Powder Bed Fabrication of Copper: A Comprehensive Literature Review

Abstract

1. Introduction

Powder Bed Fusion of Copper

2. State of the Art: Energy Source for PBF of Copper

2.1. Infrared Laser

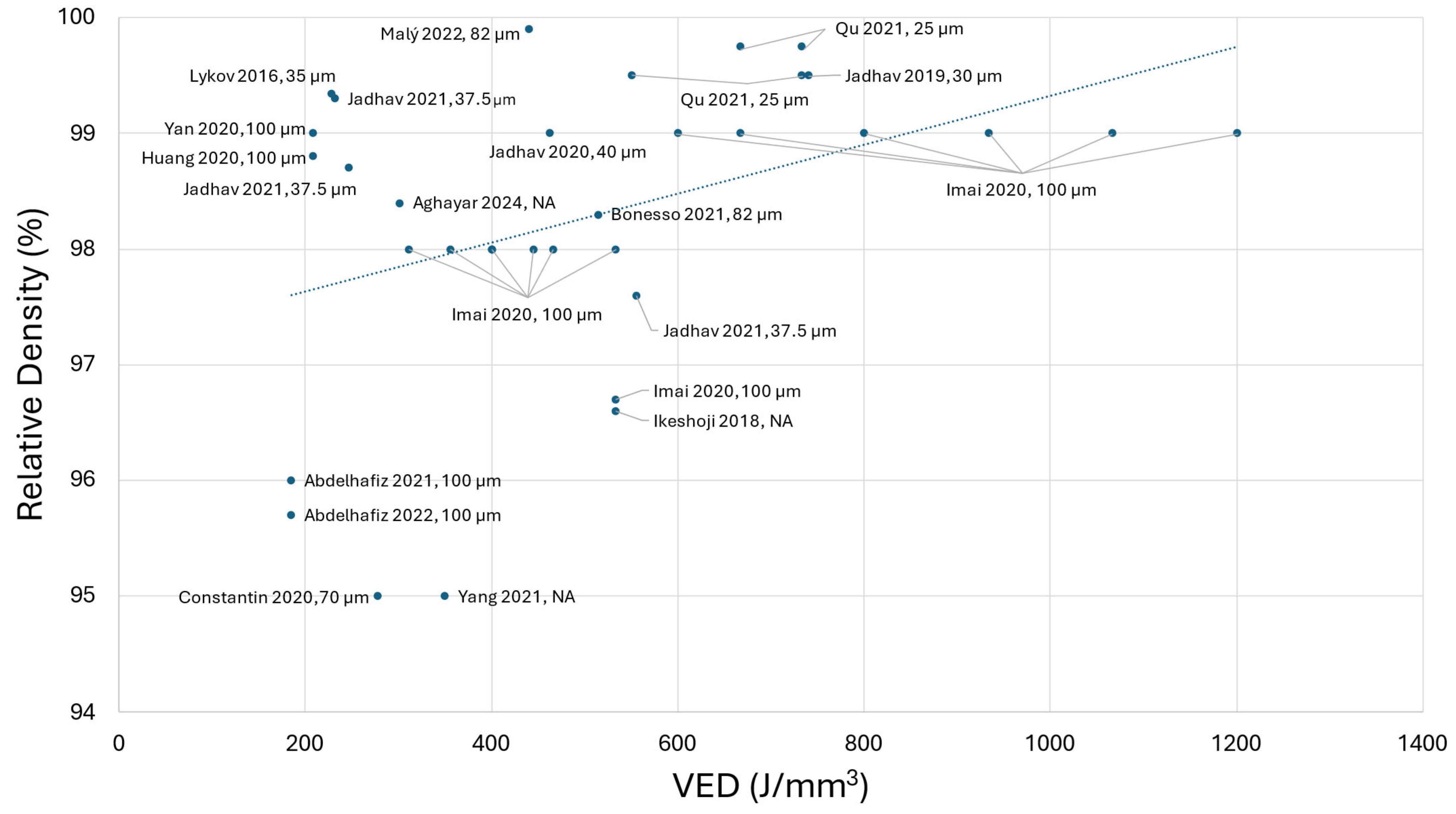

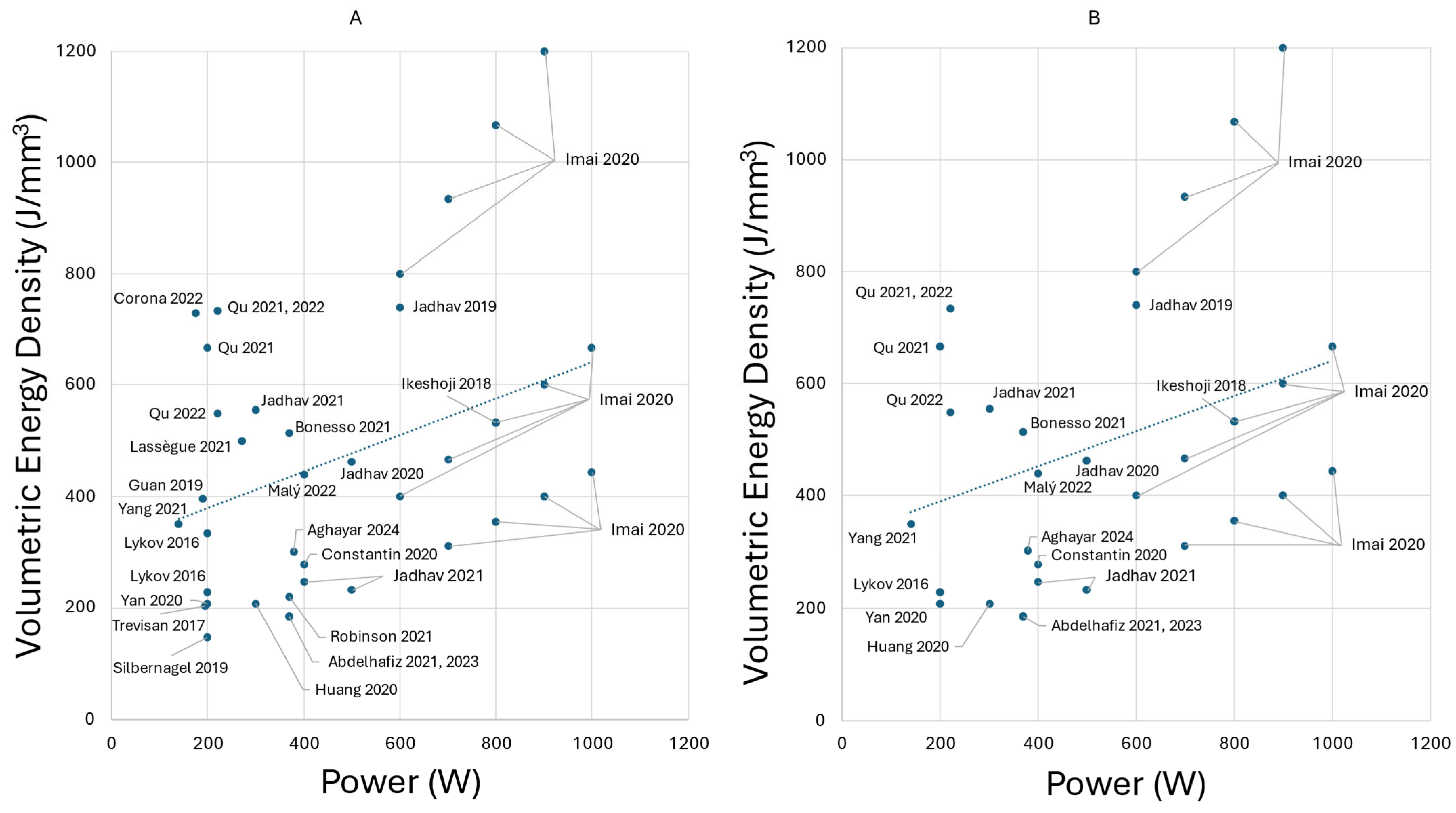

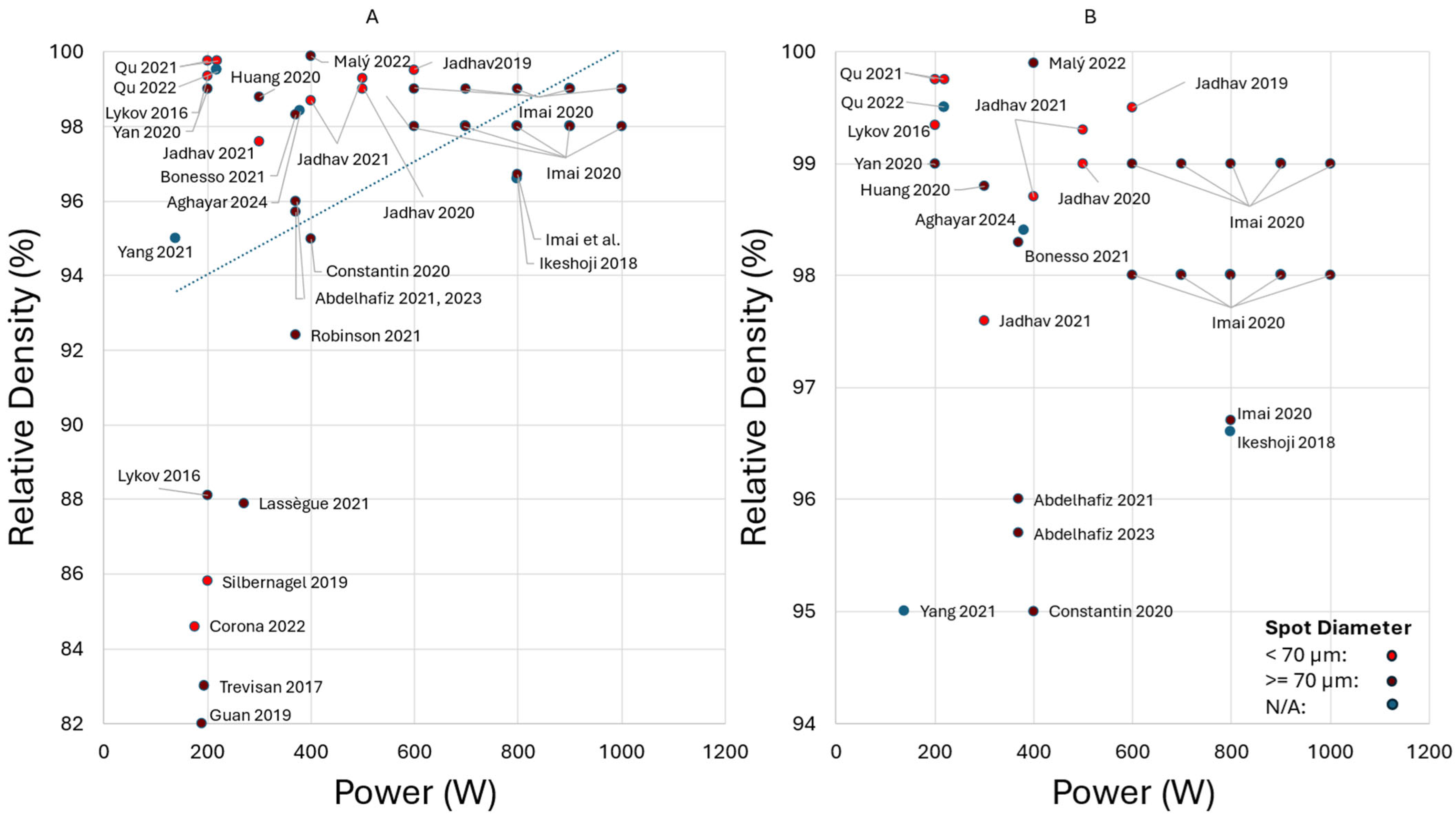

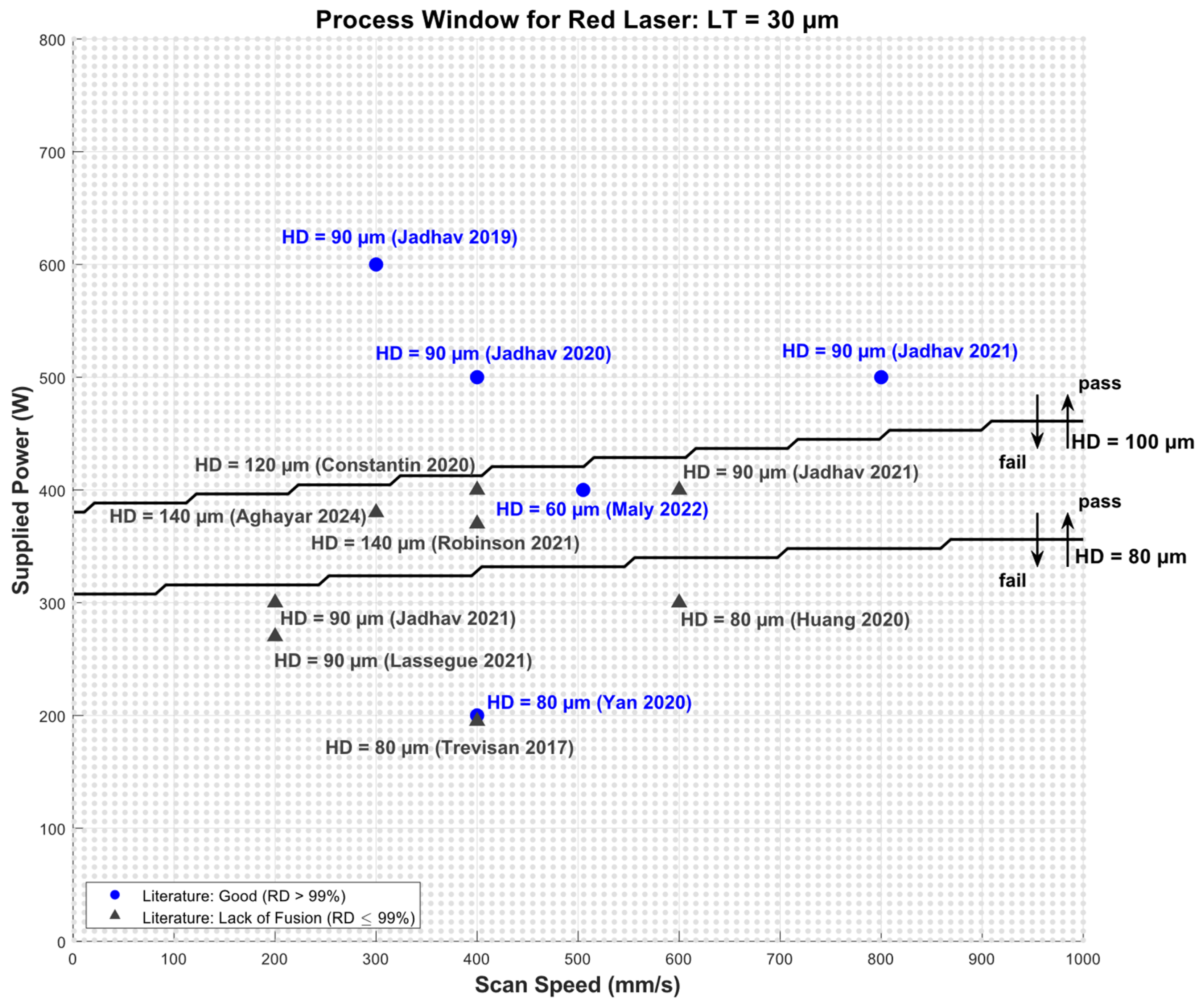

2.1.1. Process Optimization

2.1.2. Material and Post-Processing Effects

2.1.3. Surface and Functional Properties

