High-Cycle Fatigue Performance of Laser Powder Bed Fusion Ti-6Al-4V Alloy with Inherent Internal Defects: A Critical Literature Review

Abstract

1. Introduction

| Author (s) | Topics Covered | Future Direction Highlighted |

|---|---|---|

| Liu and Shin 2019 [21] | Overall overview of DED, EPBF and L-PBF processing and inherent defects including porosities, and residual stress, microstructure, tensile and fatigue properties and relevant influential factors in a nutshell. | Not available (NA) |

| Pegues et al., 2020 [22] Molaei et al., 2020 [23] | Part I reviewed the correlation between AM processing (including post-processing) and the microstructure and defects; part II reviewed the correlation between the different types of fatigue behaviors and microstructure and defects. | NA |

| Teixeira et al., 2020 [33] | Heat treatment’s role on residual stresses, microstructure, and mechanical properties including ductility, fatigue life, and hardness. |

|

| Sanaei and Fatemi 2021 [24] | Different types of intrinsic AM defects and their effects on the fatigue performance. |

|

| Singla et al., 2021 [26] | Overview of different types of intrinsic L-PBF defects and different types of post-processing treatments’ effects on defects and mechanical behavior. |

|

| Kan et al., 2022 [28] | The effects of porosities on the mechanical properties of L-PBF metal alloys. | NA |

| Nguyen et al., 2022 [30] | Microstructure of AM Ti-6Al-4V including the microstructure and the defects’ role in the fatigue properties. |

|

| Jamhari et al., 2023 [29,31] | Heat treatment and HIP on the microstructure, porosities and mechanical properties of L-PBF Ti-6Al-4V alloy. |

|

| Hasan Tusher and Ince 2023 [32] | Overview of the state of the art on the fatigue behavior of L-PBF Ti-6Al-4V alloy including L-PBF processing parameters, various types of defects, post-processing, and fatigue properties. |

|

| Wang et al., 2024 [25] | Review of different machine learning algorithms and their application in the fatigue life of AM parts |

|

2. The Internal Defects Problem of L-PBF Ti-6Al-4V

2.1. The Role of Internal Defects on the Fatigue Performance

| No. | Author (s) | Defect Type | Main Research Objective |

|---|---|---|---|

| 1 | Günther et al., 2017 [43] | Gas pore, LOF | HCF and VHCF |

| 2 | Becker et al., 2020 [44] | Porosity | Crack propagation |

| 3 | Waddell et al., 2020 [45] | Gas pore, LOF | Crack propagation |

| 4 | Hu et al., 2020 [42] | Gas pore, LOF | Correlate the defect population with the fatigue life |

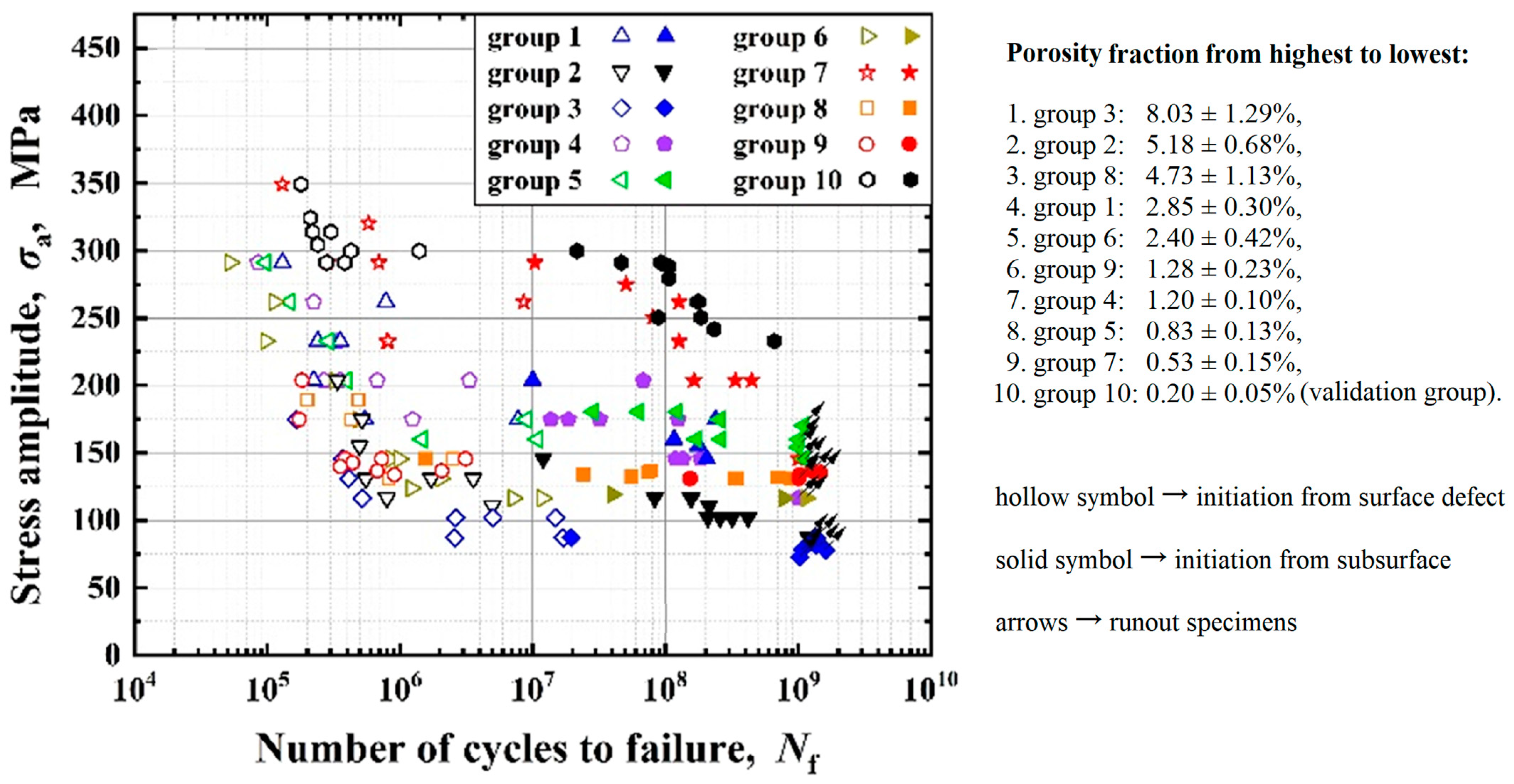

| 5 | Du et al., 2021 [38] | Gas pore, LOF | Processing parameters’ influence on the S–N curve |

| 6 | Pessard et al., 2021 [46] | Artificial surface defect, gas pore, LOF | Fatigue strength and critical defect size, 30 um |

| 7 | Xu et al., 2021 [47] | Gas pore, LOF | Microstructure, vacuum situation, microstructure |

| 8 | Akgun et al., 2022 [40] | Gas pore | Crack initiation and propagation |

| 9 | Chi et al., 2022 [48] | Artificial surface defect, gas pore, LOF | S–N curve |

| 10 | Gao et al., 2022 and 2023 [18,49] | Keyhole, Gas pore, LOF | S–N curve, fatigue life |

| 11 | Bhandari and Gaur 2023 [50] | Gas pore, LOF | Correlation between post-processing and fatigue performance |

| 12 | Mancisidor et al., 2023 [51] | Gas pore | Post-processing |

| 13 | Moquin et al., 2023 [41] | Gas pore, LOF | Microstructure, correlation of volumetric energy densities with fatigue performance |

| 14 | Önder et al., 2023 [52] | Gas pore, LOF | Post-processing |

| 15 | Qu et al., 2023 [53] | Gas pore, LOF | Coupling effects of microstructure and internal defects |

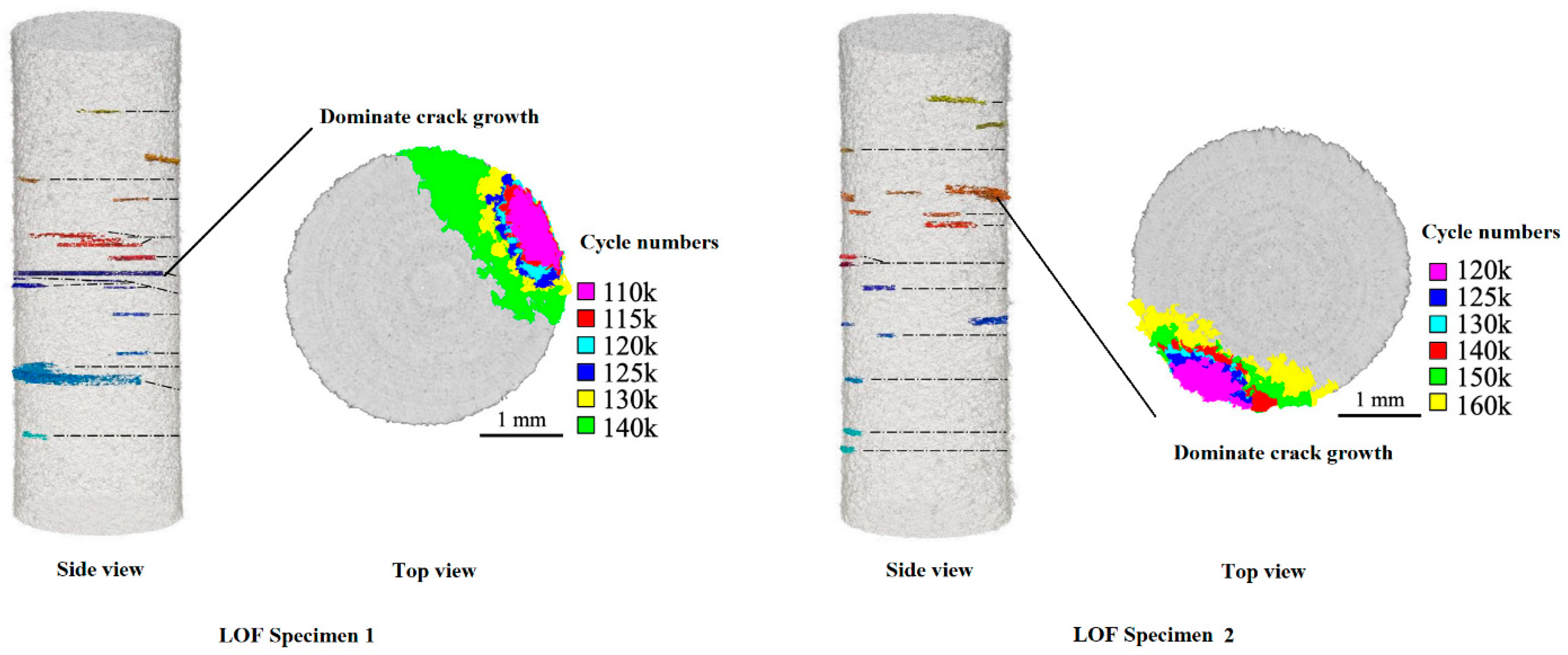

| 16 | Meng et al., 2023 [54] | Porosity, surface defect | Multi-crack initiation and propagation, image-based monitoring |

| No. | Author | Defect Type | Material | AM Process | Numerical Approaches | Fatigue Criterion |

|---|---|---|---|---|---|---|

| 1 | Siddique et al., 2015 [59] | Gas pores | AlSi12 | L-PBF | FEA | SCF |

| 2 | Wan et al., 2016 [60] | Gas pores | Ti-6Al-4V | - | Multiscale, FEA | Stiffness, S–N curve |

| 3 | Biswal et al., 2018 [56] | Gas pores | Ti-6Al-4V | L-PBF | FEA | SCF, SWT |

| 4 | Lukhi et al., 2018 [61] | Micro void | Nodular cast iron | - | Micromechanical, FEA | Stress, strain |

| 5 | Biswal et al., 2019 [57] | Gas pores | Ti-6Al-4V | WAAM | Graphic analysis, FEA | SCF, S–N curve |

| 6 | Dinh et al., 2020 [62] | Gas porosity and surface roughness | Ti-6Al-4V | L-PBF | FEA | nlSWT |

| 7 | Hu et al., 2020 [39] | Gas pores, LOF | Ti-6Al-4V | L-PBF | FEA, EXP | NASGRO method |

| 8 | Wang and Su 2021 [63] | Gas pores | 316L steel | L-PBF | FEA | SCF |

| 9 | Lauterbach et al., 2021 [58] | Gas pores | Metal | - | Immersed-Boundary-FEA | Von Mises stress |

| 10 | Pessard et al., 2021 [46] | Surface defects, sub-surface defect | Ti-6Al-4V | L-PBF | FEA | SCF |

| 11 | Li et al., 2022 [64] | LOF | Ti-6Al-4V | L-PBF | FEA | SCF |

| 12 | Xie et al., 2021 [65] | Gas pores, LOF | Al-Mg4.5 Mn | WAAM | FEA | Von Mises stress, SCF |

| 13 | Shao et al., 2023 [66] | Crack from pore | Ti-6Al-4V | L-PBF | FEA | Crack propagation |

