Analysis of Strain Hardening Stages of AISI 316 LN Stainless Steel Under Cold Rolling Conditions

Abstract

1. Introduction

- (i)

- The initial portion of the transient stage, in which θ decreases rapidly (Stage I);

- (ii)

- A stage where θ increases gradually with εT to a maximum (Stage II);

- (iii)

- A stage where θ decreases due to the onset of dynamic recovery (Stage III);

- (iv)

- A stage where θ decreases rapidly (Stage IV).

2. Material and Experimental Procedures

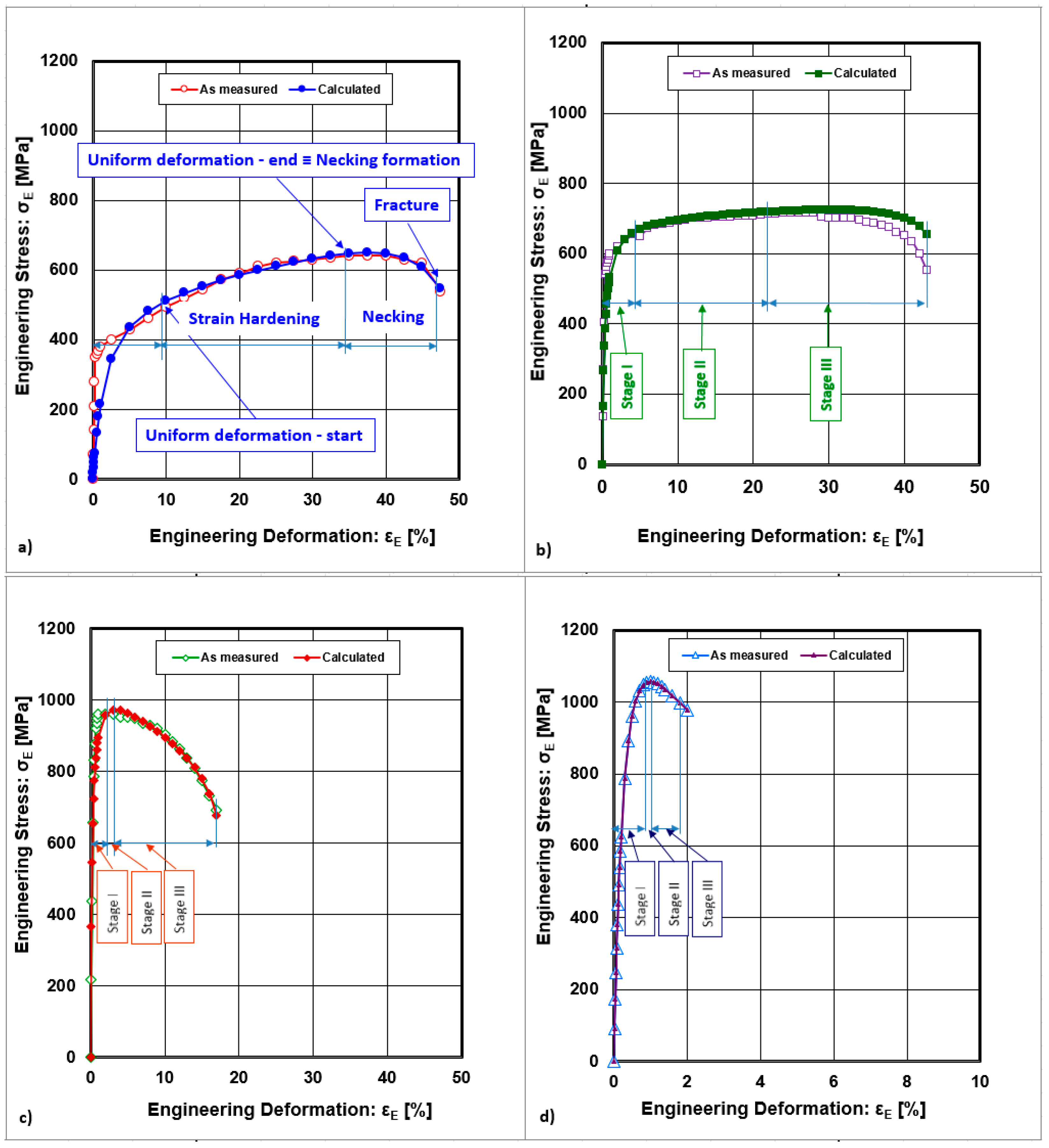

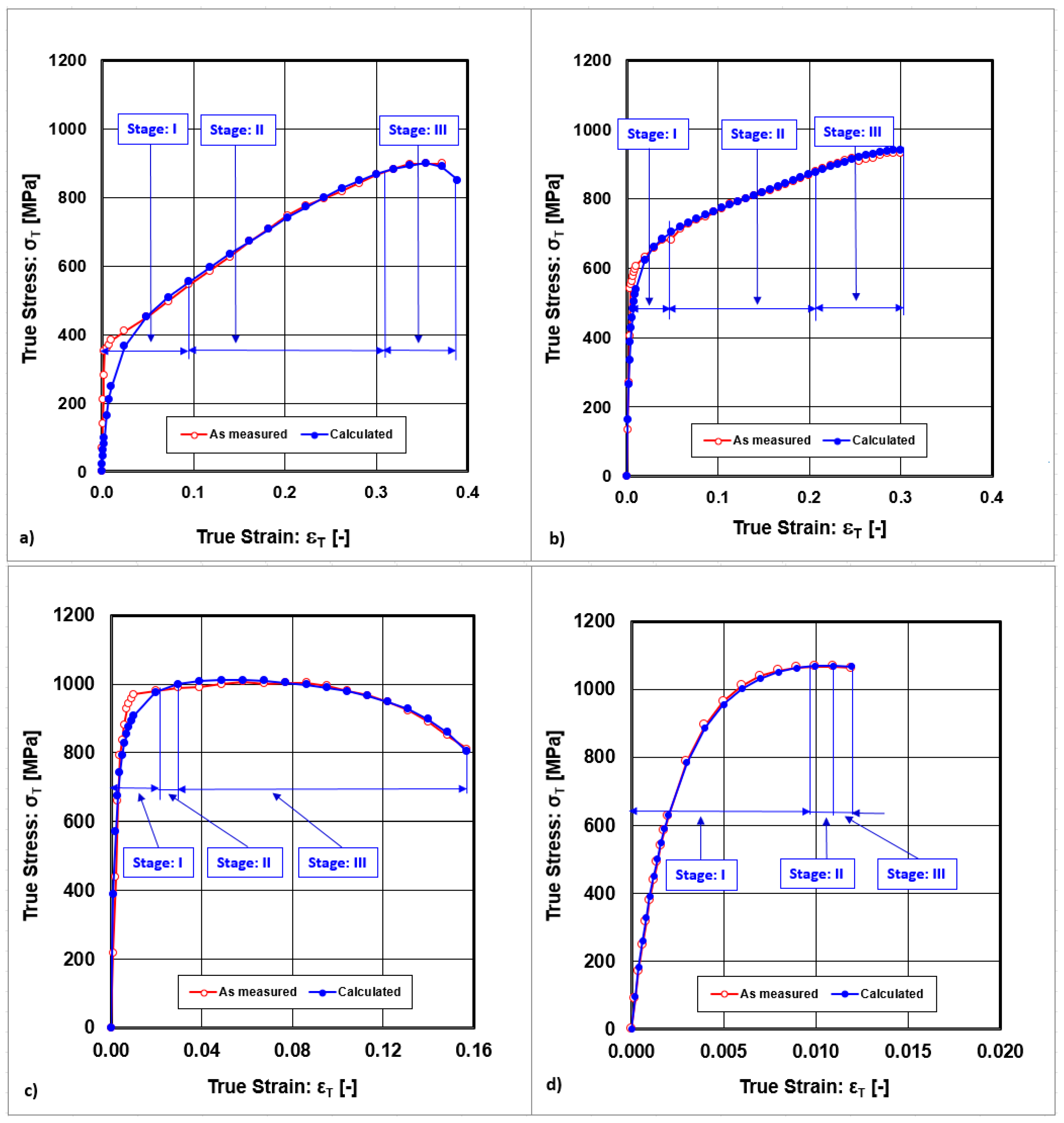

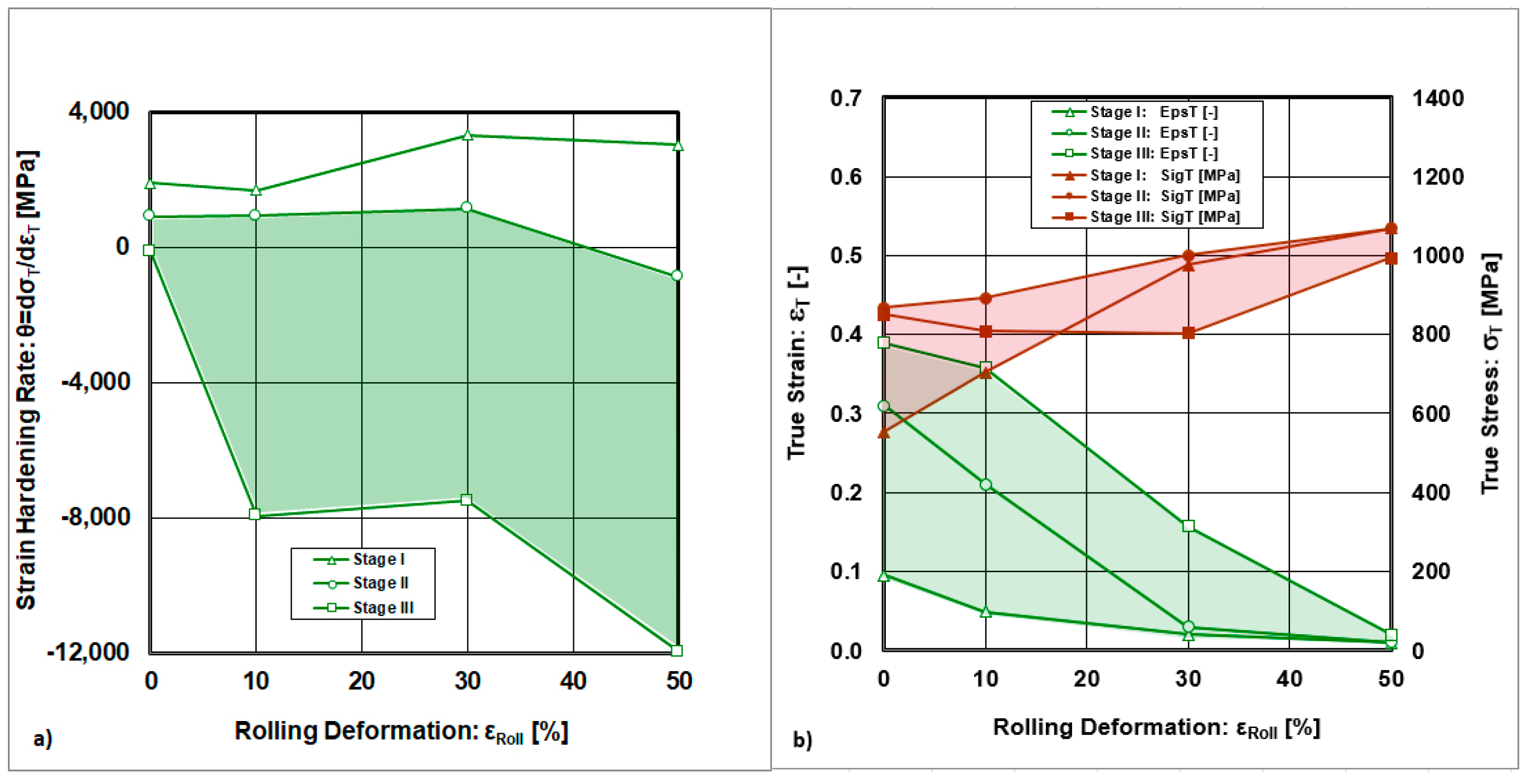

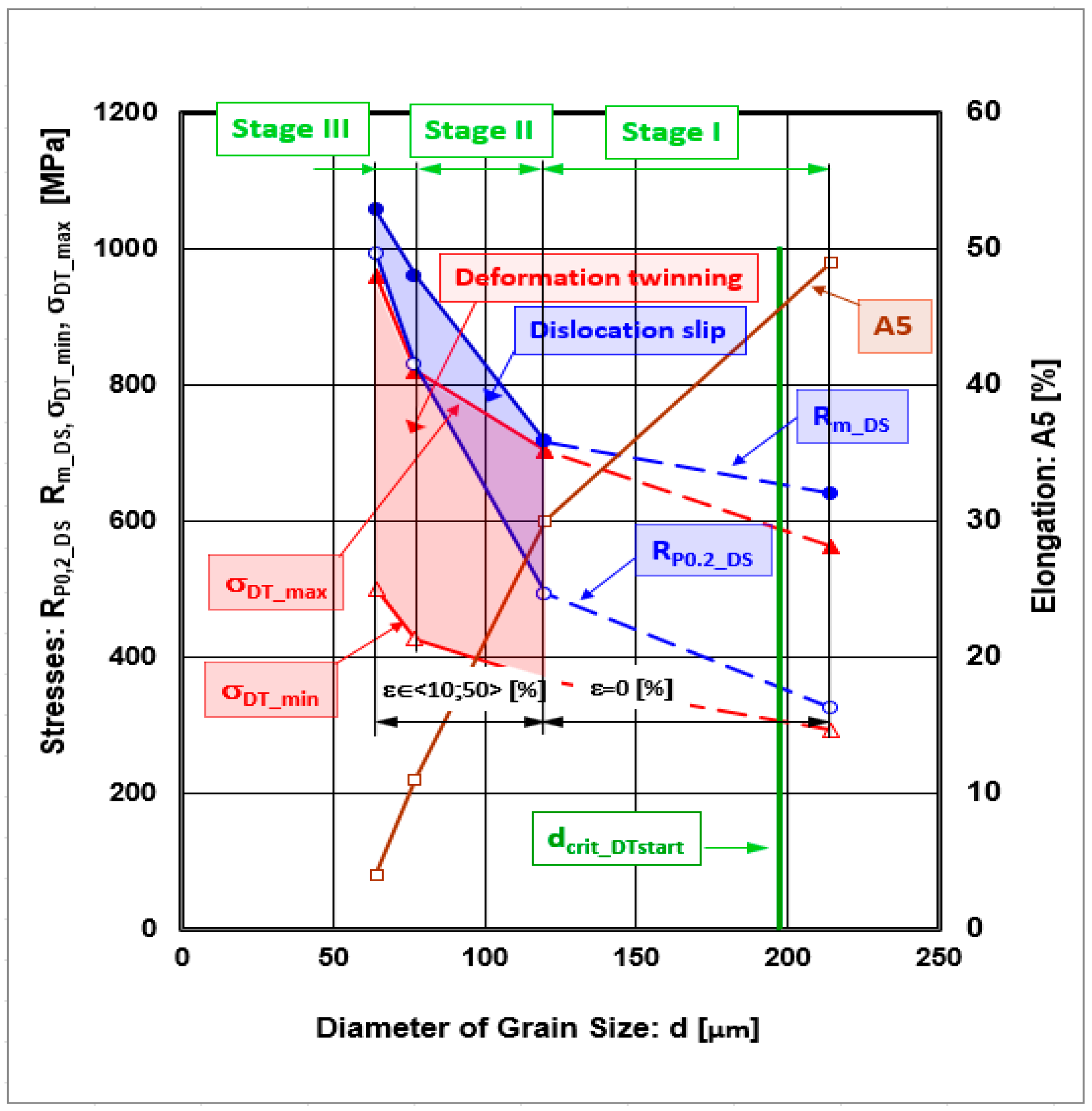

3. Results and Analysis

4. Conclusions

- Three stages of strain hardening rates were observed. Stage I lies in the interval εRoll ∈ <0;10> %, Stage II in the interval εRoll ∈ <10;30> %, and Stage III in the interval εRoll ∈ <30;50> %.

- Stage I is characterized by a rapid decline in the strain hardening rate and is accompanied by easy dislocation gliding along primary slip planes.

- Stage II is characterized by a stabilized strain hardening rate that is accompanied by multiple slips and cross-slip.

- A decrease in the strain hardening rate characterizes Stage III. This stage is defined as a region of plastic deformation instability in which dislocation interactions take place, leading to their annihilation and ultimately to the recovery of the microstructure. The mechanisms of plastic deformation are characterized as follows: Stage I—dislocation slip; Stage II—dislocation slip accompanied by deformation twinning; Stage III—deformation twinning accompanied by dislocation slip.