2.1.4. Mechanical Properties

2.2. Green Laser with 500–570 nm Wavelengths

2.3. Electron Beam Powder Bed Fusion

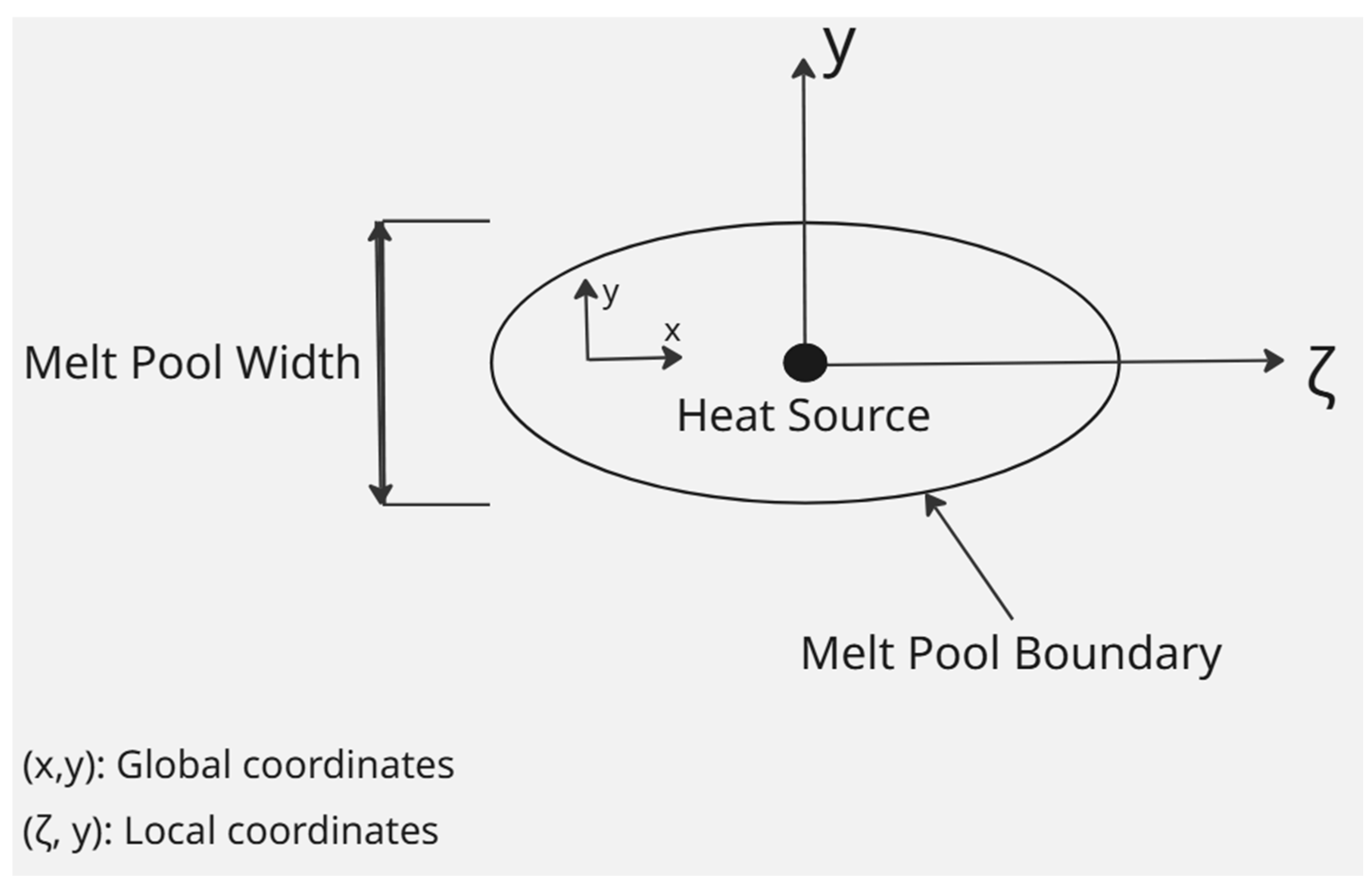

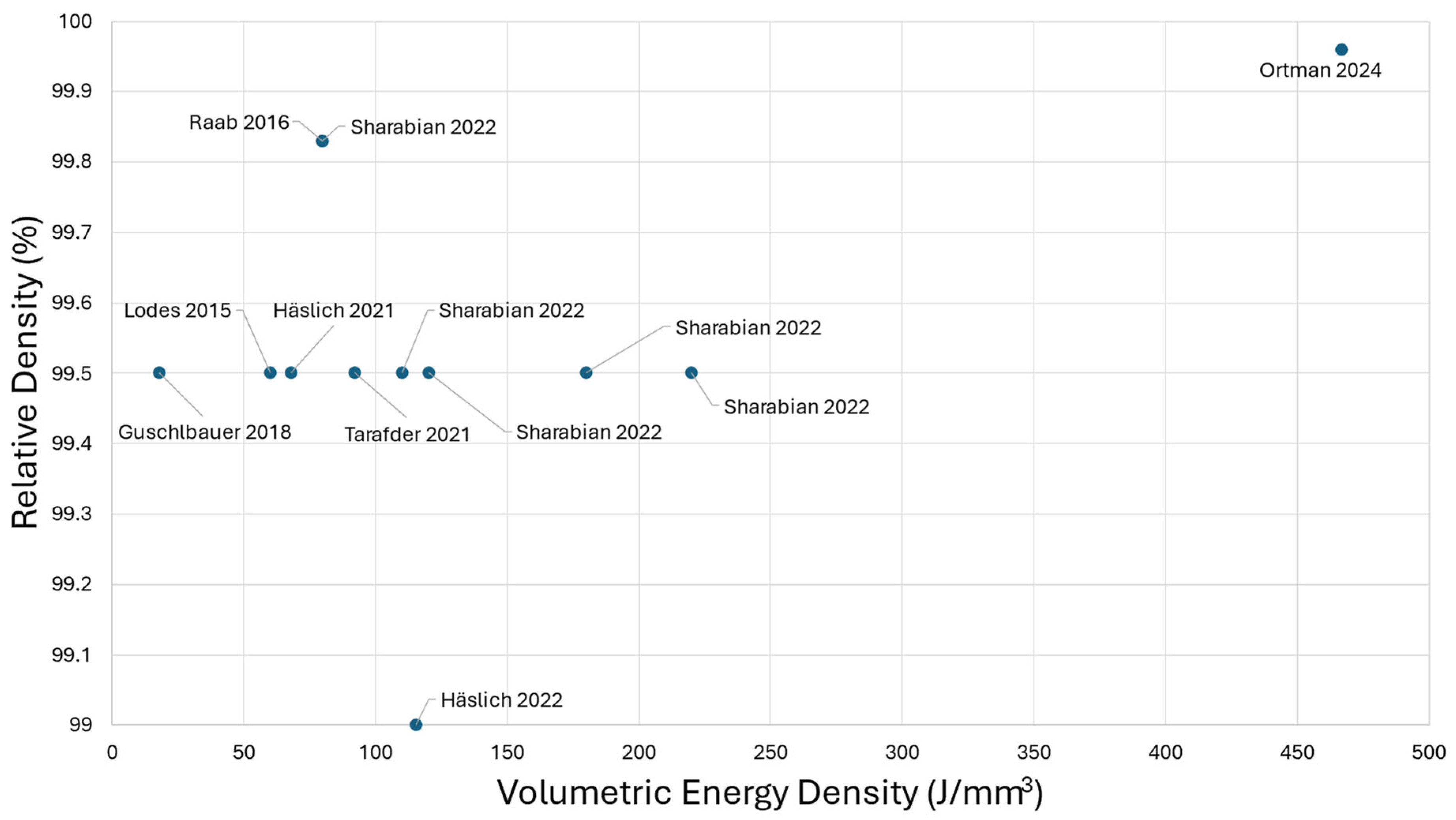

EB-PBF Parameters

2.4. Physical and Mechanical Properties of E-Beam Copper Parts

2.5. Benefits of EB-PBF/Application to Copper AM

2.6. Limitations/Issues to Resolve

3. Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Elshkaki, A.; Graedel, T.E.; Ciacci, L.; Reck, B.K. Copper demand, supply, and associated energy use to 2050. Glob. Environ. Change 2016, 39, 305–315. [Google Scholar] [CrossRef]

- Economic Impact-$160B Role in the, U.S. Economy. Available online: https://copper.org/economy/ (accessed on 7 July 2024).

- Helmenstine, A.H. Table of Electrical Resistivity and Conductivity. Available online: https://www.thoughtco.com/table-of-electrical-resistivity-conductivity-608499 (accessed on 7 July 2024).

