Assessing Tensile Strength and Electrical Conductivity of Friction Stir-Welded Joints of Copper and Aluminum Alloys

Abstract

1. Introduction

2. Materials and Methods

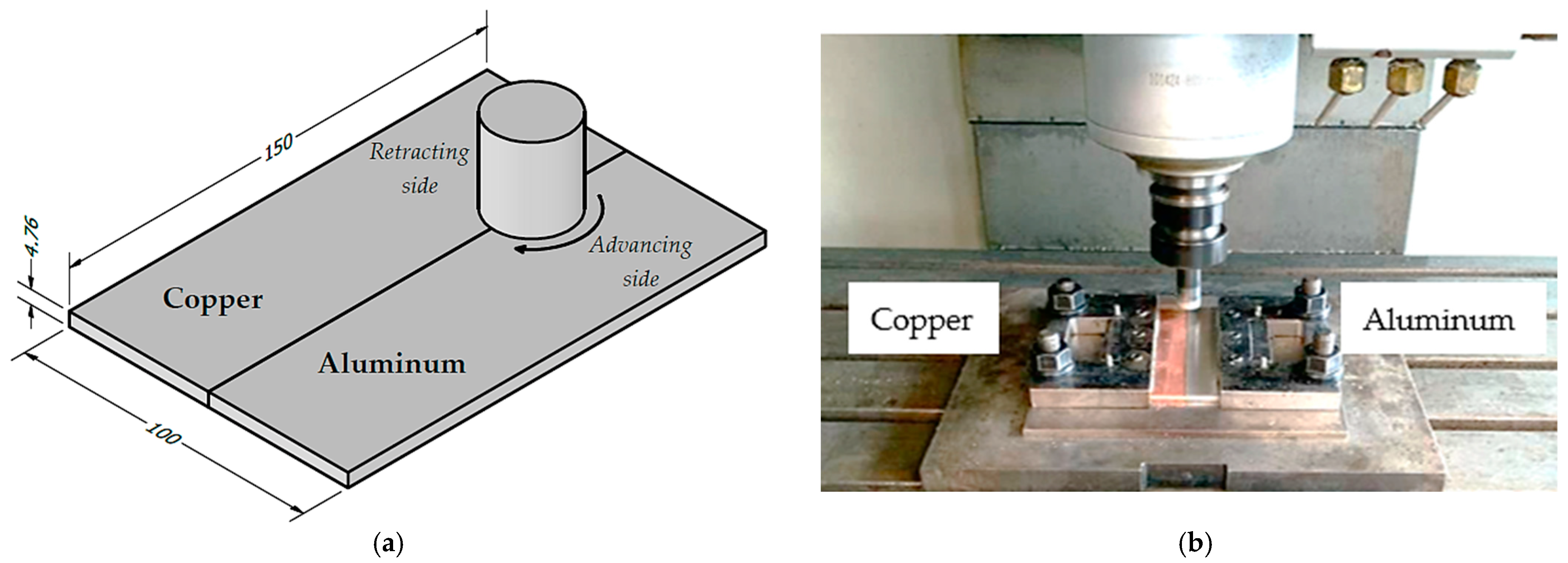

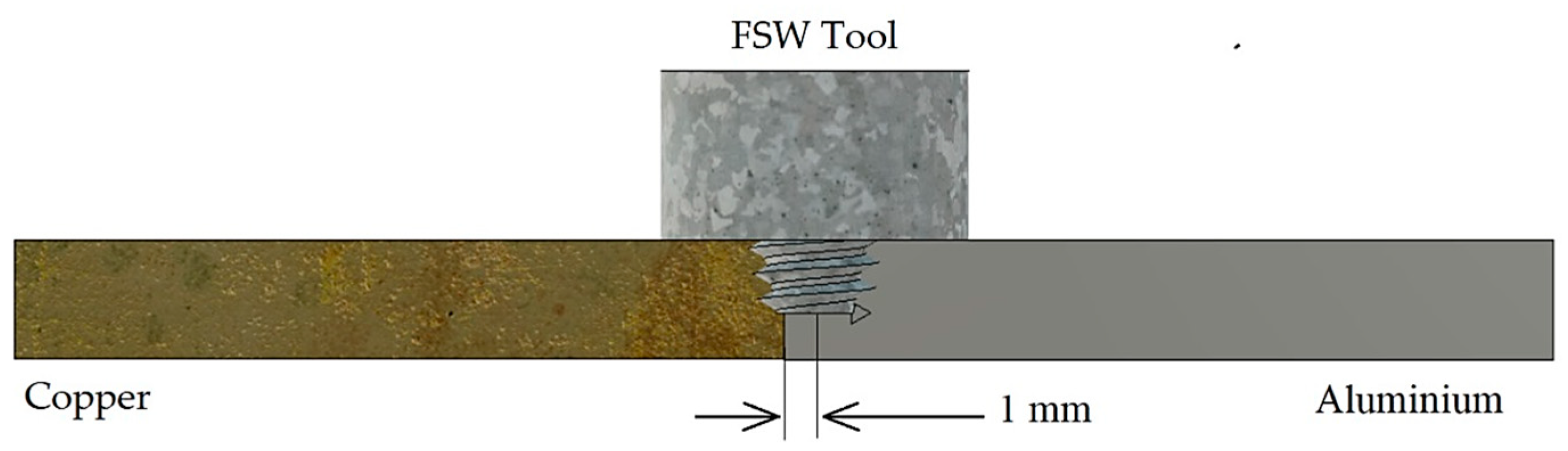

2.1. Experimental Setup

2.2. Selection of Parameters

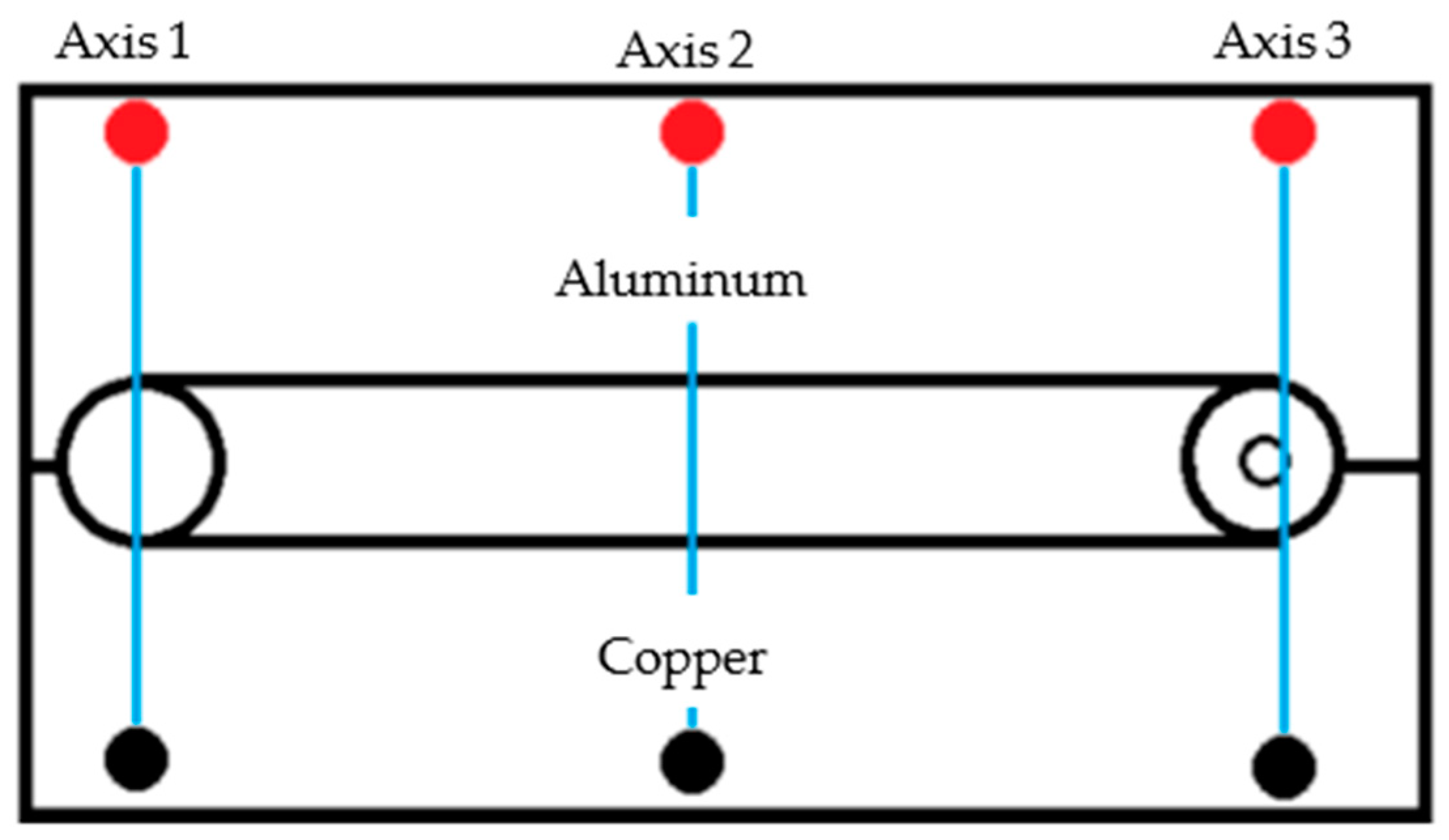

2.3. Non-Destructive Analysis

2.4. Tensile Testing

2.5. Electrical Conductivity Analysis

3. Results and Discussion

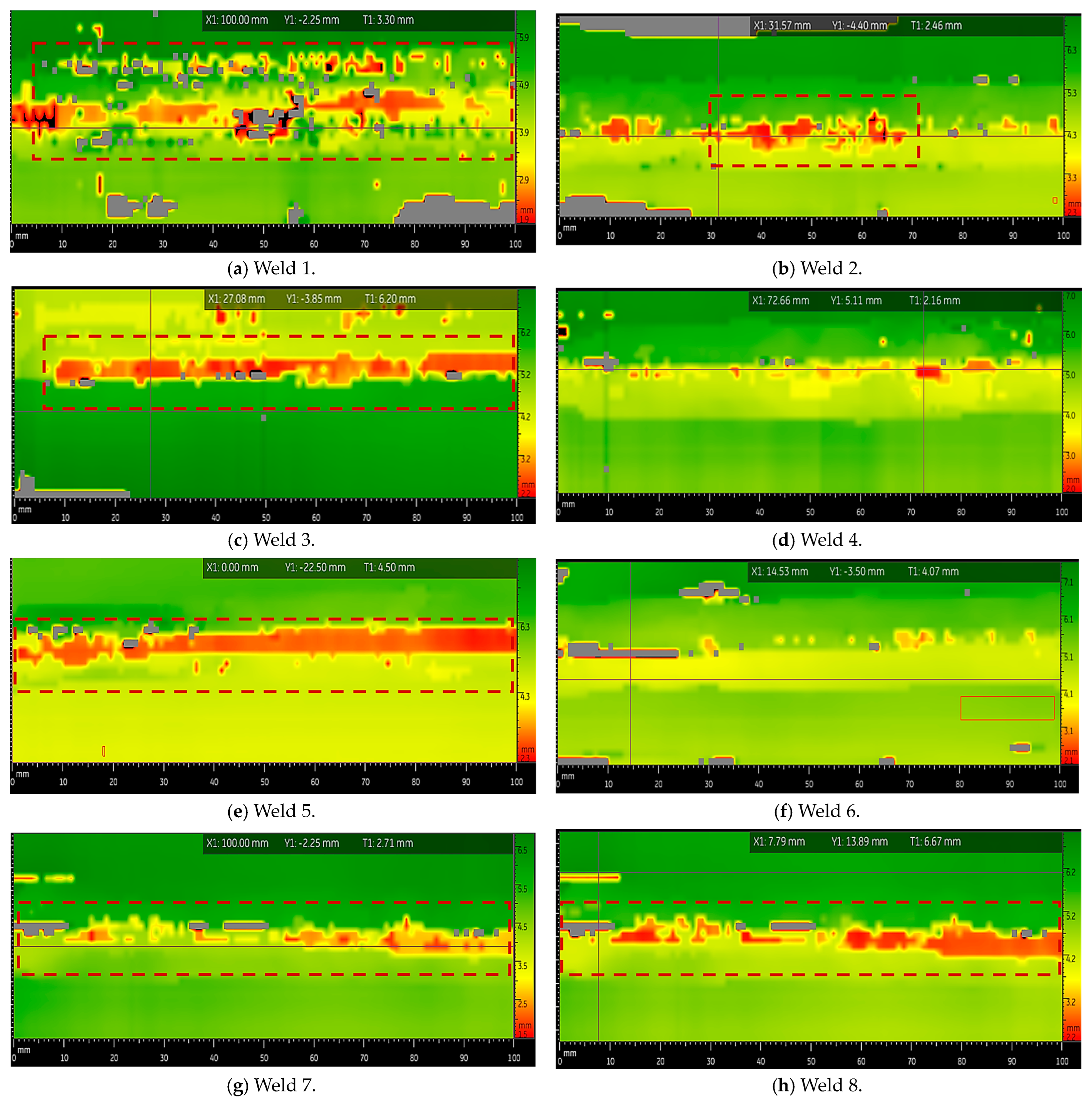

3.1. Phased-Array Ultrasound (PAU)

3.2. Electrical Properties

3.3. Tensile Testing

Statistical Analysis

- Student’s t-test

- ANOVA

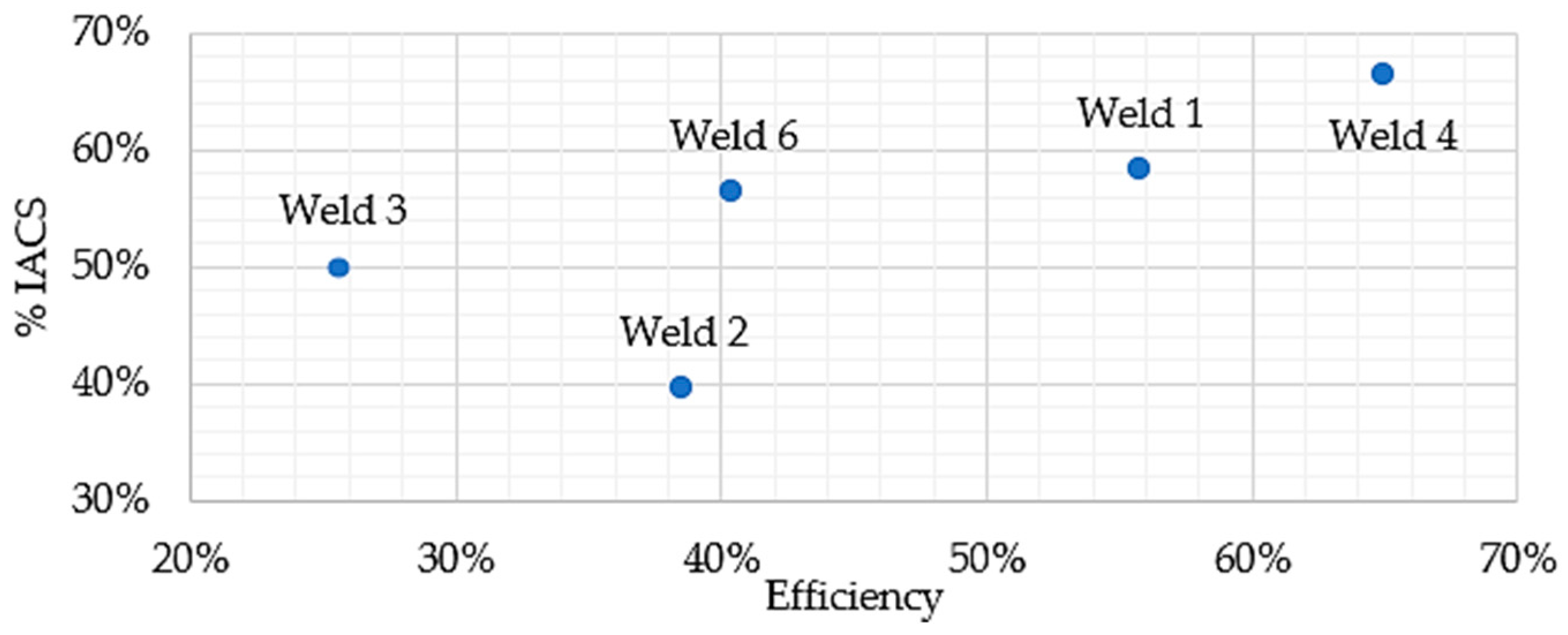

3.4. Joint Efficiency and Electrical Conductivity

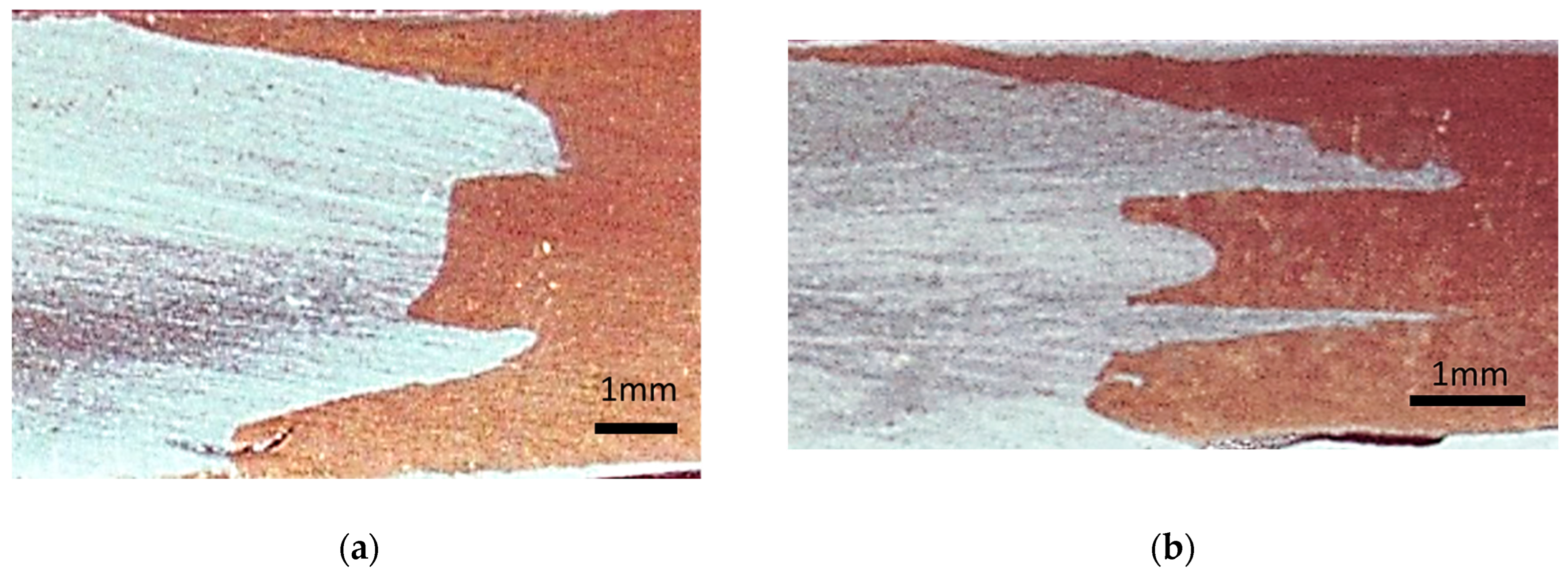

3.5. Material Flow General Overview

