Effect of Increased Extrusion Ram Speed and Liquid Nitrogen Cooling on the Mechanical Properties of 6060 Aluminum Alloy

Abstract

1. Introduction

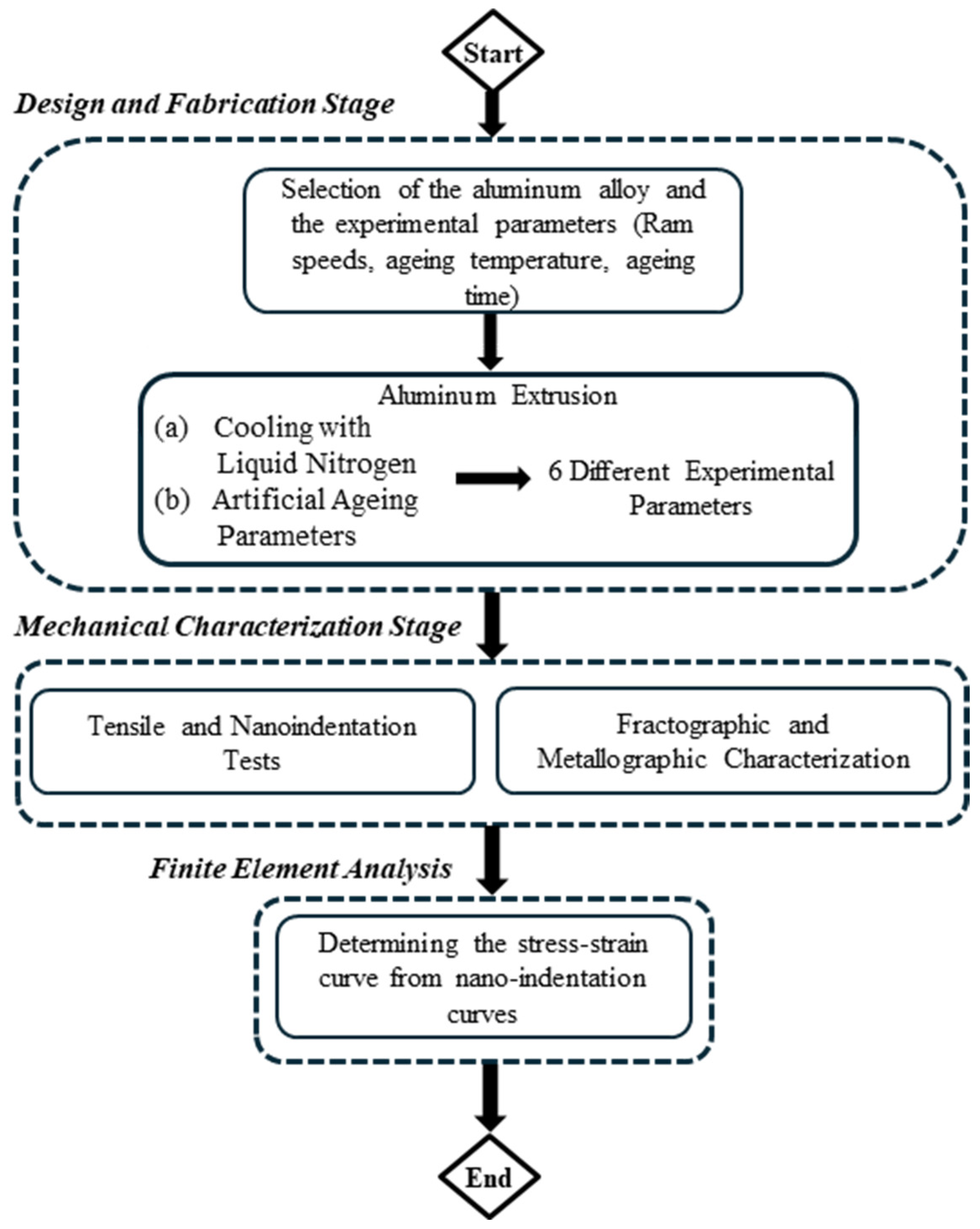

2. Methodology

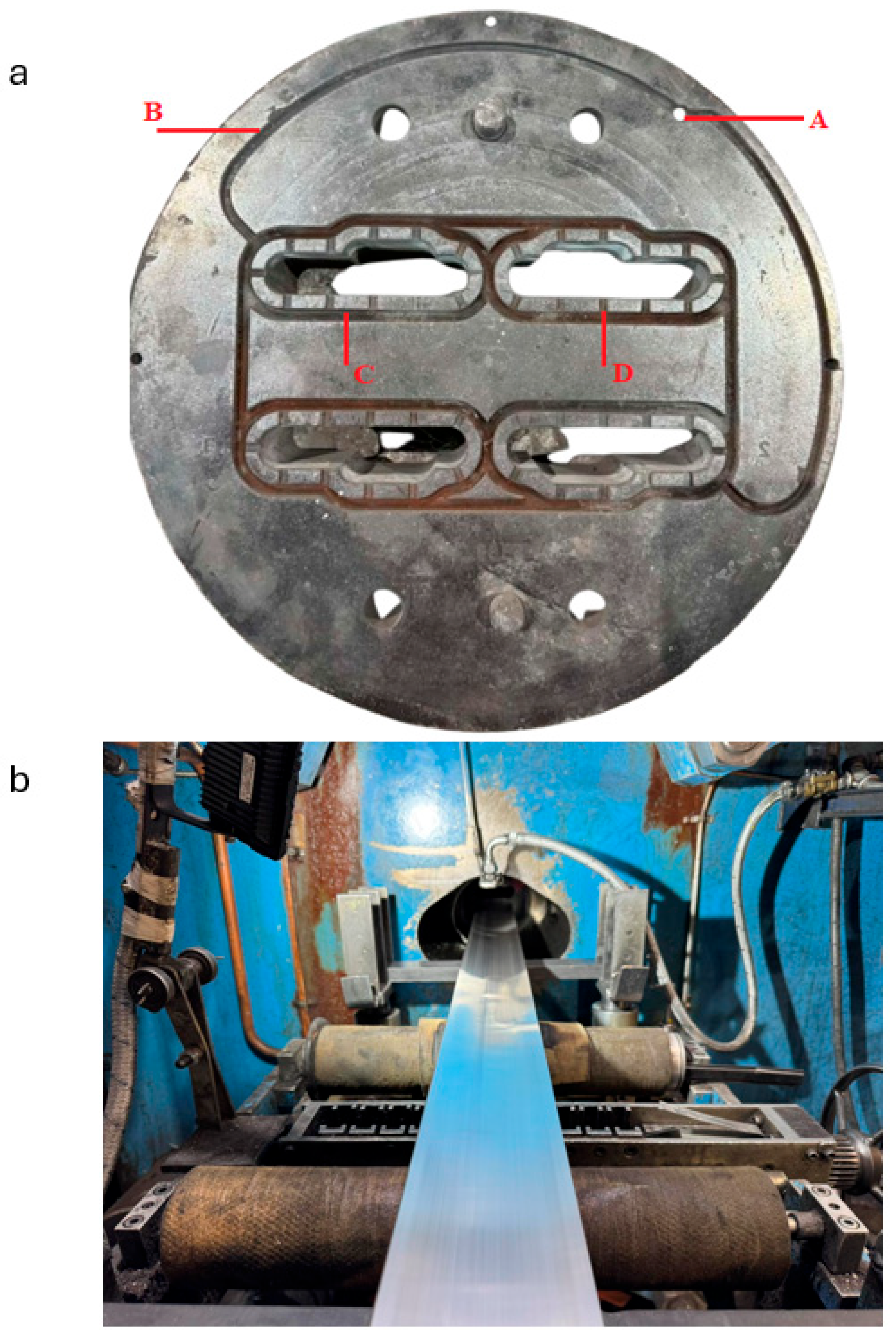

2.1. Materials and Sample Preparation

2.2. Tensile Tests

2.3. Nanoindentation Testing Supported by Finite Element Analysis

2.4. Fractographic and Metallographic Assessment Methods

3. Results and Discussion

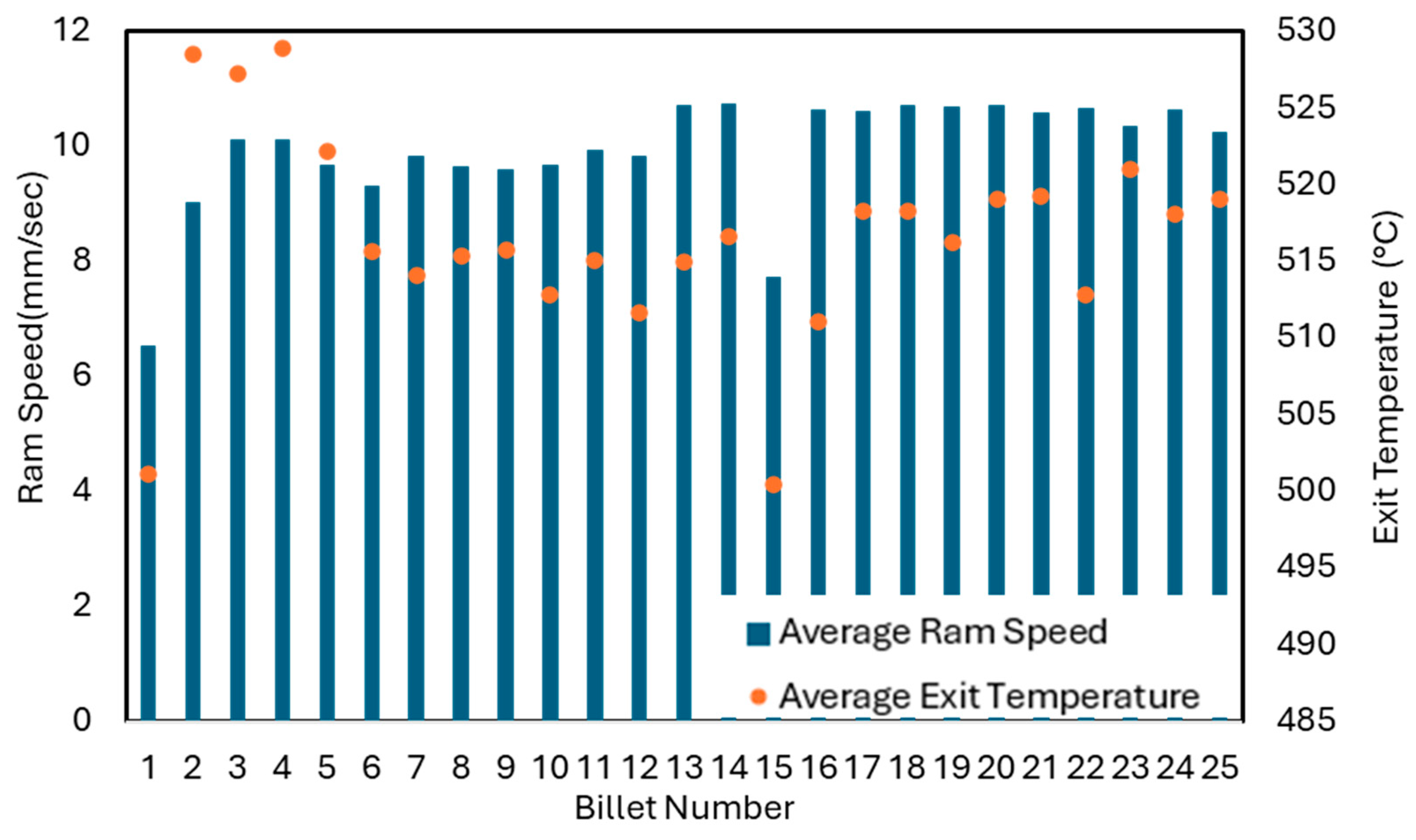

3.1. Production Data

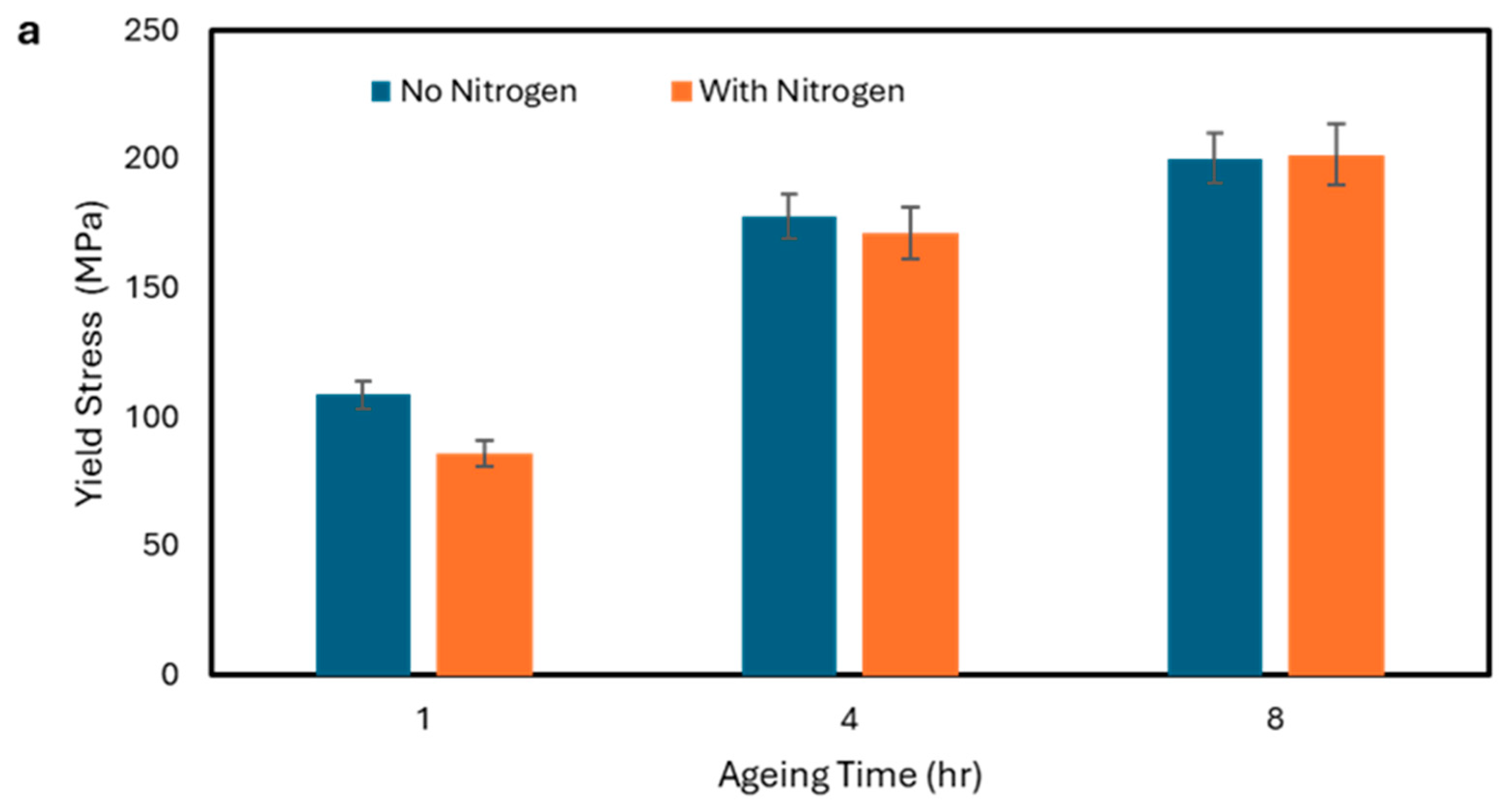

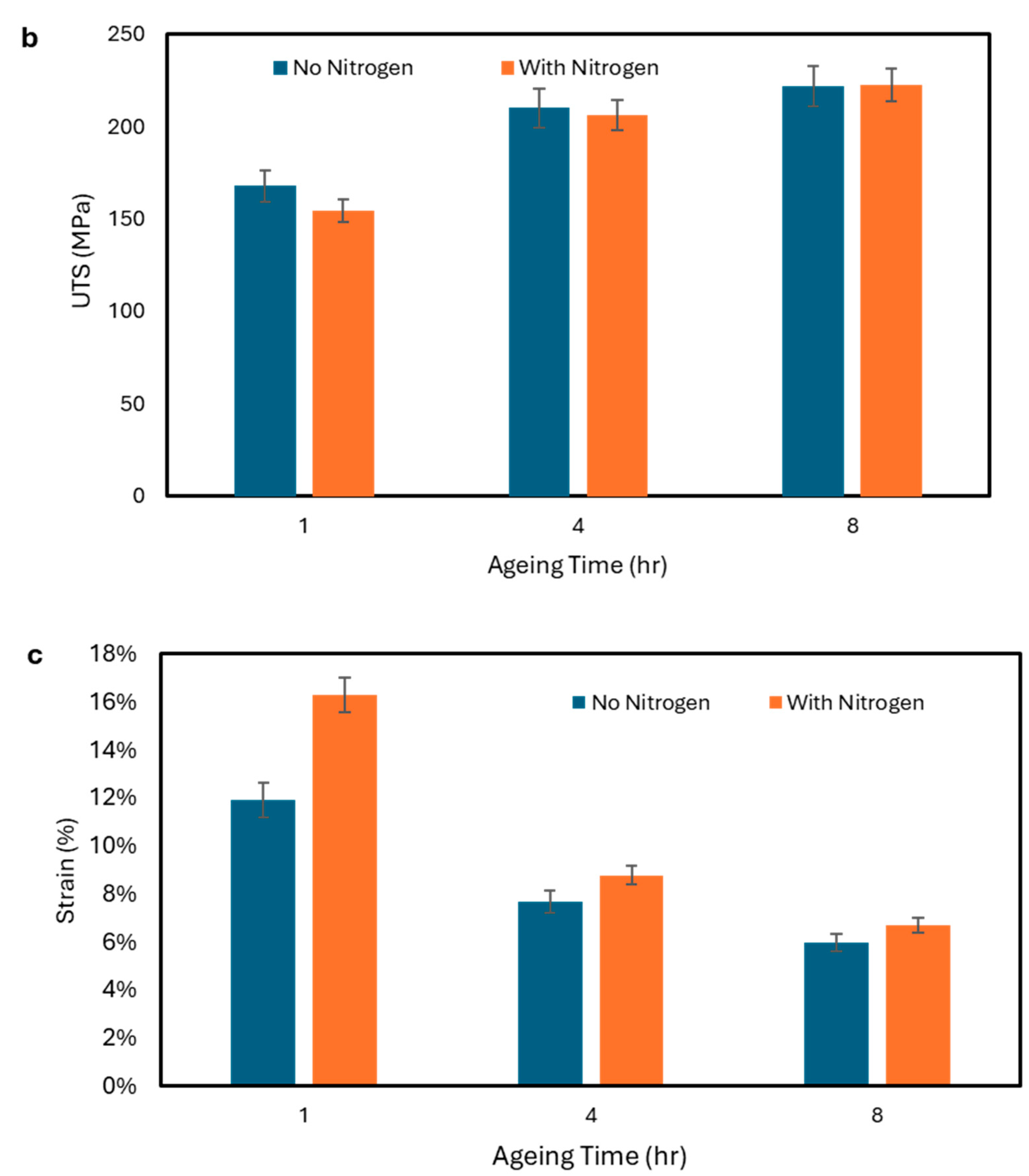

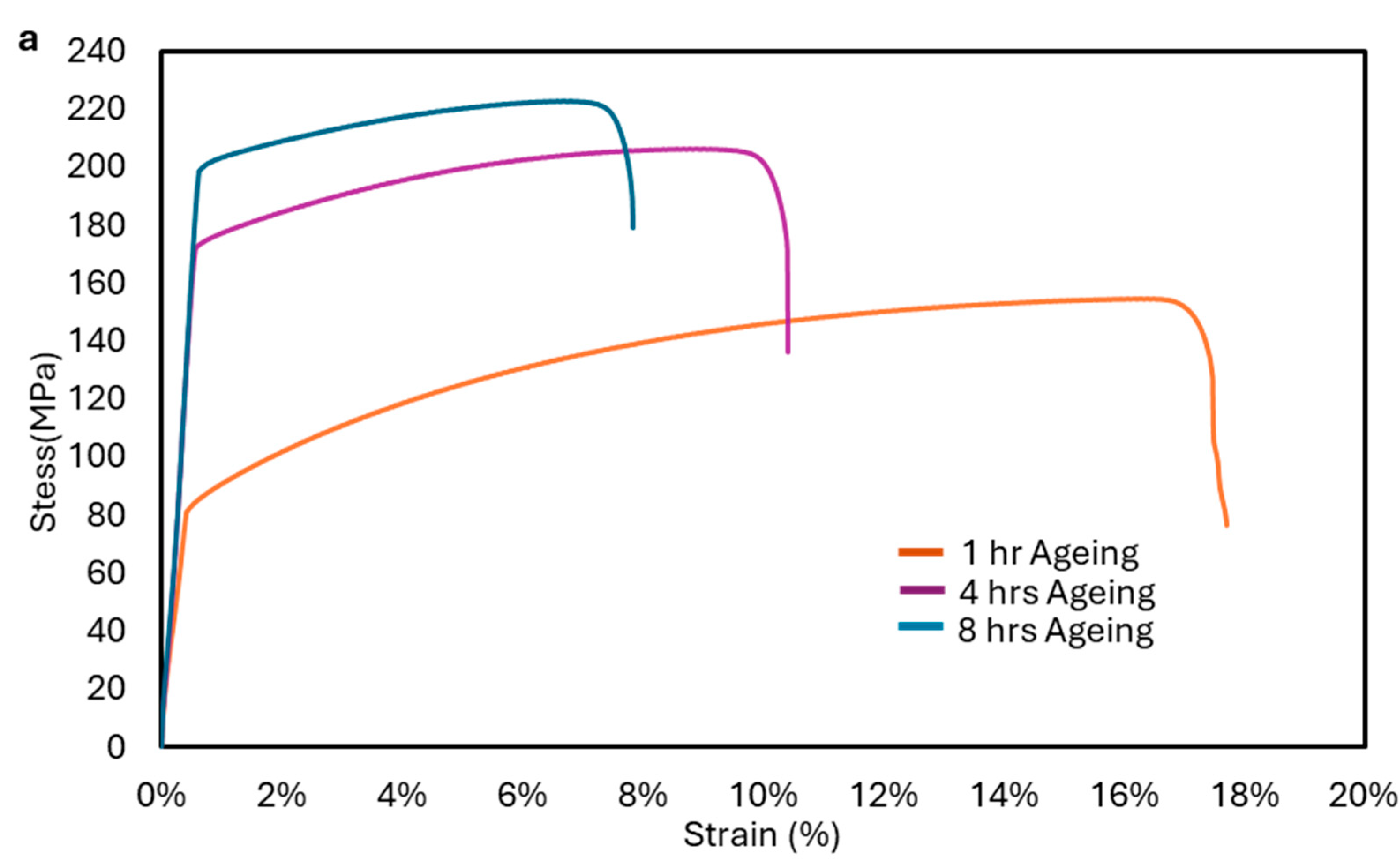

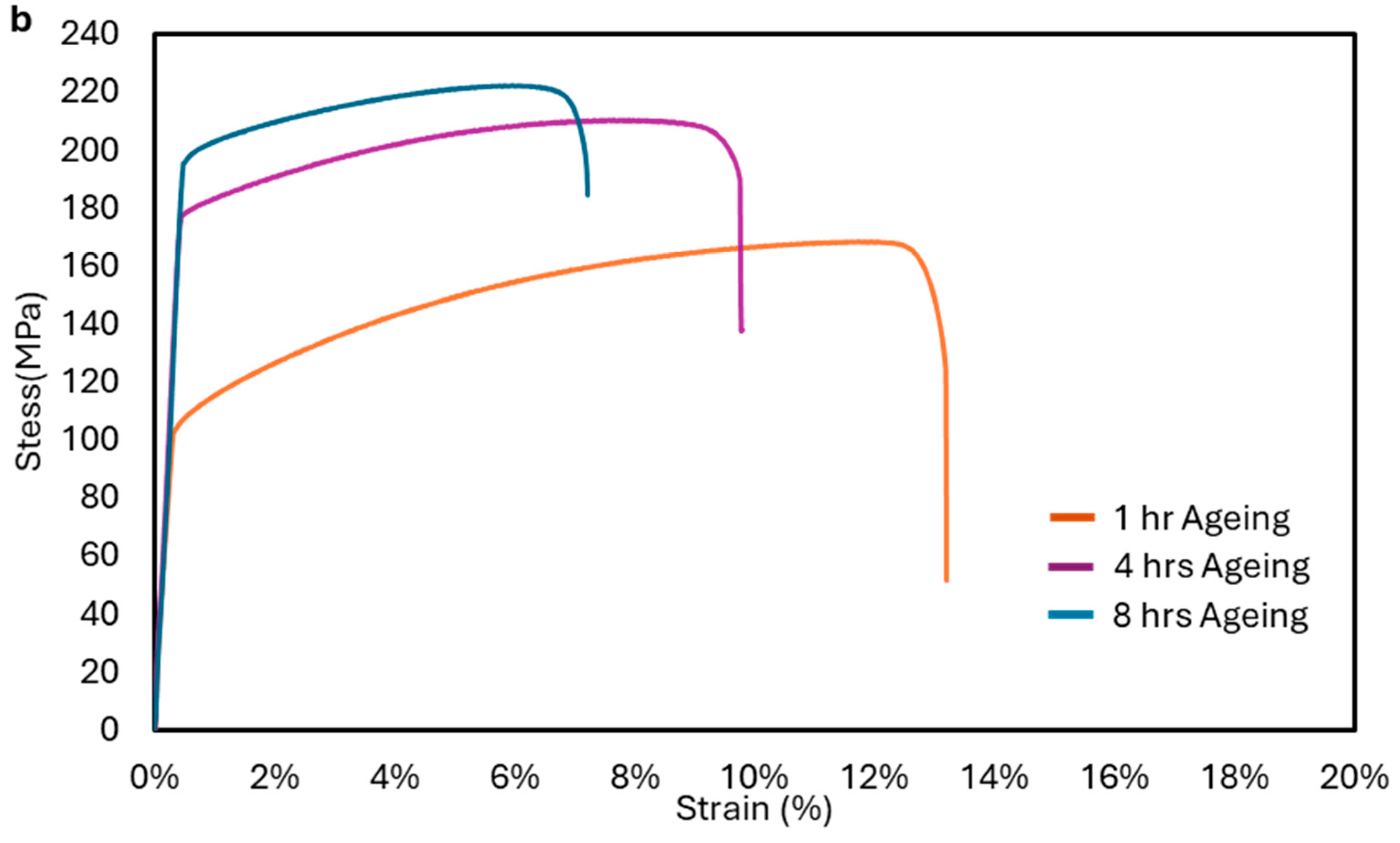

3.2. Tensile Test Results

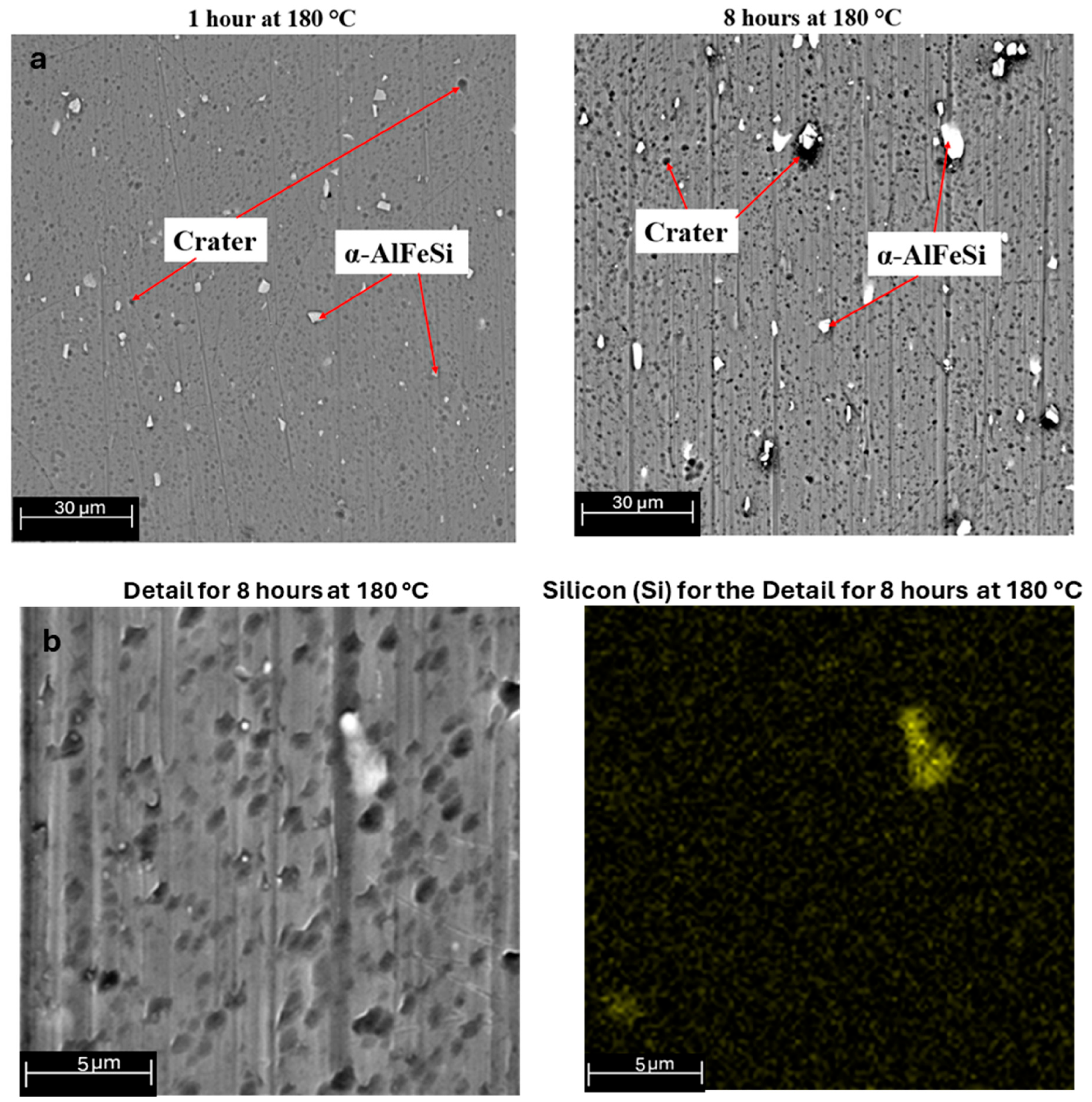

3.3. Fractographic and Metallographic Characterization

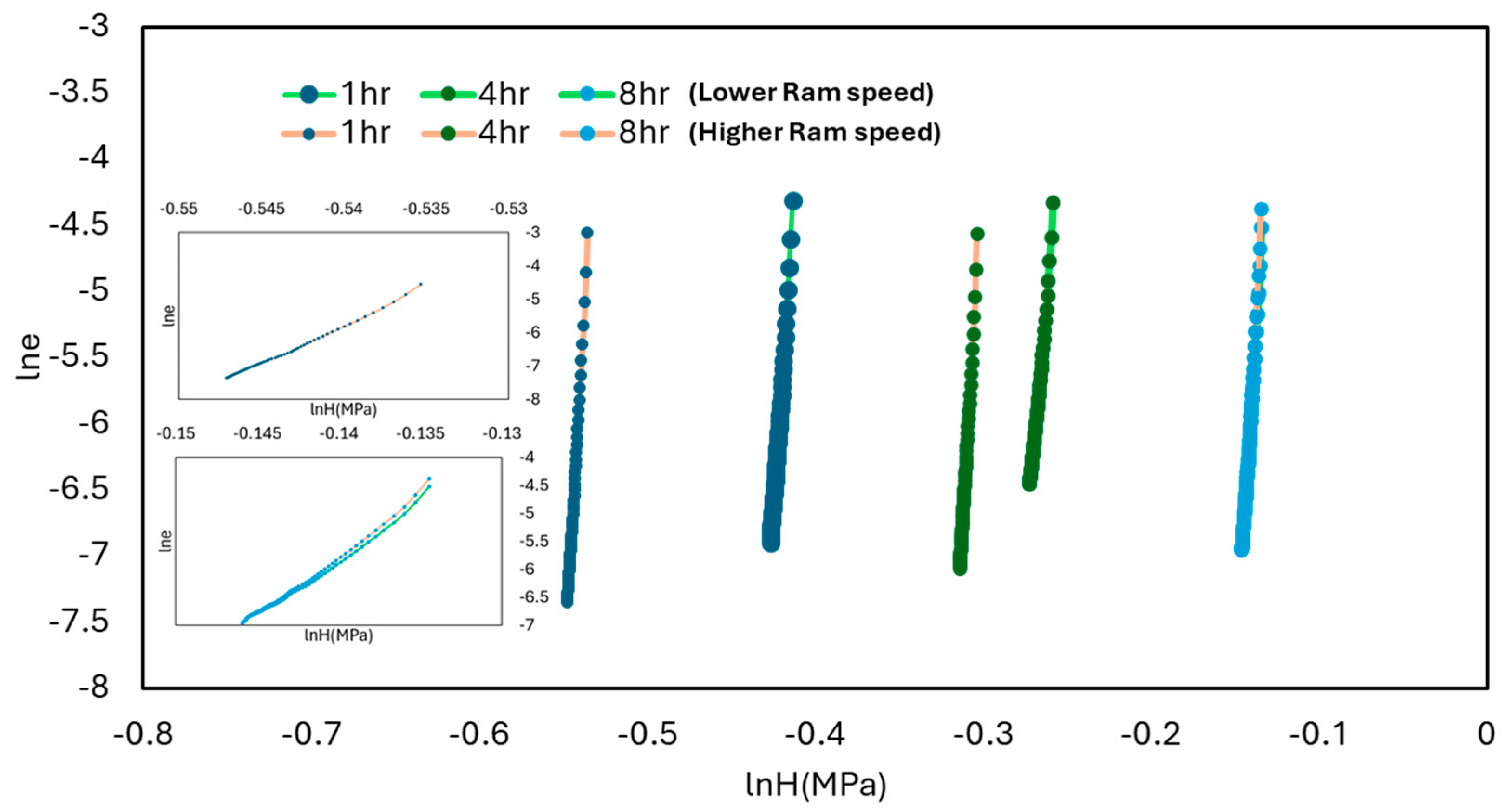

3.4. Nanoindentation Test Results

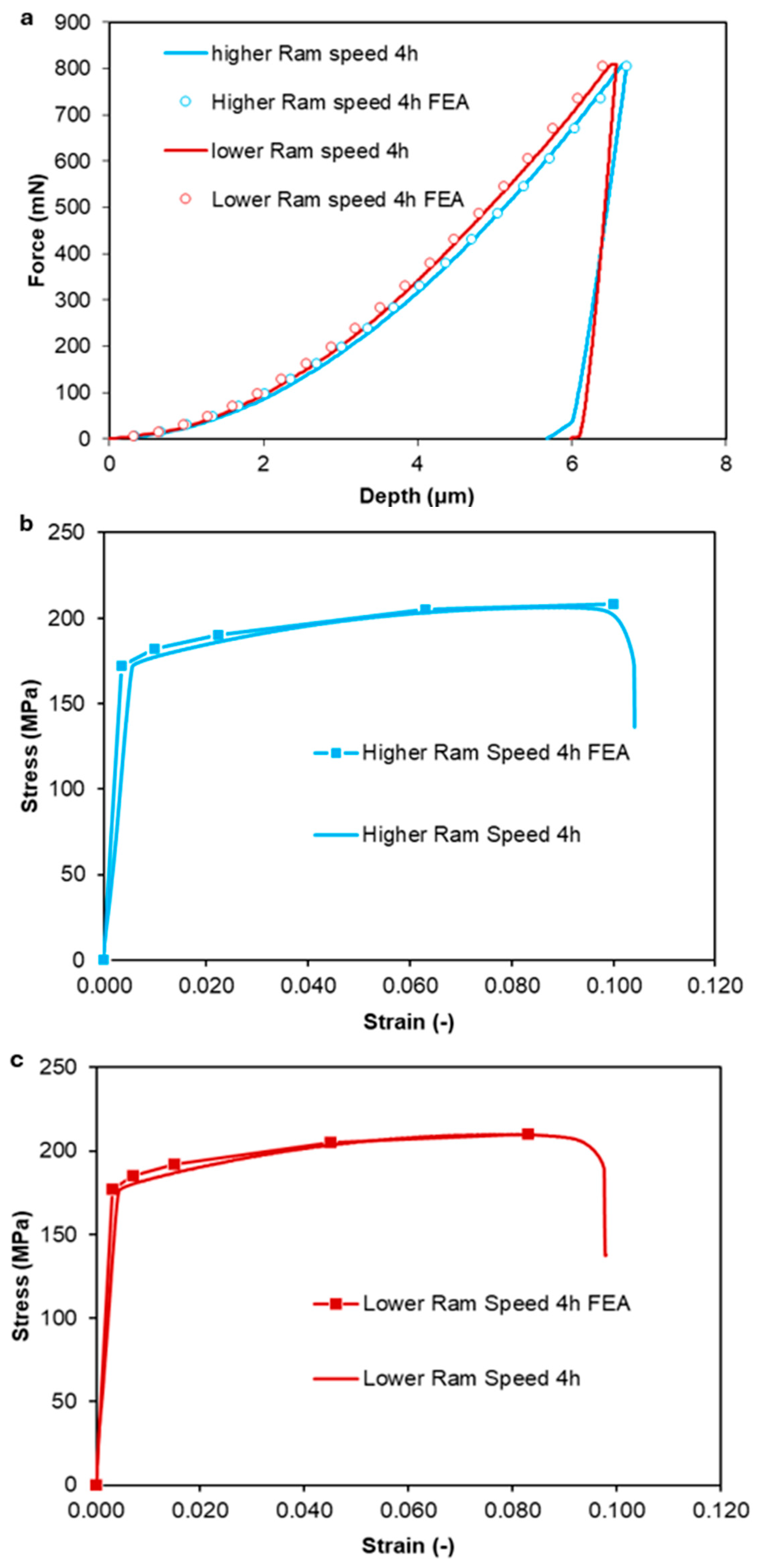

Load-Depth Curves

3.5. Finite Element Analysis Results

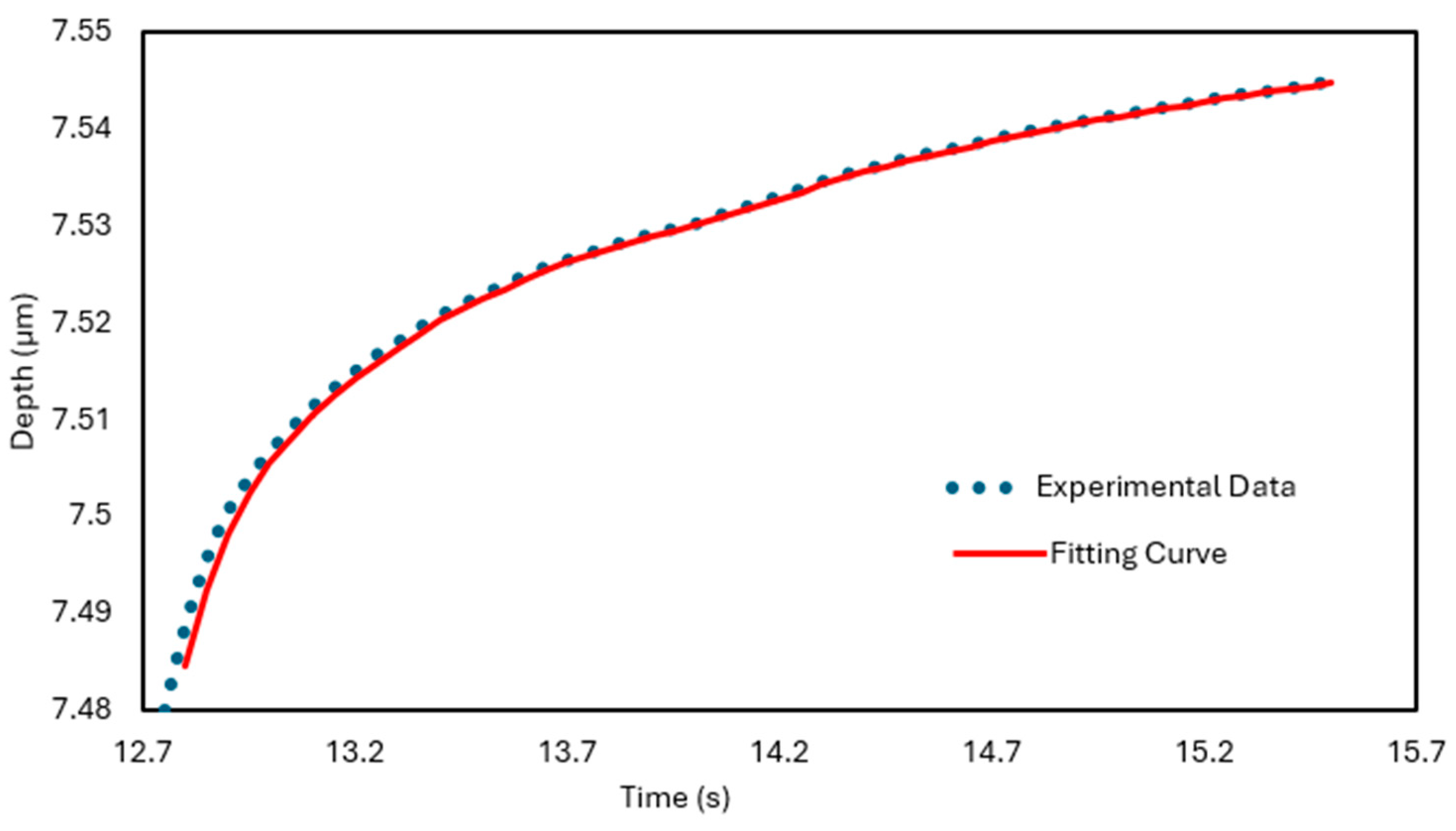

