Deep Rolling Techniques: A Comprehensive Review of Process Parameters and Impacts on the Material Properties of Commercial Steels

Abstract

1. Introduction

1.1. The Need for a Comprehensive Review of the Deep Rolling Technique

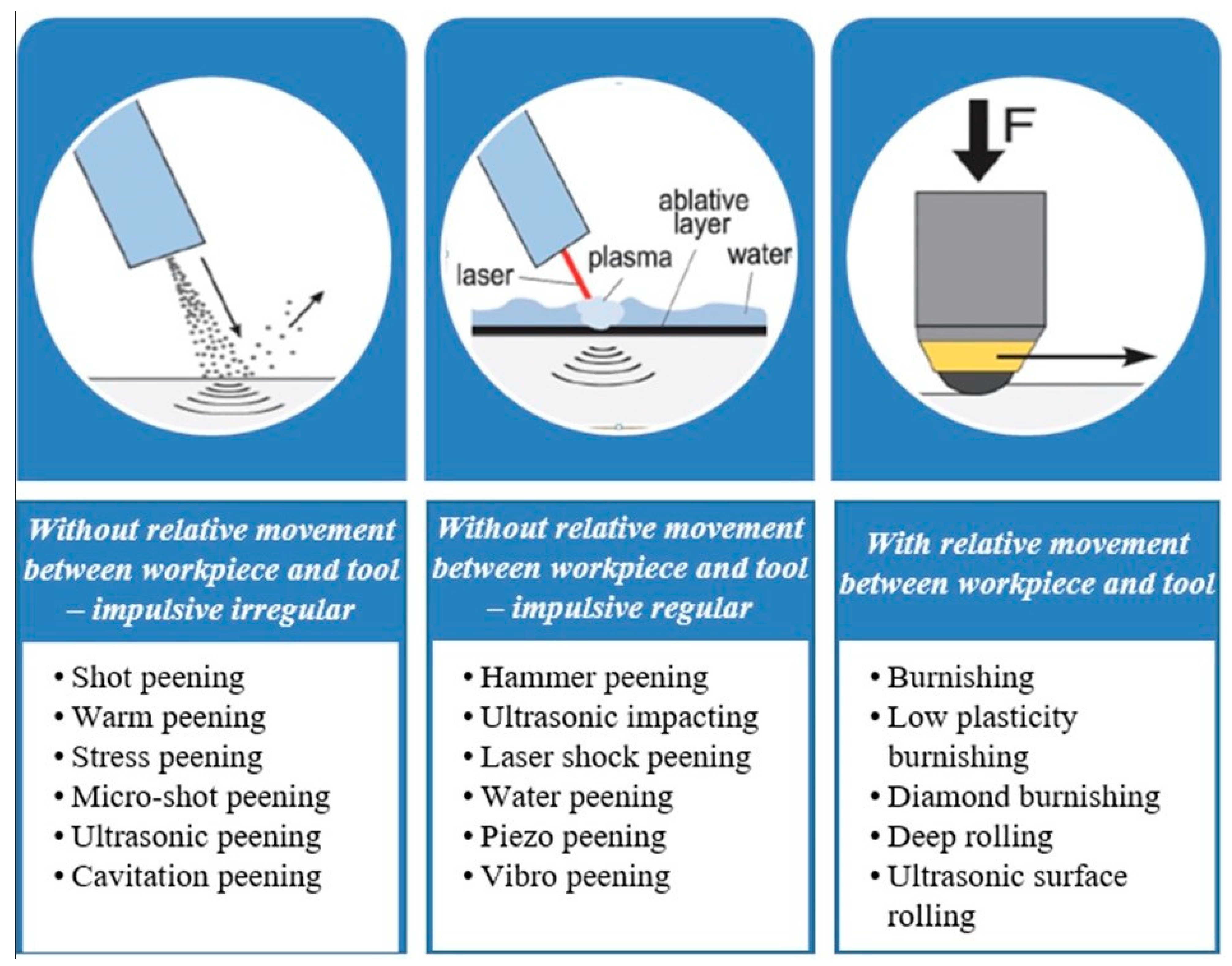

1.2. Mechanical Surface Treatments

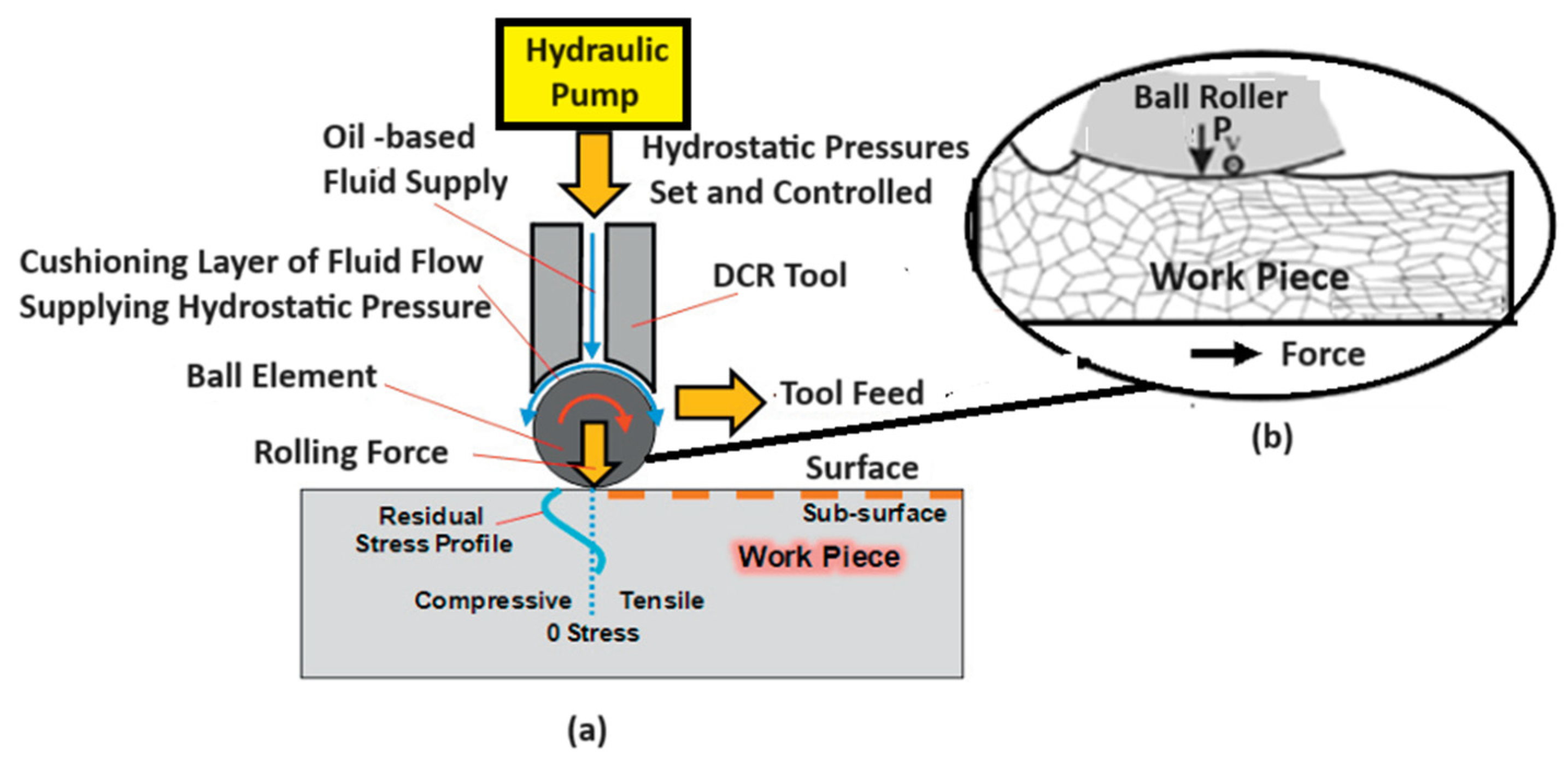

1.3. Deep Rolling

1.4. Applications of Deep Rolling

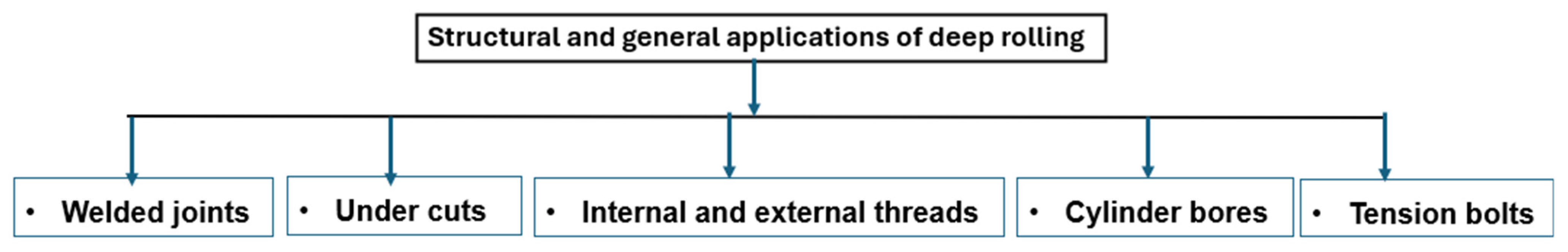

1.4.1. Structural and General Applications

1.4.2. Applications in the Automobile and Marine Industries

1.4.3. Applications in the Aerospace Industry

1.4.4. Applications in the Medical Industry

1.5. AISI 1040 Steel Material

Applications of AISI 1040 Steel

2. Literature Review

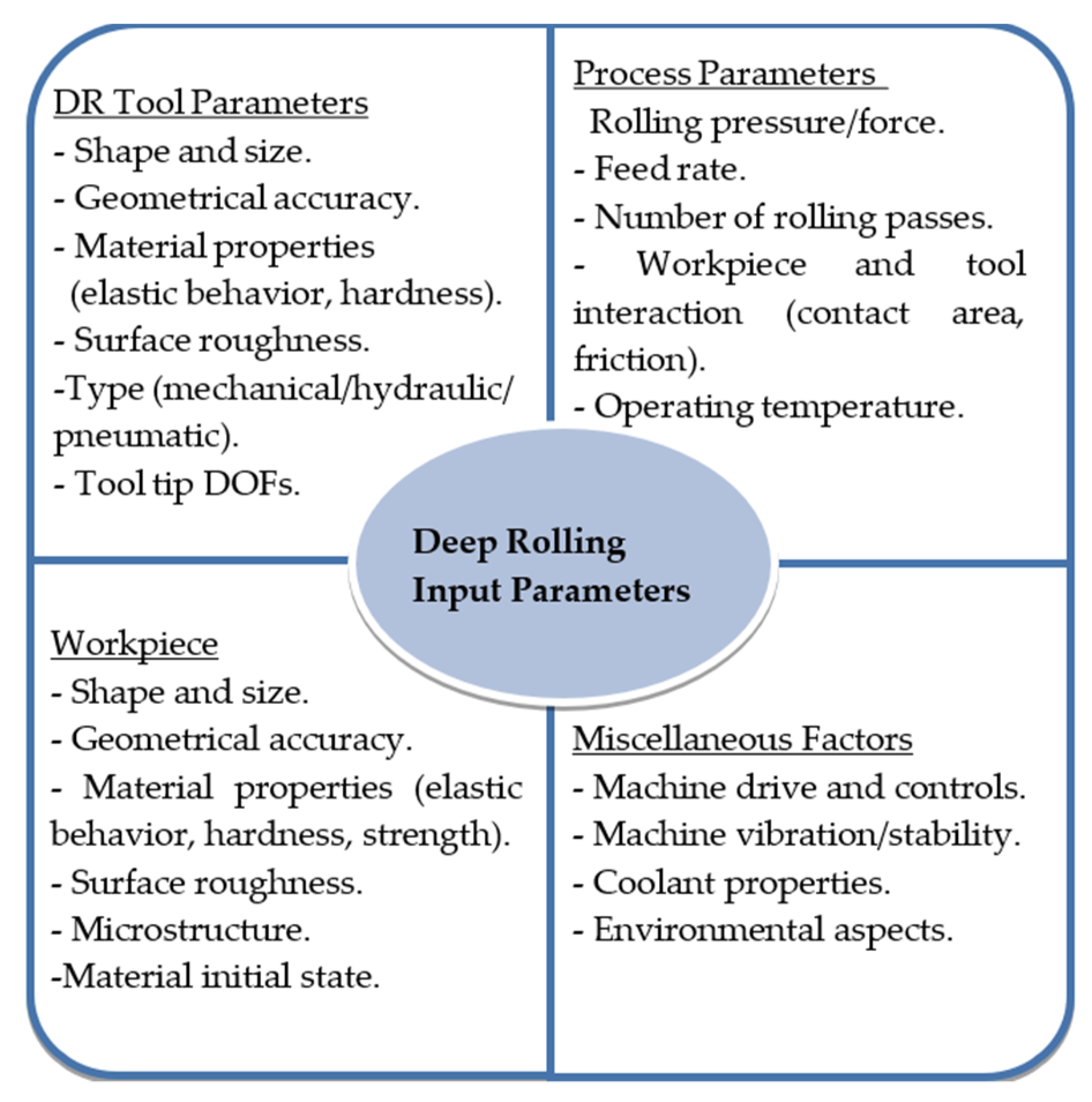

2.1. The Deep Rolling Process

2.2. Finite Element Modeling of the Deep Rolling Process

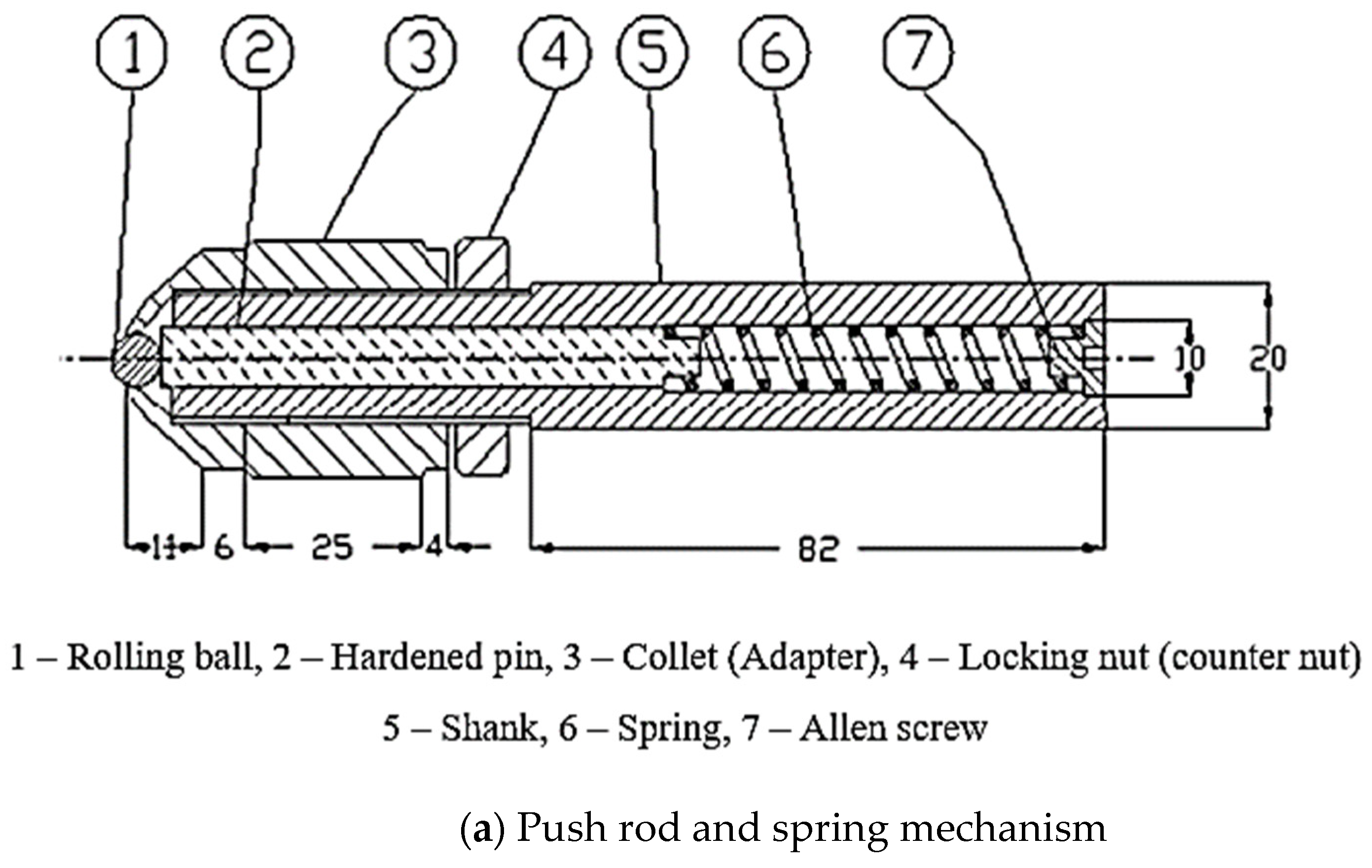

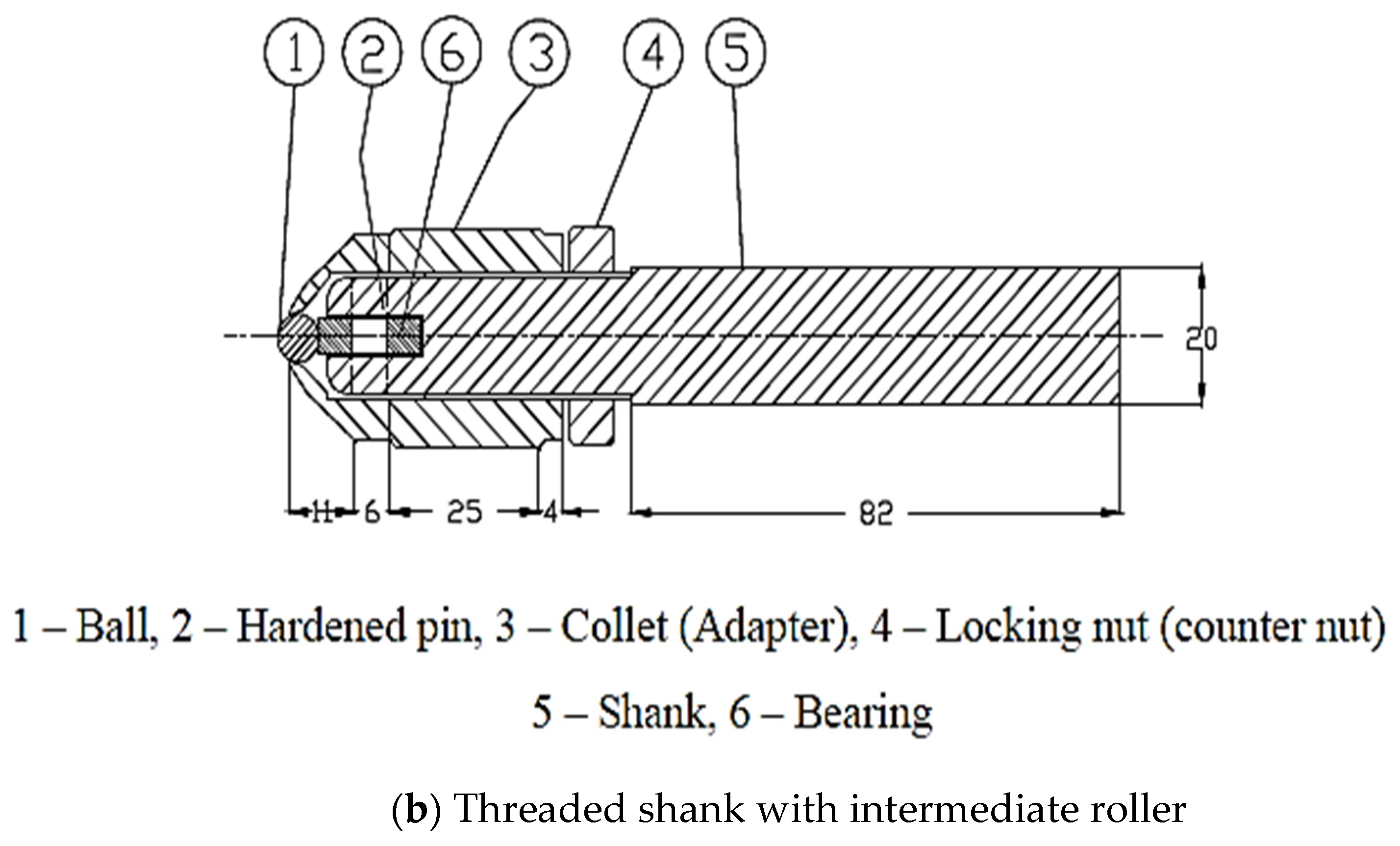

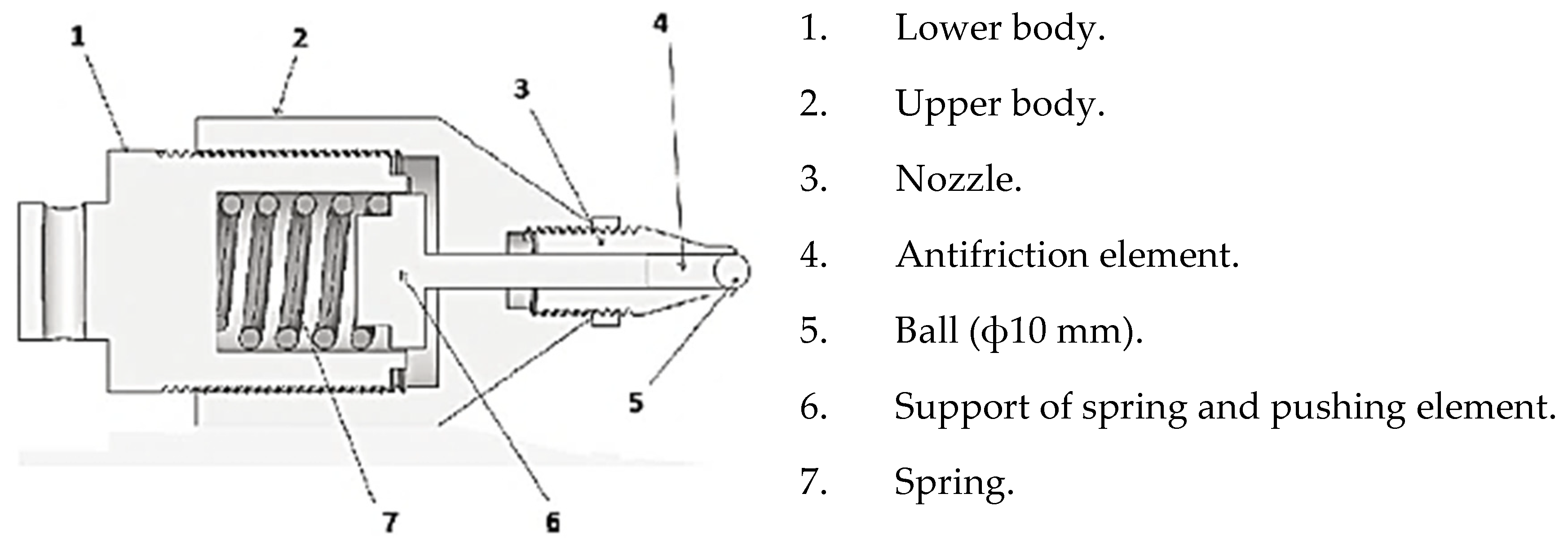

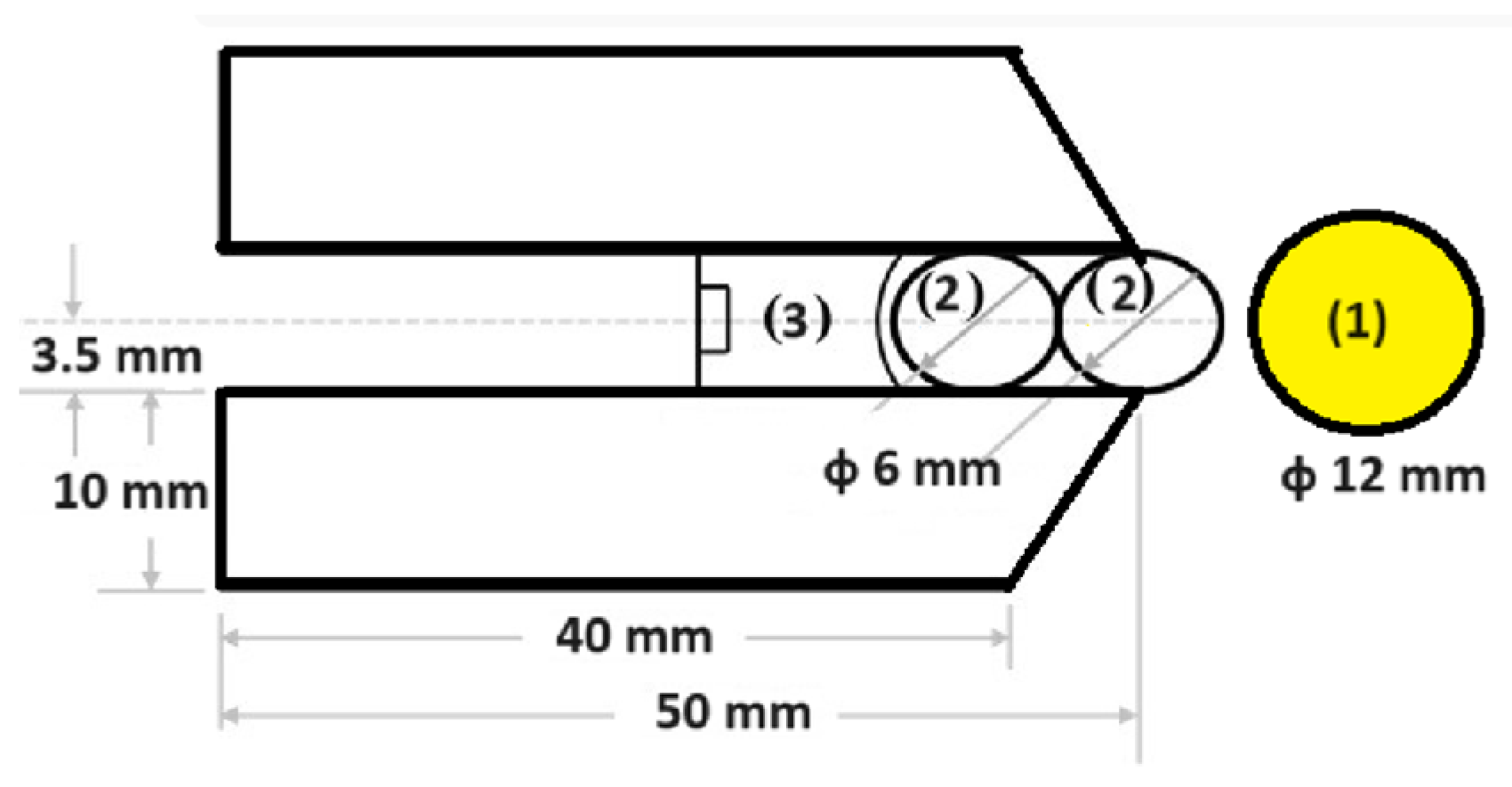

2.3. Deep Rolling Tools

2.4. Roll of ANNs in Deep Rolling Techniques

3. Conclusions and Scope for Further Study

- The literature indicates there are reliable efforts by the research community in developing the DR process, optimizing the process parameters, and studying its effect on materials or components with an objective to achieve improved in-service performance. Conversely, comparative studies on the effect of various MSTs are scarce, which could be due to the significant differences involved in the process mechanisms/parameters and their effect on the performance of the component/material. This includes, for instance, different stability and heterogeneity in induced CRS, cold work and microstructures, different responses of different metallic materials to residual stresses and mean stresses, different work-hardening capabilities, different mechanical or complex thermo-mechanical responses under cyclic load, during MSTs at elevated temperatures, etc.

