Parent Grain Reconstruction in an Additive Manufactured Titanium Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. EBSD Measurements

2.2. Reconstruction Methodology

3. Results and Discussion

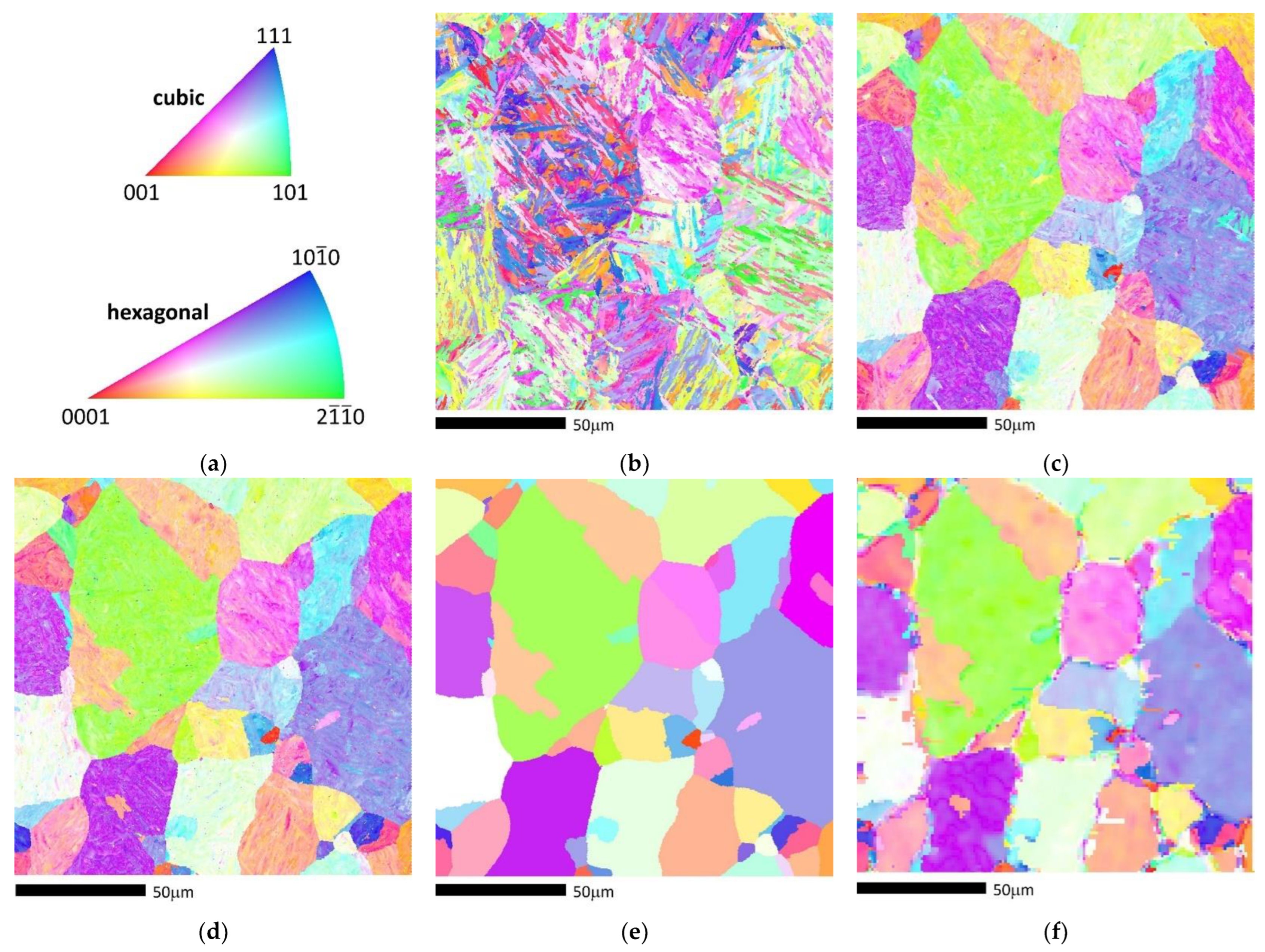

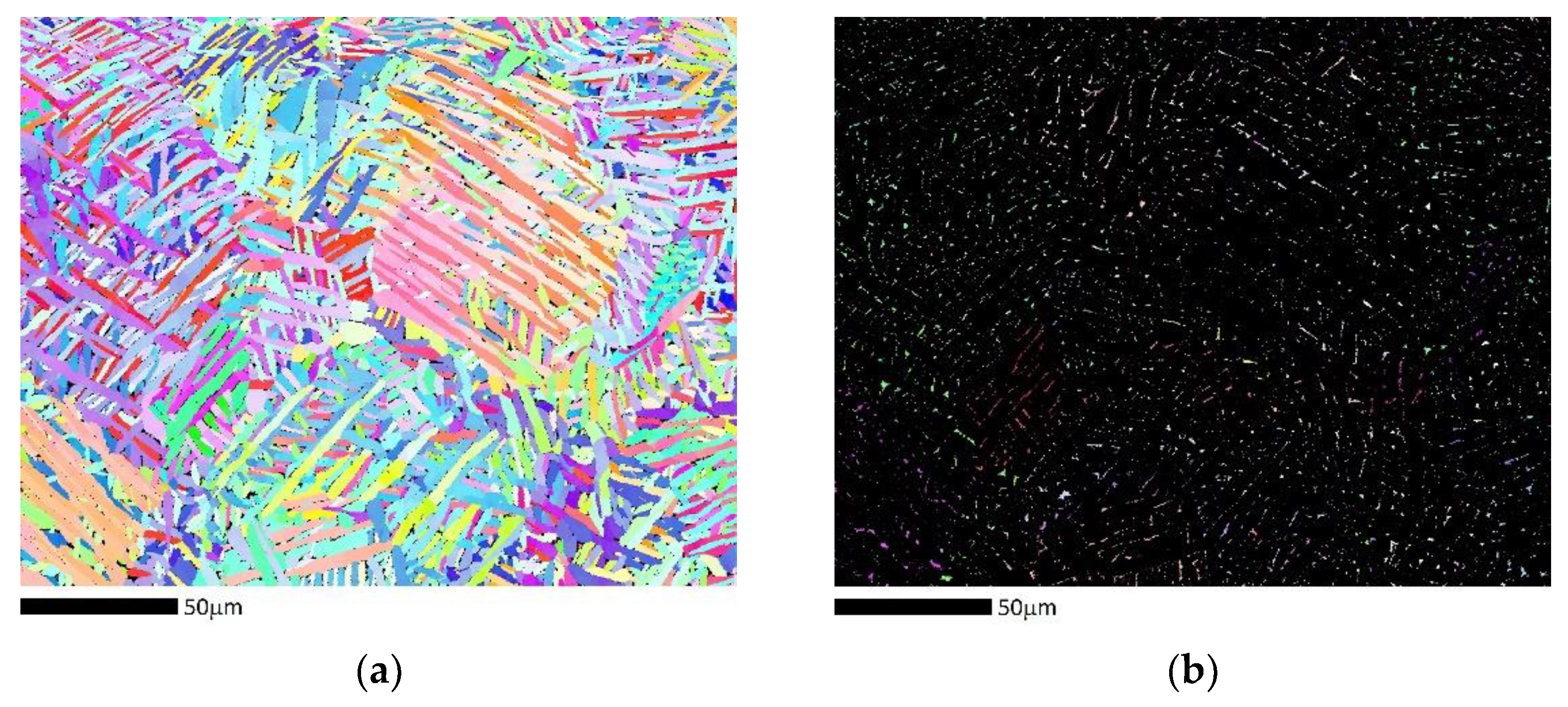

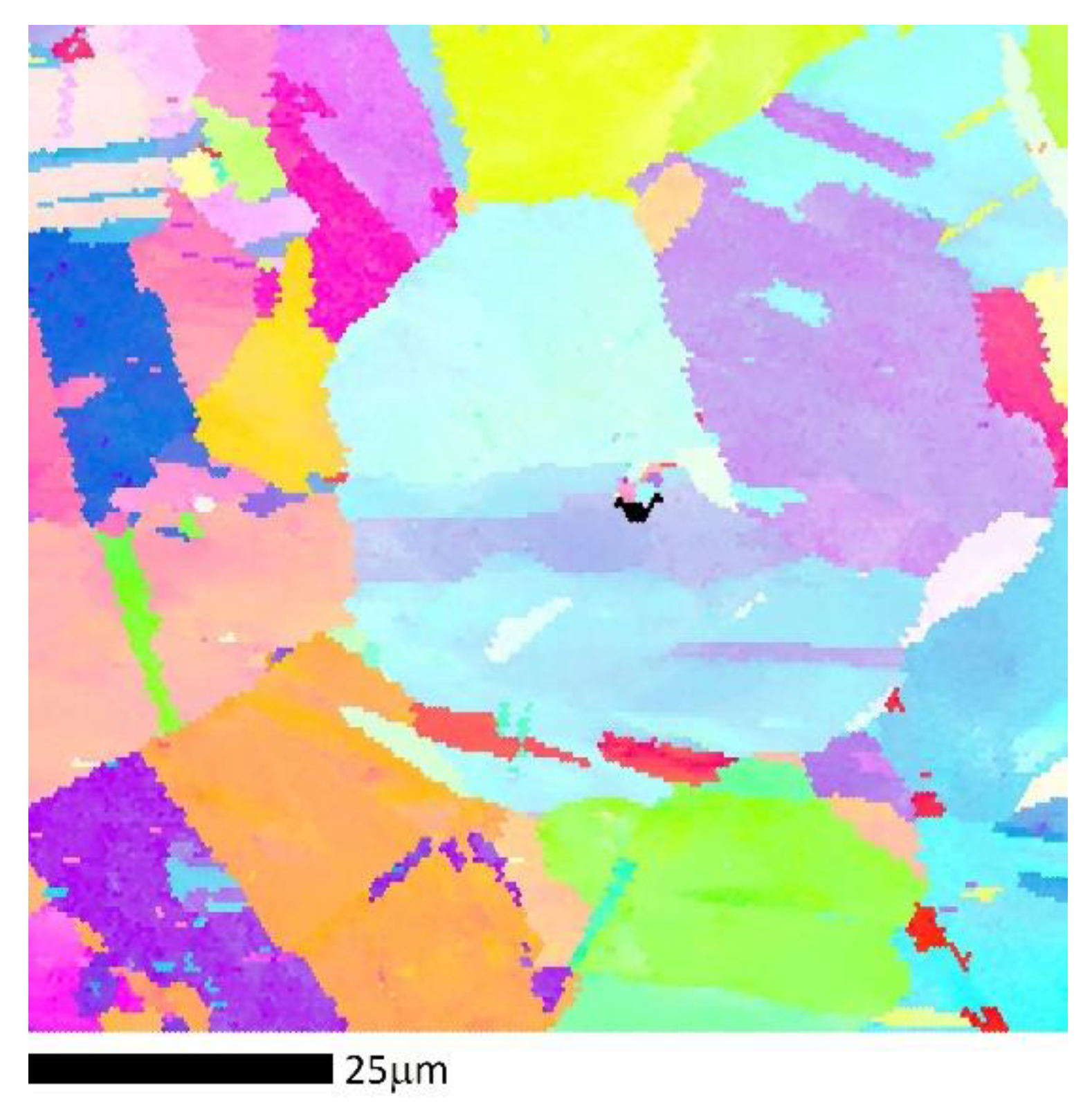

3.1. Reconstruction Fidelity

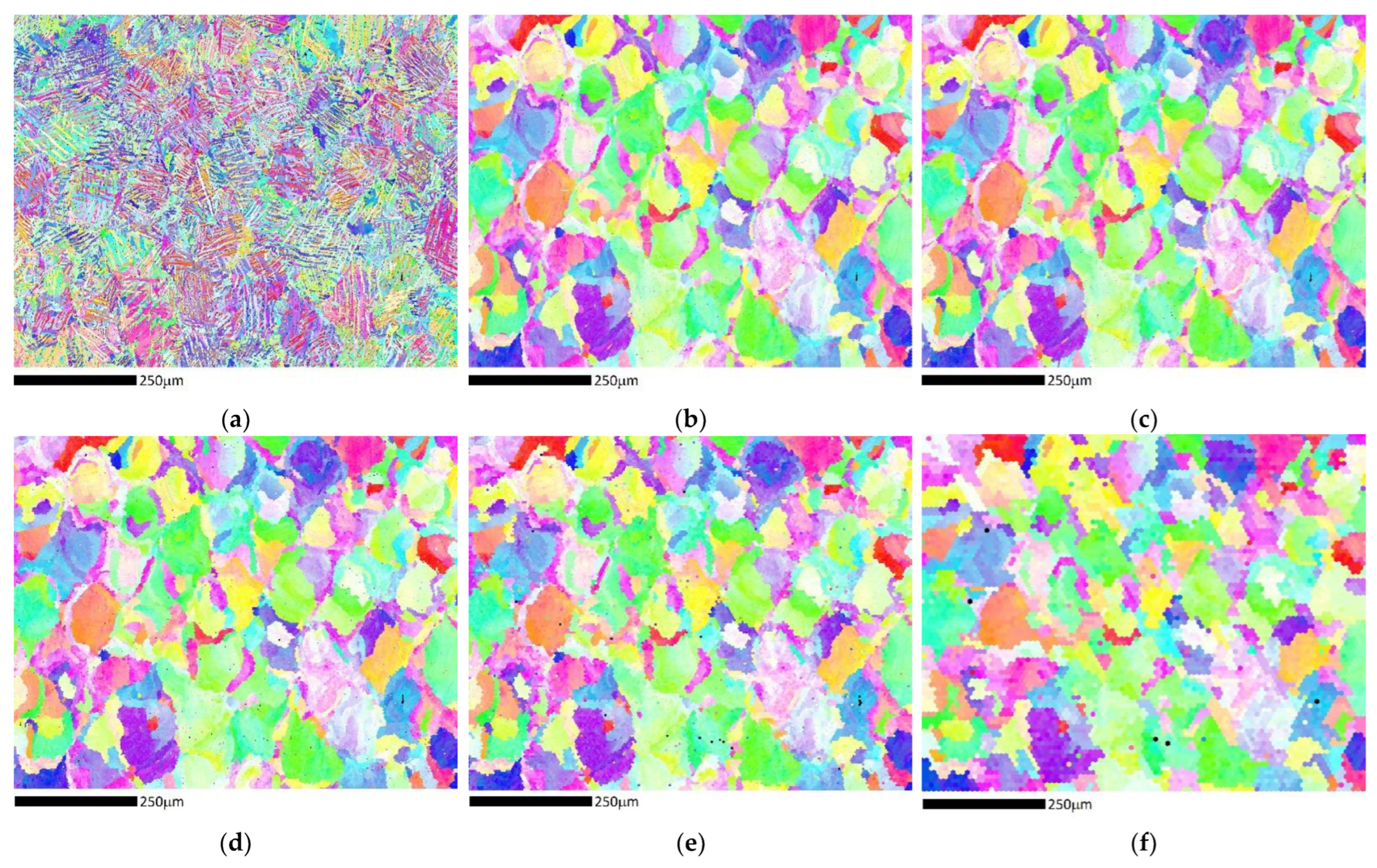

3.2. Sampling Resolution