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mishra, R.S.; Ma, Z.Y. Friction Stir Welding and Processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Rai, R.; De, A.; Bhadeshia, H.K.D.H.; DebRoy, T. Review: Friction Stir Welding Tools. Sci. Technol. Weld. Join. 2011, 16, 325–342. [Google Scholar] [CrossRef]

- Mubiayi, M.P.; Titilayo, E.; Mamookho, M. Current Trends in Friction Stir Welding (FSW) and Friction Stir Spot Welding (FSSW); Springer: Cham, Switzerland, 2019. [Google Scholar]

- Mendes, N.; Neto, P.; Loureiro, A.; Moreira, A.P. Machines and Control Systems for Friction Stir Welding: A Review. Mater. Des. 2016, 90, 256–265. [Google Scholar] [CrossRef]

- Busu, A.; Shamil Jaffarullah, M.; Yee Low, C.; Saiful Bahari Shaari, M.; Jaffar, A. A Review of Force Control Techniques in Friction Stir Process. Procedia Comput. Sci. 2015, 76, 528–533. [Google Scholar] [CrossRef]

- Zhang, Q.Z.; Gong, W.B.; Liu, W. Microstructure and Mechanical Properties of Dissimilar Al–Cu Joints by Friction Stir Welding. Trans. Nonferrous Met. Soc. China 2015, 25, 1779–1786. [Google Scholar] [CrossRef]

- Nandan, R.; DebRoy, T.; Bhadeshia, H.K.D.H. Recent Advances in Friction-Stir Welding-Process, Weldment Structure and Properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Taheri, H.; Kilpatrick, M.; Norvalls, M.; Harper, W.J.; Koester, L.W.; Bigelow, T.; Bond, L.J. Investigation of Nondestructive Testing Methods for Friction Stir Welding. Metals 2019, 9, 624. [Google Scholar] [CrossRef]

- Mehta, K.P. A Review on Friction-Based Joining of Dissimilar Aluminum-Steel Joints. J. Mater. Res. 2018, 3, 78–96. [Google Scholar] [CrossRef]

- Sathishkumar, G.B.; Sethuraman, P.; Chanakyan, C.; Sundaraselvan, S.; Arockiam, A.J.; Alagarsamy, S.V.; Elmariung, A.; Meignanamoorthy, M.; Ravichandran, M.; Jayasathyakawin, S. Friction Welding of Similar and Dissimilar Materials: A Review. Sel. Peer-Rev. Under Responsib. Sci. Comm. Int. Virtual Conf. Sustain. Mater. (IVCSM-2k20) 2021, 81, 208–211. [Google Scholar] [CrossRef]

- Agapiou, J.S.; Carlson, B.E. Friction Stir Welding for Assembly of Copper Squirrel Cage Rotors for Electric Motors. Procedia Manuf. 2020, 48, 1143–1154. [Google Scholar] [CrossRef]

- Mehta, K.P.; Badheka, V.J. A Review on Dissimilar Friction Stir Welding of Copper to Aluminum: Process, Properties, and Variants. Mater. Manuf. Process. 2016, 31, 233–254. [Google Scholar] [CrossRef]