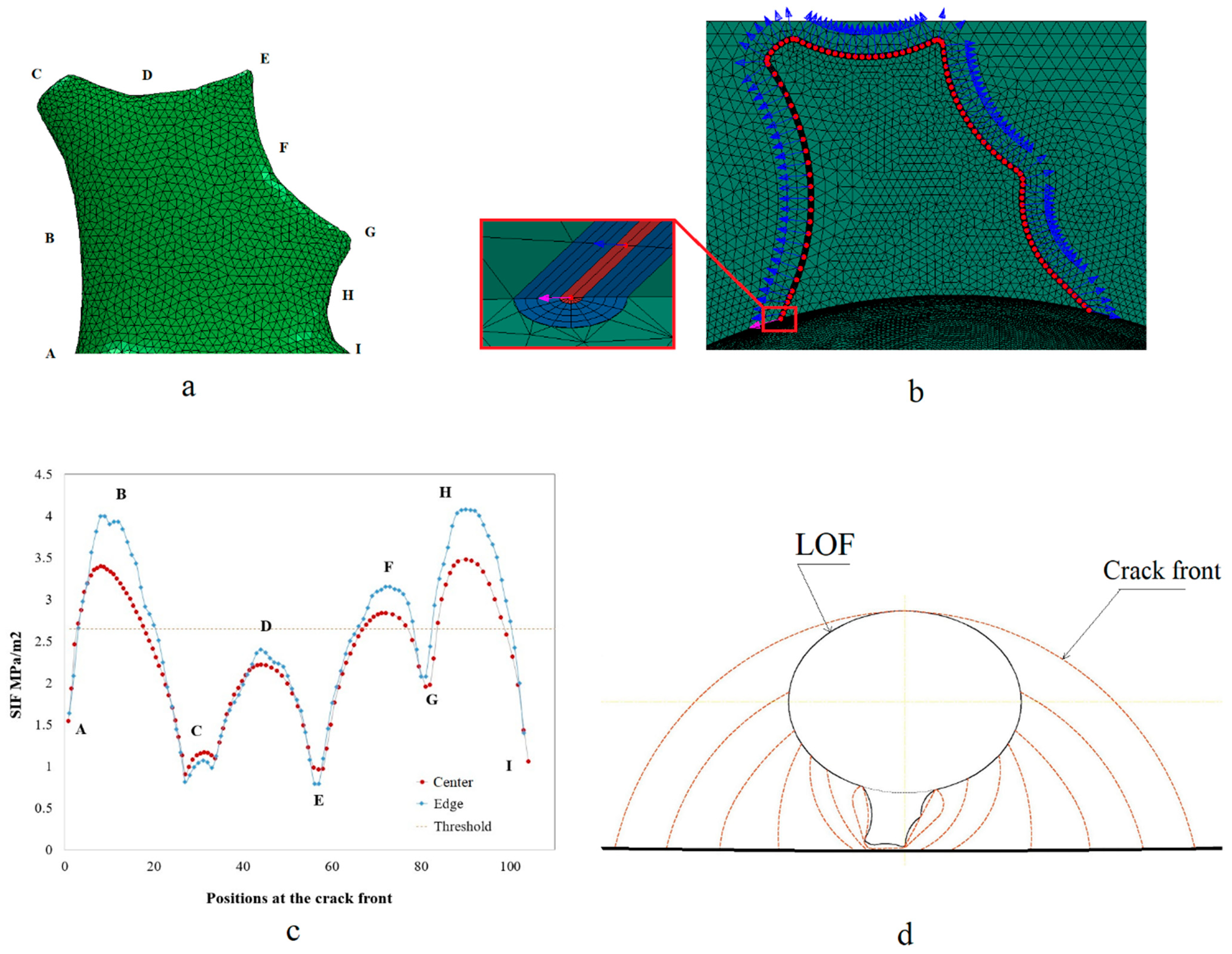

| 14 | Li et al., 2024 [55] | LOF | Ti-6Al-4V | L-PBF | Individual analysis | 3D average SWT, SIF, irregular crack propagation |

