Abstract

Large residual stress of 2219 aluminum alloy induced by Tungsten Inert Gas (TIG) welding decreases its service performances. Shot peening was adopted to decrease the residual stress of TIG welding. Numerical models of TIG welding and shot peening were established using the combined discrete and finite element methods (DEM–FEM). The results show that TIG welding induces tensile residual stress due to the heat exchange effect and the longitudinal stress is larger than that in the transverse direction. The maximum tensile stress occurs at a depth of 0.1 mm. The surface tensile stress changes to compressive stress after shot peening as the severe deformation induced by the shots changes the stress state of the plate. The maximum value of compressive stress (σm) and the peened depth with compressive stress (Z0) are adopted to describe the peening effect. The absolute value of σm increases with the increased peening speed and nozzle height. Mixed shots with a diameter of 0.8 mm and 1.2 mm induce larger value of σm than those with only a diameter of 1.2 mm. The value of Z0 increases with the ascending shots diameter and nozzle height, while it varies nonmonotonically with the peening speed. The effect of shot peening on the residual stress in TIG welding is discussed.

1. Introduction

The 2219 aluminum alloy is extensively utilized in various industries, including aerospace and defense, with high strength, stress-corrosion resistance and superior mechanical properties. TIG welding has been widely used in the aerospace field, such as the tank of the rocket. The residual stress resulting from the welding process has detrimental effects on this material. Improving the post-welding performance of aluminum alloys and achieving superior welding joints have emerged as crucial issues.

To enhance the quality of weld joints, extensive experimental research has been conducted on how to mitigate the residual stress during welding. Leggatt et al. [1] conducted investigations on the residual stress distribution in various types of welds, such as plate-to-plate welds, circumferential butt welds, and weld overlays. They identified several significant factors that influence post-weld residual stresses, including substrate manufacturing processes, material properties, geometric shapes, constraint conditions, welding processes, and post-weld treatments. Aoki et al. [2] introduced an innovative approach for the application of vibrational loads in welding, aiming to mitigate residual stresses. The implementation of random vibration proved to be an effective strategy in reducing tensile residual stresses. Lobanov et al. [3] employed an electromechanical treatment approach to mitigate residual stresses in welded joints of aircraft structures. It reduced the initial stress in the welded joint from 120 MPa to 30 MPa. Under specific geometric conditions, stress values even reached as low as −50 MPa, resulting in the formation of a compressive stress field.

There has been remarkable progress in the development of numerical models for welding. Salih et al. [4] proposed a FEM based on the coupled Euler–Lagrange method. The study provided valuable insights for the assessment of weld joint quality. Dai et al. [5] introduced a numerical research approach for optimizing displacement control simulations. They investigated the residual stresses in welded components after high-frequency mechanical impacts. They demonstrated the reliability of the simulation system in accurately predicting post-weld residual stresses and those generated by high-frequency mechanical impacts.

Shot peening is a common surface strengthening technique that has been extensively studied in terms of reducing residual stress. The primary factors of shot peening included shots size, shots mass density, peening speed, peening angle, and mass flow rate [6,7]. Although different shot peening process parameters may yield similar results, shot peening intensity and coverage were regarded as key parameters for the industry [8,9]. In the context of shot peening, coverage was defined as the percentage of the target surface area covered by indentations according to the SAE J2277 standard 2013 [10,11]. On the other hand, shot peening intensity was characterized by the Almen intensity [12]. Based on this, researchers have conducted extensive experimental research to investigate the strengthening mechanisms of shot peening. Maleki et al. [13] used various microscopy techniques to characterize the microstructure, performed microhardness, residual stress measurements and fatigue tests to understand the mechanisms of shot peening strengthening. Mohamed et al. [14] investigated the influence of process pressure, nozzle distance, shot velocity, and shot angle on coverage, saturation, and surface quality through experimental investigations. Wu et al. [15] examined the effects of shot peening coverage on residual stresses, surface roughness, microhardness, and microstructure of rolled surfaces. Furthermore, some researchers have employed neural network methods to explore the mechanisms of shot peening. However, similar to the experimental studies mentioned above, these approaches provide results without specific insights into the underlying processes. Maleki et al. [16] experimentally studied the impact of shot peening on the surface hardness of carbon steel by altering relevant parameters and used artificial neural networks to predict surface hardness after shot peening. They investigated the influence of seven parameters on the surface hardness after shot peening. These comprehensive experimental and computational investigations contribute valuable insights into the mechanisms of shot peening strengthening, laying a solid foundation for optimizing the shot peening process to enhance material properties and performance.

Numerical simulations offer advantages in terms of economic costs and time savings compared to experimental research [17,18,19,20,21,22]. Hong et al. [23] proposed a computational model for finite element coupling processes that considered the interactions between the incoming and reflected shots. Jebahi et al. [24] developed a novel discrete–continuous coupling model and a cost-effective numerical simulation method. Tu et al. [25] presented a finite element model based on sequentially coupled discrete element model (DEM) to predict residual stress and surface roughness after shot peening. Zhang et al. [26] employed a DEM–FEM coupling simulation method to predict coverage, compressive residual stresses, and surface roughness resulting from shot peening. Ahmad et al. [10] established a numerical simulation model that was experimentally validated to evaluate the impact of shot peening velocity, projectile size, and impact angle on residual stress. Marini et al. [27] explored the potential of DEM–FEM simulation for edge shot peening processes, and the predicted residual stress fields were in good agreement with the experiments. Li et al. [28] proposed a DEM–FEM method for the shot peening of titanium alloy TC4. They investigated the effects of peening parameters as control variables on the resulting residual stresses.

