High-Pressure Die Casting (HPDC) Process Parameters Optimization for Al-Mg-Fe Aluminum Alloy Structural Parts Manufacturing

Abstract

1. Introduction

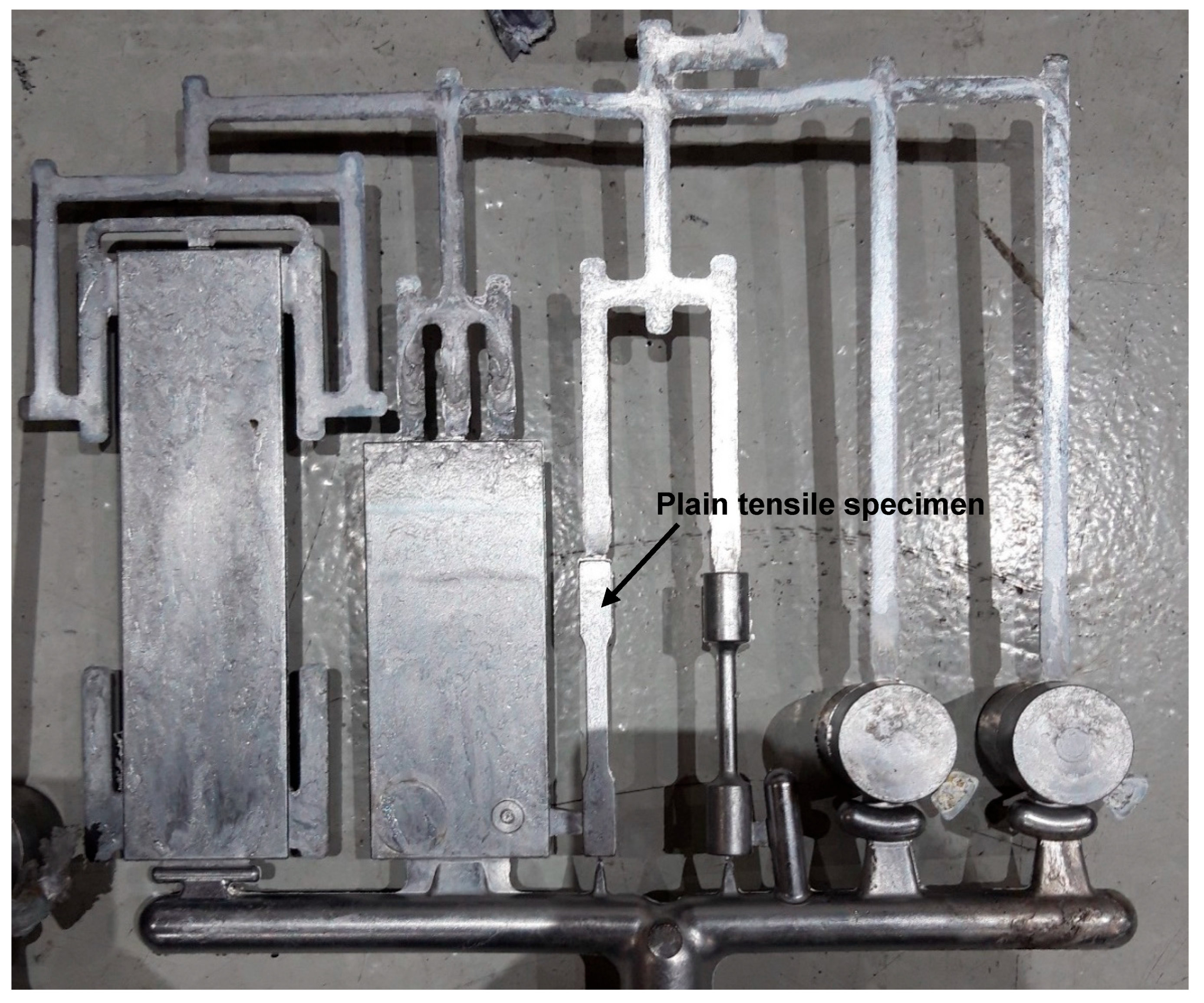

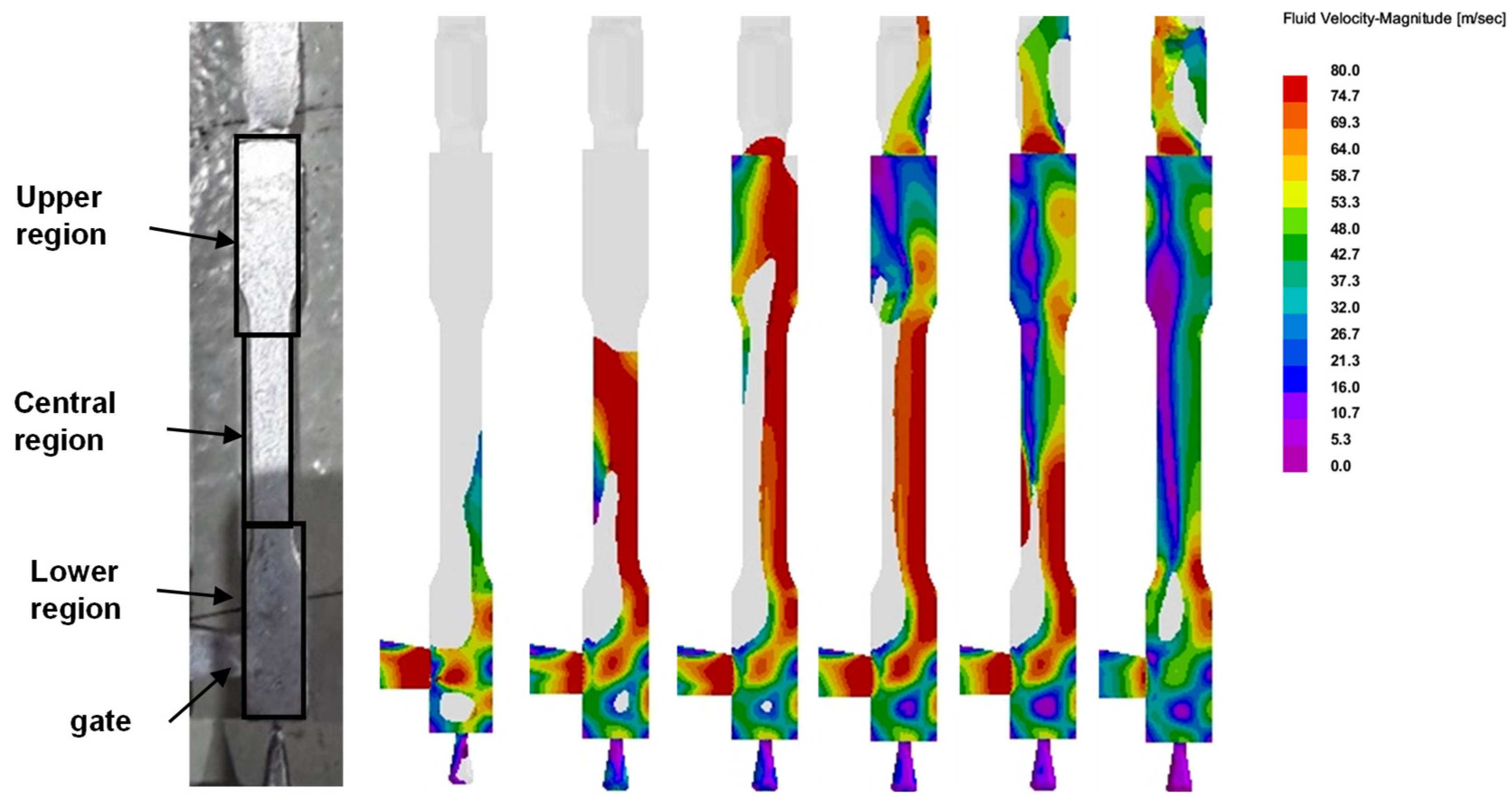

2. Materials and Methods

3. Results and Discussion

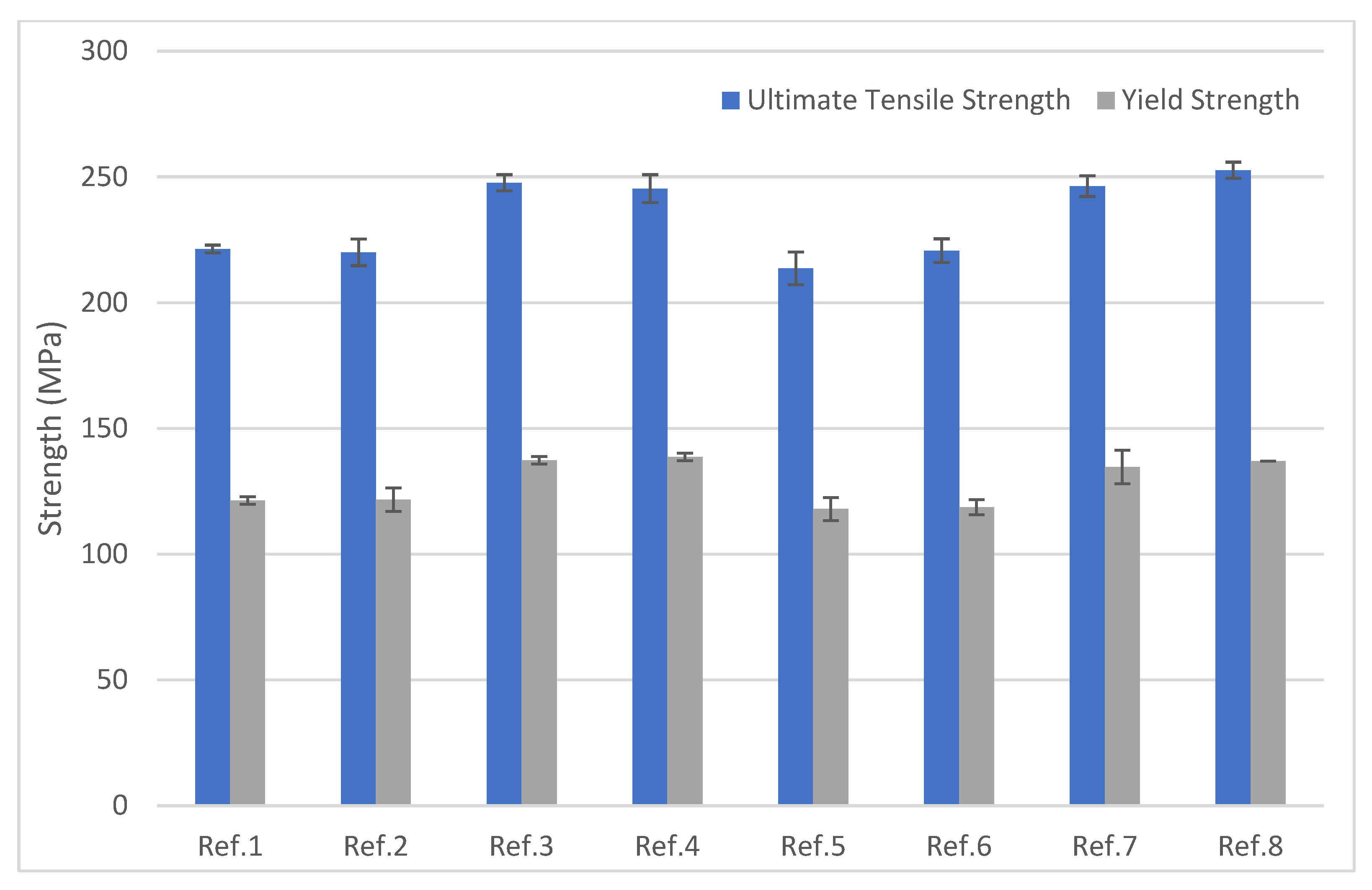

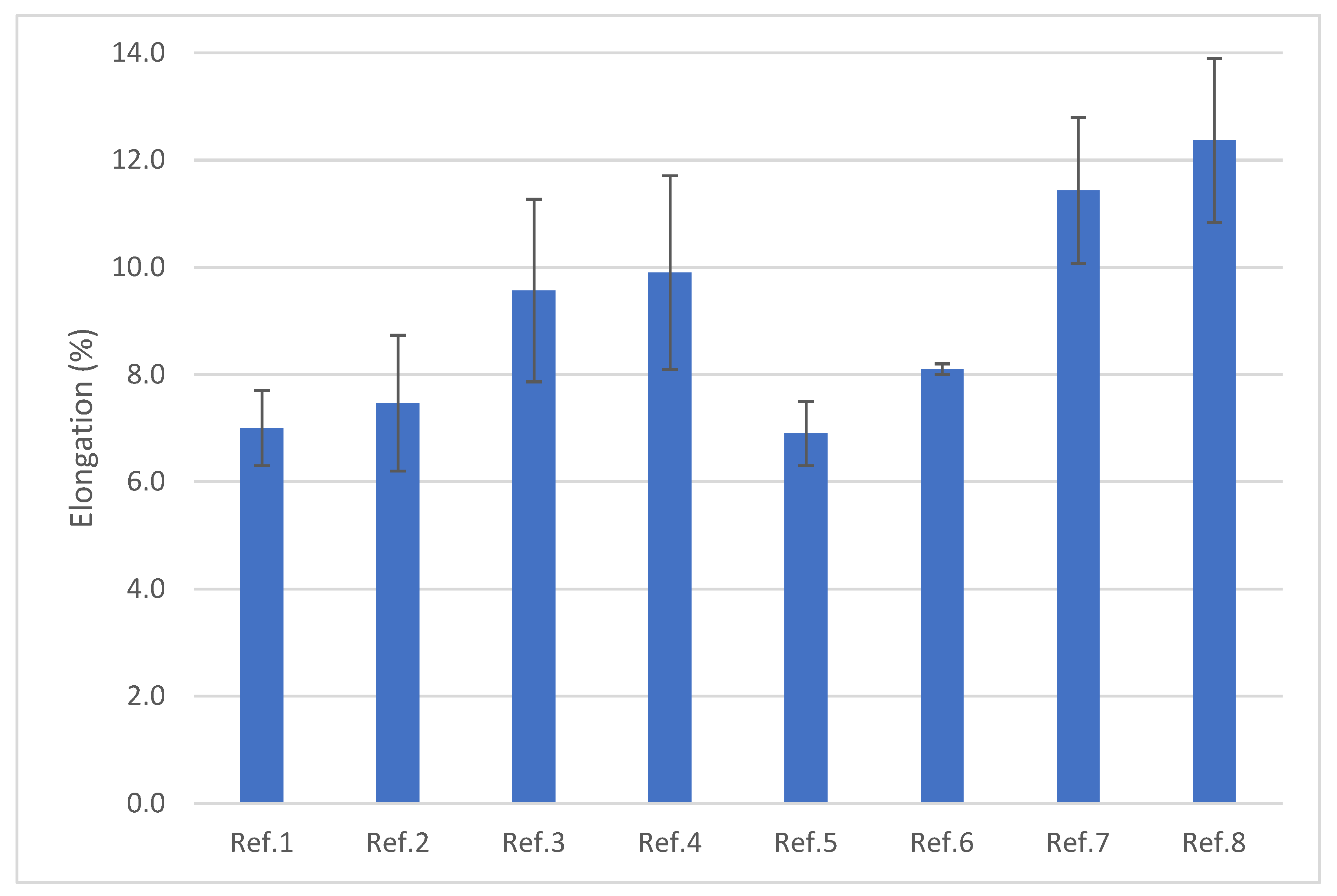

3.1. Tensile Properties

3.2. Porosity Results

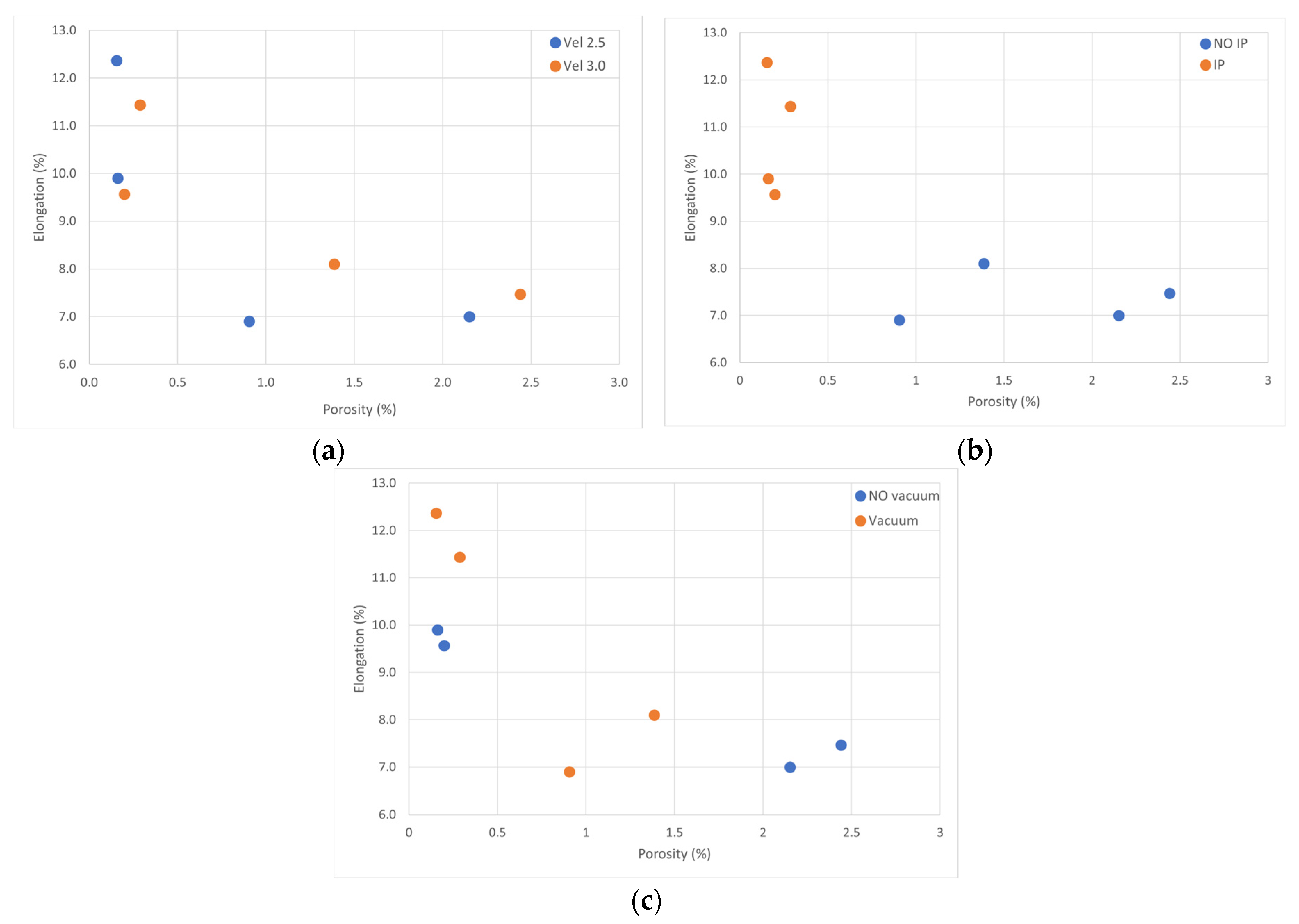

3.3. Correlation Between Elongation and Porosity

