High-Cycle Fatigue Strength Prediction Model for Ti-6Al-4V Titanium Alloy Compressor Blades Subjected to Foreign Object Damage

Abstract

1. Introduction

2. Materials and Methods

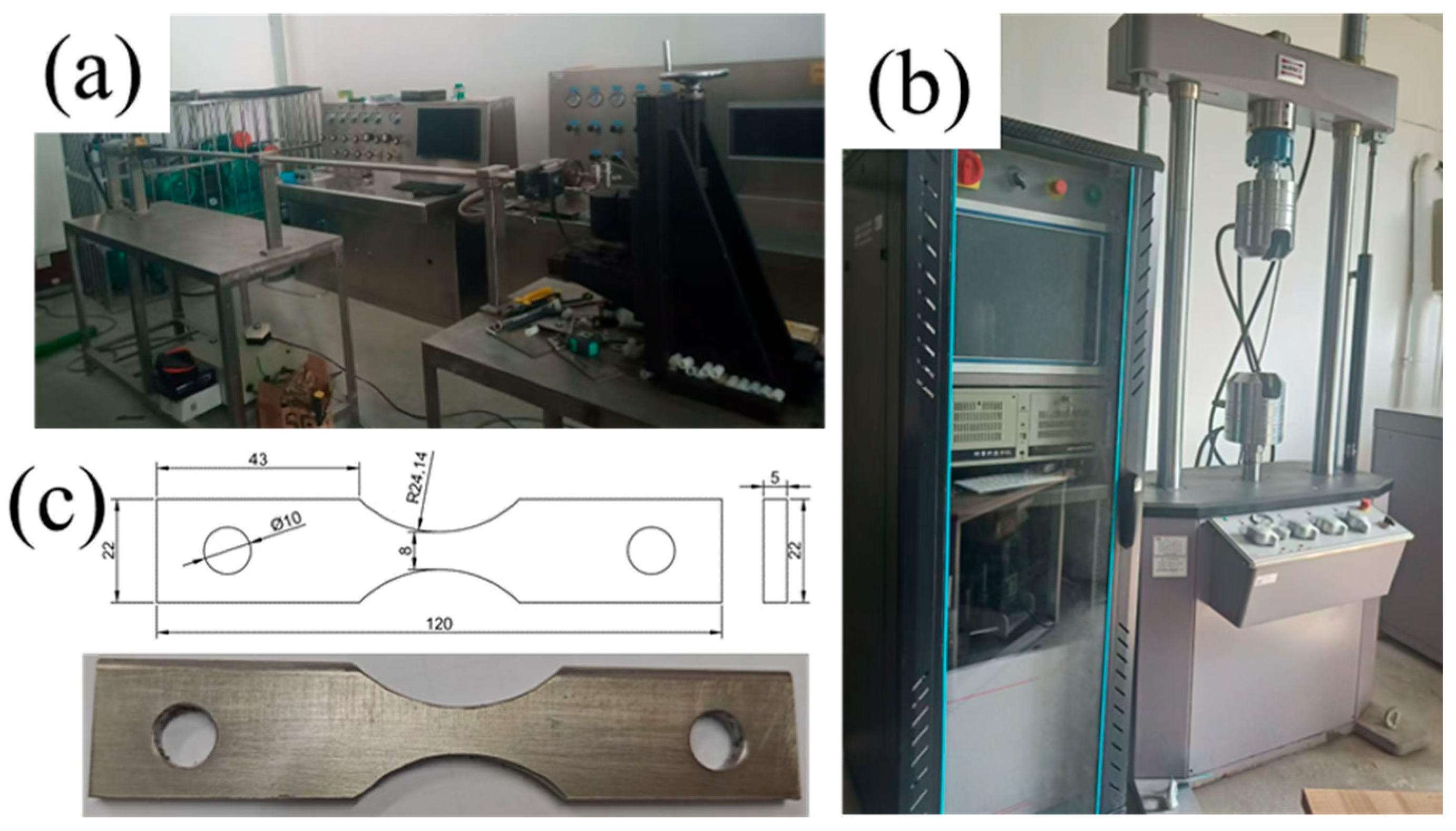

