Effect of Induction Hardening Following Carburizing–Nitriding Duplex Treatment on the Microstructure and Fatigue Strength of JIS-SCM420 Low-Alloy Steel

Abstract

1. Introduction

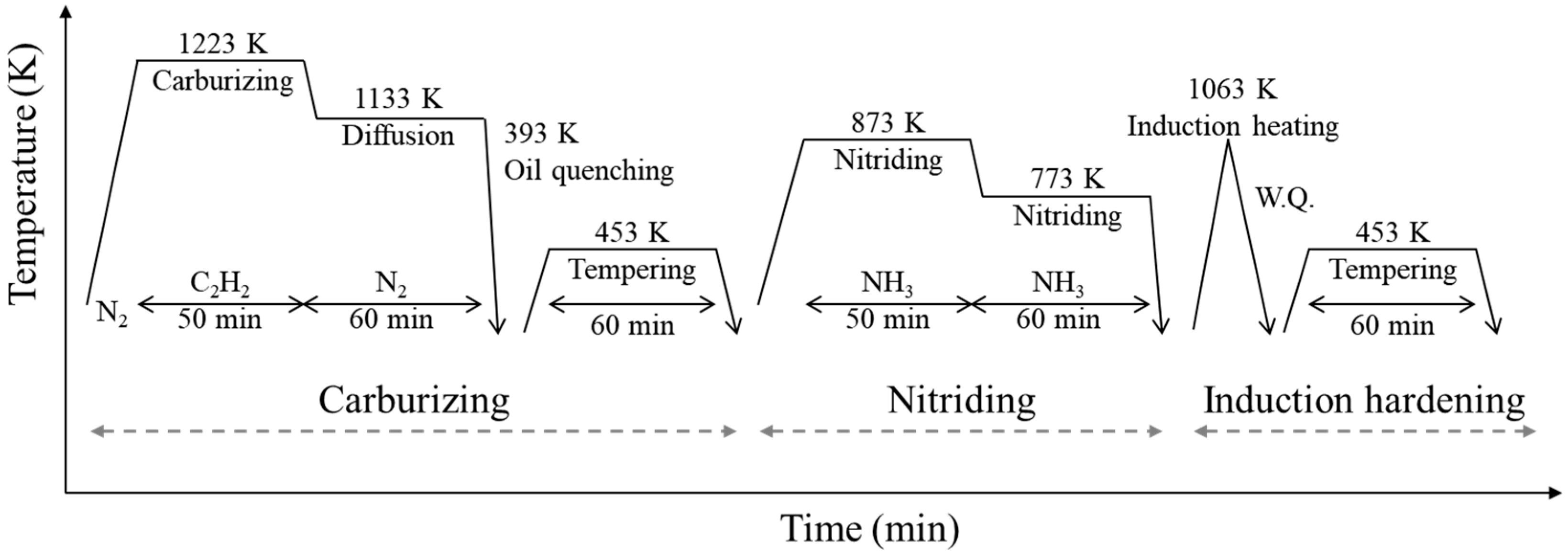

2. Experimental Procedure

2.1. Materials and Heat Treatment

2.2. Fatigue Testing

2.3. Microstructure and Surface Characterization

3. Results and Discussion

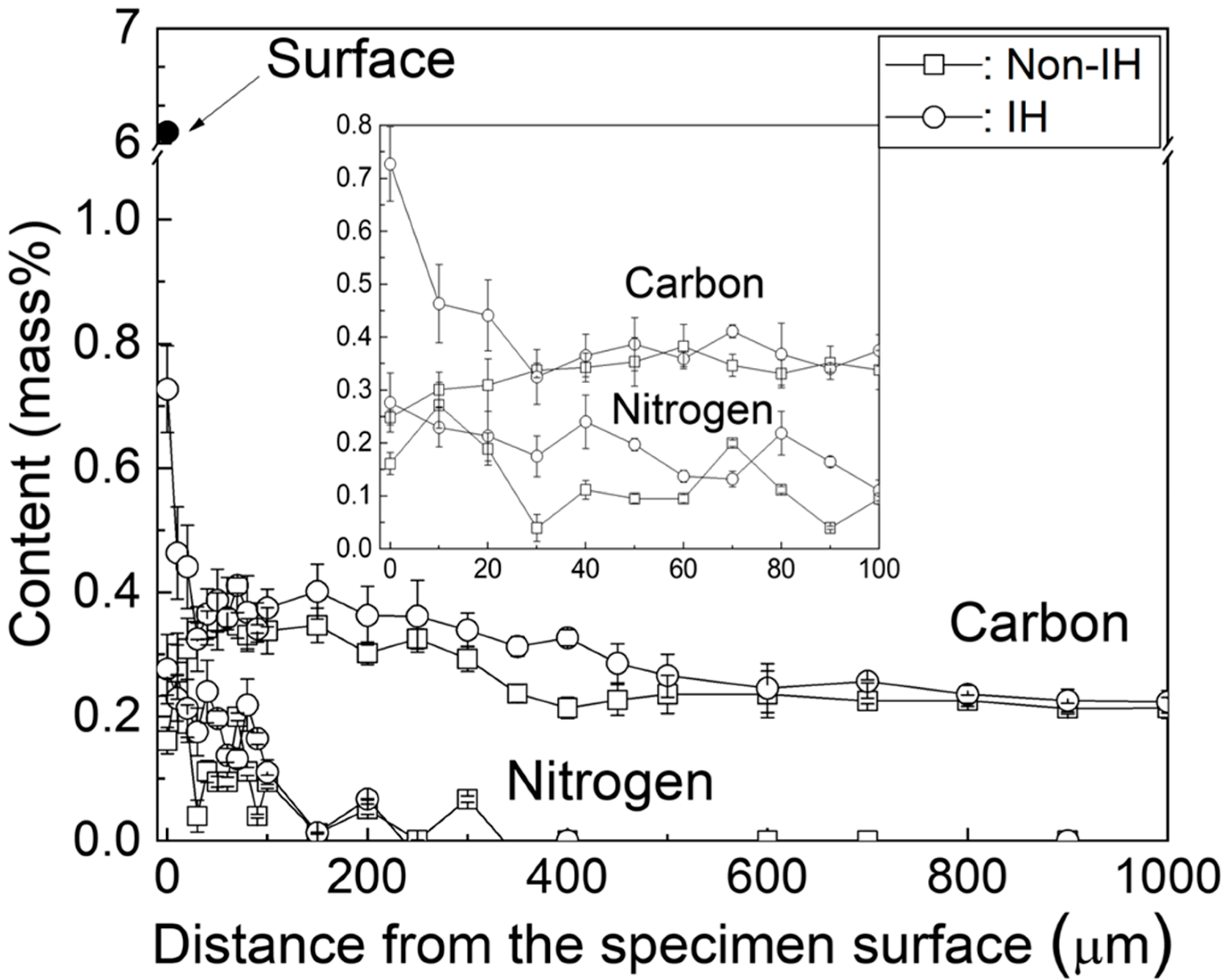

3.1. Concentration–Depth Profiles of Carbon and Nitrogen

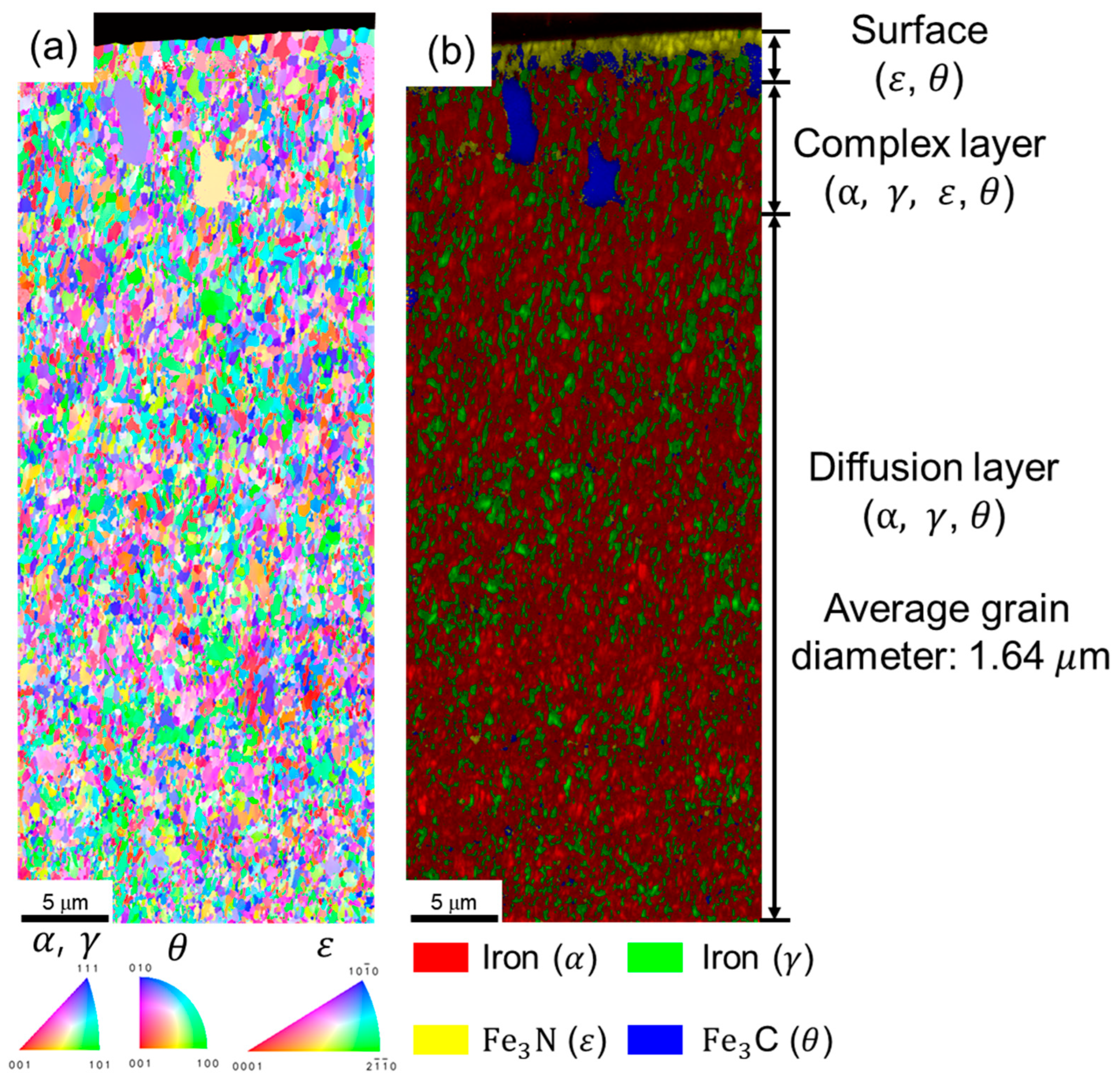

3.2. Microstructure

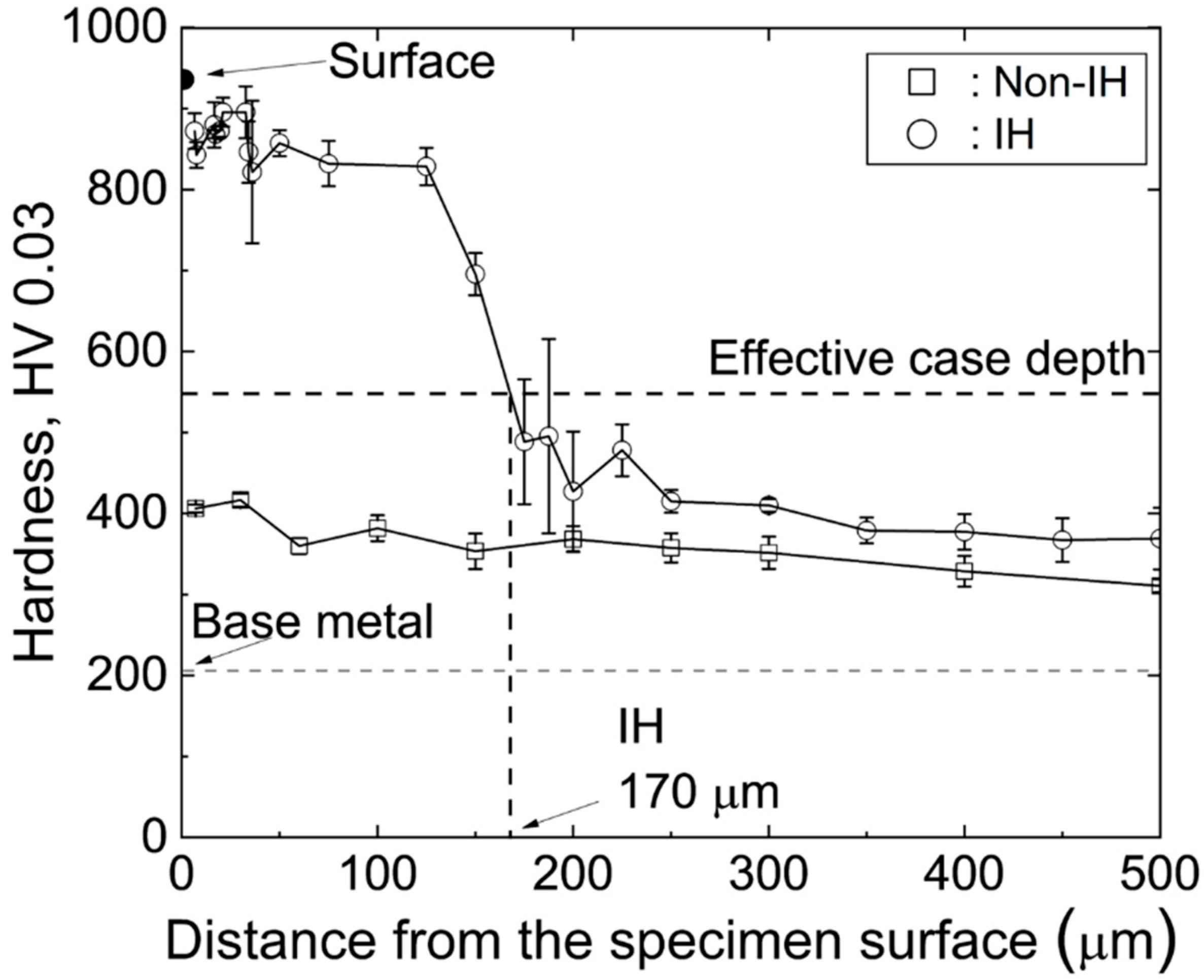

3.3. Hardness