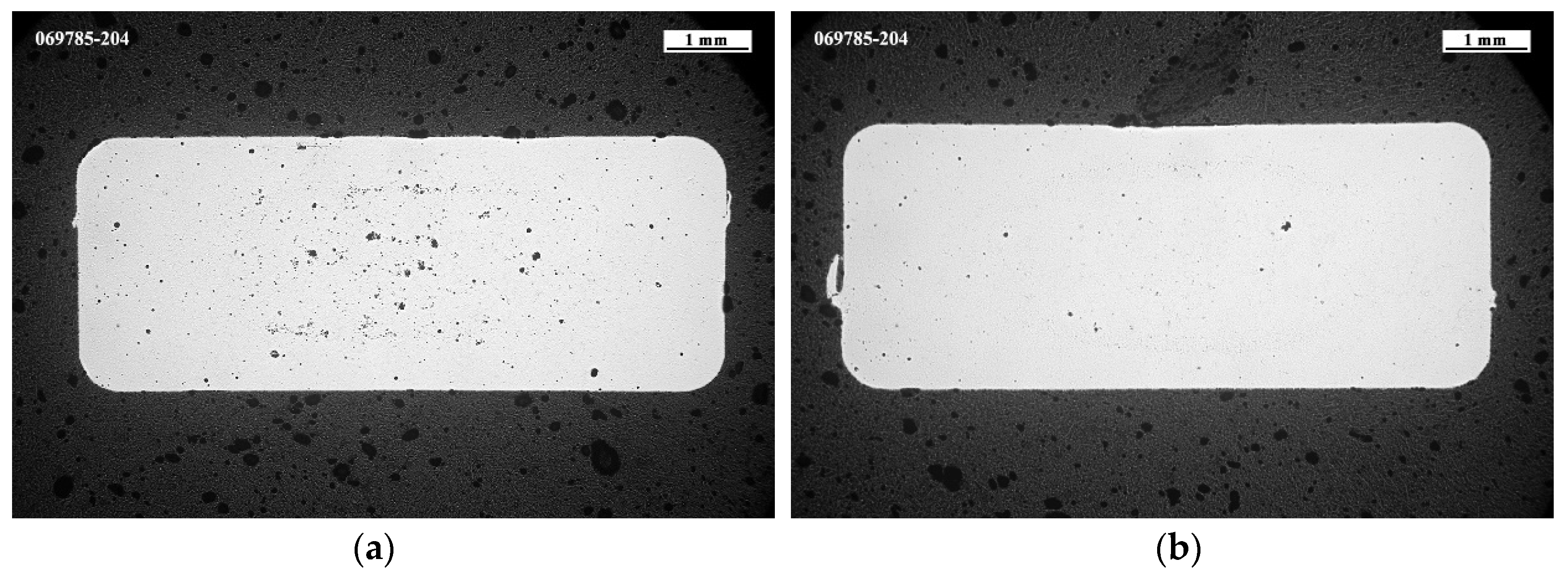

3.4. Computed Tomography

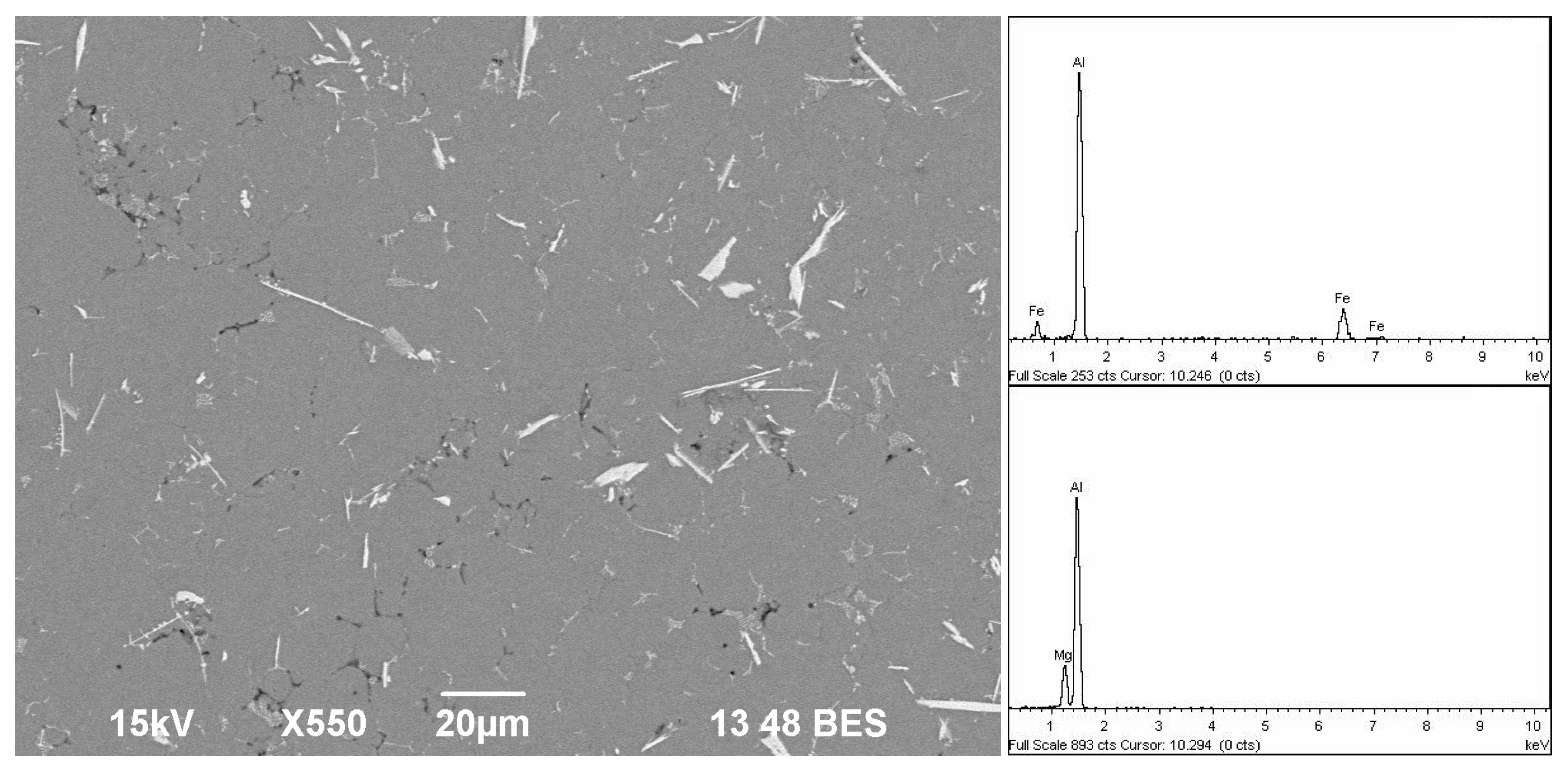

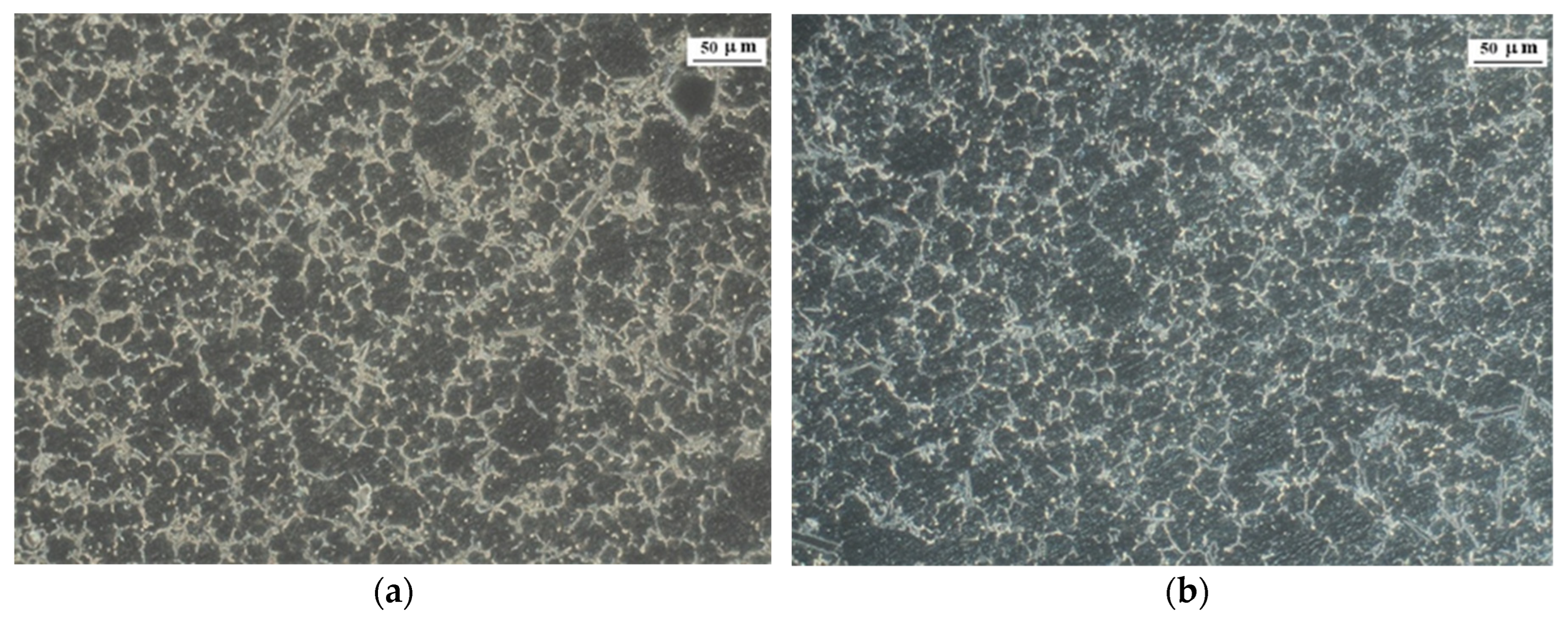

3.5. Metallographic Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| HPDC | High Pressure Die Casting |

| DoE | Desing of Experiments |

| IP | Intensification Pressure |

| NHT | Non-Heat Treatable |

| CT | Computed Tomography |

| NDT | Non-Destructive Technique |

| OEM | Original Equipment Manufacturer |

| UTS | Ultimate Tensile Strength |

| YS | Yield Strength |

