in corrosion resistance can be mitigated through composite design, as demonstrated by the addition of Ni45, offering a balanced performance improvement without a significant increase in cost.

Nickel-based alloys, although more expensive, deliver superior comprehensive performance, including excellent toughness and corrosion resistance, justifying their use in critical components such as aero-engine blades and marine equipment. The development of high-performance Ni-based coatings with optimized reinforcement content aims to maximize service life, thereby enhancing long-term cost-effectiveness. Cobalt-based alloys represent the premium tier, with their exceptional high-temperature performance and resistance to extreme environments commanding the highest price. Their use is economically viable only in niche applications where component failure would be catastrophic or where they can substantially extend service life in highly aggressive environments, such as molten metal processing.

Ultimately, the optimal material selection is not merely a technical decision but also an economic one, dependent on a thorough evaluation of the component’s operational requirements, desired service life, and total cost of ownership. Laser cladding offers tailored solutions across this entire spectrum.

3.2.3. Energy-Field-Assisted Laser Cladding for Microstructure Control and Property Improvement

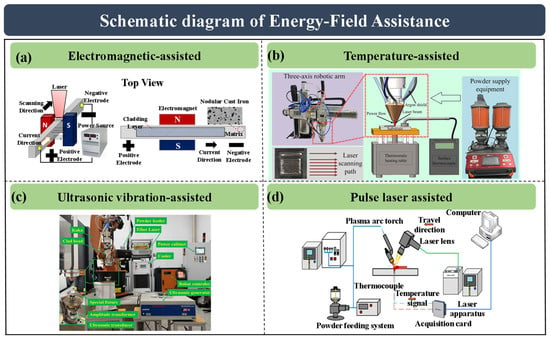

In recent years, laser cladding technology has emerged as a significant research focus. However, clad layers continue to face challenges such as deformation and cracking induced by residual stresses, alongside performance degradation resulting from metallurgical defects, including cracks, pores, and solute segregation. Early research primarily concentrated on optimizing process parameters, characterizing microstructure, and evaluating performance. However, current studies increasingly emphasize precise control over the composition, microstructure, and properties of the cladding layer. Research indicates that applying external physical fields during metal solidification can effectively improve alloy performance. Consequently, auxiliary techniques such as ultrasonic vibration, electromagnetic stirring, and thermal field assistance have been developed for laser cladding. These emerging approaches aim to reduce metallurgical defects and refine the microstructure of the clad layer. The following sections review four established energy field-assisted methods: electromagnetic field assistance, thermal field assistance, ultrasonic vibration assistance, and pulse assistance. The structure is illustrated in Figure 12.

Figure 12.

(a) Electromagnetic-assisted laser cladding. Reprinted with permission from ref. [106], (b) temperature-assisted laser cladding. Reprinted from Ref. [107], (c) ultrasonic vibration-assisted laser cladding. Reprinted from Ref. [108], (d) pulse laser-assisted AM. Reprinted from Ref. [109].

Electromagnetic field-assisted laser cladding synergistically integrates electric and magnetic fields to regulate molten pool dynamics and solidification behavior. The applied electric field leverages electromigration to homogenize elemental distribution and mitigate solute segregation, while Joule heating contributes to grain refinement and electroplasticity enhances material ductility. Concurrently, static or pulsed magnetic fields generate Lorentz forces that suppress columnar crystal growth and facilitate the removal of inclusions, with pulsed fields additionally inducing beneficial compressive residual stresses. It should be noted that magnetic field efficacy may attenuate in high-electrical-conductivity alloys due to eddy current damping effects, whereas electric fields generally maintain effectiveness across varying conductivity ranges. This dual-field approach addresses key metallurgical defects and mechanical limitations through complementary energy-field interactions.

Y.H. Wang et al. [110] investigated the effects of different types and magnitudes of electric fields under a steady magnetic field on the microstructure and properties of laser-cladded Ni-based coatings, focusing on segregation. Using a steady magnetic field with consistent magnitude and direction, along with alternating current (AC) and direct current (DC) electric fields of varying intensities, they prepared dense Ni60 coatings on 45 steel substrates via electromagnetic field-assisted laser cladding. The coatings’ elemental segregation, microstructure, and properties were characterized using optical microscopy (OM), scanning electron microscopy (SEM), X-ray diffraction (XRD), and reciprocating friction and wear testing machines. The study concluded that electromagnetic field-assisted laser cladding significantly reduced both macro- and micro-segregation in the coatings, thereby enhancing their performance. The coatings produced under the AC200 condition exhibited optimal wear resistance and corrosion resistance.