2.1. Material and Equipment

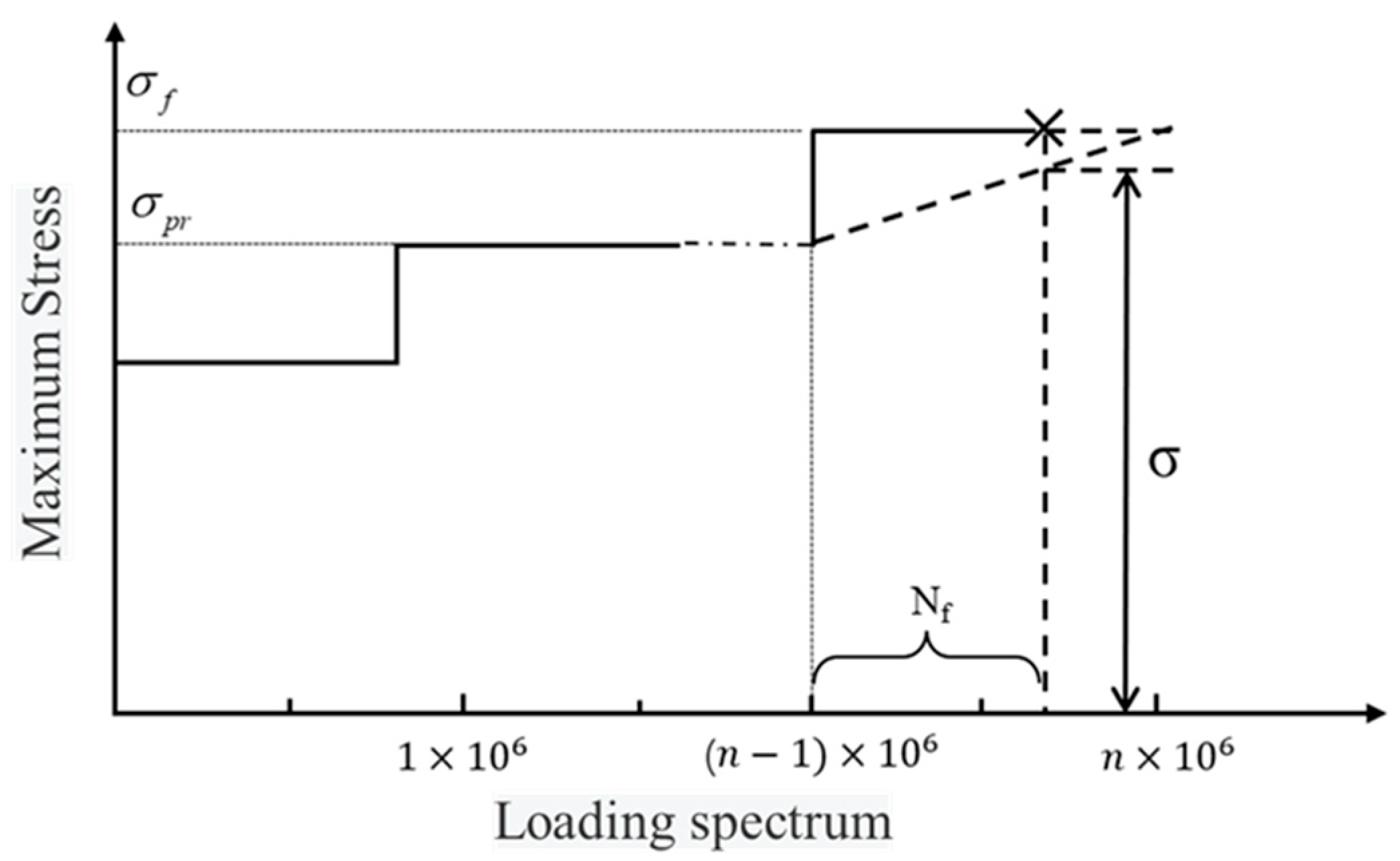

2.2. Experimental Procedure

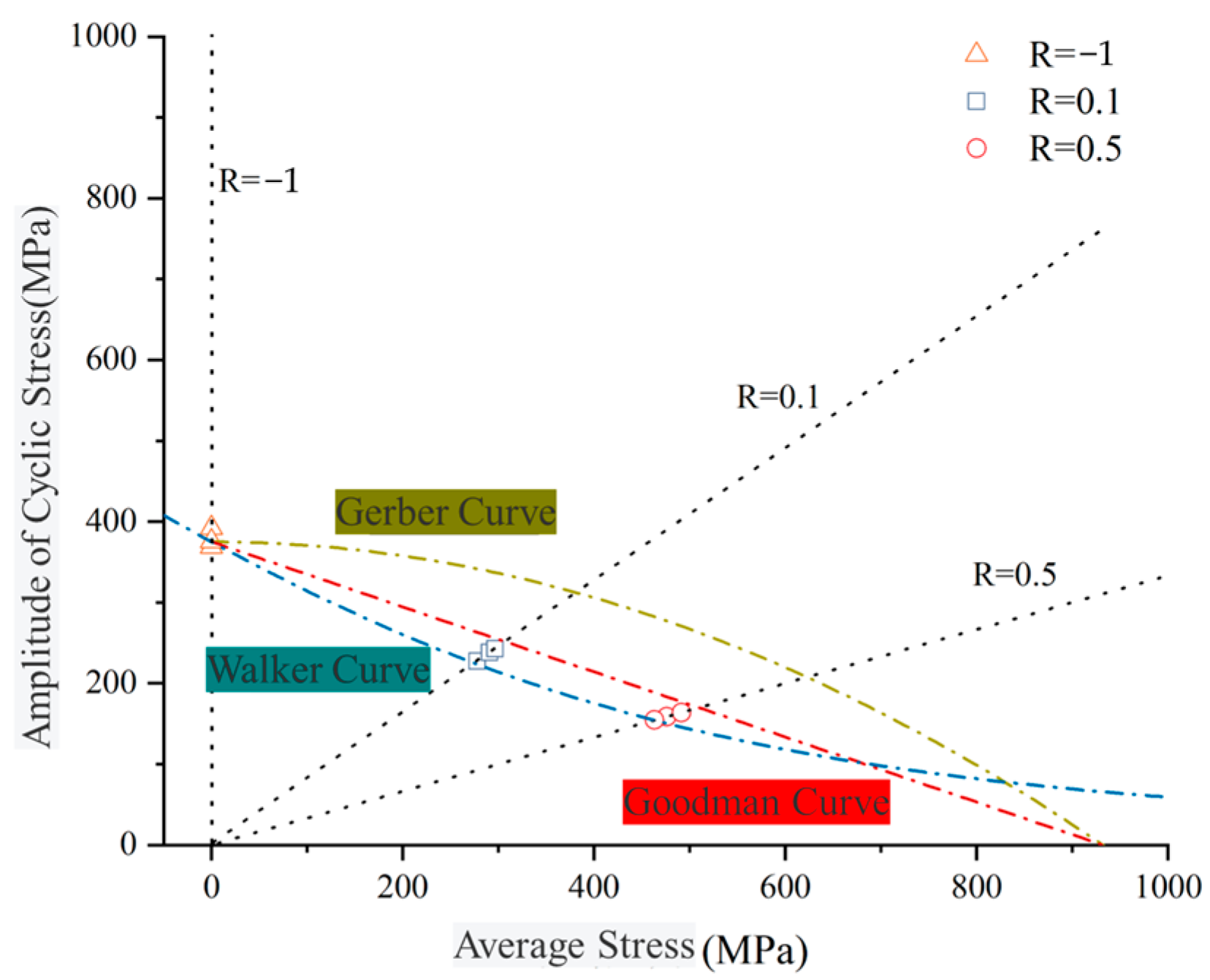

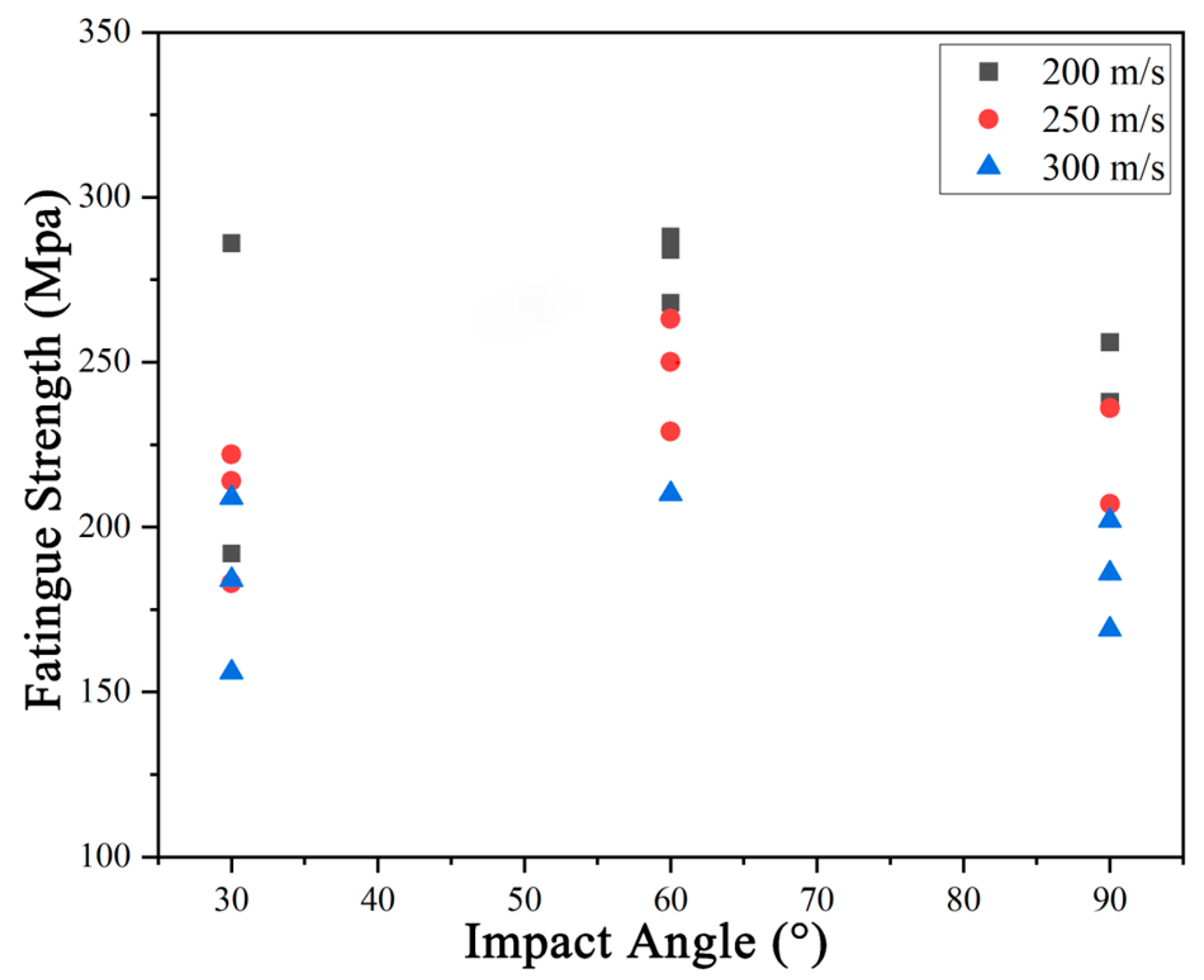

