Abstract

Shape memory alloys (SMAs) demonstrate a shape memory effect and superelasticity that can provide recovery performance to structural members. In this study, a round SMA bar was designed to replace the conventional deformed steel bar, particularly within the plastic hinge section of structural members. To integrate the SMA bar and the existing steel bar, a mechanical coupler was proposed by utilizing the advantages of both one-touch and threaded couplers. Uniaxial tensile tests were conducted to analyze the performance of the proposed coupler and the mechanical properties of the SMA–steel connected bar. Stress and strain relationships were examined for steel bars mechanically connected with the SMA bar and for SMA bars before and after exhibiting the shape memory effect. To induce the shape memory effect, SMA should be heated above the finished austenite temperature. Due to the difficulty of accurately measuring strain on the heated bar using traditional contact methods, we employed digital image correlation technology for precise strain measurement of the heated SMA bar. The experimental results indicate the effective application of SMA bars within the plastic hinge region of structural members using the proposed mechanical coupler.

1. Introduction

Concrete structures are susceptible to deformation and cracking under external loads. In particular, seismic loads cause residual deformation in structural members. This residual deformation triggers a P-Δ second-order effect that has a significant impact on the safety of structures. Moreover, residual deformation poses challenges when repairing and reinforcing structures for reuse. The integration of materials with recovery properties, such as shape memory alloys (SMAs), becomes essential in eliminating residual deformation from structural members.

The discovery of the shape memory effect in SMAs traces back to the 1950s in certain materials [1]. Active investigation into SMAs began with the discovery of Ni–Ti alloys in 1963 [2]. Subsequently, a variety of SMAs emerged, including Fe-based alloys, Cu-based alloys, Ni–Ti alloys, and HTSMAs [3]. Research into displacement and strain recovery performance according to the thermodynamic behavior of diverse SMAs continued until the 2010s [4,5,6,7,8]. The exploration of introducing SMAs into civil engineering structures commenced in the 2000s. Janke et al. [9] examined the potential introduction of SMAs into civil engineering structures, addressing the nonlinear aspects of the shape memory effect and superelasticity related to fatigue. As the feasibility of introducing SMAs to structural members gained attention, research emphasized processing SMAs into fiber forms to achieve self-centering properties by incorporating SMA fibers into cement mortar [10,11]. In addition, research has also pursued stress recovery and crack closure capabilities of cold-drawn and rolled wires [12,13]. Subsequent research has been conducted using SMA wires to prestress structural elements [14,15], and research continues to apply SMAs to structural members using various methods [16,17,18,19,20].

This study utilized an SMA bar fabricated from a nickel–titanium (Ni–Ti) alloy known for its safety, practicality, and excellent thermodynamic performance. The Ni–Ti SMA enables displacement recovery through the shape memory effect, which returns to its original shape above a specific temperature threshold, and the superelastic ability, which returns to its initial state without residual deformation even after surpassing the yield point [21,22,23]. A recent study was conducted to enhance the seismic performance of concrete walls by considering the introduction of SMA bars to replace conventional steel bars in structural members [24,25,26,27]. However, the high production costs associated with SMA bars pose an economic challenge compared to conventional steel bars. Therefore, this study developed a technique for localized SMA bar application in the plastic hinge area—the most vulnerable part of a structural member where significant displacements occur.

The localized application of SMA bars necessitates a connection method with conventional steel bars in structural members. Common joining methods used in the field include overlapping, welding, and mechanical connections. In particular, mechanical connections using couplers can resist tensile forces regardless of attachment strength and are easily implemented in the field due to their excellent constructability. Recent studies have concentrated on assessing the ductility and strength of mechanical couplers, as well as the nonlinear cyclic performance of reinforced concrete members utilizing couplers [28,29,30]. Some studies have introduced SMA bars into the plastic hinge area of concrete structures using couplers [31,32,33]. These previous approaches used threaded couplers to connect SMA bars to steel bars, which requires additional machining and labor at the end of the existing steel bar connected to the coupler. We propose a mechanical coupler that combines a one-touch coupler and a threaded coupler to enhance usability while ensuring the connection behavior between steel bars and SMA bars.

A uniaxial tensile test was conducted to evaluate the mechanical properties and structural performance of the round SMA and deformed steel bars connected by the proposed coupler. Additional tests were carried out to evaluate the mechanical performance of martensite SMA bar when heated above the transition temperature in the uniaxial tensile test. Accurate measurement of the strain values is crucial in determining the elasticity and yielding of SMA and steel bars. Therefore, we utilized digital image correlation (DIC), enabling precise measurements for both the SMA and steel bars.

2. Experiment Design

2.1. SMA Bar

Ni–Ti SMA demonstrates two distinct states, austenite and martensite, each are defined by its crystal structure. Typically, Ni–Ti alloys exist in the austenite state at high temperatures. Austenitic properties in Ni–Ti alloys are achieved through a special treatment process involving gradual cooling from a specific high temperature above room temperature. The austenitic state possesses a body-centered crystal structure that allows the material to return to its original shape when no external stress is applied. When the SMA in the high-temperature austenite state is cooled to room temperature without any special treatment, it undergoes a transformation into the martensite state, characterized by a crystal structure belonging to the monoclinic system [34,35]. Consequently, martensite SMA loses superelasticity and exhibits low ductility compared to austenite SMA.

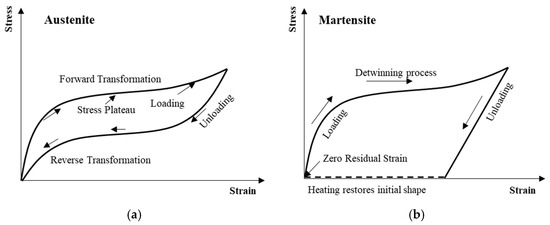

Figure 1a illustrates the stress–strain curve of austenite SMA, which demonstrates its superelastic behavior characterized by the absence of residual deformation and the return to the original state of the material, even after passing through the stress plateau region [36]. On the other hand, the stress–strain curve of martensite SMA, shown in Figure 1b, displays the detwinning process where displacement is partially recovered upon the removal of the applied load. However, complete displacement recovery does not occur, leaving residual deformation. This residual deformation can be recovered using the shape memory effect, which restores the initial shape of the material and transforms the martensite state back into the austenite states when the temperature of martensite increases.

Figure 1.

Stress–strain relationship: (a) austenite and (b) martensite SMAs.