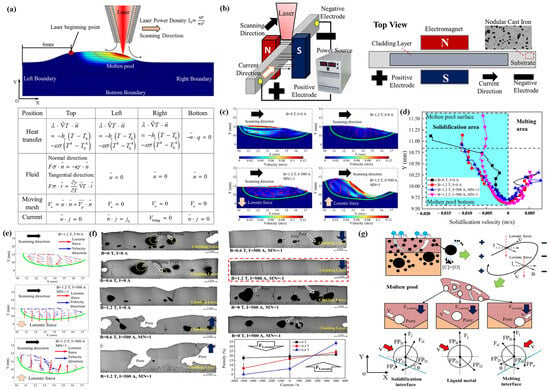

Y. Hu et al. [106] coupled an electromagnetic composite field (ECF) into the laser cladding system to generate a directional Lorentz force in the molten pool. Based on the theory of multi-physics field coupling, a laser cladding molten pool model was proposed, incorporating heat transfer, fluid flow, morphology, buoyancy, surface tension, Lorentz force, and pore movement in the molten pool. It was found that when the current is 500 A and the steady-state magnetic flux density is 1.2 T, a downward Lorentz force is generated, which can effectively increase the escape velocity of pores from the molten pool. Conversely, when the direction of the Lorentz force becomes upward, more pores are trapped within the molten pool. Experimental observations and data confirmed the model predictions (as shown in Figure 13), demonstrating that the escape behavior of pores in the laser cladding molten pool can be effectively controlled by applying the electromagnetic composite field. Owing to the downward Lorentz force, a cladding layer with high density and low porosity was successfully obtained.

Figure 13.

(a) Physical properties of nodular cast iron, (b) schematic of 3D view and top view of ECF laser cladding equipment assembly, (c) velocity distribution, (d) normal direction solidification velocity profiles, (e) Lorentz force distribution, (f) pore distributions in the longitudinal section of the cladding layer fabricated under the EM compound fields with different parameters, (g) schematic of the pores’ reaction mechanism, the Lorentz force analysis, and the pore force analysis in different positions. Reprinted with permission from ref. [106].

Temperature field assistance regulates thermal gradients through auxiliary heating or cooling systems. Controlled substrate preheating reduces cooling rates to mitigate thermal stresses and cracking susceptibility in sensitive alloys, while targeted cooling accelerates solidification at critical zones to refine microstructural features and constrain elemental diffusion. Precision thermal management further enables optimized microstructural architectures, such as directional solidification patterns in wear-resistant coatings, achieving enhanced microstructural control without compromising deposition efficiency. B. Gu et al. [107] employed a temperature field-assisted laser cladding process to deposit CrMnFeCoNi high-entropy alloy coatings on Q345 steel. The results demonstrated that applying a temperature field, particularly at 250 °C, significantly enhanced coating properties. It reduced porosity by over 50%, increased nanoindentation hardness by up to 0.55 GPa, and markedly improved corrosion resistance. The 250 °C coating exhibited a corrosion potential of –0.27 V and a current density of 0.15 μA/cm2, representing an improvement of 0.1 V and a reduction of 1.08 μA/cm2 compared to the room-temperature sample. The enhancement is attributed to improved passive film stability and a reduced pitting nucleation rate. The study concludes that an appropriate temperature field effectively enhances the overall performance of high-entropy alloy coatings.

Ultrasonic vibration assistance transmits high-frequency mechanical energy into the molten pool. Cavitation effects generate localized high-pressure zones that fragment dendritic structures and disperse nucleation sites, promoting equiaxed grain refinement. Simultaneously, acoustic streaming induces vigorous melt convection that homogenizes compositional distribution and improves dispersion of reinforcing particles. This approach concurrently reduces porosity through enhanced bubble migration and degassing mechanisms.

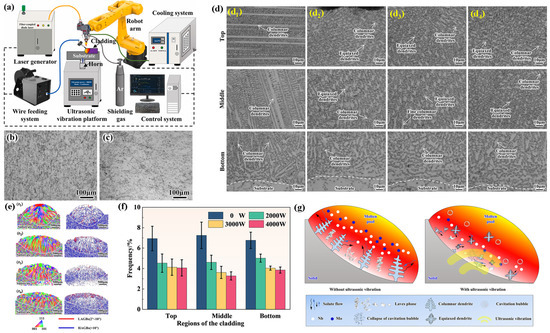

J. Chen et al. [111] explored the application of high-intensity ultrasonic vibration to refine grains and reduce Laves phases. Through experimental analysis, they investigated the mechanism by which ultrasonic vibration affects grain characteristics and inhibits Laves phase formation. As shown in Figure 14, the results indicate that high-intensity ultrasonic vibration promotes the transformation of grains from columnar to equiaxed. The average grain size decreases from 75.6 μm to 48.8 μm, while the volume fraction of Laves phases is reduced by 47.1%, with their morphology changing from elongated strips to fine particles and elemental distribution becoming more uniform. These improvements are attributed to dendrite fragmentation and the suppression of elemental segregation caused by the nonlinear effects of ultrasonic cavitation and acoustic streaming. This study confirms the significant advantages of high-intensity ultrasonic vibration in laser cladding and provides an in-depth understanding of its influence on grain evolution and Laves phase formation.