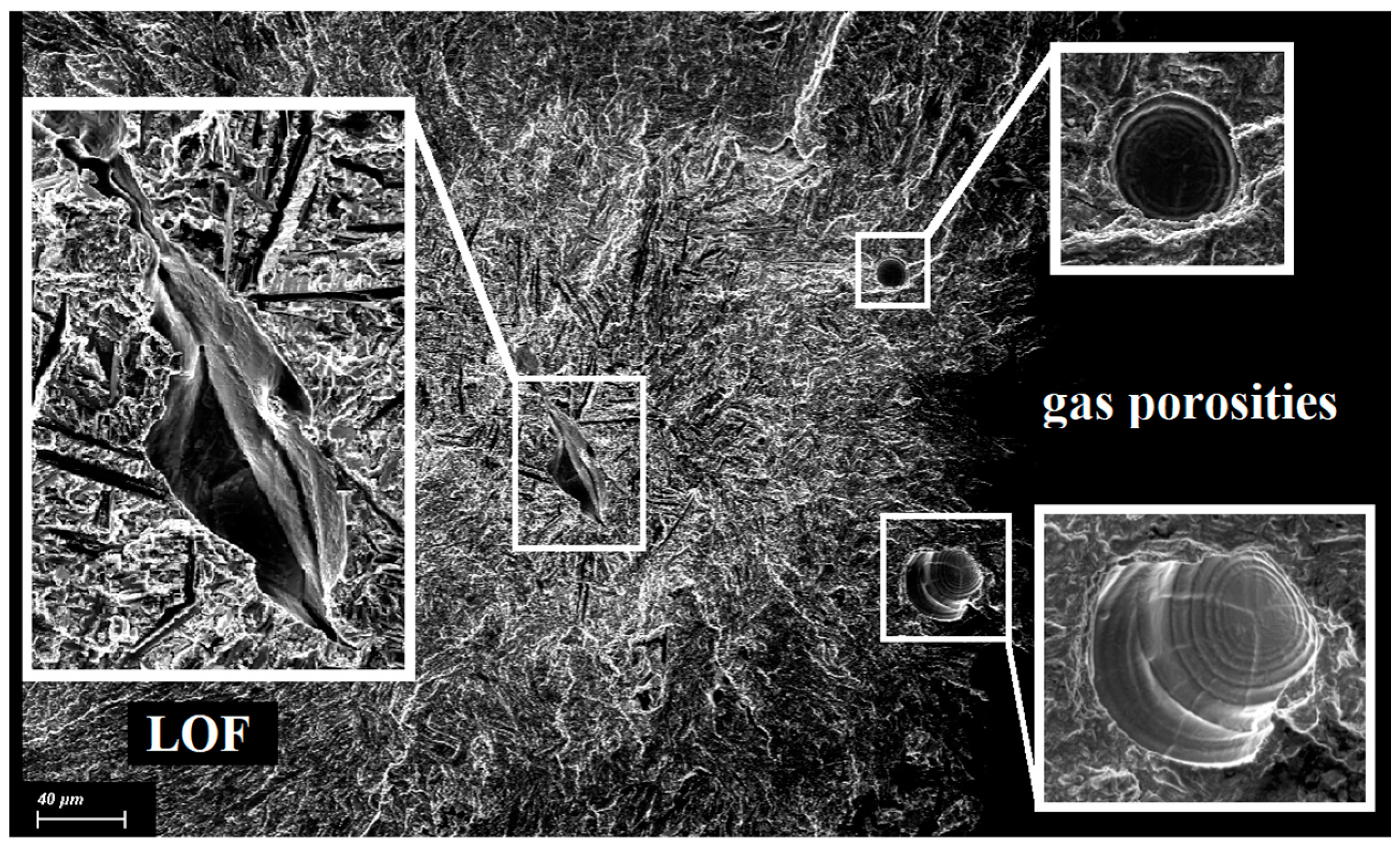

2.2. Crack Initiation and Micro-Short Crack (MSC) Propagation

2.3. Crack Propagation

3. Microstructure

3.1. Microstructure in Different States

3.1.1. As-Built Alloys

3.1.2. After Post Heat Treatments

3.1.3. After HIP

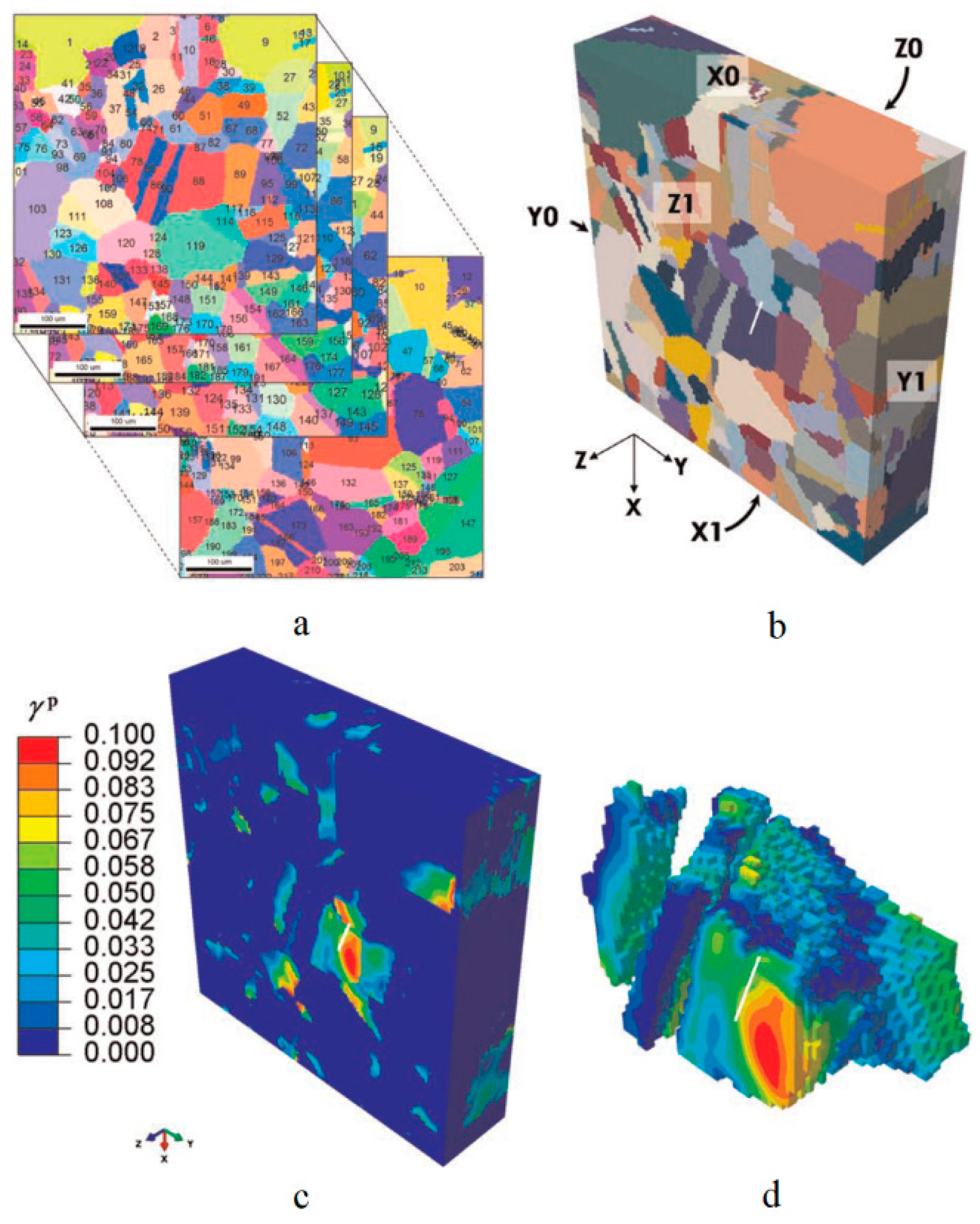

3.2. Microstructure’s Role in High-Cycle Fatigue Performance

4. Post Processing Treatments

4.1. Machining

4.2. Heat Treatment

4.3. HIP

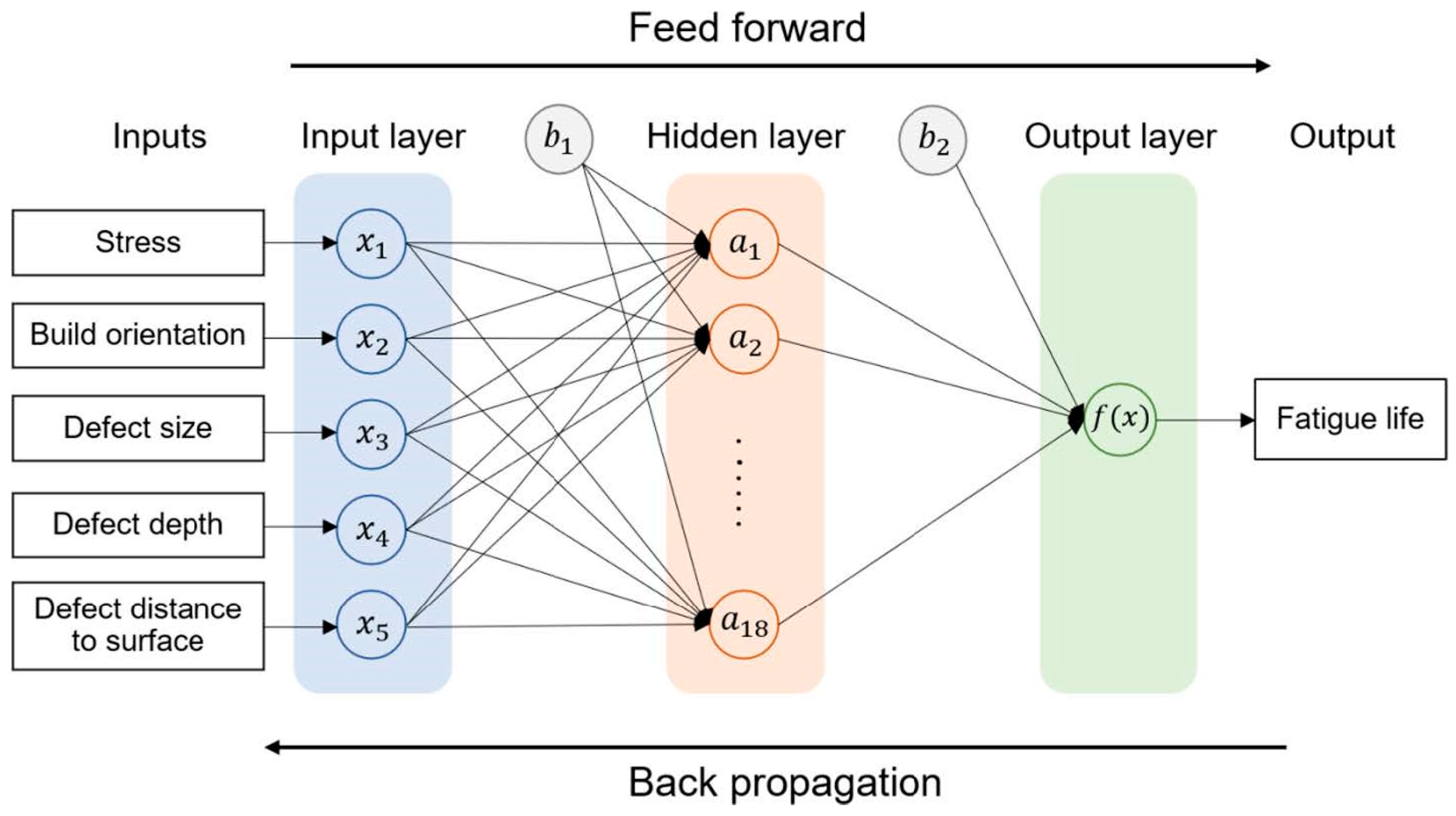

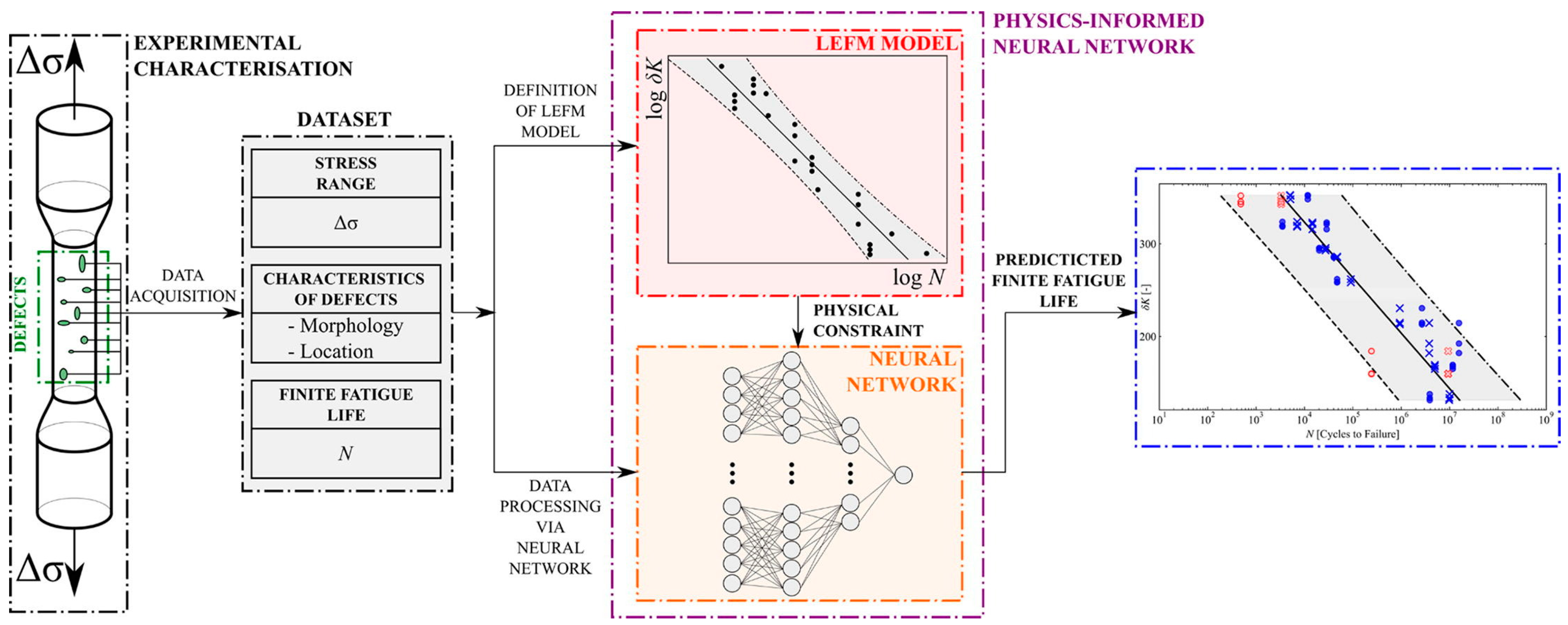

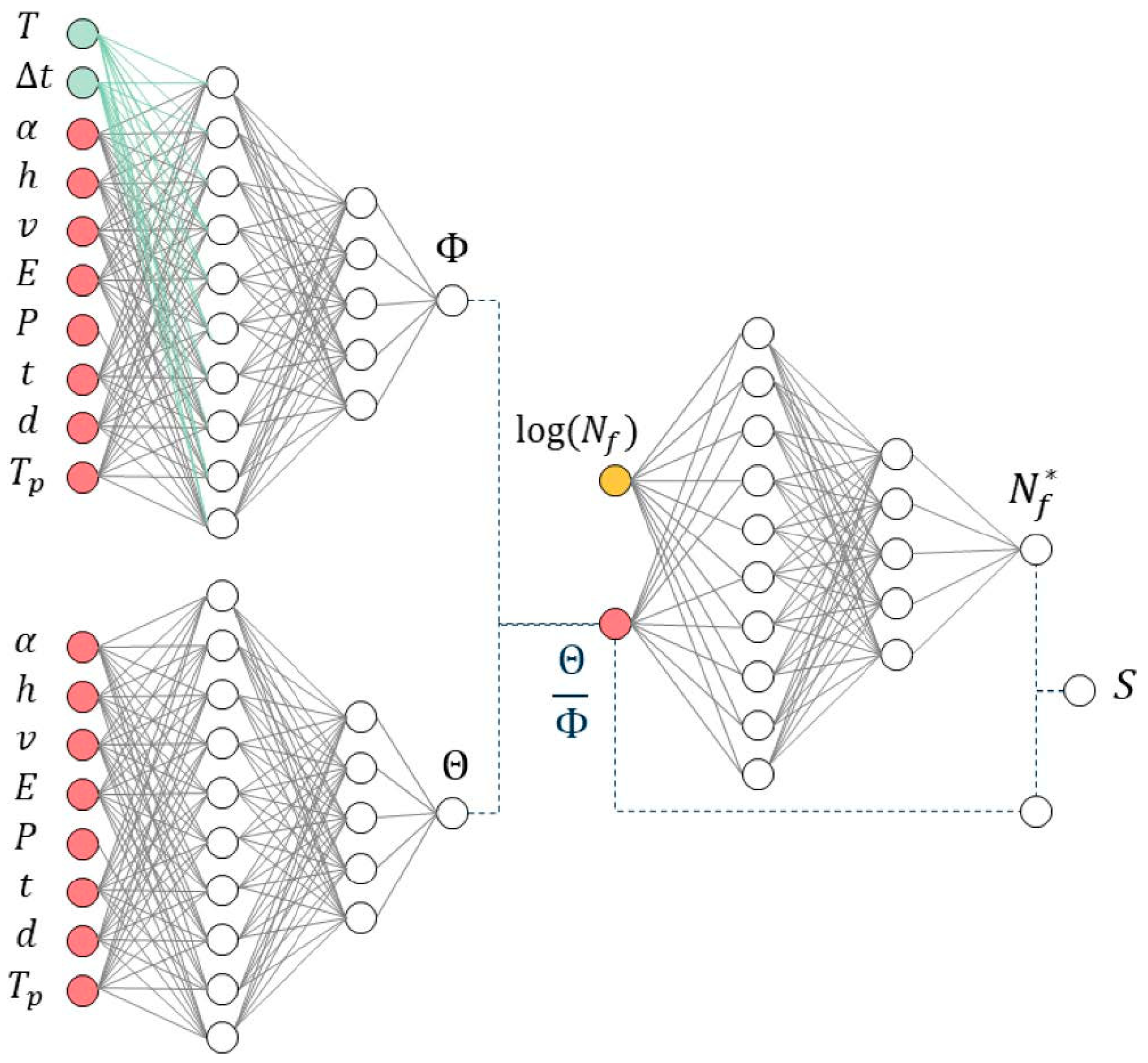

5. Machine Learning Models of Predicting Fatigue Life

6. Conclusions and Perspective for Future Research

- Research on different types of internal defects was extremely uneven, partially due to the occurrence frequency, detriment level, and difficulty of analysis for each defect type. As a result, gas porosity has been extensively and quantitatively investigated, recently followed by LOF defects. However, studies on other internal defect types, such as keyholes, balling, and α-phase facets, were rare. There is an urgent need for detailed research on these types of defects.

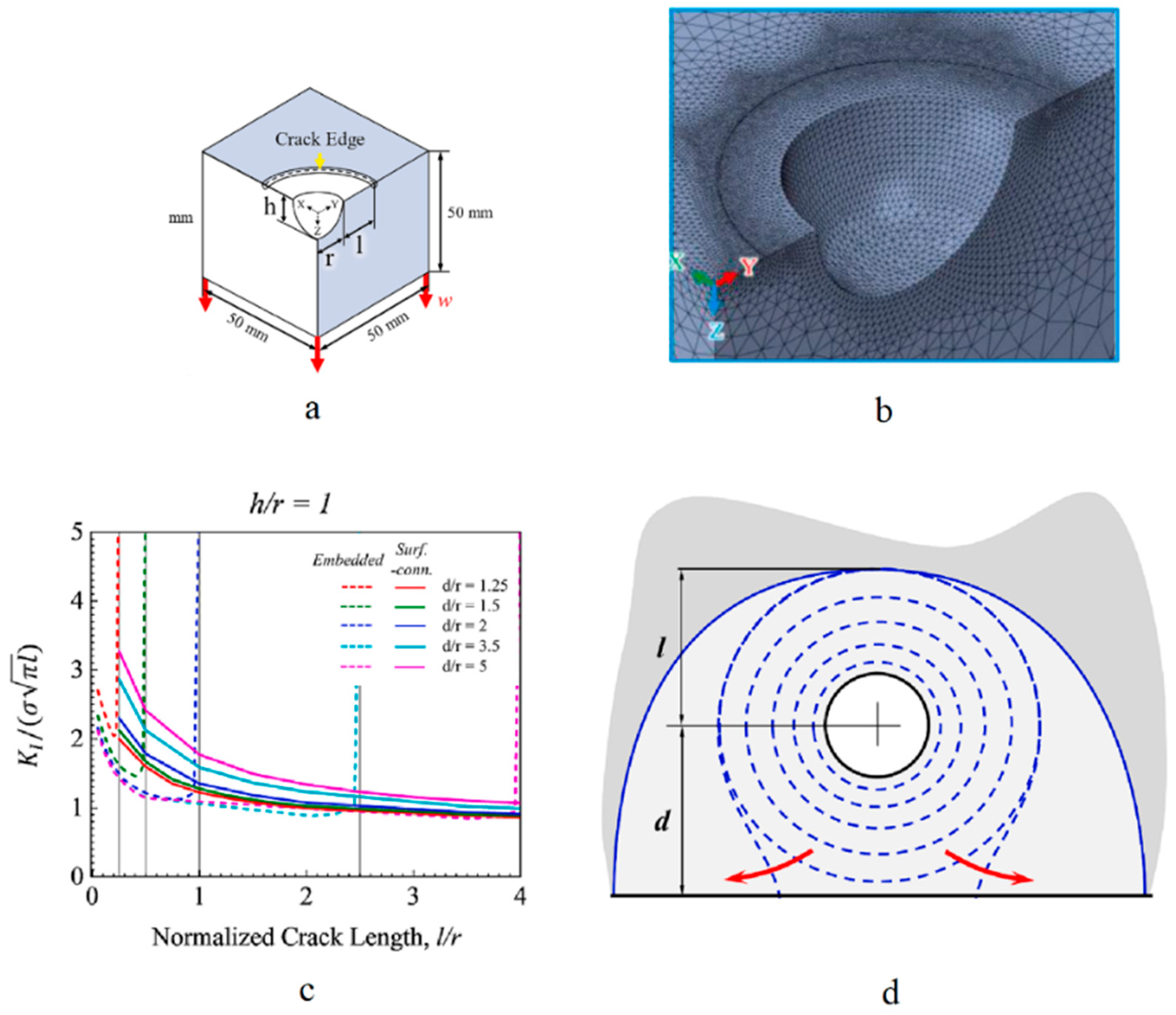

- Quantitatively correlating LOFs with fatigue life performance is challenging due to their complex topology. Recent studies suggested that LOFs can be simplified based on their main profile and most critical embedded features, using an adapted SWT method to evaluate fatigue life. Comprehensive investigations are needed to further digitalize the geometric features of LOFs with a validated analytical approach. Additionally, the influence of un-melted powders embedded in LOFs needs to be investigated and clarified.