- The literature in the open domain reveals that DR could be the most viable option because of its simple operation and tools, lower cost, and the highest level of beneficial surface properties when compared with contemporary techniques. It is identified to be one of the most effective commercially available methods to enhance the fatigue performance of metallic materials because of the remarkable improvement in surface finish, significant CRS depth up to 3 mm (material- and process parameter-dependent) with work-hardened microstructures, and directional strength enhancement.

- The reviewed literature demonstrates that standardizing the DR process is a quite challenging aspect considering the highest degree of influence of process parameters (rolling force/pressure, rolling feed, tool geometry size and material, number of roll passes, coverage/overlap of the rolling path, contact conditions, etc.) on the material or component performance. Moreover, the type and initial condition of the material are crucial in achieving desirable properties through DR. For instance, too-low rolling pressures might not induce pronounced benefits, while too-high rolling pressures might deteriorate the existing properties by inducing micro-cracks. This indicates that each study is unique and necessitates the requirement of material-specific investigation with optimized parameters to fully realize the benefits of the DR process.

- The reasonable literature recommends considering physical and mechanical characteristics (microstructure, surface topology, hardness, CRS, and cold work) over the use of empirical methods for process parameter optimization.

- Significant research on the use of FEM to simulate the DR process and analyze its effect on the material/component is available in the open domain. However, a substantial amount of the research available was observed to be case-specific, and its universal adoption is often restricted. In addition, the simulation and accuracy achieved were sensitive to variations in modeling techniques and assumed boundary conditions, which were reported to be the primary reason for the deviation among computed and measured parameters.