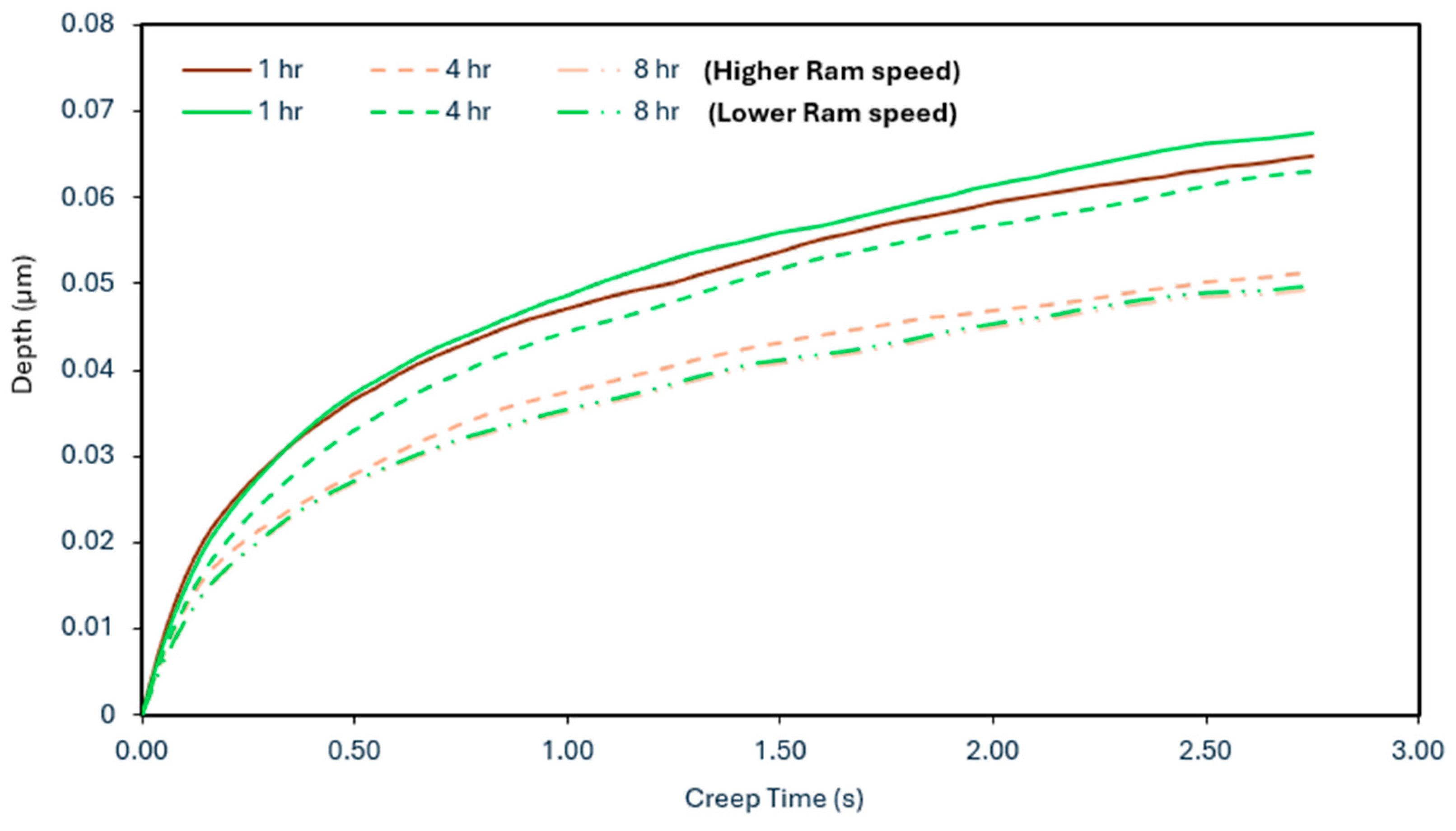

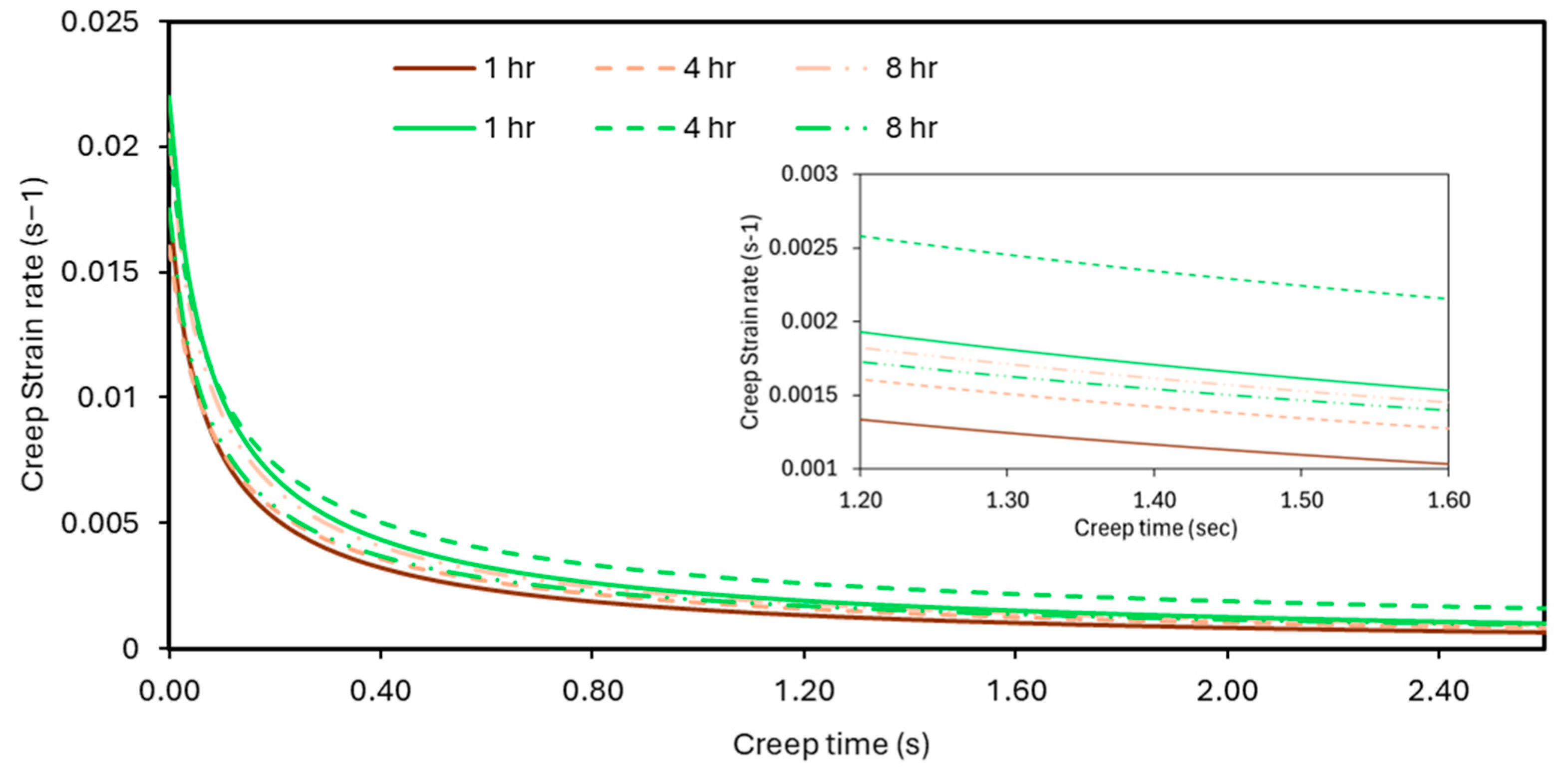

3.6. Nanoindentation Creep Behaviour

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gagliardi, F.; Ciancio, C.; Ambrogio, G. Optimization of porthole die extrusion by Grey-Taguchi relational analysis. Int. J. Adv. Manuf. Technol. 2018, 94, 719–728. [Google Scholar] [CrossRef]

- Bakhtiani, T.; El-Mounayri, H.; Zhang, J. Modeling of extrusion process of a condenser tube for investigating the effects of mandrel geometry. Int. J. Adv. Manuf. Technol. 2017, 92, 3237–3252. [Google Scholar] [CrossRef]

- Iqbal, U.M.; Kumar, V.S.S.; Gopalakannan, S. Application of Response Surface Methodology in optimizing the process parameters of Twist Extrusion process for AA6061-T6 aluminum alloy. Measurement 2016, 94, 126–138. [Google Scholar] [CrossRef]

- Wu, Y.; Liao, H. Corrosion Behavior of Extruded near Eutectic Al–Si–Mg and 6063 Alloys. J. Mater. Sci. Technol 2013, 29, 380–386. [Google Scholar] [CrossRef]