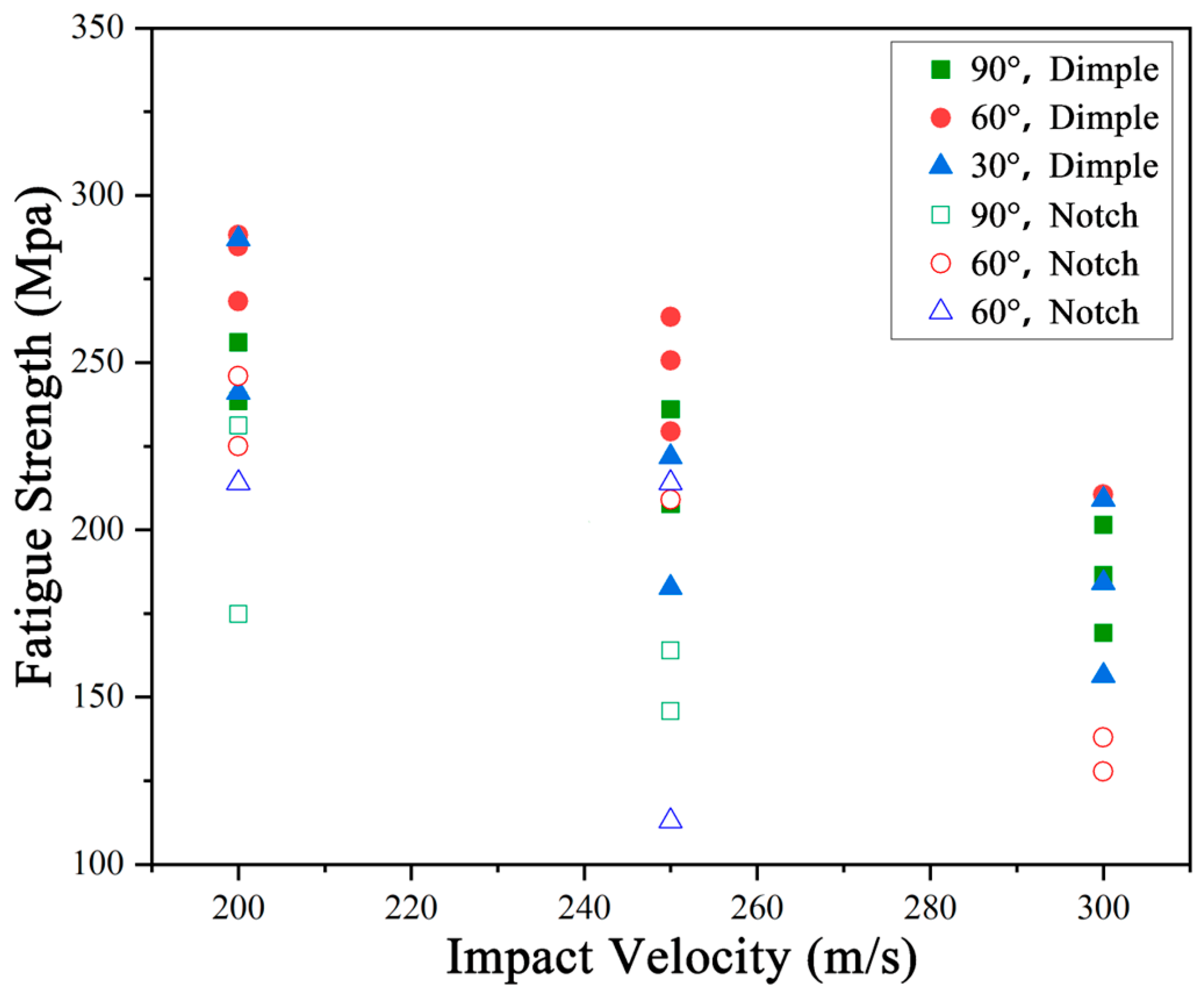

3. Experimental Results and Analysis

4. Improvement of Lifetime Prediction Model

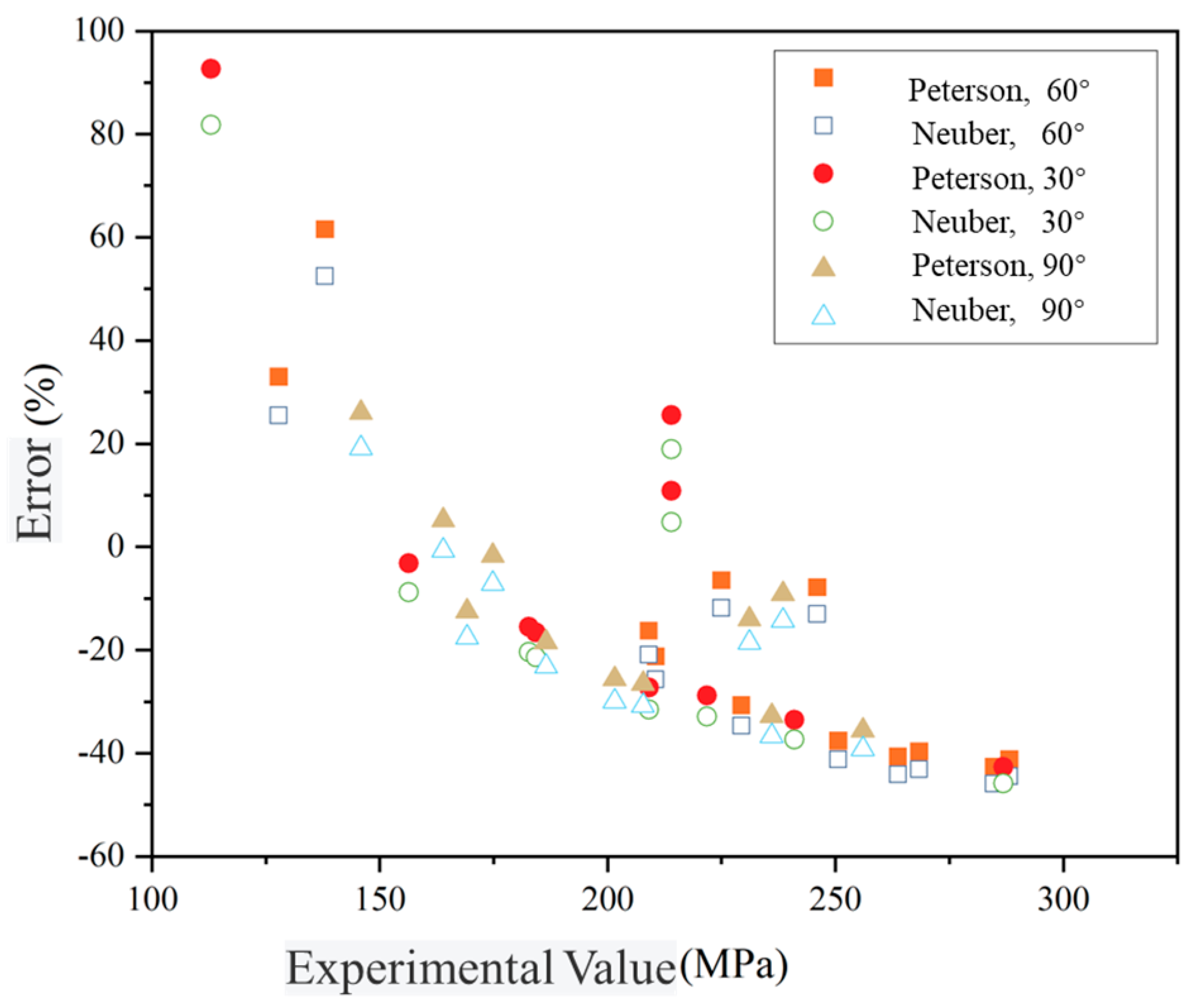

4.1. Prediction and Analysis of High-Cycle Fatigue Strength

