Numerical Study on the Heat Transfer of Confined Air-Jet Quenching of Steel Sheets

Abstract

1. Introduction

2. Methodology

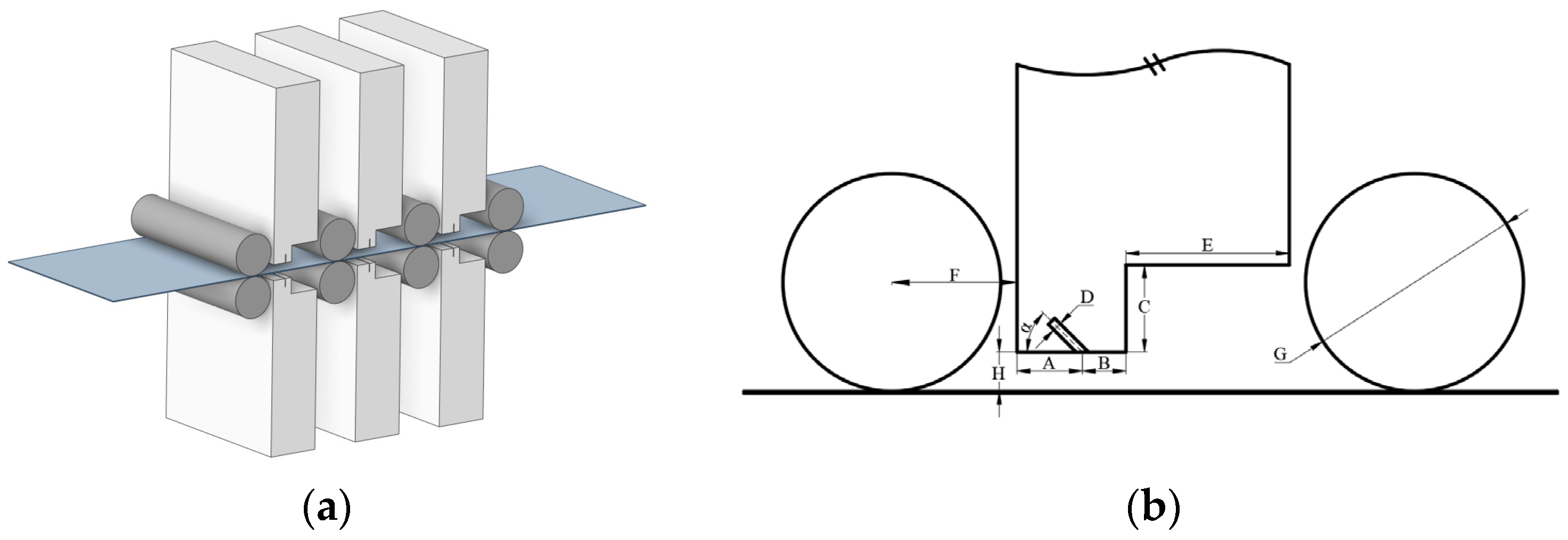

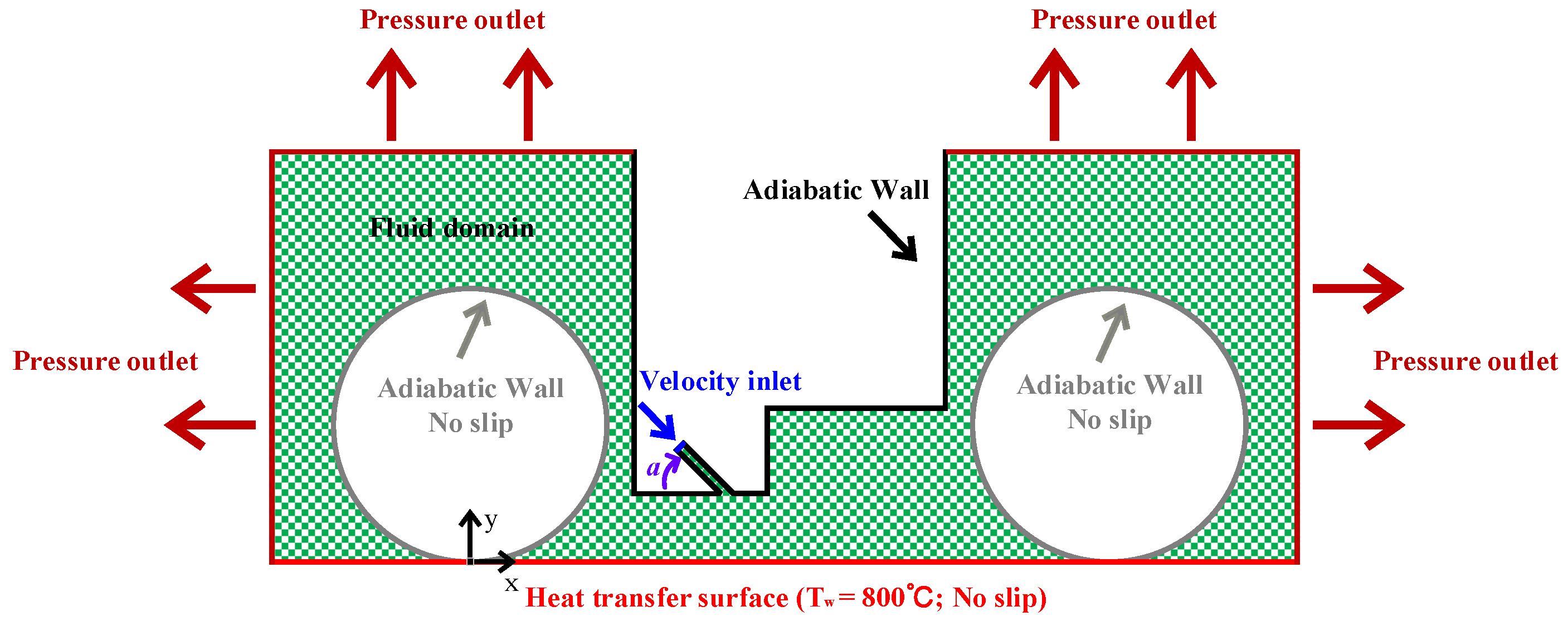

2.1. Problem Description

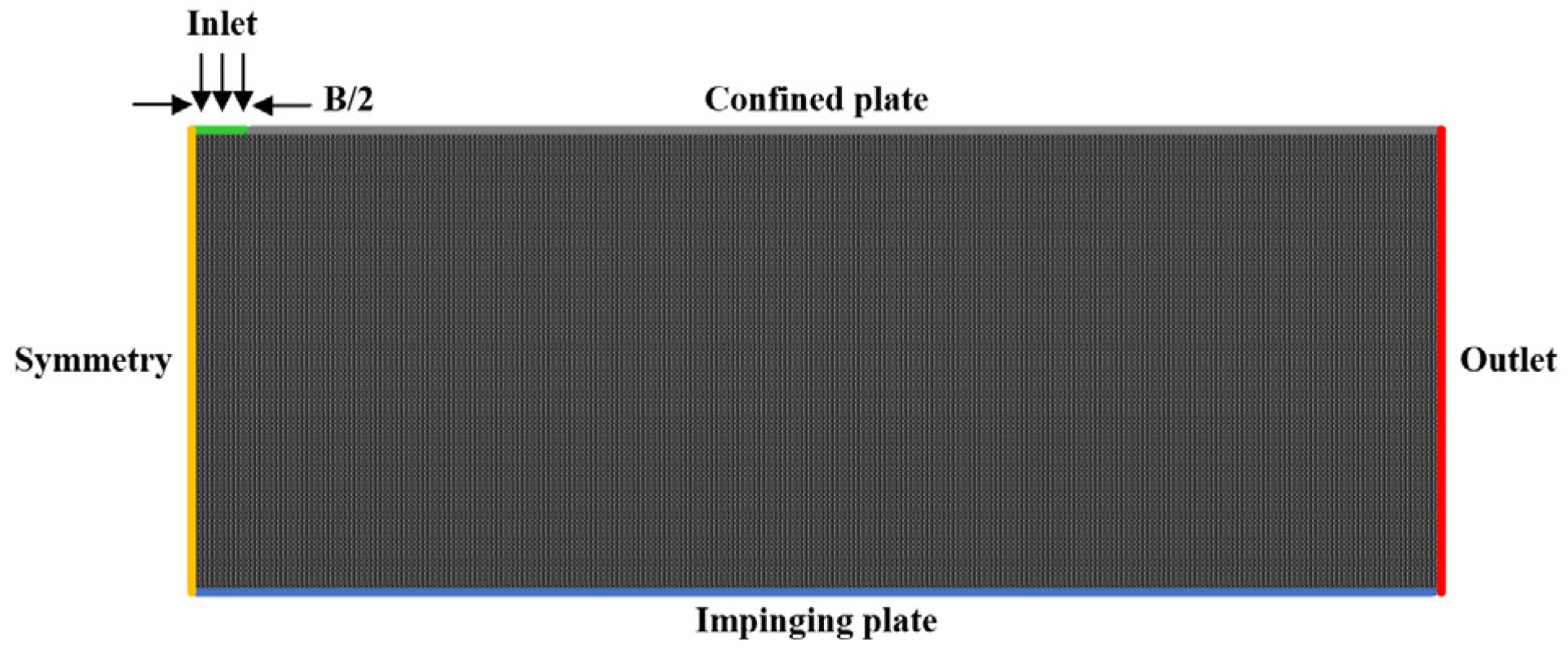

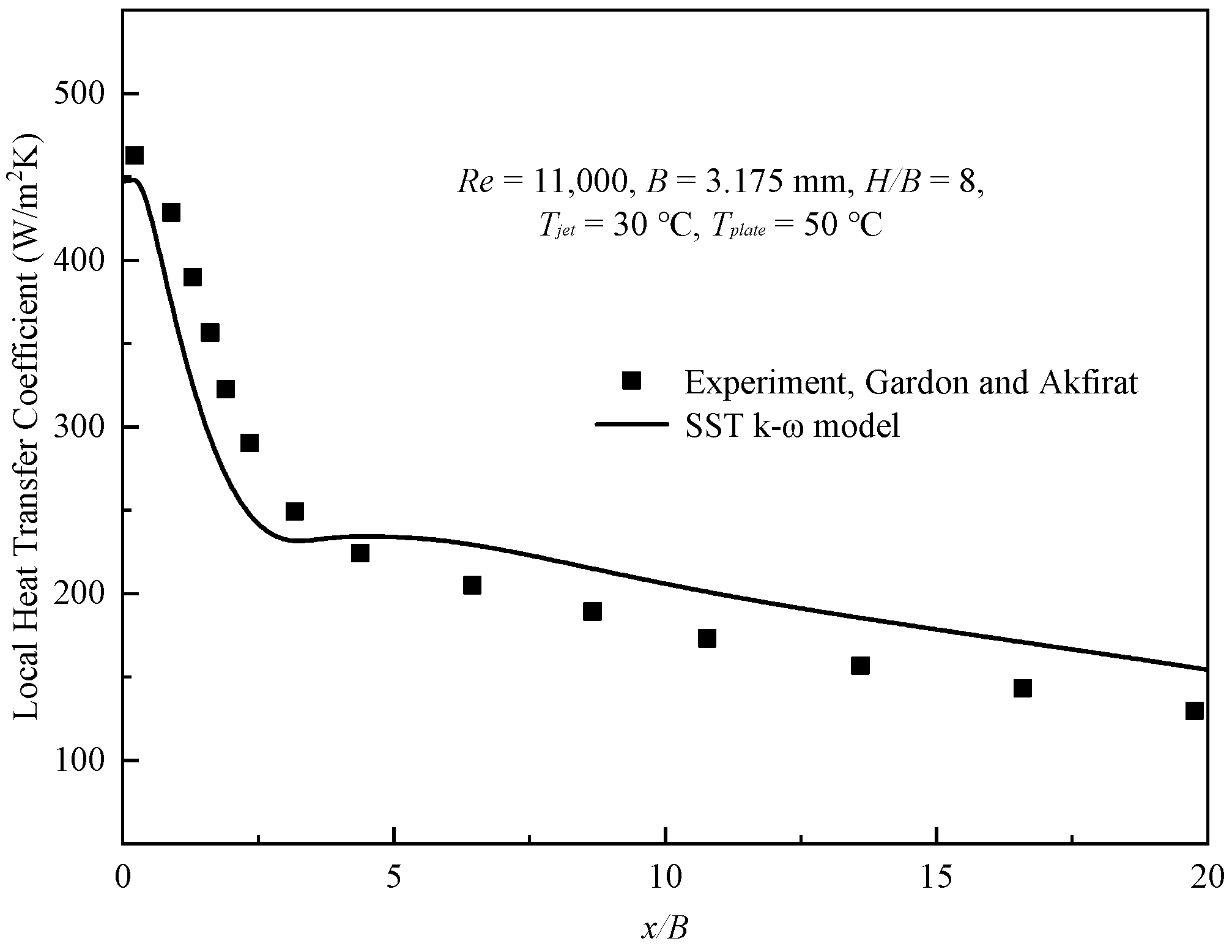

2.2. Turbulence Model and Numerical Procedure

2.3. Boundary Conditions

- The inlet Reynolds numbers were 41,076, 32,692, and 24,644. The jet temperature was 26 °C, and the turbulence intensity was maintained at 4%. The thermal conductivity, specific heat capacity, and viscosity of air were polynomial functions related to temperature [32].