In pursuit of a more realistic post-weld shot peening simulation model and more accurate simulation results, it is crucial to investigate the variations during the shot peening process and explore the factors influencing the impact of shot peening on residual stresses in welded plate components. However, there is a lack of reported studies on the combined simulation of shot peening for the reduction of residual stress fields in welded plate-to-plate joints.

In this study, in order to perform a joint simulation for shot peening of the residual stress field in welded joints of steel plates and to investigate the effect of parameters on residual stresses during the peening process, numerical models of TIG welding and shot peening were established in ABAQUS 2017 software using the combined discrete and finite element methods. The residual stress after TIG welding was introduced as the initial conditions for the shot peening model. The surface contact between the shots and the plate, as well as interactions between different shots was applied in DEM. The effect of shot peening parameters (shot peening speed, shots diameter and nozzle height) on the variation and distribution of residual stress was investigated. Finally, the accuracy of the models was validated through experiments.

2. Numerical Models

2.1. The TIG Welding Model

The material was 2219-T8 aluminum alloy. Two plates were TIG welded with an overall dimension of 300 mm × 300 mm × 10 mm. The welding process was carried out for duration of 200 s, followed by a post-weld cooling period of 30 min in the air. The temperature and residual stress distribution after cooling were analyzed.

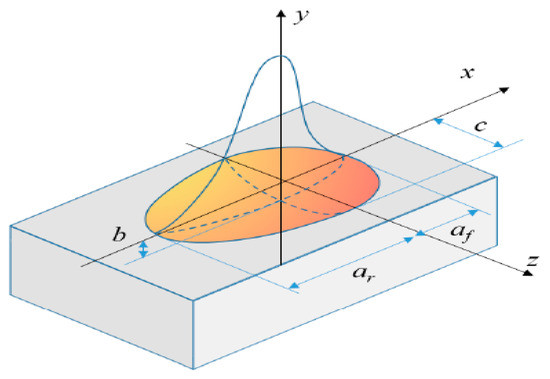

The dual ellipsoid heat source model is adopted as the heat source in TIG welding. The dual ellipsoid heat source model is schematically shown in Figure 1. The specific parameters of the double ellipsoid heat source are shown in Table 1. The mathematical expression of the dual ellipsoid heat source model is shown in Equations (1) and (2) [29]:

where qf and qr represent the heat flux densities at the front and rear ends, respectively; af and ar denote the lengths of the front and rear ellipsoids; b indicates the depth of the heat source; c represents the half-width of the heat source; ff and fr are the proportionality coefficients at the front and rear ends of the heat source, with ff + fr = 2; G denotes the effective heat input; η stands for the thermal efficiency; and U and I refer to the voltage and current, respectively.

Figure 1.

Schematic diagram of the dual ellipsoid model.

Table 1.

Parameters of the dual ellipsoid model.

For the 2219 aluminum alloy plate, the Johnson–Cook material model was adopted. This model represented a viscoplastic constitutive relationship that accurately simulated the effects of shots peening on the plate with high strain rate, work hardening and temperature effects. The fundamental formulation of the Johnson–Cook model [30] is shown in Equation (3).

The constitutive model parameters, A, B, C, m, and n, represent important factors in the Johnson–Cook material model. Here, εp denotes the equivalent plastic strain, and denotes the relative plastic strain. Tm, T0, and T correspond to the melting temperature, room temperature, and working temperature, respectively. A represents the material’s yield stress, n is the strain hardening exponent, B is a material-dependent constant, C is the strain rate sensitivity coefficient, and m is the temperature sensitivity coefficient. Table 2 provides the Johnson–Cook model parameters for the 2219 aluminum alloy, which were determined through thermal compression experiments.

Table 2.

2219 Aluminum Alloy J-C intrinsic parameters [31].

The thermal conduction between the plate and the worktable was convective heat transfer, with an empirically determined convective heat transfer coefficient of 1000 W/(m2∙°C). Both convective and radiative heat transfer effects between the plate and the environment were equivalently considered as surface convective heat transfer between the plate and the environment. The thermal conductivity coefficient was obtained from Equation (4) [32]:

h—equivalent convective heat transfer coefficient; ha—the value of the convective heat transfer coefficient between the material and the air, 20 W/(m2∙°C); ε—thermal radiation coefficient, its value is 0.75, σ—the Stefan–Boltzman constant, T—material surface temperature, and T0—air temperature.

Table 3 presents the specific thermal boundary conditions utilized during the numerical simulation of the temperature field in this study.

Table 3.

Thermal boundary parameters in TIG welding.

2.2. The Shot Peening Model

In this study, a numerical simulation of the shot peening process was conducted using the combined DEM–FEM method. Compared to the Smoothed Particle Hydrodynamics, the surface contact between the plate and the shots, as well as the interactions between different shots can be defined in the DEM–FEM method. Therefore, the diameter of the shots and the mixed shots with different diameters can be achieved.

