Microstructure and Mechanical Properties of AA 6082/AISI 304 Joints Brazed Using Al-Ge-Si Filler Metal

Abstract

1. Introduction

2. Materials and Experimental Procedure

2.1. Materials

2.2. Experimental Procedure

3. Results

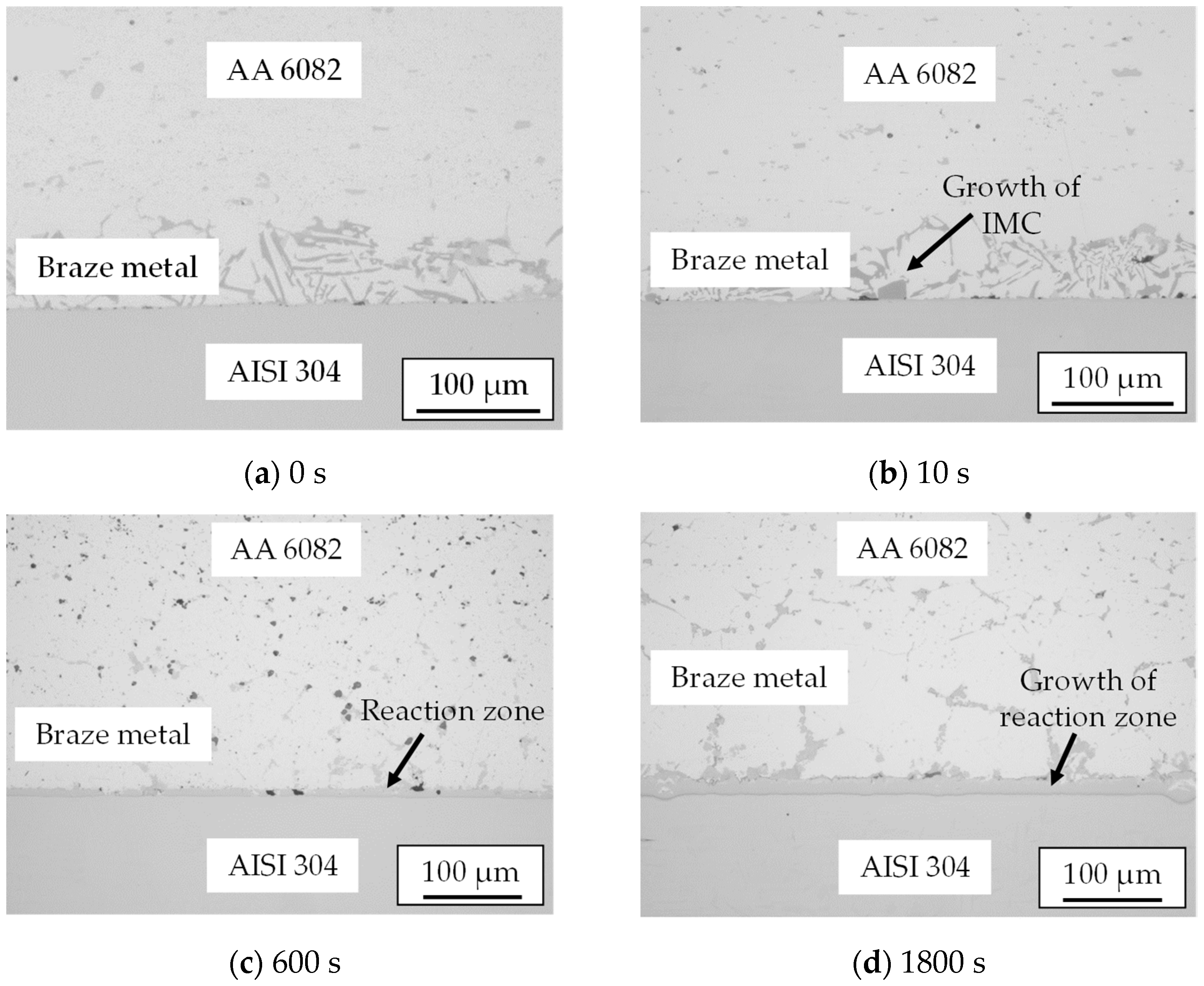

3.1. Microstructure of the AA 6082/AISI 304 Brazed Joints

3.2. Nanoindentation Results

3.3. Tensile Shear Strength of the AA 6082/AISI 304 Brazed Joints

3.4. Fatigue Behavior of the AA 6082/AISI 304 Brazed Joints

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ahn, B. Recent advances in brazing fillers for joining of dissimilar materials. Metals 2021, 11, 1037. [Google Scholar] [CrossRef]

- Wallerstein, D.; Salminen, A.; Lusquiños, F.; Comesaña, R.; García, J.D.V.; Rodríguez, A.R.; Pou, J. Recent developments in laser welding of aluminum alloys to steel. Metals 2021, 11, 622. [Google Scholar] [CrossRef]

- Fedorov, V.; Uhlig, T.; Wagner, G. Investigation of fatigue damage in aluminum/stainless steel brazed joints. Weld. World 2018, 62, 609–616. [Google Scholar] [CrossRef]