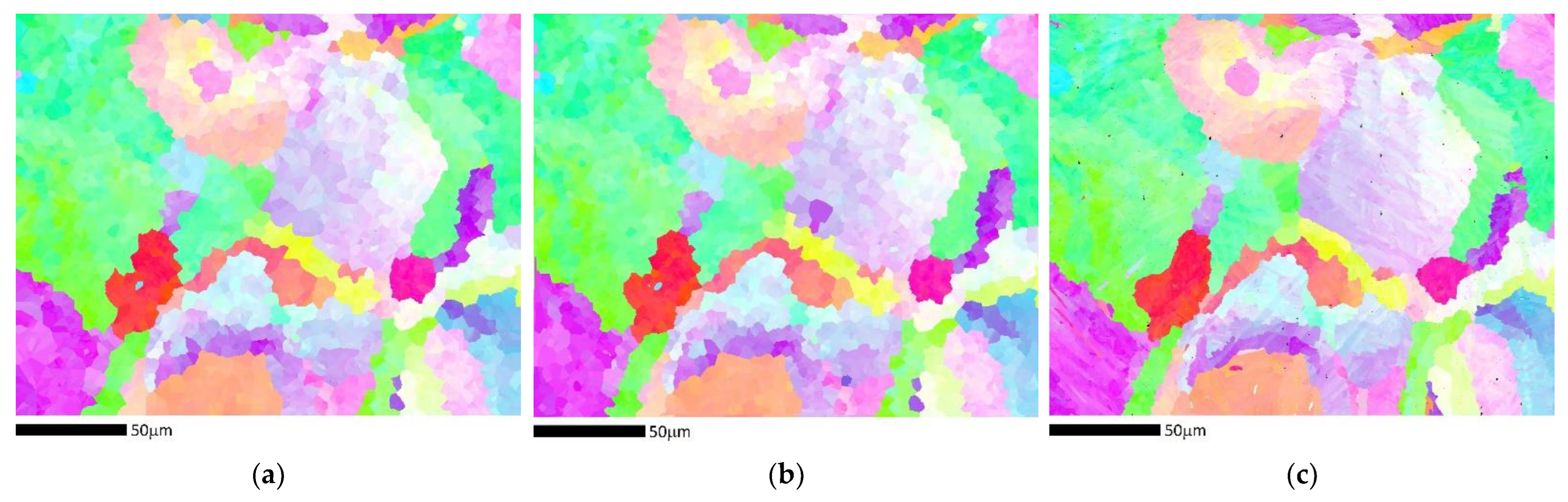

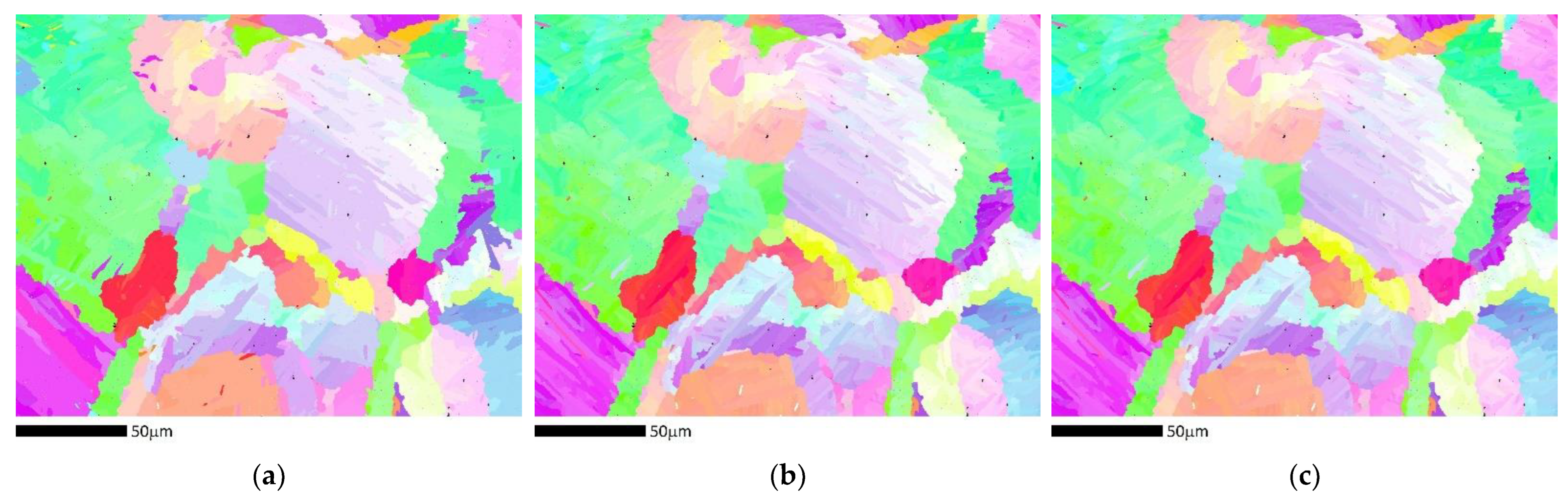

3.3. Assigning Reconstructed Orientations

- (1)

- Each point is assigned the orientation associated with the reconstructed grain to which it belongs, denoted grain-to-point.

- (2)

- Each point is assigned the orientation calculated by applying the ORV of the variant containing the specified point to the average orientation of the variant, denoted variant-to-point.

- (3)

- Each point is assigned the orientation calculated by applying the ORV of the variant containing the point to the orientation of the specified point, denoted point-to-point.