- Al-Jarrah, J.A.; Ibrahim, M.; Swalha, S.; Gharaibeh, N.S.; Al-Rashdan, M.; Al-Qahsi, D.A. Surface Morphology and Mechanical Properties of Aluminum-Copper Joints Welded by Friction Stir Welding. Contemp. Eng. Sci. 2014, 7, 219–230. [Google Scholar] [CrossRef]

- Ahmadi, M.; Pahlavani, M.; Rahmatabadi, D.; Marzbanrad, J.; Hashemi, R.; Afkar, A. An Exhaustive Evaluation of Fracture Toughness, Microstructure, and Mechanical Characteristics of Friction Stir Welded Al6061 Alloy and Parameter Model Fitting Using Response Surface Methodology. J. Mater. Eng. Perform. 2022, 31, 3418–3436. [Google Scholar] [CrossRef]

- Chowdhury, I.; Sengupta, K.; Maji, K.K.; Roy, S.; Ghosal, S. Investigation of Mechanical Properties of Dissimilar Joint of Al6063 Aluminium Alloy and C26000 Copper Alloy by Ultrasonic Assisted Friction Stir Welding. Mater. Today Proc. 2022, 50, 1527–1534. [Google Scholar] [CrossRef]

- Karrar, G.; Galloway, A.; Toumpis, A.; Li, H.; Al-Badour, F. Microstructural Characterisation and Mechanical Properties of Dissimilar AA5083-Copper Joints Produced by Friction Stir Welding. J. Mater. Res. Technol. 2020, 9, 11968–11979. [Google Scholar] [CrossRef]

- Gruber, S.; Stepien, L.; López, E.; Brueckner, F.; Leyens, C. Physical and Geometrical Properties of Additively Manufactured Pure Copper Samples Using a Green Laser Source. Materials 2021, 14, 3642. [Google Scholar] [CrossRef]

- Eslami, N.; Harms, A.; Deringer, J.; Fricke, A.; Böhm, S. Dissimilar Friction Stir Butt Welding of Aluminum and Copper with Cross-Section Adjustment for Current-Carrying Components. Metals 2018, 8, 661. [Google Scholar] [CrossRef]

- Yusof, F.; Firdaus, A.; Fadzil, M.; Hamdi, M. Ultra-Thin Friction Stir Welding (FSW) between Aluminum Alloy and Copper. In Proceedings of the 1st International Joint Symposium on Joining and Welding, Osaka, Japan, 6–8 November 2013; Elsevier: Amsterdam, The Netherlands, 2013; pp. 219–224. [Google Scholar]

- Bakhtiari Argesi, F.; Shamsipur, A.; Mirsalehi, S.E. Dissimilar Joining of Pure Copper to Aluminum Alloy via Friction Stir Welding. Acta Metall. Sin. (Engl. Lett.) 2018, 31, 1183–1196. [Google Scholar] [CrossRef]

- MatWeb Online Materials Information Resource. Available online: https://www.matweb.com/ (accessed on 21 December 2023).

- ISO 25239-4:2011; Friction Stir Welding—Aluminium 4: Specification and Qualification of Welding Procedures. ISO: Geneva, Switzerland, 2011.

- Galvão, I.; Loureiro, A.; Verdera, D.; Gesto, D.; Rodrigues, D.M. Influence of Tool Offsetting on the Structure and Morphology of Dissimilar Aluminum to Copper Friction-Stir Welds. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2012, 43, 5096–5105. [Google Scholar] [CrossRef]

- Mehta, K.P.; Badheka, V.J. Influence of Tool Pin Design on Properties of Dissimilar Copper to Aluminum Friction Stir Welding. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 2017, 27, 36–54. [Google Scholar] [CrossRef]

- Prabhu, L.; Satish Kumar, S. Tribological Characteristics of FSW Tool Subjected to Joining of Dissimilar AA6061-T6 and Cu Alloys. Mater. Today Proc. 2020, 33, 741–745. [Google Scholar] [CrossRef]

- Sharma, N.; Khan, Z.A.; Siddiquee, A.N.; Shihab, S.K.; Wahid Atif, M. Effect of Process Parameters on Microstructure and Electrical Conductivity during FSW of Al-6101 and Pure Copper. Certain. Distance Degree Based Topol. Indices Zeolite LTA Framew. 2018, 5, 11–14. [Google Scholar] [CrossRef]

- García-Navarro, D.; Ortiz-Cuellar, J.C.; Galindo-Valdés, J.S.; Gómez-Casas, J.; Muñiz-Valdez, C.R.; Rodríguez-Rosales, N.A. Effects of the FSW Parameters on Microstructure and Electrical Properties in Al 6061-T6- Cu C11000 Plate Joints. Crystals 2021, 11, 21. [Google Scholar] [CrossRef]

- Akinlabi, E.T. Effect of Shoulder Size on Weld Properties of Dissimilar Metal Friction Stir Welds. J. Mater. Eng. Perform. 2012, 21, 1514–1519. [Google Scholar] [CrossRef]

- Xue, P.; Ni, D.R.; Wang, D.; Xiao, B.L.; Ma, Z.Y. Effect of Friction Stir Welding Parameters on the Microstructure and Mechanical Properties of the Dissimilar Al-Cu Joints. Mater. Sci. Eng. A 2011, 528, 4683–4689. [Google Scholar] [CrossRef]

- Emamian, S.; Awang, M.; Hussai, P.; Meyghani, B.; Zafar, A. Influences of Tool Pin Profile on the Friction Stir Welding of AA6061. ARPN J. Eng. Appl. Sci. 2016, 11, 12258–12261. [Google Scholar]

- Ólafsson, D.; Vilaça, P.; Vesanko, J. Multiphysical Characterization of FSW of Aluminum Electrical Busbars with Copper Ends. Weld. World 2020, 64, 59–71. [Google Scholar] [CrossRef]