- Considering the cooling intensity and safety factors, dimensionless heights H/D of 24, 20, and 16 were selected.

- The nozzle angles a were 45°, 70°, 90°, 110°, and 135°, according to the left side wall of the nozzle.

- The grade of UHSS used in this paper was Q1100, and its chemical composition is shown in Table 3. The surface temperature of the steel sheet was fixed at 800 °C. At this temperature, the steel was in an austenitic state. The density was 7850 kg/m3, the specific heat was 596 J·kg−1·K−1, and the thermal conductivity was 24.8 W·m−1·K−1. The pressure roller wall and steel sheet surface were assumed to be stationary, and the roughness constant was 0.5. The walls of the air-jet box and pressure roller consisted of adiabatic boundaries. The ambient temperature was the same as the jet temperature.

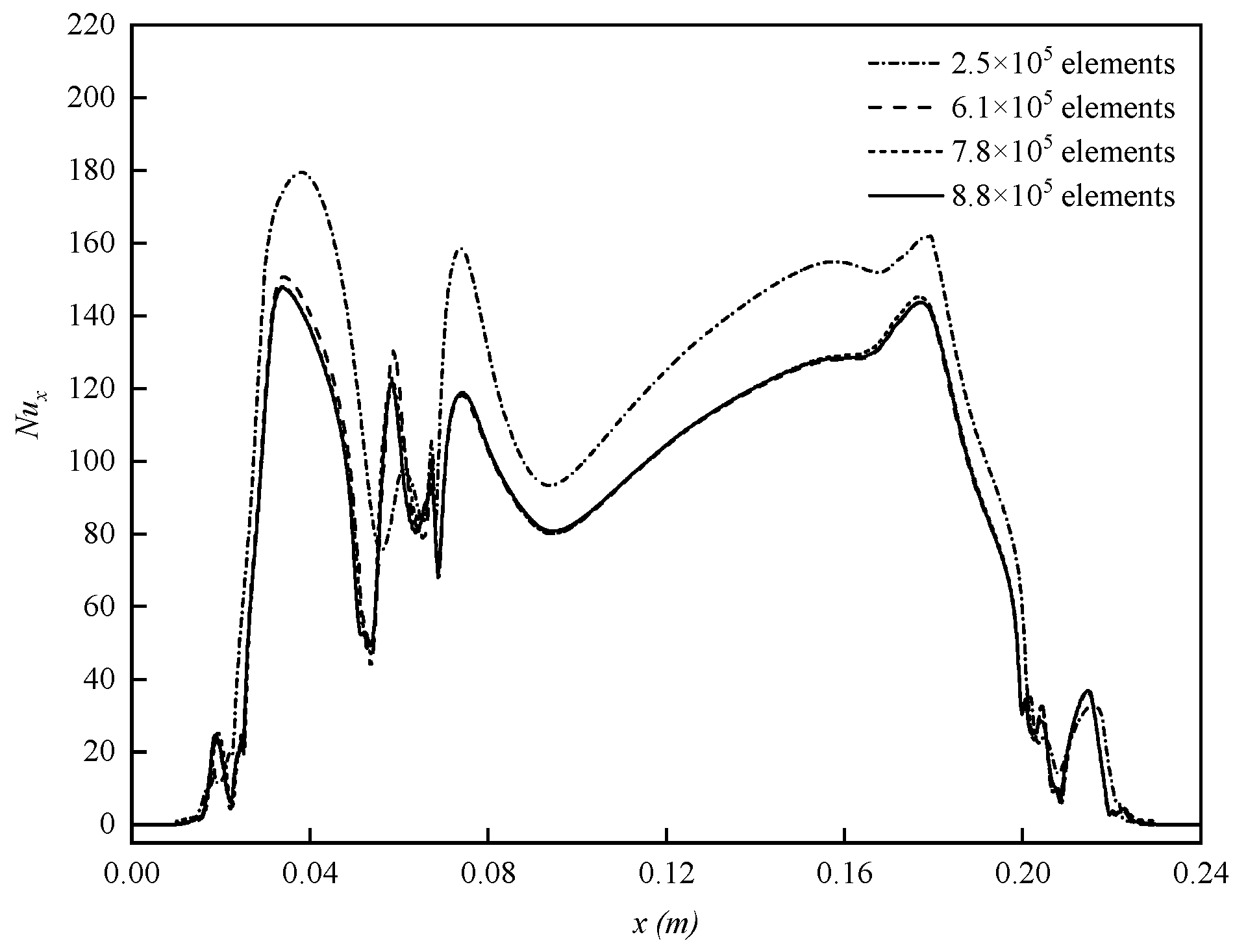

2.4. Grid Independence and Verification of the Numerical Solution Procedure

3. Results and Discussion

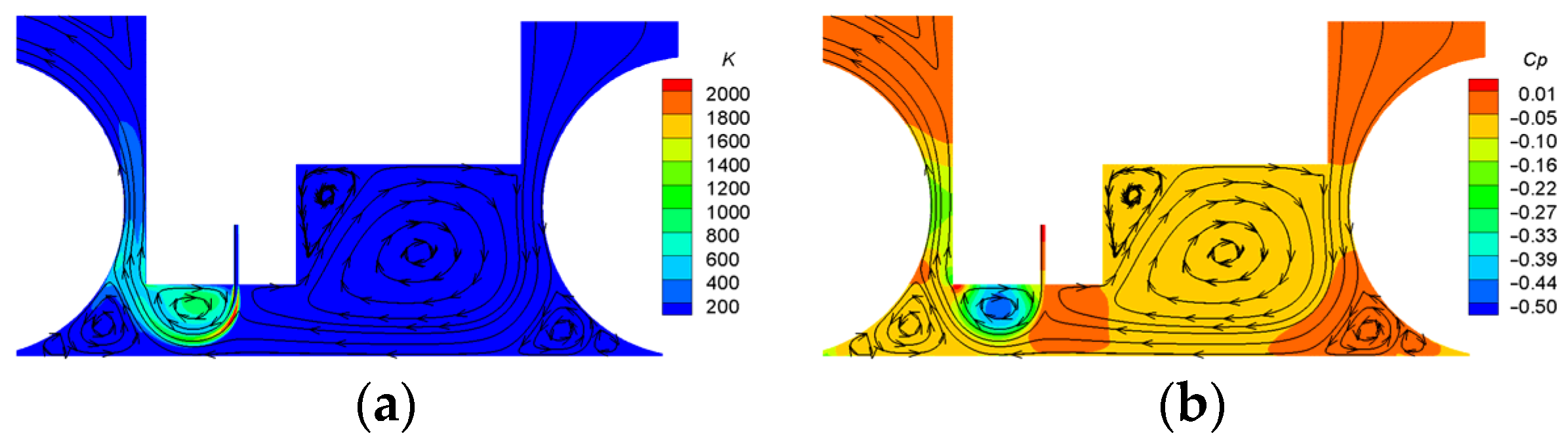

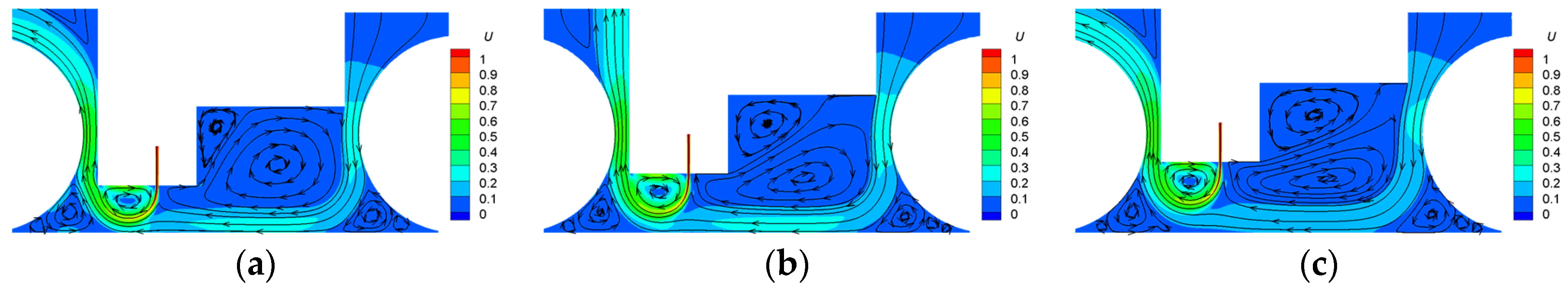

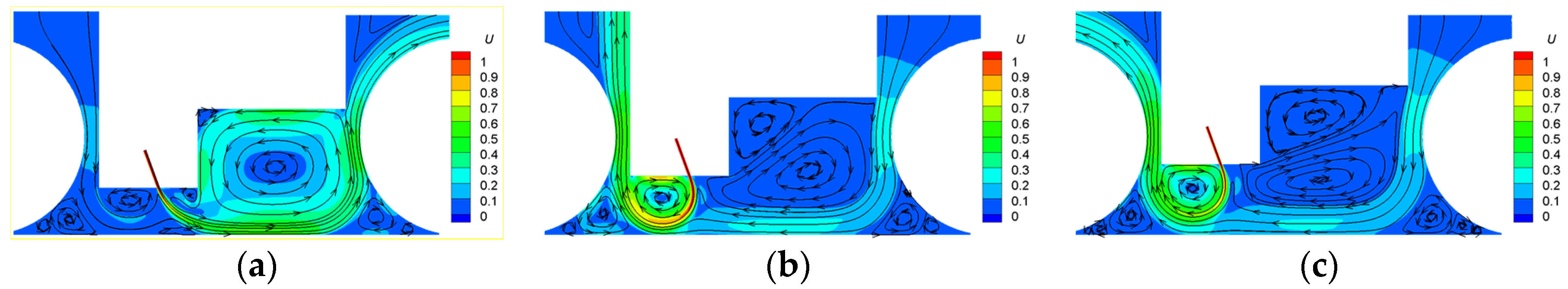