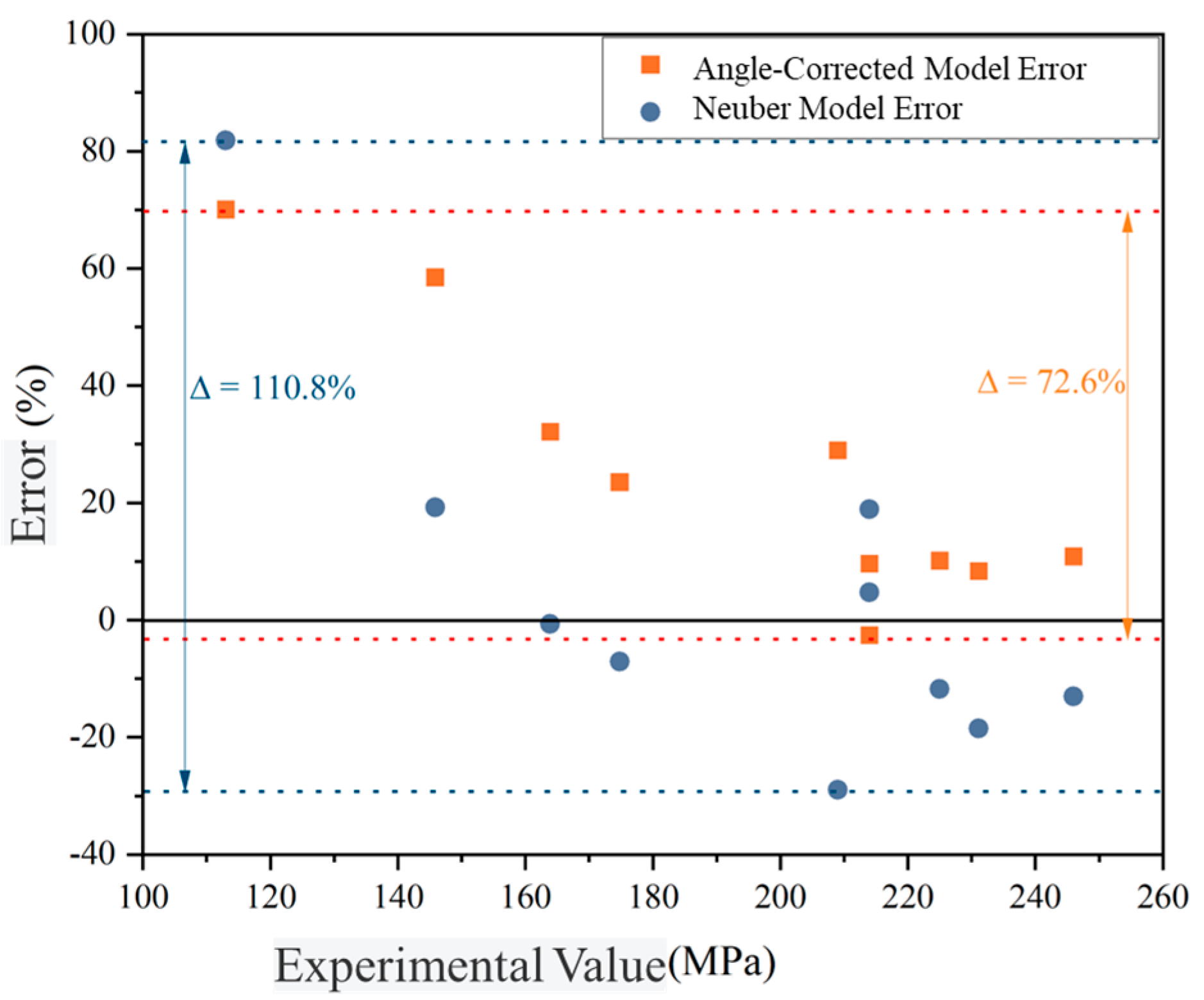

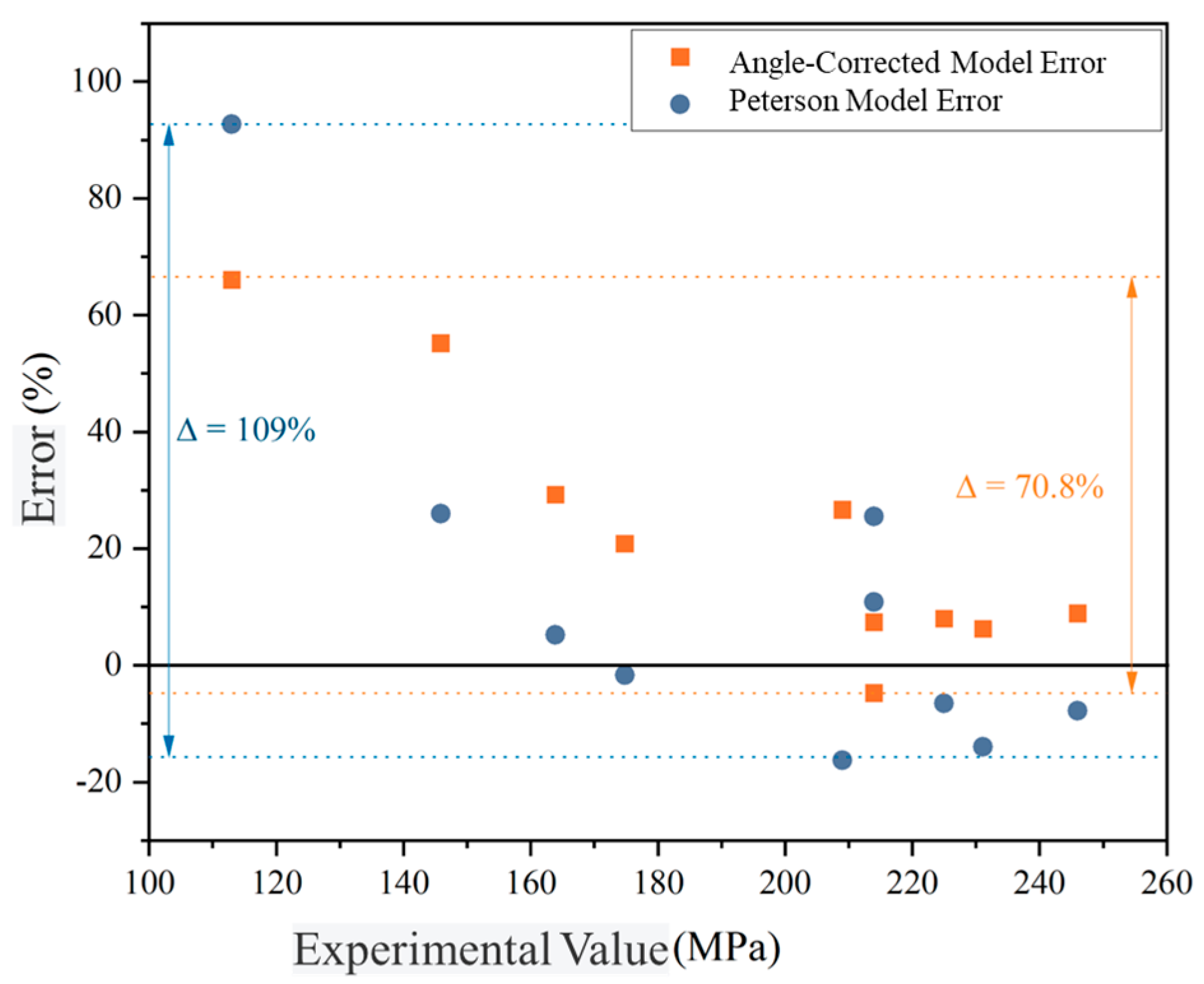

4.2. Shear Factor Adjustment to the Model

4.3. Adjustment for Residual Stress in the Model

5. Discussion

6. Conclusions

- (1)