- Yang, J.; Oliveira, J.P.; Li, Y.; Tan, C.; Gao, C.; Zhao, Y.; Yu, Z. Laser techniques for dissimilar joining of aluminum alloys to steels: A critical review. J. Mater. Process. Technol. 2022, 301, 117443. [Google Scholar] [CrossRef]

- Li, R.; Yuan, X.; Zhang, H.; Yang, J.; Wu, K.; Li, T.; Tao, S. Effect of axial magnetic field on TIG welding–brazing of AA6061 aluminum alloy to HSLA350 steel. J. Mater. Res. Technol. 2021, 12, 882–893. [Google Scholar] [CrossRef]

- Kayamoto, T.; Saito, S.; Ogusu, M.; Onzawa, T. Vacuum brazing of 2017 aluminum alloy using Al-Ge-Cu based fillers. Q. J. Jpn. Weld. Soc. 1996, 14, 63–68. [Google Scholar] [CrossRef][Green Version]

- Ostermann, F. Anwendungstechnologie Aluminium; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Bach, F.-W.; Möhwald, K.; Holländer, U.; Tiemann, S. Flussmittelfreies Hartlöten unter reaktiver Prozessgasatmosphäre—Ein alternatives Verfahren zum Fügen von Aluminiumwerkstoffen. Mater. Werkst. 2008, 39, 594–598. [Google Scholar] [CrossRef]

- Dai, W.; Xue, S.B.; Ji, F.; Lou, J.; Sun, B.; Wang, S.Q. Brazing 6061 aluminum alloy with Al-Si-Zn filler metals containing Sr. Int. J. Miner. Metall. Mater. 2013, 20, 365–370. [Google Scholar] [CrossRef]

- Yu, G.; Sun, H.; Teng, F.; Chen, S.; Huang, J.; Yang, J.; Zhao, Z. Influence of Si Addition on Microstructure, Mechanical Properties, and Corrosion Resistance of Al/Steel Brazing Joint Using Zn-15Al-XSi Filler Metals. J. Mater. Eng. Perform. 2023, 1–11. [Google Scholar] [CrossRef]

- Chuang, T.H.; Tsao, L.C.; Tsai, T.C.; Yeh, M.S.; Wu, C.S. Development of a low-melting-point filler metal for brazing aluminum alloys. Metall. Mater. Trans. A 2000, 31, 2239–2245. [Google Scholar] [CrossRef]

- Chang, S.Y.; Tsao, L.C.; Li, T.Y.; Chuang, T.H. Joining 6061 aluminum alloy with Al–Si–Cu filler metals. J. Alloys Compd. 2009, 488, 174–180. [Google Scholar] [CrossRef]

- Pei, C.; Wu, X.; Zhang, G.; Cheng, Y.; Ren, X.; Wang, W.; Xiong, H. Microstructures and mechanical properties of brazed 6063 aluminum alloy joint with Al-Cu-Si-Ni filler metal. Weld. World 2020, 64, 1933–1938. [Google Scholar] [CrossRef]

- Peng, C.; Zhu, D.; Li, K.; Du, X.; Zhao, F.; Wan, M.; Tan, Y. Research on a low melting point Al-Si-Cu (Ni) filler metal for 6063 aluminum alloy brazing. Appl. Sci. 2021, 11, 4296. [Google Scholar] [CrossRef]

- Hayes, F.H.; Longbottom, R.D.; Ahmad, E.; Chen, G. On the Al-Si, Al-Ge, and Al-Ge-Si systems and their application to brazing in high power semiconductor devices. J. Phase Equilibria 1993, 14, 425–431. [Google Scholar] [CrossRef]

- Xu, R.; Zhao, H.; Li, J.; Liu, R.; Wang, W.K. Microstructures of the eutectic and hypereutectic Al-Ge alloys solidified under different pressures. Mater. Lett. 2006, 60, 783–785. [Google Scholar] [CrossRef]

- Kötzing, B. Entwicklung Niedrigschmelzender Aluminiumbasislote zum Fügen Höherlegierter Aluminiumwerkstoffe. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 1997. [Google Scholar]

- Kim, H.J.; Lee, G.H.; Jung, J.P. A Review of the Brazeability of Low-Temperature and Nano-Reinforced Al-Based Brazing Filler Metals. J. Weld. Join. 2022, 40, 216–224. [Google Scholar]

- Niu, Z.W.; Huang, J.H.; Chen, S.H.; Zhao, X.K. Effects of germanium additions on microstructures and properties of Al–Si filler metals for brazing aluminum. Trans. Nonferrous Met. Soc. 2016, 26, 775–782. [Google Scholar] [CrossRef]

- Niu, Z.; Huang, J.; Liu, K.; Xu, F.; Chen, S.; Zhao, X. Brazing of 6061 aluminum alloy with the novel Al-Si-Ge-Zn filler metal. Mater. Lett. 2016, 179, 47–51. [Google Scholar] [CrossRef]