- Most of the conveyed FE studies are focused on the evaluation of DR-induced residual stress fields. In contrast, the use of FEM for predicting elastic recovery, surface roughness, accumulated plasticity, and fatigue life in DR specimens is quite rare. The reviewed literature indicates that DR controlling parameters, namely, the friction coefficient, rolling pressure, number of rolling passes, rolling path and overlap, roller shape and size, and surface roughness, could be the preferred input parameters in FE modeling.

- The literature on DR tool design and developments divulges that most of the work is patented. The reviewed literature emphasizes the contact mechanics of the tool and workpiece, degrees of freedom of the rolling ball, and the ability to maintain constant rolling pressures were critical aspects in tool design. Limited organizations, especially in India, are involved in the development and manufacturing of DR tools. Most of the business is restricted to the development and marketing of burnishing tools. In addition, the available tools are developed for specific applications and are fairly expensive.

- Investigations on mechanical surface treatments of AISI 1040 steel are scarce in the literature. The available work is mostly restricted to burnishing, peening (shot/liquid jet), and laser surface treatments. In particular, no plausible studies pertaining to the DR of AISI 1040 steel have been reported in the published domain so far.

- The adoption of ANNs specifically for predicting deep rolling effects is not available in the open domain for AISI 1040 steel.

- Establishing generalized standardizations for the deep rolling process does not appear to be feasible because of the multiple controlling parameters and their complex interactions. This necessitates a specific optimization study corresponding to the material of interest for process standardization.

- Investigation studies on the characterization of surface and subsurface properties of deep-rolled AISI 1040 steel and process parameters optimization are limited in the published literature.

- Detailed investigations on the microstructure and the interaction of surface/subsurface properties in deep-rolled samples are meager.