Figure 14.

(a) Diagram of the experimental setup; (b) substrate; (c) wire; (d) dendritic microstructure of the cladding layers: (d1) without ultrasound, (d2) 2000 W, (d3) 3000 W, (d4) 4000 W; (e) IPF maps and grain boundary maps of cross-section obtained by EBSD: (e1–e4) without ultrasound; with ultrasound of 2000 W, 3000 W, 4000 W; (f) volume fraction of Laves phase with and without ultrasonic vibration; (g) schematic diagram of Laves phase evolution with and without ultrasonic vibration. Reprinted with permission from ref. [111].

Pulse laser-assisted additive manufacturing utilizes intermittent high-energy laser pulses to achieve precise control over thermal history and solidification conditions during additive manufacturing. Pulsed irradiation enables periodic melting and cooling cycles, which effectively modulate the thermal distribution and reduce cumulative heat accumulation. This results in lower thermal stresses, minimized distortion, and suppressed crack initiation. Furthermore, the non-equilibrium solidification induced by pulsed lasers promotes refined grain structures and homogeneous compositional distribution by limiting elemental diffusion and enhancing nucleation rates. This method is particularly advantageous for processing refractory materials, composites, and crack-sensitive alloys, where continuous-wave lasers often lead to undesirable microstructures or defects. B. Fu et al. [112] proposed pulsed laser surface remelting combined with non-resonant vibration-assisted grinding. Leveraging the advantages of pulsed lasers’ high instantaneous energy and rapid cooling rate, a remelted layer was formed to refine silicon particles, thereby improving the machinability of the alloy. This study reveals the underlying mechanisms of pulsed lasers in laser-assisted manufacturing, opening new research avenues for precision, low-damage machining of high-silicon aluminum alloys.

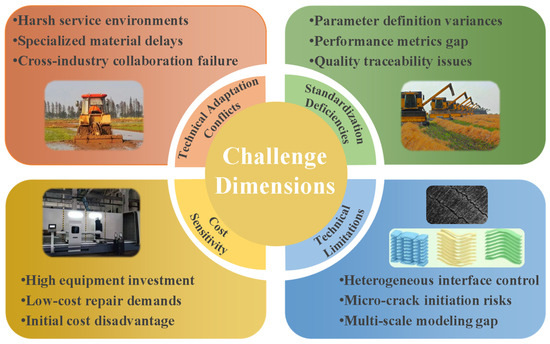

The laboratory successes of these auxiliary energy fields underscore their significant potential for enhancing laser cladding quality. However, their transition to widespread industrial adoption is contingent upon overcoming practical challenges related to cost, complexity, and scalability. Electromagnetic field assistance, while effective, requires substantial investment in power generators and cooling systems, increasing both energy consumption and operational complexity. Ultrasonic vibration faces challenges in efficiently coupling high-frequency energy into large-scale or complex components, with transducer longevity being a concern in continuous industrial operations. Thermal field assistance, particularly preheating, is relatively easier to integrate but incurs ongoing energy costs and extends process cycle times. Pulsed laser assistance demands higher capital investment and precise synchronization, thereby increasing overall process complexity.

Therefore, the selection of an auxiliary field must evolve from a purely technical decision to a holistic techno-economic assessment, balancing performance benefits against associated increases in energy expenditure, system integration effort, and process control requirements. Future research should prioritize the development of more energy-efficient and robust systems, along with comprehensive cost–benefit analyses for specific high-value applications, to bridge the gap between laboratory promise and factory-floor reality.

3.2.4. Path Planning for Geometrical Accuracy and Microstructural Homogeneity

Path planning constitutes a critical determinant of geometric accuracy, microstructural homogeneity, and residual stress distribution in laser cladding processes. The strategic sequencing of deposition trajectories directly governs thermal history and solidification behavior, thereby influencing defect formation mechanisms and final component performance. Conventional path strategies include unidirectional parallel scanning, bidirectional zigzag patterns, and contour-offset approaches, each exhibiting distinct thermal management characteristics. Unidirectional scanning minimizes directional anisotropy but induces progressive heat accumulation at terminal zones, while bidirectional methods mitigate endpoint effects at the cost of alternating thermal gradients. Contour-offset paths excel in dimensional accuracy for complex geometries yet face significant challenges in maintaining consistent inter-track overlap ratios on freeform surfaces, which is crucial for uniform material deposition and avoiding defects such as lack-of-fusion or excessive dilution.