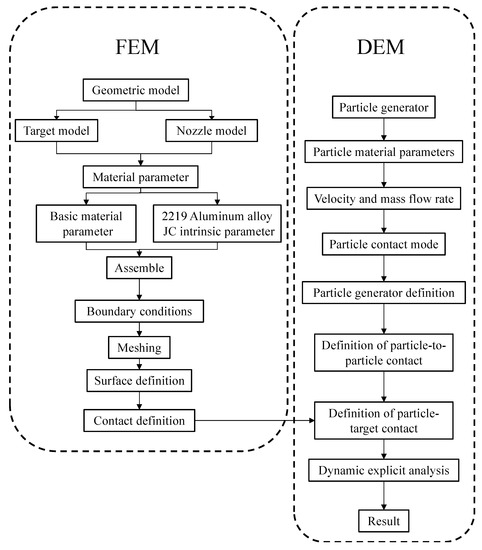

The steps of DEM–FEM coupled models are shown in Figure 2. The geometric characteristics, material constants and boundary conditions of the plate are defined in the FEM. During the shot peening process, multiple random shots with the specified diameter and peening speed are defined using DEM in this study. The shots were designed as solid, rigid objects, and its surface contact between the plate as well as interactions between different shots are applied in DEM. Then, the effect of peening parameters on the variation in the residual stress of the plate can be analyzed. The definition of the shots with DEM will be introduced in the subsequent sections.

Figure 2.

Steps of DEM–FEM coupled models.

The steel shots are adopted in the peening process and its material constants are shown in Table 4. It was known that the depth of the shot peening process of the aluminum alloy was approximately of 1 mm. To accurately capture the stress distribution at a depth of approximately 1.0 mm along the thickness direction after shot peening, the mesh size through the thickness of the plate is set as 0.2 mm. The mesh size of the welded zone is set as 0.3 × 0.3 mm.

Table 4.

Material constants of the peening shots [33].

The residual stress distribution after TIG welding is imported as the initial boundary condition for the shot peening model. The bottom surface of the plate is constrained in the shot peening process

The contact definition is the key factor for the accurate simulation of the shot peening process, which will be defined in the DEM model. Hard contact is applied to the plate surface and the shots with the friction coefficient of 0.3. As there is no viscous effect between the shots, Hertz contact is applied to the shots with the friction coefficient of 0.3 and Hertz force of 67.

The shot peening speed, shots diameter and the nozzle height play a vital role in the peening effect, thus significantly affecting the residual stress distribution. In this study, the effect of peening parameters on the variation in the residual stress is investigated, as shown in Table 5.

Table 5.

Shot peening parameters.

3. Experiment and Methods

3.1. Tig Welding

In this study, the 2219 series aluminum alloy was chosen as the research material. Both the welding plate and welding wire were of the same chemical composition, as shown in Table 6. The wire diameter is 1.2 mm. The main parameters of the welding machine used for TIG welding were shown in Table 7. The experimental parameters are the same with the numerical models. Pure argon was adopted as the shielding gas with the flow rate of 14 L/min.

Table 6.

Composition of 2219(ER2319) aluminum wire.

Table 7.

Main parameters of TIG welding.

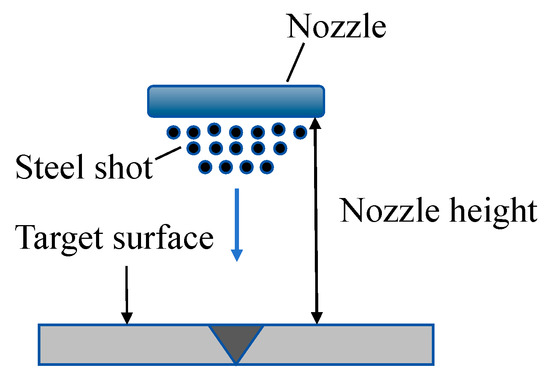

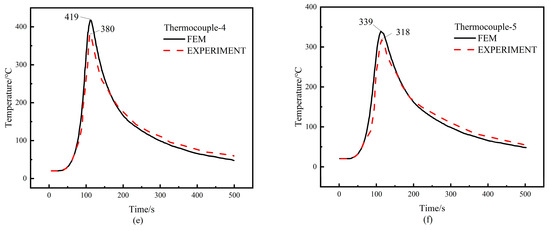

3.2. Shot Peening

The peening equipment used was the CJ-106P machine. The working pressure during the shots peening ranged from 0.3 to 0.8 MPa with a nozzle diameter of 12 mm. A constant air pressure of 0.4 MPa was maintained in the shot peening process. The nozzle was perpendicular to the surface of the plate. The center area of the weld seam of the welded plate was shot peened. Steel shots were adopted and the peening time was 1 min. The schematic diagram of shot peening is shown in Figure 3.

Figure 3.

Schematic diagram of shot peening.

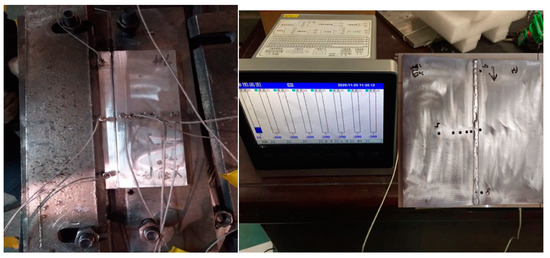

3.3. Temperature Detection

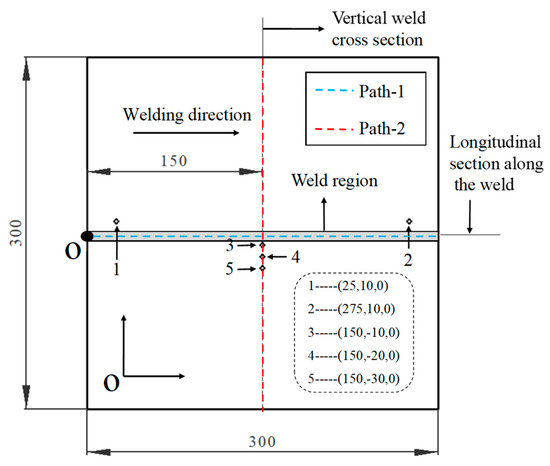

K-type thermocouples are used for temperature measurement, as shown in Figure 4, the diameter of the thermocouple is 3 mm, the depth of the punched hole is 2 mm, a total of 5 thermocouples are read in the welded arc start end, resting arc end and the middle cross-section position.