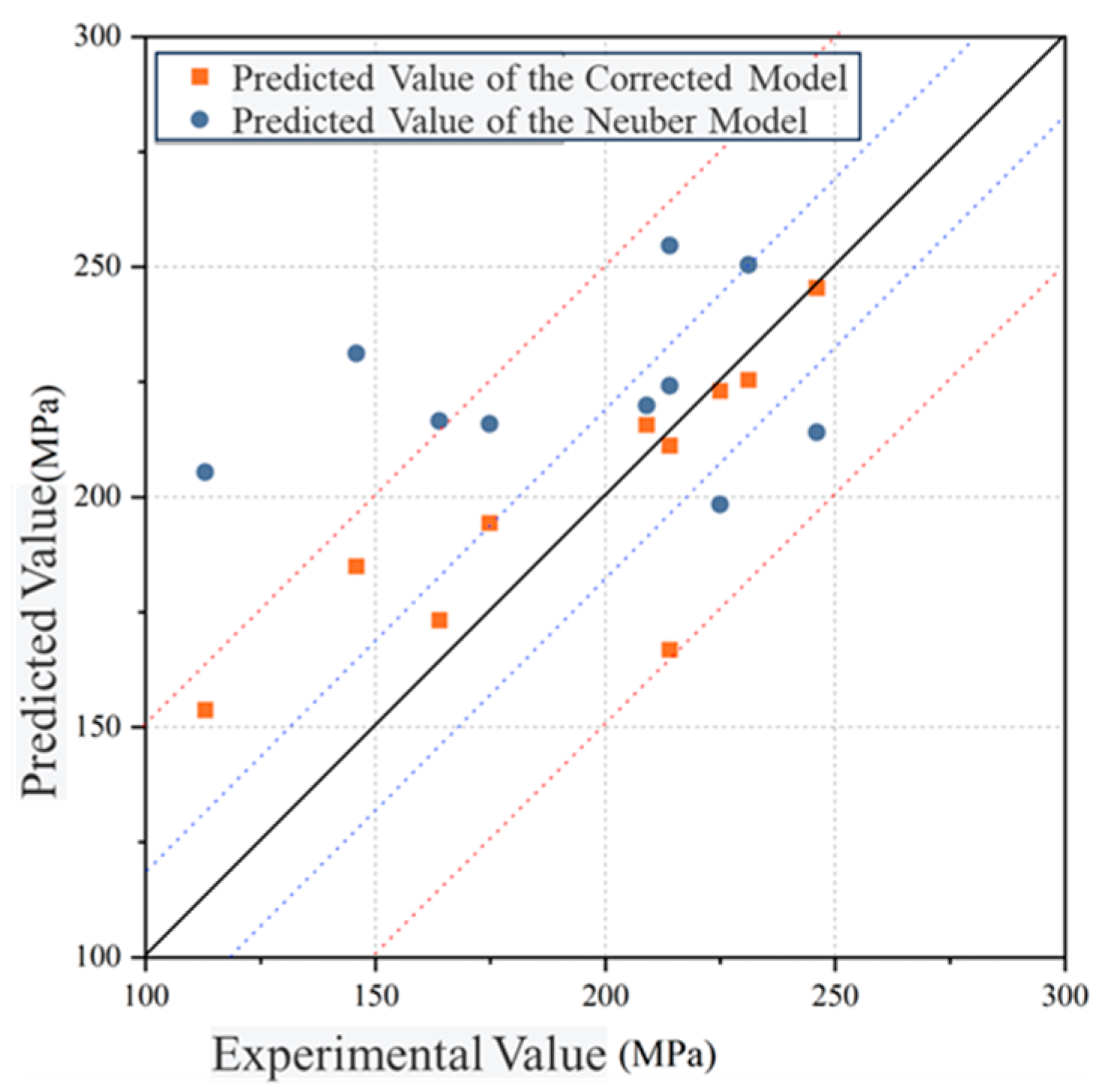

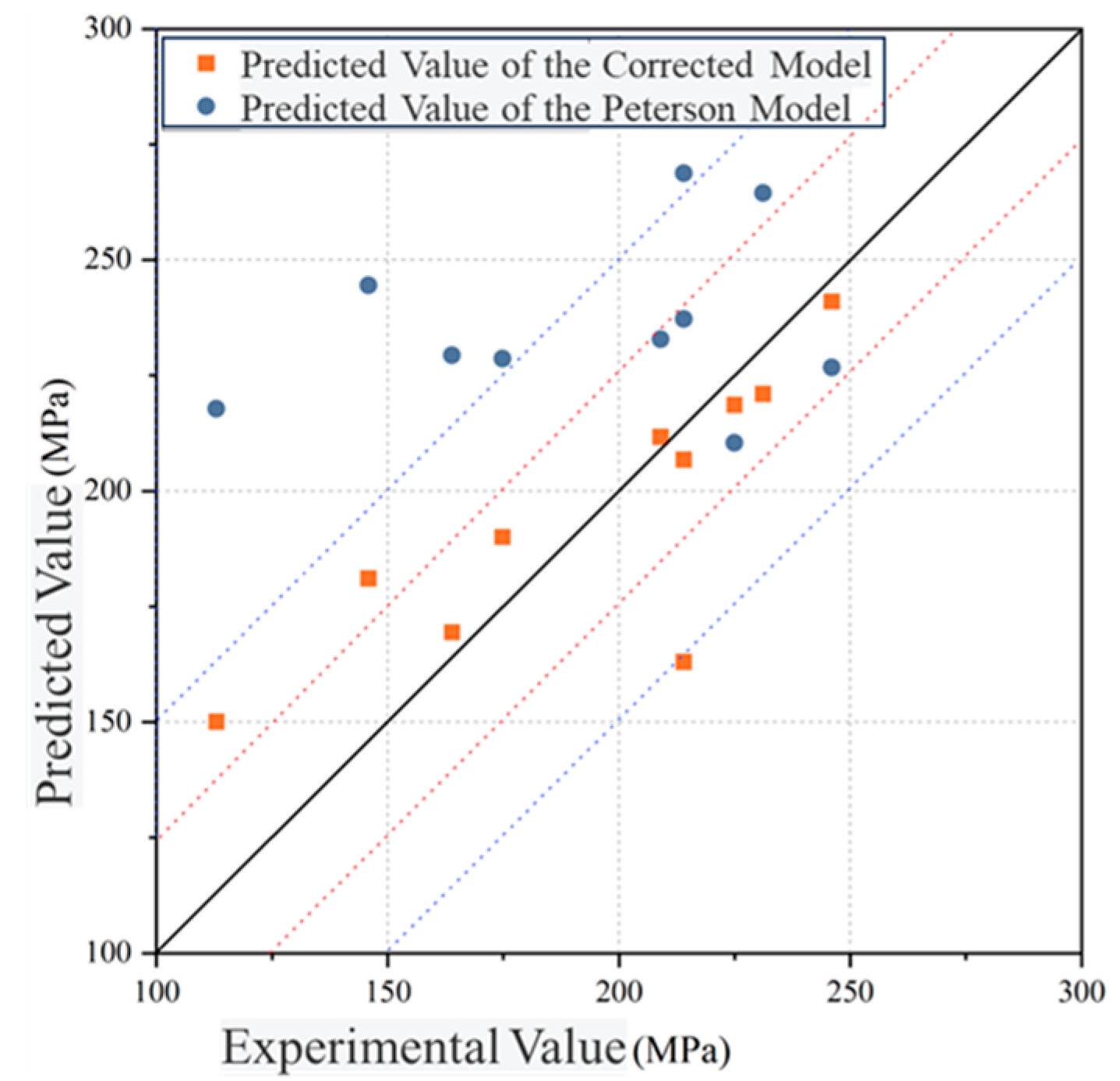

- The application of the mean stress model to predict the high-cycle fatigue strength of FOD-damaged blades showed poor performance when using both the Neuber and Peterson formulas. These methods exhibited significant prediction errors, especially for blades subjected to oblique impact damage.

- (2)

- A shear factor was proposed to describe the correction of the mean stress model due to the impact angle. The results show that the error distribution band of the corrected model was 72.6%, significantly smaller than the 100.8% of the Neuber model. This indicates that the mean stress model, considering the impact angle, reduces the variability in predicting high-cycle fatigue strength.

- (3)

- The influence of tensile residual stress on the applied mean stress was considered, and a mean stress correction model incorporating tensile residual stress was developed based on the medium-life Walker curve. The results demonstrate that only 30% and 40% of the predictions using the Neuber and Peterson models, respectively, fall within the 10% scatter band of the experimental values. In contrast, the corrected model increased the number of predictions within the 10% scatter band by 30%, significantly improving the prediction accuracy compared to the original mean stress model.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Su, C.; Liu, X. Notch-based probabilistic fatigue analysis of automobile transmission gear considering size effect. Theor. Appl. Fract. Mech. 2023, 125, 103882. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Y.; Wang, W.; Wang, P.; Li, J. The fatigue of impellers and blades. Eng. Fail. Anal. 2016, 62, 208–231. [Google Scholar] [CrossRef]

- Cui, D.; Bao, R.; Zhang, R.; Liu, B.; Ouyang, T. Overview of the Development of Aircraft Structural Fatigue and Structural Integrity. J. Aeronaut. 2021, 42, 524394. [Google Scholar]

- Zhao, Z.; Wang, L.; Liu, C.; Liu, L.; Chen, W. Prediction of High-Cycle Fatigue Performance of 1Cr11Ni2W2MoV Stainless Steel Plate after Foreign Object Damage. Int. J. Aerosp. Eng. 2020, 2020, 8837564. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, L.; Zhang, J.; Liu, L.; Chen, W. Prediction of high-cycle fatigue strength in a Ti-17 alloy blade after foreign object damage. Eng. Fract. Mech. 2021, 241, 107385. [Google Scholar] [CrossRef]