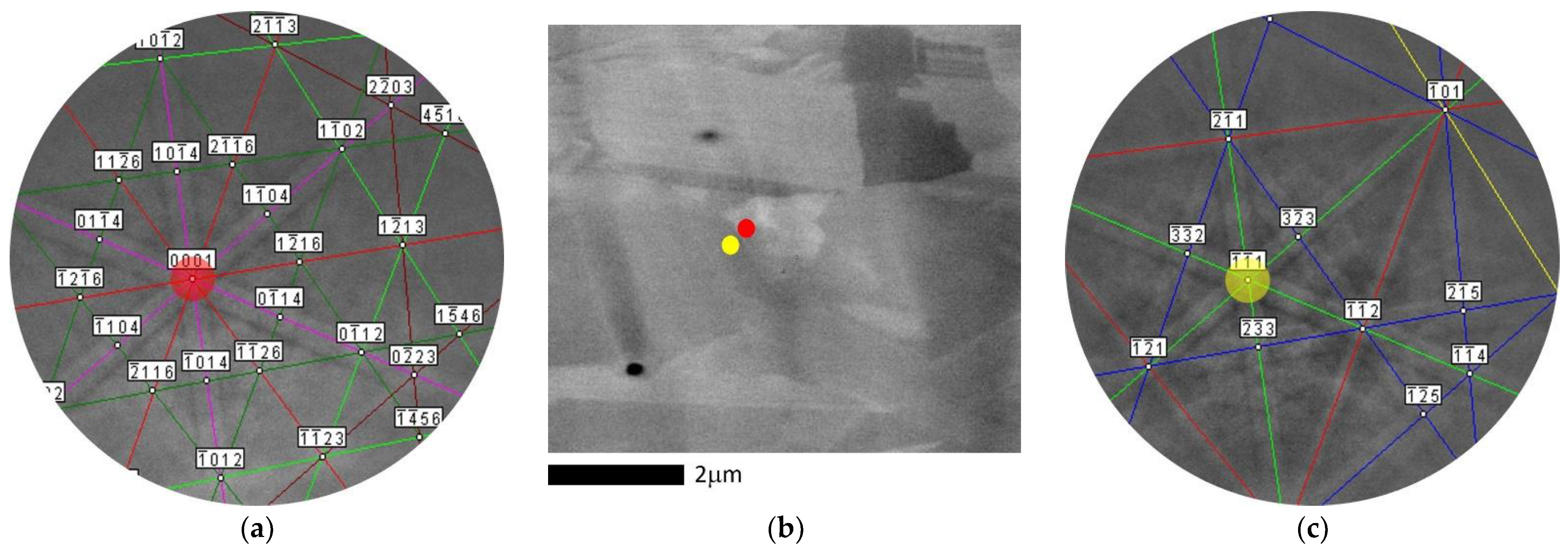

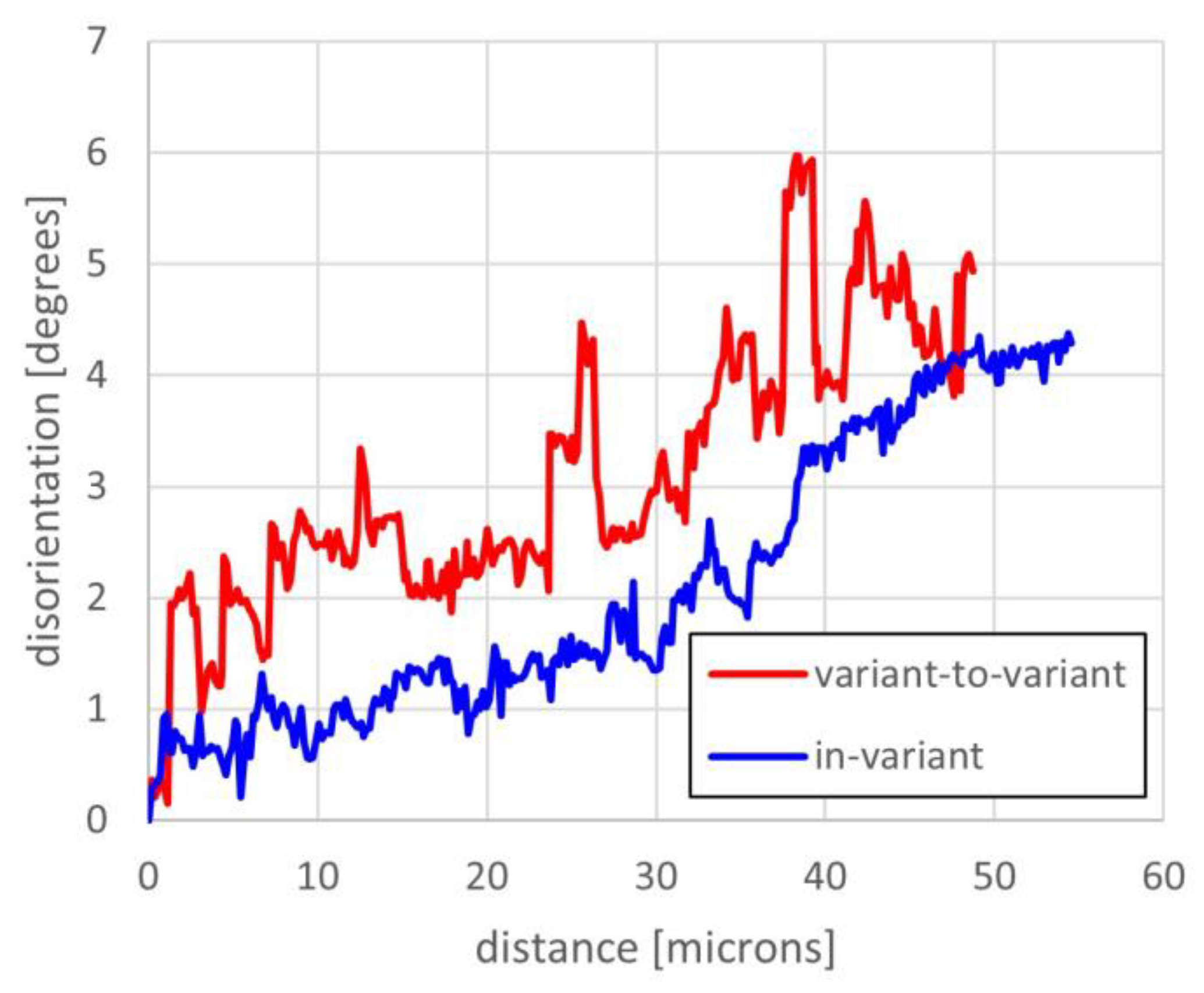

3.4. Orientation Relationship Refinement

- Collect a random set of one thousand pairs of neighboring child grains (at least the first grain in the pair is random), ensuring both child grains belong to the same parent grain.

- For each pair, calculate the disorientation between each of the two grains versus that of the parent. Add both disorientations to the global disorientation.

- Divide the summed global disorientation by the number of pairs to get the average disorientation. (Note there is more to the quaternion-based disorientation averaging scheme than described here—the actual algorithm used is an adaptation of that described in reference [15]).

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cayron, C. Crystallographic reconstruction methods to study phase transformations by EBSD. Microsc. Microanal. 2009, 15, 396–397. [Google Scholar] [CrossRef]

- Miyamoto, G.; Iwata, N.; Takayama, N.; Furuhara, T. Mapping the parent austenite orientation reconstructed from the orientation of martensite by EBSD and its application to ausformed martensite. Acta Mater. 2010, 58, 6393–6403. [Google Scholar] [CrossRef]

- Germain, L.; Gey, N.; Mercier, R.; Blaineau, P.; Humbert, M. An advanced approach to reconstructing parent orientation maps in the case of approximate orientation relations: Application to steels. Acta Mater. 2012, 60, 4551–4562. [Google Scholar] [CrossRef]

- Ranger, C.; Tari, V.; Farjami, S.; Merwin, M.J.; Germain, L.; Rollett, A. Austenite reconstruction elucidates prior grain size dependence of toughness in a low alloy steel. Metall. Mater. Trans. A 2018, 49, 4521–4535. [Google Scholar] [CrossRef]