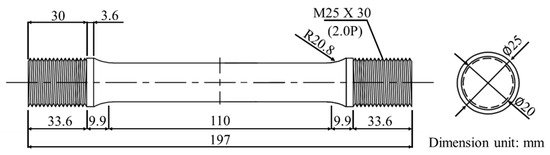

This study encompassed both austenite and martensitic SMA bars, each exhibiting superelastic and shape memory effects, respectively. The two types of SMA bars primarily consist of nickel (Ni) and titanium (Ti) components with trace elements, such as carbon (C), oxygen (O), and iron (Fe). The austenite SMA comprised 55.03% Ni and 44.84% Ti by weight ratio, gradually cooled at a temperature of 90 ± 5 °C. The martensite SMA consisted of 55.74% Ni and 44.12% Ti, cooled at 5 ± 5 °C. For connection to deformed steel bars, the SMA bars were fabricated as depicted in Figure 2. The overall length of the SMA bar was 197 mm, with a central section 110 mm in length and 20 mm in diameter. The two ends connected to the coupler were shaped to 33.6 mm in length and 25 mm in diameter. Threads were implemented at both ends of the SMA bar to minimize slip during the coupler connection and when subjected to potential stress. The spacing and depth of the thread were standardized at 2 mm. To prevent yielding or failure caused by additional stresses, such as external or frictional forces, at the coupling points where the SMA bar interfaces with the coupler, the connection points were designed with a large diameter of D25 compared to the central section diameter of D20. The section transitioned from the coupler attachment to the SMA bar to minimize the concentration of stress spanned 9.9 mm in length with a curvature radius of R20.8 mm.

Figure 2.

Drawing of SMA bar.

2.2. Mechanical Coupler

For the economic feasibility and practical application of SMA bars in real structures, the connection method with conventional steel bars is crucial. Among the various joining methods, mechanical connection with a coupler offers the advantage of avoiding the need for welding application and highly skilled labor. Therefore, we designed a mechanical coupler to connect SMA bars with conventional deformed steel bars.

Mechanical coupling typically involves a threaded coupler that incorporates threads on both the coupler and the steel bar for connection. However, threaded couplers have the drawback of the need for additional threading of the steel bar, resulting in unnecessary time and resource consumption. To overcome this challenge, we utilized a one-touch coupler that enables a straightforward connection of deformed steel bars without the need for additional machining of the steel bar. Furthermore, the one-touch coupler was combined with a threaded coupler. Specifically, the threaded connection at one end of the coupler is pre-attached to the SMA bar in a factory or another location before being transported to the construction site. Meanwhile, the one-touch connection is designed for use in the field to join deformed steel bars without requiring further machining of the steel bar.

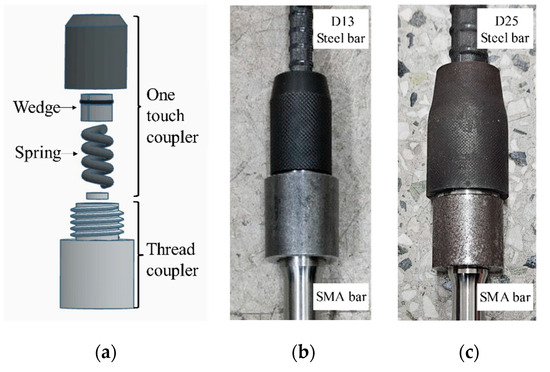

Figure 3 shows the specially designed and manufactured mechanical coupler used in this study. The upper section of the coupler in the figure represents a one-touch coupler, while the lower section depicts a threaded coupler. The one-touch coupler incorporates a spring and a wedge to connect the steel bar and prevent potential separation due to tensile forces. When a steel bar is attached to the one-touch coupler, the embedded spring forces the wedge upwards. The wedge plays a crucial role in securely fastening the coupler and the steel bar when subjected to tensile force. As the tensile force increases, the wedge coupling structure becomes more firmly fixed within the space between the coupler and the steel bar. The lower segment of the coupler is designed as a threaded coupler, ensuring a robust attachment to the SMA bar. The connection between these two types of couplers was purposefully made to be easily interchangeable using threads. This design facilitates the straightforward replacement of the one-touch coupler section, which enables easy adaptation to different sizes of steel bars. Therefore, in this study, the coupling between two types of steel bars, D13 and D25, was executed by simply replacing the one-touch coupler section without the need for additional procedures. The proposed coupler can improve the construction process of the section linked to the steel bar and ensure sufficient attachment strength of the coupler to withstand the tensile behavior of the SMA bar.

Figure 3.

Manufactured coupler details and appearance: (a) coupler detail drawing, (b) D13 coupler, and (c) D25 coupler.

3. Testing and Measurement

3.1. Test Procedure

The uniaxial tensile tests of the specimens followed the guidelines outlined in KS B 0802 [37] and ASTM A370 [38]. The connected bars are required to possess a tensile strength of at least 125% of the specified yield strength of the base bars, as stipulated in KS D 0249 [39]. The yielding point was determined using the offset method. The applied load was controlled by displacement in accordance with ASTM A370 guidelines using a universal testing machine. The maximum stress rate was maintained within the range of 1.2 to 11.5 N/mm2·s, as per ASTM A370.

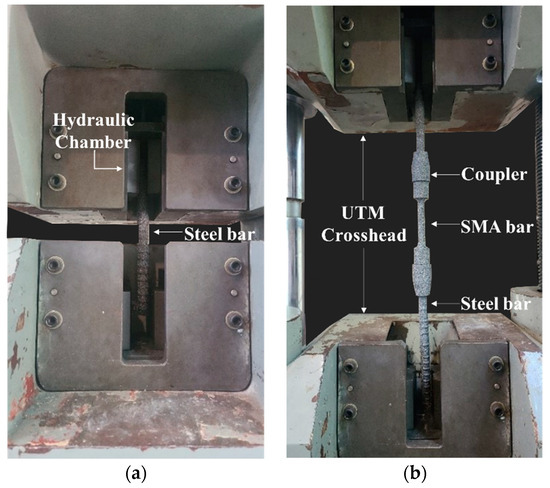

The specimens were constructed for two scenarios: when the steel bar yields and when the SMA bar yields. D13 and D25 steel bars represented the yielding of steel and SMA bars, respectively. In addition, this study encompassed both austenite and martensite SMA bars to examine the stress and deformation states in the SMA connected to a steel bar. Figure 4 illustrates the uniaxial tensile test conducted on the base steel bar and the steel bar connected to the SMA bar using the mechanical coupler. The SMA bar was attached to a 35 cm long steel bar at both ends. The steel bar portion of the specimen was clamped in a hydraulic universal testing machine for the tensile test.