- Numerical, analytical, statistical, and ANN studies are limited in comparison with experimental work on the deep rolling process.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AISI | American Iron and Steel Institute |

| ASTM | American Society for Testing and Materials |

| ANN | Artificial Neural Network |

| BSs | British standards |

| CDR | conventional deep rolling |

| CRS | compressive residual stresses |

| DIN | Deutsches Institutfür Normung e.V. (German Institute for Standardization) |

| DR/DCR | deep rolling/deep cold rolling |

| DR-CT | deep rolling at cryogenic temperature |

| DR-ET | deep rolling at elevated temperature |

| DR-RT | deep rolling at room temperature |

| ENs | European norms (European standards) |

| FE | finite element |

| FEA | finite element analysis |

| FEM | finite element method |

| FWHM | full width half maximum |

| HP | hammer peening |

| HT | heat treatment |

| HT + DR | heat treatment with deep rolling |

| IS | Indian standards |

| JIS | Japanese industrial standards |

| LSP | laser shock peening |

| MSET | mechanical surface enhancement technique |

| MSP | micro-shot peening |

| MST | mechanical surface treatment |

| PP | Piezo peening |

| SAE | Society of automotive engineers |

| SP | shot peening |

| UDR/USR | ultrasonic deep rolling/ultrasonic surface rolling |

| USP | ultrasonic shock peening |

| WP | water peening |

| XRD | X-ray diffraction |

References

- Matlock, D.K.; Alogab, K.A.; Richards, M.D.; Speer, J.G. Surface processing to improve the fatigue resistance of advanced bar steels for automotive applications. Mater. Res. 2005, 8, 453–459. [Google Scholar] [CrossRef]

- Collins, J.A.; Busby, H.R.; Staab, G.H. Mechanical Design of Machine Elements and Machines: A Failure Prevention Perspective, 2nd ed.; John Wiley and Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Suresh, S. Fatigue of Materials, 2nd ed.; Cambridge University Press: Cambridge, MA, USA, 2004. [Google Scholar]

- Juijerm, P.; Altenberger, I. Fatigue Performance Enhancement of Steels using Mechanical Surface Treatments. J. Met. Mater. Miner. 2007, 17, 59–65. Available online: https://www.researchgate.net/publication/237276226 (accessed on 15 January 2020).

- Kumar, D.; Idapalapati, S.; Wang, W.; Narasimalu, S. Effect of surface mechanical treatments on the microstructure property performance of engineering alloys. Materials 2019, 12, 2503. [Google Scholar] [CrossRef]

- Zinn, W.; Scholtes, B. Mechanical surface treatments of lightweight materials: Effects on fatigue strength and near surface microstructures. J. Mater. Eng. Perform. 1999, 8, 145–151. [Google Scholar] [CrossRef]

- Altenberger, I.; Scholtes, B. Recent developments in mechanical surface optimization. Mater. Sci. Forum 2000, 347, 382–398. [Google Scholar] [CrossRef]

- Tolga Bozdana, A. On the mechanical surface enhancement techniques in aerospace industry—A review of technology. Aircr. Eng. Aerosp. Technol. 2005, 77, 279–292. [Google Scholar] [CrossRef]

- Altenberger, I. Alternative mechanical surface treatments: Microstructures, residual stresses and fatigue behavior. In Shot Peening; Wagner, L., Ed.; Wiley-VCH Verlag GmbH and Co.: Hoboken, NJ, USA, 2006; pp. 419–434. [Google Scholar] [CrossRef]

- Klumpp, A.; Hoffmeister, J.; Schulze, V. Mechanical Surface Treatments. In Proceedings of the 12th International Conference on Shot Peening, Goslar, Germany, 15–18 September 2014; pp. 12–24. Available online: https://www.shotpeener.com/library/pdf/2014044.pdf (accessed on 20 March 2020).

- Schulze, V.; Bleicher, F.; Groche, P.; Guo, Y.B.; Pyun, Y.S. Surface modification by machine hammer peening and burnishing. CIRP Ann. 2016, 65, 809–832. [Google Scholar] [CrossRef]

- Altenberger, I. Deep rolling: The past, the present and the future. In Proceedings of the 9th International Conference on Shot Peening, Paris, France, 6–9 September 2005; pp. 144–155. Available online: https://www.shotpeener.com/library/pdf/2005065.pdf (accessed on 6 April 2020).

- Delgado, P.; Cuesta, I.I.; Alegre, J.M.; Díaz, A. State of the art of deep rolling. Precis. Eng. 2016, 46, 1–10. [Google Scholar] [CrossRef]

- Borchers, F. Comparison of different manufacturing processes of AISI 4140 steel with regard to surface modification and its influencing depth. Metals 2020, 10, 895. [Google Scholar] [CrossRef]

- Schulze, V. Modern Mechanical Surface Treatment: States, Stability, Effects; Wiley-VCH Verlag Gmbh and Co.: Hoboken, NJ, USA, 2005. [Google Scholar] [CrossRef]

- Sonntag, R.; Reinders, J.; Gibmeier, J.; Kretzer, J.P. Fatigue performance of medical Ti6Al4V alloy after mechanical surface treatments. PLoS ONE 2015, 10, e0121963. [Google Scholar] [CrossRef]

- Abrão, A.M.; Denkena, B.; Köhler, J.; Breidenstein, B.; Mörke, T.; Rodrigues, P.C.M. The influence of heat treatment and deep rolling on the mechanical properties and integrity of AISI 1060 steel. J. Mater. Process. Technol. 2014, 214, 3020–3030. [Google Scholar] [CrossRef]

- Oevermann, T.; Saalfeld, S.; Niendorf, T.; Scholtes, B. Fatigue properties of steels SAE 1045 and SAE 4140 upon integrated inductive heat treatment and deep rolling at elevated temperature. In Proceedings of the 13th International Conference on Shot Peening, Montreal, QC, Canada, 18–21 September 2017; pp. 446–451. Available online: https://www.shotpeener.com/library/pdf/2017111.pdf (accessed on 4 March 2020).

- Juijerm, P.; Altenberger, I.; Scholtes, B. Fatigue and residual stress relaxation of deep rolled differently aged aluminium alloy AA6110. Mater. Sci. Eng. A 2006, 426, 4–10. [Google Scholar] [CrossRef]

- Altenberger, I.; Nikitin, I.; Scholtes, B. Static and dynamic strain ageing of deep-rolled plain carbon steel SAE 1045 for optimized fatigue strength. In Proceedings of the 9th International Conference on Shot Peening, Marne La Vallee, France, 6–8 September 2005; pp. 253–260. Available online: http://www.shotpeener.com/library/pdf/2005094.pdf (accessed on 6 April 2020).

- Wong, C.C.; Hartawan, A.; Teo, W.K. Deep cold rolling of features on aero-engine components. Procedia CIRP 2014, 13, 350–354. [Google Scholar] [CrossRef]

- Klocke, F.; Shirobokov, A.; Trauth, D.; Mattfeld, P. Deep rolling of fine blanking punch edges: Numerical and experimental investigation of a novel deep rolling tool for filleting of cylindrical punches. Int. J. Mater. Form. 2016, 9, 489–498. [Google Scholar] [CrossRef]

- Nataliya, L.; Dirk, B. Finite element modelling and investigation of the process parameters in deep rolling of AISI 4140 steel. J. Mater. Sci. Eng. B 2015, 5, 277–287. [Google Scholar] [CrossRef][Green Version]

- Roller Burnishing, Deep Rolling, Cylinder Tube Processing. ECOROLL AG. Available online: https://www.ecoroll.de/en/ecoroll.html (accessed on 19 May 2021).

- Crankshaft Manufacturer and Remanufacturer. Ellwood Crankshaft Group. Available online: www.ellwoodcrankshaftgroup.com (accessed on 19 May 2021).

- Eigenmann, B.; Holzwarth, U.; Kachler, W.; Goske, J.; Wilcke, G.; Schuh, A. Deep rolling of titanium rods for application in total hip arthroplasty. In Proceedings of the 9th International Conference on Shot Peening, Paris, France, 6–9 September 2005; pp. 314–318. Available online: https://www.shotpeener.com/library/pdf/2005103.pdf (accessed on 4 March 2020).

- Schuh, A. Deep rolling of titanium rods for application in modular total hip arthroplasty. J. Biomed. Mater. Res. Part B Appl. Biomater. 2007, 81B, 330–335. [Google Scholar] [CrossRef]

- Bauccio, A. (Ed.) ASM Metals Reference Book, 3rd ed.; ASM International: Materials Park, OH, USA, 1993. [Google Scholar] [CrossRef]

- Chemical Composition EN8 Steel and Equivalents. Shyam Metals. Available online: http://shyammetal.com (accessed on 9 January 2020).

- Kloos, K.H.; Fuchsbauer, B.; Adelmann, J. Fatigue properties of specimens similar to components deep rolled under optimized conditions. Int. J. Fatigue 1987, 9, 35–42. [Google Scholar] [CrossRef]

- Meyer, D.; Kämmler, J. Sustainable approach of heat treatment free surface hardening by deep rolling. Int. J. Sustain. Manuf. 2018, 4, 64–78. [Google Scholar] [CrossRef]

- Scheil, J.; Müller, C.; Steitz, M.; Groche, P. Influence of process parameters on surface hardening in hammer peening and deep rolling. Key Eng. Mater. 2013, 554–557, 1819–1827. [Google Scholar] [CrossRef]

- Wang, Z.M.; Jia, Y.F.; Zhang, X.C.; Fu, Y.; Zhang, C.C.; Tu, S.T. Effects of different mechanical surface enhancement techniques on surface integrity and fatigue properties of Ti-6Al-4V: A review. Crit. Rev. Solid State Mater. Sci. 2019, 44, 445–469. [Google Scholar] [CrossRef]

- Juijerm, P.; Altenberger, I. Fatigue performance of high temperature deep rolled metallic materials. J. Met. Mater. Miner. 2007, 17, 37–41. Available online: https://pdfs.semanticscholar.org/792f/e829a700e17bd1fe011358a3428468ee15dd.pdf (accessed on 1 June 2020).