References

- Vicario, I.; Egizabal, P.; Galarraga, H.; Plaza, L.M.; Crespo, I. Study of an Al-Si-Cu HPDC Alloy with High Zn Content for the Production of Components Requiring High Ductility and Tensile Properties. Int. J. Mater. Res. 2013, 104, 392–397. [Google Scholar] [CrossRef]

- Shaffer, B.; Auffhammer, M.; Samaras, C. Make Electric Vehicles Lighter to Maximize Climate and Safety Benefits. Nature 2021, 598, 254–256. [Google Scholar] [CrossRef] [PubMed]

- Fontaras, G.; Zacharof, N.G.; Ciuffo, B. Fuel Consumption and CO2 Emissions from Passenger Cars in Europe—Laboratory versus Real-World Emissions. Prog. Energy Combust. Sci. 2017, 60, 97–131. [Google Scholar] [CrossRef]

- Robles Hernandez, F.; Martín Herrera Ramírez, J.; Mackay, R. Al-Si Alloys: Automotive, Aeronautical, and Aerospace Applications; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Kaufman, J.G.; Rooy, E. Aluminum Alloy Castings: Properties, Processes and Applications; Asm International: Almere, The Netherlands, 2004; ISBN 0871708035. [Google Scholar]

- Hu, R.; Guo, C.; Ma, M. A Study on High Strength, High Plasticity, Non-Heat Treated Die-Cast Aluminum Alloy. Materials 2022, 15, 295. [Google Scholar] [CrossRef] [PubMed]

- Vicario, I.; Anza, I.; Sáenz de Tejada, F.; García, J.C.; Galarraga, H.; Merchán, M. Development of New Al-Si9Cu3 Alloys for HPDC Components with Tailored Properties. In Proceedings of the 71st World Foundry Congress: Advanced Sustainable Foundry, WFC 2014, Bilbao, Spain, 19–21 May 2014; World Foundry Organization: Herefordshire, UK, 2014. [Google Scholar]

- Alcoa. Alcoa: Non-Heat Treat HPDC Foundry Alloys for Car Body Structures. Spotlightmetal. 2019. Available online: https://castingssa.com/alcoa-non-heat-treat-hpdc-foundry-alloys-for-car-body-structures/ (accessed on 12 September 2025).

- Wiesner, S.; Saka, Y. Characteristics of New Alloys for HPDC Structural Parts. Spotlightmetal. 2019. Available online: https://www.scribd.com/document/675046149/spotlightmetal-characteristics-of-new-alloys-for-hpdc-structural-parts-882428 (accessed on 12 September 2025).