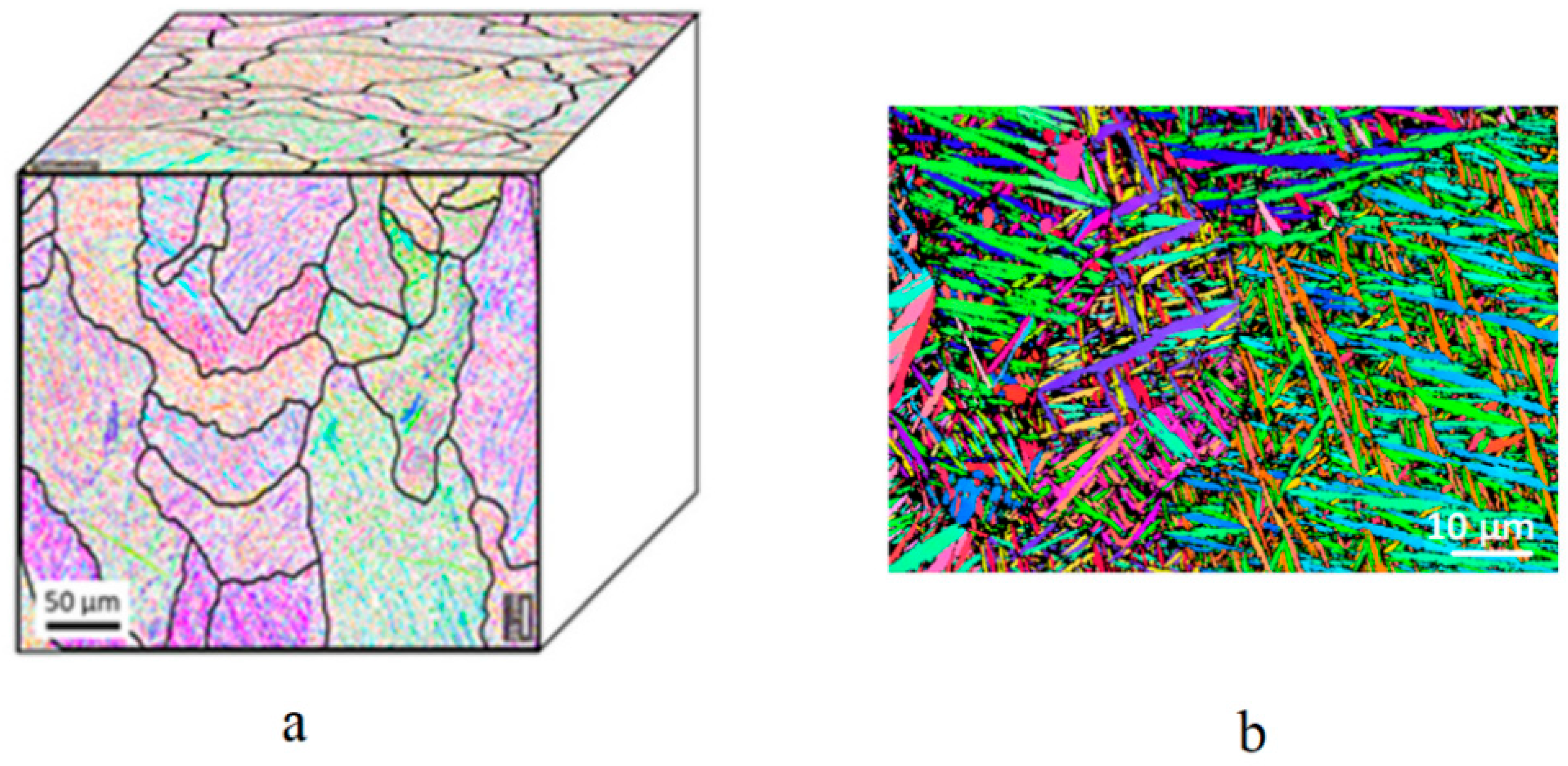

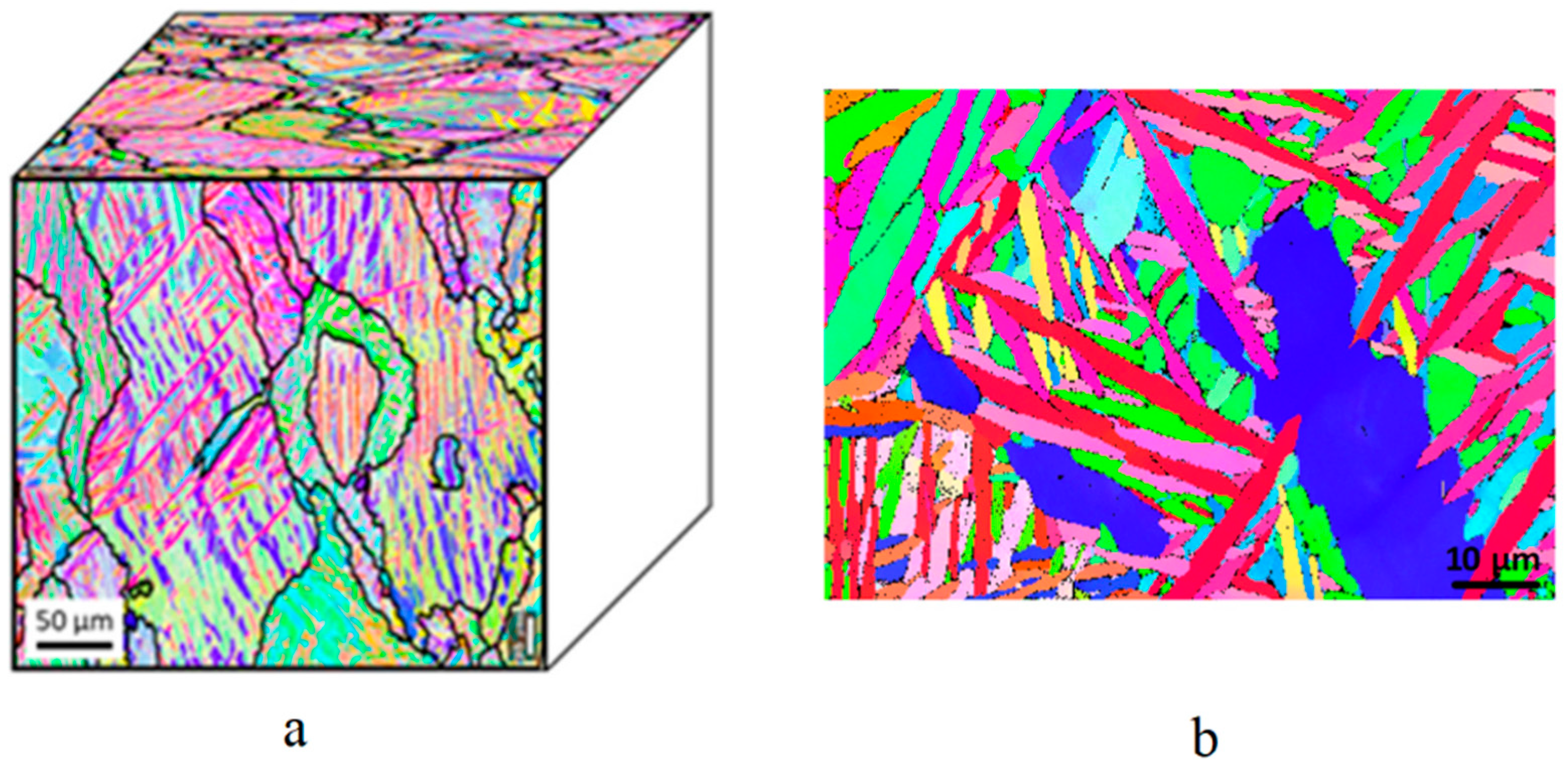

- The microstructure composition of L-PBF Ti-6Al-4V alloy, especially in the as-built state, is distinct from conventionally manufactured Ti-6Al-4V alloy. Additionally, L-PBF Ti-6Al-4V alloy have more microstructural imperfections, such as dislocations, which introduce uncertainties in quantifying the microstructure’s role in early-stage crack evolution. To address this, the microstructures of L-PBF Ti-6Al-4V alloy under various conditions need to be standardized. Subsequently, the quantification of the microstructure’s role in fatigue life performance should be progressively investigated, starting with simple cases and advancing to more complex scenarios. This could begin with the fine α + β structure after heat treatment, progress to the α′ in the β phase of the as-built condition, and eventually include the coupling effects with internal defects.

