Microstructure and Mechanical Properties of Y-Doped AlCoCrFeNi2.1 Eutectic High-Entropy Alloy Fabricated by PBF-LB/M

Abstract

1. Introduction

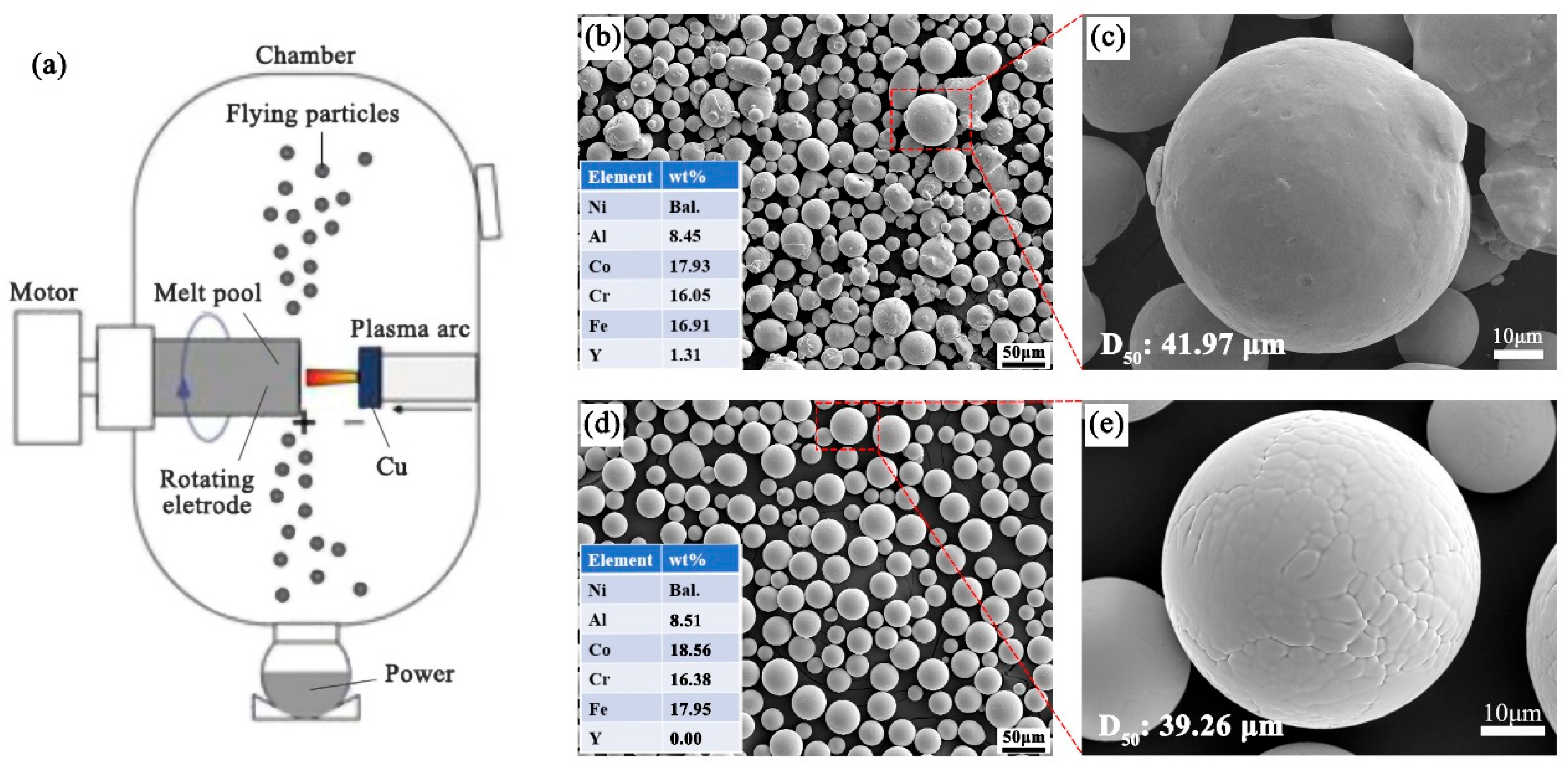

2. Materials and Methods

3. Results and Discussion

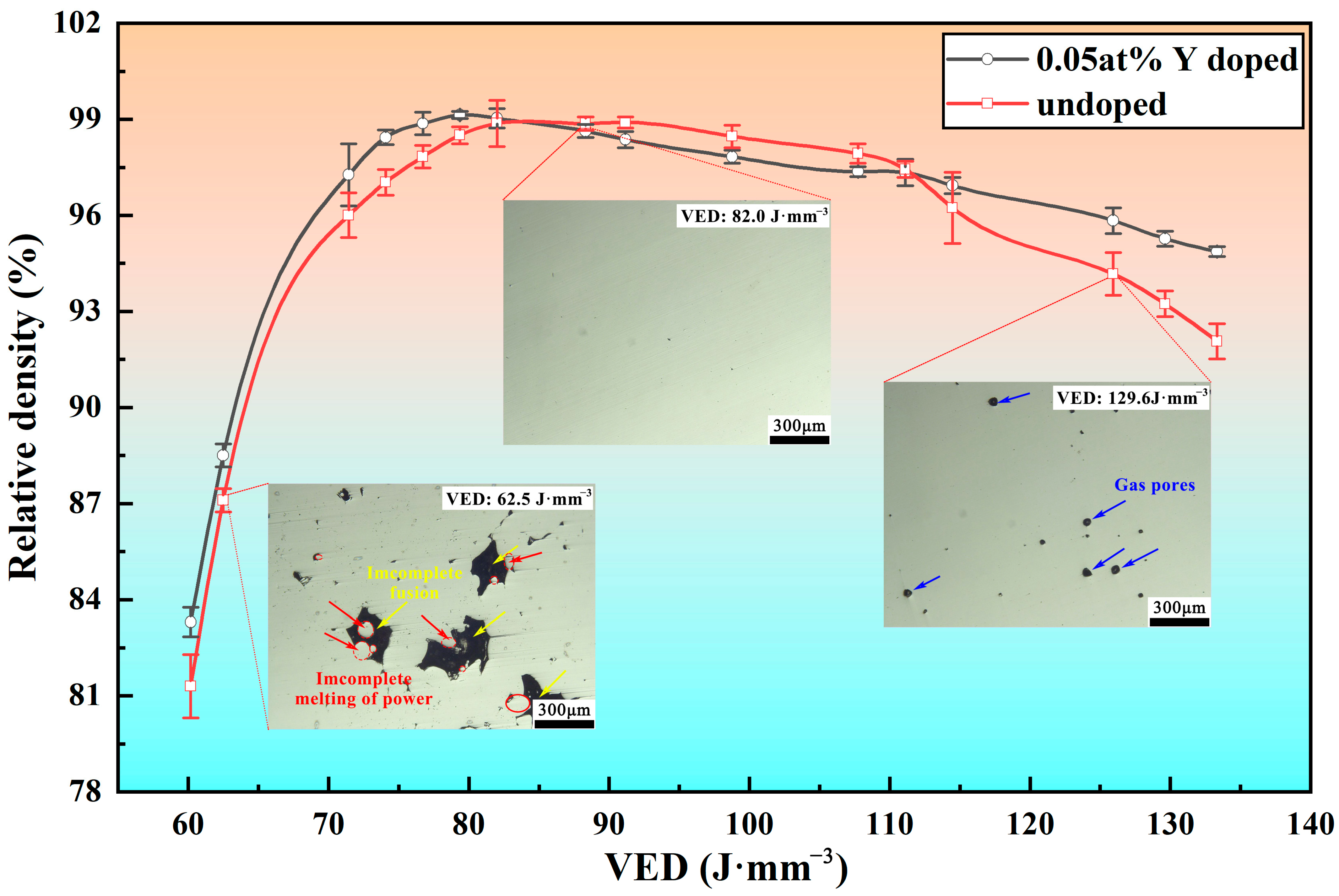

3.1. Relative Density and Processing Parameters

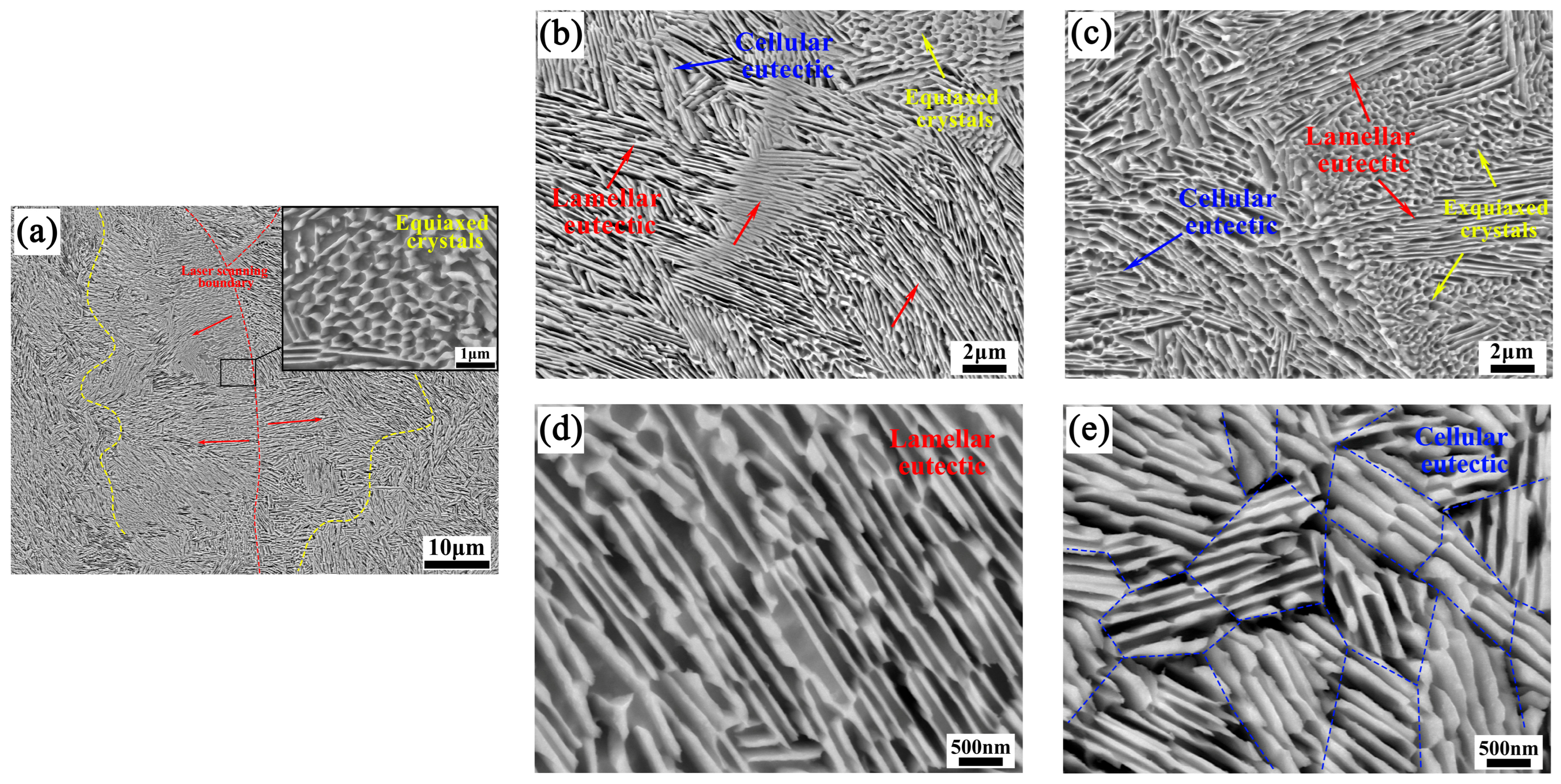

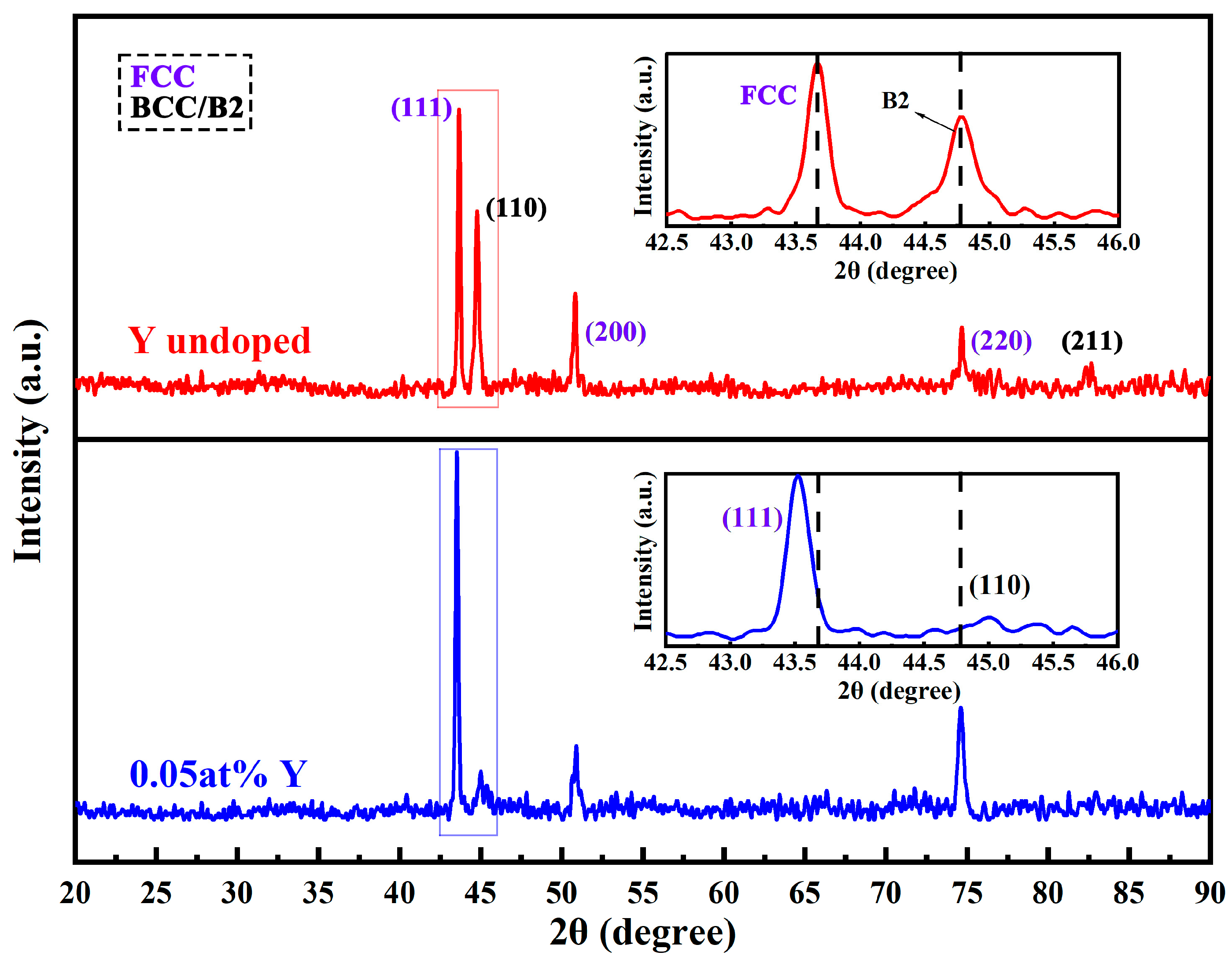

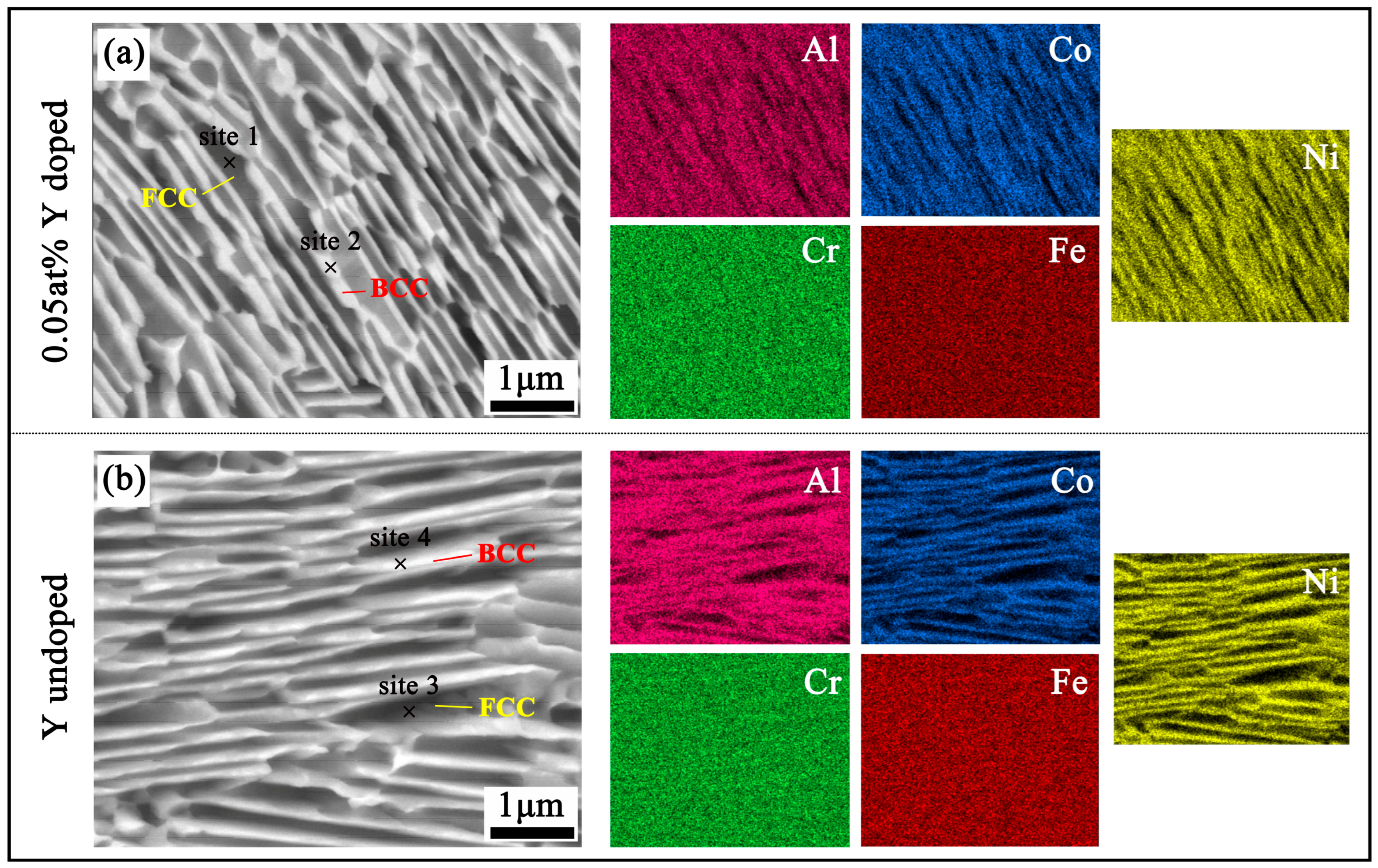

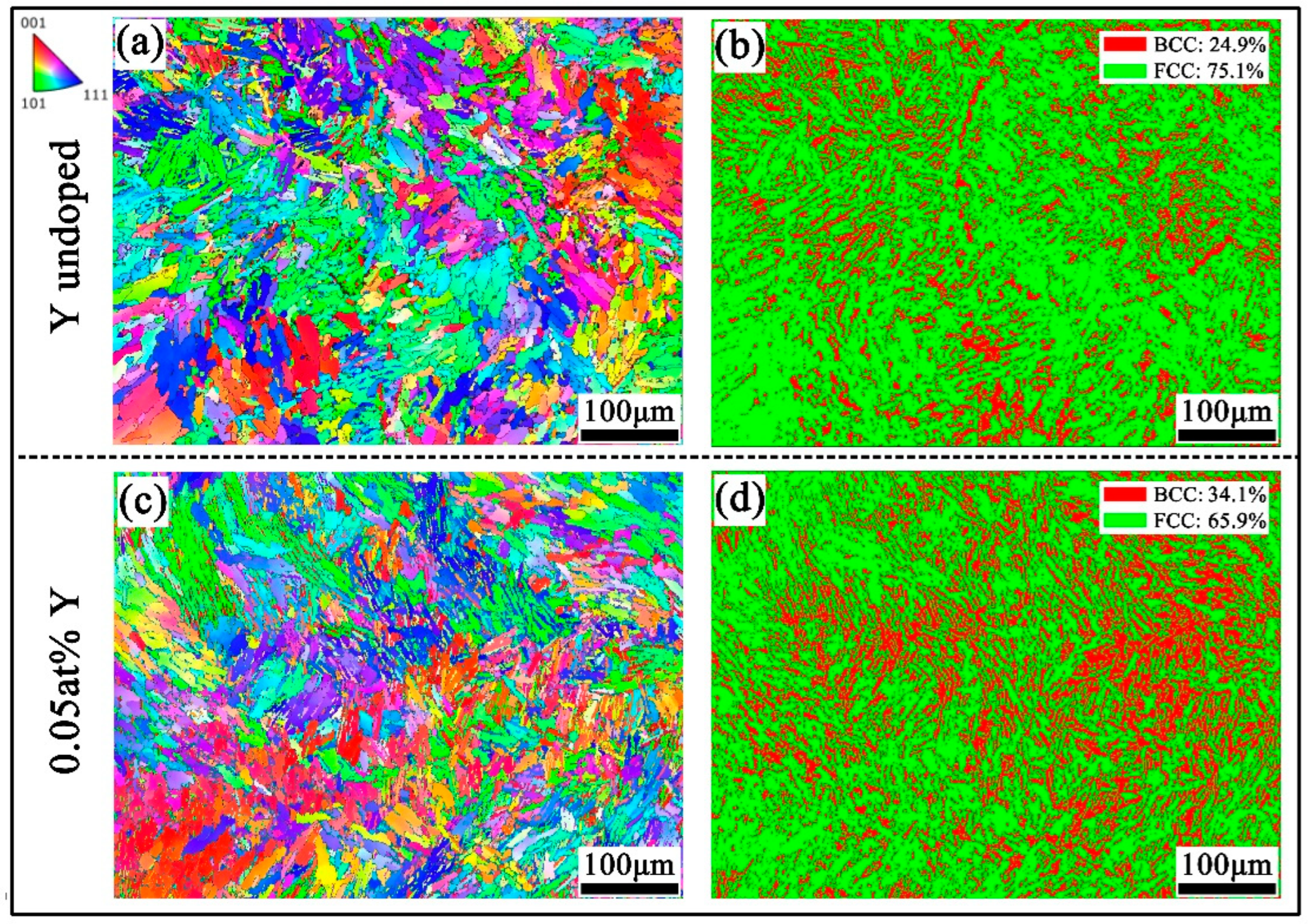

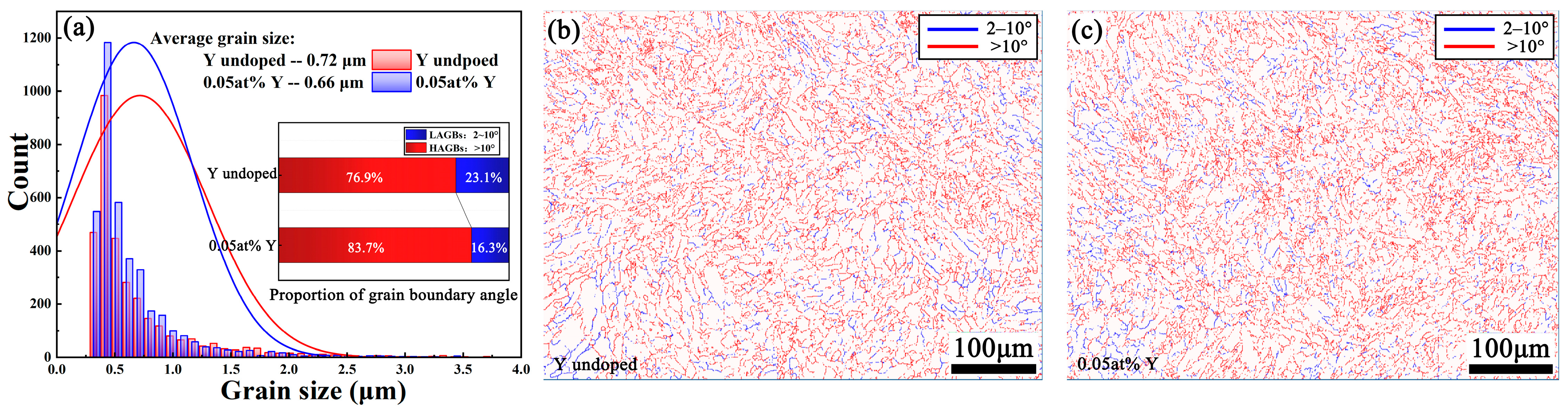

3.2. Microstructural Morphology and Phase Analysis

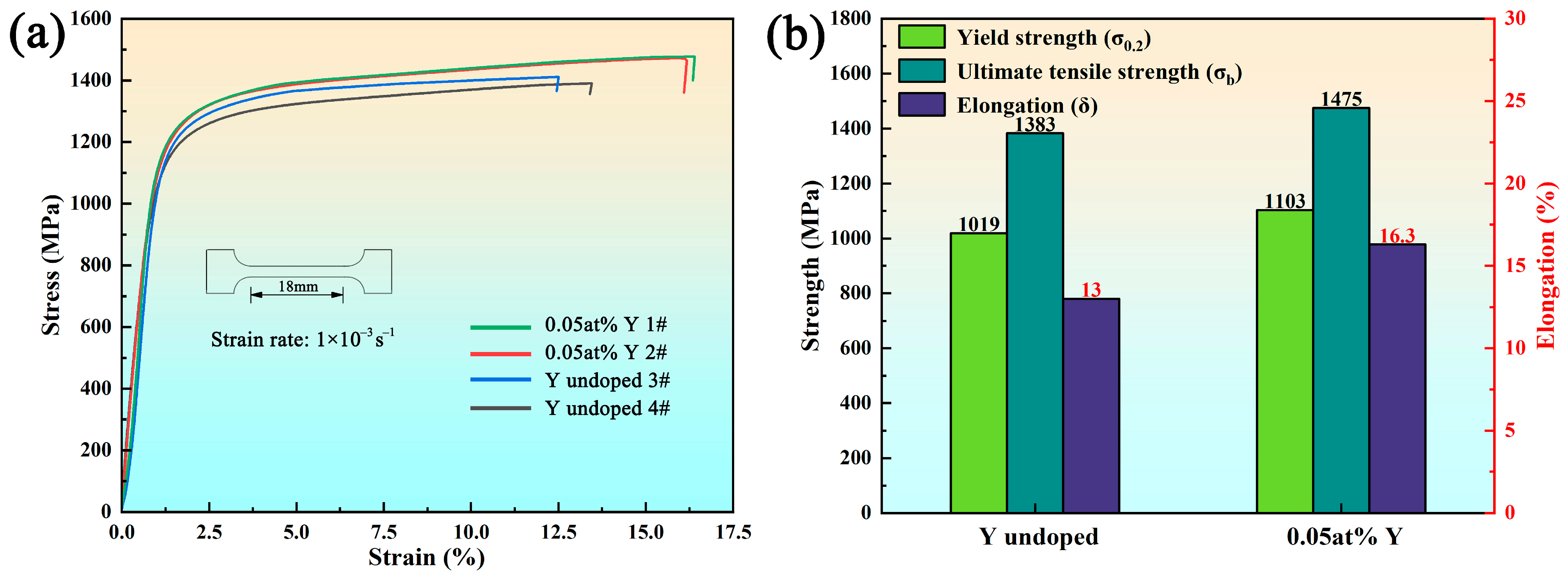

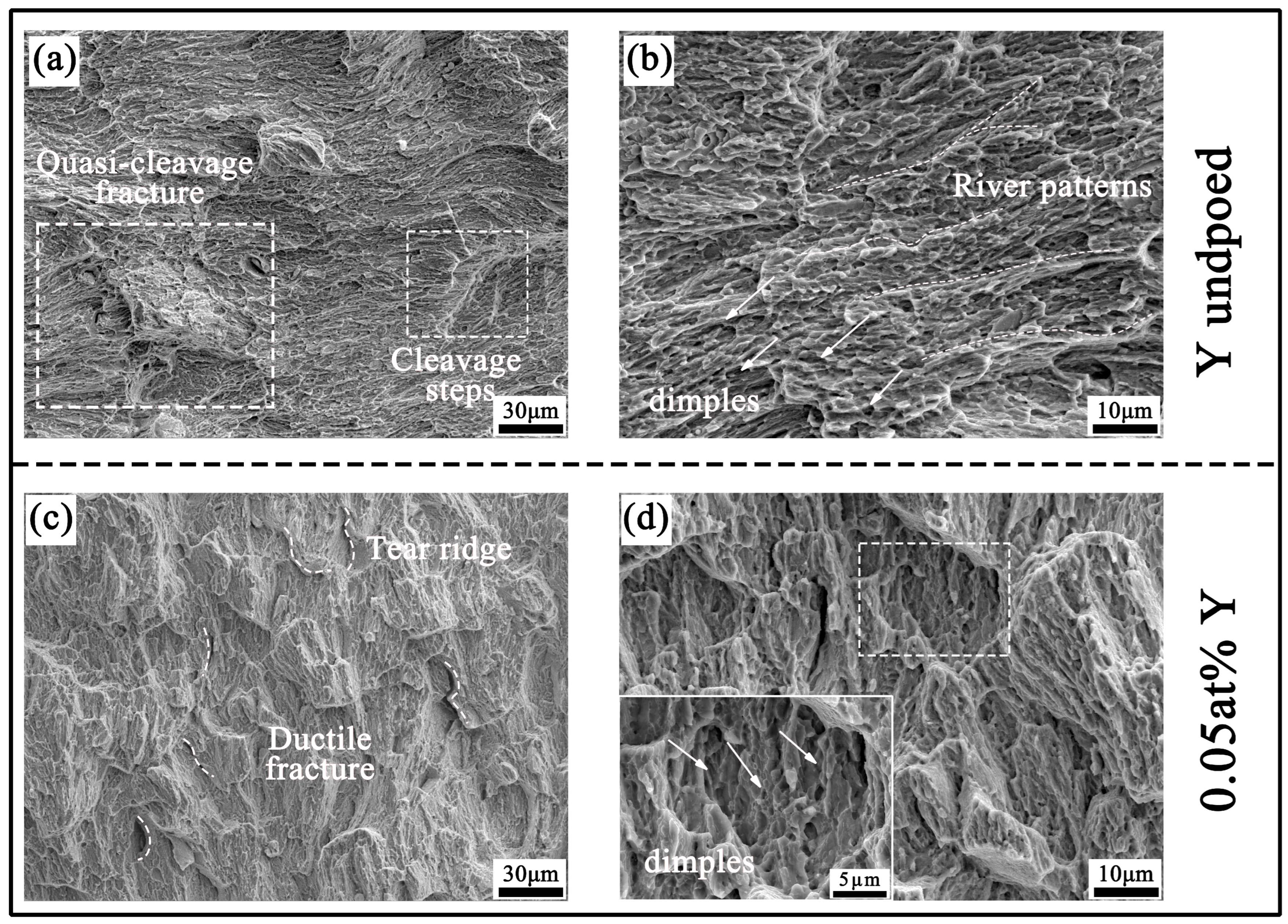

3.3. Tensile Properties and Analysis of Fracture Morphology