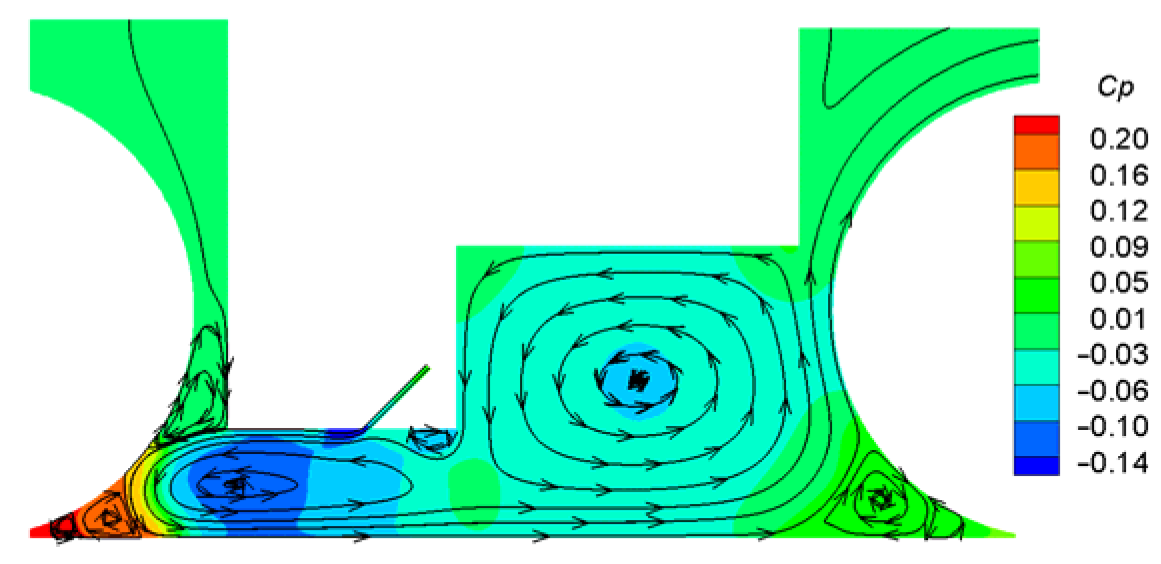

3.1. Flow Field Analysis

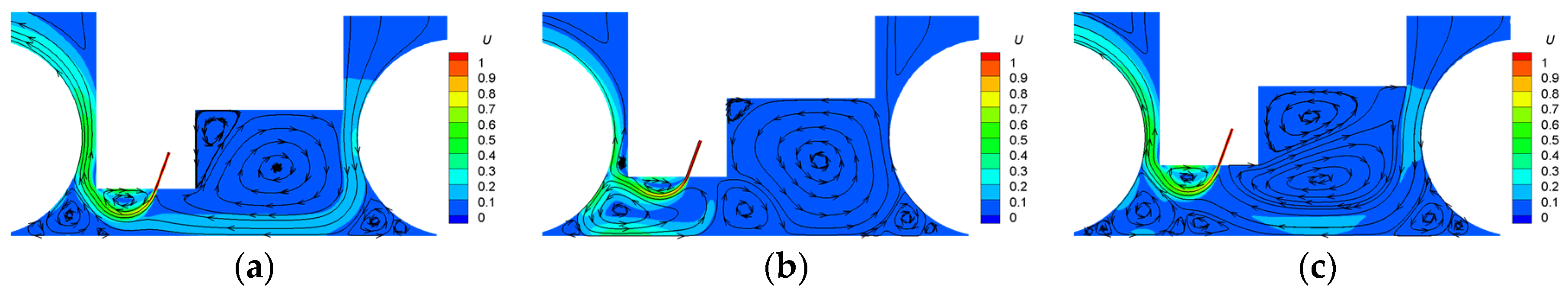

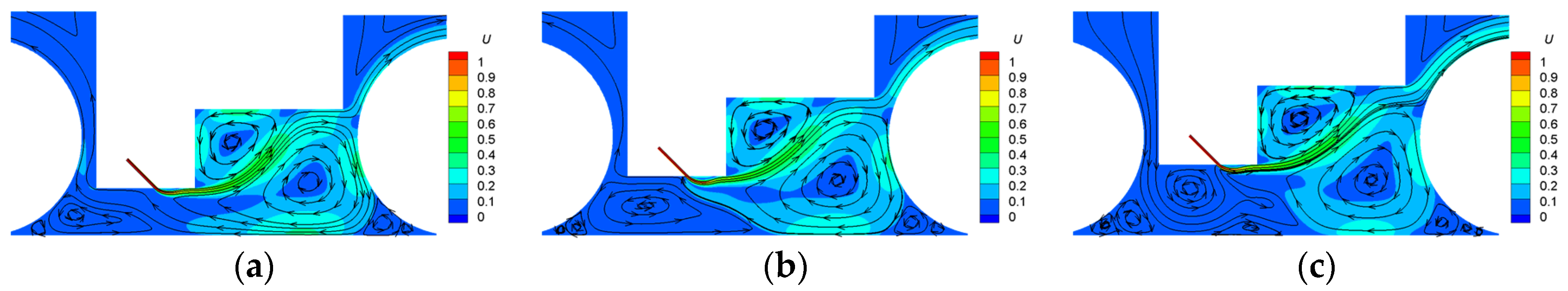

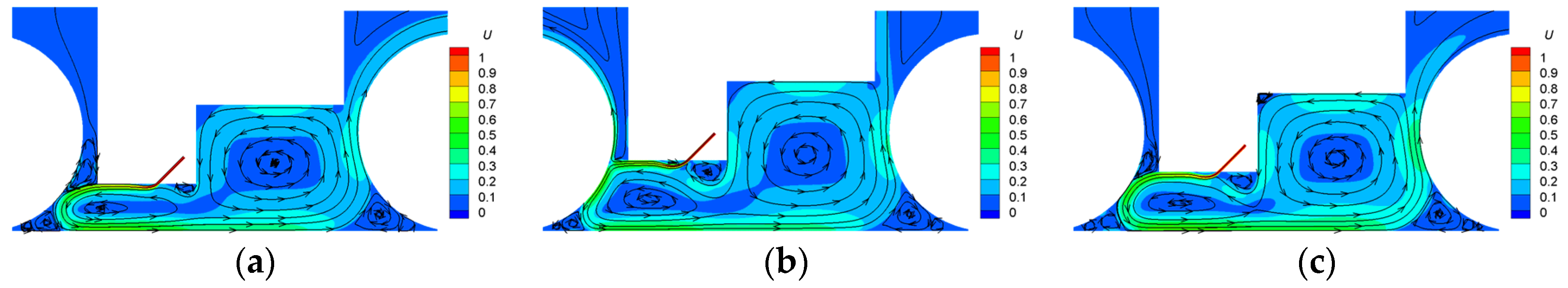

3.1.1. Perpendicular Jet

3.1.2. Nearly Perpendicular Jet

3.1.3. Small Angle Jet

3.2. Heat Transfer Analysis

4. Conclusions

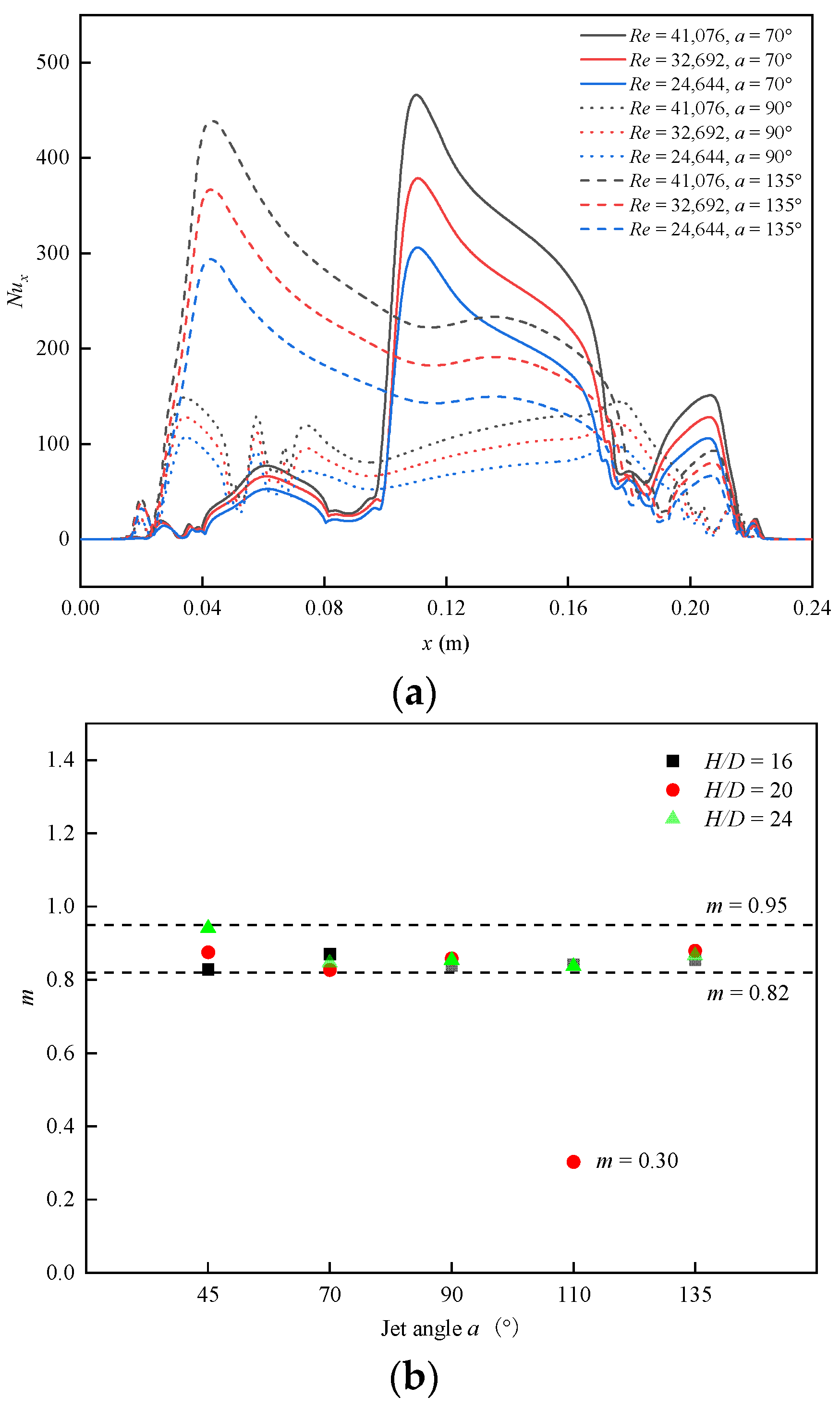

- The local Nusselt numbers Nux distributions at different Reynolds numbers demonstrated similarity, and was proportional to Rem. The exponent, m, varied mostly between 0.82 and 0.95.