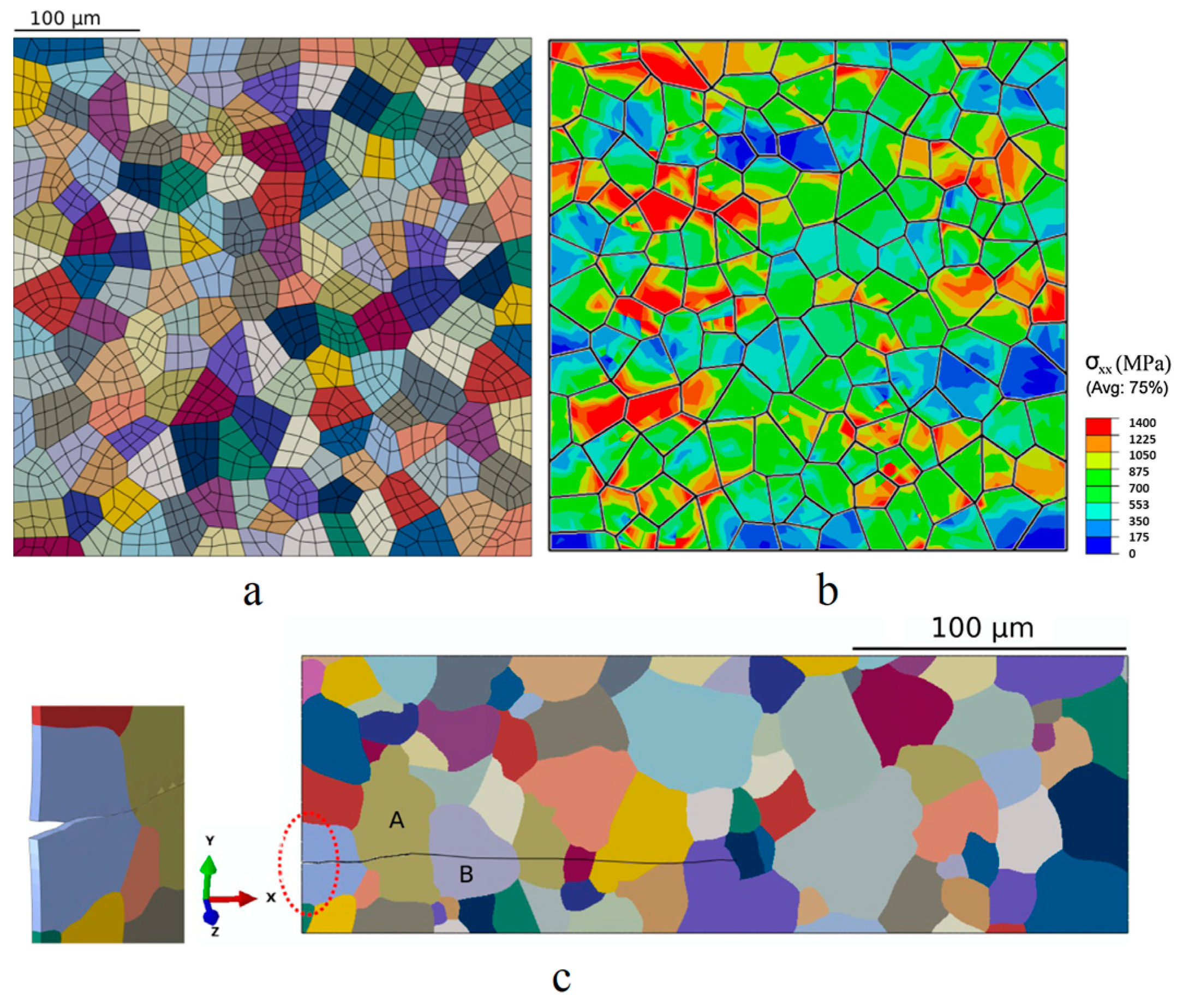

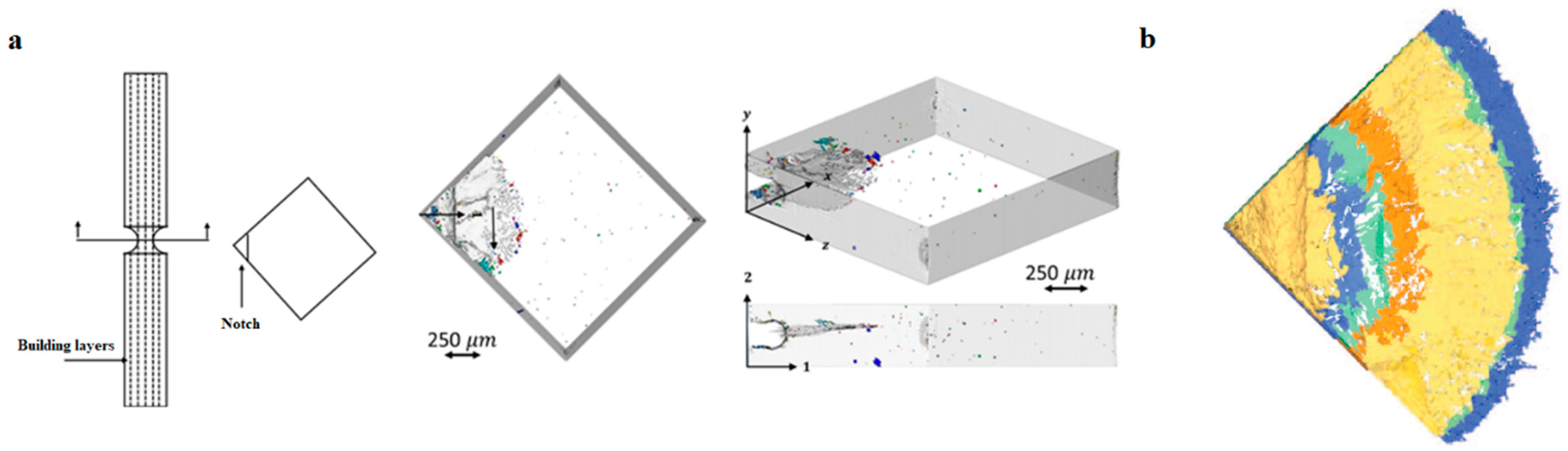

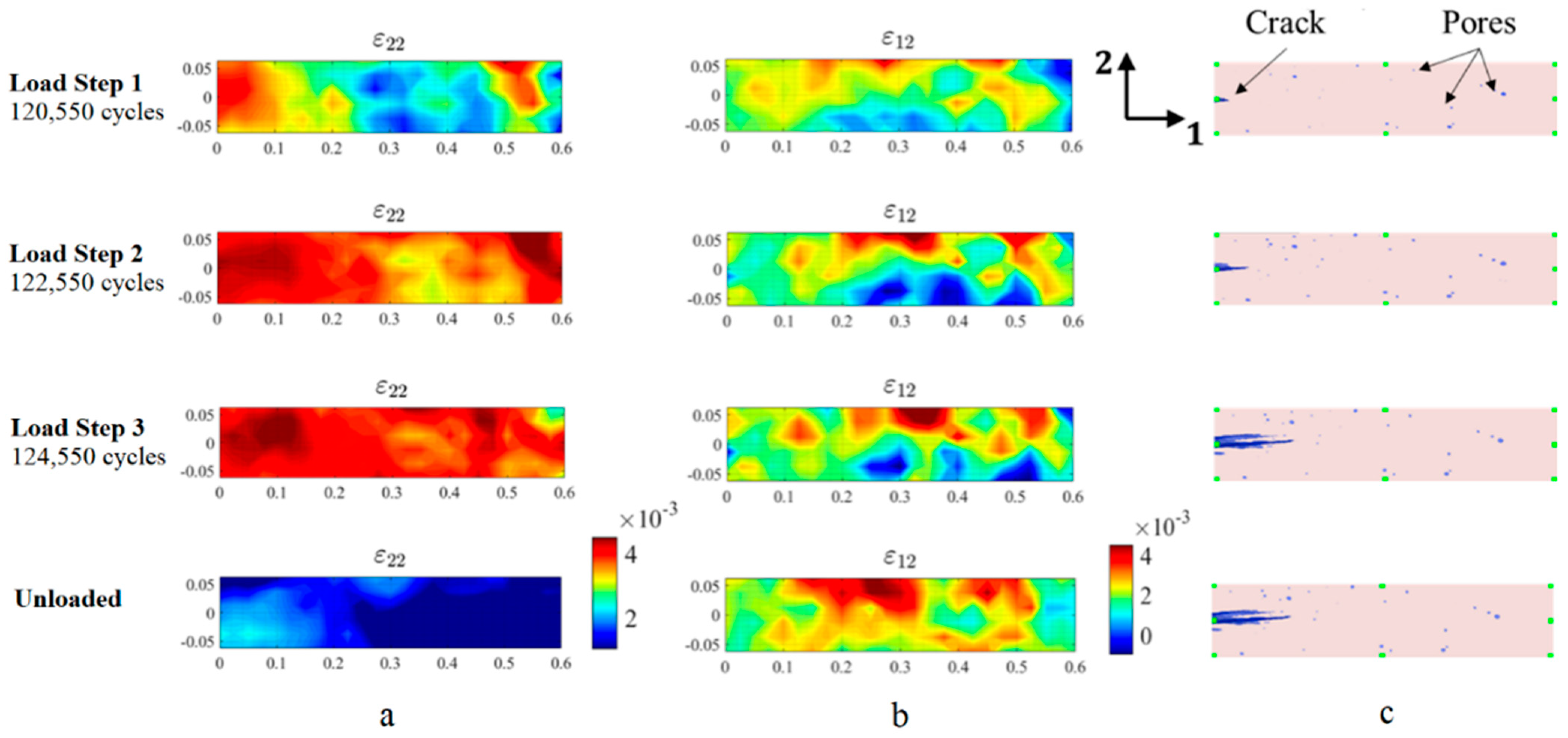

- The surrounding microstructures around internal defects significantly influence fatigue crack initiation and MSC propagation. However, relevant research on AM Ti-6Al-4V alloy was very limited. While similar investigations on other types of metal alloys can be referenced, their findings cannot be directly applied due to distinct microstructures and properties. The CPFE approach may be an ideal solution to clarify the role of microstructures in fatigue life performance and reveal the mechanisms and behaviors of MSC propagation.

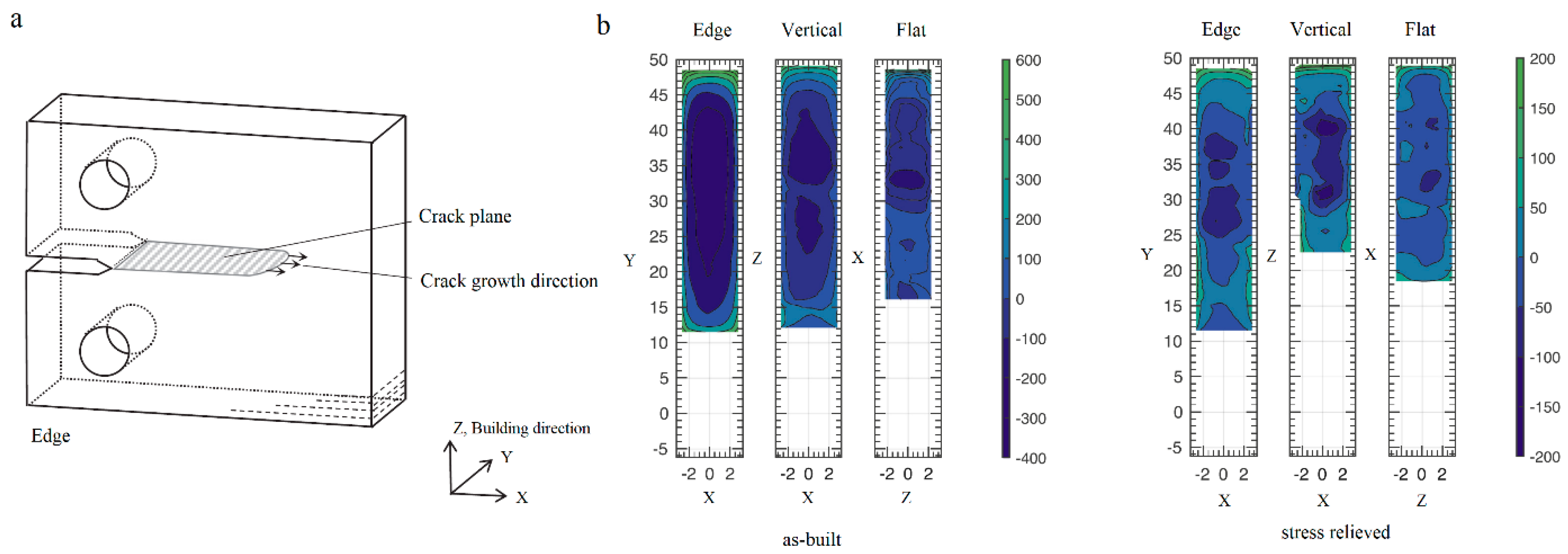

- The distribution of residual stresses in L-PBF Ti-6Al-4V alloy, in both as-built and post-treated states (e.g., machining, heat treatments, and HIP), has been investigated and visualized in recent years. Understanding the mechanism by which fatigue life performance is altered is straightforward: residual stresses superpose the remote stresses. However, there is an urgent need to quantitatively correlate residual stresses in different states with fatigue crack evolution. Numerical analysis of residual stress formation during L-PBF processing and post-processing treatments, as well as its impact on fatigue crack evolution, can be both necessary and valuable.

- Post-processing techniques have a considerable impact on the fatigue life performance of L-PBF Ti-6Al-4V alloy. There have been in-depth investigations into various post-processing parameters (e.g., heat treatment at different temperatures, HIP) and studies combining different post-processing treatments (e.g., machining, heat treatment, and HIP), as suggested by previous review papers. Further research in this direction is needed to establish standardized post-processing treatments and combinations to achieve an optimal balance of mechanical properties for various application purposes.

- Data-driven ML models seriously rely on the quantity and quality of dataset, and their contribution to the physical mechanism might be limited. Physics-informed ML models are more promising as they improve the prediction accuracy while requiring less data. In addition, they provide a deeper understanding of the physical mechanism than the pure data-driven models. FEA is an efficient solution for enlarging the dataset, on the premise of being validated.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Inagaki, I.; Takechi, T.; Shirai, Y.; Ariyasu, N. Application and features of titanium for the aerospace industry. Nippon Steel Sumitomo Met. Tech. Rep. 2014, 106, 22–27. [Google Scholar]

- Singh, P.; Pungotra, H.; Kalsi, N.S. On the characteristics of titanium alloys for the aircraft applications. Mater. Today Proc. 2017, 4, 8971–8982. [Google Scholar] [CrossRef]

- Uhlmann, E.; Kersting, R.; Klein, T.B.; Cruz, M.F.; Borille, A.V. Additive manufacturing of titanium alloy for aircraft components. Procedia Cirp 2015, 35, 55–60. [Google Scholar] [CrossRef]

- Emmelmann, C.; Scheinemann, P.; Munsch, M.; Seyda, V. Laser additive manufacturing of modified implant surfaces with osseointegrative characteristics. Phys. Procedia 2011, 12, 375–384. [Google Scholar] [CrossRef]

- Hao, Y.-L.; Li, S.-J.; Yang, R. Biomedical titanium alloys and their additive manufacturing. Rare Met. 2016, 35, 661–671. [Google Scholar] [CrossRef]

- Giannatsis, J.; Dedoussis, V. Additive fabrication technologies applied to medicine and health care: A review. Int. J. Adv. Manuf. Technol. 2009, 40, 116–127. [Google Scholar] [CrossRef]

- Bromberger, R.K.J. Additive Manufacturing: A Long-Term Game Changer for Manufacturers; McKinsey & Company: Chicago, IL, USA, 2017. [Google Scholar]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B.; Gaytan, S.M.; et al. Metal fabrication by additive manufacturing using laser and electron beam melting technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Vayre, B.; Vignat, F.; Villeneuve, F. Designing for additive manufacturing. Procedia CIrP 2012, 3, 632–637. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Spierings, A.B.; Schneider, M.U.; Eggenberger, R. Comparison of density measurement techniques for additive manufactured metallic parts. Rapid Prototyp. J. 2011, 17, 380–386. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Gu, H.; Ram, G.D.J.; Starr, T.; Stucker, B. Influence of defects on mechanical properties of Ti-6Al-4V components produced by selective laser melting and electron beam melting. Mater. Des. 2015, 86, 545–554. [Google Scholar] [CrossRef]

- Solberg, K.; Berto, F. What is going on with fatigue of additively manufactured metals? Mater. Des. Process. Commun. 2019, 1, e84. [Google Scholar] [CrossRef]

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Schijve, J. Fatigue of Structures and Materials; Springer: Dordrecht, The Netherlands, 2009; pp. 1–622. [Google Scholar]

- Morton, P.A.; Mireles, J.; Mendoza, H.; Cordero, P.M.; Benedict, M.; Wicker, R.B. Enhancement of Low-Cycle Fatigue Performance from Tailored Microstructures Enabled by Electron Beam Melting Additive Manufacturing Technology. J. Mech. Des. Trans. ASME 2015, 137, 114501. [Google Scholar] [CrossRef]

- Li, P.; Warner, D.H.; Fatemi, A.; Phan, N. Critical assessment of the fatigue performance of additively manufactured Ti-6Al-4V and perspective for future research. Int. J. Fatigue 2016, 85, 130–143. [Google Scholar] [CrossRef]

- Gao, X.; Tao, C.; Wu, S.; Chen, B.; Wu, S. X-ray imaging of defect population and the effect on high cycle fatigue life of laser additive manufactured Ti6Al4V alloys. Int. J. Fatigue 2022, 162, 106979. [Google Scholar] [CrossRef]

- Tammas-Williams, S.; Zhao, H.; Léonard, F.; Derguti, F.; Todd, I.; Prangnell, P.B. XCT analysis of the influence of melt strategies on defect population in Ti-6Al-4V components manufactured by Selective Electron Beam Melting. Mater. Charact. 2015, 102, 47–61. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal additive manufacturing: A review of mechanical properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Pegues, J.W.; Shao, S.; Shamsaei, N.; Sanaei, N.; Fatemi, A.; Warner, D.H.; Li, P.; Phan, N. Fatigue of additive manufactured Ti-6Al-4V, Part I: The effects of powder feedstock, manufacturing, and post-process conditions on the resulting microstructure and defects. Int. J. Fatigue 2020, 132, 105358. [Google Scholar] [CrossRef]

- Molaei, R.; Fatemi, A.; Sanaei, N.; Pegues, J.; Shamsaei, N.; Shao, S.; Li, P.; Warner, D.H.; Phan, N. Fatigue of additive manufactured Ti-6Al-4V, Part II: The relationship between microstructure, material cyclic properties, and component performance. Int. J. Fatigue 2020, 132, 105363. [Google Scholar] [CrossRef]