Figure 4.

Uniaxial tensile test: (a) steel bar and (b) SMA bar.

For the D13 steel bar connected to the SMA bar using the proposed mechanical coupler, SD400 grade steel, which represents a yield strength over 400 Mpa, as specified in KS D3504 [40], was utilized to induce the yielding and fracture of the steel bar during the uniaxial tensile test. Thus, the stress–strain relationships in the steel and SMA bars were analyzed to evaluate the stress states at the yielding and fracture points. In addition, the amount of slip at the mechanical coupler was assessed to evaluate the performance of the complete mechanical connection. For the base steel bars, uniaxial tensile tests were also conducted to ensure the reliability of the yielding and tensile strength. In cases where the SMA bar yielded before the steel bar, an SD600 grade D25 steel bar, which represents a yield strength over 660 Mpa, was employed to connect to the SMA bar using the proposed mechanical coupler. Similar to the uniaxial test for the yielding of the steel bar, we examined the stress and strain states at the yielding and fracture of the SMA bar and assessed the amount of slip at the mechanical coupler. In particular, an additional uniaxial test was conducted to evaluate the difference in the yielding of the martensite SMA bar before and after the shape memory effect, which involves heating the SMA bar above the transformation temperature.

3.2. Design of Heating Equipment

Martensitic SMA bars exhibit shape recovery when heated above the phase-transformation temperature. The exertion of recovery stress due to heating can change the mechanical properties of martensitic SMA. Therefore, this study conducted a tensile test on martensitic SMA bars subjected to heating above the transformation temperature.

Heating methods commonly include conduction and convection. Electrical resistance for conduction can expedite heating times and enhance temperature reliability, but it can impact surrounding and attached conductive objects and equipment. Although this study considered induction heating, this approach necessitated substantial energy for heating SMA bars and additional cooling equipment. Moreover, experiments involving connectivity with conventional deformed steel bars indicate significantly higher and faster heating in the steel bars than the SMA bar, potentially altering the material properties of the steel bar. Therefore, in this study, a heating apparatus based on a radiative heating method using near-infrared rays was designed and fabricated to minimize the heating time, ensure heating temperature reliability, and exclusively target only the heating of the SMA bar.

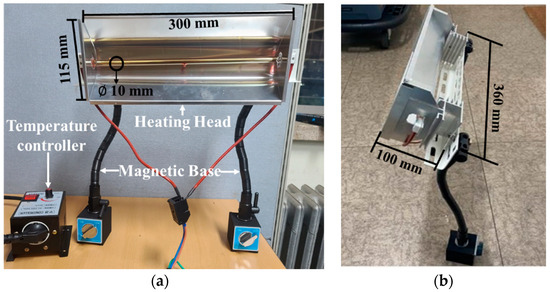

Figure 5 illustrates the fabricated heating device designed for heating the martensite SMA bar beyond its transformation temperature above the austenite finish temperature of 101 °C [41]. Operating on a power capacity of 1800 W with an AC 220 V power supply, the device integrates a temperature controller to regulate the power levels and achieve the desired heating temperatures. Positioned at a distance of 50 mm from the SMA specimen, the device heated the specimen up to 350 °C. In actual tests, the SMA bar, positioned 100 mm to 200 mm away from the heating device, attained temperatures ranging from 190 °C to 300 °C. For this study, two heating devices designed for the SMA bar specimens were positioned approximately 100 mm away from the specimens at a 45-degree angle from the rear.

Figure 5.

SMA bar heating equipment: (a) front view and (b) side view.

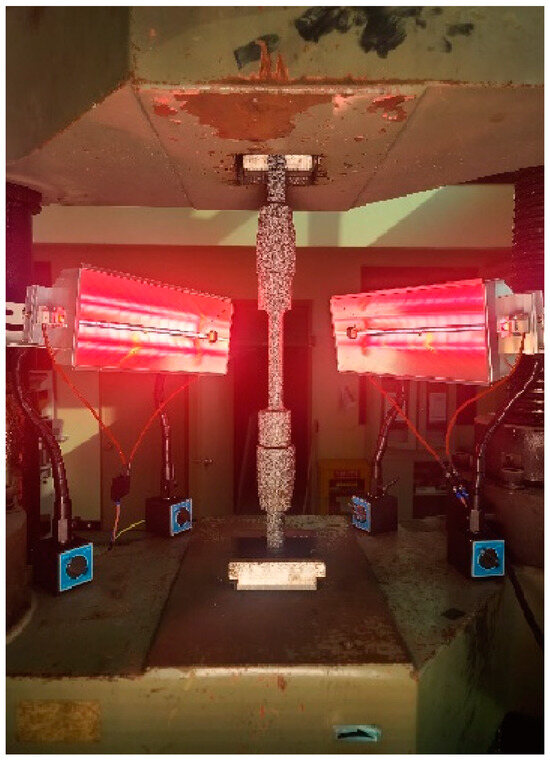

Figure 6 depicts the tensile test conducted on the martensite SMA bar using the heating equipment. The temperature was measured on the specimen using Fluke’s Tis10 thermal imaging camera with a sensitivity of 0.15 °C (150 mK). The SMA bar was heated to 190 °C for approximately 5 min. The temperature was maintained for an additional 5 min to ensure that the entire cross-section reached the transformation temperature. The temperature of the SMA bar remained above the transformation temperature until the end of the tensile test.

Figure 6.

SMA bar heating tensile test.

3.3. DIC-Based Displacement Measurement

Conventional measurement techniques using extensometers and strain gauges necessitate direct physical contact. On the other hand, digital image correlation (DIC) offers a non-contact approach for strain measurement [42,43,44], which is particularly advantageous when multi-point data are required and specimen numbers and test repetitions are limited. Moreover, DIC can analyze strain and displacement at desired locations from immediate recalibration using stored images. In experiments where specimens are subjected to high temperatures, contact sensors can undergo deformation or damage due to temperatures, while DIC can mitigate measurement errors caused by such deformations and temperatures.

