Effect of Nd on Functional Properties of Biodegradable Zn Implants in In Vitro Environment

Abstract

1. Introduction

2. Experimental Methods

2.1. Preparation of Tested Alloys

2.2. Microstructure Analysis

2.3. Mechanical Properties

2.4. Corrosion Resistance and Electrochemical Performance

2.5. Cytotoxicity Evaluation

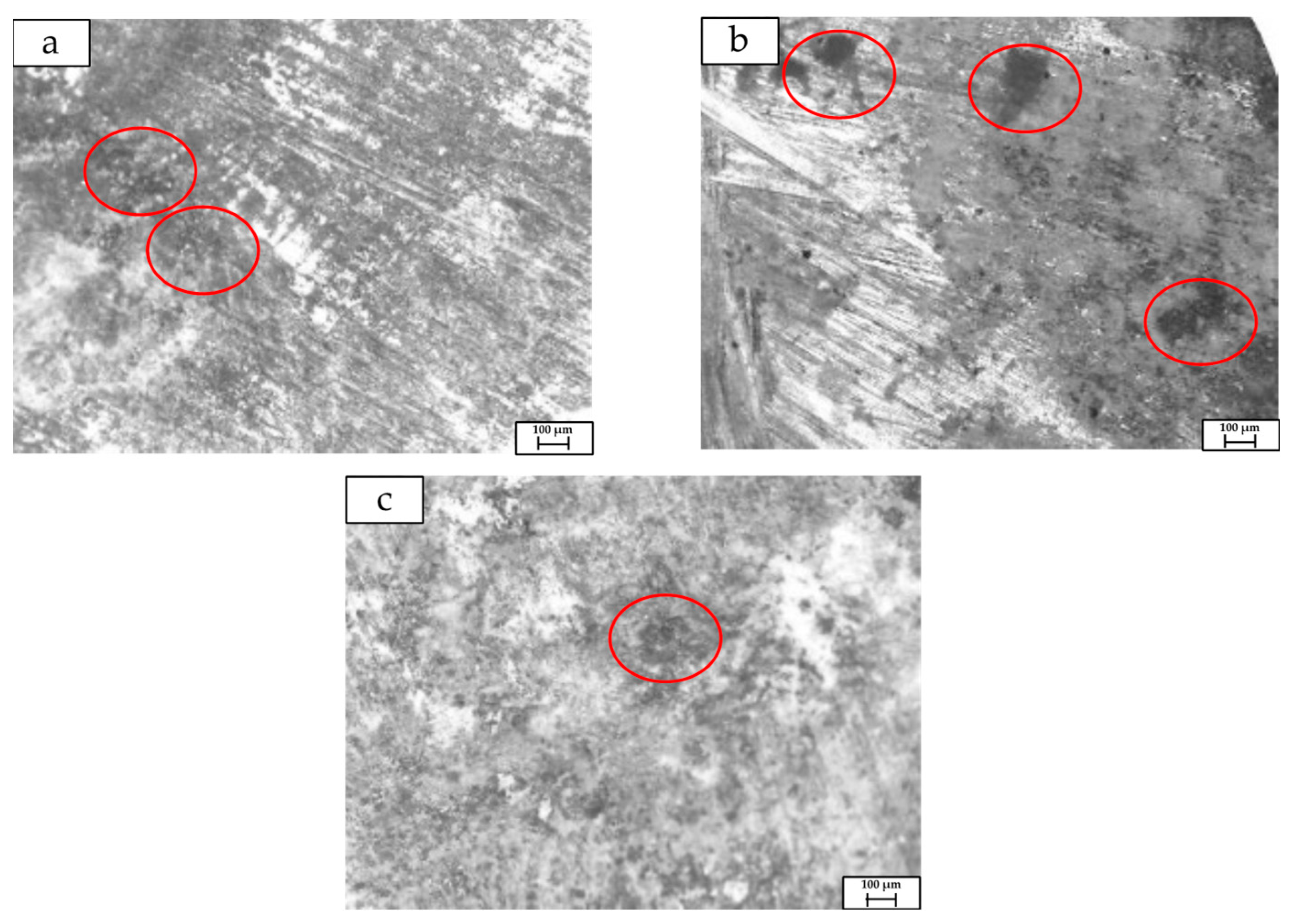

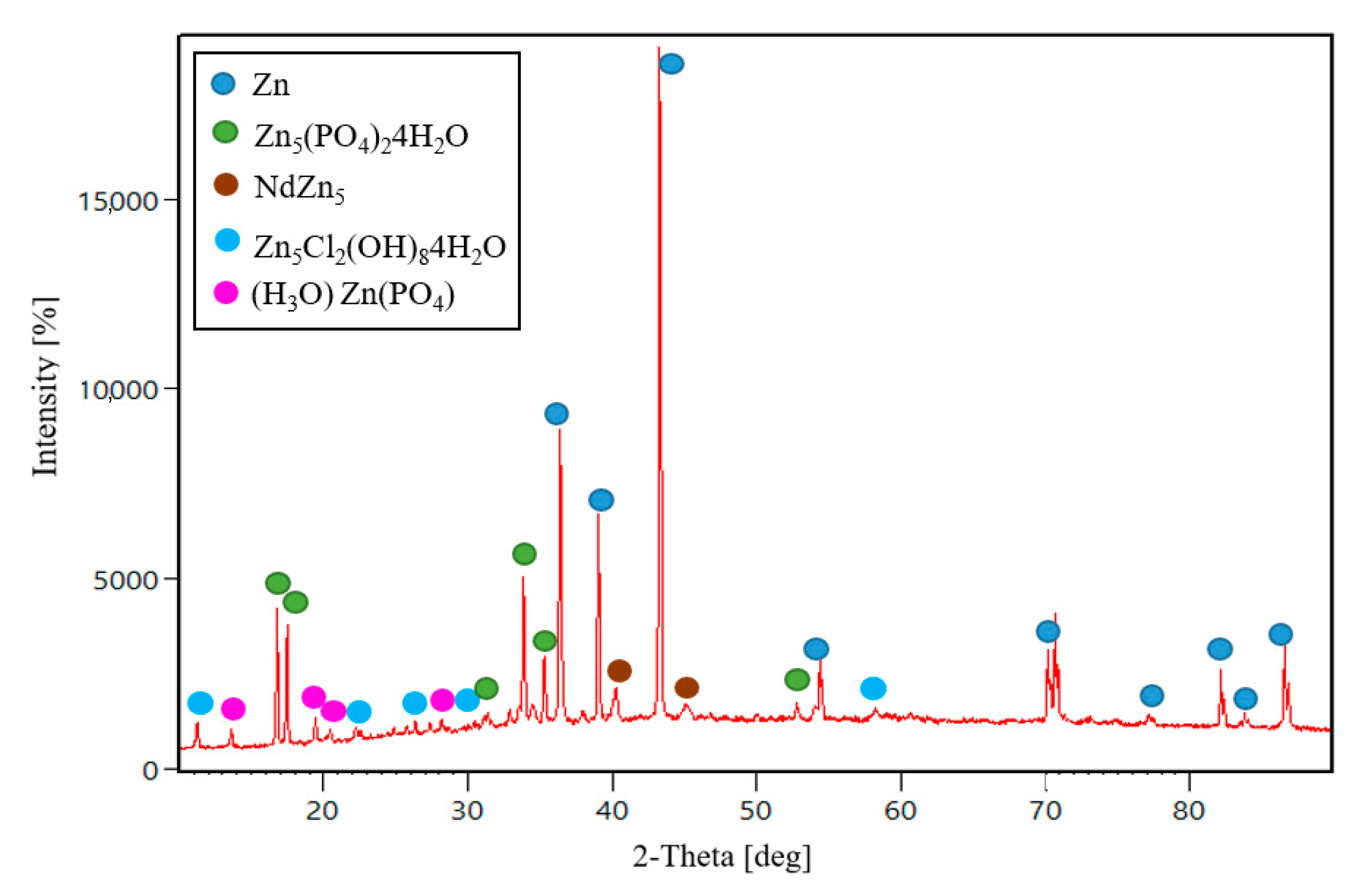

3. Results

4. Discussion

5. Conclusions

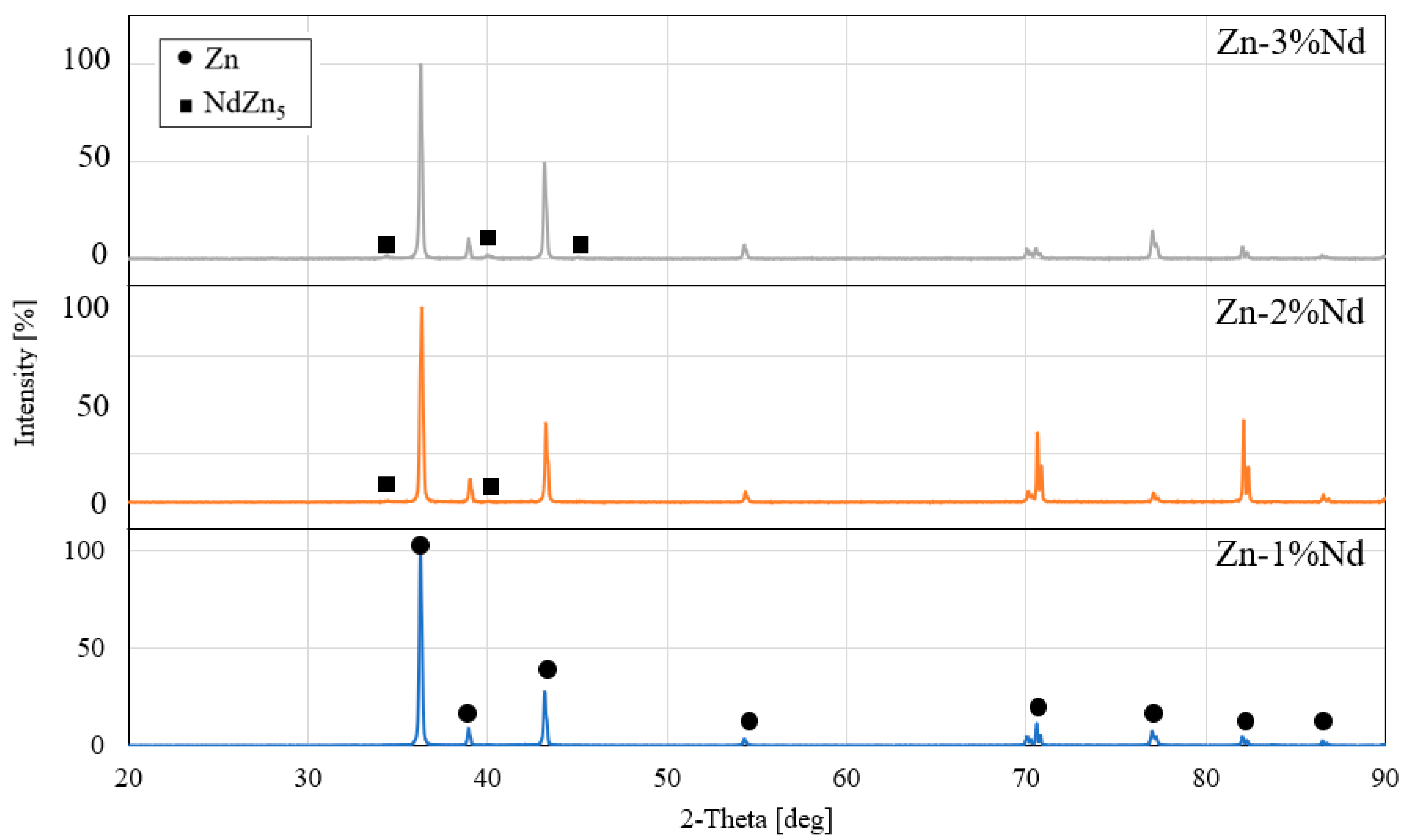

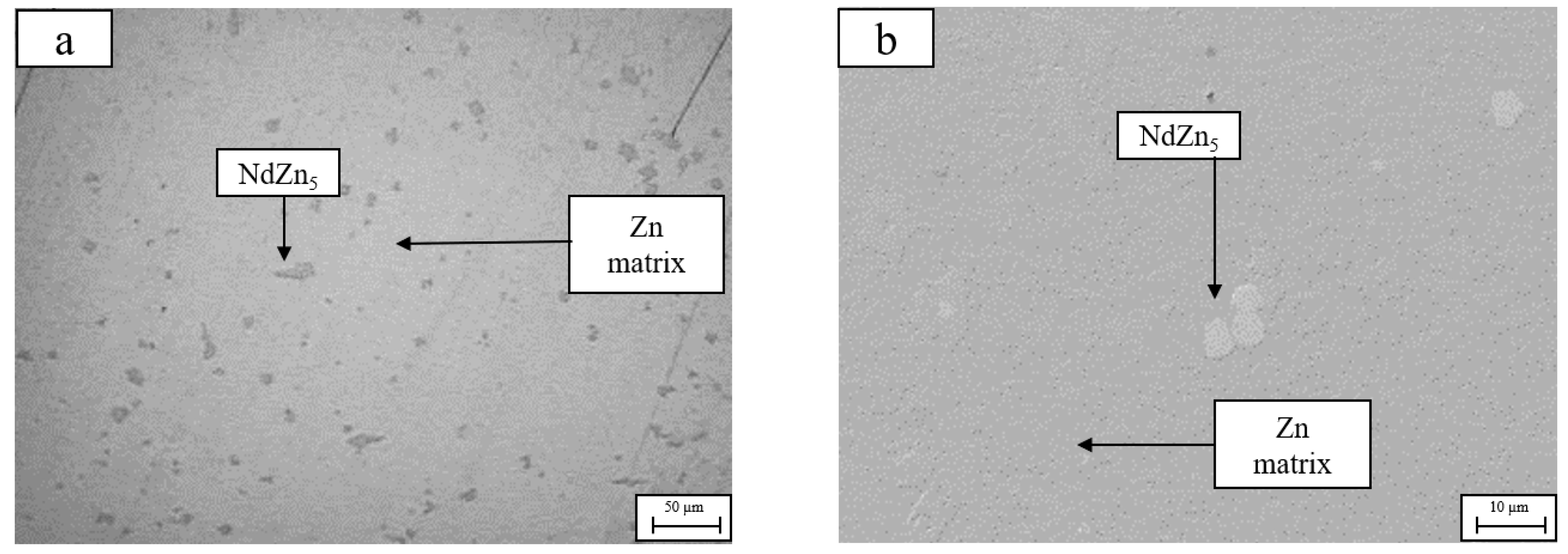

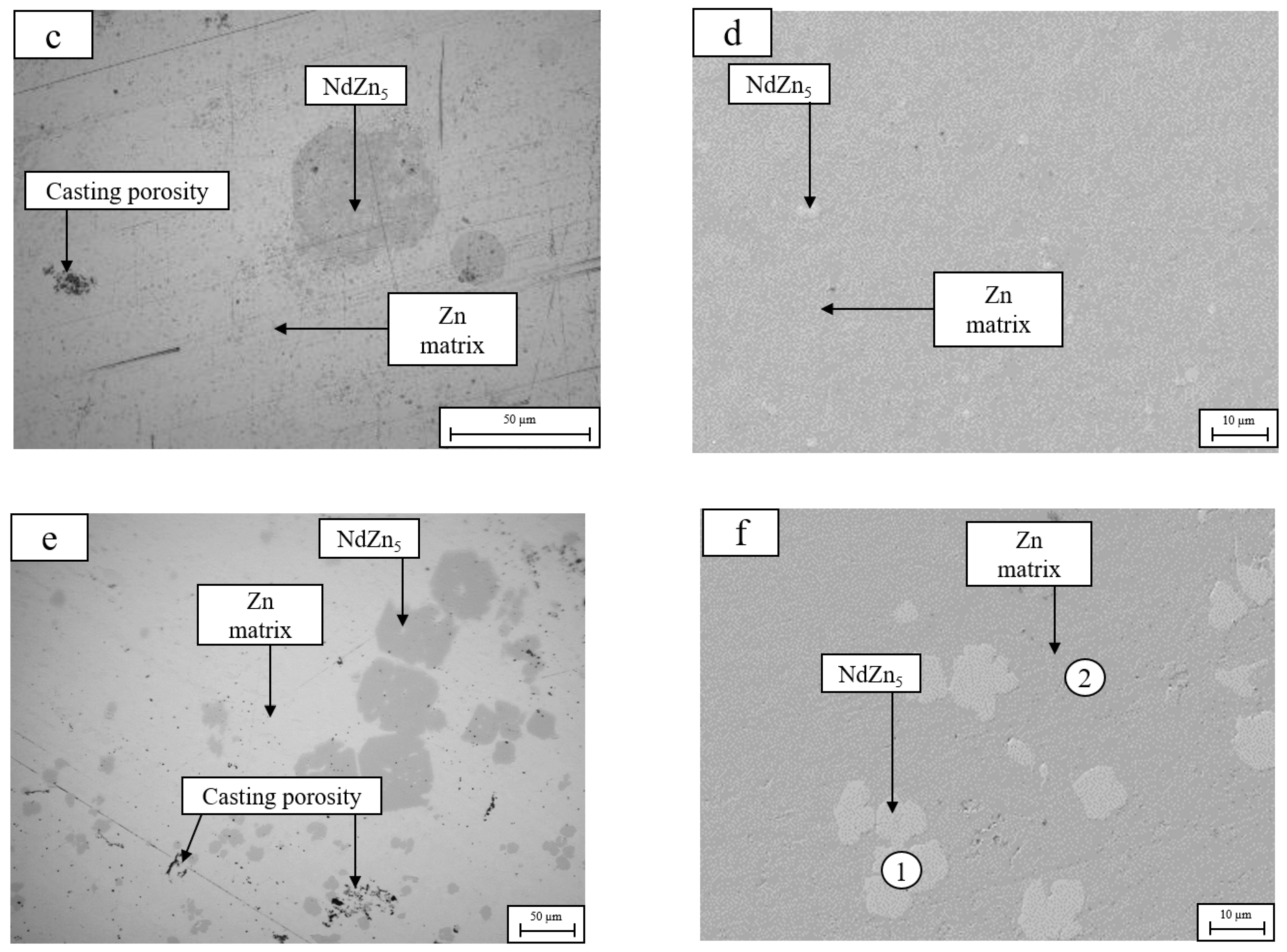

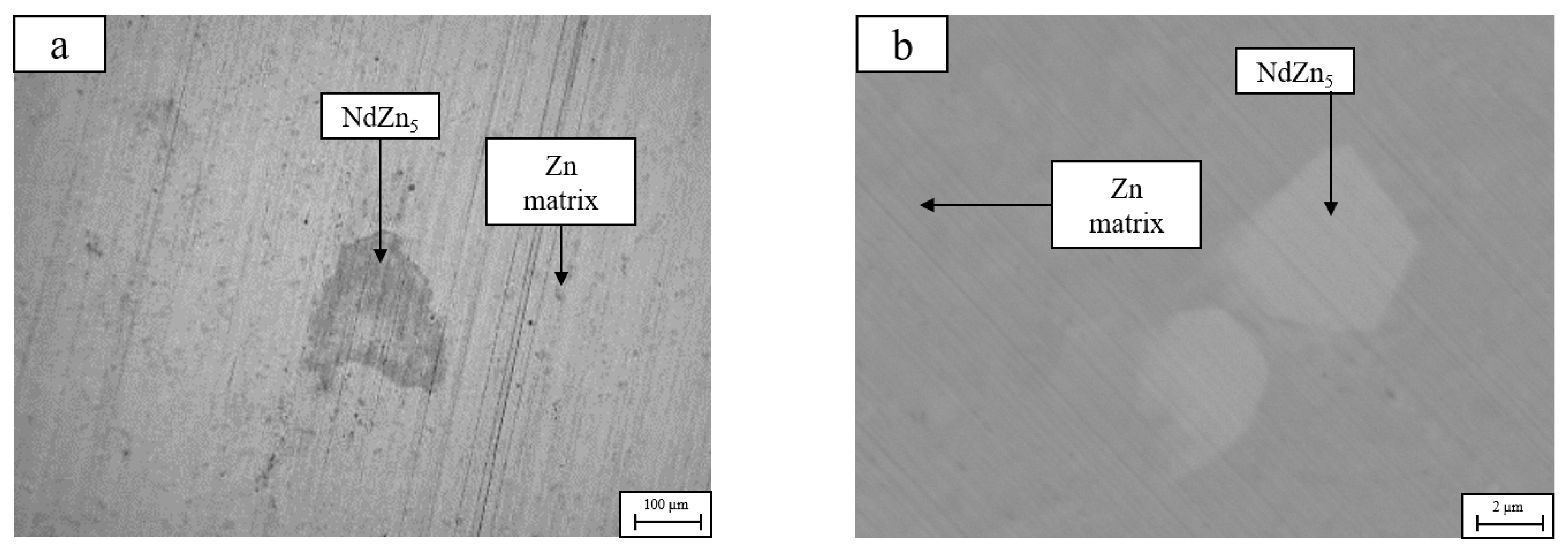