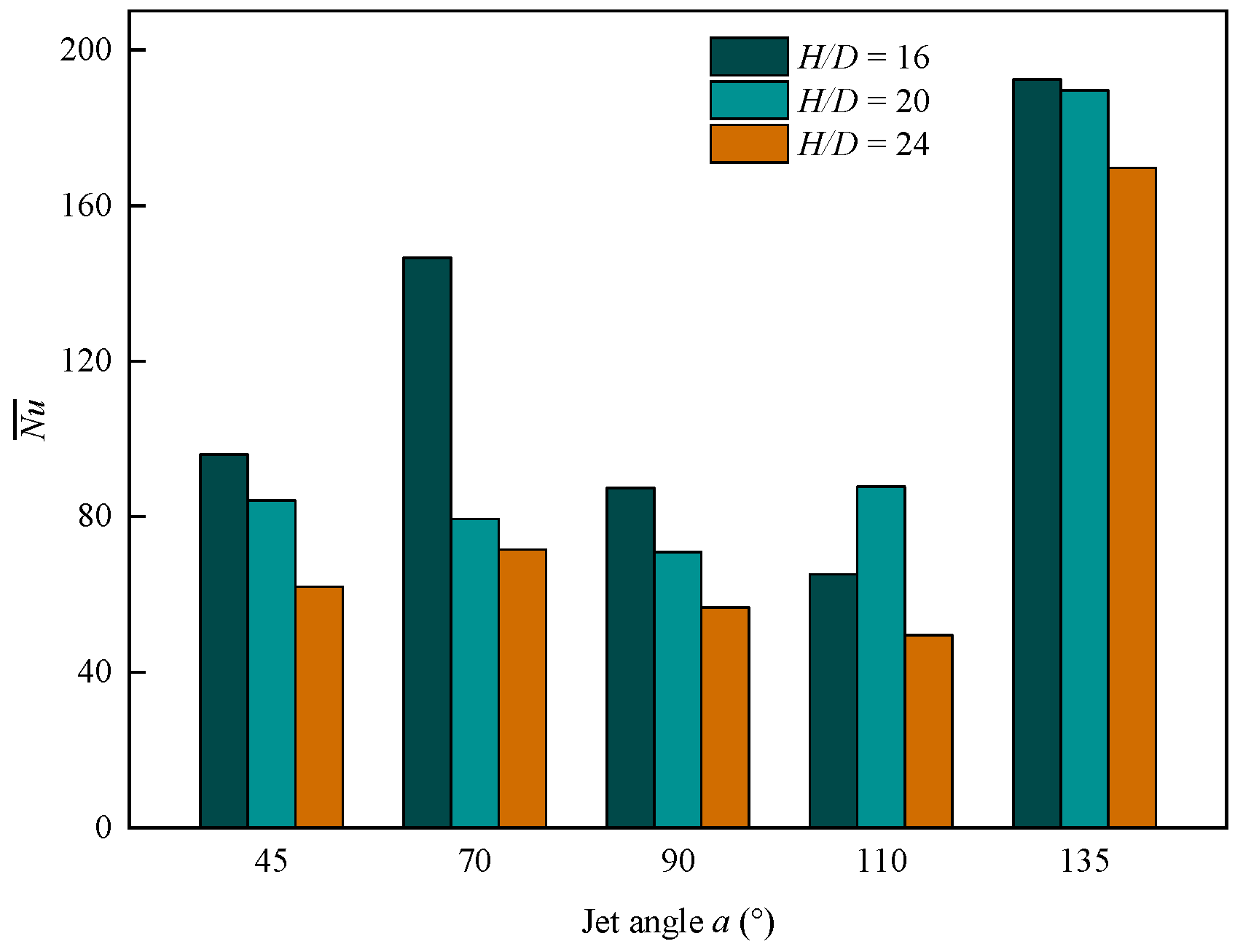

- By altering the impact angle of the jet on the pressure roller and the heat transfer wall, the jet angle and jet height could modify the wall heat transfer mode and the effective heat transfer area. When jet angle a and jet height H/D were properly combined, high-intensity convective heat transfer could be achieved, increasing by 2.89 times at the same Reynolds number.

- The Coanda effect altered the jet’s direction when the small jet angle was directed toward the entrance side of the steel sheet. This caused the high value Numax to appear at the entrance side, increasing the cooling rate in the high temperature region and quenching temperature, which was advantageous for the successful completion of the quenching process.

- It should be noted that although numerical models have great advantages in theoretical analysis, they idealize the complex industrial environment and can only guide but not replace industrial tests. Therefore, it is the most economical and reliable way to carry out industrial tests on the basis of sufficient theoretical research. In the future, the microstructure evolution and stress–strain behavior of steel sheets during air-jet quenching need to be further studied. This will further promote the production and application of high-flatness UHSS sheets.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, K.; Yang, T.; Gong, N.; Wu, J.; Wu, X.; Zhang, D.Z.; Murr, L.E. Additive manufacturing of ultra-high strength steels: A review. J. Alloys Compd. 2023, 965, 171390. [Google Scholar] [CrossRef]

- Tümer, M.; Schneider-Bröskamp, C.; Enzinger, N. Fusion welding of ultra-high strength structural steels—A review. J. Manuf. Process. 2022, 82, 203–229. [Google Scholar] [CrossRef]

- Maraveas, C.; Gernay, T.; Franssen, J. Buckling of steel plates at elevated temperatures: Theory of Perfect Plates vs Finite Element Analysis. In Proceedings of the 2nd International Conference on Structural Safety under Fire and Blast Loading–CONFAB, London, UK, 10 September 2017. [Google Scholar]

- Samuel, A.; Prabhu, K.N. Residual Stress and Distortion during Quench Hardening of Steels: A Review. J. Mater. Eng. Perform. 2022, 31, 5161–5188. [Google Scholar] [CrossRef]