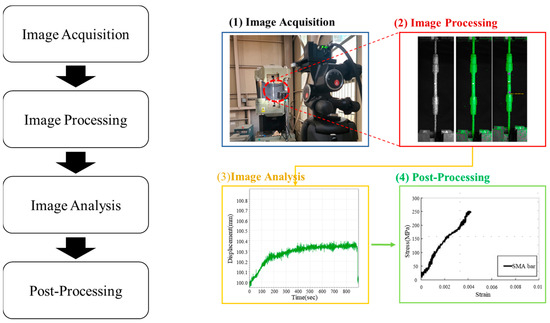

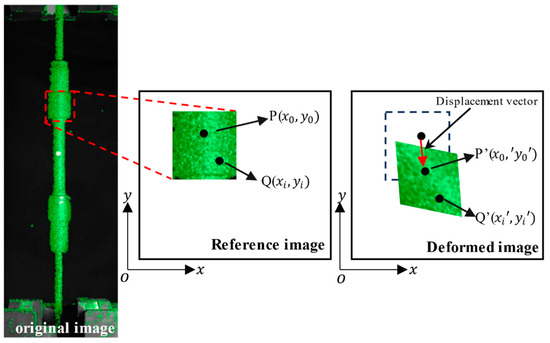

DIC consists of four main stages: image acquisition, image processing, image analysis, and post-processing, as illustrated in Figure 7. The image acquisition phase involves capturing the entire test procedure using video capturing equipment and storing these images on a connected digital storage device. In the image-processing phase, the targeted analysis area is identified within the images, and extraneous elements are eliminated. Recognition utilizes a predefined irregular dot pattern applied to the target and analyzes the surrounding color information of the pixels [45]. During the image analysis phase, displacement is calculated using the pixels within the recognized area. Figure 8 shows the process for computing displacement in the images, which involves calculating the pixel distance between sets of pixels from the reference and deformed images. Finally, post-processing is performed to derive stress–strain curves from the time data acquired through DIC and the load data obtained from the universal testing machine.

Figure 7.

Flow chart of stages, from image acquisition to post-processing.

Figure 8.

Relationship between the reference and deformed sets.

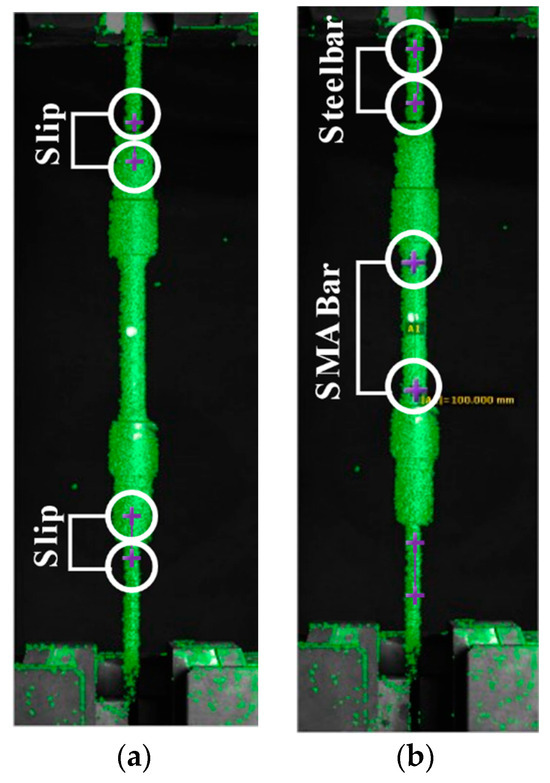

Figure 9 shows the measurement positions for the steel and SMA bars using DIC during the uniaxial tensile test. Strain measurements were taken over a target length five times the diameter of each specimen. Therefore, for the D20 SMA bar, D13 steel bar, and D25 steel bar, the designated strain measurement distances were set at 10 cm, 6.5 cm, and 12.5 cm, respectively. The gauge length for slip measurements were determined as 2 cm above and below the connection of the coupler and steel bar, respectively. The measurement data were captured at intervals of 0.1 s. All specimens were positioned at a consistent distance from the camera to maintain a scale factor of approximately 0.45 to 0.42 mm per pixel, representing the real-world size per pixel in the image.

Figure 9.

Locations for the stress–strain relationship and slip measurement: (a) slip and (b) strain.

4. Experimental Results and Discussion

4.1. Tensile Performance of Steel Bars

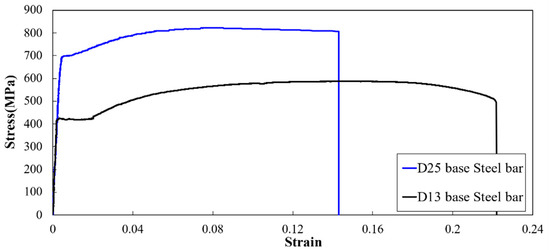

Tensile tests were conducted on two specimens each for the D13 and D25 base steel bars to examine the mechanical properties of the steel bars. Figure 10 shows the stress–strain curve obtained from one of the D13 and D25 base steel bar specimens. The curve for the D13 base steel bar presents extended perfectly plastic and strain-hardening regions compared to that of the D25 base steel bar. This difference in ductility can be attributed to the difference in strength, as strength and ductility typically have an inverse relationship.

Figure 10.

Stress–strain curves of the base steel bars.

The D13 and D25 base steel bars correspond to the SD400 and SD 600 grades, which represent yield strengths of more than 400 MPa and 600 MPa, respectively. The average yield strength of the D25 base steel bar was 691 MPa, which was 1.67 times that of the D13 base steel bar. The D13 base steel bar, which possesses a lower yield strength than the D25 bar, exhibits higher ductility. Table 1 summarizes the mechanical properties of the tested base steel bars, including the yield strength (), elastic modulus (E), and yield strain (). The elastic modulus for both types of steel bars obtained from the test ranged from 190 to 203 GPa, with a difference of less than 5%. The average tensile strength () of the D25 base steel bar measured 822 MPa, which is 1.40 times higher than the measurement of 587 MPa for the D13 base steel bar. In contrast, the ultimate strain () of the D25 base steel bar averaged 0.0812, which was 0.52 times that of the D13 base steel bar.

Table 1.

Mechanical properties of the base steel bars.

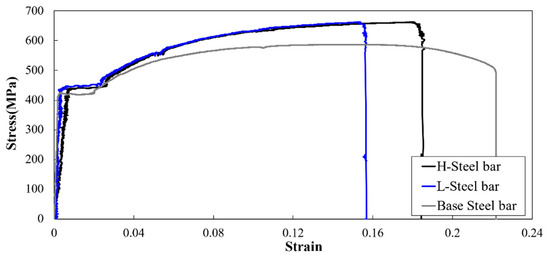

4.2. Connected Steel–SMA Bars: Steel Bar Yielding

To assess the tensile capacity of the steel bar when mechanically joined with an SMA bar, a D13 steel bar was connected to the austenite or martensite SMA bars. Figure 11 and Figure 12 show the stress–strain curves obtained from the upper and lower steel bars connected to the martensite and austenite SMA bars, respectively. The strain values, as mentioned previously, were measured over a target length five times the diameter of each rebar. In the graph, the H-steel and L-steel bars represent the steel bars located above and below the connected SMA bar, respectively. All connected steel bars exhibited perfectly plastic and strain-hardening regions similar to the D13 base steel bar.