Figure 4.

Thermocouple distribution diagram.

3.4. Residual Stress Detection

The surface residual stresses of the post-welded and shot−peened plates were measured using an X-ray detection device (Xstress 3000 G2/G2R, X-ray Stress Analyzer, Stresstech brand, located in Finland, was purchased from Beijing Hua-OU Century Optoelectronic Technology Co., Ltd., Beijing, China). The parameters used for the diffractometer are listed in Table 8.

Table 8.

X-ray diffractometer test parameters.

Electrolytic polishing equipment was employed to polish the surface of the plate for measuring the residual stresses through the thickness direction, as shown in Figure 5. The depth of each removal layer of the plate can be controlled by constant parameters in electrolytic polishing process. The polishing duration at the desired locations was set to 5 s. After the removal of the material with a certain thickness, the surface residual stress was measured. As a result, the residual stress through the thickness of the plate can be obtained by several times of polishing and measurements.

Figure 5.

Electrolytic polishing experimental equipment diagram.

4. Results and Discussion

4.1. Temperature Variation in TIG Welding

The residual stress after TIG welding is related to the variation in the temperature during and after welding process. Based on the FEM analysis, the peak temperature at the center of the weld is approximately 885 °C, and its width is 9 mm. To study the temperature distribution in TIG welding, five points are selected, as shown in Figure 6.

Figure 6.

Schematic diagram of the five thermocouples. 1−5 indicates the location of the temperature measuring point.

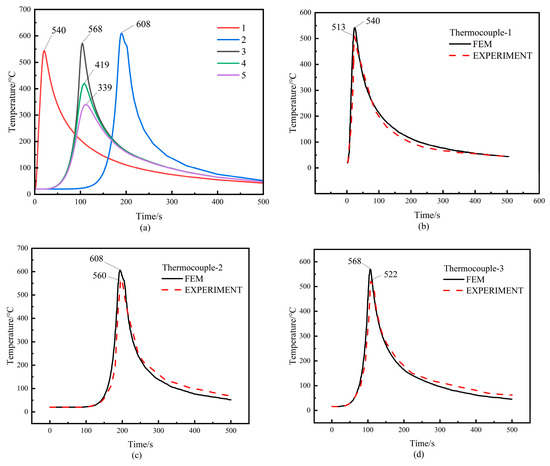

The temperature at the start position (Point 1) of the weld increases quickly and then decreases with the movement of the welding torch, as shown in Figure 7. It can be seen that the peak temperature at the start position is smaller than that at the end position (Point 2) due to the heat sink effect at the start position of the weld. Despite of the distance between Point 3 and the center line of the weld, Point 3 shows larger peak temperature than that in Point 1, indicating that the heat accumulation increases with the movement of the welding torch. As a result, Point 2 shows the highest temperature due to the heat accumulation and the torch delay during the end position in TIG welding process. Point 4 and Point 5 show the similar variation with Point 3, and its peak temperature decreases with the increased distance from the center line of the weld due to the heat exchange between the weld and the plate.

Figure 7.

(a) Temperature variation in the key points. (b–f) Comparison between simulated and experimental temperature results.

The comparison between the experimental temperature cycle curves and the ones obtained from finite element simulations is shown in Figure 7. The peak temperatures obtained from the finite element simulations at the positions of the five thermocouples agree with the experiment, confirming the accuracy and reliability of FEM.

4.2. Residual Stress Variation in TIG Welding

The formation of residual stress is related to the cooling process after TIG welding. To investigate the distribution of the residual stress after TIG welding, the variation in residual stress on the longitudinal section (parallel to the moving direction of the torch) and the cross-section (perpendicular to the moving direction of the torch) is analyzed. As shown in Figure 6, the residual stresses in both directions on the surface of each point of path 1 in the longitudinal section and path 2 in the transverse section were measured by X-ray. Each path was measured at 11 points, with 25 mm between every two points. In order to analyze the residual stress distribution of the welded zone, the residual stress of the key points in two sections is measured. As shown in Figure 8, the transverse residual stress of this point is measured. The longitudinal residual stress of this point can be measured by rotating the probe with 90°.

Figure 8.

Residual stress diagram for X-ray diffraction measurement.