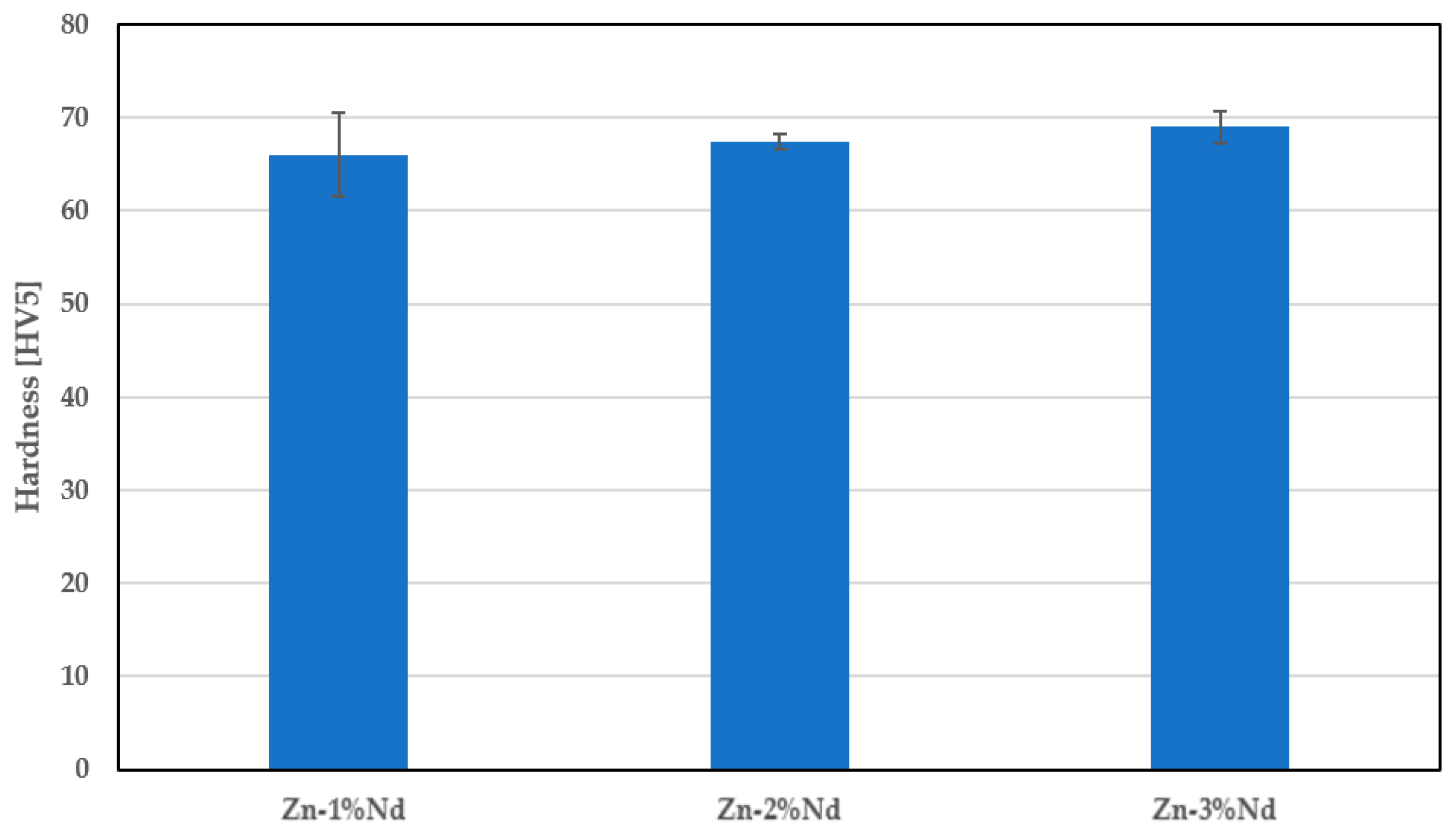

- The addition of up to 3%Nd to pure Zn has a significant strengthening effect in terms of mechanical properties and a minor favorable effect on ductility. The reinforcing effect was mainly attributed to the generation of a secondary phase NdZn5.