4. Conclusions

- Y addition significantly refines the eutectic microstructure and increases the volume fraction of the BCC phase, while simultaneously suppressing the long-range ordering of the B2 structure due to lattice distortion and solute redistribution effects.

- EBSD analysis reveals a reduced grain size and a notable decrease in the proportion of low-angle grain boundaries, indicating enhanced intergranular misorientation and refined grain boundary structures, which contribute to both strength and ductility improvement.

- Tensile tests demonstrate a simultaneous enhancement in mechanical performance, with yield strength increasing from 1019 MPa to 1103 MPa, ultimate tensile strength from 1383 MPa to 1475 MPa, and elongation from 13.0% to 16.3%. These improvements are attributed to multiple strengthening mechanisms including dislocation hardening, grain boundary strengthening, and second-phase strengthening.

- Fractography confirms a transition from quasi-cleavage to ductile fracture mode upon Y addition, with the fracture surface showing abundant dimples and tear ridges, indicative of enhanced microvoid coalescence and improved plastic deformability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wani, I.S.; Bhattacharjee, T.; Sheikh, S.; Lu, Y.P.; Chatterjee, S.; Bhattacharjee, P.P.; Guo, S.; Tsuji, N. Ultrafine-Grained AlCoCrFeNi2.1 Eutectic High-Entropy Alloy. Mater. Res. Lett. 2016, 4, 174–179. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, F.; Shen, S.; Yang, K.; Han, D.; Li, Y.; Lu, C.; Zhang, Y.; Tang, X. The staggered dual-phase structure in AlCoCrFeNi2.1 eutectic high-entropy alloys for superior irradiation and corrosion resistance. Intermetallics 2024, 173, 108427. [Google Scholar] [CrossRef]

- Dan, X.; Ren, C.; Song, Z.; Waqar, S.; Zhang, D.; Wang, M.; Liu, Q.; Sun, Y.; Chen, X.; Jiang, W.; et al. Exceptional strength and ductility in heterogeneous multi-gradient TiAl alloys through additive manufacturing. Acta Mater. 2024, 281, 120395. [Google Scholar] [CrossRef]

- Guo, Y.; Su, H.; Zhou, H.; Shen, Z.; Liu, Y.; Zhang, J.; Liu, L.; Fu, H. Unique strength-ductility balance of AlCoCrFeNi2.1 eutectic high entropy alloy with ultra-fine duplex microstructure prepared by selective laser melting. J. Mater. Sci. Technol. 2022, 111, 298–306. [Google Scholar] [CrossRef]

- Guo, Q.; Li, Z.; Wu, Q.; Luo, S.; Luo, Z. Influence of laser energy density on the microstructure and properties of AlCoCrFeNi2.1-eutectic high entropy alloy by selective laser melting. J. Alloys Compd. 2025, 1037, 182447. [Google Scholar] [CrossRef]

- Luo, W.; Yuan, X.; Zhang, Z.; Cheng, C.; Liu, H.; Qiu, H.; Cheng, X. Effect of volumetric energy density on the mechanical properties and corrosion resistance of laser-additive-manufactured AlCoCrFeNi2.1 high-entropy alloys. J. Alloys Compd. 2025, 1010, 178032. [Google Scholar] [CrossRef]

- Peng, X.; Kong, L.; An, H.; Dong, G. A Review of In Situ Defect Detection and Monitoring Technologies in Selective Laser Melting. 3D Print. Addit. Manuf. 2023, 10, 438–466. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, Z.; Xie, J. Effects of rare earth elements doping on ordered structures and ductility improvement of Fe–6.5 wt%Si alloy. Mater. Lett. 2016, 184, 294–297. [Google Scholar] [CrossRef]

- Zhao, Y.; Rajkowski, M.; Gong, Y.; Laube, S.; Perrière, L.; Kauffmann, A.; Couzinié, J.-P.; Laplanche, G.; Li, T. Role of oxygen in phase stability and mechanical behavior of the bcc HfNbTaTiZr high-entropy alloy during aging. Acta Mater. 2025, 298, 121400. [Google Scholar] [CrossRef]