- Sanaei, N.; Fatemi, A. Defects in additive manufactured metals and their effect on fatigue performance: A state-of-the-art review. Prog. Mater. Sci. 2021, 117, 100724. [Google Scholar] [CrossRef]

- Wang, H.; Gao, S.L.; Wang, B.T.; Ma, Y.T.; Guo, Z.J.; Zhang, K.; Yang, Y.; Yue, X.Z.; Hou, J.; Huang, H.J.; et al. Recent advances in machine learning-assisted fatigue life prediction of additive manufactured metallic materials: A review. J. Mater. Sci. Technol. 2024, 198, 111–136. [Google Scholar] [CrossRef]

- Singla, A.K.; Banerjee, M.; Sharma, A.; Singh, J.; Bansal, A.; Gupta, M.K.; Khanna, N.; Shahi, A.S.; Goyal, D.K. Selective laser melting of Ti6Al4V alloy: Process parameters, defects and post-treatments. J. Manuf. Process. 2021, 64, 161–187. [Google Scholar] [CrossRef]

- Cao, S.; Zou, Y.; Lim, C.V.S.; Wu, X. Review of laser powder bed fusion (LPBF) fabricated Ti-6Al-4V: Process, post-process treatment, microstructure, and property. Light Adv. Manuf. 2021, 2, 20. [Google Scholar] [CrossRef]

- Kan, W.H.; Chiu, L.N.S.; Lim, C.V.S.; Zhu, Y.; Tian, Y.; Jiang, D.; Huang, A. A critical review on the effects of process-induced porosity on the mechanical properties of alloys fabricated by laser powder bed fusion. J. Mater. Sci. 2022, 57, 9818–9865. [Google Scholar] [CrossRef]

- Jamhari, F.I.; Foudzi, F.M.; Buhairi, M.A.; Muhamad, N.; Mohamed, I.F.; Sulong, A.B.; Radzuan, N.A.M. Impact of hot isostatic pressing on surface quality, porosity and performance of Ti6Al4V manufactured by laser powder bed fusion: A brief review. J. Tribol. 2023, 36, 1–15. [Google Scholar]

- Nguyen, H.D.; Pramanik, A.; Basak, A.K.; Dong, Y.; Prakash, C.; Debnath, S.; Shankar, S.; Jawahir, I.S.; Dixit, S.; Buddhi, D. A critical review on additive manufacturing of Ti-6Al-4V alloy: Microstructure and mechanical properties. J. Mater. Res. Technol. 2022, 18, 4641–4661. [Google Scholar] [CrossRef]

- Jamhari, F.I.; Foudzi, F.M.; Buhairi, M.A.; Sulong, A.B.; Radzuan, N.A.M.; Muhamad, N.; Mohamed, I.F.; Jamadon, N.H.; Tan, K.S. Influence of heat treatment parameters on microstructure and mechanical performance of titanium alloy in LPBF: A brief review. J. Mater. Res. Technol. 2023, 24, 4091–4110. [Google Scholar] [CrossRef]

- Tusher, M.M.H.; Ince, A. High Cycle Fatigue and Very High Cycle Fatigue Performance of Selective Laser Melting Ti-6Al-4V Titanium Alloy—A Review. Mater. Perform. Charact. 2023, 12, 2. [Google Scholar] [CrossRef]

- Teixeira, Ó.; Silva, F.J.G.; Ferreira, L.P.; Atzeni, E. A review of heat treatments on improving the quality and residual stresses of the Ti–6Al–4V parts produced by additive manufacturing. Metals 2020, 10, 1006. [Google Scholar] [CrossRef]

- Singh, J.; Singh, H.; Singh, G. Effect of Post-Heat Treatment on the Properties of Additive Manufacturing Parts. In Innovative Processes and Materials in Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2022; pp. 19–57. [Google Scholar]

- Wanhill, R.; Barter, S. Fatigue of Beta Processed and Beta Heat-Treated Titanium Alloys; Springer Science & Business Media: Berlin, Germany, 2011. [Google Scholar]

- Hagiwara, M.; Kitaura, T.; Ono, Y.; Yuri, T.; Ogata, T.; Kanou, O. High cycle fatigue properties of a minor boron-modified Ti–6Al–4V alloy. Mater. Trans. 2012, 53, 1486–1494. [Google Scholar] [CrossRef]

- Hagiwara, M.; Kaieda, Y.; Kawabe, Y.; Miura, S. Fatigue property enhancement of α-β titanium alloys by blended elemental P/M approach. ISIJ Int. 1991, 31, 922–930. [Google Scholar] [CrossRef]

- Du, L.; Qian, G.; Zheng, L.; Hong, Y. Influence of processing parameters of selective laser melting on high-cycle and very-high-cycle fatigue behaviour of Ti-6Al-4V. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 240–256. [Google Scholar] [CrossRef]

- Hu, Y.N.; Wu, S.C.; Withers, P.J.; Zhang, J.; Bao, H.Y.X.; Fu, Y.N.; Kang, G.Z. The effect of manufacturing defects on the fatigue life of selective laser melted Ti-6Al-4V structures. Mater. Des. 2020, 192, 108708. [Google Scholar] [CrossRef]

- Akgun, E.; Zhang, X.; Lowe, T.; Zhang, Y.; Doré, M. Fatigue of laser powder-bed fusion additive manufactured Ti-6Al-4V in presence of process-induced porosity defects. Eng. Fract. Mech. 2022, 259, 108140. [Google Scholar] [CrossRef]

- Moquin, E.; Letenneur, M.; Kreitcberg, A.; Poulin-Masson, J.R.; Brailovski, V. High cycle fatigue resistance of laser powder bed fused Ti–6Al–4V alloys with processing-induced porosity: Towards damage-tolerant design of printed components. Mater. Sci. Eng. A 2023, 884, 145509. [Google Scholar] [CrossRef]

- Hu, Y.N.; Wu, S.C.; Wu, Z.K.; Zhong, X.L.; Ahmed, S.; Karabal, S.; Xiao, X.H.; Zhang, H.O.; Withers, P.J. A new approach to correlate the defect population with the fatigue life of selective laser melted Ti-6Al-4V alloy. Int. J. Fatigue 2020, 136, 105584. [Google Scholar] [CrossRef]

- Günther, J.; Krewerth, D.; Lippmann, T.; Leuders, S.; Tröster, T.; Weidner, A.; Biermann, H.; Niendorf, T. Fatigue life of additively manufactured Ti–6Al–4V in the very high cycle fatigue regime. Int. J. Fatigue 2017, 94, 236–245. [Google Scholar] [CrossRef]

- Becker, T.H.; Dhansay, N.M.; Haar, G.M.T.; Vanmeensel, K. Near-threshold fatigue crack growth rates of laser powder bed fusion produced Ti-Aal-4V. Acta Mater. 2020, 197, 269–282. [Google Scholar] [CrossRef]

- Waddell, M.; Walker, K.; Bandyopadhyay, R.; Kapoor, K.; Mallory, A.; Xiao, X.; Chuang, A.C.; Liu, Q.; Phan, N.; Sangid, M.D. Small fatigue crack growth behavior of Ti-6Al-4V produced via selective laser melting: In situ characterization of a 3D crack tip interactions with defects. Int. J. Fatigue 2020, 137, 105638. [Google Scholar] [CrossRef]

- Pessard, E.; Lavialle, M.; Laheurte, P.; Didier, P.; Brochu, M. High-cycle fatigue behavior of a laser powder bed fusion additive manufactured Ti-6Al-4V titanium: Effect of pores and tested volume size. Int. J. Fatigue 2021, 149, 106206. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, A.; Wang, X.; Liu, B.; Guo, M. Fatigue limit prediction model and fatigue crack growth mechanism for selective laser melting Ti6Al4V samples with inherent defects. Int. J. Fatigue 2021, 143, 106008. [Google Scholar] [CrossRef]

- Chi, W.; Wang, W.; Li, Y.; Xu, W.; Sun, C. Defect induced cracking and modeling of fatigue strength for an additively manufactured Ti-6Al-4V alloy in very high cycle fatigue regime. Theor. Appl. Fract. Mech. 2022, 119, 103380. [Google Scholar] [CrossRef]

- Gao, X.; Tao, C.; Wu, S. Anisotropic high cycle fatigue property estimation for laser additive manufactured Ti6Al4V alloy dependence on tomographic imaging of defect population. J. Mater. Res. Technol. 2023, 22, 1971–1982. [Google Scholar] [CrossRef]

- Bhandari, L.; Gaur, V. Different post-processing methods to improve fatigue properties of additively built Ti-6Al-4V alloy. Int. J. Fatigue 2023, 176, 107850. [Google Scholar] [CrossRef]

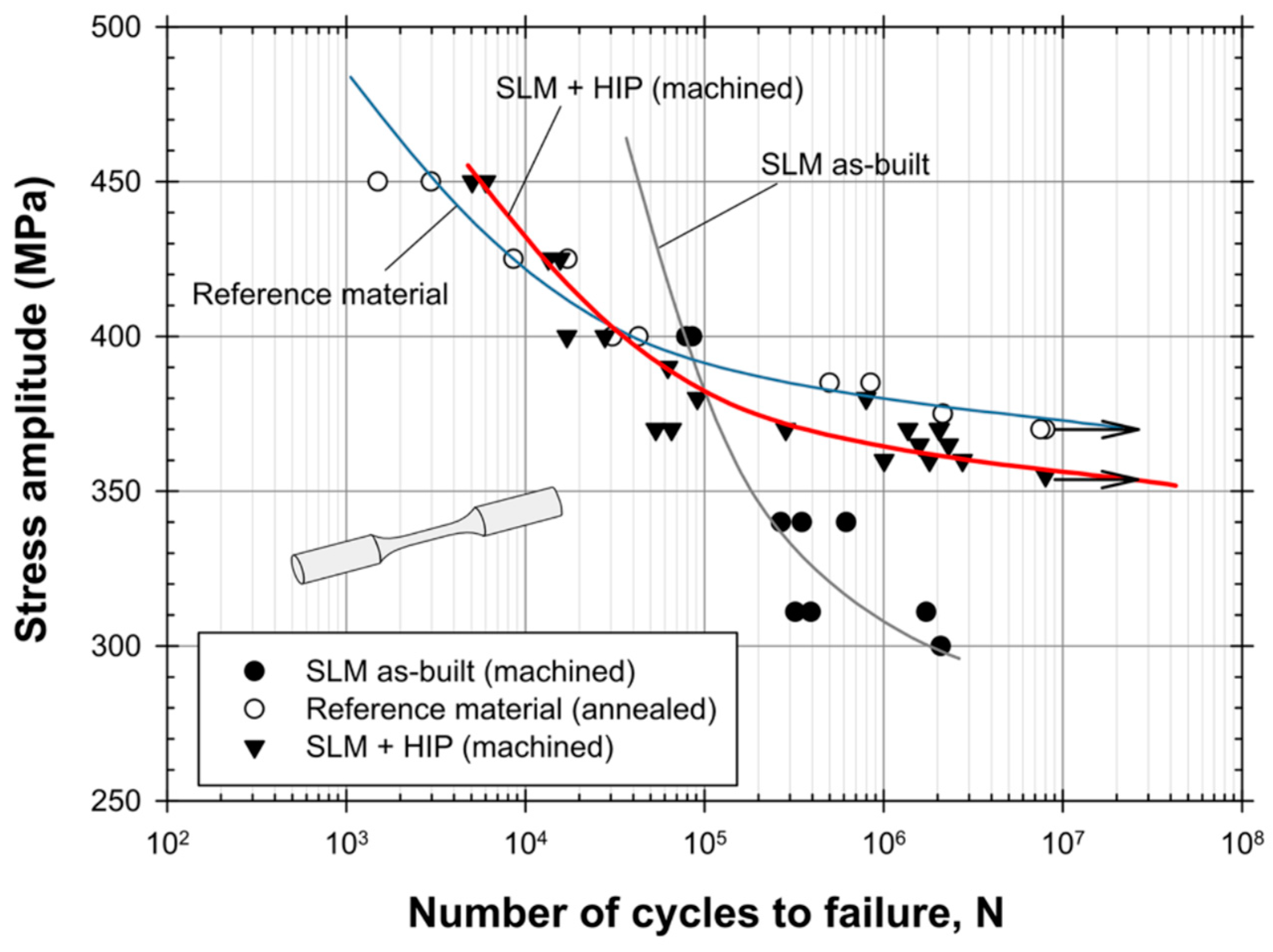

- Mancisidor, A.M.; García-Blanco, M.B.; Quintana, I.; Arrazola, P.J.; Espinosa, E.; Cuesta, M.; Albizuri, J.; Garciandia, F. Effect of Post-Processing Treatment on Fatigue Performance of Ti6Al4V Alloy Manufactured by Laser Powder Bed Fusion. J. Manuf. Mater. Process. 2023, 7, 119. [Google Scholar] [CrossRef]

- Önder, S.; Saklakoğlu, N.; Sever, A. Selective laser melting of Ti6Al4V alloy: Effect of post-processing on fatigue life, residual stress, microstructure, microhardness and surface roughness. Mater. Charact. 2023, 196, 112571. [Google Scholar] [CrossRef]

- Qu, Z.; Zhang, Z.J.; Zhu, Y.K.; Liu, R.; Lu, S.L.; Li, S.J.; Duan, Q.Q.; Zhang, B.N.; Zhao, M.X.; Eckert, J.; et al. Coupling effects of microstructure and defects on the fatigue properties of laser powder bed fusion Ti-6Al-4V. Addit. Manuf. 2023, 61, 103355. [Google Scholar] [CrossRef]