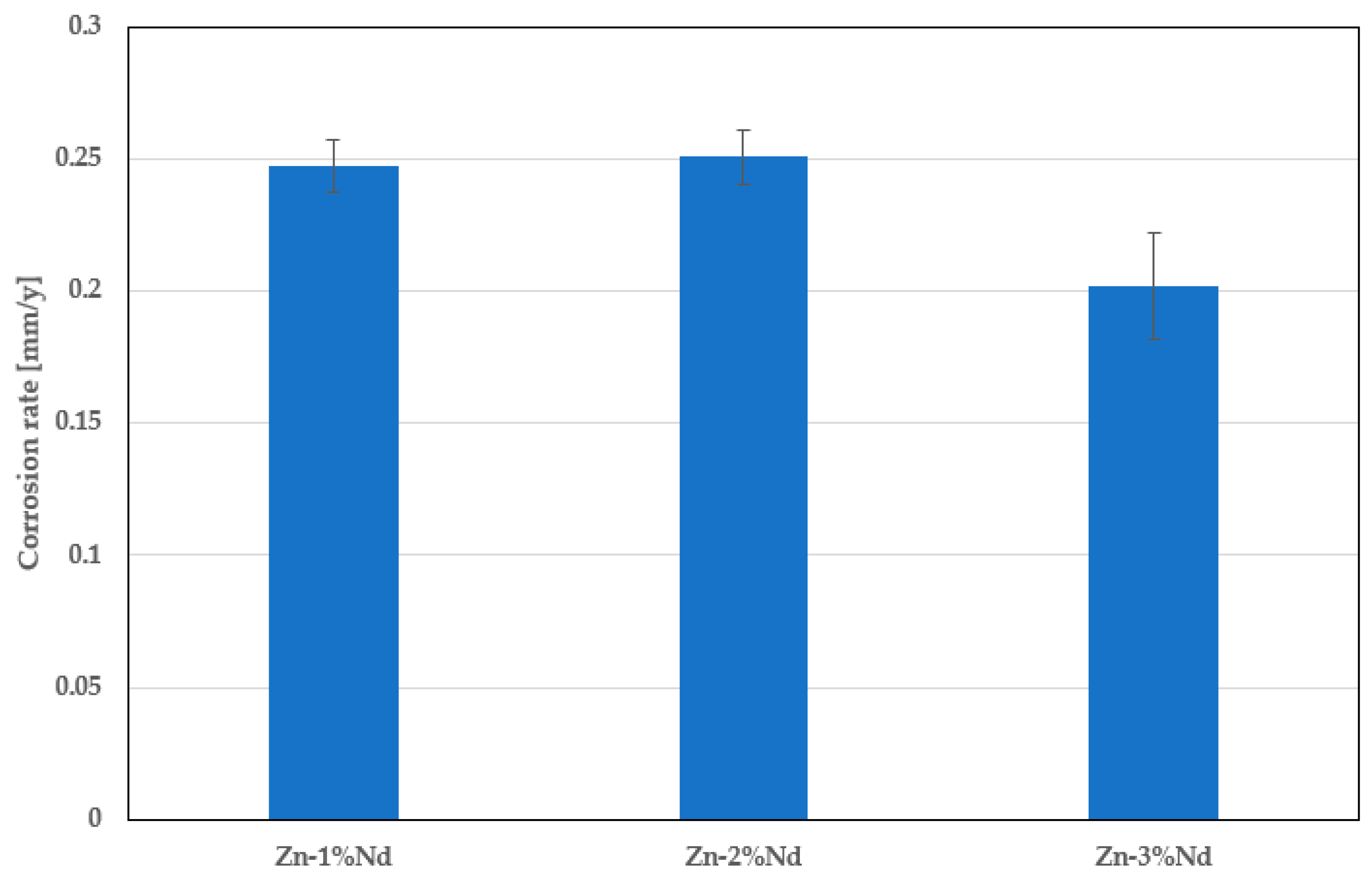

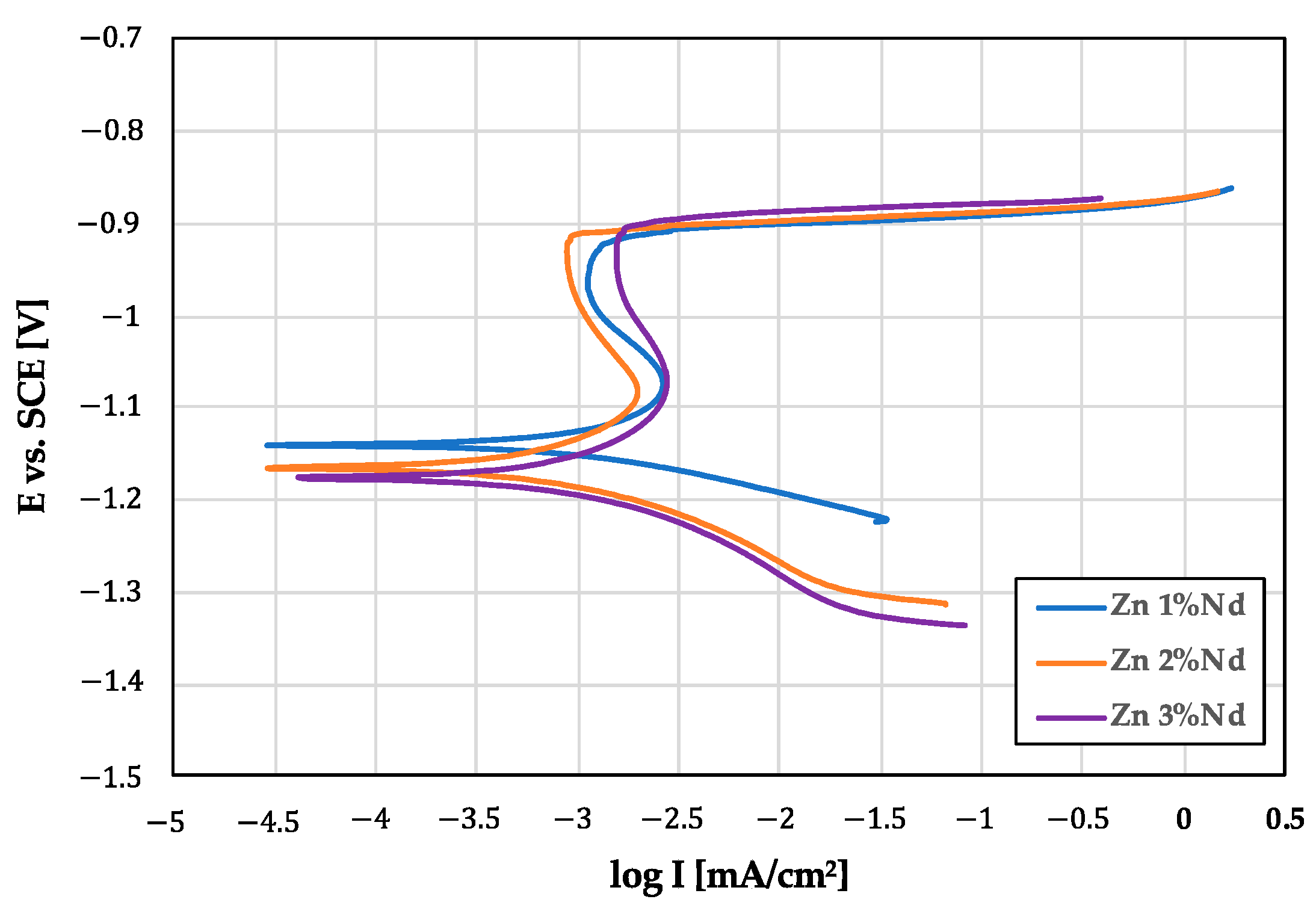

- In vitro corrosion assessment in simulated environmental conditions (PBS solution at 37 °C) showed that the addition of Nd did not have any deteriorating effect on the corrosion resistance.