- Askeland, D.R. The Science and Engineering of Materials; Springer: Boston, MA, USA, 1996. [Google Scholar] [CrossRef]

- Zhou, H.; Chang, A.; Fan, J.; Cao, J.; An, B.; Xia, J.; Yao, J.; Cui, X.; Zhang, Y. Copper Wire Bonding: A Review. Micromachines 2023, 14, 1612. [Google Scholar] [CrossRef]

- Robinson, J.; Arjunan, A.; Baroutaji, A.; Stanford, M. Mechanical and thermal performance of additively manufactured copper, silver and copper–silver alloys. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 239, 1877–1891. [Google Scholar] [CrossRef]

- Khan, Z.A. A Novel Transmission Line Structure for High-Speed High-Density Copper Interconnects. IEEE Trans. Compon. Packag. Manufact. Technol. 2016, 6, 1077–1086. [Google Scholar] [CrossRef]

- Thieman, M.; Kamm, R.; Jorstad, J. Copper motor rotors: Energy saving efficiency, now also economic feasibility. In 2007 Electrical Insulation Conference and Electrical Manufacturing Expo; IEEE: Nashville, TN, USA, 2007; pp. 328–333. [Google Scholar] [CrossRef]

- Stark, C.; Cowie, J.G.; Peters, D.T.; Brush, E.F. Copper in the Rotor for Lighter, Longer Lasting Motors. Available online: https://www.researchgate.net/profile/John-Cowie/publication/265097366_Copper_in_the_Rotor_for_Lighter_Longer_Lasting_Motors/links/54411c5e0cf2a76a3cc7ca04/Copper-in-the-Rotor-for-Lighter-Longer-Lasting-Motors.pdf (accessed on 3 November 2024).

- Liu, Y.; Yin, L.; Bliznakov, S.; Kondos, P.; Borgesen, P.; Henderson, D.W.; Parks, C.; Wang, J.; Cotts, E.J.; Dimitrov, N. Improving Copper Electrodeposition in the Microelectronics Industry. IEEE Trans. Comp. Packag. Technol. 2010, 33, 127–137. [Google Scholar] [CrossRef]

- Siau, S.; Vervaet, A.; Van Vaeck, L.; Schacht, E.; Demeter, U.; Van Calster, A. Adhesion Strength of the Epoxy Polymer/Copper Interface for Use in Microelectronics. J. Electrochem. Soc. 2005, 152, C442. [Google Scholar] [CrossRef]

- Zhao, M.; Kariuki, S.; Dewald, H.D.; Lemke, F.R.; Staniewicz, R.J.; Plichta, E.J.; Marsh, R.A. Electrochemical Stability of Copper in Lithium-Ion Battery Electrolytes. J. Electrochem. Soc. 2000, 147, 2874. [Google Scholar] [CrossRef]

- Zeng, X.; He, P.; Hu, M.; Zhao, W.; Chen, H.; Liu, L.; Sun, J.; Yang, J. Copper inks for printed electronics: A review. Nanoscale 2022, 14, 16003–16032. [Google Scholar] [CrossRef]

- Tomotoshi, D.; Kawasaki, H. Surface and Interface Designs in Copper-Based Conductive Inks for Printed/Flexible Electronics. Nanomaterials 2020, 10, 1689. [Google Scholar] [CrossRef]

- Jason, N.N.; Shen, W.; Cheng, W. Copper Nanowires as Conductive Ink for Low-Cost Draw-On Electronics. ACS Appl. Mater. Interfaces 2015, 7, 16760–16766. [Google Scholar] [CrossRef]

- Jia, S.Q.; Yang, F. High thermal conductive copper/diamond composites: State of the art. J. Mater. Sci. 2021, 56, 2241–2274. [Google Scholar] [CrossRef]

- Miner, D.K. New Technology for Copper and Brass Radiators. In Proceedings of the SAE International Congress and Exposition, McLean, VA, USA, 1 February 1987. [Google Scholar] [CrossRef]

- Sharma, M.; Narayan Vishwakarma, P.; Sharma, A.; Shubham, P. Performance Investigation of Copper and Aluminium Radiators for Lower HP Tractor Engines. J. Phys. Conf. Ser. 2022, 2178, 012011. [Google Scholar] [CrossRef]

- Dhaou, H.; Ben Khedher, N.; Mellouli, S.; Souahlia, A.; Askri, F.; Jemni, A.; Ben Nasrallah, S. Improvement of thermal performance of spiral heat exchanger on hydrogen storage by adding copper fins. Int. J. Therm. Sci. 2011, 50, 2536–2542. [Google Scholar] [CrossRef]

- Pakalka, S.; Valančius, K.; Streckienė, G. Experimental comparison of the operation of PCM-based copper heat exchangers with different configurations. Appl. Therm. Eng. 2020, 172, 115138. [Google Scholar] [CrossRef]

- Barros, L.Y.; Poletto, J.C.; Neis, P.D.; Ferreira, N.F.; Pereira, C.H.S. Influence of copper on automotive brake performance. Wear 2019, 426, 741–749. [Google Scholar] [CrossRef]

- Österle, W.; Prietzel, C.; Kloß, H.; Dmitriev, A.I. On the role of copper in brake friction materials. Tribol. Int. 2010, 43, 2317–2326. [Google Scholar] [CrossRef]

- Arendsen, L.P.; Thakar, R.; Sultan, A.H. The Use of Copper as an Antimicrobial Agent in Health Care, Including Obstetrics and Gynecology. Clin. Microbiol. Rev. 2019, 32, e00125-18. [Google Scholar] [CrossRef]

- Vincent, M.; Hartemann, P.; Engels-Deutsch, M. Antimicrobial applications of copper. Int. J. Hyg. Environ. Health 2016, 219, 585–591. [Google Scholar] [CrossRef]

- Casey, A.L.; Adams, D.; Karpanen, T.J.; Lambert, P.A.; Cookson, B.D.; Nightingale, P.; Miruszenko, L.; Shillam, R.; Christian, P.; Elliott, T.S.J. Role of copper in reducing hospital environment contamination. J. Hosp. Infect. 2010, 74, 72–77. [Google Scholar] [CrossRef]

- Marais, F.; Mehtar, S.; Chalkley, L. Antimicrobial efficacy of copper touch surfaces in reducing environmental bioburden in a South African community healthcare facility. J. Hosp. Infect. 2010, 74, 80–82. [Google Scholar] [CrossRef]

- Ibrahim, Z.; Petrusan, A.J.; Hooke, P.; Hinsa-Leasure, S.M. Reduction of bacterial burden by copper alloys on high-touch athletic center surfaces. Am. J. Infect. Control 2018, 46, 197–201. [Google Scholar] [CrossRef]

- Cervantes, H.I.; Álvarez, J.A.; Muñoz, J.M.; Arreguín, V.; Mosqueda, J.L.; Macías, A.E. Antimicrobial activity of copper against organisms in aqueous solution: A case for copper-based water pipelines in hospitals? Am. J. Infect. Control 2013, 41, e115–e118. [Google Scholar] [CrossRef]

- Sudha, V.B.P.; Singh, K.O.; Prasad, S.R.; Venkatasubramanian, P. Killing of enteric bacteria in drinking water by a copper device for use in the home: Laboratory evidence. Trans. R. Soc. Trop. Med. Hyg. 2009, 103, 819–822. [Google Scholar] [CrossRef] [PubMed]

- Bisht, N.; Dwivedi, N.; Kumar, P.; Venkatesh, M.; Yadav, A.K.; Mishra, D.; Solanki, P.; Verma, N.K.; Lakshminarayanan, R.; Ramakrishna, S.; et al. Recent advances in copper and copper-derived materials for antimicrobial resistance and infection control. Curr. Opin. Biomed. Eng. 2022, 24, 100408. [Google Scholar] [CrossRef] [PubMed]

- Fateh, A.; Aliofkhazraei, M.; Rezvanian, A.R. Review of corrosive environments for copper and its corrosion inhibitors. Arab. J. Chem. 2020, 13, 481–544. [Google Scholar] [CrossRef]

- Vargas, I.T.; Alsina, M.A.; Pavissich, J.P.; Jeria, G.A.; Pastén, P.A.; Walczak, M.; Pizarro, G.E. Multi-technique approach to assess the effects of microbial biofilms involved in copper plumbing corrosion. Bioelectrochemistry 2014, 97, 15–22. [Google Scholar] [CrossRef]

- Schock, M.R.; Lytle, D.A. Control of Copper Corrosion of Household Plumbing Materials; United States Environmental Protection Agency: Cincinnati, OH, USA, 1995. [Google Scholar]