- Fukuda, H.; Nakata, N.; Kijima, H.; Kuroki, T.; Fujibayashi, A.; Takata, Y.; Hidaka, S. Effects of Surface Conditions on Spray Cooling Characteristics. ISIJ Int. 2016, 56, 628–636. [Google Scholar] [CrossRef]

- Zhu, J.; Dou, R.; Hu, Y.; Zhang, S. Wang, Heat transfer of multi-slot nozzles air jet impingement with different Reynolds number. Appl. Therm. Eng. 2021, 186, 116470. [Google Scholar] [CrossRef]

- Wan, F.; Wang, Y.; Qin, S. Modeling of Strip Temperature in Rapid Cooling Section of Vertical Continuous Annealing Furnace. J. Iron Steel Res. Int. 2012, 19, 27–32. [Google Scholar] [CrossRef]

- Cademartori, S.; Cravero, C.; Marini, M.; Marsano, D. CFD Simulation of the Slot Jet Impingement Heat Transfer Process and Application to a Temperature Control System for Galvanizing Line of Metal Band. Appl. Sci. 2021, 11, 1149. [Google Scholar] [CrossRef]

- Perry, K.P. Heat Transfer by Convection from a Hot Gas Jet to a Plane Surface. Proc. Inst. Mech. Eng. 1954, 168, 775–784. [Google Scholar] [CrossRef]

- Martin, H. Heat and Mass Transfer between Impinging Gas Jets and Solid Surfaces. In Advances in Heat Transfer; Hartnett, J.P., Irvine, T.F., Eds.; Elsevier: Amsterdam, The Netherlands, 1977; Volume 13, pp. 1–60. [Google Scholar]

- Barbosa, F.V.; Teixeira, S.F.C.F.; Teixeira, J.C.F. Convection from multiple air jet impingement—A review. Appl. Therm. Eng. 2023, 218, 119307. [Google Scholar] [CrossRef]

- Shukla, A.K.; Dewan, A. Flow and thermal characteristics of jet impingement: Comprehensive review. Int. J. Heat Technol. 2017, 35, 153–166. [Google Scholar] [CrossRef]

- Dewan, A.; Dutta, R.; Srinivasan, B. Recent trends in computation of turbulent jet impingement heat transfer. Heat Transf. Eng. 2012, 33, 447–460. [Google Scholar] [CrossRef]

- Celik, N. Effects of dimples’ arrangement style of rough surface and jet geometry on impinging jet heat transfer. Heat Mass Transf. 2020, 56, 339–354. [Google Scholar] [CrossRef]

- Barbosa, F.V.; Sousa, S.D.T.; Teixeira, S.F.C.F.; Teixeira, J.C.F. Application of Taguchi Method for the Analysis of a Multiple Air Jet Impingement System with and without Target Plate Motion. Int. J. Heat Mass Transf. 2021, 176, 121504. [Google Scholar] [CrossRef]

- Barbosa, F.V.; Teixiera, S.F.C.F.; Teixeira, J.C.F. 2D PIV analysis of the flow dynamics of multiple jets impinging on a complex moving plate. Int. J. Heat Mass Transf. 2022, 188, 122600. [Google Scholar] [CrossRef]

- Taguchi, G.; Chowdhury, S.; Taguchis, W.Y. Quality Engineering Handbook, 1st ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2005. [Google Scholar]

- Attalla, M.; Maghrabie, H.M.; Specht, E. Effect of inclination angle of a pair of air jets on heat transfer into the flat surface. Exp. Therm. Fluid Sci. 2017, 85, 85–94. [Google Scholar] [CrossRef]

- Ingole, S.B.; Sundaram, K.K. Experimental average Nusselt number characteristics with inclined non-confined jet impingement of air for cooling application. Exp. Therm. Fluid Sci. 2016, 77, 124–131. [Google Scholar] [CrossRef]

- Jensen, M.V.; Walther, J.H. Numerical Analysis of Jet Impingement Heat Transfer at High Jet Reynolds Number and Large Temperature Difference. Heat Transf. Eng. 2013, 34, 801–809. [Google Scholar] [CrossRef]

- Shariatmadar, H.; Mousavian, S.; Sadoughi, M.; Ashjaee, M. Experimental and numerical study on heat transfer characteristics of various geometrical arrangement of impinging jet arrays. Int. J. Therm. Sci. 2016, 102, 26–38. [Google Scholar] [CrossRef]

- Goodro, M.; Park, J.; Ligrani, P.; Fox, M.; Moon, H. Effects of Mach number and Reynolds number on jet array impingement heat transfer. Int. J. Heat Mass Transf. 2007, 50, 367–380. [Google Scholar] [CrossRef]

- Li, W.; Yang, L.; Li, X.; Ren, J.; Jiang, H. Effect of Reynolds Number, Hole Patterns, and Target Plate Thickness on the Cooling Performance of an Impinging Jet Array—Part II: Conjugate Heat Transfer Results and Optimization. J. Turbomach. 2017, 139, 101001. [Google Scholar] [CrossRef]

- Ozmen, Y.; Ipek, G. Investigation of flow structure and heat transfer characteristics in an array of impinging slot jets. Heat Mass Transf. 2016, 52, 773–787. [Google Scholar] [CrossRef]

- Wen, Z.; He, Y.; Cao, X.; Yan, C. Numerical study of impinging jets heat transfer with different nozzle geometries and arrangements for a ground fast cooling simulation device. Int. J. Heat Mass Transf. 2016, 95, 321–335. [Google Scholar] [CrossRef]

- Sarkar, A.; Singh, R.P. Spatial variation of convective heat transfer coefficient in air impingement applications. J. Food Sci. 2003, 68, 910–916. [Google Scholar] [CrossRef]

- Attalla, M.; Salem, M. Heat transfer from a flat surface to an inclined impinging jet. Heat Mass Transf. 2014, 50, 915–922. [Google Scholar] [CrossRef]

- Li, W.; Xu, M.; Ren, J.; Jiang, H. Experimental investigation of local and average heat transfer coefficients under aninline impinging jet array, including jets with low impingement distance and inclined angle. J. Heat Transf. 2017, 139, 12201. [Google Scholar] [CrossRef]

- Garimella, S.V.; Schroeder, V.P. Local heat transfer distributions in confined multiple air jet impingement. J. Electron. Packag. 2001, 123, 165–172. [Google Scholar] [CrossRef]

- Ichikawa, Y.; Motosuke, M.; Kameya, Y.; Yamamoto, M.; Honami, S. Three-dimensional flow characterization of a square array of multiple circular impinging jets using stereoscopic PIV and heat transfer relation. J. Vis. 2016, 19, 89–101. [Google Scholar] [CrossRef]