- Khajeh, R.; Jafarian, H.R.; Seyedein, S.H.; Jabraeili, R.; Eivani, A.R.; Park, N.; Kim, Y.; Heidarzadeh, A. Microstructure, Mechanical and Electrical Properties of Dissimilar Friction Stir Welded 2024 Aluminum Alloy and Copper Joints. J. Mater. Res. Technol. 2021, 14, 1945–1957. [Google Scholar] [CrossRef]

- Rasaee, S.; Mirzaei, A.H.; Almasi, D.; Hayati, S. A Comprehensive Study of Parameters Effect on Mechanical Properties of Butt Friction Stir Welding in Aluminium 5083 and Copper. Trans. Indian Inst. Met. 2018, 71, 1553–1561. [Google Scholar] [CrossRef]

- Mehta, K.P.; Badheka, V.J. Effects of Tilt Angle on the Properties of Dissimilar Friction Stir Welding Copper to Aluminum. Mater. Manuf. Process. 2016, 31, 255–263. [Google Scholar] [CrossRef]

- Bisadi, H.; Tavakoli, A.; Tour Sangsaraki, M.; Tour Sangsaraki, K. The Influences of Rotational and Welding Speeds on Microstructures and Mechanical Properties of Friction Stir Welded Al5083 and Commercially Pure Copper Sheets Lap Joints. Mater. Des. 2013, 43, 80–88. [Google Scholar] [CrossRef]

- Montes-González, F.A.; Rodríguez-Rosales, N.A.; Ortiz-Cuellar, J.C.; Muñiz-Valdez, C.R.; Gómez-Casas, J.; Galindo-Valdés, J.S.; Gómez-Casas, O. Experimental Analysis and Mathematical Model of Fsw Parameter Effects on the Corrosion Rate of Al 6061-T6-Cu C11000 Joints. Crystals 2021, 11, 294. [Google Scholar] [CrossRef]

- View of Feasibility Study of Friction Stir Welding of Dissimilar Metals between 6063 Aluminium Alloy and Pure Copper. Available online: https://ph01.tci-thaijo.org/index.php/nuej/article/view/70365/72339 (accessed on 15 May 2022).

- Christon, L.; Samuel, K. Balachandar Experimental Investigation on Friction Stir Welded Aluminium Alloy (6063-O)–Pure Copper Joint-Document-Gale Academic OneFile. Available online: https://go.gale.com/ps/i.do?id=GALE%7CA466052674&sid=googleScholar&v=2.1&it=r&linkaccess=abs&issn=19950772&p=AONE&sw=w&userGroupName=anon%7E5b1f7ab6 (accessed on 15 May 2022).

- Bhattacharya, T.K.; Das, H.; Pal, T.K. Influence of Welding Parameters on Material Flow, Mechanical Property and Intermetallic Characterization of Friction Stir Welded AA6063 to HCP Copper Dissimilar Butt Joint without Offset. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 2015, 25, 2833–2846. [Google Scholar] [CrossRef]

- Panaskar, N.; Terkar, R. Effect of Process Parameters on Defect Features and Mechanical Performance of Friction Stir Lap Welded AA6063 and ETP Copper Joints. Int. J. Recent Technol. Eng. 2019, 8, 879–883. [Google Scholar] [CrossRef]

- Al-Roubaiy, A.O.; Nabat, S.M.; Batako, A.D.L. Experimental and Theoretical Analysis of Friction Stir Welding of Al–Cu Joints. Int. J. Adv. Manuf. Technol. 2014, 71, 1631–1642. [Google Scholar] [CrossRef]

- Li, X.W.; Zhang, D.T.; Qiu, C.; Zhang, W. Microstructure and Mechanical Properties of Dissimilar Pure Copper/1350 Aluminum Alloy Butt Joints by Friction Stir Welding. Trans. Nonferrous Met. Soc. China 2012, 22, 1298–1306. [Google Scholar] [CrossRef]

- Ghangas, G.; Goyat, V.; Sirohi, S.; Sharma, S.K.; Dhull, S. Investigation for Mechanical Properties of Dissimilar Friction Stir Welded Joints of AA5083 and Pure Cu. Mater. Today Proc. 2022, 56, 77–81. [Google Scholar] [CrossRef]

- Kadian, A.K.; Biswas, P. The Study of Material Flow Behaviour in Dissimilar Material FSW of AA6061 and Cu-B370 Alloys Plates. J. Manuf. Process. 2018, 34, 96–105. [Google Scholar] [CrossRef]

- Fotoohi, Y.; Rasaee, S.; Bisadi, H.; Zahedi, M. Effect of Friction Stir Welding Parameters on the Mechanical Properties and Microstructure of the Dissimilar Al5083–Copper Butt Joint. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2014, 228, 334–340. [Google Scholar] [CrossRef]

- Khodir, S.A.; Ahmed, M.M.Z.; Ahmed, E.; Mohamed, S.M.R.; Abdel-Aleem, H. Effect of Intermetallic Compound Phases on the Mechanical Properties of the Dissimilar Al/Cu Friction Stir Welded Joints. J. Mater. Eng. Perform. 2016, 25, 4637–4648. [Google Scholar] [CrossRef]

- Afsari, A.; Heidari, S.; Jafari, J. Evaluation of Optimal Conditions, Microstructure, and Mechanical Properties of Aluminum to Copper Joints Welded by FSW. J. Mod. Process. Manuf. Prod. 2020, 9, 61–81. [Google Scholar]

- Galvão, I.; Verdera, D.; Gesto, D.; Loureiro, A.; Rodrigues, D.M. Analysing the Challenge of Aluminum to Copper FSW. In Proceedings of the 9th International Symposium on Friction Stir Welding, Huntsville, AL, USA, 15–17 May 2012. [Google Scholar]