- Meng, C.; Chen, J.; Hase, L.; Liu, Y. Image-based study on fatigue crack initiation mechanism of Ti-6Al-4V fabricated by laser-based powder bed fusion. Addit. Manuf. 2024, 86, 104216. [Google Scholar] [CrossRef]

- Li, Z.; Gut, A.; Burda, I.; Michel, S.; Gwerder, D.; Schuetz, P.; Romancuk, D.; Affolter, C. Investigation of individual lack-of-fusion defects in the fatigue performance of additive manufactured Ti6Al4V parts. 2024; under review. [Google Scholar]

- Biswal, R.; Syed, A.K.; Zhang, X. Assessment of the effect of isolated porosity defects on the fatigue performance of additive manufactured titanium alloy. Addit. Manuf. 2018, 23, 433–442. [Google Scholar] [CrossRef]

- Biswal, R.; Zhang, X.; Shamir, M.; Al Mamun, A.; Awd, M.; Walther, F.; Syed, A.K. Interrupted fatigue testing with periodic tomography to monitor porosity defects in wire + arc additive manufactured Ti-6Al-4V. Addit. Manuf. 2019, 28, 517–527. [Google Scholar] [CrossRef]

- Lauterbach, B.; Fieres, J.; Nigge, K.-M. Berücksichtigung von fertigungsbedingten Defekten in der strukturmechanischen Simulation. NAFEMS Mag. 2021, 1, 57. [Google Scholar]

- Siddique, S.; Imran, M.; Rauer, M.; Kaloudis, M.; Wycisk, E.; Emmelmann, C.; Walther, F. Computed tomography for characterization of fatigue performance of selective laser melted parts. Mater. Des. 2015, 83, 661–669. [Google Scholar] [CrossRef]

- Wan, H.; Wang, Q.; Jia, C.; Zhang, Z. Multi-scale damage mechanics method for fatigue life prediction of additive manufacture structures of Ti-6Al-4V. Mater. Sci. Eng. A. 2016, 669, 269–278. [Google Scholar] [CrossRef]

- Lukhi, M.; Kuna, M.; Hütter, G. Numerical investigation of low cycle fatigue mechanism in nodular cast iron. Int. J. Fatigue 2018, 113, 290–298. [Google Scholar] [CrossRef]

- Dinh, T.D.; Vanwalleghem, J.; Xiang, H.; Erdelyi, H.; Craeghs, T.; Paepegem, W.V. A unified approach to model the effect of porosity and high surface roughness on the fatigue properties of additively manufactured Ti6-Al4-V alloys. Addit. Manuf. 2020, 33, 101139. [Google Scholar] [CrossRef]

- Wang, Y.; Su, Z. Effect of micro-defects on fatigue lifetime of additive manufactured 316L stainless steel under multiaxial loading. Theor. Appl. Fract. Mech. 2021, 111, 102849. [Google Scholar] [CrossRef]

- Li, Z.; Gut, A.; Burda, I.; Michel, S.; Romancuk, D.; Affolter, C. The role of an individual lack-of-fusion defect in the fatigue performance of additive manufactured Ti-6Al-4V parts. In Proceedings of the I-AM 2022 International Additive Manufacturing Conference, Lisbon, Portugal, 19–20 October 2022. [Google Scholar]

- Xie, C.; Wu, S.; Yu, Y.; Zhang, H.; Hu, Y.; Zhang, M.; Wang, G. Defect-correlated fatigue resistance of additively manufactured Al-Mg4.5Mn alloy with in situ micro-rolling. J. Mater. Process. Technol. 2021, 291, 117039. [Google Scholar] [CrossRef]

- Shao, S.; Poudel, A.; Shamsaei, N. A linear elastic finite element approach to fatigue life estimation for defect laden materials. Eng. Fract. Mech. 2023, 285, 109298. [Google Scholar] [CrossRef]

- Murakami, Y.; Beretta, S. Small defects and inhomogeneities in fatigue strength: Experiments, models and statistical implications. Extremes 1999, 2, 123–147. [Google Scholar] [CrossRef]

- Sanaei, N.; Fatemi, A.; Phan, N. Defect characteristics and analysis of their variability in metal L-PBF additive manufacturing. Mater. Des. 2019, 182, 108091. [Google Scholar] [CrossRef]

- Yukitaka, M.; Masahiro, E. Quantitative evaluation of fatigue strength of metals containing various small defects or cracks. Eng. Fract. Mech. 1983, 17, 1–15. [Google Scholar] [CrossRef]

- Sterling, A.J.; Torries, B.; Shamsaei, N.; Thompson, S.M.; Seely, D.W. Fatigue behavior and failure mechanisms of direct laser deposited Ti-6Al-4V. Mater. Sci. Eng. A. 2016, 655, 100–112. [Google Scholar] [CrossRef]

- Vastola, G.; Pei, Q.X.; Zhang, Y.W. Predictive model for porosity in powder-bed fusion additive manufacturing at high beam energy regime. Addit. Manuf. 2018, 22, 817–822. [Google Scholar] [CrossRef]

- Wöhler, A. Versuche über die Festigkeit der Eisenbahnwagenachsen. Z. Für Bauwes. 1860, 10, 160–161. [Google Scholar]

- Basquin, O.H. The exponential law of endurance tests. Am. Soc. Test. Mater. Proc. 1910, 10, 625–630. [Google Scholar]

- Smith, K.; Topper, T.; Watson, P. A stress-strain function for the fatigue of metals. J. Mater. 1970, 5, 767–778. [Google Scholar]

- Anderson, T.L.; Anderson, T.L. Fracture Mechanics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Stephens, R.I.; Fatemi, A.; Stephens, R.R.; Fuchs, H.O. Metal Fatigue in Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2000. [Google Scholar]

- Haile, J.M. Molecular Dynamics Simulation: Elementary Methods; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1992. [Google Scholar]

- Hirth, J.P.; Lothe, J.; Mura, T. Theory of dislocations. J. Appl. Mech. 1983, 50, 476–477. [Google Scholar] [CrossRef]

- Dieter, G.E.; Bacon, D. Mechanical Metallurgy; McGraw-hill: New York, NY, USA, 1976. [Google Scholar]

- Yang, X.; Ma, W.; Zhang, Z.; Liu, S.; Tang, H. Ultra-high specific strength Ti6Al4V alloy lattice material manufactured via selective laser melting. Mater. Sci. Eng. A 2022, 840, 142956. [Google Scholar] [CrossRef]

- Muiruri, A.; Maringa, M.; Preez, W.D. Evaluation of dislocation densities in various microstructures of additively manufactured Ti6Al4V (ELI) by the method of x-ray diffraction. Materials 2020, 13, 5355. [Google Scholar] [CrossRef] [PubMed]

- Shamir, M.; Syed, A.K.; Janik, V.; Biswal, R.; Zhang, X. The role of microstructure and local crystallographic orientation near porosity defects on the high cycle fatigue life of an additive manufactured Ti-6Al-4V. Mater. Charact. 2020, 169, 110576. [Google Scholar] [CrossRef]

- Signor, L.; Villechaise, P.; Ghidossi, T.; Lacoste, E.; Gueguen, M.; Courtin, S. Influence of local crystallographic configuration on microcrack initiation in fatigued 316LN stainless steel: Experiments and crystal plasticity finite elements simulations. Mater. Sci. Eng. A 2016, 649, 239–249. [Google Scholar] [CrossRef]

- Natkowski, E.; Durmaz, A.R.; Sonnweber-Ribic, P.; Münstermann, S. Fatigue lifetime prediction with a validated micromechanical short crack model for the ferritic steel EN 1.4003. Int. J. Fatigue 2021, 152, 106418. [Google Scholar] [CrossRef]

- Musinski, W.D.; McDowell, D.L. Simulating the effect of grain boundaries on microstructurally small fatigue crack growth from a focused ion beam notch through a three-dimensional array of grains. Acta Mater. 2016, 112, 20–39. [Google Scholar] [CrossRef]

- Farukh, F.; Zhao, L.; Jiang, R.; Reed, P.; Proprentner, D.; Shollock, B. Realistic microstructure-based modelling of cyclic deformation and crack growth using crystal plasticity. Comput. Mater. Sci. 2016, 111, 395–405. [Google Scholar] [CrossRef]

- Kuhn, J.; Schneider, M.; Sonnweber-Ribic, P.; Böhlke, T. Fast methods for computing centroidal Laguerre tessellations for prescribed volume fractions with applications to microstructure generation of polycrystalline materials. Comput. Methods Appl. Mech. Eng. 2020, 369, 113175. [Google Scholar] [CrossRef]

- McDowell, D.; Dunne, F. Microstructure-sensitive computational modeling of fatigue crack formation. Int. J. Fatigue 2010, 32, 1521–1542. [Google Scholar] [CrossRef]

- Castelluccio, G.M. A Study on the Influence of Microstructure on Small Fatigue Cracks. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2012. [Google Scholar]

- Petrișor, S.M.; Savin, A.; Stanciu, M.D.; Prevorovsky, Z.; Soare, M.; Nový, F.; Steigmann, R. Complementary Methods for the Assessment of the Porosity of Laser Additive-Manufactured Titanium Alloy. Materials 2023, 16, 6383. [Google Scholar] [CrossRef]

- Ben, D.D.; Yang, H.J.; Ji, H.B.; Lian, D.L.; Meng, L.X.; Chen, J.; Yi, J.L.; Wang, L.; De Hosson, J.T.; Yang, R.; et al. Fatigue crack growth behavior in additive manufactured Ti6Al4V alloy with intentionally embedded spherical defect. Mater. Sci. Eng. A 2023, 885, 145612. [Google Scholar] [CrossRef]

- Ansari, M.A.; Crampton, A.; Garrard, R.; Cai, B.; Attallah, M. A Convolutional Neural Network (CNN) classification to identify the presence of pores in powder bed fusion images. Int. J. Adv. Manuf. Technol. 2022, 120, 5133–5150. [Google Scholar] [CrossRef]

- Walker, K.F.; Liu, Q.; Brandt, M. Evaluation of fatigue crack propagation behaviour in Ti-6Al-4V manufactured by selective laser melting. Int. J. Fatigue 2017, 104, 302–308. [Google Scholar] [CrossRef]

- Zhang, H.; Toda, H.; Qu, P.C.; Sakaguchi, Y.; Kobayashi, M.; Uesugi, K.; Suzuki, Y. Three-dimensional fatigue crack growth behavior in an aluminum alloy investigated with in situ high-resolution synchrotron X-ray microtomography. Acta Mater. 2009, 57, 3287–3300. [Google Scholar] [CrossRef]

- Qian, W.; Wu, S.; Wu, Z.; Ahmed, S.; Zhang, W.; Qian, G.; Withers, P.J. In situ X-ray imaging of fatigue crack growth from multiple defects in additively manufactured AlSi10Mg alloy. Int. J. Fatigue 2022, 155, 106616. [Google Scholar] [CrossRef]

- Tsay, L.; Shan, Y.-P.; Chao, Y.-H.; Shu, W. The influence of porosity on the fatigue crack growth behavior of Ti–6Al–4V laser welds. J. Mater. Sci. 2006, 41, 7498–7505. [Google Scholar] [CrossRef]

- Lee, J.; Hyun, S.; Kim, M.; Kim, M.; Ide, T.; Nakajima, H. Ductility improvement of intermetallic compound NiAl by unidirectional pores. Mater. Lett. 2012, 74, 213–216. [Google Scholar] [CrossRef]

- Mishurova, T.; Cabeza, S.; Artzt, K.; Haubrich, J.; Klaus, M.; Genzel, C.; Requena, G.; Bruno, G. An assessment of subsurface residual stress analysis in SLM Ti-6Al-4V. Materials 2017, 10, 348. [Google Scholar] [CrossRef]

- Xiao, Z.; Chen, C.; Zhu, H.; Hu, Z.; Nagarajan, B.; Guo, L.; Zeng, X. Study of residual stress in selective laser melting of Ti6Al4V. Mater. Des. 2020, 193, 108846. [Google Scholar] [CrossRef]

- Yakout, M.; Elbestawi, M.; Veldhuis, S.C. A study of the relationship between thermal expansion and residual stresses in selective laser melting of Ti-6Al-4V. J. Manuf. Process. 2020, 52, 181–192. [Google Scholar] [CrossRef]

- Xiao, Z.; Chen, C.; Hu, Z.; Zhu, H.; Zeng, X. Effect of rescanning cycles on the characteristics of selective laser melting of Ti6Al4V. Opt. Laser Technol. 2020, 122, 105890. [Google Scholar] [CrossRef]

- Wu, A.S.; Brown, D.W.; Kumar, M.; Gallegos, G.F.; King, W.E. An experimental investigation into additive manufacturing-induced residual stresses in 316L stainless steel. Metall. Mater. Trans. A 2014, 45, 6260–6270. [Google Scholar] [CrossRef]

- Li, C.; Liu, Z.; Fang, X.; Guo, Y. On the simulation scalability of predicting residual stress and distortion in selective laser melting. J. Manuf. Sci. Eng. 2018, 140, 041013. [Google Scholar] [CrossRef]

- Beghini, M.; Bertini, L. Fatigue crack propagation through residual stress fields with closure phenomena. Eng. Fract. Mech. 1990, 36, 379–387. [Google Scholar] [CrossRef]

- Vasudeven, A.; Sadananda, K.; Louat, N. A review of crack closure, fatigue crack threshold and related phenomena. Mater. Sci. Eng. A 1994, 188, 1–22. [Google Scholar] [CrossRef]