- Kumar, N.; Sengupta, P.; Das, S.R.; Sahu, S.K.; Pahari, S.; Panigrahi, A. Phase and Microstructure Evolution in SPS-Processed CoCrFeMnNi High Entropy Alloy: Effects of Heat Treatment and Oxidation. Metall. Mater. Trans. A 2025, 56, 4391–4409. [Google Scholar] [CrossRef]

- Ke, L.; Meng, L.; Fang, S.; Lin, C.; Tan, M.; Qi, T. High-Temperature Oxidation Behaviors of AlCrTiSi0.2 High-Entropy Alloy Doped with Rare Earth La and Y. Crystals 2023, 13, 1169. [Google Scholar] [CrossRef]

- Wang, Y.; You, Y.; Yan, M.; Zhang, Y.; Sheng, W.; Wang, Y.; Xu, S.; Gu, F.; Wang, C.; Cheng, W. An effective and innovative application of rare-earth plasma nitriding on high entropy alloy CoCrCuFeNi. Mater. Lett. 2024, 371, 136870. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, H.; Chen, Y.; Li, L.; Liu, X.; Xiao, W.; Ni, N.; Zhao, X.; Guo, F.; Xiao, P. Y-doped AlCoCrFeNi2.1 eutectic high-entropy alloy with excellent oxidation resistance and structure stability at 1000 °C and 1100 °C. Corros. Sci. 2021, 180, 109191. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, X.; Chen, J.; Sun, H.; Fang, Y.; Zhang, Y.; Cheng, H. Microstructure and mechanical properties of TiZrVMnCu high entropy alloy by addition of Er element. Mater. Lett. 2023, 330, 133322. [Google Scholar] [CrossRef]

- Zhao, Q.; Wang, X.; Pan, Z.; Wei, Y.; Cheng, H.; Ma, Y.; Luo, H.; Li, X. Effects of rare earth elements addition on mechanical properties and corrosion behavior of GCr15 bearing steel under different heat treatment conditions. Corros. Commun. 2023, 9, 65–76. [Google Scholar] [CrossRef]

- Zhou, H.; Mao, J.; Jiang, H.; Zhang, H.; Wei, W.; Qin, S.; Tingjun, L.; Xu, J. Effect of rare-earth element Y addition on microstructure and mechanical properties of CrFeNi2 medium entropy alloy. Intermetallics 2023, 163, 108079. [Google Scholar] [CrossRef]

- El Garah, M.; Patout, L.; Bouissil, A.; Charai, A.; Sanchette, F. The Effect of Yttrium Addition on Microstructure and Mechanical Properties of Refractory TiTaZrHfW High-Entropy Films. Coatings 2023, 13, 1380. [Google Scholar] [CrossRef]

- Wan, X.; Tian, C.; Li, Y.; Zhou, J.; Qian, S.; Su, L.; Wang, L. Effect of Y2O3 Addition on Microstructure and Properties of Laser Cladded Al-Si Coatings on AZ91D Magnesium Alloy. Materials 2023, 16, 338. [Google Scholar] [CrossRef]

- Li, X.; Du, J.; Xu, J.; Wang, S.; Shen, M.; Jiang, C. Crack Inhibition and Performance Modification of NiCoCr-Based Superalloy with Y2O3 Nanoparticles by Laser Metal Deposition. Materials 2023, 16, 3616. [Google Scholar] [CrossRef]

- Wang, G.; Xu, X.; Yuan, R.; Lv, X. Effect of laser spot diameter on the processing and microstructural properties of AlCoCrFeNi2.1 eutectic high-entropy alloy formed by selective laser melting. J. Mater. Res. Technol. 2025, 38, 1070–1082. [Google Scholar] [CrossRef]

- Li, Q.; Hou, W.; Liang, J.; Zhang, C.; Li, J.; Zhou, Y.; Sun, X. Controlling the anisotropy behaviour of 3D printed ceramic cores: From intralayer particle distribution to interlayer pore evolution. Addit. Manuf. 2022, 58, 103055. [Google Scholar] [CrossRef]

- Zhai, W.; Zhou, W.; Nai, S.M.L. Effect of Interface Wettability on Additively Manufactured Metal Matrix Composites: A Case Study of 316L-Y2O3 Oxide Dispersion-Strengthened Steel. Metals 2024, 14, 170. [Google Scholar] [CrossRef]

- Hou, W.; Stubbs, T.; DeBeer-Schmitt, L.; Chang, Y.-T.; Charpagne, M.-A.; Smith, T.M.; Huang, A.; Cordero, Z.C. Dissolution zone model of the oxide structure in additively manufactured dispersion-strengthened alloys. arXiv 2024. [Google Scholar] [CrossRef]

- Yin, H.; Wei, B.; Shmatok, A.; Yang, J.; Salek, F.; Beckingham, L.; Prorok, B.; Wang, J.; Lou, X. On the nanoscale oxide dispersion via in-situ atmospheric oxidation during laser powder bed fusion. J. Mater. Process. Technol. 2023, 322, 118191. [Google Scholar] [CrossRef]

- Nagase, T.; Takemura, M.; Matsumuro, M.; Maruyama, T. Solidification Microstructure of AlCoCrFeNi2.1 Eutectic High Entropy Alloy Ingots. Mater. Trans. 2018, 59, 255–264. [Google Scholar] [CrossRef]

- Xu, T.; Hao, Z. Microstructure and Mechanical Properties of As-Cast and Laser Powder Bed Fused AlCoCrFeNi2.1 Eutectic High-Entropy Alloy. Acta Metall. Sin. 2024, 60, 1461–1470. [Google Scholar]

- Shu, X.; Su, Y.; Li, J.; Fu, H.; Lee, S.W.; Tang, J. Effect of Y Addition on Microstructure and Mechanical Properties of CoCrFeNi HEA Coatings by Laser Cladding. Coatings 2024, 14, 1561. [Google Scholar] [CrossRef]

- Fritscher, K. The Reactive Element Effect. Metall. Mater. Trans. A 2022, 54, 64–74. [Google Scholar] [CrossRef]