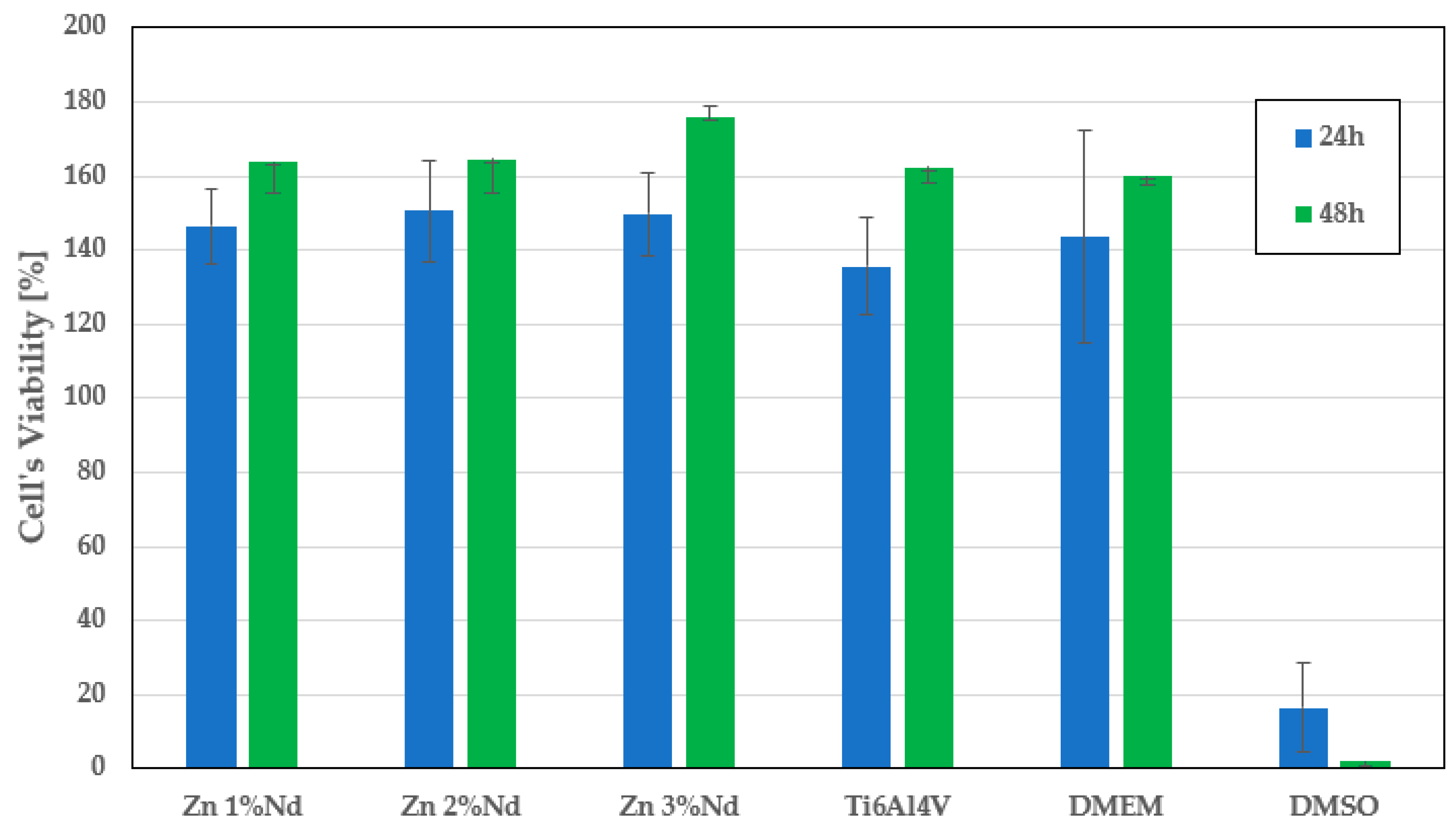

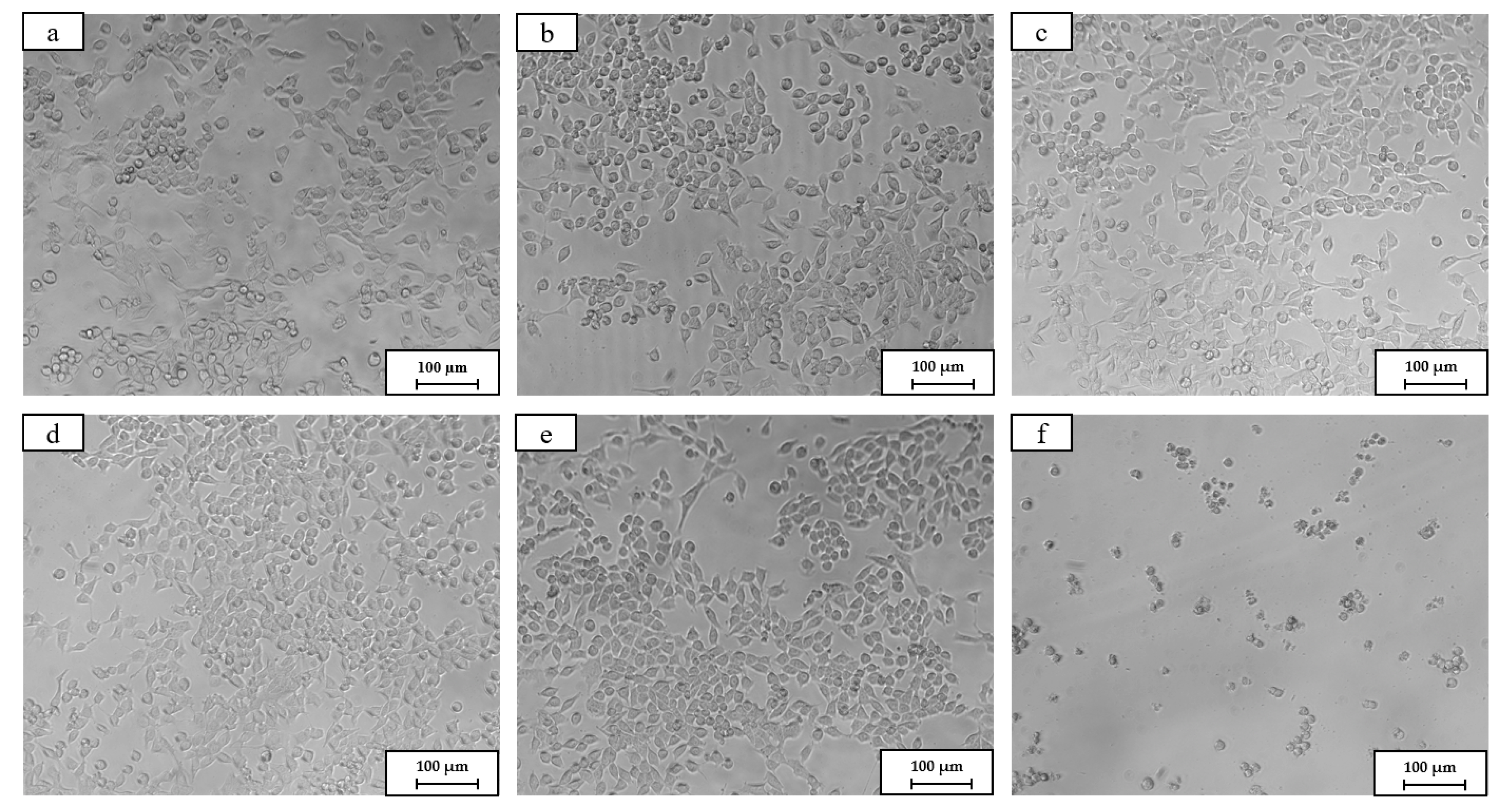

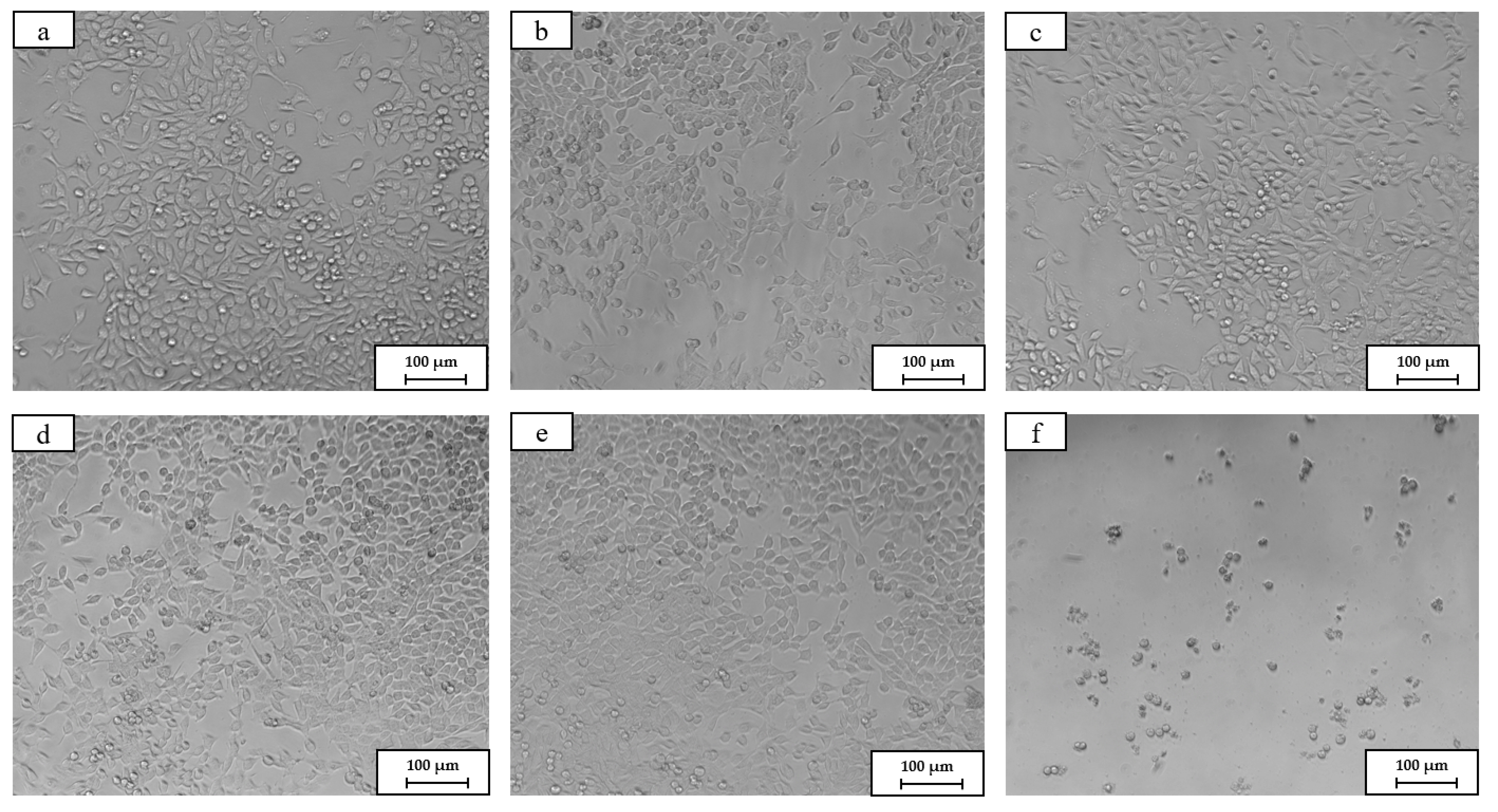

- Cytotoxicity assessment, in terms of indirect cell viability analysis, indicated that the tested alloys have a strong favorable effect on cell viability, particularly within prolonged incubation periods (after 48 h). This was probably mainly due to the inherent anti-inflammatory characteristics of Zn. Furthermore, the cell viability tendency was widened as the Nd content was increased from 1 to 3%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, Y.F.; Gu, X.N.; Witte, F.J.M.S. Biodegradable Metals. Mater. Sci. Eng. R Rep. 2014, 77, 1–34. [Google Scholar] [CrossRef]

- Su, Y.; Yang, H.; Gao, J.; Qin, Y.X.; Zheng, Y.; Zhu, D. Interfacial Zinc Phosphate is the Key to Controlling Biocompatibility of Metallic Zinc Implants. Adv. Sci. 2019, 6, 1900112. [Google Scholar] [CrossRef]

- Sheikh, Z.; Najeeb, S.; Khurshid, Z.; Verma, V.; Rashid, H.; Glogauer, M. Biodegradable materials for bone repair and tissue engineering applications. Materials 2015, 8, 5744–5794. [Google Scholar] [CrossRef] [PubMed]

- Bowen, P.K.; Shearier, E.R.; Zhao, S.; Guillory, R.J.; Zhao, F.; Goldman, J.; Drelich, J.W. Biodegradable Metals for Cardiovascular Stents: From Clinical Concerns to Recent Zn-Alloys. In Advanced Healthcare Materials; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2016; Volume 5, pp. 1121–1140. [Google Scholar] [CrossRef]

- Li, H.; Zheng, Y.; Qin, L. Progress of biodegradable metals. In Progress in Natural Science: Materials International; Elsevier: Amsterdam, The Netherlands, 2014; Volume 24, pp. 414–422. [Google Scholar] [CrossRef]

- Liu, X.; Sun, J.; Yang, Y.; Zhou, F.; Pu, Z.; Li, L.; Zheng, Y. Microstructure, mechanical properties, in vitro degradation behavior and hemocompatibility of novel Zn-Mg-Sr alloys as biodegradable metals. Mater. Lett. 2016, 162, 242–245. [Google Scholar] [CrossRef]

- Liu, Q.; Li, A.; Liu, S.; Fu, Q.; Xu, Y.; Dai, J.; Li, P.; Xu, S. Cytotoxicity of Biodegradable Zinc and Its Alloys: A Systematic Review. J. Funct. Biomater. 2023, 14, 206. [Google Scholar] [CrossRef]