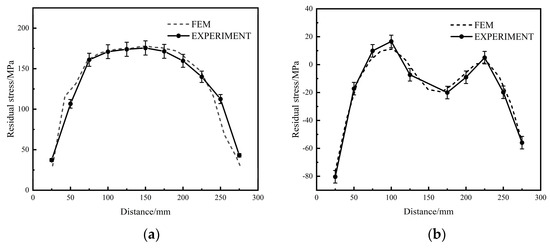

As depicted in Figure 9a, TIG welding induces tensile residual stress in the longitudinal direction on the longitudinal section of the weld, and its value ranges from 30.2 MPa to 177.5 MPa. The peak value of the longitudinal residual stress occurs at the center of the weld. The longitudinal residual stress shows an “arch-like” distribution with smaller values at both ends. The transverse residual stress on the longitudinal section of the weld shows different variation compared to that of the longitudinal direction. Tensile stress is generated at the center of the weld while compressive stress appears near the arc start and arc end positions. The peak value of transverse residual tensile stress is 11.2 MPa, which is quite smaller than that in the longitudinal direction. The reasons for the difference between the residual stresses at the beginning and end of the weld and in the middle position are as follows: the heat exchange at the arc start and arc end position is sufficient due to the large contact area to the cold plate without welding, thus resulting in smaller residual stress at both ends. The heat exchange between the material at center part of the weld and the plate is quite different in two directions. The cooling rate at center part of the weld in the longitudinal direction is small due to its adjacent material with high temperature. However, the cooling rate in the transverse direction is much larger as there is sufficient heat exchange between the weld and the plate with low temperature.

Figure 9.

(a) Longitudinal and (b) transverse residual stress on the longitudinal section of the weld.

Figure 10a shows the longitudinal residual stress on the cross-section at the center of the weld. The region around the center of the weld exhibits higher tensile stress, with the maximum value of 177.5 MPa. In contrast, the stress far from the weld is relatively smaller and tends to approach a state of zero stress. The reason for this behavior is that the material far from the weld experiences less influence from the temperature increase during the TIG welding, resulting in a weaker thermal expansion effect and lower stress. As shown in Figure 10b, it can be observed that the transverse stress is mainly concentrated in the central part of the weld, similar to the longitudinal residual stress distribution. The value of transverse stress is much smaller than that in the longitudinal dire.

Figure 10.

(a) Longitudinal and (b) transverse residual stress on the cross-section of the weld.

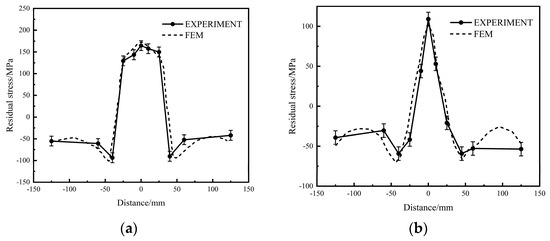

In order to investigate the effect of shot peening on the variation in residual stress, the distribution of residual stress through the thickness direction of the plate is analyzed, as shown in the Figure 11. The longitudinal residual stress is primarily tensile stress and the maximum tensile stress occurs at a depth of 0.1 mm with a value of 243.8 MPa. The transverse residual stress exhibits tensile stress on the surface of the plate, and with mixed tensile and compressive stress through the thickness of the plate.

Figure 11.

Distribution of (a) longitudinal and (b) transverse residual stress through the thickness direction.

4.3. Residual Stress Variation in Shot Peening

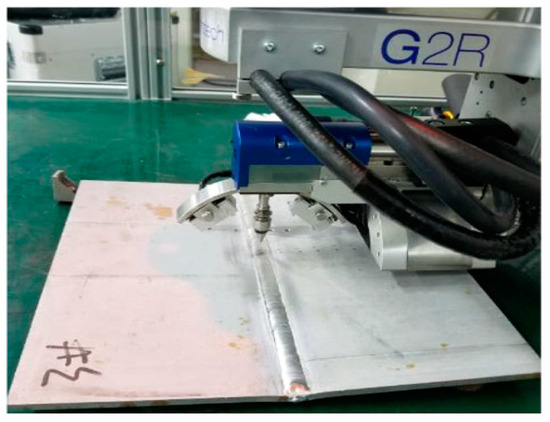

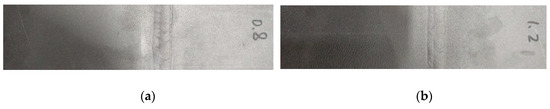

One-pass TIG welding induces deformation after removing the constraint of the plate. The maximum distortion of the plate after TIG welding is 2 mm and it decreases to 0.9 mm after shot peening process. Shot peening is beneficial for the decrease in the plate deformation. This distortion shows little effect on the analysis of the residual stress in this study. As shown in Figure 12 are some pictures after shot peening.

Figure 12.

(a) A 0.8 mm steel shot blasting surface; (b) a 1.2 mm steel shot blasting surface.

4.3.1. Effect of Shot Peening Speed

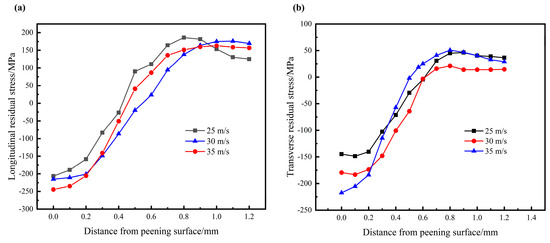

Figure 13 shows the effect of shot peening speed on variation in longitudinal and transverse residual stress. The shot peening transforms the tensile residual stress after TIG welding to compressive residual stress on the peened surface. The shot peening process can induce the compressive residual stress with a specified depth, and the compressive stress gradually changes to tensile stress with the increased depth. As a result, the residual stress will be self-balanced through the thickness of the plate. To qualitatively describe the peening effect, two parameters are defined, the maximum value of compressive stress (σmax) and the peened depth with compressive stress (Dc).

Figure 13.

Effect of shot peening speed on variation in: (a) longitudinal and (b) transverse residual stress (D = 1.2 mm, H = 50 mm).