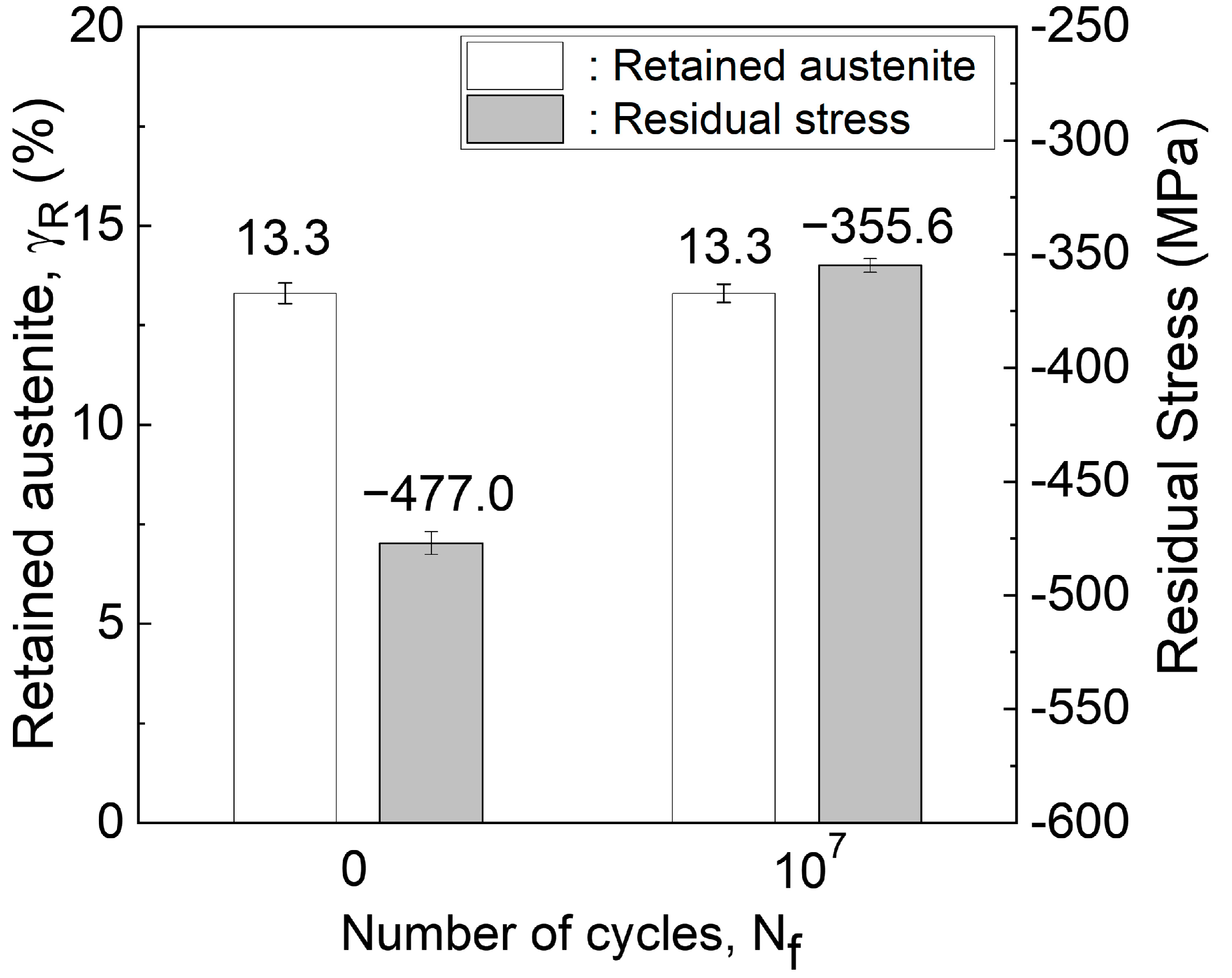

3.4. Progression of Retained Austenite (γR) and Residual Stress During Fatigue Testing

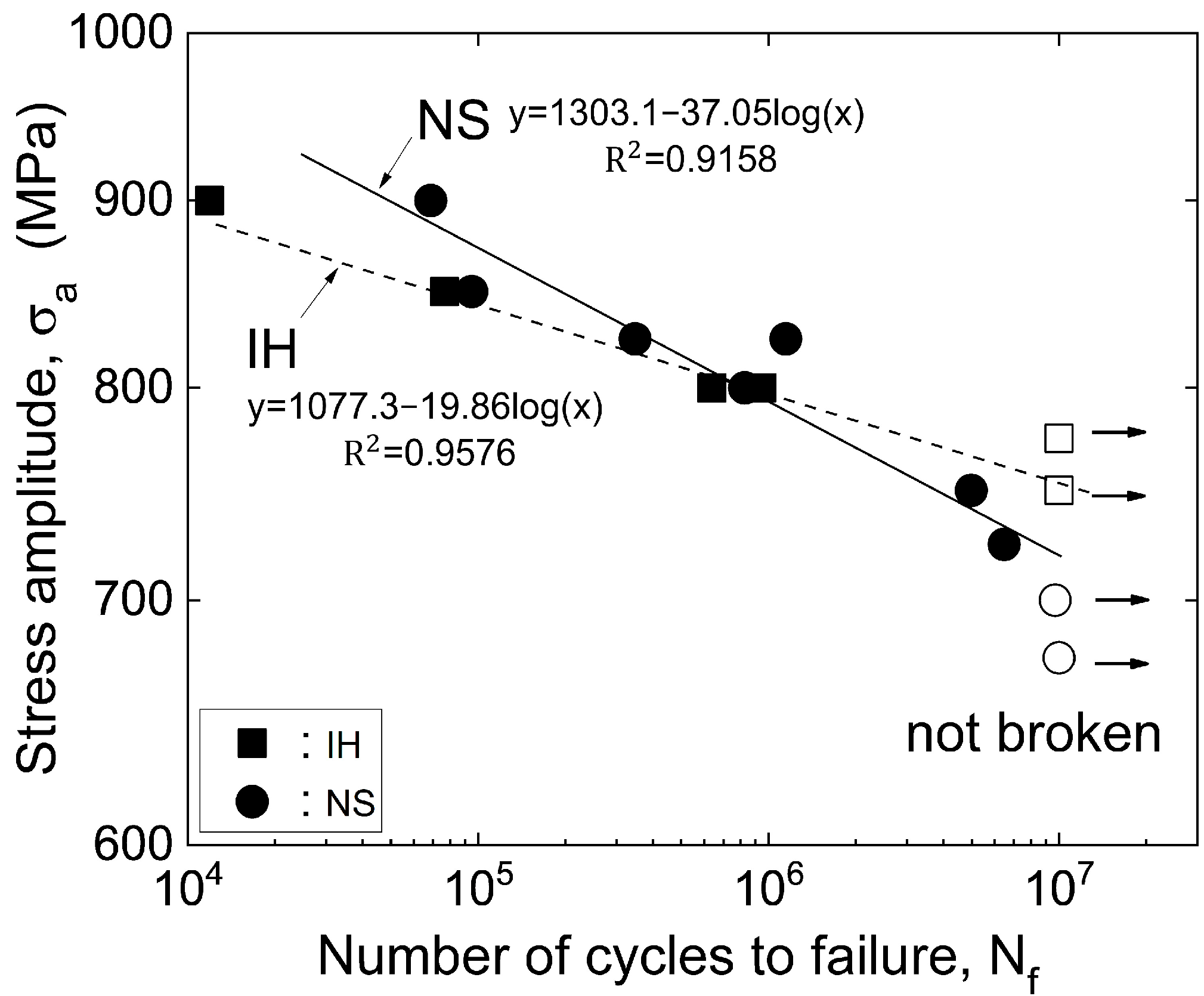

3.5. S–N Data

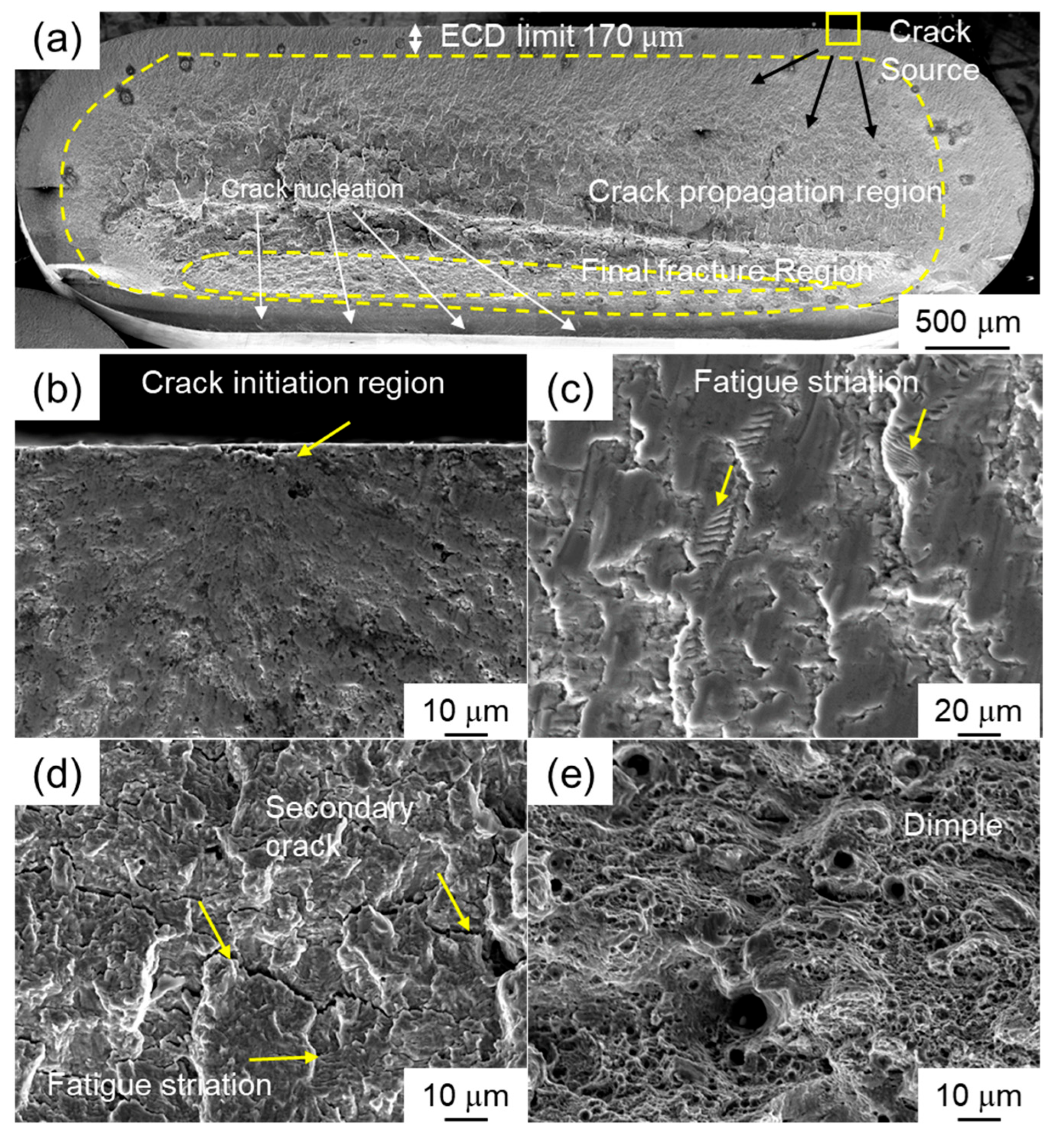

3.6. Bending Fatigue Fractured Surfaces

3.7. Formation of the ε-Carbonitride Layer by Re-Precipitation During Induction Hardening

4. Conclusions

Author Contributions

Funding

Data availability Statement

Conflicts of Interest

Correction Statement

References

- Boniardi, M.; D’Errico, F.; Tagliabue, C. Influence of carburizing and nitriding on failure of gears–A case study. Eng. Fail. Anal. 2006, 13, 312–339. [Google Scholar] [CrossRef]