- Murakami, Y.; Takagi, T.; Wada, K.; Matsunaga, H. Essential structure of SN curve: Prediction of fatigue life and fatigue limit of defective materials and nature of scatter. Int. J. Fatigue 2021, 146, 106138. [Google Scholar] [CrossRef]

- Gao, J.W.; Yu, M.H.; Liao, D.; Zhu, S.P.; Han, J.; Lesiuk, G.; Correia, J.A.F.O.; De Jesus, A.M.P. Fatigue and damage tolerance assessment of induction hardened S38C axles under different foreign objects. Int. J. Fatigue 2021, 149, 106276. [Google Scholar] [CrossRef]

- Maxwell, D.C.; Nicholas, T. A Rapid Method for Generation of a Haigh Diagram for High Cycle Fatigue; Fatigue and Fracture Mechanics: 29th Volume; ASTM International: West Conshohocken, PA, USA, 1999. [Google Scholar]

- Ruschau, J.J.; Nicholas, T.; Thompson, S.R. Influence of foreign object damage (FOD) on the fatigue life of simulated Ti-6Al-4 V airfoils. Int. J. Impact Eng. 2001, 25, 233–250. [Google Scholar] [CrossRef]

- Thompson, S.R.; Nicholas, T.; Ruschau, J.J.; Thompson, S.R. An investigation into impacting techniques for simulating foreign object damage and their influences on the fatigue limit strength of Ti-6Al-4V. STAR 2007, 45, 23. [Google Scholar]

- Bao, Z. Study on the Effect of Notches on the High-Cycle Fatigue Strength of Ti-6Al-4V and Prediction Methods. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2014. [Google Scholar]

- Jia, X. Study on the Effect of Centrifugal Force Field on FOD Titanium Alloy Blade HCF and Methods for Determining the Usable Limits. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2020. [Google Scholar]

- Hu, X. Foreign Object Damage and Its Effect on the High-Cycle Fatigue Strength of Titanium Alloy Blades. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2009. [Google Scholar]

- Yang, X.; Wu, P.; Dong, Z. Notch fatigue life prediction in metals: A critical distance model with microstructure and geometry effects. Theor. Appl. Fract. Mech. 2025, 141, 105213. [Google Scholar] [CrossRef]

- Hu, X.; Wan, Y.; Jiang, R.; Song, Y.D. Fatigue strength prediction of TC4 titanium alloy following foreign object damage based on contour feature. J. Mech. Sci. Technol. 2019, 33, 4727–4734. [Google Scholar] [CrossRef]

- Wang, C.; Shang, Y.; Zhou, L.; Zhao, Z.; Zhang, X.; Wang, L.; Li, B.; He, W.; Chen, W. High cycle fatigue limit assessment of foreign object damaged aerofoil blades considering the residual stress induced by impact. Eng. Fract. Mech. 2025, 318, 110993. [Google Scholar] [CrossRef]