- Murr, L.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Rodela, A.; Martinez, E.Y.; Hernandez, D.H.; Martinez, E.; Medina, F.; Wicker, R.B. Microstructure and mechanical behavior of Ti–6Al–4V produced by rapid-layer manufacturing, for biomedical applications. J. Mech. Behav. Biomed. Mater. 2009, 2, 20–32. [Google Scholar] [CrossRef]

- Vandenbroucke, B.; Kruth, J.P. Selective laser melting of biocompatible metals for rapid manufacturing of medical parts. Rapid Prototyp. J. 2007, 13, 196–203. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.-D. As-fabricated and heat-treated microstructures of the Ti-6Al-4V alloy processed by selective laser melting. Metall. Mater. Trans. A 2011, 42, 3190–3199. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; Van Humbeeck, J. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Han, J.; Yang, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Microstructure and mechanical property of selective laser melted Ti6Al4V dependence on laser energy density. Rapid Prototyp. J. 2017, 23, 217–226. [Google Scholar] [CrossRef]

- Li, H.; Jia, D.; Yang, Z.; Liao, X.; Jin, H.; Cai, D.; Zhou, Y. Effect of heat treatment on microstructure evolution and mechanical properties of selective laser melted Ti–6Al–4V and TiB/Ti–6Al–4V composite: A comparative study. Mater. Sci. Eng. A 2021, 801, 140415. [Google Scholar] [CrossRef]

- Yan, X.; Yin, S.; Chen, C.; Huang, C.; Bolot, R.; Lupoi, R.; Kuang, M.; Ma, W.; Coddet, C.; Liao, H.; et al. Effect of heat treatment on the phase transformation and mechanical properties of Ti6Al4V fabricated by selective laser melting. J. Alloys Compd. 2018, 764, 1056–1071. [Google Scholar] [CrossRef]

- Zhang, X.-Y.; Fang, G.; Leeflang, S.; Böttger, A.J.; Zadpoor, A.A.; Zhou, J. Effect of subtransus heat treatment on the microstructure and mechanical properties of additively manufactured Ti-6Al-4V alloy. J. Alloys Compd. 2018, 735, 1562–1575. [Google Scholar] [CrossRef]

- Wu, S.; Lu, Y.; Gan, Y.; Huang, T.; Zhao, C.; Lin, J.; Guo, S.; Lin, J. Microstructural evolution and microhardness of a selective-laser-melted Ti–6Al–4V alloy after post heat treatments. J. Alloys Compd. 2016, 672, 643–652. [Google Scholar] [CrossRef]

- Su, C.; Yu, H.; Wang, Z.; Yang, J.; Zeng, X. Controlling the tensile and fatigue properties of selective laser melted Ti–6Al–4V alloy by post treatment. J. Alloys Compd. 2021, 857, 157552. [Google Scholar] [CrossRef]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; Wiley Online Library: Hoboken, NJ, USA, 2006. [Google Scholar]

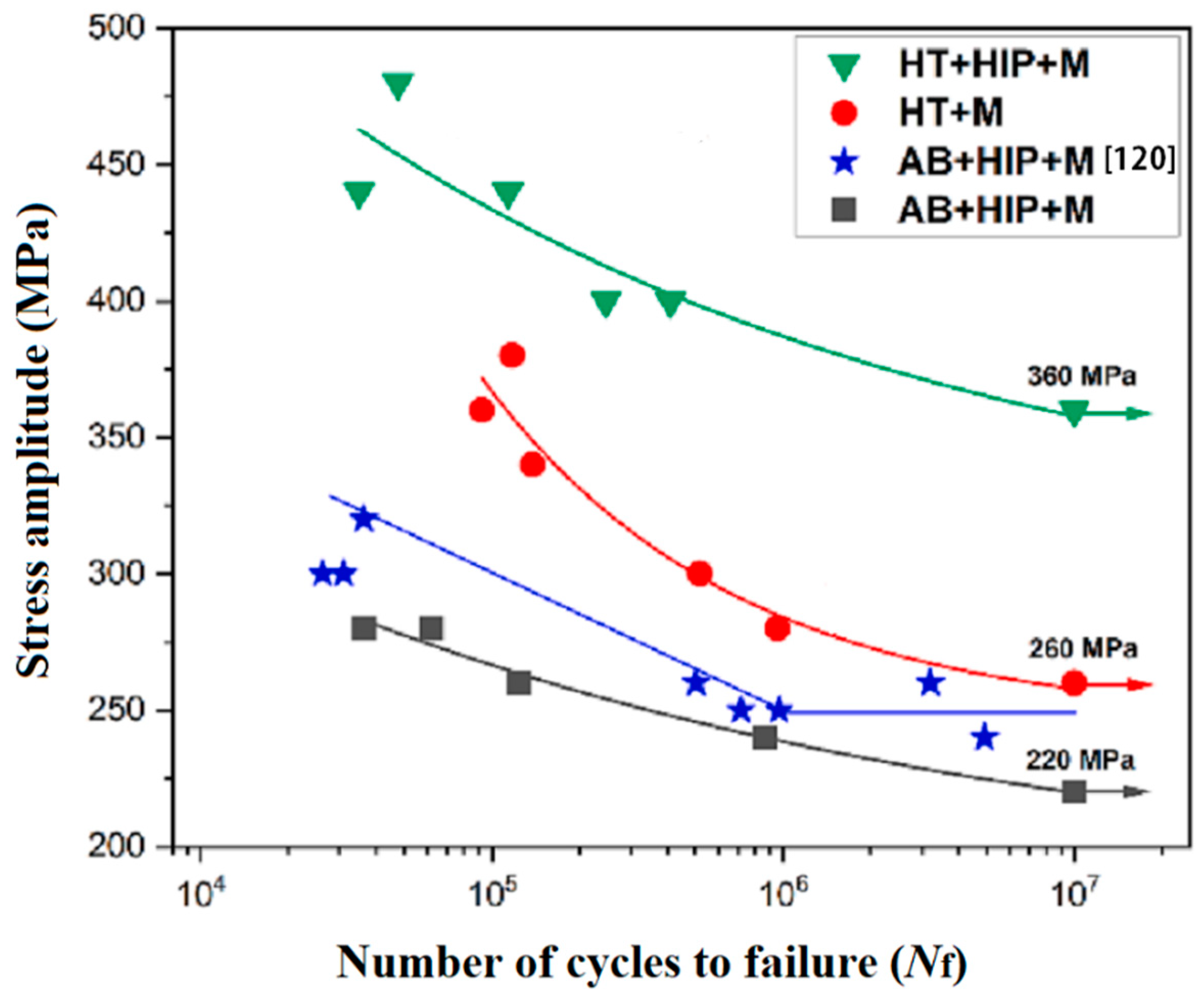

- Alegre, J.M.; Díaz, A.; García, R.; Peral, L.B.; Cuesta, I.I. Effect of HIP post-processing at 850 °C/200 MPa in the fatigue behavior of Ti-6Al-4V alloy fabricated by Selective Laser Melting. Int. J. Fatigue 2022, 163, 107097. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti–6Al–4V. Mater. Sci. Eng. A 2014, 616, 1–11. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Titanium Matrix Composites; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Moridi, A.; Demir, A.G.; Caprio, L.; Hart, A.J.; Previtali, B.; Colosimo, B.M. Deformation and failure mechanisms of Ti–6Al–4V as built by selective laser melting. Mater. Sci. Eng. A 2019, 768, 138456. [Google Scholar] [CrossRef]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.A.; Maier, H.J. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Plessis, A.D.; Macdonald, E. Hot isostatic pressing in metal additive manufacturing: X-ray tomography reveals details of pore closure. Addit. Manuf. 2020, 34, 101191. [Google Scholar] [CrossRef]

- Sun, C.; Chi, W.; Wang, W.; Duan, Y. Characteristic and mechanism of crack initiation and early growth of an additively manufactured Ti-6Al-4V in very high cycle fatigue regime. Int. J. Mech. Sci. 2021, 205, 106591. [Google Scholar] [CrossRef]

- Zhang, L.-L.; Fei, Y.-H.; Liu, X.-Y.; Li, M.-X. On the formation mechanisms of fine granular area (FGA) on the fracture surface for high strength steels in the VHCF regime. Int. J. Fatigue 2016, 82, 402–410. [Google Scholar]

- Hills, M.A.; Malcolm, J.S.; Dhansay, N.M.; Becker, T.H. High cycle fatigue strength of hot isostatically pressed and chemically etched laser powder bed fusion produced Ti-6Al-4V. Int. J. Fatigue 2023, 175, 107774. [Google Scholar] [CrossRef]

- Li, J.; Yang, Z.; Qian, G.; Berto, F. Machine learning based very-high-cycle fatigue life prediction of Ti-6Al-4V alloy fabricated by selective laser melting. Int. J. Fatigue 2022, 158, 106764. [Google Scholar] [CrossRef]

- Horňas, J.; Běhal, J.; Homola, P.; Senck, S.; Holzleitner, M.; Godja, N.; Pásztor, Z.; Hegedüs, B.; Doubrava, R.; Růžek, R.; et al. Modelling fatigue life prediction of additively manufactured Ti-6Al-4V samples using machine learning approach. Int. J. Fatigue 2023, 169, 107483. [Google Scholar] [CrossRef]

- Wang, H.; Li, B.; Xuan, F.-Z. Fatigue-life prediction of additively manufactured metals by continuous damage mechanics (CDM)-informed machine learning with sensitive features. Int. J. Fatigue 2022, 164, 107147. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, B.; Feng, X.; Song, Z.M.; Qi, X.B.; Li, C.P.; Chen, G.F.; Zhang, G.P. Pore-affected fatigue life scattering and prediction of additively manufactured Inconel 718: An investigation based on miniature specimen testing and machine learning approach. Mater. Sci. Eng. A 2021, 802, 140693. [Google Scholar] [CrossRef]

- Zhan, Z.; Hu, W.; Meng, Q. Data-driven fatigue life prediction in additive manufactured titanium alloy: A damage mechanics based machine learning framework. Eng. Fract. Mech. 2021, 252, 107850. [Google Scholar] [CrossRef]

- Zhan, Z.; Li, H. Machine learning based fatigue life prediction with effects of additive manufacturing process parameters for printed SS 316L. Int. J. Fatigue 2021, 142, 105941. [Google Scholar] [CrossRef]

- Zhan, Z.; Li, H. A novel approach based on the elastoplastic fatigue damage and machine learning models for life prediction of aerospace alloy parts fabricated by additive manufacturing. Int. J. Fatigue 2021, 145, 106089. [Google Scholar] [CrossRef]

- Jia, Y.; Fu, R.; Ling, C.; Shen, Z.; Zheng, L.; Zhong, Z.; Hong, Y. Fatigue life prediction based on a deep learning method for Ti-6Al-4V fabricated by laser powder bed fusion up to very-high-cycle fatigue regime. Int. J. Fatigue 2023, 172, 107645. [Google Scholar] [CrossRef]

- Salvati, E.; Tognan, A.; Laurenti, L.; Pelegatti, M.; De Bona, F. A defect-based physics-informed machine learning framework for fatigue finite life prediction in additive manufacturing. Mater. Des. 2022, 222, 111089. [Google Scholar] [CrossRef]

- Murakami, Y.; Endo, M. Effects of hardness and crack geometries on delta k sub th of small cracks emanating from small defects. In The Behaviour of Short Fatigue Cracks; Mechanical Engineering Publications: London, UK, 1986; pp. 275–293. [Google Scholar]

- Ciampaglia, A.; Tridello, A.; Paolino, D.; Berto, F. Data driven method for predicting the effect of process parameters on the fatigue response of additive manufactured AlSi10Mg parts. Int. J. Fatigue 2023, 170, 107500. [Google Scholar] [CrossRef]

| No. | Method | Pros | Cons | References |

|---|---|---|---|---|

| 1 | Natural internal defects | Conform to reality | Difficult to control the initiation site | [45,90] |

| 2 | Artificial defect by computer aid design (CAD) | Size, morphology, and location are controlled, regarded as an internal defect | (1) Defects are usually much larger than natural defects; (2) residual stress is not natural; (3) unfused powders inside | [91,92] |

| 3 | Manual notch | Crack initiation site is controlled | (1) Not desirable for crack propagation at early stages; (2) cracks do not initiate from internal defects | [45] |

| 4 | CT specimen | Standardized crack propagation approach | Only to study crack propagation | [44] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Affolter, C. High-Cycle Fatigue Performance of Laser Powder Bed Fusion Ti-6Al-4V Alloy with Inherent Internal Defects: A Critical Literature Review. Metals 2024, 14, 972. https://doi.org/10.3390/met14090972

Li Z, Affolter C. High-Cycle Fatigue Performance of Laser Powder Bed Fusion Ti-6Al-4V Alloy with Inherent Internal Defects: A Critical Literature Review. Metals. 2024; 14(9):972. https://doi.org/10.3390/met14090972

Chicago/Turabian StyleLi, Zongchen, and Christian Affolter. 2024. "High-Cycle Fatigue Performance of Laser Powder Bed Fusion Ti-6Al-4V Alloy with Inherent Internal Defects: A Critical Literature Review" Metals 14, no. 9: 972. https://doi.org/10.3390/met14090972

APA StyleLi, Z., & Affolter, C. (2024). High-Cycle Fatigue Performance of Laser Powder Bed Fusion Ti-6Al-4V Alloy with Inherent Internal Defects: A Critical Literature Review. Metals, 14(9), 972. https://doi.org/10.3390/met14090972