Figure 11.

Stress–strain curves of the D13 steel bar coupled with austenite SMA bar.

Figure 12.

Stress–strain curves of the D13 steel bar coupled with martensite SMA bar.

Table 2 presents the yield strength (), tensile strength (), yield strain (), ultimate strain (), and elastic modulus (E) of the steel bars coupled with the SMA bars for two specimens. The average yield strength of the D13 steel bar connected to the austenite SMA bar was 429 MPa for the H-steel and 425 MPa for the L-steel. Similarly, the H-steel and L-steel bars connected to the martensite SMA bar also exhibited average yield strengths of 415 MPa and 416 MPa, respectively. The yield strains for the H-steel and L-steel bars connected to both types of SMA bars ranged from 0.0020 to 0.0023. The yield strength and strain of the D13 steel bars connected to the SMA bars using the proposed coupler closely matched those of the D13 base steel bar. The elastic modulus derived from the yield strength and strain of the connected D13 bars was very similar to that of the base steel bar with a difference of less than 5%. Therefore, the D13 steel bars connected to the SMA bars using the proposed mechanical coupler exhibited mechanical behavior similar to the base steel bar in terms of strength and stiffness. Moreover, the fracture strength of these connected D13 bars, ranging from 601 MPa to 658 MPa, satisfied the requirement of more than 125% of the yield strength of the base bar for a fully mechanical connection, as specified in KS D 0249 [39].

Table 2.

Mechanical properties of the steel bars coupled with SMA bar.

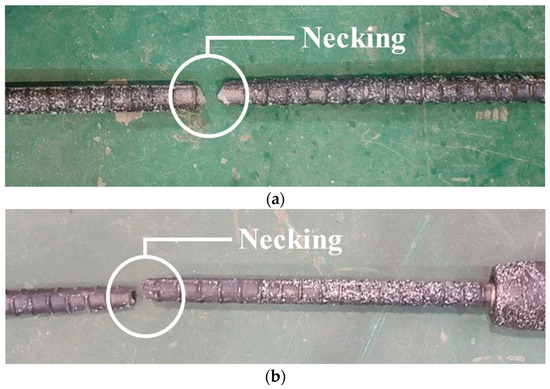

Figure 13 shows the fractured specimens. The D13 base steel bar underwent yielding and necking, followed by fracture during the uniaxial tensile test. Similarly, the steel bar connected to the SMA using the coupler exhibited a failure model from yielding to fracture within the steel bar section. The strength and stiffness of the steel bars showed minimal changes due to the proposed coupler connection up to the tensile fracture of the steel bar.

Figure 13.

Failure shape: (a) D13 base bar and (b) D13 bar coupled with SMA bar.

4.3. Connected Steel–SMA Bars: SMA Bar Yielding

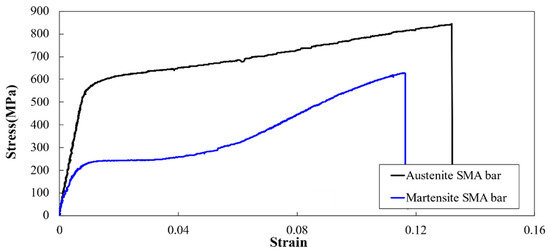

Tensile tests were conducted to analyze the mechanical properties of the SMA bar connected to the D25 steel bar. The SMA bar, mechanically joined with the D25 steel bars, exhibited yielding, necking, and eventually fracture in the section of the SMA bar, as shown in Figure 14. On the other hand, the D25 steel bar connected to the SMA bar maintained elastic behavior. Figure 15 shows the stress–strain curves obtained from one specimen of the austenite and martensite SMA bars. Both SMA bars exhibited a linear increase in stress within the elastic region, followed by distinct yielding points and eventual tensile fracture. Upon surpassing the yielding point, the austenite SMA bar demonstrated a linearly increasing strain-hardening region until fracture, while the martensite SMA bar exhibited a perfectly plastic region and transitioned into a strain-hardening phase, leading to fracture.

Figure 14.

Failure shape of the SMA bar coupled with the D25 steel bar.

Figure 15.

Stress–strain curves of the SMA bars.

Table 3 provides a summary of the yield strength (), tensile strength (), yield strain (), ultimate strain (), and elastic modulus (E) of the SMA bars. The stress–strain curve reveals that both the austenite and martensite SMA bars exhibited similar yield strain values. However, the austenite SMA bar demonstrated an average yield strength and elastic modulus approximately 2.66 times and 2.54 times those of the martensite SMA bar, respectively. In addition, the austenite SMA bar showed an average tensile strength of 844 MPa and an average ultimate strain of 0.1321, which were 1.34 times and 1.12 times those of the martensite SMA bar.

Table 3.

Mechanical properties of the SMA bar coupled with the D 25 steel bar.

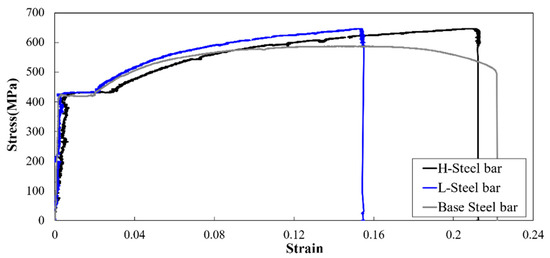

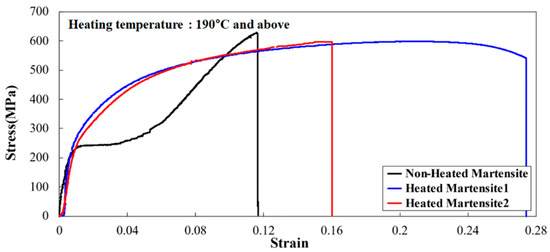

4.4. Connected Steel–SMA Bars: Heated SMA Bar Yielding

Heating the SMA bar is essential for the activation of its shape memory ability, which can influence the mechanical properties of the SMA material. Therefore, the fabricated equipment was used to heat the martensite SMA bar to approximately 190 °C above the austenite finish temperature of 101 °C. This temperature was maintained for approximately 5 min to reach the transformation temperature across the entire cross-section. Subsequently, a tensile test was conducted to assess the changes in the mechanical properties of the SMA bar after the introduction of the shape memory effect due to heating. The results of the heating tensile tests were compared with those of the non-heated martensite SMA bar for two specimens.