- Huang, C.Y.; Ni, H.C.; Yen, H.W. New protocol for orientation reconstruction from martensite to austenite in steels. Materialia 2022, 9, 100554. [Google Scholar] [CrossRef]

- Brust, A.; Payton, E.; Hobbs, T.; Sinha, V.; Yardley, V.; Niezgoda, S. Probabilistic reconstruction of austenite microstructure from electron backscatter diffraction observations of martensite. Microsc. Microanal. 2021, 27, 1035–1055. [Google Scholar] [CrossRef] [PubMed]

- Hielscher, R.; Nyyssönen, T.; Niessen, F.; Gazder, A.A. The variant graph approach to improved parent grain reconstruction. Materialia 2022, 22, 101399. [Google Scholar] [CrossRef]

- Adams, B.L.; Wright, S.I.; Kunze, K. Orientation Imaging: The Emergence of a New Microscopy. Metall. Trans. A 1993, 24, 819–831. [Google Scholar] [CrossRef]

- Nowell, M.M.; Field, D.P.; Wright, S.I.; Dingley, D.; Scutts, P.; Suzuki, S. Orientation Imaging of Recrystallization, Grain Growth and Phase Transformations using In-Situ Heating. Microsc. Microanal. 2005, 11, 1494–1495. [Google Scholar] [CrossRef][Green Version]

- Wright, S.I. Random thoughts on non-random misorientation distributions. Mater. Sci. Technol. 2006, 22, 1287–1296. [Google Scholar] [CrossRef]

- Aurenhammer, F.; Klein, R.; Lee, D.-T. Handbook of Discrete and Computational Geometry; World Scientific Publishing Company: Singapore, 2013. [Google Scholar] [CrossRef]

- Delaunay, B. Sur la sphère vide. A la mémoire de Georges Voronoï. Bulletin de l’Académie des Sciences de l’URSS. Cl. Sci. Math. Nat. 1934, 6, 793–800. [Google Scholar]