- Akansu, Y.E.; Sarioglu, M.; Kuvvet, K.; Yavuz, T. Flow field and heat transfer characteristics in an oblique slot jet impinging on a flat plate. Int. Commun. Heat Mass Transf. 2008, 35, 873–880. [Google Scholar] [CrossRef]

- Pawar, S.; Patel, D.K. Study of conjugate heat transfer from the impingement of an inclined free slot jet onto the moving hot surface. Int. Commun. Heat Mass Transf. 2020, 111, 104429. [Google Scholar] [CrossRef]

- Mousa, M.H.; Miljkovic, N.; Nawaz, K. Review of heat transfer enhancement techniques for single phase flows. Renew. Sustain. Energy Rev. 2021, 137, 110566. [Google Scholar] [CrossRef]

- Ramesh, K.N.; Sharma, T.K.; Rao, G.A.P. Latest Advancements in Heat Transfer Enhancement in the Micro-channel Heat Sinks: A Review. Arch. Comput. Methods Eng. 2021, 28, 3135–3165. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Pulat, E.; Beyazoglu, E. Computational investigation of confined wall inclination effects on impinging jet fluid flow and heat transfer. Int. J. Therm. Sci. 2021, 163, 106749. [Google Scholar] [CrossRef]

- ZAhmed, U.; Al-Abdeli, Y.M.; Guzzomi, F.G. Flow field and thermal behaviour in swirling and non-swirling turbulent impinging jets. Int. J. Therm. Sci. 2017, 114, 241–256. [Google Scholar]

- Hofmann, H.M.; Kaiser, R.; Kind, M.; Martin, H. Calculations of steady and pulsating impinging jets—An assessment of 13 widely used turbulence models. Numer. Heat Transf. Part B-Fundam. 2007, 51, 565–583. [Google Scholar] [CrossRef]

- Qu, S.; Liu, S.; Ong, M.C. An evaluation of different RANS turbulence models for simulating breaking waves past a vertical cylinder. Ocean. Eng. 2021, 234, 109195. [Google Scholar] [CrossRef]

- Li, Z.; Lu, X.; Wu, Y.; Han, G. Quantitative investigation of the turbulence model effect on high-pressure-ratio centrifugal compressor performance prediction. Int. Commun. Heat Mass Transf. 2023, 142, 106644. [Google Scholar] [CrossRef]

- Tepe, A.Ü.; Uysal, Ü.; Yetişken, Y.; Arslan, K. Jet impingement cooling on a rib-roughened surface using extended jet holes. Appl. Therm. Eng. 2020, 178, 115601. [Google Scholar] [CrossRef]

- Huang, H.; Sun, T.; Zhang, G.; Liu, M.; Zhou, B. The effects of rough surfaces on heat transfer and flow structures for turbulent round jet impingement. Int. J. Therm. Sci. 2021, 166, 106982. [Google Scholar] [CrossRef]

- Huang, H.; Sun, T.; Zhang, G.; Li, D.; Wei, H. Evaluation of a developed SST k-ω turbulence model for the prediction of turbulent slot jet impingement heat transfer. Int. J. Heat Mass Transf. 2019, 139, 700–712. [Google Scholar] [CrossRef]

- Chitsazan, A.; Glasmacher, B. Numerical Investigation of Heat Transfer and Pressure Force from Multiple Jets Impinging on a Moving Flat Surface. Int. J. Heat Technol. 2020, 38, 601–610. [Google Scholar] [CrossRef]

- Kadiyala, P.K.; Chattopadhyay, H. Numerical Analysis of Heat Transfer from a Moving Surface Due to Impingement of Slot Jets. Heat Transf. Eng. 2018, 39, 98–106. [Google Scholar] [CrossRef]

- Zhang, R.; Li, Z.; Zhang, Y.; Chen, D.; Yuan, G. Numerical investigation of jet layout for annular jet cooling on a steel tube. Appl. Therm. Eng. 2022, 213, 118825. [Google Scholar] [CrossRef]

- Gardon, R.; Akfirat, J.C. Heat transfer characteristics of impinging two-dimensional air jets. J. Heat Transf. 1966, 88, 101–107. [Google Scholar] [CrossRef]

- Tepe, A.Ü.; Yetişken, Y.; Uysal, Ü.; Arslan, K. Experimental and numerical investigation of jet impingement cooling using extended jet holes. Int. J. Heat Mass Transf. 2020, 158, 119945. [Google Scholar] [CrossRef]

- Jambunathan, K.; Lai, E.; Moss, M.; Button, B.L. A review of heat transfer data for single circular jet impingement. Int. J. Heat Fluid Flow 1992, 13, 106–115. [Google Scholar] [CrossRef]

| A [mm] | B [mm] | C [mm] | D [mm] | E [mm] | F [mm] | G [mm] | H [mm] |

|---|---|---|---|---|---|---|---|

| 30 | 20 | 40 | 1.5 | 75 | 57.5 | 100 | ≥24 |

| α1 | α2 | β1 | β2 | β* | σk1 | σk2 | σω1 | σω2 |

|---|---|---|---|---|---|---|---|---|

| 5/9 | 0.44 | 3/40 | 0.0828 | 0.09 | 0.85 | 1 | 0.5 | 0.856 |

| C | Si | Mn | Cr | B | S | P |

|---|---|---|---|---|---|---|

| 0.17–0.20 | 0.20–0.30 | 0.80–1.20 | 0.40–0.60 | 0.001–0.002 | <0.005 | <0.010 |

| Jet Angle [°] | X Coordinate of Maximum Numax [m] | Value of Maximum Numax | H/D |

|---|---|---|---|

| 45 | 0.190 | 240 | 16 |

| 70 | 0.110 | 466 | 16 |

| 90 | 0.034 | 148 | 16 |

| 110 | 0.037 | 292 | 20 |

| 135 | 0.043 | 438 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, Y.; Fu, T.; Liu, G.; Wang, G. Numerical Study on the Heat Transfer of Confined Air-Jet Quenching of Steel Sheets. Metals 2024, 14, 377. https://doi.org/10.3390/met14040377

Ye Y, Fu T, Liu G, Wang G. Numerical Study on the Heat Transfer of Confined Air-Jet Quenching of Steel Sheets. Metals. 2024; 14(4):377. https://doi.org/10.3390/met14040377

Chicago/Turabian StyleYe, Yanqi, Tianliang Fu, Guanghao Liu, and Guodong Wang. 2024. "Numerical Study on the Heat Transfer of Confined Air-Jet Quenching of Steel Sheets" Metals 14, no. 4: 377. https://doi.org/10.3390/met14040377

APA StyleYe, Y., Fu, T., Liu, G., & Wang, G. (2024). Numerical Study on the Heat Transfer of Confined Air-Jet Quenching of Steel Sheets. Metals, 14(4), 377. https://doi.org/10.3390/met14040377