- Chang, H.; Borghesani, P.; Peng, Z. Investigation on the relationship between macropits and wear particles in a gear fatigue process. Wear 2021, 484–485, 203724. [Google Scholar] [CrossRef]

- Karimbaev, R.; Pyun, Y.-S.; Maleki, E.; Unal, O.; Amanov, A. An improvement in fatigue behavior of AISI 4340 steel by shot peening and ultrasonic nanocrystal surface modification. Mater. Sci. Eng. A 2020, 791, 139752. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, J.; Wu, C.; Xu, Z.; Lyu, S. The evaluation of contact fatigue strength for 20MnCr5 carburized gear. Int. J. Precis. Eng. Manuf. 2014, 15, 117–121. [Google Scholar] [CrossRef]

- Qin, S.; Wang, L.; Di, L.; Zhang, C.; Zhao, M. Effect of carburizing process on bending fatigue performance of notched parts of 18CrNiMo7-6 alloy steel. Eng. Fail. Anal. 2023, 147, 107161. [Google Scholar] [CrossRef]

- Xiao, N.; Hui, W.; Zhang, Y.; Zhao, X.; Chen, Y.; Dong, H. High cycle fatigue behavior of a low carbon alloy steel: The influence of vacuum carburizing treatment. Eng. Fail. Anal. 2020, 109, 104215. [Google Scholar] [CrossRef]