- Zhan, H.; Mol, J.M.C.; Hannour, F.; Zhuang, L.; Terryn, H.; De Wit, J.H.W. The influence of copper content on intergranular corrosion of model AlMgSi(Cu) alloys. Mater. Corros. 2008, 59, 670–675. [Google Scholar] [CrossRef]

- Zang, R.; Ning, Y.; Ding, L.; Jia, Z.; Xiang, K.; Liu, Q.; Cao, L.; Li, Y. Study on properties and precipitation behavior of 6000 series alloys with high Mg/Si ratios and Cu contents. Mater. Charact. 2022, 194, 112402. [Google Scholar] [CrossRef]

- Lesniak, D.; Gromek, P. Estimation of extrusion welding conditions for 6xxx aluminum alloys. Procedia Manuf. 2020, 47, 253–260. [Google Scholar] [CrossRef]

- Hannard, F.; Pardoen, T.; Maire, E.; Le Bourlot, C.; Mokso, R.; Simar, A. Characterization and micromechanical modelling of microstructural heterogeneity effects on ductile fracture of 6xxx aluminium alloys. Acta Mater. 2016, 103, 558–572. [Google Scholar] [CrossRef]

- Mróz, A.; Mania, R.J. The complex influence of aluminium aging on the dynamic response of the thin-walled AL-6060 alloy profil. Thin-Walled Struct. 2014, 79, 147–153. [Google Scholar] [CrossRef]