- Ghiasvand, A.; Kazemi, M.; Mahdipour Jalilian, M.; Ahmadi Rashid, H. Effects of Tool Offset, Pin Offset, and Alloys Position on Maximum Temperature in Dissimilar FSW of AA6061 and AA5086. Int. J. Mech. Mater. Eng. 2020, 15, 1–14. [Google Scholar] [CrossRef]

- Bakkiyaraj, M.; Bernard, S.S.; Saikrishnan, G.; Guruyogesh, S.; Guruprasanna, T.G.; Dineshkumar, K. Effect of Tool Offset Condition on Mechanical and Metallurgical Properties of FSW Dissimilar Al-Cu Joint. In Proceedings of the Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; Volume 43, pp. 824–827. [Google Scholar]

- Akinlabi, E.T.; Levy, A.C.S.; Akinlabi, S.A. Non-Destructive Testing of Dissimilar Friction Stir Welds. In Proceedings of the World Congress on Engineering, London, UK, 4–6 July 2012. [Google Scholar]

- Mandache, C.; Levesque, D.; Dubourg, L.; Gougeon, P. Non-Destructive Detection of Lack of Penetration Defects in Friction Stir Welds. Sci. Technol. Weld. Join. 2012, 17, 295–303. [Google Scholar] [CrossRef]

- ASTM. E8 Standard Test Methods of Tension Testing of Metallic Materials. In Annual Book or ASTM Standards; American Society for Testing and Materials: Montgomery, PA, USA, 2024; Volume 3.01. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments, 9th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2022. [Google Scholar]

| Material | Si | Cu | Zn | Fe | Mn | Cr | Sn | Ti | Mg | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| AA6061-T6 | 0.4 | 0.16 | 0.025 | 0.7 | 0.15 | 0.04 | 0.05 | 0.15 | 0.8 | 95.8 |

| C11000 | - | 99.9 | - | - | - | - | - | - | - | 0.1 |

| Material | Electrical Conductivity in Terms of % IACS |

|---|---|

| AA6061-T6 | 39 |

| C11000 | 97 |

| Aluminum Alloy | Copper | Thickness (mm) | Rotational Speed (RPM) | Traverse Speed (mm/min) | Offset (mm) | Joint Efficiency (%) | Reference |

|---|---|---|---|---|---|---|---|

| AA6061 | DHP | 3 | 1118 | 60 | 2 | 54.84% | [13] |

| AA6063 | C26000 | 5 | 600 | 15 | - | 70.3% | [15] |

| AA5083 | Pure | 3 | 1400 | 120 | 0 | 96.4% | [16] |

| AA5083-H111 | DHP R204 | 1 | 750 | 160 | - | - | [48] |

| AA6082-T6 | Pure | 3 | 1000 | 200 | 1.9 | - | [23] |

| AA6061 | Pure | 3 | 710 | 355 | - | - | [12] |

| AA6063-T651 | ETP | 6.3 | 1500 | 50 | 2 | 40.5% | [24] |

| AA6061-T6 | Pure | 3 | 1300 | 70 | - | - | [25] |

| AA6061-T6 | Pure | 2.8 | 900 | 63 | 0.5 | - | [26] |

| AA6061-T6 | C11000 | 3.1 | 1300 | 20 | 2 | - | [27] |

| AA5754 | C11000 | 3.175 | 950 | 50 | 0 | 78% | [28] |

| AA1060 | Pure | 5 | 600 | 100 | 2 | 44% | [29] |

| AA1060 | Pure | 3 | 1050 | 30 | 1 | 58% | [6] |

| AA6061-T651 | Pure | 6.3 | 1500 | 40 | 2 | 58% | [30] |

| AA1050-H14 | Pure | 6 | 800 | 125 | 1.4 | 85% | [31] |

| AA2024 | Pure | 2 | 948 | 85 | 70.2% | [32] | |

| AA5083 | Pure | 5 | 800 | 40 | 1 | 69.4% | [33] |

| AA6061 | Pure | 6.3 | 1300 | 40 | 2 | - | [34] |

| AA6061 | C11000 | 3.2 | 1000 | 40 | - | - | [35] |

| AA5083 | Pure | 3 | 825 | 32 | - | - | [36] |

| AA5754 | C11000 | 3.1 | 950 | 50 | - | 86% | [28] |

| AA6063 | Pure | 6 | 1800 | 20 | - | - | [37] |

| AA6063 | Pure | 6 | 900 | 25 | 0 | - | [38] |

| AA6063 | HCP | 3 | 800 | 20 | 0 | - | [39] |

| AA6063 | ETP | 3 | 1200 | 15 | 0 | - | [40] |

| AA5086 | Pure | 6.3 | 710 | 69 | - | - | [41] |

| AA1350 | Pure | 3 | 1000 | 80 | 2 | 50% | [42] |

| AA5083 | Pure | 5 | 1200 | 30 | - | 58% | [43] |

| AA6061 | B370 | 6 | 1100 | 120 | - | - | [44] |

| AA5083 | Pure | 5 | 600 | 40 | - | 96% | [45] |

| AA1050-H14 | Pure | 2 | 1400 | 20 | 2 | 88% | [46] |

| AA1050-H14 | Pure | 2 | 1200 | 20 | 2 | 96% | [46] |

| AA5082 | B36 | 2 | 1300 | 35 | - | 82% | [47] |

| Weld Number | Rotational Speed (RPM) | Traverse Speed (mm/min) | Offset (mm) |

|---|---|---|---|

| 1 | 1000 | 40 | 1 |

| 2 | 1200 | 40 | 0 |

| 3 | 1000 | 40 | 0 |

| 4 | 1400 | 40 | 1 |

| 5 | 1200 | 40 | 1 |

| 6 | 1400 | 40 | 0 |

| 7 | 1400 | 40 | 1 |

| 8 | 1400 | 40 | 0 |

| Weld Number | Axes | Resistance (Ohm) | Resistivity (Ω.m) | Electrical Conductivity (S/m) | % IACS | Average |