- Xue, Y.; Yan, Y.; Yu, W.; Dong, M.; Shi, J.; Wang, M. Microstructure and fatigue properties of 17Cr2Ni2MoVNb gear steel after gas carburizing and low-pressure carburizing. Int. J. Fatigue 2023, 167, 107314. [Google Scholar] [CrossRef]

- Genel, K.; Demirkol, M.; Capa, M. Effect of ion nitriding on fatigue behaviour of AISI 4140 steel. Mater. Sci. Eng. A 2000, 279, 207–216. [Google Scholar] [CrossRef]

- Kim, M.; Umezawa, O. Influence of prior quenching and tempering treatment on cementite formation during nitriding at 913 K for SCM440 steel. ISIJ Int. 2025, 65, 982–991. [Google Scholar] [CrossRef]

- Mittemeijer, E.J.; Somers, M.A. Thermochemical Surface Engineering of Steels; Woodhead Publishing Oxford: Oxford, UK, 2015. [Google Scholar]

- Silva, W.D.M.; Dulcy, J.; Ghanbaja, J.; Redjaimia, A.; Michel, G.; Thibault, S.; Belmonte, T. Carbonitriding of low alloy steels: Mechanical and metallurgical responses. Mater. Sci. Eng. A 2017, 693, 225–232. [Google Scholar] [CrossRef]

- Wang, B.; Liu, B.; Gu, J.; Somers, M.A. Gaseous carbonitriding of high carbon chromium bearing steel: Correlation between composition, microstructure and stability. Surf. Coat. Technol. 2022, 438, 128408. [Google Scholar] [CrossRef]