- Keevil, C.W. The physico-chemistry of biofilm-mediated pitting corrosion of copper pipe supplying potable water. Water Sci. Technol. 2004, 49, 91–98. [Google Scholar] [CrossRef]

- Lin, S.; Li, D.; Zhou, Q.; Chu, M.; Sun, Y.; Liu, M.; Zheng, K.; Qiao, S.; Zhao, L.; Zhao, L.; et al. Study on corrosion perforation behavior of copper nickel alloy pipe during service in marine environment. Eng. Fail. Anal. 2023, 153, 107628. [Google Scholar] [CrossRef]

- Gilbert, P.T. Corrosion Resisting Properties of 90/10 Copper–Nickel–Iron Alloy with Particular Reference to Offshore Oil and Gas Applications. Br. Corros. J. 1979, 14, 20–25. [Google Scholar] [CrossRef]

- Wallinder, I.O.; Verbiest, P.; He, W.; Leygraf, C. Effects of exposure direction and inclination on the runff rates of zinc and copper roofs. Corros. Sci. 2000, 42, 1471–1487. [Google Scholar] [CrossRef]

- Pennington, S.L.; Webster-Brown, J.G. Stormwater runoff quality from copper roofing, Auckland, New Zealand. N. Z. J. Mar. Freshw. Res. 2008, 42, 99–108. [Google Scholar] [CrossRef]

- Özkavak, H.V.; Gode, C. Machinability of pure copper before and after processing by severe plastic deformation method. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022, 236, 1526–1534. [Google Scholar] [CrossRef]

- Yang, H.M.; Guo, Z.; Xiong, S.M. Microstructure and mechanical properties of high-pressure die cast pure copper. J. Mater. Process. Technol. 2020, 275, 116377. [Google Scholar] [CrossRef]

- Smith, P.H. Cutting Casting Costs. Sci. Am. 1935, 152, 254–257. [Google Scholar] [CrossRef]

- Idodo, P.; Rayan, S. Reducing Casting Defects in Pure Copper Castings. Bachelor’s Thesis, Jönköping School of Engineering, Jönköping, Sweden, 2022. [Google Scholar]

- Malec, W.; Kulasa, J.; Brudny, A.; Hury, A.; Adamczyk, B.; Rzepecki, R.; Sekula, R.; Kmita, G.; Rybak, A. Comparative Studies of the Properties of Copper Components: Conventional vs. Additive Manufacturing Technologies. Metals 2024, 14, 975. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, P.; Yu, Z.; Shi, H.; Wu, D.; Yan, H.; Ye, X.; Lu, Q.; Tian, Y. A Review on Additive Manufacturing of Pure Copper. Coatings 2021, 11, 740. [Google Scholar] [CrossRef]

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. ISRN Mech. Eng. 2012, 2012, 208760. [Google Scholar] [CrossRef]

- Derekar, K.S. A review of wire arc additive manufacturing and advances in wire arc additive manufacturing of aluminium. Mater. Sci. Technol. 2018, 34, 895–916. [Google Scholar] [CrossRef]

- Casalino, G.; Karamimoghadam, M.; Contuzzi, N. Metal Wire Additive Manufacturing: A Comparison between Arc Laser and Laser/Arc Heat Sources. Inventions 2023, 8, 52. [Google Scholar] [CrossRef]

- Osipovich, K.; Kalashnikov, K.; Chumaevskii, A.; Gurianov, D.; Kalashnikova, T.; Vorontsov, A.; Zykova, A.; Utyaganova, V.; Panfilov, A.; Nikolaeva, A.; et al. Wire-Feed Electron Beam Additive Manufacturing: A Review. Metals 2023, 13, 279. [Google Scholar] [CrossRef]

- Shaikh, M.O.; Chen, C.-C.; Chiang, H.-C.; Chen, J.-R.; Chou, Y.-C.; Kuo, T.-Y.; Ameyama, K.; Chuang, C.-H. Additive manufacturing using fine wire-based laser metal deposition. RPJ 2019, 26, 473–483. [Google Scholar] [CrossRef]

- Taheri, H. Powder-based additive manufacturing–a review of types of defects, generation mechanisms, detection, property evaluation and metrology. Int. J. Addit. Subtractive Mater. Manuf. 2017, 1, 172–209. [Google Scholar] [CrossRef]

- Shanthar, R.; Chen, K.; Abeykoon, C. Powder-Based Additive Manufacturing: A Critical Review of Materials, Methods, Opportunities, and Challenges. Adv. Eng. Mater. 2023, 25, 2300375. [Google Scholar] [CrossRef]

- Ziaee, M.; Crane, N.B. Binder jetting: A review of process, materials, and methods. Addit. Manuf. 2019, 28, 781–801. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Medová, D.; Knaislová, A.; Strakosova, A.; Molnárová, O.; Čapek, J.; Voňavková, I.; Vojtěch, D. Comparison of direct energy deposition and powder bed fusion technology in the preparation of Ti–6Al–4V alloy. J. Mater. Res. Technol. 2025, 35, 3825–3840. [Google Scholar] [CrossRef]

- Babuska, T.F.; Krick, B.A.; Susan, D.F.; Kustas, A.B. Comparison of powder bed fusion and directed energy deposition for tailoring mechanical properties of traditionally brittle alloys. Manuf. Lett. 2021, 28, 30–34. [Google Scholar] [CrossRef]

- Demeneghi, G.; Gradl, P.; Mayeur, J.R.; Hazeli, K. GRCop-42: Comparison between laser powder Bed fusion and direct energy deposition. Addit. Manuf. Lett. 2024, 10, 100224. [Google Scholar] [CrossRef]

- DIN EN ISO/ASTM 52900:2022-03; Additive Fertigung_- Grundlagen_- Terminologie (ISO/ASTM 52900:2021); Deutsche Fassung EN_ISO/ASTM 52900. DIN Media GmbH: Berlin, Germany, 2021. [CrossRef]

- Tran, T.Q.; Chinnappan, A.; Lee, J.K.Y.; Loc, N.H.; Tran, L.T.; Wang, G.; Kumar, V.V.; Jayathilaka, W.A.D.M.; Ji, D.; Doddamani, M.; et al. 3D Printing of Highly Pure Copper. Metals 2019, 9, 756. [Google Scholar] [CrossRef]

- Ladani, L.; Sadeghilaridjani, M. Review of Powder Bed Fusion Additive Manufacturing for Metals. Metals 2021, 11, 1391. [Google Scholar] [CrossRef]

- Tang, M.; Pistorius, P.C.; Beuth, J.L. Prediction of lack-of-fusion porosity for powder bed fusion. Addit. Manuf. 2017, 14, 39–48. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Chia, H.Y.; Yan, W. Mechanism of keyhole pore formation in metal additive manufacturing. npj Comput. Mater. 2022, 8, 22. [Google Scholar] [CrossRef]

- Qu, S.; Ding, J.; Fu, J.; Fu, M.; Zhang, B.; Song, X. High-precision laser powder bed fusion processing of pure copper. Addit. Manuf. 2021, 48, 102417. [Google Scholar] [CrossRef]

- Huang, J.; Yan, X.; Chang, C.; Xie, Y.; Ma, W.; Huang, R.; Zhao, R.; Li, S.; Liu, M.; Liao, H. Pure copper components fabricated by cold spray (CS) and selective laser melting (SLM) technology. Surf. Coat. Technol. 2020, 395, 125936. [Google Scholar] [CrossRef]

- Domine, A.; Verdy, C.; Penaud, C.; Vitu, L.; Fenineche, N.; Dembinski, L. Selective laser melting (SLM) of pure copper using 515-nm green laser: From single track analysis to mechanical and electrical characterization. Int. J. Adv. Manuf. Technol. 2023, 1–12. [Google Scholar] [CrossRef]

- Advantages and Development Prospects of 405nm 445nm 450nm and Other Blue Lasers. Available online: https://www.s-laser.com/info/advantages-development-prospects-blue-laser-77888493.html (accessed on 7 July 2025).