- Ding, W.; Zhao, X.; Chen, T.; Zhang, H.; Liu, X.; Cheng, Y.; Lei, D. Effect of rare earth Y and Al–Ti–B master alloy on the microstructure and mechanical properties of 6063 aluminum alloy. J. Alloys Compd. 2020, 830, 154685. [Google Scholar] [CrossRef]

- Cui, S.; Lei, S.; Li, Y.; Zhang, J.; Hu, S.; Xue, Z. Effect of rare earth element Y content on microstructure, magnetic properties, and electrochemical properties of the as-annealed FeCoNiAl0.2Yx high-entropy alloys. J. Vac. Sci. Technol. A 2024, 42, 043202. [Google Scholar] [CrossRef]

- Muñoz-Saldaña, J.; Valencia-Ramirez, A.; Castillo-Perea, L.A.; la Torre, S.D.-D.; Caceres-Diaz, L.A.; Orozco, J.M.A.; Giraldo Betancur, A.L.; Schulz, U. Oxidation behavior of dense Yttrium doped B2-NiAl bulk material fabricated by ball milling self-propagating high-temperature synthesis and densified by spark plasma sintering. Surf. Coat. Technol. 2021, 421, 127448. [Google Scholar] [CrossRef]

- Shen, J.; Agrawal, P.; Rodrigues, T.A.; Lopes, J.; Schell, N.; Zeng, Z.; Mishra, R.S.; Oliveira, J. Gas tungsten arc welding of as-cast AlCoCrFeNi2.1 eutectic high entropy alloy. Mater. Des. 2022, 223, 111176. [Google Scholar] [CrossRef]

- Charkhchian, J.; Zarei-Hanzaki, A.; Moshiri, A.; Abedi, H.; Shen, J.; Oliveira, J.; Chadha, K.; Aranas, C. On the short-time thermal phase-stability of as-cast AlCoCrFeNi2.1 eutectic high entropy alloy. J. Mater. Res. Technol. 2022, 20, 551–560. [Google Scholar] [CrossRef]

- Zhao, Z.; Guan, K.; Cui, R.; Qin, J.; Huang, Z. Effect of Y on Oxidation Behavior of Directionally Solidified Ni-Based Single-Crystal Superalloy. Chin. J. Mech. Eng. 2024, 37, 100. [Google Scholar] [CrossRef]

- Ahmad, F.; Shah, S.; Kai, X.; Rajendren, V.B.; Abdullah, M.R.; Khan, S.U.; Zia, A.W.; Zhao, Y. Impact of Y and Er on recrystallization behavior and mechanical properties of AA7085/Al2O3 + ZrB2 composites. J. Mater. Res. Technol. 2025, 36, 5259–5272. [Google Scholar] [CrossRef]

- Song, C.; Xiang, L.; Shi, C.; Qiao, J.; Liu, J.; Qiu, S. Effect of Rare Earth La–Ce on Solidification Structure of 3.2%Si-0.9%Al Non-oriented Silicon Steel. ISIJ Int. 2024, 64, 1000–1009. [Google Scholar] [CrossRef]

- Chen, M.-J.; Xie, D.; Fensin, S.; Hunter, A.; Li, N.; Zikry, M.A. Intergranular fracture, grain-boundary structure, and dislocation-density interactions in FCC bicrystals. Sci. Rep. 2024, 14, 20911. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Wu, Q.; Zhu, J.; Jia, Y.; He, F.; Wang, L.; Wang, J.; Li, J.; Wang, Z. Concurrently enhancing precipitation strengthening of FCC and B2 phases in dual-phase high-entropy alloys via Ti and Ta microalloying. J. Mater. Sci. Technol. 2025, 250, 243–256. [Google Scholar] [CrossRef]

- Winkens, G.; Kauffmann, A.; Herrmann, J.; Czerny, A.K.; Obert, S.; Seils, S.; Boll, T.; Baruffi, C.; Rao, Y.; Curtin, W.A.; et al. The influence of lattice misfit on screw and edge dislocation-controlled solid solution strengthening in Mo-Ti alloys. Commun. Mater. 2023, 4, 26. [Google Scholar] [CrossRef]

| Parameters | Laser power P, [W] | Scanning speed v, [mm/s] | Scanning spacing d, [mm] | VED, [J/mm−3] |

| Value | 130~180 | 500~800 | 0.09 | 60.2~133.3 |

| Point | Element, at% | ||||

|---|---|---|---|---|---|

| Al | Co | Cr | Fe | Ni | |

| Site 1 | 0.94 | 23.34 | 22.57 | 23.38 | 29.77 |

| Site 2 | 12.13 | 15.27 | 7.12 | 13.25 | 52.23 |

| Site 3 | 1.16 | 23.26 | 24.82 | 23.54 | 27.22 |

| Site 4 | 9.81 | 16.64 | 7.88 | 13.13 | 52.54 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Xu, X.; Zhang, R.; Yuan, R.; Lv, X. Microstructure and Mechanical Properties of Y-Doped AlCoCrFeNi2.1 Eutectic High-Entropy Alloy Fabricated by PBF-LB/M. Metals 2025, 15, 1130. https://doi.org/10.3390/met15101130

Wang G, Xu X, Zhang R, Yuan R, Lv X. Microstructure and Mechanical Properties of Y-Doped AlCoCrFeNi2.1 Eutectic High-Entropy Alloy Fabricated by PBF-LB/M. Metals. 2025; 15(10):1130. https://doi.org/10.3390/met15101130

Chicago/Turabian StyleWang, Gang, Xiangyu Xu, Runbo Zhang, Ren Yuan, and Xuteng Lv. 2025. "Microstructure and Mechanical Properties of Y-Doped AlCoCrFeNi2.1 Eutectic High-Entropy Alloy Fabricated by PBF-LB/M" Metals 15, no. 10: 1130. https://doi.org/10.3390/met15101130

APA StyleWang, G., Xu, X., Zhang, R., Yuan, R., & Lv, X. (2025). Microstructure and Mechanical Properties of Y-Doped AlCoCrFeNi2.1 Eutectic High-Entropy Alloy Fabricated by PBF-LB/M. Metals, 15(10), 1130. https://doi.org/10.3390/met15101130