- Altenberger, I.; Nikitin, I.; Juijerm, P.; Scholtes, B. Residual stress stability in high temperature fatigued mechanically surface treated metallic materials. Mater. Sci. Forum 2006, 524–525, 57–62. [Google Scholar] [CrossRef]

- Abrão, A.M.; Denkena, B.; Köhler, J.; Breidenstein, B.; Mörke, T. The inducement of residual stress through deep rolling of AISI 1060 steel and its subsequent relaxation under cyclic loading. Int. J. Adv. Manuf. Technol. 2015, 79, 1939–1947. [Google Scholar] [CrossRef]

- Dos Santos, F.F.; Silva, S.C.; Abrão, A.M.; Denkena, B.; Breidenstein, B.; Meyer, K. Influence of deep rolling on the surface integrity of AISI 1020 steel. Rev. Mater. 2020, 25, 1–13. [Google Scholar] [CrossRef]

- Dos, S.F.F.; Silva, S.D.C.; Abrão, A.M.; Denkena, B.; Breidenstein, B.; Meyer, K. Influence of the carbon content on the surface integrity of deep rolled steels. J. Tribol. 2021, 143, 081702. [Google Scholar] [CrossRef]

- Nikitin, I.; Altenberger, I.; Scholtes, B. Effect of deep rolling at elevated and low temperatures on the isothermal fatigue behavior of AISI 304. In Proceedings of the 9th International Conference on Shot Peening, Paris, France, 6–9 September 2005; pp. 185–190. Available online: http://www.shotpeener.com/library/pdf/2005070.pdf (accessed on 6 April 2020).

- Nikitin, I.; Besel, M. Residual stress relaxation of deep rolled austenitic steel. Scr. Mater. 2008, 58, 239–242. [Google Scholar] [CrossRef]

- Altenberger, I.; Scholtes, B.; Martin, U.; Oettel, H. Cyclic deformation and near surface microstructures of shot peened or deep rolled austenitic stainless steel AISI 304. Mater. Sci. Eng. A 1999, 264, 1–16. [Google Scholar] [CrossRef]

- Muñoz-Cubillos, J.; Coronado, J.J.; Rodríguez, S.A. Deep rolling effect on fatigue behavior of austenitic stainless steels. Int. J. Fatigue 2017, 95, 120–131. [Google Scholar] [CrossRef]

- Tadi, A.J. Formation of surface nano/ultrafine structure using deep rolling process on the AISI 316L stainless steel. Mater. Sci. Eng. Int. J. 2017, 1, 88–93. [Google Scholar] [CrossRef]

- Prabhu, P.R.; Sharma, S.S.; Kulkarni, S.M.; Gowrishankar, M.C. Turn-assisted deep cold rolling: An innovative manufacturing method for the improvement of fatigue life. Int. J. Appl. Eng. Res. 2015, 10, 64–68. [Google Scholar]

- Prabhu, P.R.; Kulkarni, S.M.; Sharma, S.S. Multi response optimization of the turn-assisted deep cold rolling process parameters for enhanced surface characteristics and residual stress of AISI 4140 steel shafts. J. Mater. Res. Technol. 2020, 9, 11402–11423. [Google Scholar] [CrossRef]

- Prabhu, P.R.; Prabhu, D.; Sharma, S.; Kulkarni, S.M. Surface properties and corrosion behavior of turn assisted deep cold rolled AISI 4140 steel. J. Mater. Eng. Perform. 2020, 29, 5871–5885. [Google Scholar] [CrossRef]

- Lyubenova, N. Impact of the process parameters, the measurement conditions and the pre-machining on the residual stress state of deep rolled specimens. J. Manuf. Mater. Process. 2019, 3, 56. [Google Scholar] [CrossRef]

- Martins, A.M.; Rodrigues, P.C.; Abrão, A.M. Influence of machining parameters and deep rolling on the fatigue life of AISI 4140 steel. Int. J. Adv. Manuf. Technol. 2022, 121, 6153–6167. [Google Scholar] [CrossRef]

- Martins, A.M.; Oliveira, D.A.D.; de Castro Magalhães, F.; Abrão, A.M. Relationship between surface characteristics and the fatigue life of deep rolled AISI 4140 steel. Int. J. Adv. Manuf. Technol. 2023, 129, 1127–1143. [Google Scholar] [CrossRef]

- Meyer, D.; Kämmler, J. Surface integrity of AISI 4140 after deep rolling with varied external and internal loads. Procedia CIRP 2016, 45, 363–366. [Google Scholar] [CrossRef]

- Kämmler, J.; Wielki, N.; Meyer, D. Surface integrity after internal load oriented multistage contact deep rolling. Procedia CIRP 2018, 71, 490–495. [Google Scholar] [CrossRef]

- Luo, X. Effect of deep surface rolling on microstructure and properties of AZ91 magnesium alloy. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 2019, 29, 1424–1429. [Google Scholar] [CrossRef]

- Salahshoor, M.; Guo, Y.B. Process mechanics in deep rolling of magnesium-calcium (Mgca) biomaterial. In Proceedings of the 2011 ASME International Manufacturing Science and Engineering Conference MSEC2011, Corvallis, OR, USA, 13–17 June 2017; pp. 303–311. Available online: https://asmedigitalcollection.asme.org/MSEC/proceedings-abstract/MSEC2011/303/345482 (accessed on 12 March 2020).

- Noster, U.; Altenberger, I.; Scholtes, B. Combined mechanical and thermal surface treatment of magnesium wrought alloy AZ31. Comput. Exp. Methods 2001, 6, 3–12. [Google Scholar] [CrossRef]

- Xin, C.; Sun, Q.; Xiao, L.; Sun, J. Biaxial fatigue property enhancement of gradient ultra-fine-grained Zircaloy-4 prepared by surface mechanical rolling treatment. J. Mater. Sci. 2018, 53, 12492–12503. [Google Scholar] [CrossRef]

- Juijerm, P.; Altenberger, I. Effects of deep rolling and its modification on fatigue performance of aluminium alloy AA6110. In Aluminium Alloys: New Trends in Fabrication and Applications; Ahmad, Z., Ed.; Intech Open: London, UK, 2012; Chapter 5; pp. 123–136. [Google Scholar] [CrossRef][Green Version]

- Juijerm, P.; Noster, U.; Altenberger, I.; Scholtes, B. Fatigue of deep rolled AlMg4.5Mn (AA5083) in the temperature range 20-300 °C. Mater. Sci. Eng. A 2004, 379, 286–292. [Google Scholar] [CrossRef]

- Juijerm, P.; Altenberger, I. Effective boundary of deep-rolling treatment and its correlation with residual stress stability of Al-Mg-Mn and Al-Mg-Si-Cu alloys. Scr. Mater. 2007, 56, 745–748. [Google Scholar] [CrossRef]

- Mombeini, D.; Atrian, A. Experimental and numerical investigation of the effects of deep cold rolling on the bending fatigue tolerance of C38500 brass alloy. Int. J. Adv. Manuf. Technol. 2018, 97, 3039–3053. [Google Scholar] [CrossRef]

- Majzoobi, G.H.; Jouneghani, F.Z.; Khademi, E. Experimental and numerical studies on the effect of deep rolling on bending fretting fatigue resistance of Al7075. Int. J. Adv. Manuf. Technol. 2016, 82, 2137–2148. [Google Scholar] [CrossRef]

- Zhou, Y.; Chu, X.; Zang, S.; Sun, J.; Yang, L.; Gao, J. Effect of surface integrity on fatigue life of 7075-T6 aluminum alloy by combination of fine turning with hydrostatic deep rolling. Arch. Civ. Mech. Eng. 2022, 23, 41. [Google Scholar] [CrossRef]

- Lehmann, J.; Keller, S.; Esterl, F.; Kashaev, N.; Klusemann, B.; Ben Khalifa, N. Deep Rolling for Tailoring Residual Stresses of AA2024 Sheet Metals. In Proceedings of the 14th International Conference on the Technology of Plasticity—Current Trends in the Technology of Plasticity. ICTP 2023. Lecture Notes in Mechanical Engineering; Mocellin, K., Bouchard, P.O., Bigot, R., Balan, T., Eds.; Springer: Cham, Switzerland, 2024; pp. 352–362. [Google Scholar] [CrossRef]

- Kloos, K.H.; Adelmann, J. Effect of deep rolling on fatigue properties of cast irons. J. Mech. Behav. Mater. 2011, 2, 75–86. [Google Scholar] [CrossRef]

- Nagarajan, B.; Kumar, D.; Fan, Z.; Castagne, S. Effect of deep cold rolling on mechanical properties and microstructure of nickel-based superalloys. Mater. Sci. Eng. A 2018, 728, 196–207. [Google Scholar] [CrossRef]

- Kumar, D.; Idapalapati, S.; Wang, W.; Bhowmik, A. Microstructural characteristics and strengthening mechanisms in a polycrystalline Ni-based superalloy under deep cold rolling. Mater. Sci. Eng. A 2019, 753, 285–299. [Google Scholar] [CrossRef]

- Lindemann, J.; Grossmann, K.; Raczek, T.; Wagner, L. Influence of shot peening and deep rolling on high temperature fatigue of the Ni-superalloy udimet 720 LI. In Shot Peening; Wagner, L., Ed.; Wiley Online Library: Hoboken, NJ, USA, 2006; pp. 454–460. [Google Scholar] [CrossRef]

- Lim, A.; Castagne, S.; Wong, C.C. Effect of deep cold rolling on residual stress distributions between the treated and untreated regions on Ti-6Al-4V alloy. J. Manuf. Sci. Eng. 2016, 138, 111005. [Google Scholar] [CrossRef]

- Nalla, R.K.; Altenberger, I.; Noster, U.; Liu, G.Y.; Scholtes, B.; Ritchie, R.O. On the influence of mechanical surface treatments-deep rolling and laser shock peening-on the fatigue behavior of Ti-6Al-4V at ambient and elevated temperatures. Mater. Sci. Eng. A 2003, 355, 216–230. [Google Scholar] [CrossRef]

- Han, K.; Zhang, D.; Yao, C.; Tan, L.; Zhou, Z.; Zhao, Y. Investigation of residual stress distribution induced during deep rolling of Ti-6Al-4V alloy. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 186–197. [Google Scholar] [CrossRef]

- Sattari, S.; Atrian, A. Effects of the deep rolling process on the surface roughness and properties of an Al−3vol%SiC nanoparticle nanocomposite fabricated by mechanical milling and hot extrusion. Int. J. Miner. Metall. Mater. 2017, 24, 814–825. [Google Scholar] [CrossRef]

- Sattari, S.; Atrian, A. Investigation of deep rolling effects on the fatigue life of Al-SiC nanocomposite. Mater. Res. Express 2018, 5, 015052. [Google Scholar] [CrossRef]

- Wagner, L. Mechanical surface treatments on titanium, aluminium and magnesium alloys. Mater. Sci. Eng. A 1999, 263, 210–216. [Google Scholar] [CrossRef]

- Saalfeld, S.; Wegener, T.; Scholtes, B.; Niendorf, T. Thermal stability of residual stresses in differently deep rolled surface layers of steel SAE 1045. J. Mater. Eng. Perform. 2021, 30, 6160–6166. [Google Scholar] [CrossRef]

- Oevermann, T.; Wegener, T.; Niendorf, T. On the evolution of residual stresses, microstructure and cyclic performance of high manganese austenitic TWIP steel after deep rolling. Metals 2019, 9, 825. [Google Scholar] [CrossRef]

- Cherif, A.; Hochbein, H.; Zinn, W.; Scholtes, B. Increase of fatigue strength and lifetime by deep rolling at elevated temperature of notched specimens made of steel SAE 4140. HTM J. Heat Treat. Mater. 2011, 66, 342–348. [Google Scholar] [CrossRef]

- Primee, S.Y.; Juijerm, P. Modified mechanical surface treatment for optimized fatigue performance of martensitic stainless steel AISI 420. Met. Mater. Int. 2019, 27, 946–952. [Google Scholar] [CrossRef]

- Meyer, D. Cryogenic deep rolling: An energy-based approach for enhanced cold surface hardening. CIRP Ann. 2012, 61, 543–546. [Google Scholar] [CrossRef]

- Usami, H.; Sato, S.; Saito, M.; Ando, M. Combined effects of micro shot peening and deep rolling on the fatigue. In Proceedings of the 13th International Conference on shot Peening (ICSP-13), Montreal, QC, Canada, 18–21 September 2017; pp. 478–482. Available online: https://www.shotpeener.com/library/pdf/2017116.pdf (accessed on 4 March 2020).