- Kim, M.; Umezawa, O. Influence of carbonitriding and sub-zero treatment on the microstructure and fatigue strength of JIS-SCM420 low-alloy steel. Mater. Sci. Eng. A 2025, 923, 147751. [Google Scholar] [CrossRef]

- Jung, M.; Meka, S.R.; Rheingans, B.; Mittemeijer, E.J. Coupling inward diffusion and precipitation kinetics; the case of nitriding iron-based alloys. Metall. Mater. Trans. A 2016, 47, 1425–1439. [Google Scholar] [CrossRef]

- Wei, Y. Simulation, Optimization and Development of Thermo-Chemical Diffusion Processes. Ph.D. Thesis, Worcester Polytechnic Institute, Worcester, MA, USA, 2013. [Google Scholar]

- Sun, Y.; Bell, T. Plasma surface engineering of low alloy steel. Mater. Sci. Eng. A 1991, 140, 419–434. [Google Scholar] [CrossRef]

- Aswad, M.F.; Mohammed, A.J.; Faraj, S.R. Induction surface hardening: A review. J. Phys. Conf. Ser. 2021, 1973, 012087. [Google Scholar] [CrossRef]

- Fisk, M.; Lindgren, L.-E.; Datchary, W.; Deshmukh, V. Modelling of induction hardening in low alloy steels. Finite Elem. Anal. Des. 2018, 144, 61–75. [Google Scholar] [CrossRef]

- Gao, K.; Qin, X.; Wang, Z.; Zhu, S. Effect of spot continual induction hardening on the microstructure of steels: Comparison between AISI 1045 and 5140 steels. Mater. Sci. Eng. A 2016, 651, 535–547. [Google Scholar] [CrossRef]

- Grum, J. Induction hardening. In Failure Analysis of Heat Treated Steel Components; ASM International: Almere, The Netherlands, 2008; pp. 417–501. [Google Scholar]

- Yang, B.; Hattiangadi, A.; Li, W.; Zhou, G.; McGreevy, T. Simulation of steel microstructure evolution during induction heating. Mater. Sci. Eng. A 2010, 527, 2978–2984. [Google Scholar] [CrossRef]

- Okada, K.; Obayashi, K.; Todaka, Y.; Adachi, N. Crack propagation behavior of impact fracture in case hardening steel subjected to combined heat treatment with excess vacuum carburizing and subsequent induction hardening. ISIJ Int. 2020, 60, 2576–2585. [Google Scholar] [CrossRef]

- Totten, G.E. Handbook of Residual Stress and Deformation of Steel; ASM International: Almere, The Netherlands, 2002. [Google Scholar]

- Ul-Hamid, A.; Tawancy, H.M.; Mohammed, A.-R.I.; Al-Jaroudi, S.S.; Abbas, N.M. Quantitative WDS analysis using electron probe microanalyzer. Mater. Charact. 2006, 56, 192–199. [Google Scholar] [CrossRef]

- Mittemeijer, E. Fundamentals of nitriding and nitrocarburizing. In Steel Heat Treating Fundamentals and Processes; ASM International: Almere, The Netherlands, 2013; pp. 619–646. [Google Scholar]

- Wu, D.; Ge, Y.; Kahn, H.; Ernst, F.; Heuer, A. Diffusion profiles after nitrocarburizing austenitic stainless steel. Surf. Coat. Technol. 2015, 279, 180–185. [Google Scholar] [CrossRef]

- Kelly, P.; Nutting, J. The martensite transformation in carbon steels. Proc. R. Soc. Lond. A. Math. Phys. Sci. 1961, 259, 45–58. [Google Scholar]

- Cryderman, R.; Garrett, D.; Schlittenhart, Z.; Seo, E.J. Effects of rapid induction heating on transformations in 0.6% C steels. J. Mater. Eng. Perform. 2020, 29, 3502–3515. [Google Scholar] [CrossRef]

- Lee, J.B.; Kang, N.; Park, J.T.; Ahn, S.-T.; Park, Y.-D.; Choi, I.-D.; Kim, K.-R.; Cho, K.-M. Kinetics of carbide formation for quenching and tempering steels during high-frequency induction heat treatment. Mater. Chem. Phys. 2011, 129, 365–370. [Google Scholar] [CrossRef]

- Wang, Y.; Mehari, Z.A.; Wu, J.; Han, J. Effect of induction heating temperature on the microstructure and mechanical properties of HSLA square tubes. Mater. Res. Express 2022, 9, 106504. [Google Scholar] [CrossRef]

- Prokoshkina, V.; Kaputkina, L. Peculiarities of martensitic transformations and martensite structure in high nitrogen steels. Mater. Sci. Eng. A 2008, 481–482, 762–765. [Google Scholar] [CrossRef]

- Galindo-Nava, E.; Rivera-Díaz-del-Castillo, P. Understanding the factors controlling the hardness in martensitic steels. Scr. Mater. 2016, 110, 96–100. [Google Scholar] [CrossRef]