|---|---|---|---|---|---|---|

| 1 | 1 | 6.60 × 10−5 | 3.37 × 10−8 | 2.97 × 107 | 51.2% | 58.2% |

| 2 | 6.20 × 10−5 | 3.16 × 10−8 | 3.16 × 107 | 54.5% | ||

| 3 | 4.90 × 10−5 | 2.50 × 10−8 | 4.00 × 107 | 69.0% | ||

| 2 | 1 | 6.70 × 10−5 | 3.42 × 10−8 | 2.93 × 107 | 50.4% | 39.5% |

| 2 | 1.07 × 10−4 | 5.46 × 10−8 | 1.83 × 107 | 31.6% | ||

| 3 | 9.30 × 10−5 | 4.74 × 10−8 | 2.11 × 107 | 36.3% | ||

| 3 | 1 | 6.90 × 10−5 | 3.52 × 10−8 | 2.84 × 107 | 49.0% | 49.8% |

| 2 | 5.70 × 10−5 | 2.91 × 10−8 | 3.44 × 107 | 59.3% | ||

| 3 | 8.20 × 10−5 | 4.18 × 10−8 | 2.39 × 107 | 41.2% | ||

| 4 | 1 | 5.30 × 10−5 | 2.70 × 10−8 | 3.70 × 107 | 63.8% | 66.3% |

| 2 | 4.10 × 10−5 | 2.09 × 10−8 | 4.78 × 107 | 82.4% | ||

| 3 | 6.40 × 10−5 | 3.27 × 10−8 | 3.06 × 107 | 52.8% | ||

| 5 | 1 | 9.60 × 10−5 | 4.90 × 10−8 | 2.04 × 107 | 35.2% | 35.8% |

| 2 | 9.40 × 10−5 | 4.80 × 10−8 | 2.09 × 107 | 36.0% | ||

| 3 | 9.30 × 10−5 | 4.74 × 10−8 | 2.11 × 107 | 36.3% | ||

| 6 | 1 | 6.60 × 10−5 | 3.37 × 10−8 | 2.97 × 107 | 51.2% | 56.3% |

| 2 | 5.70 × 10−5 | 2.91 × 10−8 | 3.44 × 107 | 59.3% | ||

| 3 | 5.80 × 10−5 | 2.96 × 10−8 | 3.38 × 107 | 58.3% | ||

| 7 | 1 | 9.60 × 10−5 | 4.90 × 10−8 | 2.04 × 107 | 35.2% | 49.3% |

| 2 | 5.30 × 10−5 | 2.70 × 10−8 | 3.70 × 107 | 63.8% | ||

| 3 | 6.90 × 10−5 | 3.52 × 10−8 | 2.84 × 107 | 49.0% | ||

| 8 | 1 | 8.20 × 10−5 | 4.18 × 10−8 | 2.39 × 107 | 41.2% | 55.5% |

| 2 | 5.60 × 10−5 | 2.86 × 10−8 | 3.50 × 107 | 60.3% | ||

| 3 | 5.20 × 10−5 | 2.65 × 10−8 | 3.77 × 107 | 65.0% |

| Weld Number | Specimen | UTS (MPa) | Efficiency (%) |

|---|---|---|---|

| 1 | p1 | 125 | 55.8 |

| 2 | p2 | 72.4 | 32.3 |

| p3 | 100.5 | 44.9 | |

| 3 | p1 | 57.7 | 25.8 |

| 4 | p1 | 136.7 | 61.0 |

| p2 | 168.3 | 75.1 | |

| p3 | 131.6 | 58.8 | |

| 6 | p1 | 65 | 29.0 |

| p2 | 96.7 | 43.2 | |

| p3 | 110.3 | 49.2 |

| Weld Number | Quantity | Degrees of Freedom | Standard Deviation | Alpha Value | Width of Confidence Interval |

|---|---|---|---|---|---|

| 2 | 3 | 2 | 0.0627 | 0.05 | 0.1558 |

| 4 | 3 | 2 | 0.0725 | 0.05 | 0.1801 |

| 6 | 3 | 2 | 0.0847 | 0.05 | 0.2104 |

| Source of Variation | Sum of Squares | Degrees of Freedom | Mean Squares | F-Value | Probability | Critical F-Value |

|---|---|---|---|---|---|---|

| Between Groups | 0.1106 | 2 | 0.0553 | 65,535 | ∞ | 5.1433 |

| Within Groups | 0 | 6 | 0 | |||

| Total | 0.1106 | 8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoyos, E.; Serna, M.C.; Montoya, Y.; Córdoba, J.H. Assessing Tensile Strength and Electrical Conductivity of Friction Stir-Welded Joints of Copper and Aluminum Alloys. Metals 2024, 14, 631. https://doi.org/10.3390/met14060631

Hoyos E, Serna MC, Montoya Y, Córdoba JH. Assessing Tensile Strength and Electrical Conductivity of Friction Stir-Welded Joints of Copper and Aluminum Alloys. Metals. 2024; 14(6):631. https://doi.org/10.3390/met14060631

Chicago/Turabian StyleHoyos, Elizabeth, María Camila Serna, Yesid Montoya, and Jorge Hernán Córdoba. 2024. "Assessing Tensile Strength and Electrical Conductivity of Friction Stir-Welded Joints of Copper and Aluminum Alloys" Metals 14, no. 6: 631. https://doi.org/10.3390/met14060631

APA StyleHoyos, E., Serna, M. C., Montoya, Y., & Córdoba, J. H. (2024). Assessing Tensile Strength and Electrical Conductivity of Friction Stir-Welded Joints of Copper and Aluminum Alloys. Metals, 14(6), 631. https://doi.org/10.3390/met14060631