- Gopinath, A.; Lim, A.; Nagarajan, B.; Wong, C.C.; Maiti, R.; Castagne, S. Introduction of enhanced compressive residual stress profiles in aerospace components using combined mechanical surface treatments. IOP Conf. Ser. Mater. Sci. Eng. 2016, 157, 012013. [Google Scholar] [CrossRef]

- Gryadunov, I.M.; Radchenko, S.Y.; Dorokhov, D.O.; Morrev, P.G. Deep hardening of inner cylindrical surface by periodic deep rolling—Burnishing process. Mod. Appl. Sci. 2015, 9, 251–258. [Google Scholar] [CrossRef]

- Zheng, J.; Hou, Y.; Ming, P. Basic experiment of ultrasonic deep rolling with longitudinal-torsional vibration. Key Eng. Mater. 2016, 667, 29–34. [Google Scholar] [CrossRef]

- Bozdana, A.T.; Gindy, N.N.Z.; Li, H. Deep cold rolling with ultrasonic vibrations—A new mechanical surface enhancement technique. Int. J. Mach. Tools Manuf. 2005, 45, 713–718. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Z.; Deng, J.; Yang, M.; Dai, Q.; Zhang, T. Optimum design of compressive residual stress field caused by ultrasonic surface rolling with a mathematical model. Appl. Math. Model. 2019, 76, 800–831. [Google Scholar] [CrossRef]

- Ren, S. Enhanced surface mechanical properties of Cr12MoV using ultrasonic surface rolling process and deep cryogenic treatment. Solid State Phenom. 2018, 279, 143–147. [Google Scholar] [CrossRef]

- Kuhlemann, P.; Denkena, B.; Krödel, A.; Beblein, S. Influence of thermal effects in turn-rolling. CIRP J. Manuf. Sci. Technol. 2020, 31, 294–304. [Google Scholar] [CrossRef]

- Martins, A.M.; Leal, C.A.; Campidelli, A.F.; Abrao, A.M.; Rodrigues, P.C.; Magalhães, F.C.; Denkena, B.; Meyer, K. Assessment of the temperature distribution in deep rolling of hardened AISI 4140 steel. J. Manuf. Process. 2022, 73, 686–694. [Google Scholar] [CrossRef]

- Breidenstein, B.; Wichmann, M.; Voelker, H. Marker-free identification of turned, ground and deep rolled workpieces using wavelet transformation. Procedia CIRP 2023, 118, 1120–1125. [Google Scholar] [CrossRef]

- Strodick, S.; Vogel, F.; Tilger, M.; Denstorf, M.; Kipp, M.; Baak, N.; Kukui, D.; Biermann, D.; Barrientos, M.M.; Walther, F. Innovative X-ray diffraction and micromagnetic approaches for reliable residual stress assessment in deep rolled and microfinished AISI 4140 components. J. Mater. Res. Technol. 2022, 20, 2942–2959. [Google Scholar] [CrossRef]

- Maiß, O.; Röttger, K. Monitoring the Surface Quality for Various Deep Rolling Processes–Limits and Experimental Results. Procedia CIRP 2022, 108, 857–862. [Google Scholar] [CrossRef]

- Lyubenova, N.; Jacquemin, M.; Bähre, D. Influence of the pre-stressing on the residual stresses induced by deep rolling. Mater. Res. Proc. 2016, 2, 253–258. [Google Scholar] [CrossRef][Green Version]

- Mueller, E. A systematic investigation of the induced residual stresses by deep rolling in dependence of the prestress at spring steel. In Proceedings of the 13th International Conference on shot Peening (ICSP-13), Montreal, QC, Canada, 18–21 September 2017; pp. 401–406. Available online: https://www.shotpeener.com/library/pdf/2017103.pdf (accessed on 6 March 2020).

- Jia, Y.F. Enhanced surface strengthening of titanium treated by combined surface deep-rolling and oxygen boost diffusion technique. Corros. Sci. 2019, 157, 256–267. [Google Scholar] [CrossRef]

- Yutanorm, W.; Juijerm, P. Diffusion enhancement of low-temperature pack aluminizing on austenitic stainless steel AISI 304 by deep rolling process. Kov. Mater. 2016, 54, 227–232. [Google Scholar] [CrossRef]

- Axinte, D.A.; Gindy, N. Turning assisted with deep cold rolling—A cost efficient hybrid process for workpiece surface quality enhancement. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2004, 218, 807–811. [Google Scholar] [CrossRef]

- Denkena, B.; Poll, G.; Maiß, O.; Neubauer, T. Affecting the life time of roller bearings by an optimal surface integrity design after hard turning and deep rolling. Adv. Mater. Res. 2014, 966–967, 425–434. [Google Scholar] [CrossRef]

- Maiß, O.; Denkena, B.; Grove, T. Hybrid machining of roller bearing inner rings by hard turning and deep rolling. J. Mater. Process. Technol. 2016, 230, 211–216. [Google Scholar] [CrossRef]

- Guan, R.G.; Wang, X.; Zhao, Z.Y.; Wang, W.W.; Cao, F.R.; Liu, C.M. Microstructure and properties of A2017 alloy strips processed by a novel process by combining semisolid rolling, deep rolling, and heat treatment. Int. J. Miner. Metall. Mater. 2013, 20, 770–778. [Google Scholar] [CrossRef]

- Zhao, Z.Y. Effects of dynamic recrystallisation during deep rolling of semisolid slab and heat treatment on microstructure and properties of AZ31 alloy. Mater. Sci. Technol. 2014, 30, 309–315. [Google Scholar] [CrossRef]

- Meyer, D.; Wielki, N. Internal reinforced domains by intermediate deep rolling in additive manufacturing. CIRP Ann. 2019, 68, 579–582. [Google Scholar] [CrossRef]

- Hönnige, J.R. Residual stress and texture control in Ti-6Al-4V wire + arc additively manufactured intersections by stress relief and rolling. Mater. Des. 2018, 150, 193–205. [Google Scholar] [CrossRef]

- Uhlmann, L.; Weiser, I.F.; Herrig, T.; Bergs, T. Deep Rolling of Bores Using Centrifugal Force. Eng. Proc. 2022, 26, 20. [Google Scholar] [CrossRef]

- Wielki, N.; Heinz, N.; Meyer, D. Characterizing the local material properties of different Fe–C–Cr-steels by using deep rolled single tracks. Materials 2020, 13, 4987. [Google Scholar] [CrossRef]

- Yentzer, T.; Stillman, B.; Fisher, M.; Pardue, B.; Krafsur, D.; Khaled, T. Fatigue life and residual stresses in cold rolled propeller blades. In Proceedings of the Conference on Aging Aircrafts, Albuquerque, Mexico. 1999, pp. 1–24. Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=379f667d02f0ca5e5477c2db471d89c7f4921a2e (accessed on 12 August 2019).

- Schieber, C.; Hettig, M.; Zaeh, M.F.; Heinzel, C. Combination of Thermal and Mechanical Strategies to Compensate for Distortion Effects during Profile Grinding. Machines 2022, 10, 1240. [Google Scholar] [CrossRef]

- Klocke, F.; Mader, S. Fundamentals of the deep rolling of compressor blades for turbo aircraft engines. Steel Res. Int. 2005, 76, 229–235. [Google Scholar] [CrossRef]

- Zhuang, W.; Wicks, B. Mechanical surface treatment technologies for gas turbine engine components. J. Eng. Gas Turbines Power 2003, 125, 1021–1025. [Google Scholar] [CrossRef]

- Fu, H.; Liu, Y.; Xu, Q.; Yan, X.; Yang, G.; Chen, H. Effect of deep rolling parameters on surface integrity of LZ50 axles. Int. J. Mod. Phys. B 2019, 33, 1950298. [Google Scholar] [CrossRef]

- Regazzi, D.; Beretta, S.; Carboni, M. An investigation about the influence of deep rolling on fatigue crack growth in railway axles made of a medium strength steel. Eng. Fract. Mech. 2014, 131, 587–601. [Google Scholar] [CrossRef]

- Pertoll, T.; Buzzi, C.; Dutzler, A.; Leitner, M.; Seisenbacher, B.; Winter, G.; Boronkai, L. Experimental and numerical investigation of the deep rolling process focusing on 34CrNiMo6 railway axles. Int. J. Mater. Form. 2023, 16, 51. [Google Scholar] [CrossRef]

- Udalov, A.A.; Parshin, S.V.; Udalov, A.V.; Vasilevykh, S.L. Power parameters of the process of hardening of cylindrical parts by a toroidal roller by the method of surface plastic deformation. J. Phys. Conf. Ser. 2019, 1210, 012150. [Google Scholar] [CrossRef]

- Qiao, Y.; Chen, H.; Qi, K.; Guo, P. Research on mechanical properties of 210cr12 shaft surface processed with rolling. Coatings 2020, 10, 611. [Google Scholar] [CrossRef]

- Galzy, F.; Michaud, H.; Sprauel, J.M. Approach of residual stress generated by deep rolling application to the reinforcement of the fatigue resistance of crankshafts. Mater. Sci. Forum 2005, 490–491, 384–389. [Google Scholar] [CrossRef]