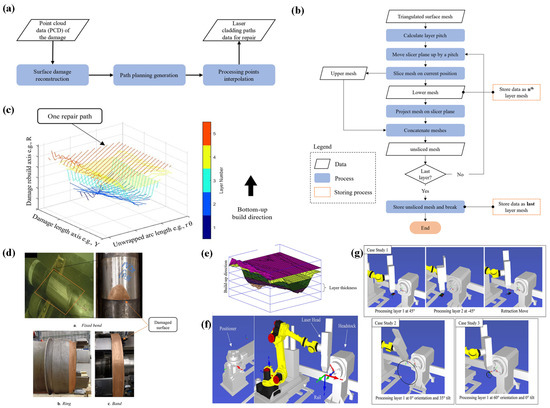

To address the challenge of efficient and geometrically adaptive path planning, particularly for complex geometries, A.M. Hamdan et al. [113] developed a robotic laser cladding path planning method for surface damage repair. Their approach utilized a surface unwrapping technique and Delaunay-based mesh reconstruction to enable layer-by-layer rebuilding. Key innovations include adjustable clad orientation angles for cross-hatching patterns and surface-normal vector control to minimize tool attitude changes. The method achieved a 75% faster path generation speed compared to existing methods and was validated through three industrial case studies (fixed bend, ring, and band damages) with successful simulation in RoboDK 2021, as comprehensively illustrated in Figure 15.

Figure 15.

(a) Overall proposed damage path planning procedure, (b) proposed damaged surface reconstruction method, (c) an example of the cladding paths generated using the proposed algorithm in an unwrapped CYL format, (d) actual case studies, e.g., fixed bend, ring, band, (e) reconstructed damage, (f) virtual robot system in RoboDK software, (g) toolpath simulation in RoboDK. Reprinted with permission from ref. [113].

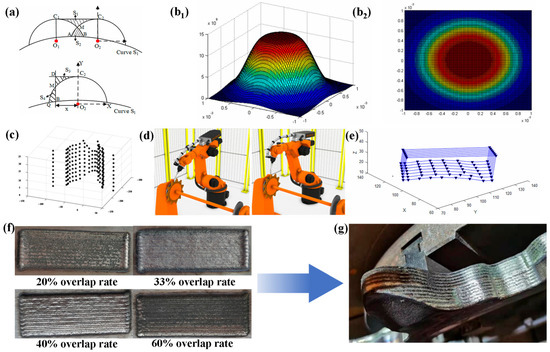

Simultaneously, achieving consistent and optimal overlap between adjacent cladding tracks, particularly on curved surfaces—identified as a critical factor in the first section—is crucial for coating quality and uniformity. To address this challenge, J.D. Liu et al. [114] proposed a strategy for selecting overlap ratios in multi-pass cladding based on key parameters such as surface curvature, mass conservation, and single-track coating profiles. They established a multi-pass overlap model to quantify the relationship between coating morphology and overlap ratio, enabling the determination of optimal track spacing for high-quality coating remanufacturing. To validate the effectiveness of this method, the researchers conducted laser cladding experiments using nickel-based powder on metal gear surfaces (as shown in Figure 16). Comparative results demonstrated that when the optimized overlap ratio was applied, the coating morphology on the gear tooth surfaces was significantly improved, with enhanced geometric accuracy and minimal defects. These findings confirm that the proposed model can effectively predict the optimal overlap ratio, thereby improving the surface quality and structural uniformity of laser-clad coatings on complex curved components such as gears.

Figure 16.

(a) Schematic of a multi-track overlay on a curved surface, (b1,b2) three-dimensional energy distribution diagram of extended top-hat Gaussian light source, (c) path point pose, (d) simulation posture diagram, (e) schematic of a laser head pose, (f) the cladding surface with four different overlap rates, (g) comparison of gear post-coating morphology. Adapted from Ref. [114].

3.3. Post-Processing Technologies

Following the core laser cladding remanufacturing stage, post-processing constitutes the critical final phase in the laser remanufacturing workflow for agricultural machinery components. This stage focuses on optimizing surface integrity, dimensional accuracy, and functional performance characteristics of the repaired parts, ensuring they not only meet but potentially exceed their original specifications. Laser remanufactured components undergo essential post-processing treatments to achieve final dimensional accuracy, surface integrity, and operational reliability. These procedures address inherent challenges including residual stresses, geometric deviations, and microstructural inconsistencies resulting from the laser deposition process.