- Casarotto, F.; Franke, A.J.; Franke, R. High-Pressure Die-Cast (HPDC) Aluminum Alloys for Automotive Applications. In Advanced Materials in Automotive Engineering; Elsevier: Amsterdam, The Netherlands, 2012; pp. 109–149. [Google Scholar]

- Cho, J.-S.; Kim, J.-H.; Sim, W.-J.; Im, H.-J. The Influence of Alloying Elements on the Fluidity of Al-Zn-Mg Alloys. J. Korea Foundry Soc. 2012, 32, 127–132. [Google Scholar] [CrossRef][Green Version]

- Soares, G.; Neto, R.; Madureira, R.; Soares, R.; Silva, J.; Silva, R.P.; Araújo, L. Characterization of Al Alloys Injected through Vacuum-Assisted HPDC and Influence of T6 Heat Treatment. Metals 2023, 13, 389. [Google Scholar] [CrossRef]

- Vivas, J.; Fernández-Calvo, A.I.; Aldanondo, E.; Irastorza, U.; Álvarez, P. Friction Stir Weldability at High Welding Speed of Two Structural High Pressure Die Casting Aluminum Alloys. J. Manuf. Mater. Process. 2022, 6, 160. [Google Scholar] [CrossRef]

- Zhang, Y.; Lordan, E.; Dou, K.; Wang, S.; Fan, Z. Influence of Porosity Characteristics on the Variability in Mechanical Properties of High Pressure Die Casting (HPDC) AlSi7MgMn Alloys. J. Manuf. Process 2020, 56, 500–509. [Google Scholar] [CrossRef]

- Dou, K.; Lordan, E.; Zhang, Y.; Jacot, A.; Fan, Z. A Novel Approach to Optimize Mechanical Properties for Aluminum Alloy in High Pressure Die Casting (HPDC) Process Combining Experiment and Modelling. J. Mater. Process Technol. 2021, 296, 117193. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, F.; Zheng, J.; Münstermann, S.; Li, T.; Han, W.; Huang, S. Ductility Prediction of HPDC Aluminum Alloy Using a Probabilistic Ductile Fracture Model. Theor. Appl. Fract. Mech. 2022, 119, 103381. [Google Scholar] [CrossRef]

- Adamane, A.R.; Arnberg, L.; Fiorese, E.; Timelli, G.; Bonollo, F. Influence of Injection Parameters on the Porosity and Tensile Properties of High-Pressure Die Cast Al-Si Alloys: A Review. Int. J. Met. 2015, 9, 43–53. [Google Scholar] [CrossRef]

- Wilczek, A.; Długosz, P.; Hebda, M. Porosity Characterization of Aluminum Castings by Using Particular Non-Destructive Techniques. J. Nondestruct. Eval. 2015, 34, 26. [Google Scholar] [CrossRef]

- Li, Z.; Jing, Y.; Guo, H.; Sun, X.; Yu, K.; Yu, A.; Jiang, X.; Yang, X.J. Study of 3D Pores and Its Relationship with Crack Initiation Factors of Aluminum Alloy Die Castings. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2019, 50, 1204–1212. [Google Scholar] [CrossRef]

- Lordan, E.; Lazaro-Nebreda, J.; Zhang, Y.; Dou, K.; Blake, P.; Fan, Z. On the Relationship between Internal Porosity and the Tensile Ductility of Aluminum Alloy Die-Castings. Mater. Sci. Eng. A 2020, 778, 139107. [Google Scholar] [CrossRef]

- Yu, W.; Yuan, Z.; Guo, Z.; Xiong, S. Characterization of A390 Aluminum Alloy Produced at Different Slow Shot Speeds Using Vacuum Assisted High Pressure Die Casting. Trans. Nonferrous Met. Soc. China 2017, 27, 2529–2538. [Google Scholar] [CrossRef]

- Brown, J.R. Foseco Non-Ferrous Foundryman’s Handbook; Butterworth-Heinemann: Oxford, UK, 2016. [Google Scholar]

- Schaffer, P.L.; Laukli, H.I. Recent Developments in Aluminum High Pressure Die Castings. Die Cast. Eng. 2012, 56, 20–22. [Google Scholar]

- Otarawanna, S.; Laukli, H.I.; Gourlay, C.M.; Dahle, A.K. Feeding Mechanisms in High-Pressure Die Castings. Metall. Mater. Trans. A 2010, 41, 1836–1846. [Google Scholar] [CrossRef]

- Watanabe, I.; Watkins, J.H.; Nakajima, H.; Atsuta, M.; Okabe, T. Effect of Pressure Difference on the Quality of Titanium Casting. J. Dent. Res. 1997, 76, 773–779. [Google Scholar] [CrossRef]

- Li, X.; Xiong, S.M.; Guo, Z. Correlation between Porosity and Fracture Mechanism in High Pressure Die Casting of AM60B Alloy. J. Mater. Sci. Technol. 2016, 32, 54–61. [Google Scholar] [CrossRef]

- dos Santos, S.L.; Antunes, R.A.; Santos, S.F. Influence of Injection Temperature and Pressure on the Microstructure, Mechanical and Corrosion Properties of a AlSiCu Alloy Processed by HPDC. Mater. Des. 2015, 88, 1071–1081. [Google Scholar] [CrossRef]

- Rheinfelden Alloys. HPDC Alloys for Structural Casts in Vehicle Construction; Rheinfelden Alloys: Rheinfelden, Germany, 2017. [Google Scholar]