- Michaud, H.; Sprauel, J.M.; Galzy, F. The residual stresses generated by deep rolling and their stability in fatigue and application to deep rolled crankshafts. Mater. Sci. Forum 2006, 524–525, 45–50. [Google Scholar] [CrossRef]

- Cevik, M.C.; Hochbein, H.; Rebbert, M. Potentials of crankshaft fillet rolling process. SAE Int. J. Engines 2012, 5, 622–632. [Google Scholar] [CrossRef]

- Bertini, L.; Santus, C.; Merlo, A.; Bandini, M. A fretting fatigue setup for testing shrink-fit connections and experimental evidence of the strength enhancement induced by deep rolling. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 230, 1432–1439. [Google Scholar] [CrossRef]

- Cheng, M.; Zhang, D.; Chen, H.; Qin, W. Development of ultrasonic thread root rolling technology for prolonging the fatigue performance of high strength thread. J. Mater. Process. Technol. 2014, 214, 2395–2401. [Google Scholar] [CrossRef]

- Wang, X.; Xiong, X.; Huang, K.; Ying, S.; Tang, M.; Qu, X.; Ji, W.; Qian, C.; Cai, Z. Effects of Deep Rolling on the Microstructure Modification and Fatigue Life of 35Cr2Ni4MoA Bolt Threads. Metals 2022, 12, 1224. [Google Scholar] [CrossRef]

- Reggiani, B.; Olmi, G. Experimental investigation on the effect of shot peening and deep rolling on the fatigue response of high strength fasteners. Metals 2019, 9, 1093. [Google Scholar] [CrossRef]

- Perenda, J.; Trajkovski, J.; Žerovnik, A.; Prebil, I. Modeling and experimental validation of the surface residual stresses induced by deep rolling and presetting of a torsion bar. Int. J. Mater. Form. 2016, 9, 435–448. [Google Scholar] [CrossRef]

- Močilnik, V.; Gubeljak, N.; Predan, J. Effect of residual stresses on the fatigue behaviour of torsion bars. Metals 2020, 10, 1056. [Google Scholar] [CrossRef]

- Maiß, O.; Röttger, K.; Meyer, K. Increase the Ressource Efficiency by Evaluation of the Effects of Deep Rolling within the Design and Manufacturing Phase. In Future Automotive Production Conference 2022, Zukunftstechnologien für den Multifunktionalen Leichtbau; Dröder, K., Vietor, T., Eds.; Springer: Wiesbaden, Germany, 2023; pp. 86–96. [Google Scholar] [CrossRef]

- Baisukhan, A.; Nakkiew, W. Influence of deep rolling process parameters on surface residual stress of aa7075-t651 aluminum alloy friction stir welded joint. Mater. Sci. Forum 2018, 939, 23–30. [Google Scholar] [CrossRef]

- Baisukhan, A.; Nakkiew, W. Effects of deep rolling on surface residual stress and Microhardness of JIS SS400 MIG welding. Mater. Sci. Forum 2018, 939, 31–37. [Google Scholar] [CrossRef]

- Heikebrügge, S.; Breidenstein, B.; Bergmann, B.; Dänekas, C.; Schaumann, P. Experimental and Numerical Investigations of the Deep Rolling Process to Analyze the Local Deformation Behavior of Welded Joints. J. Manuf. Mater. Process. 2022, 6, 50. [Google Scholar] [CrossRef]

- Dänekas, C.; Heikebrügge, S.; Schubnell, J.; Schaumann, P.; Breidenstein, B.; Bergmann, B. Influence of deep rolling on surface layer condition and fatigue life of steel welded joints. Int. J. Fatigue 2022, 162, 106994. [Google Scholar] [CrossRef]

- Schubnell, J.; Dahmen, M.; Luke, M. Strength improvement of laser beam welded joints in cold worked high-manganese-steel by means of deep rolling. Procedia CIRP 2022, 111, 457–461. [Google Scholar] [CrossRef]

- Bhargava, V.; Hahn, G.T.; Rubin, C.A. An elastic-plastic finite element model of rolling contact. Part 1: Analysis of single contacts. J. Appl. Mech. 1985, 52, 67–74. [Google Scholar] [CrossRef]

- Bhargava, V.; Hahn, G.T.; Rubin, C.A. An elastic-plastic finite element model of rolling contact. Part 2: Analysis of repeated contacts. J. Appl. Mech. 1985, 52, 75–82. [Google Scholar] [CrossRef]

- Donzella, G.; Guagliano, M.; Vergani, L. Experimental investigations and numerical analyses on deep rolling residual stresses. Trans. Eng. Sci. 1993, 2, 589–598. [Google Scholar] [CrossRef]

- Guagliano, M.; Vergani, L. Residual stresses induced by deep rolling in notched components. J. Mech. Behav. Mater. 1998, 9, 129–140. [Google Scholar] [CrossRef]

- Demurger, J.; Forestier, R.; Kieber, B.; Lasne, P. Deep rolling process simulation: Impact of kinematic hardening on residual stresses. In Proceedings of the 9th International Conference on Material Forming ESAFORM, Glasgow, UK, 26–28 April 2006; pp. 1–5. Available online: https://www.researchgate.net/profile/Demurger-Joelle/publication/283993247 (accessed on 3 March 2020).

- Choi, K.S.; Pan, J. Simulations of stress distributions in crankshaft sections under fillet rolling and bending fatigue tests. Int. J. Fatigue 2009, 31, 544–557. [Google Scholar] [CrossRef]

- Majzoobi, G.H.; Azadikhah, K.; Nemati, J. The effects of deep rolling and shot peening on fretting fatigue resistance of Aluminum-7075-T6. Mater. Sci. Eng. A 2009, 516, 235–247. [Google Scholar] [CrossRef]

- Bäcker, V.; Klocke, F.; Wegner, H.; Timmer, A.; Grzhibovskis, R.; Rjasanow, S. Analysis of the deep rolling process on turbine blades using the FEM/BEM-coupling. IOP Conf. Ser. Mater. Sci. Eng. 2014, 10, 012134. [Google Scholar] [CrossRef]

- Manouchehrifar, A.; Alasvand, K. Simulation and research on deep rolling process parameters. Int. J. Adv. Des. Manuf. Technol. 2012, 5, 31–37. [Google Scholar]

- Nicoletto, G.; Saletti, A. Fatigue assessment of notched steel including residual stresses obtained by the rolling process. SDHM Struct. Durab. Health Monit. 2012, 8, 131–148. [Google Scholar] [CrossRef]

- Liou, J.J.; El-Wardany, T.I. Numerical investigation of lubricated deep rolling process in a complex roller path. Adv. Mater. Res. 2014, 966–967, 406–424. [Google Scholar] [CrossRef]

- Kumar, P.K.; Raviraj, A.; Prabhu, P.R.; Laxmikanth, K. Deep cold rolling simulation of AISI 4140 steel using ANSYS LSDYNA. In Proceedings of the 3rd World Conference on Applied Sciences, Engineering and Technology, San Francisco, CA, USA, 22–24 October 2014; pp. 27–29. [Google Scholar]

- Lim, A.; Castagne, S.; Wong, C.C. Effect of friction coefficient on finite element modeling of the deep cold rolling process. In Proceedings of the 12th International Conference on Shot Peening, Goslar, Germany, 15–18 September 2014; Volume 12, pp. 376–380. Available online: https://www.shotpeener.com/library/pdf/2014106.pdf (accessed on 15 January 2020).

- Hassani-Gangaraj, S.M.; Carboni, M.; Guagliano, M. Finite element approach toward an advanced understanding of deep rolling induced residual stresses, and an application to railway axles. Mater. Des. 2015, 83, 689–703. [Google Scholar] [CrossRef]

- Lyubenova, N.; Bahre, D. The impact of the material modeling on the calculated residual stresses induced by deep rolling the impact of the material modeling on the calculated residual stresses induced by deep rolling. In Proceedings of the International Materials Research Meeting in the Greater Region: Current Trends in the Characterization of Materials and Surface Modification, Saarbruecken, Germany, 6–7 April 2017; pp. 65–66. Available online: https://www.researchgate.net/profile/Nataliya-Lyubenova/publication/317955696 (accessed on 4 March 2020).

- Zaharevskis, V.; Kurushin, A.; Kovzels, O. Use of FEM numerical simulation approach for surface rolling process control. Eng. Rural. Dev. 2018, 17, 1378–1383. [Google Scholar] [CrossRef]

- Kinner-Becker, T.; Sölter, J.; Karpuschewski, B. A simulation-based analysis of internal material loads and material modifications in multi-step deep rolling. Procedia CIRP 2020, 87, 515–520. [Google Scholar] [CrossRef]

- Kinner-Becker, T.; Hettig, M.; Sölter, J.; Meyer, D. Analysis of internal material loads and Process Signature Components in deep rolling. CIRP J. Manuf. Sci. Technol. 2021, 35, 400–409. [Google Scholar] [CrossRef]

- Kinner-Becker, T.; Sölter, J. Influence of initial stress on the residual stress generated by deep rolling. Procedia CIRP 2023, 117, 128–132. [Google Scholar] [CrossRef]

- Bialowas, J.; Pletz, M.; Gapp, S.; Maierhofer, J. A method to reduce computation time in finite element simulations of deep rolling. Procedia Struct. Integr. 2023, 46, 49–55. [Google Scholar] [CrossRef]

- Fonseca, L.G.A.; Faria, A.R.D. A deep rolling finite element analysis procedure for automotive crankshafts. J. Strain Anal. Eng. Des. 2018, 53, 178–188. [Google Scholar] [CrossRef]

- Fonseca, L.G.A.; Faria, A.R.D. Crankshaft deep rolling analysis through energy balance simulation output. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 430. [Google Scholar] [CrossRef]

- Pertoll, T.; Buzzi, C.; Leitner, M.; Boronkai, L. Numerical parameter sensitivity analysis of residual stresses induced by deep rolling for a 34CrNiMo6 steel railway axle. Int. J. Adv. Manuf. Technol. 2024, 131, 483–504. [Google Scholar] [CrossRef]

- Morrev, P.G.; Gordon, V.A. Simulation of surface hardening in the deep rolling process by means of an axial symmetric nodal averaged finite element. J. Phys. Conf. Ser. 2018, 973, 012013. [Google Scholar] [CrossRef]

- Heikebrügge, S.; Breidenstein, B.; Bergmann, B.; Dänekas, C.; Schaumann, P.; Schubnell, J. Identification of material properties for finite element simulation of the deep rolling process applied to welded joints. Procedia CIRP 2022, 115, 30–35. [Google Scholar] [CrossRef]