- Johnson, L.L.; Vandyk, G.E. Metal and Biodegradable Interference Screws: Comparison of Failure Strength. Arthrosc. J. Arthrosc. Relat. Surg. 1996, 12, 452–456. [Google Scholar] [CrossRef]

- Levy, G.K.; Goldman, J.; Aghion, E. The Prospects of Zinc as a Structural Material for Biodegradable Implants—A Review Paper. Metals 2017, 7, 402. [Google Scholar] [CrossRef]

- Zander, D.; Zumdick, N.A. Influence of Ca and Zn on the microstructure and corrosion of biodegradable Mg-Ca-Zn alloys. Corros. Sci. 2015, 93, 222–233. [Google Scholar] [CrossRef]

- Králová, Z.O.; Gorejová, R.; Oriňaková, R.; Petráková, M.; Oriňak, A.; Kupková, M.; Hrubovčáková, M.; Sopčák, T.; Baláž, M.; Maskaľová, I.; et al. Biodegradable zinc-iron alloys: Complex study of corrosion behavior, mechanical properties and hemocompatibility. Prog. Nat. Sci. Mater. Int. 2021, 31, 279–287. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, E.; Yang, K. Microstructure, corrosion properties and bio-compatibility of calcium zinc phosphate coating on pure iron for biomedical application. Mater. Sci. Eng. C 2014, 34, 201–206. [Google Scholar] [CrossRef]

- Gao, C.; Li, S.; Liu, L.; Bin, S.; Yang, Y.; Peng, S.; Shuai, C. Dual alloying improves the corrosion resistance of biodegradable Mg alloys prepared by selective laser melting. J. Magnes. Alloys 2021, 9, 305–316. [Google Scholar] [CrossRef]

- Schinhammer, M.; Gerber, I.; Hänzi, A.C.; Uggowitzer, P.J. On the Cytocompatibility of Biodegradable Fe-Based Alloys. Mater Sci. Eng. C Mater Biol. Appl. 2013, 33, 782–789. [Google Scholar] [CrossRef]

- Schinhammer, M.; Hänzi, A.C.; Löffler, J.F.; Uggowitzer, P.J. Design strategy for biodegradable Fe-based alloys for medical applications. Acta Biomater. 2010, 6, 1705–1713. [Google Scholar] [CrossRef]

- Montani, M.; Demir, A.G.; Mostaed, E.; Vedani, M.; Previtali, B. Processability of pure Zn and pure Fe by SLM for biodegradable metallic implant manufacturing. Rapid Prototyp. J. 2017, 23, 514–523. [Google Scholar] [CrossRef]

- Liu, B.; Zheng, Y.F. Effects of Alloying Elements (Mn, Co, Al, W, Sn, B, C and S) on Biodegradability and in Vitro Biocompatibility of Pure Iron. Acta Biomater. 2011, 7, 1407–1420. [Google Scholar] [CrossRef] [PubMed]