- Herman, E.A. (NADCA) Die Casting Process Control; North America Die Casting Association: Arlington Heights, IL, USA, 2003. [Google Scholar]

- Anglada, E.; Meléndez, A.; Vicario, I.; Arratibel, E.; Aguillo, I. Adjustment of a High Pressure Die Casting Simulation Model Against Experimental Data. Procedia Eng. 2015, 132, 966–973. [Google Scholar] [CrossRef]

- Anglada, E.; Meléndez, A.; Vicario, I.; Idoiaga, J.K.; Mugarza, A.; Arratibel, E. Prediction and Validation of Shape Distortions in the Simulation of High Pressure Die Casting. J. Manuf. Process 2018, 33, 228–237. [Google Scholar] [CrossRef]

- Anglada, E.; Boto, F.; De Cortazar, M.G.; Garmendia, I. Metamodels’ Development for High Pressure Die Casting of Aluminum Alloy. Metals 2021, 11, 1747. [Google Scholar] [CrossRef]

- UNE-EN ISO 6892-1; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. AENOR International, S.A.U: Madrid, Spain, 2020.

- ASTM E407; Standard Practice for Microetching Metals and Alloys. ASTM International: West Conshohocken, PA, USA, 2007.

- Cao, H.; Luo, Z.; Wang, C.; Wang, J.; Hu, T.; Xiao, L.; Che, J. The Stress Concentration Mechanism of Pores Affecting the Tensile Properties in Vacuum Die Casting Metals. Materials 2020, 13, 3019. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.; Zhu, X.; Ji, S. Effect of Super Vacuum Assisted High Pressure Die Casting on the Repeatability of Mechanical Properties of Al-Si-Mg-Mn Die-Cast Alloys. J. Mater. Process Technol. 2019, 266, 105–113. [Google Scholar] [CrossRef]

- Wang, C.; Yao, J.; Zhao, H.; Yang, R. Influence of Intensification Pressures on Pores in Die-Cast ADC12 Alloys. China Foundry 2019, 16, 184–189. [Google Scholar] [CrossRef]

- Cao, H.; Shen, C.; Wang, C.; Xu, H.; Zhu, J. Direct Observation of Filling Process and Porosity Prediction in High Pressure Die Casting. Materials 2019, 12, 1099. [Google Scholar] [CrossRef]

- Karban, R., Jr. The Effects of Intensification Pressure, Gate Velocity, and Intermediate Shot Velocity on the Internal Quality of Aluminum Die Castings. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2000. [Google Scholar]

- Dou, K.; Lordan, E.; Zhang, Y.J.; Jacot, A.; Fan, Z.Y. Numerical Simulation of Fluid Flow, Solidification and Defects in High Pressure Die Casting (HPDC) Process. IOP Conf. Ser. Mater. Sci. Eng. 2019, 529, 012058. [Google Scholar] [CrossRef]

- ASTM E112; Standard Test Methods for Determining Average Grain Size. ASTM International: West Conshohocken, PA, USA, 2024.

| Experiment Ref. | Vacuum | Intensification Pressure | Plunger Speed (m/s) |

|---|---|---|---|

| 1 | No | No | 2.5 |

| 2 | No | No | 3.0 |

| 3 | No | Yes | 3.0 |

| 4 | No | Yes | 2.5 |

| 5 | Yes | No | 2.5 |

| 6 | Yes | No | 3.0 |

| 7 | Yes | Yes | 3.0 |

| 8 | Yes | Yes | 2.5 |

| Element | Si | Fe | Cu | Mn | Mg | Zn | Ti |

|---|---|---|---|---|---|---|---|

| Wt.% | 0.29 | 1.71 | 0.044 | 0.035 | 4.88 | 0.070 | 0.034 |

| Focal Spot Size (mm) | Hardware Filters | Voltage (kV) | Current (mA) | Exposure Time (ms) | Projections | Voxel Size (µm) |

|---|---|---|---|---|---|---|

| 0.4 | 1 mm Cu & 0.5 mm Sn | 150 | 4 | 100 | 1440 | 91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Merchán, M.; Pascual, A.; Jiménez, A.; García, J.C.; Anglada, E.; Galarraga, H.; Ortega, N. High-Pressure Die Casting (HPDC) Process Parameters Optimization for Al-Mg-Fe Aluminum Alloy Structural Parts Manufacturing. Metals 2025, 15, 1071. https://doi.org/10.3390/met15101071

Merchán M, Pascual A, Jiménez A, García JC, Anglada E, Galarraga H, Ortega N. High-Pressure Die Casting (HPDC) Process Parameters Optimization for Al-Mg-Fe Aluminum Alloy Structural Parts Manufacturing. Metals. 2025; 15(10):1071. https://doi.org/10.3390/met15101071

Chicago/Turabian StyleMerchán, Mikel, Alejandro Pascual, Ane Jiménez, José Carlos García, Eva Anglada, Haize Galarraga, and Naiara Ortega. 2025. "High-Pressure Die Casting (HPDC) Process Parameters Optimization for Al-Mg-Fe Aluminum Alloy Structural Parts Manufacturing" Metals 15, no. 10: 1071. https://doi.org/10.3390/met15101071

APA StyleMerchán, M., Pascual, A., Jiménez, A., García, J. C., Anglada, E., Galarraga, H., & Ortega, N. (2025). High-Pressure Die Casting (HPDC) Process Parameters Optimization for Al-Mg-Fe Aluminum Alloy Structural Parts Manufacturing. Metals, 15(10), 1071. https://doi.org/10.3390/met15101071