- Ammu, V.; Raju, I.; Chouhan, R.N.; Agnihotri, A. Effect of ram speed on surface quality and mechanical properties during extrusion of AA2024 alloy. Mater. Today Proc. 2024, 113, 258–263. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, C.; Li, Z.; Bao, S.; Ye, P.; Chen, Y. Effect of extrusion speed on microstructure and mechanical properties of Mg-Al-Ca-Sn alloy. Mater. Res. Express 2022, 9, 056508. [Google Scholar] [CrossRef]

- Li, J.; Zhang, A.; Pan, H.; Ren, Y.; Zeng, Z.; Huang, Q.; Yang, C.; Ma, L.; Qin, G. Effect of extrusion speed on microstructure and mechanical properties of the Mg-Ca binary alloy. J. Magnes. Alloy. 2021, 9, 1297–1303. [Google Scholar] [CrossRef]

- Zhao, Y.; Pei, J.; Guo, L.; Yun, X.; Ma, H. Effects of extrusion speed of continuous extrusion with double billets on welding performance of 6063 Al alloy. Trans. Nonferrous Met. Soc. China 2021, 31, 1561–1571. [Google Scholar] [CrossRef]

- Saha, P.K. Aluminum Extrusion Technology; ASM International: Materials Park, OH, USA, 2000; Chapter 2. [Google Scholar]