- The scientific results resulting from the determination of the plastic stability regions of the investigated material can be transferred to the design of optimized deformation plans for cold rolling in industrial conditions. By determining optimal deformation plans, the possibility of material defects during cold rolling processes is eliminated.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Properties and Selection: Irons, Steels, and High-Performance Alloys—ASM International. In ASM Handbook; 1990; Volume 1, ISBN 978-0-87170-377-4. Available online: https://www.asminternational.org/asm-handbook-volume-1-properties-and-selection-irons-steels-and-high-performance-alloys/results/-/journal_content/56/06181G/PUBLICATION (accessed on 27 November 2024).

- Brytan, Z.; Dagnaw, M.; Bidulska, J.; Bidulsky, R. Corrosion evaluation of LPBF-manufactured duplex stainless steel. Acta Metall. Slovaca 2024, 30, 34–40. [Google Scholar] [CrossRef]

- Hu, J.; Liu, Y.; Wang, G.; Li, Q.; Wen, J.; Yan, L.; Chen, S.; Gu, Y. Effect of Tempering Treatment on Microstructural Evolution and Mechanical Behavior of Heavy-Wall Heat Induction Seamless Bend Pipe. Materials 2021, 15, 259. [Google Scholar] [CrossRef]

- Vargas, B.R.R.; Albini, L.; Tiracorrendo, G.; Massi, R.; Stornelli, G.; Di Schino, A. Effect of Ultrafast Heating on AISI 304 Austenitic Stainless Steel. Acta Metall. Slovaca 2023, 29, 104–107. [Google Scholar] [CrossRef]

- Kvackaj, T.; Bidulska, J.; Fedorikova, A.; Bidulsky, R. Mechanical Properties and Strengthening Contributions of AISI 316 LN Austenitic Stainless Steel Grade. Materials 2025, 18, 499. [Google Scholar] [CrossRef]

- Janda, T.; Jeníček, Š.; Kučerová, L.; Leták, R.; Jandová, D. Influence of Higher Stabilization Temperatures on the Microstructure and Mechanical Properties of Austenitic Stainless Steel 08Ch18N10T. Metals 2023, 13, 975. [Google Scholar] [CrossRef]

- Kučerová, L.; Benediktová, A.; Burdová, K.; Jandová, D. Low-temperature precipitation strengthening of maraging steel 1.2709 produced by powder bed fusion. Mater. Des. 2024, 241, 112938. [Google Scholar] [CrossRef]

- Stornelli, G.; Albini, L.; Di Nunzio, P.E.; Tiracorrendo, G.; Rodriguez Vargas, B.R.; di Schino, A. Effect of ultrafast heating on AISI 441 ferritic stainless steel. Acta Metall. Slovaca 2023, 29, 22–25. [Google Scholar] [CrossRef]

- El-Danaf, E.; Kalidindi, S.R.; Doherty, R.D. Influence of deformation path on the strain hardening behavior and microstructure evolution in low SFE FCC metals. Int. J. Plast. 2001, 17, 1245–1265. [Google Scholar] [CrossRef]

- Cui, Z.; He, S.; Tang, J.; Fu, D.; Teng, J.; Jiang, F. Effect of Grain Size on the Plastic Deformation Behaviors of a Fe-18Mn-1.3Al-0.6C Austenitic Steel. Materials 2022, 15, 8717. [Google Scholar] [CrossRef]

- Soares, G.C.; Gonzalez, B.M.; de Arruda Santos, L. Strain hardening behavior and microstructural evolution during plastic deformation of dual phase, non-grain oriented electrical and AISI 304 steels. Mater. Sci. Eng. A 2017, 684, 577–585. [Google Scholar] [CrossRef]

- Ding, H.; Ding, H.; Song, D.; Tang, Z.; Yang, P. Strain hardening behavior of a TRIP/TWIP steel with 18.8% Mn. Mater. Sci. Eng. A 2011, 528, 868–873. [Google Scholar] [CrossRef]

- Kaščák, L.; Mucha, J.; Varga, J.; Slota, J.; Kaščáková, E. Analysis of hybrid joining of microalloyed steel sheets HX300LAD. Acta Metall. Slovaca 2024, 30, 188–191. [Google Scholar] [CrossRef]

- Feaugas, X. On the origin of the tensile flow stress in the stainless steel AISI 316L at 300 K: Back stress and effective stress. Acta Mater. 1999, 47, 3617–3632. [Google Scholar] [CrossRef]

- Wu, T.Y.; Bassani, J.L.; Laird, C. Latent Hardening in Single Crystals I. Theory and Experiments. Proc. R. Soc. A Math. Phys. Eng. Sci. 1991, 435, 1–19. [Google Scholar] [CrossRef]