As shown in Table 9, it is obvious that the value of σmax in the longitudinal and transverse directions both increase with the increased shot peening speed. The peened depth with compressive residual stress (Dc) first increases with the shot peening speed ranging from 25 m/s to 30 m/s, and then decreases when the shot peening speed increases to 35 m/s. The increment of the σmax in the longitudinal direction is 20 MPa with the shot peening speed ranging from 25 m/s to 30 m/s, which is larger than that of 14 MPa with the range from 30 m/s to 35 m/s. The transverse residual stress shows the same variations. Therefore, an optimized shot peening speed can be acquired according to the requirement for larger compressive residual stress or larger peened depth.

Table 9.

Effect of shot peening speed on variation in residual stress and peened depth.

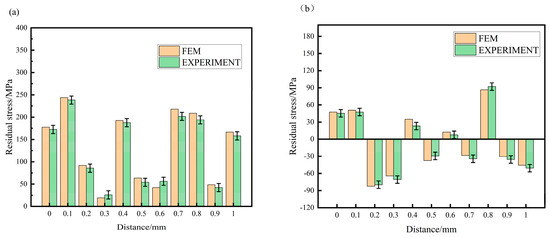

4.3.2. Effect of the Shots Diameter

To study the effect of the shots diameter on the variation in residual stress, three conditions are comparatively analyzed: using steel shots with a diameter of 0.8 mm, 1.2 mm and the mixed shots of 0.8 + 1.2 mm with equal proportion.

As shown in Figure 14, the value of σmax in longitudinal and transverse directions and its peened depth Dc both increase with the increased shots diameter. The peening energy is related to the shots mass with a given shot peening speed, which depends on the shots diameter. A shots diameter of 1.2 mm induces larger peening energy to the welded plate, thus resulting in larger and deeper compressive residual stress.

Figure 14.

Effect of the shots diameter on variation in: (a) longitudinal and (b) transverse residual stress (V = 25 m/s, H = 50 mm).

As shown in Table 10, the larger value of σmax in the longitudinal direction can be obtained with the mixed shots of 0.8 + 1.2 mm compared to that with a shots diameter of 1.2 mm. Nevertheless, the mixed shots induce a smaller value of σmax in the transverse direction compared to that with a shots diameter of 1.2 mm. The peened depth Dc of both directions is between a shots diameter of 0.8 mm and 1.2 mm. It can be inferred that the the shots diameter mainly affects the peened depth, and a larger shots diameter induces a larger peened depth due to the larger peening energy. There may be interactions between the shots with mixed diameter, which shows different variations in the longitudinal and transverse residual stress. The peened depth in the transverse direction is larger than that in the longitudinal direction, indicating that the shot peening process shows better effect on the transverse residual stress.

Table 10.

Effect of the shots diameter on variation in residual stress and peened depth.

In conclusion, a larger shots diameter results in a larger peened depth while a mixed shots diameter induces larger compressive residual stress compared to that with the shots of the same diameter.

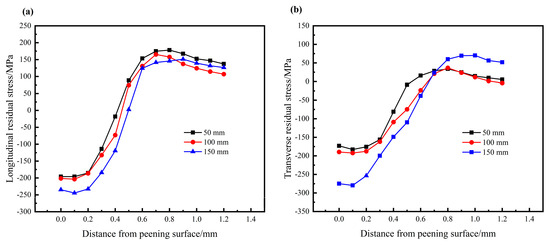

4.3.3. Effect of Nozzle Height

With the increased nozzle height, the value of σmax and the peened depth Dc in two directions both increase, as shown in Table 11 and Figure 15. The increment of the σmax in the longitudinal direction is 4 MPa with the nozzle height ranging from 50 mm to 100 mm, while it is 36 MPa with the range from 100 mm to 150 mm. For the transverse residual stress, the increments are 39 MPa and 103 Mpa, respectively, which is much larger than that of the longitudinal direction. Additionally, the nozzle height induces a larger peened depth in the transverse direction compared to that in the longitudinal direction.

Table 11.

Effect of nozzle height on variation in residual stress and peened depth.

Figure 15.

Effect of nozzle height on variation in: (a) longitudinal and (b) transverse residual stress (V = 25 m/s, D = 1.2 mm).

4.3.4. Experimental Verification

Firstly, the reliability of the DEM-based shot peening model was validated by experiment. The parameters for shot peening are described as follows: shot peening speed 30 mm/s, shots diameter 1.2 mm and nozzle height 50 mm. The residual stress and the peened depth are measured by X-ray detection device, as shown in Table 12. Good agreement between simulated and experimental results validates the accuracy of the FEM-DEM models.

Table 12.

Comparison between simulated and experimental results.

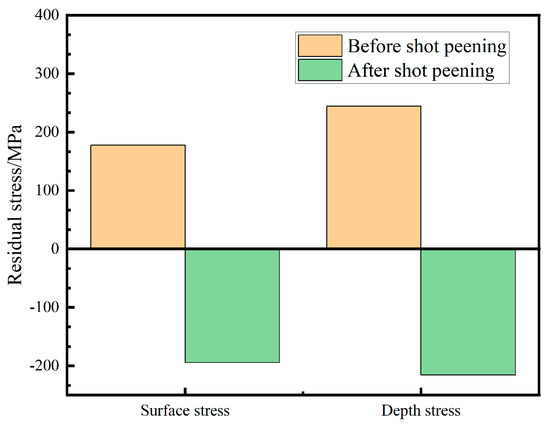

Through simulation and experimental analysis, it has been observed that shot peening effectively transforms the residual tensile stresses near the weld joint into compressive stresses. The experimental results illustrate the changes in peak residual stresses, as depicted in. Prior to shot peening, the maximum residual tensile stress on the surface of the plate was measured to be 177.5 MPa. After shot peening treatment, the maximum surface compressive stress reached −194.3 MPa, and the value of Dc was approximately 0.518 mm. Along the depth direction, the maximum value of compressive stress was recorded at −215.4 MPa.