- Zasadziński, J.; Libura, W.; Richert, J. Fundamentals of Advanced Aluminum Extrusion Processes. In Proceedings of the 8th International Extrusion Technology Seminar, Orlando, Florida, 18–21 May 2004; Volume 2, pp. 391–397. [Google Scholar]

- Klaus, A. How to Benefit from Isothermal Extrusion. In Proceedings of the 11th International Extrusion Technology Seminar, Chicago, IL, USA, 2–6 May 2016; Volume 2, pp. 215–220. [Google Scholar]

- Stratton, P. Raising productivity of aluminum extrusion with nitrogen. Int. Heat. Treat. Surf. Eng. 2008, 2, 105–108. [Google Scholar] [CrossRef]

- Ward, T.J.; Kelly, R.M.; Jones, G.A.; Heffron, J.F. Effects of nitrogen—Liquid and gaseous—On aluminum extrusion. JOM 1984, 36, 29–33. [Google Scholar] [CrossRef]

- Ruppin, D.; Mueller, K. Influence of mandrel cooling in the direct extrusion of aluminum tubing using stationary or moving mandrels. Alum. Dusseld. 1982, 58, 402–406. [Google Scholar]

- Kim, H.H.; Cho, S.H.; Kang, C.G. Evaluation of microstructure and mechanical properties by using nano/micro-indentation and nanoscratch during aging treatment of rheo-forged Al 6061 alloy. Mater. Sci. Eng. A 2008, 485, 272–281. [Google Scholar] [CrossRef]

- Peng, G.; Ma, Y.; Hu, J.; Jiang, W.; Huan, Y.; Chen, Z.; Zhang, T. Nanoindentation hardness distribution and strain field and fracture evolution in dissimilar friction stir-welded AA 6061-AA 5A06 aluminum alloy joints. Adv. Mater. Sci. Eng. 2018, 2018, 4873571. [Google Scholar] [CrossRef]

- Ogura, T.; Ueda, K.; Saito, Y.; Hirose, A. Evaluation of interfacial microstructures in dissimilar joints of aluminum alloys to steel using nanoindentation technique. Mater. Trans. 2011, 52, 979–984. [Google Scholar] [CrossRef]

- Charitidis, C.A.; Dragatogiannis, D.A.; Koumoulos, E.P. A study on time dependent properties of aluminum alloy by nanoindentation technique. Int. J. Struct. Integr. 2013, 4, 33–54. [Google Scholar] [CrossRef]

- Chen, J.; Bull, S.J. The investigation of creep of electroplated Sn and Ni–Sn coating on copper at room temperature by nanoindentation. Surf. Coat. Technol. 2009, 203, 1609–1617. [Google Scholar] [CrossRef]

- Blum, W.; Li, Y.; Breutinger, F. Deformation kinetics of coarse-grained and ultrafine-grained commercially pure Ti. Mater. Sci. Eng. A 2006, 462, 275–278. [Google Scholar] [CrossRef]

- Chatterjee, A.; Srivastava, M.; Sharma, G.; Chakravartty, J.K. Investigations on plastic flow and creep behaviour in nano and ultrafine grain Ni by nanoindentation. Mater. Lett. 2014, 130, 29–31. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Q.; Zhao, X.; Yang, X.; Luo, L. Ambient-temperature nanoindentation creep in ultrafine-grained titanium processed by ECAP. Mater. Sci. Eng. A 2016, 676, 73–79. [Google Scholar] [CrossRef]

- Giarmas, E.; Tzimtzimis, E.; Tzetzis, D. The influence of ageing conditions and liquid nitrogen cooling of extrusion dies on nanoindentation creep in 6060 alumiium alloy. Int. J. Adv. Manuf. Technol 2025, 137, 6187–6205. [Google Scholar] [CrossRef]

- EN ISO 6892-1:2019; Metallic Materials—Tensile Testing. International Organization for Standardization: Geneva, Switzerland, 2019.