- Molkeri, A.; Pahlevani, F.; Emmanuelawati, I.; Sahajwalla, V. Thermal and mechanical stability of retained austenite in high carbon steel: An in-situ investigation. Mater. Lett. 2016, 163, 209–213. [Google Scholar] [CrossRef]

- Umemoto, M.; Ohtsuka, H. Mechanical properties of cementite. ISIJ Int. 2022, 62, 1313–1333. [Google Scholar] [CrossRef]

- SAE. Methods of Measuring Case Depth—J423; SAE International: Warrendale, PA, USA, 1998. [Google Scholar]

- Yang, Z.; Ji, Y.; Zhang, F.; Zhang, M.; Nawaz, B.; Zheng, C. Microstructural evolution and performance change of a carburized nanostructured bainitic bearing steel during rolling contact fatigue process. Mater. Sci. Eng. A 2018, 725, 98–107. [Google Scholar] [CrossRef]

- Zhu, Z.; Liang, Y.; Yin, C.; Ren, X.; Yang, M.; Zou, J. Influence of friction-induced retained austenite transformation to martensite on the wear properties of a carburized layer of 23CrNi3MoA steel. Appl. Surf. Sci. 2022, 595, 153548. [Google Scholar] [CrossRef]

- Ooi, G.T.C.; Roy, S.; Sundararajan, S. Investigating the effect of retained austenite and residual stress on rolling contact fatigue of carburized steel with XFEM and experimental approaches. Mater. Sci. Eng. A 2018, 732, 311–319. [Google Scholar] [CrossRef]

- Qin, S.; Feng, M.; Tian, Q.; Song, Z.; Zhao, M. Influence of cold treatment on fatigue performance of 18CrNiMo7-6 carburized steel. Int. J. Fatigue 2024, 183, 108242. [Google Scholar] [CrossRef]

- Qin, S.; Zhang, C.; Zhang, B.; Ma, H.; Zhao, M. Effect of carburizing process on high cycle fatigue behavior of 18CrNiMo7-6 steel. J. Mater. Res. Technol. 2022, 16, 1136–1149. [Google Scholar] [CrossRef]

- Wang, J.; Van Der Zwaag, S. Stabilization mechanisms of retained austenite in transformation-induced plasticity steel. Metall. Mater. Trans. A 2001, 32, 1527–1539. [Google Scholar] [CrossRef]

- Oh, G. Effective stress and fatigue life prediction with mean stress correction models on a ferritic stainless steel sheet. Int. J. Fatigue 2022, 157, 106707. [Google Scholar] [CrossRef]

- Agnani, M.; Findley, K.O.; Thompson, S.W. Effects of retained austenite and martensite microstructure on fatigue crack propagation in quenched and tempered high carbon steels. Int. J. Fatigue 2024, 188, 108529. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, L.; Xu, G.; Wang, G.; Zhao, M. Fatigue fracture of surface-modified layers in 18CrNiMo7-6 carburized steel. Eng. Fail. Anal. 2022, 131, 105839. [Google Scholar] [CrossRef]

- Fomin, A.; Voyko, A.; Fomina, M.; Mokrousov, S.; Koshuro, V. Functionally graded Ti(C,N) coatings and their production on titanium using solid-state carburization associated with induction heat treatment. Compos. Struct. 2020, 245, 112393. [Google Scholar] [CrossRef]

- Gathmann, M.; Tönnißen, N.; Baron, C.; Kostka, A.; Steinbacher, M.; Springer, H. Surface hardening of high modulus steels through carburizing and nitriding: First insights into microstructure property relationships. Surf. Coat. Technol. 2024, 494, 131354. [Google Scholar] [CrossRef]

- Nový, F.; Harvanec, J.; Mičian, M. The Influence of Induction Hardening, Nitriding and Boronising on the Mechanical Properties of Conventional and Sintered Steels. Coatings 2024, 14, 1602. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.; Umezawa, O. Effect of Induction Hardening Following Carburizing–Nitriding Duplex Treatment on the Microstructure and Fatigue Strength of JIS-SCM420 Low-Alloy Steel. Metals 2025, 15, 944. https://doi.org/10.3390/met15090944

Kim M, Umezawa O. Effect of Induction Hardening Following Carburizing–Nitriding Duplex Treatment on the Microstructure and Fatigue Strength of JIS-SCM420 Low-Alloy Steel. Metals. 2025; 15(9):944. https://doi.org/10.3390/met15090944

Chicago/Turabian StyleKim, Minheon, and Osamu Umezawa. 2025. "Effect of Induction Hardening Following Carburizing–Nitriding Duplex Treatment on the Microstructure and Fatigue Strength of JIS-SCM420 Low-Alloy Steel" Metals 15, no. 9: 944. https://doi.org/10.3390/met15090944

APA StyleKim, M., & Umezawa, O. (2025). Effect of Induction Hardening Following Carburizing–Nitriding Duplex Treatment on the Microstructure and Fatigue Strength of JIS-SCM420 Low-Alloy Steel. Metals, 15(9), 944. https://doi.org/10.3390/met15090944