Figure 16 shows the stress–strain curves for the martensite SMA bar before and after heating above the finish austenite temperature. As previously described, the non-heated martensite SMA bar exhibited a distinct yield region, followed by a perfectly plastic region and subsequent strain hardening until failure. For the heated martensite SMA bar, the perfectly plastic region disappeared, and immediately after the yield region, nonlinear strain hardening appeared and extended up to failure. In particular, a clear yielding point was absent in the heated martensite, necessitating the use of the 0.2% offset method to determine the yield strength.

Figure 16.

Stress–strain curves of the heated martensite SMA bars.

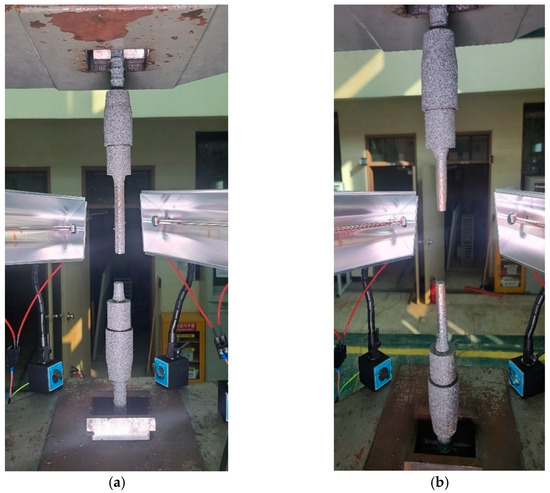

Table 4 summarizes the yield strength (), tensile strength (), yield strain (), ultimate strain (), and elastic modulus (E) for the heated and non-heated martensite SMA bars. The heated martensite SMA bars exhibited an average strength of 220 MPa with a yield strain of 0.0074, which are very similar to those of the non-heated SMA bar. The elastic modulus for the two heated two martensite SMA bars ranged from 27 GPa to 33 GPa, which showed a maximum difference of approximately 10% from the non-heated SMA bar. The mechanical properties of the martensite SMA bars up to the yielding point exhibited minimal differences before and after the activation of the shape memory effect. However, after yielding, the ultimate tensile strain for the heated martensite SMA bar showed an increase of approximately 38% to 79% compared to the non-heated martensite SMA bar. The tensile strength of the heated martensite SMA bar was approximately 5% lower than that of the non-heated bar; the difference was deemed negligible. Figure 17 shows the tensile fracture of the heated specimens. Both specimens fractured near the center of the SMA bar. In particular, the heated martensite SMA bar showed a high elongation and significant deformation.

Table 4.

Mechanical properties of the heated martensite SMA bars.

Figure 17.

Failure shape of the heated martensite SMA bar coupled with the D25 steel bar: (a) heated martensite 1 and (b) heated martensite 2.

4.5. Slip Evaluation of Connected Steel–SMA Bars

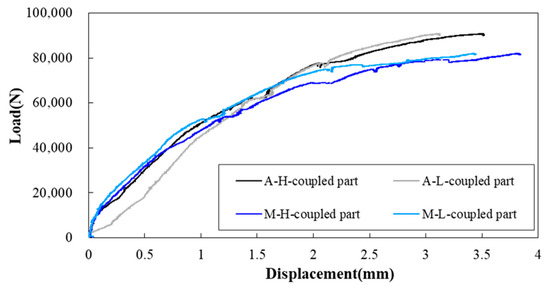

Slip in a mechanical joint can affect the usability of the mechanical coupler in concrete structures. Therefore, we evaluated the slip that may occur at mechanical connections during tensile testing. Figure 18 shows the load–displacement relationship at the connection between the D13 steel and SMA bars. Slip measurements were obtained from a 4 cm segment of the connection between the one-touch coupler and the D13 steel bar, divided into 2 cm intervals extending toward both the steel bar and the coupler from the connection point. The A-H-coupled and A-L-coupled parts in the graph represent the regions between the steel bar and one-touch coupler at the top and bottom of the austenite SMA bar, respectively. Similarly, the M-H-coupled and M-L-coupled parts denote variations in displacement at the top and bottom of the martensite SMA bar during the tensile test. The absence of an abrupt increase or change in displacement at the outset of the tensile load indicates no initial slip in the proposed coupler used for the D13 steel bar.

Figure 18.

Load–displacement curves between the D13 and SMA bars.

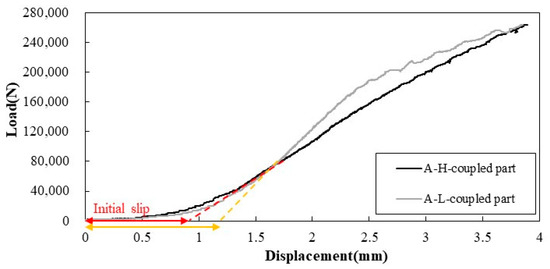

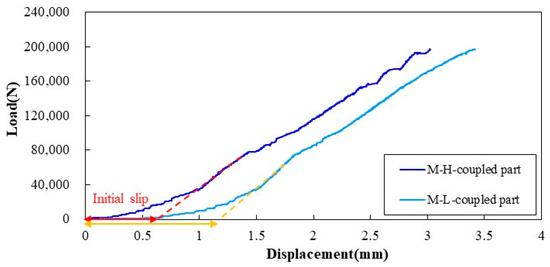

Figure 19 and Figure 20 show the load–displacement relationship at the connection between the D25 steel and SMA bars. In the D25 steel and austenite SMA bar specimen, initial slips of 0.9 mm and 1.2 mm occurred at the top and bottom of the SMA bar, respectively. The martensite SMA bar also showed initial slips of 0.6 mm and 1.2 mm at the top and bottom when joined with the D25 steel bar using the one-touch coupler, respectively. When considering the use of the one-touch coupler with large steel bars, caution should be exercised during field connections, or the SMA bar should be extended adequately beyond the plastic region of the structure to accommodate the coupler.

Figure 19.

Load–displacement curves at the connection of the D25 and austenite SMA bars.

Figure 20.

Load–displacement curves at the connection of the D25 and martensite SMA bars.