- Oliver, W.; Pharr, G. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Mansour, G.; Tzetzis, D.; Bouzakis, K.D. A nanomechanical approach on the measurement of the elastic properties of epoxy reinforced carbon nanotube nanocomposites. Tribol. Ind. 2013, 35, 190–199. [Google Scholar]

- Tzetzis, D.; Mansour, G.; Tsiafis, I.; Pavlidou, E. Nanoindentation measurements of fumed silica epoxy reinforced nanocomposites. J. Reinf. Plast. Compos. 2013, 32, 163–173. [Google Scholar] [CrossRef]

- Mansour, G.; Tzetzis, D. Nanomechanical Characterization of Hybrid Multiwall Carbon Nanotube and Fumed Silica Epoxy Nanocomposites. Polym. Plast. Technol. Eng. 2013, 52, 1054–1062. [Google Scholar] [CrossRef]

- Tzetzis, D.; Tsongas, K.; Mansour, G. Determination of the mechanical properties of epoxy silica nanocomposites through FEA-supported evaluation of ball indentation test results. Mater. Res. 2017, 20, 1571–1578. [Google Scholar] [CrossRef]

- Tsongas, K.; Tzetzis, D.; Karantzalis, A.; Banias, G.; Exarchos, D.; Ahmadkhaniha, D.; Zanella, C.; Matikas, T.; Bochtis, D. Microstructural, surface topology and nanomechanical characterization of electrodeposited Ni-P/SiC nanocomposite coatings. Appl. Sci. 2019, 9, 2901. [Google Scholar] [CrossRef]

- EN 755-9; Aluminium and Aluminium Alloys—Extruded Rod/Bar, Tube and Profiles—Part 9: Profiles, Tolerances on Dimensions and Form. National Standards Authority of Ireland: Dublin, Ireland, 2016.

- Mayo, M.J.; Siegel, R.W.; Liao, Y.X.; Nix, W.D. Nanoindentation of nanocrystalline ZnO. J. Mater. Res. 1992, 7, 973–979. [Google Scholar] [CrossRef]

- Grote, K.H.; Antonsson, E.K. Springer Handbook of Mechanical Engineering; Springer: New York, NY, USA, 2009. [Google Scholar]

- Shen, L.; Cheong, W.C.D.; Foo, Y.L.; Chen, Z. Nanoindentation creep of tin and aluminium: A comparative study between constant load and constant strain rate methods. Mater. Sci. Eng. A 2012, 532, 505–510. [Google Scholar] [CrossRef]

- Lucas, B.N.; Oliver, W.C. Indentation power-law creep of high-purity indium. Metall. Mater. Trans. A 1999, 30, 601–610. [Google Scholar] [CrossRef]

- Ding, Z.Y.; Song, Y.X.; Ma, Y.; Huang, X.W.; Zhang, T.H. Nanoindentation Investigation on the Size-Dependent Creep Behavior in a Zr-Cu-Ag-Al Bulk Metallic Glass. Metals 2019, 9, 613. [Google Scholar] [CrossRef]

- Lin, P.; Chou, H.; Huang, J.; Chuang, W.; Jang, J.; Nieh, T. Elevated-temperature creep of high-entropy alloys via nanoindentation. MRS Bull. 2019, 44, 860–866. [Google Scholar] [CrossRef]

- Ma, Z.; Long, S.; Zhou, Y.; Pan, Y. Indentation scale dependence of tip-in creep behavior in Ni thin films. Scr. Mater. 2008, 59, 195–198. [Google Scholar] [CrossRef]

- Ma, Y.; Feng, Y.; Debela, T.T.; Peng, G.; Zhang, T. Nanoindentation study on the creep characteristics of high-entropy alloy films: Fcc versus bcc structures. Int. J. Refract. Met. Hard Mater. 2016, 54, 395–400. [Google Scholar] [CrossRef]

- Kang, Y.B.; Shim, S.H.; Lee, K.H.; Hong, S.I. Dislocation creep behavior of CoCrFeMnNi high entropy alloy at intermediate temperatures. Mater. Res. Lett. 2018, 6, 689–695. [Google Scholar] [CrossRef]

- Karantzalis, A.E.; Sioulas, D.; Poulia, A.; Mathiou, C.; Georgatis, E. A first approach on the assessment of the creep behavior of MoTaNbVxTi high entropy alloys by indentation testing. SN Appl. Sci. 2020, 2, 950. [Google Scholar] [CrossRef]

- Sokoli, V.; Kamnis, S.; Delibasis, K.; Georgatis, E.; Kiape, S.; Karantzalis, A.E. The Advanced Assessment of Nanoindentation-Based Mechanical Properties of a Refractory MoTaNbWV High-Entropy Alloy: Metallurgical Considerations and Extensive Variable Correlation Analysis. Appl. Sci. 2024, 14, 2752. [Google Scholar] [CrossRef]

- Huda, Z. Creep Behavior of Materials. In Mechanical Behavior of Materials, Mechanical Engineering Series; Springer: Berlin, Germany, 2002. [Google Scholar]

| Alloy | Mg | Si | Fe | Mn | Cu | Cr | Zn | Ti |

|---|---|---|---|---|---|---|---|---|

| 6060 | 0.38 | 0.5 | 0.23 | 0.019 | 0.021 | 0.005 | 0.061 | 0.014 |

| Billet Length (mm) | Temp. at Zone 1 (°C) | Temp. at Zone 2 (°C) | Temp. at Zone 3 (°C) |

|---|---|---|---|

| 1000 | 470 | 450 | 430 |

| Set of Parameters | Asymptotic Standard Error | |

|---|---|---|

| a = −0.0236804 | ±0.005829 | (24.62%) |

| b = 0.137568 | ±0.03071 | (22.32%) |

| c = −0.0827564 | ±0.03781 | (45.69%) |

| hi = 7.4573 | ±0.01295 | (0.1737%) |

| ti = 12.7157 | ±0.01287 | (0.09366%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giarmas, E.; Tzimtzimis, E.; Tsongas, K.; Korlos, A.; David, C.; Tzetzis, D. Effect of Increased Extrusion Ram Speed and Liquid Nitrogen Cooling on the Mechanical Properties of 6060 Aluminum Alloy. Metals 2025, 15, 1136. https://doi.org/10.3390/met15101136

Giarmas E, Tzimtzimis E, Tsongas K, Korlos A, David C, Tzetzis D. Effect of Increased Extrusion Ram Speed and Liquid Nitrogen Cooling on the Mechanical Properties of 6060 Aluminum Alloy. Metals. 2025; 15(10):1136. https://doi.org/10.3390/met15101136

Chicago/Turabian StyleGiarmas, Evangelos, Emmanouil Tzimtzimis, Konstantinos Tsongas, Apostolos Korlos, Constantine David, and Dimitrios Tzetzis. 2025. "Effect of Increased Extrusion Ram Speed and Liquid Nitrogen Cooling on the Mechanical Properties of 6060 Aluminum Alloy" Metals 15, no. 10: 1136. https://doi.org/10.3390/met15101136

APA StyleGiarmas, E., Tzimtzimis, E., Tsongas, K., Korlos, A., David, C., & Tzetzis, D. (2025). Effect of Increased Extrusion Ram Speed and Liquid Nitrogen Cooling on the Mechanical Properties of 6060 Aluminum Alloy. Metals, 15(10), 1136. https://doi.org/10.3390/met15101136