- Sabadash, O.M.; Maksymova, S.V. Fluxless brazing of aluminium alloys by brazing filler metal of Al-Ge system. Autom. Weld. 2023, 4, 50–56. [Google Scholar] [CrossRef]

- Schubert, T.H.; Loser, W.; Teresiak, A.; Mattern, N.; Bauer, H.D. Preparation and phase transformations of melt-spun Al-Ge-Si brazing foils. J. Mater. Sci. 1997, 32, 2181–2189. [Google Scholar] [CrossRef]

- Ivannikov, A.; Fedorov, V.; Abramov, A.; Penyaz, M.; Bachurina, D.; Uhlig, T.; Suchkov, A.; Wagner, G.; Morokhov, P.; Sevryukov, O. Development of Rapidly-Quenched Al-Ge-Si Filler Alloys for the Joining of Stainless Steel AISI 304 and Aluminum Alloy AA6082. Metals 2021, 11, 1926. [Google Scholar] [CrossRef]

- Ivannikov, A.; Abramov, A.; Popov, N.; Penyaz, M.; Suchkov, A.; Pukhareva, N.; Sevryukov, O. Joining Stainless-Steel AISI 304 and High-Strength Aluminum Alloy AA 6082 by Brazing Using Al-Ge-Si Foils. Metals 2023, 13, 149. [Google Scholar] [CrossRef]

- Fedorov, V.; Uhlig, T.; Wagner, G. Structure-Property Relationship in High-Strength Aluminum Alloys/Stainless Steel Brazed Joints. Metals 2023, 13, 242. [Google Scholar] [CrossRef]

- ISO 14577-1:2015; Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters—Part 1: Test method. International Organization for Standardization: Geneva, Switzerland, 2015. Available online: https://www.iso.org/standard/56626.html (accessed on 1 July 2015).

- Bull, S.J. Extracting hardness and Young’s modulus from load–displacement curves. Int. J. Mater. Res. 2022, 93, 870–874. [Google Scholar] [CrossRef]

- Sudharshan Phani, P.; Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by load and depth sensing indentation: Improvements to the technique based on continuous stiffness measurement. J. Mater. Res. 2021, 36, 2137–2153. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Wittke, K. Löten. In Wissenschaftliche Schriftenreihe der Technischen Hochschule Karl-Marx-Stadt; Technische Hochschule: Karl-Marx-Stadt, Germany, 1980; Volume 10, pp. 1–94. [Google Scholar]

- Müller, W. Löttechnik: Leitfaden für die Praxis; DVS-Verlag: Düsseldorf, Germany, 1995. [Google Scholar]

| Alloy | Element Content (wt.%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Al | Fe | Ge | Cr | Ni | Si | Mn | Mg | C | Other | |

| AA 6082 | bal. | 0.5 | - | 0.25 | - | 0.8 | 1 | 1 | - | 0.4 |

| AISI 304 | - | bal. | - | 18 | 8 | 0.4 | 1.4 | - | 0.08 | 0.3 |

| Al-Ge-Si | bal. | - | 40 | - | - | 3.4 | - | - | - | - |

| Brazing Process | Brazing Temperature [°C] | Holding Time [s] | |

|---|---|---|---|

| Induction brazing | 530 | 0 | 10 |

| Vacuum furnace brazing | 530 | 600 | 1800 |

| Measurement Points | Element Content (at.%) | Microstructural Constituents | ||||

|---|---|---|---|---|---|---|

| Al | Ge | Si | Fe | Cr | ||

| Braze Metal | ||||||

| 1 | 97 | 3 | - | - | - | (Al) |

| 2 | - | 45 | 55 | - | - | (SiGe) |

| 3 | 70 | - | 11 | 18 | 1 | Al7Fe2Si |

| 4 | 5 | 95 | - | - | - | (Ge) |

| Reaction Zone | ||||||

| 5 | - | 41 | 59 | - | - | (SiGe) |

| 6 | 65 | - | 9 | 18 | 5 | Al7Fe2(Si,Cr) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fedorov, V.; Uhlig, T.; Wagner, G. Microstructure and Mechanical Properties of AA 6082/AISI 304 Joints Brazed Using Al-Ge-Si Filler Metal. Metals 2023, 13, 1574. https://doi.org/10.3390/met13091574

Fedorov V, Uhlig T, Wagner G. Microstructure and Mechanical Properties of AA 6082/AISI 304 Joints Brazed Using Al-Ge-Si Filler Metal. Metals. 2023; 13(9):1574. https://doi.org/10.3390/met13091574

Chicago/Turabian StyleFedorov, Vasilii, Thomas Uhlig, and Guntram Wagner. 2023. "Microstructure and Mechanical Properties of AA 6082/AISI 304 Joints Brazed Using Al-Ge-Si Filler Metal" Metals 13, no. 9: 1574. https://doi.org/10.3390/met13091574

APA StyleFedorov, V., Uhlig, T., & Wagner, G. (2023). Microstructure and Mechanical Properties of AA 6082/AISI 304 Joints Brazed Using Al-Ge-Si Filler Metal. Metals, 13(9), 1574. https://doi.org/10.3390/met13091574