- Tepylo, N.; Huang, X.; Patnaik, P.C. Laser-Based Additive Manufacturing Technologies for Aerospace Applications. Adv. Eng. Mater. 2019, 21, 1900617. [Google Scholar] [CrossRef]

- Kim, Y.-Y.; Joo, J.-Y.; Kim, J.-M.; Lee, S.-K. Compact Measurement of the Optical Power in High-Power LED Using a Light-Absorbent Thermal Sensor. Sensors 2021, 21, 4690. [Google Scholar] [CrossRef]

- Ikeshoji, T.-T.; Nakamura, K.; Yonehara, M.; Imai, K.; Kyogoku, H. Selective Laser Melting of Pure Copper. JOM 2018, 70, 396–400. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Dadbakhsh, S.; Goossens, L.; Kruth, J.-P.; Van Humbeeck, J.; Vanmeensel, K. Influence of selective laser melting process parameters on texture evolution in pure copper. J. Mater. Process. Technol. 2019, 270, 47–58. [Google Scholar] [CrossRef]

- TRUMPF Introduces Precious Metal and Copper 3D Printing Powered by Green Laser-3D Printing Industry. Available online: https://3dprintingindustry.com/news/trumpf-introduces-precious-metal-and-copper-3d-printing-powered-by-green-laser-143689/ (accessed on 10 September 2024).

- Hori, E.; Sato, Y.; Shibata, T.; Tojo, K.; Tsukamoto, M. Development of SLM process using 200 W blue diode laser for pure copper additive manufacturing of high density structure. J. Laser Appl. 2021, 33, 012008. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Vleugels, J.; Kruth, J.; Van Humbeeck, J.; Vanmeensel, K. Mechanical and electrical properties of selective laser-melted parts produced from surface-oxidized copper powder. Mat. Des. Process. Comms. 2020, 2, e94. [Google Scholar] [CrossRef]

- Colopi, M.; Caprio, L.; Demir, A.G.; Previtali, B. Selective laser melting of pure Cu with a 1 kW single mode fiber laser. Procedia CIRP 2018, 74, 59–63. [Google Scholar] [CrossRef]

- Colopi, M.; Demir, A.G.; Caprio, L.; Previtali, B. Limits and solutions in processing pure Cu via selective laser melting using a high-power single-mode fiber laser. Int. J. Adv. Manuf. Technol. 2019, 104, 2473–2486. [Google Scholar] [CrossRef]

- Abdelhafiz, M.; Al-Rubaie, K.S.; Emadi, A.; Elbestawi, M.A. Process–Structure–Property Relationships of Copper Parts Manufactured by Laser Powder Bed Fusion. Materials 2021, 14, 2945. [Google Scholar] [CrossRef] [PubMed]

- Lykov, P.; Baytimerov, R.; Vaulin, S.; Safonov, E.; Zherebtsov, D. Selective Laser Melting of Copper by 200 W CO2 Laser. In Proceedings of the SAE 2016 World Congress and Exhibition, Chelyabinsk, Russia, 5 April 2016. [Google Scholar] [CrossRef]

- Sharabian, E.; Leary, M.; Fraser, D.; Gulizia, S. Electron beam powder bed fusion of copper components: A review of mechanical properties and research opportunities. Int. J. Adv. Manuf. Technol. 2022, 122, 513–532. [Google Scholar] [CrossRef]

- Yan, X.; Chang, C.; Dong, D.; Gao, S.; Ma, W.; Liu, M.; Liao, H.; Yin, S. Microstructure and mechanical properties of pure copper manufactured by selective laser melting. Mater. Sci. Eng. A 2020, 789, 139615. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Goossens, L.R.; Kinds, Y.; Hooreweder, B.V.; Vanmeensel, K. Laser-based powder bed fusion additive manufacturing of pure copper. Addit. Manuf. 2021, 42, 101990. [Google Scholar] [CrossRef]

- Aghayar, Y.; Moazzen, P.; Behboodi, B.; Shahriari, A.; Shakerin, S.; Lloyd, A.; Mohammadi, M. Laser powder bed fusion of pure copper electrodes. Mater. Des. 2024, 239, 112742. [Google Scholar] [CrossRef]

- Qu, S.; Ding, J.; Fu, J.; Fu, M.; Song, X. Anisotropic material properties of pure copper with fine-grained microstructure fabricated by laser powder bed fusion process. Addit. Manuf. 2022, 59, 103082. [Google Scholar] [CrossRef]

- Bonesso, M.; Rebesan, P.; Gennari, C.; Mancin, S.; Dima, R.; Pepato, A.; Calliari, I. Effect of Particle Size Distribution on Laser Powder Bed Fusion Manufacturability of Copper. BHM Berg-Und Huettenmaenn Monatsh. 2021, 166, 256–262. [Google Scholar] [CrossRef]

- Abdelhafiz, M.; Emadi, A.; Elbestawi, M.A. On the Fabrication of High-Performance Additively Manufactured Copper Winding Using Laser Powder Bed Fusion. Materials 2023, 16, 4694. [Google Scholar] [CrossRef]

- Constantin, L.; Wu, Z.; Li, N.; Fan, L.; Silvain, J.-F.; Lu, Y.F. Laser 3D printing of complex copper structures. Addit. Manuf. 2020, 35, 101268. [Google Scholar] [CrossRef]

- Yang, P.; Guo, X.; He, D.; Tan, Z.; Shao, W.; Fu, H. Selective Laser Melting of High Relative Density and High Strength Parts Made of Minor Surface Oxidation Treated Pure Copper Powder. Metals 2021, 11, 1883. [Google Scholar] [CrossRef]

- Malý, M.; Koutný, D.; Pantělejev, L.; Pambaguian, L.; Paloušek, D. Effect of high-temperature preheating on pure copper thick-walled samples processed by laser powder bed fusion. J. Manuf. Process. 2022, 73, 924–938. [Google Scholar] [CrossRef]

- Imai, K.; Ikeshoji, T.-T.; Sugitani, Y.; Kyogoku, H. Densification of pure copper by selective laser melting process. Mech. Eng. J. 2020, 7, 19–00272. [Google Scholar] [CrossRef]

- Ma, Z.-X.; Ning, J.; Yu, B.; Zhang, L.-J.; Fan, J.-H.; Yuan, L.-G. Effects of process parameters and scanning patterns on quality of thin-walled copper flanges manufactured by selective laser melting. J. Manuf. Process. 2021, 72, 419–430. [Google Scholar] [CrossRef]

- Lassègue, P.; Salvan, C.; De Vito, E.; Soulas, R.; Herbin, M.; Hemberg, A.; Godfroid, T.; Baffie, T.; Roux, G. Laser powder bed fusion (L-PBF) of Cu and CuCrZr parts: Influence of an absorptive physical vapor deposition (PVD) coating on the printing process. Addit. Manuf. 2021, 39, 101888. [Google Scholar] [CrossRef]

- Silbernagel, C.; Gargalis, L.; Ashcroft, I.; Hague, R.; Galea, M.; Dickens, P. Electrical resistivity of pure copper processed by medium-powered laser powder bed fusion additive manufacturing for use in electromagnetic applications. Addit. Manuf. 2019, 29, 100831. [Google Scholar] [CrossRef]

- Corona, D.; Giannini, O.; Guarino, S.; Ponticelli, G.S.; Zarcone, M. Experimental investigation on the electrical, thermal, and mechanical properties of laser powder bed fused copper alloys. J. Manuf. Process. 2022, 76, 320–334. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.C.; Lorusso, M.; Lombardi, M. Selective laser melting of chemical pure copper. In Proceedings Euro PM 2017: International Powder Metallurgy Congress and Exhibition; European Powder Metallurgy Association (EPMA): Chantilly, France, 2017. [Google Scholar]

- Guan, J.; Zhang, X.; Jiang, Y.; Yan, Y. Insights into fabrication mechanism of pure copper thin wall components by selective infrared laser melting. RPJ 2019, 25, 1388–1397. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Easton, M. Powder bed fusion processes. In Laser Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2017; pp. 55–77. [Google Scholar] [CrossRef]

- Sinico, M.; Cogo, G.; Benettoni, M.; Calliari, I.; Pepato, A. Influence of powder particle size distribution on the printability of pure copper for selective laser melting. In Proceedings of the 30th Annual International Solid Freeform Fabrication Symposium–An Additive Manufacturing Conference; University of Texas at Austin: Austin, TX, USA, 2019. [Google Scholar]

- Gordon, J.V.; Narra, S.P.; Cunningham, R.W.; Liu, H.; Chen, H.; Suter, R.M.; Beuth, J.L.; Rollett, A.D. Defect structure process maps for laser powder bed fusion additive manufacturing. Addit. Manuf. 2020, 36, 101552. [Google Scholar] [CrossRef]

- Rosenthal, D. Mathematical theory of heat distribution during welding and cutting. Weld. J. 1941, 20, 220–234. [Google Scholar]

- Wang, D.; Li, K.; Yao, J.; Du, B.; Xu, Y. Porosity, texture, and mechanical properties of pure copper fabricated by fine green laser powder bed fusion. Opt. Laser Technol. 2025, 181, 112009. [Google Scholar] [CrossRef]

- Copper, Cu; Annealed. Available online: https://www.matweb.com/search/DataSheet.aspx?MatGUID=9aebe83845c04c1db5126fada6f76f7e&ckck=1 (accessed on 6 October 2025).