- Kafri, A.; Ovadia, S.; Yosafovich-Doitch, G.; Aghion, E. The Effects of 4%Fe on the Performance of Pure Zinc as Biodegradable Implant Material. Ann. Biomed. Eng. 2019, 47, 1400–1408. [Google Scholar] [CrossRef] [PubMed]

- Rivkin, B.; Akbar, F.; Otto, M.; Beyer, L.; Paul, B.; Kosiba, K.; Gustmann, T.; Hufenbach, J.; Medina-Sánchez, M. Remotely Controlled Electrochemical Degradation of Metallic Implants. Small 2024. Online Version of Record. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.H.; Hiam, D. Corrosion Resistance of Galvannealed Steel. Corrosion 1989, 45, 852–856. [Google Scholar] [CrossRef]

- Esmaily, M.; Svensson, J.; Fajardo, S.; Birbilis, N.; Frankel, G.; Virtanen, S.; Arrabal, R.; Thomas, S.; Johansson, L.-G. Fundamentals and Advances in Magnesium Alloy Corrosion. Prog. Mater. Sci. 2017, 89, 2169. [Google Scholar] [CrossRef]

- Gu, X.N.; Zheng, Y.F. A review on magnesium alloys as biodegradable materials. Front. Mater. Sci. China 2010, 4, 111–115. [Google Scholar] [CrossRef]

- Li, H.F.; Shi, Z.Z.; Wang, L.N. Opportunities and challenges of biodegradable Zn-based alloys. J. Mater. Sci. Technol. 2020, 46, 136–138. [Google Scholar] [CrossRef]

- Staiger, M.; Pietak, A.; Huadmai, J.; Biomaterials, G.D. Magnesium and Its Alloys as Orthopedic Biomaterials: A Review. Biomaterials 2006, 27, 1728–1734–1734. [Google Scholar] [CrossRef] [PubMed]

- Kafri, A.; Ovadia, S.; Yosafovich-Doitch, G.; Aghion, E. In Vivo Performances of Pure Zn and Zn–Fe Alloy as Biodegradable Implants. J. Mater. Sci. Mater. Med. 2018, 29, 94. [Google Scholar] [CrossRef] [PubMed]

- Frank, W. The History of Biodegradable Magnesium Implants: A Review. Acta Biomater. 2010, 6, 1680–1692. [Google Scholar]

- Aghion, E.; Gueta, Y.; Moscovitch, N.; Bronfin, B. Effect of Yttrium Additions on the Properties of Grain-Refined Mg-3%Nd Alloy. J. Mater. Sci. 2008, 43, 4870–4875. [Google Scholar] [CrossRef]

- Avior, O.; Ghedalia-Peled, N.b.; Ron, T.; Metals, R.V. The Effect of ca on in Vitro Behavior of Biodegradable Zn-Fe Alloy in Simulated Physiological Environments. Metals 2020, 10, 1624. [Google Scholar] [CrossRef]

- Jia, B.; Yang, H.; Han, Y.; Zhang, Z.; Qu, X.; Zhuang, Y.; Wu, Q.; Zheng, Y.; Dai, K. In vitro and in vivo studies of Zn-Mn biodegradable metals designed for orthopedic applications. Acta Biomater. 2020, 108, 358–372. [Google Scholar] [CrossRef] [PubMed]

- Tong, X.; Zhang, D.; Zhang, X.; Su, Y.; Shi, Z.; Wang, K.; Lin, J.; Li, Y.; Lin, J.; Wen, C. Microstructure, mechanical properties, biocompatibility, and in vitro corrosion and degradation behavior of a new Zn–5Ge alloy for biodegradable implant materials. Acta Biomater. 2018, 82, 197–204. [Google Scholar] [CrossRef] [PubMed]

- Sikora-Jasinska, M.; Mostaed, E.; Mostaed, A.; Beanland, R.; Mantovani, D.; Vedani, M. Fabrication, mechanical properties and in vitro degradation behavior of newly developed Zn[sbnd]Ag alloys for degradable implant applications. Mater. Sci. Eng. C 2017, 77, 1170–1181. [Google Scholar] [CrossRef]

- Tang, Z.; Niu, J.; Huang, H.; Zhang, H.; Pei, J.; Ou, J.; Yuan, G. Potential biodegradable Zn-Cu binary alloys developed for cardiovascular implant applications. J. Mech. Behav. Biomed. Mater. 2017, 72, 182–191. [Google Scholar] [CrossRef]

- Sun, S.; Ren, Y.; Wang, L.; Yang, B.; Li, H.; Qin, G. Abnormal effect of Mn addition on the mechanical properties of as-extruded Zn alloys. Mater. Sci. Eng. A 2017, 701, 129–133. [Google Scholar] [CrossRef]

- Kubásek, J.; Vojtěch, D.; Jablonská, E.; Pospíšilová, I.; Lipov, J.; Ruml, T. Structure, mechanical characteristics and in vitro degradation, cytotoxicity, genotoxicity and mutagenicity of novel biodegradable Zn-Mg alloys. Mater. Sci. Eng. C 2016, 58, 24–35. [Google Scholar] [CrossRef]

- Zou, Y.; Chen, X.; Chen, B. Effects of Ca concentration on degradation behavior of Zn-x Ca alloys in Hank’s solution. Mater. Lett. 2018, 218, 193–196. [Google Scholar] [CrossRef]

- Kafri, A.; Ovadia, S.; Goldman, J.; Drelich, J.; Aghion, E. The suitability of Zn-1.3%Fe alloy as a biodegradable implant material. Metals 2018, 8, 153. [Google Scholar] [CrossRef]

- Berg, J.M.; Shi, Y. The Galvanization of Biology: A Growing Appreciation for the Roles of Zinc. Science 1996, 271, 1081–1085. [Google Scholar] [CrossRef] [PubMed]

- Mostaed, E.; Sikora-Jasinska, M.; Mostaed, A.; Loffredo, S.; Demir, A.G.; Previtali, B.; Mantovani, D.; Beanland, R.; Vedani, M. Novel Zn-based alloys for biodegradable stent applications: Design, development and in vitro degradation. J. Mech. Behav. Biomed. Mater. 2016, 60, 581–602. [Google Scholar] [CrossRef]

- Zhu, D.; Cockerill, I.; Su, Y.; Zhang, Z.; Fu, J.; Lee, K.W.; Ma, J.; Okpokwasili, C.; Tang, L.; Zheng, Y.; et al. Mechanical strength, biodegradation, and in vitro and in vivo biocompatibility of Zn biomaterials. ACS Appl. Mater. Interfaces 2019, 11, 6809–6819. [Google Scholar] [CrossRef]

- Wei, Z.; Burwinkel, M.; Palissa, C.; Ephraim, E.; Schmidt, M.F. Antiviral activity of zinc salts against transmissible gastroenteritis virus in vitro. Veter-Microbiol. 2012, 160, 468–472. [Google Scholar] [CrossRef]

- Gabay, N.; Ron, T.; Vago, R.; Shirizly, A.; Materials, E.A. Evaluating the Prospects of Ti-Base Lattice Infiltrated with Biodegradable Zn-2% Fe Alloy as a Structural Material for Osseointegrated Implants—In Vitro Study. Materials 2021, 14, 4682. [Google Scholar] [CrossRef]

- Wang, X.M.; Lu, G.J.; Cui, L.Y.; Liu, C.B.; Kannan, M.B.; Zhang, F.; Li, S.Q.; Zou, Y.H.; Zeng, R.C. In vitro degradation and biocompatibility of vitamin C loaded Ca-P coating on a magnesium alloy for bioimplant applications. Corros. Commun. 2022, 6, 16–28. [Google Scholar] [CrossRef]

- Cai, L.; Guo, H.-R.; Zhu, Y.-Q.; Du, F.-S.; Qi, J.-T.; Cui, L.-Y.; Liu, C.-B.; Zeng, R.-C. Biodegradation mechanisms of pure Mg in presence of glucose, vitamin C, and citric acid. Smart Mater. Manuf. 2023, 1, 100014. [Google Scholar] [CrossRef]

- Ben Tzion-Mottye, L.; Ron, T.; Eliezer, D.; Aghion, E. The Effect of Mn on the Mechanical Properties and In Vitro Behavior of Biodegradable Zn-2%Fe Alloy. Metals 2022, 12, 1291. [Google Scholar] [CrossRef]

- Stroganov, G.B.; Savitski, E.M.; Tikhov, N.M.; Terekhova, V.F.; Volkov, M.V.; Sivash, K.M.; Borodkin, V.S. U.S. Patent 3687135, 29 August 1972.