5. Conclusions

In this study, a mechanical connection method was proposed to locally reinforce round SMA bars in the plastic hinge zone. Uniaxial tests were then conducted to evaluate the performance of the SMA and steel bars connected using the proposed coupler. For precise multi-point measurements, in particular, for the heated section of the SMA bar, the DIC technique was utilized to obtain variations in the strains and displacements of the connected SMA and steel bars during tensile testing. The main outcomes of the study are as follows:

The connected steel bar, when yielding during tensile testing, exhibited mechanical behavior similar to the base steel bar concerning strength and stiffness. The yield strength, elastic modulus, and yield strain of the connected steel bar closely resembled those of the base steel bars. Moreover, the fracture strength of the connected steel bar satisfied the requirement of exceeding 125% of the yield strength of the base bar for a fully mechanical connection.

The austenite SMA bars demonstrated a significantly high yield strength and elastic modulus, approximately 2.66 times and 2.54 times those of the martensite SMA bars on average, respectively. The average tensile strength and ultimate strain were also 1.34 times and 1.12 times higher than the martensite SMA bars, respectively. However, two types of SMA bars exhibited similar yield strain values.

The martensite SMA bars displayed no distinct yielding or perfectly plastic regions after the activation of the shape memory effect due to heating. The mechanical properties of the heated martensite SMA bar, including the yield strength and strain, tensile strength, and elastic modulus, showed minimal differences. However, the ultimate tensile strain increased significantly by approximately 38% to 79%, resulting in considerable elongation and significant deformation.

The one-touch coupler section of the proposed coupler showed no abrupt increase or change in the initial slip for the D13 steel bar, whereas the D25 steel bar exhibited a maximum initial slip of 1.2 mm. When utilizing the one-touch coupler with large steel bars, cautious field connection and adequate extension of the SMA bar beyond the plastic region would be necessary.

Author Contributions

Conceptualization, J.-H.L. and E.C.; methodology, J.-H.L. and E.C.; validation, J.-H.L., M.-K.S. and E.C.; formal analysis, J.-H.L., M.-K.S. and E.C.; writing—original draft preparation, M.-K.S.; writing—review and editing, J.-H.L.; funding acquisition, J.-H.L. and E.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Inha University.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors acknowledge the National Research Foundation of Korea (NRF) (Project No. NRF 2020R1A4A-1018826) for providing the samples and SMA bars.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Chang, L.C.; Read, T.A. Plastic deformation and diffusionless phase changes in metals—The gold-cadmium beta phase. J. Miner. Met. Mater. Soc. 1951, 3, 47–52. [Google Scholar] [CrossRef]

- Buehler, W.J.; Gilfrich, J.V.; Wiley, R.C. Effect of low-temperature phase changes on the mechanical properties of alloys near composition TiNi. J. Appl. Phys. 1963, 34, 1475–1477. [Google Scholar] [CrossRef]

- Van Humbeeck, J.; Stalmans, R. Shape memory alloys, types and functionalities. In Encyclopedia of Smart Materials, 2nd ed.; Schwartz, M., Ed.; John Wiley and Sons: New York, NY, USA, 2002. [Google Scholar]

- Dong, Z.; Klotz, U.E.; Leinenbach, C.; Bergamini, A.; Czaderski, C.; Motavalli, M. A novel Fe-Mn-Si shape memory alloy with improved shape recovery properties by VC precipitation. Adv. Eng. Mater. 2009, 11, 40–44. [Google Scholar] [CrossRef]

- Sadiq, H.; Wong, M.B.; Al-Mahaidi, R.; Zhao, X.L. The effects of heat treatment on the recovery stresses of shape memory alloys. Smart Mater. Struct. 2010, 19, 035021. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Ramesh, K.T.; Van Humbeeck, J. High strain rate deformation of martensitic NiTi shape memory alloy. Scr. Mater. 1999, 41, 89–95. [Google Scholar] [CrossRef]

- Huang, X.; Liu, Y. Effect of annealing on the transformation behavior and superelasticity of NiTi shape memory alloy. Scr. Mater. 2001, 45, 153–160. [Google Scholar] [CrossRef]

- Mahmud, A.S.; Yang, H.; Tee, S.; Rio, G.; Liu, Y. Effect of annealing on deformation-induced martensite stabilisation of NiTi. Intermetallics 2008, 16, 209–214. [Google Scholar] [CrossRef]

- Janke, L.; Czaderski, C.; Motavalli, M.; Ruth, J. Applications of shape memory alloys in civil engineering structures—Overview, limits and new ideas. Mater. Struct. 2005, 38, 578–592. [Google Scholar]

- Shajil, N.; Srinivasan, S.M.; Santhanam, M. Self-centering of shape memory alloy fiber reinforced cement mortar members subjected to strong cyclic loading. Mater. Struct. 2013, 46, 651–661. [Google Scholar] [CrossRef]

- Jung, C.Y.; Lee, J.H. Crack closure and flexural tensile capacity with SMA fibers randomly embedded on tensile side of mortar beams. Nanotechnol. Rev. 2020, 9, 369–381. [Google Scholar] [CrossRef]

- Choi, E.; Ostadrahimi, A.; Lee, J.H. Pullout resistance of crimped reinforcing fibers using cold-drawn NiTi SMA wires. Constr. Build. Mater. 2020, 265, 120858. [Google Scholar] [CrossRef]

- Choi, E.; Kim, H.S.; Nam, T.H. Effect of crimped SMA fiber geometry on recovery stress and pullout resistance. Compos. Struct. 2020, 247, 112466. [Google Scholar] [CrossRef]

- Dębska, A.; Gwoździewicz, P.; Seruga, A.; Balandraud, X.; Destrebecq, J.F. The application of Ni–Ti SMA wires in the external prestressing of concrete hollow cylinders. Materials 2021, 14, 1354. [Google Scholar] [CrossRef]

- Schleiting, M.; Wetzel, A.; Bauer, A.; Frenck, J.M.; Niendorf, T.; Middendorf, B. Potential of Fe-Mn-Al-Ni Shape Memory Alloys for Internal Prestressing of Ultra-High Performance Concrete. Materials 2023, 16, 3816. [Google Scholar] [CrossRef] [PubMed]

- Beßling, M.; Czaderski, C.; Orlowsky, J. Prestressing effect of shape memory alloy reinforcements under serviceability tensile loads. Buildings 2021, 11, 101. [Google Scholar] [CrossRef]

- Qian, H.; Zhang, Q.; Zhang, X.; Deng, E.; Gao, J. Experimental investigation on bending behavior of existing RC beam retrofitted with SMA-ECC composites materials. Materials 2021, 15, 12. [Google Scholar] [CrossRef] [PubMed]