Figure 16 shows the residual stress distribution after TIG welding and shot peening process. Tensile stress of 177.5 MPa after TIG welding changes to compressive stress of −194.3 MPa on the peened surface. Meanwhile, TIG welding induces the maximum tensile stress of 243.1 MPa, which decreases to −215.4 MPa after shot peening. It is obvious that the shot peening significantly transform the tensile stress to compressive stress. Large compressive stress on the surface of the plate is beneficial to prevent fatigue corrosion and damage, thereby reducing crack initiation and its propagation as well as increasing the fatigue life of the plate.

Figure 16.

Residual stress variation after TIG welding and shot peening.

5. Conclusions

- TIG welding induces tensile residual stresses in the longitudinal direction with the maximum value at a depth of 0.1 mm. The longitudinal residual stress is larger than that in the transverse direction after TIG welding.

- Shot peening effectively transforms the tensile residual stress after TIG welding into compressive stress with a certain depth.

- Increased shot peening speed leads to larger values of the maximum compressive residual stress (σmax) in both directions. However, the shot peening speed shows limited effect on the increase in the peened depth with compressive residual stress.

- The value of σmax in the longitudinal and transverse directions and its peened depth Dc both increase with the increased shots diameter. Mixed shots of 0.8 + 1.2 mm induce a larger value of σmax in the longitudinal direction compared to that with shots diameter of 1.2 mm.

- The value of σmax and the peened depth Dc in two directions both increase with the increased nozzle height.

Author Contributions

Conceptualization, analysis and writing, T.Z.; experimentation, methodology and analysis, J.C. and H.L.; conceptualization, resources and reviews, H.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by State Key Laboratory of Precision Manufacturing for Extreme Service Performance, Central South University (ZZYJKT2021-05).

Data Availability Statement

The data presented in this study are available in this article.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; and in the decision to publish the results.

References

- Leggatt, R.H. Residual stresses in welded structures. Int. J. Press. Vessel. Piping 2008, 85, 144–151. [Google Scholar] [CrossRef]

- Aoki, S.; Nishimura, T.; Hiroi, T. Reduction method for residual stress of welded joint using random vibration. Nucl. Eng. Des. 2005, 235, 1441–1445. [Google Scholar] [CrossRef]

- Lobanov, L.M.; Pashchin, N.A.; Mikhodui, O.L.; Khokhlova, J.A. Investigation of residual stresses in welded joints of heat-resistant magnesium alloy ML10 after electrodynamic treatment. J. Magnes. Alloys 2016, 4, 77–82. [Google Scholar] [CrossRef]

- Salih, O.S.; Ou, H.; Sun, W. Heat generation, plastic deformation and residual stresses in friction stir welding of aluminium alloy. Int. J. Mech. Sci. 2023, 238, 107827. [Google Scholar] [CrossRef]

- Dai, P.; Kyaw, P.M.; Osawa, N.; Rashed, S.; Ma, D.; Okada, J.; Honnami, M. Numerical study on local residual stresses induced by high frequency mechanical impact post-weld treatment using the optimized displacement-controlled simulation method. J. Manuf. Process. 2023, 92, 262–271. [Google Scholar] [CrossRef]

- Lin, Q.; Liu, H.; Zhu, C.; Chen, D.; Zhou, S. Effects of different shot peening parameters on residual stress, surface roughness and cell size. Surf. Coat. Technol. 2020, 398, 126054. [Google Scholar] [CrossRef]

- Ongtrakulkij, G.; Khantachawana, A.; Kondoh, K. Effects of media parameters on enhance ability of hardness and residual stress of Ti6Al4V by fine shot peening. Surf. Interfaces 2020, 18, 100424. [Google Scholar] [CrossRef]

- Wu, J.; Liu, H.; Wei, P.; Lin, Q.; Zhou, S. Effect of shot peening coverage on residual stress and surface roughness of 18CrNiMo7-6 steel. Int. J. Mech. Sci. 2020, 183, 105785. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O. Roles of surface coverage increase and repeening on properties of AISI 1045 carbon steel in conventional and severe shot peening processes. Surf. Interfaces 2020, 11, 82–90. [Google Scholar] [CrossRef]

- Ahmad, A.S.; Wu, Y.; Gong, H. Coupled finite and discrete element shot peening simulation based on Johnson–Cook material model. Proc. Inst. Mech. Eng. Part L 2020, 234, 974–987. [Google Scholar] [CrossRef]

- SAE J2277; Shot Peening Coverage Determination. American Society of Motor Vehicle Engineers: Warrendale, PA, USA, 2013.