- Abrão, A.M.; Denkena, B.; Breidenstein, B.; Mörke, T. Surface and subsurface alterations induced by deep rolling of hardened AISI 1060 steel. Prod. Eng. 2014, 8, 551–558. [Google Scholar] [CrossRef]

- Prabhu, P.R. Investigation on Effect of Process Parameters for Fatigue Life Improvement Using Turn Assisted Deep Cold Rolling Process. Ph.D. Thesis, Manipal University, Manipal, India, 2014. [Google Scholar]

- Esme, U.; Sagbas, A.; Kahraman, F.; Kulekci, K. Use of artificial neural networks in ball burnishing process for the prediction of surface roughness of AA 7075 aluminum alloy. Mater. Tehnol. 2008, 42, 215–219. [Google Scholar]

- Tang, S.H.; Hakim, N.; Khaksar, W.; Sulaiman, S.; Ariffin, M.K.A.; Samin, R. Artificial Neural Network (ANN) Approach for Predicting Friction Coefficient of Roller Burnishing AL6061. Int. J. Mach. Learn. Comput. 2012, 2, 825–830. Available online: https://www.ijmlc.org/papers/246-K30002.pdf (accessed on 3 March 2020). [CrossRef][Green Version]

- Kluz, R.; Antosz, K.; Trzepieciński, T.; Bucior, M. Modelling the influence of slide burnishing parameters on the surface roughness of shafts made of 42CrMo4 heat-treatable steel. Materials 2021, 14, 1175. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Nguyen, T.A.; Trinh, Q.H.; Le, X.B.; Pham, L.H.; Le, X.H. Artificial neural network-based optimization of operating parameters for minimum quantity lubrication-assisted burnishing process in terms of surface characteristics. Neural Comput. Appl. 2022, 34, 7005–7031. [Google Scholar] [CrossRef]

| AISI/SAE (ASTM A29) | IS (5517) | BS 970 (1955 EN) | BS 970 (1983/1991) | DIN (10083-1) | Werk Stoff | JIS (G4051) |

| 1040 | 40C8 | EN 8 | 080M40 | C40 | 1.1186 | S40C |

| Elements | C | Mn | Si | S | P | Cu | Fe |

|---|---|---|---|---|---|---|---|

| Range | 0.35–0.45 | 0.6–1.0 | 0.03–0.35 | 0.06 (max) | 0.06 (max) | 0.06 (max) | balance |

| Standard | 0.4 | 0.11 | 0.03 | 0.03 | 0.01 | 0.03 | balance |

| Properties | Parameters | Metric Units |

|---|---|---|

| Physical Properties | Density | 7845 kg/m3 |

| Melting point | 1521 °C | |

| Mechanical Properties | Tensile strength | 620 MPa |

| Yield strength | 415 MPa | |

| Elongation at fracture | 25% | |

| Reduction of area | 50% | |

| Elastic modulus | 200 GPa | |

| Bulk modulus | 140 GPa | |

| Shear modulus | 80 GPa | |

| Poison’s ratio | 0.29 | |

| Hardness (BHN) | 201 | |

| Hardness (HRB) | 93 | |

| Hardness (HRC) | 13 | |

| Hardness (HV) | 211 | |

| Izod Impact (as-rolled) | 49 J | |

| Thermal Properties | Coefficient of thermal expansion | 11.3 μm/°C |

| Thermal conductivity | 50.7 W/mK |

| Author and Year | Materials, Process Parameters, etc. | Methods and Characterization | Key Findings |

|---|---|---|---|

| A. M. Abrao et al., 2014, 2015 [17,36] | Material: AISI 1060; Process: DR; Parameters: Rolling pressure/force, tool passes, ball diameter, and initial state of the material. | Experimental: Surface roughness, hardness, and CRS state and stability under cyclic loads. |

|

| D. Meyer and J. Kammler, 2016 [50] | Material: AISI 4140 steel; Process: DR; Parameters: Rolling pressure/force and ball diameter. | Analytical: Equivalent stress for estimating surface stress fields; Experimental: Residual stress state. |

|

| A. Tadi et al., 2017 [43] | Material: AISI 316L steel; Process: DR; Parameters: Rolling pressure/ force, feed, and tool passes (15 and 26). | Experimental: Hardness and microstructure. |

|

| J. M. Cubillos et al., 2017 [42] | Material: AISI 304 and AISI 316 steels; Process: DR; Parameters: Rolling pressure/ force, and feed. | Experimental: Surface roughness, hardness, residual stress state, and fatigue performance. |

|

| D. Meyer and J. Kammler, 2018 [31] | Material: X210Cr12, X120CrMn5 and X150CrMn9 steels; Process: DR; Parameters: At constant rolling pressure, feed, speed, and ball diameter. | Analytical: Equivalent stress for estimating surface stress fields; Experimental: Surface hardness and phase. |

|

| N. Lyubenova et al., 2019 [47] | Material: AISI 4140 steel; Process: DR; Parameters: Rolling pressure, number of tool passes, overlap percentage, pre-machining state, and measurement techniques. | Experimental: Residual stress state. |

|

| P. R. Prabhu et al., 2015, 2020 [44,45,46] | Material: AISI 4140 steel; Process: DR; Parameters: Rolling ball material and size, rolling pressure/force, number of roll passes, initial surface roughness, coolant, feed rate, and speed. | Experimental: Surface roughness, hardness, residual stress state, fatigue performance, and corrosion resistance; Statistical: To establish the appropriate combination of parameters; Numerical: Residual stress states. |

|

| F. F. Do-Santos et al., 2021 [38] | Material: AISI 1020, AISI 1065, and AISI 1080 steels; Process: DR; Parameters: Impact of the carbon fraction, rolling pressure/force, tool passes, feed rate, and speed. | Experimental: Surface roughness, hardness, and microstructure. |

|

| A. M. Martins et al., 2022, 2023 [48,49] | Material: AISI 4140 steel; Process: Turning with subsequent DR; Turning Parameters: Depth of cut, feed, cutting speed; DR parameters: Rolling pressure, speed, feed, and turned surface state. | Experimental: Surface roughness, fatigue performance, fractography, microstructure, and microhardness; Statistical: To determine the parameter effect and establish the appropriate combination of parameters. |

|

| Author and Year | Materials, Process, Parameters, etc. | Methods and Characterization | Key Findings |

|---|---|---|---|

| K. Kumar et al., 2014 [138] | Workpiece: AISI 4140 steel, elastic–plastic deformable body, Cowper–Symonds model. DR Tool: Ball, rigid body, revolves about the axis and translates. FEA tool: ANSYS LS-DYNA explicit dynamics module. | Simulation: 2D, displacement-controlled. Parameter: Residual stress state, surface roughness. Validation: experimental results. |

|

| S. M. Gangaraj et al., 2015 [140] | Workpiece: EA4T steel, elastic–plastic deformable body, JC model. DR Tool: Roller, rigid body, revolves about the axis and translates. FEA tool: ABAQUS, explicit dynamics module. | Simulation: 3D, load-controlled. Parameter: Residual stress state. Validation: Experimental results. |

|

| J. Perenda et al., 2016 [119] | Workpiece: TORKA steel, elastic–plastic deformable body, LC model. DR Tool: Roller, rigid body, revolves about the axis and translates. FEA tool: ABAQUS, explicit dynamics module. | Simulation: 3D, load-controlled. Parameter: Residual stress state, equivalent plastic strain. Validation: Experimental results. |

|

| N. Lyubenova and D. Bahre, 2017 [141] | Workpiece: AISI 4140 steel, elastic–plastic deformable body, four different material models. DR Tool: Ball, rigid body, revolves about axis and translates. FEA tool: ABAQUS 6.14v, explicit dynamics module. | Simulation: 3D, load-controlled. Parameter: Residual stress state. Validation: Experimental results. |

|

| V. Zaharevskis et al., 2018 [142] | Workpiece: Material not specified; deformable condition modeled with stress–strain data, revolves about axis. DR Tool: Roller, rigid body, revolves about the axis and translates. FEA tool: MSC Marc and Mentat. | Simulation: 3D, load-controlled. Parameter: Hardening quality. Validation: Ring-cut method experimental results. |

|

| T. Kinner-Becker et al., 2020, 2021, 2023 [143,144,145] | Workpiece: AISI 4140 steel, deformable body, Chaboche nonlinear kinematic hardening material model. DR Tool: Ball, rigid body, revolves about the axis and translates. FEA tool: ABAQUS, quasi-static implicit and explicit approaches. | Simulation: 3D, both load- and displacement-controlled. Parameter: Residual stress state, equivalent plastic strain. Validation: Experimental results. |

|

| J. Bialowas et al., 2023 [146] | Workpiece: Railway axel material, cyclic material behavior, combined isotropic–kinematic hardening material model.DR Tool: Roller, rigid body, revolves about the axis and translates. FEA tool: ABAQUS, implicit analysis with periodic boundary conditions. | Simulation: 3D, load-/displacement-controlled. Parameter: Residual stress state, equivalent plastic strain, FE computation time. Validation: Not reported. |

|

| Author and Year | Key Findings |

|---|---|

| C. C. Wong et al., 2014 [21] |

|

| A. M. Abrao et al. 2014 [152] |

|

| P. R. Prabhu et al. 2014 [153] |

|

| S. Sattari and A. Atrian, 2017 [70] |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noronha, D.J.; Sharma, S.; Prabhu Parkala, R.; Shankar, G.; Kumar, N.; Doddapaneni, S. Deep Rolling Techniques: A Comprehensive Review of Process Parameters and Impacts on the Material Properties of Commercial Steels. Metals 2024, 14, 667. https://doi.org/10.3390/met14060667

Noronha DJ, Sharma S, Prabhu Parkala R, Shankar G, Kumar N, Doddapaneni S. Deep Rolling Techniques: A Comprehensive Review of Process Parameters and Impacts on the Material Properties of Commercial Steels. Metals. 2024; 14(6):667. https://doi.org/10.3390/met14060667

Chicago/Turabian StyleNoronha, Dilifa Jossley, Sathyashankara Sharma, Raghavendra Prabhu Parkala, Gowri Shankar, Nitesh Kumar, and Srinivas Doddapaneni. 2024. "Deep Rolling Techniques: A Comprehensive Review of Process Parameters and Impacts on the Material Properties of Commercial Steels" Metals 14, no. 6: 667. https://doi.org/10.3390/met14060667

APA StyleNoronha, D. J., Sharma, S., Prabhu Parkala, R., Shankar, G., Kumar, N., & Doddapaneni, S. (2024). Deep Rolling Techniques: A Comprehensive Review of Process Parameters and Impacts on the Material Properties of Commercial Steels. Metals, 14(6), 667. https://doi.org/10.3390/met14060667