- Ladani, L.; Razmi, J.; Lowe, T.C. Manufacturing of High Conductivity, High Strength Pure Copper with Ultrafine Grain Structure. J. Manuf. Mater. Process. 2023, 7, 137. [Google Scholar] [CrossRef]

- Gruber, S.; Stepien, L.; López, E.; Brueckner, F.; Leyens, C. Physical and Geometrical Properties of Additively Manufactured Pure Copper Samples Using a Green Laser Source. Materials 2021, 14, 3642. [Google Scholar] [CrossRef]

- Nordet, G.; Gorny, C.; Mayi, Y.; Daligault, J.; Dal, M.; Effernelli, A.; Blanchet, E.; Coste, F.; Peyre, P. Absorptivity measurements during laser powder bed fusion of pure copper with a 1 kW cw green laser. Opt. Laser Technol. 2022, 147, 107612. [Google Scholar] [CrossRef]

- Kang, S.-G.; Gainov, R.; Heußen, D.; Bieler, S.; Sun, Z.; Weinberg, K.; Dehm, G.; Ramachandramoorthy, R. Green laser powder bed fusion based fabrication and rate-dependent mechanical properties of copper lattices. Mater. Des. 2023, 231, 112023. [Google Scholar] [CrossRef]

- Wagenblast, P.; Myrell, A.; Thielmann, M.; Scherbaum, T.; Coupek, D. Additive manufacturing with green disk lasers. In Laser 3D Manufacturing VII; Helvajian, H., Gu, B., Chen, H., Eds.; SPIE: San Francisco, CA, USA, 2020; p. 18. [Google Scholar] [CrossRef]

- Demir, A.G.; Colopi, M.; Previtali, B. The use of a ns-pulsed, high repetition rate green laser for SLM of 99.9% pure Cu. In Proceedings of the Lasers in Manufacturing Conference; Politecnico di Milano: Munich, Germany, 2019. [Google Scholar]

- Singh, A.; Caprio, L.; Previtali, B.; Demir, A.G. Processability of pure Cu by LPBF using a ns-pulsed green fiber laser. Opt. Laser Technol. 2022, 154, 108310. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J.; Xu, R.; Chen, T.G.; Zhou, K.S.; Zhang, H.H. Measurement of scoliosis Cobb angle by end vertebra tilt angle method. J. Orthop. Surg. Res. 2018, 13, 223. [Google Scholar] [CrossRef]

- de Terris, T.; Baffie, T.; Ribiere, C. Comparison of two different methods to manufacture pure copper by laser-powder bed fusion (L-PBF). In Euro PM2021-European Metallurgy Conference; Grenoble Alpes University: Grenoble, France, 2021. [Google Scholar]

- Mayerhofer, M.; Brenner, S.; Dickmann, M.; Doppler, M.; Gruber, S.; Helm, R.; Lopez, E.; Maier, V.; Mitteneder, J.; Neukirchen, C.; et al. Red and Green Laser Powder Bed Fusion of Pure Copper in Combination with Chemical Post-Processing for RF Cavity Fabrication. Instruments 2024, 8, 39. [Google Scholar] [CrossRef]

- Zaied, M.; Msolli, S.; Fourment, H.; Aubry, E.; Bolot, R.; Lebaal, N.; Fenineche, N.; Promoppatum, P. The contribution of 515-nm green laser L-PBF to the thermal performance of lattice-based heat exchangers for hydrogen storage applications. Int. J. Adv. Manuf. Technol. 2024, 133, 1501–1518. [Google Scholar] [CrossRef]

- Hecht, C.; Ockel, M.; Stoll, T.; Franke, J. Fabrication of metal-ceramic substrates by laser powder bed fusion using a high-power green laser and high temperature preheating. In Laser 3D Manufacturing XI; Gu, B., Chen, H., Eds.; SPIE: San Francisco, CA, USA, 2024; p. 19. [Google Scholar] [CrossRef]

- Horn, M.; Schmitt, M.; Schafnitzel, M.; Husen, A.V.; Wagenblast, P.; Auernhammer, S.; Heyder, J.; Hauck, C.; Barz, J.; Ott, M.; et al. Powder Bed Fusion of highly filigree copper features using a green laser. Procedia CIRP 2022, 111, 81–86. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Fu, Z.; Körner, C. Actual state-of-the-art of electron beam powder bed fusion. Eur. J. Mater. 2022, 2, 54–116. [Google Scholar] [CrossRef]

- Ortmann, R.; Hankel, J.; Grimm, T.; Röttger, A.; Sehrt, J.T. Powder bed fusion of pure copper using an electron beam–achieving high conductivity by real-time process monitoring and control. MATEC Web Conf. 2024, 406, 05001. [Google Scholar] [CrossRef]

- Häslich, F.; Kirchner, A.; Klöden, B.; Weißgärber, T. Parameter Window, Microstructure and Properties of Pure Copper Processed by Selective Electron Beam Melting. World Metall. 2021, 74, 1–8. [Google Scholar]

- Ledford, C.; Rock, C.; Tung, M.; Wang, H.; Schroth, J.; Horn, T. Evaluation of Electron Beam Powder Bed Fusion Additive Manufacturing of High Purity Copper for Overhang Structures Using In-Situ Real Time Backscatter Electron Monitoring. Procedia Manuf. 2020, 48, 828–838. [Google Scholar] [CrossRef]

- Karimi, P.; Keshavarz, M.K.; Sadeghi, E.; Habibnejad, M.; Vlasea, M. Interplay of process, microstructure, and mechanical performance in electron beam-powder bed fusion of Ti48Al2Nb2Cr. Addit. Manuf. 2023, 77, 103811. [Google Scholar] [CrossRef]

- Raab, S.J.; Guschlbauer, R.; Lodes, M.A.; Körner, C. Thermal and Electrical Conductivity of 99.9% Pure Copper Processed via Selective Electron Beam Melting. Adv. Eng. Mater. 2016, 18, 1661–1666. [Google Scholar] [CrossRef]

- Sharabian, E. Simulation and Characterisation of Morphology of Meltpool in Electron Beam Powder Bed Fusion of Copper. Ph.D. Thesis, RMIT University, Melbourne, VIC, Australia, 2024. [Google Scholar]

- Guschlbauer, R.; Momeni, S.; Osmanlic, F.; Körner, C. Process development of 99.95% pure copper processed via selective electron beam melting and its mechanical and physical properties. Mater. Charact. 2018, 143, 163–170. [Google Scholar] [CrossRef]

- Lodes, M.A.; Guschlbauer, R.; Körner, C. Process development for the manufacturing of 99.94% pure copper via selective electron beam melting. Mater. Lett. 2015, 143, 298–301. [Google Scholar] [CrossRef]

- Tarafder, P.; Rock, C.; Horn, T. Quasi-Static Tensile Properties of Unalloyed Copper Produced by Electron Beam Powder Bed Fusion Additive Manufacturing. Materials 2021, 14, 2932. [Google Scholar] [CrossRef]

- Ledford, C.; Rock, C.; Carriere, P.; Frigola, P.; Gamzina, D.; Horn, T. Characteristics and Processing of Hydrogen-Treated Copper Powders for EB-PBF Additive Manufacturing. Appl. Sci. 2019, 9, 3993. [Google Scholar] [CrossRef]