- Denkena, B.; Mai, O.; Poll, G.; Neubauer, T. Enhanced boundary zone rolling contact fatigue strength through hybrid machining by hard turn-rolling. In Proceedings of the Bearing World, Hannover, Germany, 12–13 April 2016. [Google Scholar]

- Wang, Y.; Ma, H.; Zhang, Y. Effect of the notch depth on fracture behavior of TC4 titanium alloy sheets. Eng. Fract. Mech. 2023, 277, 108947. [Google Scholar] [CrossRef]

- Liu, Q. Manufacturing Technology and Failure Analysis of Titanium Alloy Blades for Aircraft Engines; Aviation Industry Press: Beijing, China, 2018. [Google Scholar]

- GB/T 3075-2008; Metallic Materials—Fatigue Testing—Axial-Force-Controlled Method. Standardization Administration of China: Beijing, China, 2008.

| Property | E (GPa) | Poisson’s Ratio | Yield Strength (MPa) | Tensile Strength (MPa) | |

|---|---|---|---|---|---|

| Value | 4430 | 113 | 0.31 | 860 | 932 |

| Dynamic Load | ±50 kN | Test Frequency | 0.01–50 Hz |

|---|---|---|---|

| Piston Stroke | 0–150 mm | Clamping Pressure | 0–21 MPa |

| Force Control Accuracy | <0.5% | Displacement Control Accuracy | <0.5% |

| Measurement Range | ±75 mm | Sampling Frequency | 10 kHz |

| No. | Max Cyclic Stress (MPa) | Stress Ratio R | Cyclic Life (×104) | HCF (MPa) |

|---|---|---|---|---|

| S01 | 360 | −1 | 100 | 368.7 |

| 390 | −1 | 29 | ||

| S02 | 360 | −1 | 100 | 391.9 |

| 390 | −1 | 100 | ||

| 420 | −1 | 6.2 | ||

| S03 | 360 | −1 | 100 | 375.9 |

| 390 | −1 | 53 | ||

| S04 | 480 | 0.1 | 100 | 504.8 |

| 520 | 0.1 | 62 | ||

| S05 | 480 | 0.1 | 100 | 528.8 |

| 520 | 0.1 | 100 | ||

| 560 | 0.1 | 22 | ||

| S06 | 480 | 0.1 | 100 | 539.2 |

| 520 | 0.1 | 100 | ||

| 560 | 0.1 | 48 | ||

| S07 | 600 | 0.5 | 100 | 635 |

| 650 | 0.5 | 70 | ||

| S08 | 600 | 0.5 | 100 | 618 |

| 650 | 0.5 | 36 | ||

| S09 | 600 | 0.5 | 100 | 655.5 |

| 650 | 0.5 | 100 | ||

| 700 | 0.5 | 11 |

| No. | Velocity v (m/s) | Impact Angle (°) | Notch Depth H (mm) | Notch Width L1 (mm) | Notch Length L2 (mm) | R | (MPa) |

|---|---|---|---|---|---|---|---|

| D01 | 200 | 90 | 1.19 | 2.32 | 2.37 | 0.1 | 238.48 |

| D02 | 200 | 90 | 1.14 | 2.34 | 2.34 | 0.1 | 256.01 |

| D04 | 200 | 90 | 0.58 | 1.92 | 0.99 | 0.1 | 231.13 |

| D05 | 200 | 90 | 0.99 | 2.38 | 2.27 | 0.1 | 174.81 |

| D07 | 200 | 60 | 1.04 | 2.37 | 2.97 | 0.1 | 288.14 |

| D08 | 200 | 60 | 1.21 | 2.46 | 2.86 | 0.1 | 268.37 |

| D09 | 200 | 60 | 1.18 | 2.17 | 2.67 | 0.1 | 284.74 |

| D10 | 200 | 60 | 1.31 | 2.61 | 0.91 | 0.1 | 225.00 |

| D12 | 200 | 60 | 1.02 | 2.76 | 1.03 | 0.1 | 246.00 |

| D13 | 200 | 30 | 1.15 | 2.61 | 3.21 | 0.1 | 286.85 |

| D14 | 200 | 30 | 0.54 | 2.28 | 2.51 | 0.1 | 214.00 |

| D15 | 200 | 30 | 1.26 | 2.41 | 2.80 | 0.1 | 241.00 |

| D19 | 250 | 90 | 1.30 | 2.78 | 2.84 | 0.1 | 235.99 |

| D20 | 250 | 90 | 1.47 | 2.97 | 3.06 | 0.1 | 207.74 |

| D21 | 250 | 90 | 0.78 | 3.17 | 1.35 | 0.1 | 145.86 |

| D23 | 250 | 90 | 0.98 | 2.91 | 2.06 | 0.1 | 163.91 |

| D25 | 250 | 60 | 1.36 | 2.88 | 3.19 | 0.1 | 250.62 |

| D26 | 250 | 60 | 1.36 | 2.89 | 3.01 | 0.1 | 263.68 |

| D27 | 250 | 60 | 1.29 | 2.99 | 3.34 | 0.1 | 229.32 |

| D28 | 250 | 60 | 0.93 | 2.88 | 3.60 | 0.1 | 209.02 |

| D31 | 250 | 30 | 1.32 | 2.48 | 3.48 | 0.1 | 221.80 |

| D34 | 250 | 30 | 1.42 | 2.95 | 3.26 | 0.1 | 182.71 |

| D35 | 250 | 30 | 0.87 | 3.06 | 3.45 | 0.1 | 214.00 |

| D36 | 250 | 30 | 1.17 | 3.07 | 2.84 | 0.1 | 113.00 |

| D37 | 300 | 90 | 1.49 | 2.78 | 3.01 | 0.1 | 186.47 |

| D38 | 300 | 90 | 1.56 | 2.94 | 2.87 | 0.1 | 201.50 |

| D39 | 300 | 90 | 1.62 | 2.97 | 3.06 | 0.1 | 169.17 |

| D43 | 300 | 60 | 1.12 | 3.01 | 3.73 | 0.1 | 210.53 |

| D44 | 300 | 60 | 1.08 | 2.86 | 2.48 | 0.1 | 138.00 |

| D45 | 300 | 60 | 1.03 | 2.95 | 1.75 | 0.1 | 127.82 |

| D49 | 300 | 30 | 1.44 | 3.06 | 2.72 | 0.1 | 184.21 |

| D50 | 300 | 30 | 1.49 | 2.99 | 2.48 | 0.1 | 209.10 |

| D51 | 300 | 30 | 1.51 | 3.02 | 2.62 | 0.1 | 156.39 |

| No. | Impact Angle (°) | Velocity (m/s) | Depth (mm) | Experimental (MPa) | Peterson Prediction (MPa) | Error | Neuber Prediction (MPa) | Error |