- Sung, M.; Andrawes, B. Innovative local prestressing system for concrete crossties using shape memory alloys. Eng. Struct. 2021, 247, 113048. [Google Scholar] [CrossRef]

- Raza, S.; Shafei, B.; Saiidi, M.S.; Motavalli, M.; Shahverdi, M. Shape memory alloy reinforcement for strengthening and self-centering of concrete structures—State of the art. Constr. Build. Mater. 2022, 324, 126628. [Google Scholar] [CrossRef]

- Alshannag, M.J.; Alqarni, A.S.; Higazey, M.M. Superelastic Nickel–Titanium (NiTi)-Based Smart Alloys for Enhancing the Performance of Concrete Structures. Materials 2023, 16, 4333. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Bratushka, S.N.; Beresnev, V.M.; Levintant-Zayonts, N. Shape memory effect and superelasticity of titanium nickelide alloys implanted with high ion doses. Russ. Chem. Rev. 2013, 82, 1135. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Attarilar, S.; Gode, C.; Kandavalli, S.R.; Shamsborhan, M.; Wang, Q. Conceptual Analysis on Severe Plastic Deformation Processes of Shape Memory Alloys: Mechanical Properties and Microstructure Characterization. Metals 2023, 13, 447. [Google Scholar] [CrossRef]

- Nespoli, A.; Ninarello, D.; Fanciulli, C. A Review on Shape Memory Alloys with Martensitic Transition at Cryogenic Temperatures. Metals 2023, 13, 1311. [Google Scholar] [CrossRef]

- Abraik, E.; El-Fitiany, S.F.; Youssef, M.A. Seismic performance of concrete core walls reinforced with shape memory alloy bars. Structures 2020, 27, 1479–1489. [Google Scholar] [CrossRef]

- Abraik, E.; Youssef, M.A. Ductility and overstrength of shape-memory-alloy reinforced-concrete shear walls. Eng. Struct. 2021, 239, 112236. [Google Scholar] [CrossRef]

- Siddiquee, K.N.; Billah, A.M.; Issa, A. Seismic collapse safety and response modification factor of concrete frame buildings reinforced with superelastic shape memory alloy (SMA) rebar. J. Build. Eng. 2021, 42, 102468. [Google Scholar] [CrossRef]

- Ferraioli, M.; Concilio, A.; Molitierno, C. Seismic performance of a reinforced concrete building retrofitted with self-centering shape memory alloy braces. Earthq. Eng. Eng. Vib. 2022, 21, 785–809. [Google Scholar] [CrossRef]

- Bompa, D.V.; Elghazouli, A.Y. Ductility considerations for mechanical reinforcement couplers. Structures 2017, 12, 115–119. [Google Scholar] [CrossRef]

- Bompa, D.V.; Elghazouli, A.Y. Inelastic cyclic behaviour of RC members incorporating threaded reinforcement couplers. Eng. Struct. 2019, 180, 468–483. [Google Scholar] [CrossRef]

- Ben-dahou, A.; Ferrier, E.; Gabor, A.; Michel, L.; Gardes, R.; Boisson, R.; Poissonnet, C.; Dolo, J.M. Influence of rebar couplers on the cracking behavior of reinforced concrete beams. Nucl. Eng. Des. 2024, 416, 112801. [Google Scholar] [CrossRef]

- Pareek, S.; Suzuki, Y.; Araki, Y.; Youssef, M.A.; Meshaly, M. Plastic hinge relocation in reinforced concrete beams using Cu-Al-Mn SMA bars. Eng. Struct. 2018, 175, 765–775. [Google Scholar] [CrossRef]

- Billah, A.M.; Alam, M.S. Plastic hinge length of shape memory alloy (SMA) reinforced concrete bridge pier. Eng. Struct. 2016, 117, 321–331. [Google Scholar] [CrossRef]

- Molod, M.A.; Spyridis, P.; Barthold, F.J. Applications of shape memory alloys in structural engineering with a focus on concrete construction—A comprehensive review. Constr. Build. Mater. 2022, 337, 127565. [Google Scholar] [CrossRef]

- Otsuka, K.; Sawamura, T.; Shimizu, K. Crystal structure and internal defects of equiatomic TiNi martensite. Phys. Status Solidi (A) 1971, 5, 457–470. [Google Scholar] [CrossRef]

- Chowdhury, P.; Sehitoglu, H. Deformation physics of shape memory alloys-fundamentals at atomistic frontier. Prog. Mater. Sci. 2017, 88, 49–88. [Google Scholar] [CrossRef]

- Dolce, M.; Cardone, D. Mechanical behaviour of shape memory alloys for seismic applications 2. Austenite NiTi wires subjected to tension. Int. J. Mech. Sci. 2001, 43, 2657–2677. [Google Scholar] [CrossRef]

- KS B 0802: Korean Standard (KS); Method of Tensile Test for Metallic Materials. Korean Standards Association: Seoul, Republic of Korea, 2003.

- ASTM A370-23; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM International: West Conshohocken, PA, USA, 2020.

- KS D 0249: Korean Standard (KS); Method of Inspection for Mechanical Splicing Joint of Bars for Concrete Reinforcement. Korean Standards Association: Seoul, Republic of Korea, 2019.

- KS D 3504: Korean Standard (KS); Steel Bars for Concrete Reinforcement. Korean Standards Association: Seoul, Republic of Korea, 2021.

- Choi, E.; Jeon, J.S.; Lee, J.H. Self-centering capacity of RC columns with smart plastic hinges of martensitic NiTi SMA bars. Smart Mater. Struct. 2023, 32, 115015. [Google Scholar] [CrossRef]

- Quanjin, M.; Rejab, M.R.M.; Halim, Q.; Merzuki, M.N.M.; Darus, M.A.H. Experimental investigation of the tensile test using digital image correlation (DIC) method. Mater. Today Proc. 2020, 27, 757–763. [Google Scholar] [CrossRef]

- Chu, T.C.; Ranson, W.F.; Sutton, M.A. Applications of digital-image-correlation techniques to experimental mechanics. Exp. Mech. 1985, 25, 232–244. [Google Scholar] [CrossRef]

- Bruck, H.A.; McNeill, S.R.; Sutton, M.A.; Peters, W.H. Digital image correlation using Newton-Raphson method of partial differential correction. Exp. Mech. 1989, 29, 261–267. [Google Scholar] [CrossRef]

- Pan, B. Recent progress in digital image correlation. Exp. Mech. 2011, 51, 1223–1235. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).