- Kundu, A.; Field, D.P.; Chakraborti, P.C. Effect of strain and strain rate on the development of deformation heterogeneity during tensile deformation of a solution annealed 304 LN austenitic stainless steel: An EBSD study. Mater. Sci. Eng. A 2020, 773, 138854–138864. [Google Scholar] [CrossRef]

- Ivanov, S.; Mendagaliev, R.; Samoilov, S.; Akhmedianov, A.; Lebedeva, N.; Udin, I.; Turichin, G. Temperature dependence of tensile mechanical properties and work hardening behavior in direct laser deposited austenitic stainless steel 316L. Mater. Today Commun. 2024, 39, 108613. [Google Scholar] [CrossRef]

- Ruban, R.; Vijayanand, V.D.; Sivapirakasam, S.P.; Prasad Reddy, G.V. Influence of thermo-mechanical treatment on the flow behavior of 14Cr-15Ni stainless steel. Can. Metall. Q. 2025, 64, 873–878. [Google Scholar] [CrossRef]

- Arrayago, I.; Real, E.; Gardner, L. Description of stress–strain curves for stainless steel alloys. Mater. Des. 2015, 87, 540–552. [Google Scholar] [CrossRef]

- Wang, Y.; Hou, Q.; Li, X.; Li, Z.; Wu, F.; Chen, S.; Lv, C.; He, Q.; Ye, X.; Yu, Y.; et al. Strain rate-dependent tensile response and deformation mechanism of laser powder bed fusion 316L stainless steel. Mater. Sci. Eng. A 2024, 893, 146124. [Google Scholar] [CrossRef]

- Yu, B.; Zhang, B.; Shi, R.; Mao, F.; Wei, S.; Yang, D. Dynamic Recrystallization Model of High-Temperature Deformation and Finite Element Analysis of Microstructure Evolution of 14Cr1Mo Pressure Vessel Steel. Materials 2025, 18, 3531. [Google Scholar] [CrossRef]

- Christopher, J.; Choudhary, B.K. On the assessment of tensile work hardening behaviour of type 316L(N) austenitic stainless steel in the framework of θσd vs. σd using flow stress contribution from dislocations. Int. J. Press. Vessels Pip. 2016, 146, 151–160. [Google Scholar] [CrossRef]

- Argon, A.S. Mechanical properties of single-phase crystalline media: Deformation at low temperatures. In Physical Metallurgy; Cahn, R.W., Haasen, P., Eds.; North-Holland: Amsterdam, The Netherlands, 1996; ISBN 9780080538945. [Google Scholar]

- Asgari, S.; El-Danaf, E.; Kalidindi, S.R.; Doherty, R.D. Strain hardening regimes and microstructural evolution during large strain compression of low stacking fault energy fcc alloys that form deformation twins. Metall. Mater. Trans. A 1997, 28, 1781–1795. [Google Scholar] [CrossRef]

- Praveen, K.V.U.; Sastry, G.V.S.; Singh, V. Work-Hardening Behavior of the Ni-Fe Based Superalloy IN718. Metall. Mater. Trans. A 2008, 39, 65–78. [Google Scholar] [CrossRef]

- Kalidindi, S.A. Modeling the strain hardening response of low SFE FCC alloys. Int. J. Plast. 1998, 14, 1265–1277. [Google Scholar] [CrossRef]

- Finfrock, C.B.; Thrun, M.M.; Bhattacharya, D.; Ballard, T.J.; Clarke, A.J.; Clarke, K.D. Strain Rate Dependent Ductility and Strain Hardening in Q&P Steels. Metall. Mater. Trans. A 2021, 52, 928–942. [Google Scholar] [CrossRef]

- Angella, G. Strain hardening analysis of an austenitic stainless steel at high temperatures based on the one-parameter model. Mater. Sci. Eng. A 2012, 532, 381–391. [Google Scholar] [CrossRef]

- Isaac Samuel, E.; Choudhary, B.K.; Bhanu Sankara Rao, K. Influence of temperature and strain rate on tensile work hardening behaviour of type 316 LN austenitic stainless steel. Scr. Mater. 2002, 46, 507–512. [Google Scholar] [CrossRef]