|---|---|---|---|---|---|---|---|---|

| D01 | 90 | 200 | 1.19 | 238.48 | 216.63 | −9.16% | 204.32 | −14.3% |

| D02 | 90 | 200 | 1.14 | 256.01 | 219.42 | −14.29% | 207.00 | −39.2% |

| D04 | 90 | 200 | 0.58 | 231.13 | 264.43 | 14.40% | 250.44 | −18.5% |

| D05 | 90 | 200 | 0.99 | 174.81 | 228.66 | 30.80% | 215.90 | −7.1% |

| D07 | 60 | 200 | 1.04 | 288.14 | 225.42 | −21.77% | 212.78 | −44.5% |

| D08 | 60 | 200 | 1.21 | 268.37 | 215.55 | −19.68% | 203.28 | −43.0% |

| D09 | 60 | 200 | 1.18 | 284.74 | 217.17 | −23.73% | 204.85 | −45.9% |

| D10 | 60 | 200 | 1.31 | 225.00 | 210.42 | 16.31% | 198.37 | −11.8% |

| D12 | 60 | 200 | 1.02 | 246.00 | 226.70 | 16.81% | 214.01 | −13.0% |

| D13 | 30 | 200 | 1.15 | 286.85 | 218.85 | −23.71% | 206.46 | −45.9% |

| D14 | 30 | 200 | 0.54 | 214.00 | 268.75 | 15.92% | 254.63 | 18.9% |

| D15 | 30 | 200 | 1.26 | 241.00 | 212.93 | −11.65% | 200.77 | −37.4% |

| D19 | 90 | 250 | 1.30 | 235.99 | 210.92 | −10.62% | 198.84 | −36.6% |

| D20 | 90 | 250 | 1.47 | 207.74 | 203.07 | −2.25% | 191.31 | −30.8% |

| D21 | 90 | 250 | 0.78 | 145.86 | 244.50 | 67.62% | 231.17 | 19.2% |

| D23 | 90 | 250 | 0.98 | 163.91 | 229.33 | 39.91% | 216.54 | −0.7% |

| D25 | 60 | 250 | 1.36 | 250.62 | 208.02 | −17.00% | 196.06 | −41.2% |

| D26 | 60 | 250 | 1.36 | 263.68 | 208.02 | −21.11% | 196.06 | −44.1% |

| D27 | 60 | 250 | 1.29 | 229.32 | 211.41 | −7.81% | 199.32 | −34.7% |

| D28 | 60 | 250 | 0.93 | 209.02 | 232.79 | 35.92% | 219.88 | −20.9% |

| D31 | 30 | 250 | 1.32 | 221.80 | 209.94 | −5.35% | 197.90 | −32.9% |

| D34 | 30 | 250 | 1.42 | 182.71 | 205.27 | 12.35% | 193.42 | −20.4% |

| D35 | 30 | 250 | 0.87 | 214.00 | 237.22 | 3.25% | 224.14 | 4.7% |

| D36 | 30 | 250 | 1.17 | 113.00 | 217.73 | 80.48% | 205.38 | 81.8% |

| D37 | 90 | 300 | 1.49 | 186.47 | 202.22 | 8.45% | 190.49 | −23.2% |

| D38 | 90 | 300 | 1.56 | 201.50 | 199.32 | −1.08% | 187.72 | −30.0% |

| D39 | 90 | 300 | 1.62 | 169.17 | 196.96 | 16.42% | 185.45 | −17.6% |

| D43 | 60 | 300 | 1.12 | 210.53 | 220.57 | 4.77% | 208.11 | −25.7% |

| D44 | 60 | 300 | 1.08 | 138.00 | 222.95 | 95.35% | 210.40 | 52.5% |

| D45 | 60 | 300 | 1.03 | 127.82 | 226.05 | 80.01% | 213.39 | 25.5% |

| D49 | 30 | 300 | 1.44 | 184.21 | 204.38 | 10.95% | 192.57 | −21.4% |

| D50 | 30 | 300 | 1.49 | 209.10 | 202.22 | −3.29% | 190.49 | −31.5% |

| D51 | 30 | 300 | 1.51 | 156.39 | 201.38 | 28.76% | 189.69 | −8.8% |

| Property | a1 | b1 | c1 | a2 | b2 | c2 |

|---|---|---|---|---|---|---|

| value | 17.1 | 0.0425 | −1.0485 | 16.2 | 0.0444 | 1.9716 |

| No. | Experimental Value (MPa) | Correct Kt | M-Peterson Prediction (MPa) | Error | M-Neuber Prediction (MPa) | Error |

|---|---|---|---|---|---|---|

| D04 | 231.13 | 2.24 | 250.44 | 8.4% | 245.55 | 6.2% |

| D05 | 174.81 | 2.62 | 215.90 | 23.5% | 211.16 | 20.8% |

| D10 | 225.00 | 2.37 | 237.92 | 5.7% | 242.91 | 8.0% |

| D12 | 246.00 | 2.15 | 260.78 | 6.0% | 267.79 | 8.9% |

| D14 | 214.00 | 2.40 | 234.61 | 9.6% | 229.76 | 7.4% |

| D21 | 145.86 | 2.44 | 231.17 | 58.5% | 226.34 | 55.2% |

| D23 | 163.91 | 2.62 | 216.54 | 32.1% | 211.80 | 29.2% |

| D28 | 209.02 | 2.07 | 269.55 | 29.0% | 264.64 | 26.6% |

| D35 | 214.00 | 2.72 | 208.48 | −2.6% | 203.79 | −4.8% |

| D36 | 113.00 | 2.97 | 192.15 | 70.0% | 187.61 | 66.0% |

| No. | Experimental Value (MPa) | Corrected Kt Value | Correction Neuber Model (MPa) | Correction Error | Correction Peterson Model (MPa) | Correction Error |

|---|---|---|---|---|---|---|

| D04 | 231.13 | 2.24 | 225.40 | −2.5% | 220.99 | −4.4% |

| D05 | 17 5.31 | 2.62 | 194.31 | 11.2% | 190.04 | 8.7% |

| D10 | 225.00 | 2.37 | 223.02 | −0.9% | 218.62 | −2.8% |

| D12 | 246.00 | 2.15 | 245.43 | −0.2% | 241.01 | −2.0% |

| D14 | 214.00 | 2.40 | 211.15 | −1.3% | 206.78 | −3.4% |

| D21 | 145.86 | 2.44 | 184.94 | 26.8% | 181.07 | 24.1% |

| D23 | 163.91 | 2.62 | 173.23 | 5.7% | 169.44 | 3.4% |

| D28 | 209.02 | 2.07 | 215.64 | 3.2% | 211.71 | 1.3% |

| D35 | 214.00 | 2.72 | 166.78 | −22.1% | 163.03 | −23.8% |

| D36 | 113.00 | 2.97 | 153.72 | 36.0% | 150.09 | 32.8% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, W.; Liu, Y.; He, X.; Tian, Z. High-Cycle Fatigue Strength Prediction Model for Ti-6Al-4V Titanium Alloy Compressor Blades Subjected to Foreign Object Damage. Metals 2025, 15, 1150. https://doi.org/10.3390/met15101150

Yin W, Liu Y, He X, Tian Z. High-Cycle Fatigue Strength Prediction Model for Ti-6Al-4V Titanium Alloy Compressor Blades Subjected to Foreign Object Damage. Metals. 2025; 15(10):1150. https://doi.org/10.3390/met15101150

Chicago/Turabian StyleYin, Wangtian, Yongbao Liu, Xing He, and Zegang Tian. 2025. "High-Cycle Fatigue Strength Prediction Model for Ti-6Al-4V Titanium Alloy Compressor Blades Subjected to Foreign Object Damage" Metals 15, no. 10: 1150. https://doi.org/10.3390/met15101150

APA StyleYin, W., Liu, Y., He, X., & Tian, Z. (2025). High-Cycle Fatigue Strength Prediction Model for Ti-6Al-4V Titanium Alloy Compressor Blades Subjected to Foreign Object Damage. Metals, 15(10), 1150. https://doi.org/10.3390/met15101150