- De Terris, T.; Baffie, T.; Ribière, C. Additive manufacturing of pure copper: A review and comparison of physical, microstructural, and mechanical properties of samples manufactured with Laser-Powder Bed Fusion (L-PBF), Electron Beam Melting (EBM) and Metal Fused Deposition Modelling (MFDM) technologies. Int. J. Mater. Form. 2023, 16, 32. [Google Scholar] [CrossRef]

- Guschlbauer, R.; Burkhardt, A.K.; Fu, Z.; Körner, C. Effect of the oxygen content of pure copper powder on selective electron beam melting. Mater. Sci. Eng. A 2020, 779, 139106. [Google Scholar] [CrossRef]

- Ladani, L.; Razmi, J.; Farhan Choudhury, S. Mechanical Anisotropy and Strain Rate Dependency Behavior of Ti6Al4V Produced Using E-Beam Additive Fabrication. J. Eng. Mater. Technol. 2014, 136, 031006. [Google Scholar] [CrossRef]

- Ladani, L. Local and Global Mechanical Behavior and Microstructure of Ti6Al4V Parts Built Using Electron Beam Melting Technology. Metall. Mater. Trans. A 2015, 46, 3835–3841. [Google Scholar] [CrossRef]

- Aravind Shanmugasundaram, S.; Razmi, J.; Mian, M.J.; Ladani, L. Mechanical Anisotropy and Surface Roughness in Additively Manufactured Parts Fabricated by Stereolithography (SLA) Using Statistical Analysis. Materials 2020, 13, 2496. [Google Scholar] [CrossRef]

- Ledford, J.C. Development of Processing Techniques for the Fabrication of Pure Copper Components Utilizing Eb-Pbf. Available online: https://www.proquest.com/dissertations-theses/development-processing-techniques-fabrication/docview/2569992905/se-2?accountid=4485 (accessed on 9 April 2025).

- Ladani, L. Additive Manufacturing of Metals: Materials, Processes, Tests, and Standards; DEStech Publications Inc.: Lancaster, PA, USA, 2021. [Google Scholar]

- Sadeghilaridjani, M.; Ladani, L. Location-dependent deformation behavior of additively manufactured copper and copper-carbon nanotube composite. J. Alloys Compd. 2022, 909, 164800. [Google Scholar] [CrossRef]

- Zheng, R.; Cui, J.; Yang, Y.; Li, S.; Misra, R.D.K.; Kondoh, K.; Zhu, Q.; Lu, Y.; Li, X. Enhanced densification of copper during laser powder bed fusion through powder surface alloying. J. Mater. Process. Technol. 2022, 305, 117575. [Google Scholar] [CrossRef]

- Speidel, A.; Wadge, M.D.; Gargalis, L.; Cooper, T.P.; Reynolds, W.; Grant, D.; Hague, R.; Clare, A.T.; Murray, J.W. The interaction of volatile metal coatings during the laser powder bed fusion of copper. J. Mater. Process. Technol. 2022, 299, 117332. [Google Scholar] [CrossRef]

- Wong, H.; Dawson, K.; Ravi, G.A.; Howlett, L.; Jones, R.O.; Sutcliffe, C.J. Multi-Laser Powder Bed Fusion Benchmarking—Initial Trials with Inconel 625. Int. J. Adv. Manuf. Technol. 2019, 105, 2891–2906. [Google Scholar] [CrossRef]

- Kranz, J.; Herzog, D.; Emmelmann, C. Design guidelines for laser additive manufacturing of lightweight structures in TiAl6V4. J. Laser Appl. 2015, 27, S14001. [Google Scholar] [CrossRef]

- Cherian, R.P.; Midha, P.S.; Smith, L.N.; Pipe, A.G. Knowledge based and adaptive computational techniques for concurrent design of powder metallurgy parts. Adv. Eng. Softw. 2001, 32, 455–465. [Google Scholar] [CrossRef]

- Danninger, H.; De Oro Calderon, R.; Gierl-Mayer, C. Powder Metallurgy and Sintered Materials. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley, V.C.H., Ed.; Wiley: Weinheim, Germany, 2017. [Google Scholar] [CrossRef]

- Deepanraj, B.; Senthilkumar, N.; Tamizharasan, T. Sintering parameters consequence on microstructure and hardness of copper alloy prepared by powder metallurgy. Mater. Today Proc. 2023, 80, 2468–2473. [Google Scholar] [CrossRef]

- Alsaddah, M.; Khan, A.; Groom, K.; Mumtaz, K. Use of 450-808 nm diode lasers for efficient energy absorption during powder bed fusion of Ti6Al4V. Int. J. Adv. Manuf. Technol. 2021, 113, 2461–2480. [Google Scholar] [CrossRef]

- Indhu, R.; Vivek, V.; Sarathkumar, L.; Bharatish, A.; Soundarapandian, S. Overview of Laser Absorptivity Measurement Techniques for Material Processing. Lasers Manuf. Mater. Process. 2018, 5, 458–481. [Google Scholar] [CrossRef]

| Reference | Relative Density (%) | VED (J/mm3) | Power (Watts) | Speed (mm/s) | Hatching Distance (µm) | Layer Thickness (µm) |

|---|---|---|---|---|---|---|

| Yang et al., 2021 [85] | 95 | 350 | 140 | 400 | 50 | 20 |

| Corona et al., 2022 [91] | 84.6 | 729.17 | 175 | 600 | 40 | 10 |

| Guan et al., 2019 [93] | 82 | 395.83 | 190 | 400 | 60 | 20 |

| Trevisan et al., 2017 [92] | 83 | 203.13 | 195 | 400 | 80 | 30 |

| Physical Properties | LPBF Copper | Pure Copper [99] |

|---|---|---|

| Electrical conductivity (% IACS) | 41–96 [62,63] | 100 |

| Thermal conductivity (W/m·K) | 185–383 [79,81] | 398 |

| Ultimate strength (MPa) | 129–294 [81,91] | 210 |

| Yield strength (MPa) | 125–255 [79,82] | 33.3 |

| Elastic modulus (GPa) | 18.3–83 [6,95] | 110 |

| Hardness (HV) | 56–97 [81,93] | 50 |

| Physical Properties | LPBF Copper | Annealed Copper [99] |

|---|---|---|

| Electrical conductivity (% IACS) | ~100 [104,111] | 100 |

| Thermal conductivity (W/m·K) | ~400 [108,110] | 398 |

| Ultimate strength (MPa) | 187–241 [101,104] | 210 |

| Yield strength (MPa) | 127–161 [101,104] | 33.3 |

| Elastic modulus (GPa) | 90–144 [101] | 110 |

| Hardness (HV) | 46–67 [103,108] | 50 |

| Physical and Mechanical Properties | EB-PBF Copper | Pure Copper |

|---|---|---|

| Electrical conductivity (% IACS) | ~101 [115,116,119,121] | 100 |

| Thermal conductivity (W/m·K) | 360–400 [116,119,121] | 385 |

| Ultimate strength (MPa) | 166.2–231 [123,126] | 210 |

| Yield strength (MPa) | 52.2–102 [123] | 33.3 |

| Elastic modulus (GPa) | 80–145.5 [116,126] | 110 |

| Hardness (HV) | 46–164 [77,121] | 50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ho, V.; Ladani, L.; Razmi, J.; Gruber, S.; Murphy, A.B.; Chen, C.; East, D.; Lopez, E. Powder Bed Fabrication of Copper: A Comprehensive Literature Review. Metals 2025, 15, 1114. https://doi.org/10.3390/met15101114

Ho V, Ladani L, Razmi J, Gruber S, Murphy AB, Chen C, East D, Lopez E. Powder Bed Fabrication of Copper: A Comprehensive Literature Review. Metals. 2025; 15(10):1114. https://doi.org/10.3390/met15101114

Chicago/Turabian StyleHo, Vi, Leila Ladani, Jafar Razmi, Samira Gruber, Anthony Bruce Murphy, Cherry Chen, Daniel East, and Elena Lopez. 2025. "Powder Bed Fabrication of Copper: A Comprehensive Literature Review" Metals 15, no. 10: 1114. https://doi.org/10.3390/met15101114

APA StyleHo, V., Ladani, L., Razmi, J., Gruber, S., Murphy, A. B., Chen, C., East, D., & Lopez, E. (2025). Powder Bed Fabrication of Copper: A Comprehensive Literature Review. Metals, 15(10), 1114. https://doi.org/10.3390/met15101114