- Field, D.P. Recent advances in the application of orientation imaging. Ultramicroscopy 1997, 67, 1–9. [Google Scholar] [CrossRef]

- Hata, K.; Wakita, M.; Fujiwara, K.; Kawano, K. Development of a reconstruction method of prior austenite microstructure using EBSD data of martensite. Nippon. Steel Sumitomo Met. Tech. Rep. 2017, 114, 26–31. [Google Scholar]

- Cheng, Y.; Crassidis, J.L.; Oshman, Y. Averaging quaternions. J. Guid. Control Dyn. 2007, 30, 1193–1197. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Bate, P.S.; Hurley, P.J. Orientation average of electron backscattered diffraction data. J. Microsc. 2001, 201, 50–58. [Google Scholar] [CrossRef] [PubMed]

- Godfrey, A, Edge preservation near triple junctions during orientation averaging of EBSP data. Scr. Mater. 2004, 50, 1097–1101. [CrossRef]

- Cho, J.H.; Rollet, A.D.; Oh, K.H. Determination of a mean orientation in electron backscatter diffraction measurements. Metall. Mater. Trans. A 2005, 36, 3427–3438. [Google Scholar] [CrossRef]

- Chen, D.; Kuo, J.C. Bilateral filter-based orientation smoothing of EBSD data. Ultramicroscopy 2010, 110, 1297–1305. [Google Scholar] [CrossRef]

- Nyyssönen, T. Quenching and Partitioning of High-Aluminum Steels. Ph.D. Thesis, Tamper University of Technology, Tampere, Finland, 2017. Available online: http://urn.fi/URN:ISBN:978-952-15-3896-4 (accessed on 17 December 2023).

- Nyyssönen, T.; Isakov, M.; Peura, P.; Kuokkala, V.T. Iterative determination of the orientation relationship between austenite and martensite from a large amount of grain pair misorientations. Metall. Mater. Trans. A 2016, 47, 2587–2590. [Google Scholar] [CrossRef]

- Gockel, J.; Sheridan, L.; Narra, S.P.; Klingbeil, N.W.; Beuth, J. Trends in solidification grain size and morphology for additive manufacturing of Ti-6Al-4V. JOM 2017, 69, 2706–2710. [Google Scholar] [CrossRef]

- Bermingham, M.; StJohn, D.; Easton, M.; Yuan, L.; Dargusch, M. Revealing the mechanisms of grain nucleation and formation during additive manufacturing. JOM 2020, 72, 1065–1073. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, W.; Xie, Y.; Li, H.; Zeng, C.; Xu, M.; Zhang, H. In-situ monitoring plume, spattering behavior and revealing their relationship with melt flow in laser powder bed fusion of nickel-based superalloy. J. Mater. Res. Technol. 2024, 177, 44–58. [Google Scholar] [CrossRef]

- Qu, M.; Guo, Q.; Escano, L.I.; Nabaa, A.; Hojjatzadeh, S.M.H.; Young, Z.A.; Chen, L. Controlling process instability for defect lean metal additive manufacturing. Nat. Commun. 2022, 13, 1079. [Google Scholar] [CrossRef]

- Pauza, J.G.; Tayon, W.A.; Rollett, A.D. Computer simulation of microstructure development in powder-bed additive manufacturing with crystallographic texture. Model. Simul. Mater. Sci. Eng. 2021, 29, 055019. [Google Scholar] [CrossRef]

| Element | α | β | α/β |

|---|---|---|---|

| Titanium | 1459 | 1424 | 1.02 |

| Aluminum | 185 | 221 | 0.83 |

| Vanadium | 278 | 308 | 0.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wright, S.I.; Lenthe, W.C.; Nowell, M.M. Parent Grain Reconstruction in an Additive Manufactured Titanium Alloy. Metals 2024, 14, 51. https://doi.org/10.3390/met14010051

Wright SI, Lenthe WC, Nowell MM. Parent Grain Reconstruction in an Additive Manufactured Titanium Alloy. Metals. 2024; 14(1):51. https://doi.org/10.3390/met14010051

Chicago/Turabian StyleWright, Stuart I., William C. Lenthe, and Matthew M. Nowell. 2024. "Parent Grain Reconstruction in an Additive Manufactured Titanium Alloy" Metals 14, no. 1: 51. https://doi.org/10.3390/met14010051

APA StyleWright, S. I., Lenthe, W. C., & Nowell, M. M. (2024). Parent Grain Reconstruction in an Additive Manufactured Titanium Alloy. Metals, 14(1), 51. https://doi.org/10.3390/met14010051