- Miao, H.Y.; Larose, S.; Perron, C.; Lévesque, M. An analytical approach to relate shot peening parameters to Almen intensity. Surf. Coat. Technol. 2010, 205, 2055–2066. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Amanov, A. Novel experimental methods for the determination of the boundaries between conventional, severe and over shot peening processes. Surf. Interfaces 2018, 13, 233–254. [Google Scholar] [CrossRef]

- AL-Mokhtar, O.; Mohamed; Zoheir, F.; Andrew, W.; Gillis, J. Effect of a moving automated shot peening and peening parameters on surface integrity of Low carbon steel. J. Mater. Process. Technol. 2020, 227, 116399. [Google Scholar]

- Wu, J.; Liu, H.; Wei, P.; Zhu, C.; Lin, Q. Effect of shot peening coverage on hardness, residual stress and surface morphology of carburized rollers. Surf. Coat. Technol. 2020, 384, 125273. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O. Optimization of shot peening effective parameters on surface hardness improvement. Met. Mater. Int. 2020, 27, 3173–3185. [Google Scholar] [CrossRef]

- Gariépy, A.; Miao, H.Y.; Lévesque, M. Simulation of the shot peening process with variable shot diameters and impacting velocities. Adv. Eng. Softw. 2017, 114, 121–133. [Google Scholar] [CrossRef]

- Bagherifard, S.; Ghelichi, R.; Guagliano, M. Numerical and experimental analysis of surface roughness generated by shot peening. Appl. Surf. Sci. 2012, 258, 6831–6840. [Google Scholar] [CrossRef]

- Maleki, E.; Farrahi, G.H.; Kashyzadeh, K.R.; Unal, O.; Gugaliano, M.; Bagherifard, S. Effects of conventional and severe shot peening on residual stress and fatigue strength of steel AISI 1060 and residual stress relaxation due to fatigue loading: Experimental and numerical simulation. Met. Mater. Int. 2020, 27, 2575–2591. [Google Scholar] [CrossRef]

- Zhang, Y.; Lai, F.; Qu, S.; Ji, V.; Liu, H.; Li, X. Effect of shot peening on residual stress distribution and tribological behaviors of 17Cr2Ni2MoVNb steel. Surf. Coat. Technol. 2020, 386, 125497. [Google Scholar] [CrossRef]

- Sherafatnia, K.; Farrahi, G.H.; Mahmoudi, A.H. Effect of initial surface treatment on shot peening residual stress field: Analytical approach with experimental verification. Int. J. Mech. Sci. 2018, 137, 171–181. [Google Scholar] [CrossRef]

- Zhao, C.; Shi, C.; Wang, Q.; Gao, Y.; Yang, Q. Residual stress field of high-strength steel after shot peening by numerical simulation. J. Mater. Eng. Perform. 2020, 29, 358–364. [Google Scholar] [CrossRef]

- Hong, T.; Ooi, S.B. A numerical simulation to relate the shot peening parameters to the induced residual stresses. Eng. Fail. Anal. 2008, 15, 1097–1110. [Google Scholar] [CrossRef]

- Jebahi, M.; Gakwaya, A.; Lévesque, J.; Mechri, O.; Ba, K. Robust methodology to simulate real shot peening process using discrete continuum coupling method. Int. J. Mech. Sci. 2016, 107, 21–33. [Google Scholar] [CrossRef]

- Tu, F.; Delbergue, D.; Klotz, T.; Bag, A.; Miao, H.; Bianchetti, C.; Brochu, M.; Bocher, P.; Levesque, M. Discrete element-periodic cell coupling model and investigations on shot stream expansion, Almen intensities and target materials. Int. J. Mech. Sci. 2018, 145, 353–366. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, S.; Wu, T.; Zhou, Z.; Zhang, W. An evaluation on SP surface property by means of combined FEM-DEM shot dynamics simulation. Adv. Eng. Softw. 2018, 115, 283–296. [Google Scholar] [CrossRef]

- Marini, M.; Piona, F.; Fontanari, V.; Bandini, M.; Benedetti, M. A new challenge in the DEM/FEM simulation of the shot peening process: The residual stress field at a sharp edge. Int. J. Mech. Sci. 2020, 169, 105327. [Google Scholar] [CrossRef]

- Li, K.; Wang, C.; Hu, X.; Zhou, Y.; Lai, Y.; Wang, C. DEM-FEM coupling simulation of residual stresses and surface roughness induced by shot peening of TC4 titanium alloy. Int. J. Adv. Manuf. Technol. 2021, 118, 1469–1483. [Google Scholar] [CrossRef]

- Ding, J.; Colegrove, P.; Mehnen, J.; Ganguly, S.; Sequeira, A.P.M.; Wang, F.; Williams, S. Thermo-mechanical analysis of Wire and Arc Additive Layer Manufacturing process on large multi-layer parts. Comput. Mater. Sci. 2011, 50, 3315–3322. [Google Scholar] [CrossRef]

- Mirza, F.A.; Daolun, C.; Dejiang, L.I.; Zeng, X. A modified Johnson-Cook constitutive relationship for a rare-earth containing magnesium alloy. J. Rare Earths 2013, 31, 1202–1207. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, Z.; Wei, Q. Dynamic mechanical properties and constitutive equations of 2219 aluminum alloy. J. Mater. Eng. 2017, 45, 47–51. [Google Scholar]

- Kim, D.; Badarinarayan, H.; Kim, J.H.; Kim, C.; Okamoto, K.; Wagoner, R.H.; Chung, K. Numerical simulation of friction stir butt welding process for AA5083-H18 sheets. J. Mech. Theor. Appl. 2010, 29, 204–215. [Google Scholar] [CrossRef]

- Ahmad, A.S.; Wu, Y.; Gong, H.; Alhassan, Y. Numerical simulation of post-weld shot peening using combined discrete and finite element methods (DEM-FEM). Proc. Inst. Mech. Eng. Part B 2023, 237, 261–275. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).