- Quach, N.C.; Uggowitzer, P.J.; Schmutz, P. Corrosion behaviour of an Mg–Y–RE alloy used in biomedical applications studied by electrochemical techniques. Comptes Rendus. Chim. 2008, 11, 1043–1054. [Google Scholar] [CrossRef]

- Du, S.; Shen, Y.; Zheng, Y.; Cheng, Y.; Xu, X.; Chen, D.; Xia, D. Systematic in vitro and in vivo study on biodegradable binary Zn-0.2 at% Rare Earth alloys (Zn-RE: Sc, Y, La-Nd, Sm-Lu). Bioact. Mater. 2023, 24, 507–523. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.-S.; Lim, C.-H.; Shin, S.-H.; Kim, J.-C. Twenty-Eight-Day Repeated Inhalation Toxicity Study of Nano-Sized Neodymium Oxide in Male Sprague-Dawley Rats. Toxicol. Res. 2017, 33, 239–253. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.; Cheng, Z.; Hu, R.; Cui, Y.; Cai, J.; Li, N.; Gui, S.; Sang, X.; Sun, Q.; Wang, L.; et al. Immune dys-function and liver damage of mice following exposure to lanthanoids. Environ. Toxicol. 2014, 29, 64–73. [Google Scholar] [CrossRef] [PubMed]

- Shi, Z.; Yu, J.; Liu, X.F. Microalloyed Zn-Mn Alloys: From Extremely Brittle to Extraordinarily Ductile at Room Temperature. Mater. Des. 2018, 144, 343–352. [Google Scholar] [CrossRef]

- Wang, J.; Witte, F.; Xi, T.; Zheng, Y.; Yang, K.; Yang, Y.; Zhao, D.; Meng, J.; Li, Y.; Li, W.; et al. Recommendation for Modifying Current Cytotoxicity Testing Standards for Biodegradable Magnesium-Based Materials. Acta Biomater. 2015, 21, 237–249. [Google Scholar] [CrossRef] [PubMed]

- Kaya, A.A.; Uzan, P.; Eliezer, D.; Aghion, E. Electron microscopical investigation of as cast AZ91D alloy. Mater. Sci. Technol. 2000, 16, 1001–1006. [Google Scholar] [CrossRef]

- Vander Voort, G.F. Metallography, Principles and Practice; ASM International: Almere, The Netherlands, 1999. [Google Scholar]

- Leon, A.; Shirizly, A.; Aghion, E. Corrosion behavior of AlSi10Mg alloy produced by additive manufacturing (AM) vs. Its counterpart gravity cast alloy. Metals 2016, 6, 148. [Google Scholar] [CrossRef]

- Proksch, E. pH in nature, humans and skin. J. Dermatol. 2018, 45, 1044–1052. [Google Scholar] [CrossRef] [PubMed]

- ISO 10993-12; Biological Evaluation of Medical Devices—Part 12: Sample Preparation and Reference Materials. International Organization for Standardization (ISO): Geneva, Switzerland, 2012.

- Shuai, C.J.; Yang, M.l.; Deng, F.; Yang, Y.W.; Peng, S.P.; Qi, F.W.; He, C.X.; Shen, L.D.; Liang, H.x. Forming quality, mechanical properties, and anti-inflammatory activity of additive manufactured Zn-Nd alloy. J. Zhejiang Univ. Sci. A 2020, 21, 876–891. [Google Scholar] [CrossRef]

- Cabibbo, M.; Paoletti, C.; Minárik, P.; Král, R.; Zemková, M. Secondary phase precipitation and thermally stable microstructure refinement induced by ECAP on Mg-Y-Nd (WN43) alloy. Mater. Lett. 2019, 237, 5–8. [Google Scholar] [CrossRef]

- Dutra, C.A.M.; Codaro, E.N.; Nakazato, R.Z. Electrochemical behavior and corrosion study of electrodeposits of Zn and Zn-Fe-Co on steel. Mater. Sci. Appl. 2012, 3, 348–354. [Google Scholar]

- Veys-Renaux, D.; Guessoum, K.; Rocca, E.; David, N.; Belhamel, K. New zinc-rare earth alloys: Influence of intermetallic compounds on the corrosion resistance. Corros. Sci. 2013, 77, 342–349. [Google Scholar] [CrossRef]

- Ron, T.; Leon, A.; Kafri, A.; Ashraf, A.; Na, J.; Babu, A.; Banerjee, R.; Brookbank, H.; Muddaluri, S.; Little, K.; et al. Nerve regeneration with a scaffold incorporating an absorbable Zinc-2% Iron alloy filament to improve axonal guidance. Pharmaceutics 2023, 15, 2595. [Google Scholar] [CrossRef]

- Peng, F.; Xie, J.; Liu, H.; Zheng, Y.; Qian, X.; Zhou, R.; Zhong, H.; Zhang, Y.; Li, M. Shifting focus from bacteria to host neutrophil extracellular traps of biodegradable pure Zn to combat implant centered infection. Bioact. Mater. 2023, 21, 436–449. [Google Scholar] [CrossRef]

- Thian, E.S.; Konishi, T.; Kawanobe, Y.; Lim, P.N.; Choong, C.; Ho, B.; Aizawa, M. Zinc-substituted hydroxyapatite: A biomaterial with enhanced bioactivity and antibacterial properties. J. Mater. Sci. Mater. Med. 2013, 24, 437–445. [Google Scholar] [CrossRef]

| Tested Alloy | Nd | S | Zn |

|---|---|---|---|

| Zn-1%Nd | 0.9 | 0.082 | Bal. |

| Zn-2%Nd | 2.4 | 0.102 | Bal. |

| Zn-3%Nd | 3.1 | 0.067 | Bal. |

| Point of Measurement | Zn (wt.%) | Nd (wt.%) | Dominant Phases |

|---|---|---|---|

| 1 | 94.0 | 6.0 | NdZn5 |

| 2 | 99.4 | 0.6 | Zn-base matrix |

| 3 | 93.2 | 6.8 | NdZn5 |

| 4 | 99.8 | 0.2 | Zn-base matrix |

| Tested Alloy | Y.P. [MPa] | UTS [MPa] | Elongation [%] |

|---|---|---|---|

| Zn-1%Nd | 90 ± 0.1 | 135.9 ± 1.1 | 34.9 ± 1.5 |

| Zn-2%Nd | 91.5 ± 0.5 | 140.0 ± 0.4 | 36.7 ± 6.0 |

| Zn-3%Nd | 98.5 ± 1.5 | 148.9 ± 0.5 | 37.2 ± 1.4 |

| Tested Alloy | O | P | Cl | Nd | Zn |

|---|---|---|---|---|---|

| Zn-3%Nd | 18.49 | 9.37 | 0.8 | 3.04 | Bal. |

| Tested Alloy | Ecorr vs. SCE [V] | Icorr [µA/cm2] | Corrosion Rate [mmpy] |

|---|---|---|---|

| Zn 1%Nd | −1.16 | 1.62 | 0.23 |

| Zn 2%Nd | −1.2 | 1.34 | 0.19 |

| Zn 3%Nd | −1.19 | 2.41 | 0.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hazan-Paikin, E.; Ben Tzion-Mottye, L.; Bassis, M.; Ron, T.; Aghion, E. Effect of Nd on Functional Properties of Biodegradable Zn Implants in In Vitro Environment. Metals 2024, 14, 655. https://doi.org/10.3390/met14060655

Hazan-Paikin E, Ben Tzion-Mottye L, Bassis M, Ron T, Aghion E. Effect of Nd on Functional Properties of Biodegradable Zn Implants in In Vitro Environment. Metals. 2024; 14(6):655. https://doi.org/10.3390/met14060655

Chicago/Turabian StyleHazan-Paikin, Efrat, Lital Ben Tzion-Mottye, Maxim Bassis, Tomer Ron, and Eli Aghion. 2024. "Effect of Nd on Functional Properties of Biodegradable Zn Implants in In Vitro Environment" Metals 14, no. 6: 655. https://doi.org/10.3390/met14060655

APA StyleHazan-Paikin, E., Ben Tzion-Mottye, L., Bassis, M., Ron, T., & Aghion, E. (2024). Effect of Nd on Functional Properties of Biodegradable Zn Implants in In Vitro Environment. Metals, 14(6), 655. https://doi.org/10.3390/met14060655