- Ho, H.S.; Sun, L.L.; Liu, K.K.; Niu, P.H.; Zhang, E.L. Microstructural evolution and strain hardening behavior of AISI 316L type austenitic stainless steel. Int. J. Mater. Res. 2019, 110, 287–296. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Wang, J.J.; Tao, N.R. Tensile ductility and deformation mechanisms of a nanotwinned 316L austenitic stainless steel. J. Mater. Sci. Technol. 2020, 36, 65–69. [Google Scholar] [CrossRef]

- Kocks, U.F.; Mecking, H. Physics and phenomenology of strain hardening: The FCC case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Prinz, F.B.; Argon, A.S. The evolution of plastic resistance in large strain plastic flow of single phase subgrain forming metals. Acta Metall. 1984, 32, 1021–1028. [Google Scholar] [CrossRef]

- Zehetbauer, M. Cold work hardening in stages IV and V of F.C.C. metals-II. Model fits and physical results. Acta Metall. Mater. 1993, 41, 589–599. [Google Scholar] [CrossRef]

- Park, N. Precise Flow Stress Analysis for the Occurrence of Dynamic Ferritic Transformation and Dynamic Recrystallization of Austenite in Low Carbon Steel. Korean J. Met. Mater. 2018, 56, 779–786. [Google Scholar] [CrossRef]

- Nes, E. Modelling of work hardening and stress saturation in FCC metals. Prog. Mater. Sci. 1997, 41, 129–193. [Google Scholar] [CrossRef]

- ASTM E8/E8M-03; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2003.

- Srinivas, B.; Dhal, A.; Panigrahi, S.K. A mathematical prediction model to establish the role of stacking fault energy on the cryo-deformation behavior of FCC materials at different strain levels. Int. J. Plast. 2017, 97, 159–177. [Google Scholar] [CrossRef]

| C | Mn | Si | P | S | Cr | Ni | Mo | V | Ti | Nb | N | B |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.06 | 1.5 | 0.5 | 0.007 | 0.003 | 18.76 | 13.73 | 1.87 | 0.02 | 0.004 | 0.02 | 0.13 | 0.001 |

| Cold Rolling Deformation εRoll [%] | Uniform True Strain (εT,Stage I) [-] | Uniform True Stress (σT,Stage I) [MPa] |

|---|---|---|

| 0 | 0.095 | 554 |

| 10 | 0.049 | 704 |

| 30 | 0.02 | 976 |

| 50 | 0.01 | 1068 |

| Cold Rolling Deformation εRoll [%] | Uniform True Strain (εT,Stage II) [-] | Uniform True Stress (σT,Stage II) [MPa] |

|---|---|---|

| 0 | 0.31 | 868 |

| 10 | 0.21 | 892 |

| 30 | 0.03 | 1000 |

| 50 | 0.0109 | 1069 |

| Cold Rolling Deformation εRoll [%] | Uniform True Strain (εT,Stage III) [-] | Uniform True Stress (σT,Stage III) [MPa] |

|---|---|---|

| 0 | 0.389 | 850 |

| 10 | 0.358 | 808 |

| 30 | 0.157 | 803 |

| 50 | 0.0198 | 993 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kvačkaj, T.; Bidulská, J.; Kaščák, Ľ.; Fedoríková, A.; Bidulský, R. Analysis of Strain Hardening Stages of AISI 316 LN Stainless Steel Under Cold Rolling Conditions. Metals 2025, 15, 1060. https://doi.org/10.3390/met15101060

Kvačkaj T, Bidulská J, Kaščák Ľ, Fedoríková A, Bidulský R. Analysis of Strain Hardening Stages of AISI 316 LN Stainless Steel Under Cold Rolling Conditions. Metals. 2025; 15(10):1060. https://doi.org/10.3390/met15101060

Chicago/Turabian StyleKvačkaj, Tibor, Jana Bidulská, Ľuboš Kaščák, Alica Fedoríková, and Róbert Bidulský. 2025. "Analysis of Strain Hardening Stages of AISI 316 LN Stainless Steel Under Cold Rolling Conditions" Metals 15, no. 10: 1060. https://doi.org/10.3390/met15101060

APA StyleKvačkaj, T., Bidulská, J., Kaščák, Ľ., Fedoríková, A., & Bidulský, R. (2025). Analysis of Strain Hardening Stages of AISI 316 LN Stainless Steel Under Cold Rolling Conditions. Metals, 15(10), 1060. https://doi.org/10.3390/met15101060