1. Introduction

The welding industry, which is part of metallurgical industry, has been strongly criticized in recent decades for being a major consumer of raw materials. This has negative effects on the degradation of ecosystems, loss of biodiversity, and water and soil pollution. Additionally, the consumption of huge amounts of energy needed to transform these raw materials into new metals and alloys. Emitting greenhouse gases, as well as generating waste and fumes that significantly affect human health. This contributes to the global problem of climate change. In addition to these environmental impacts, there is also the economic importance it brings to society. In some countries, such as Spain, this sector represents 40% of the country’s industrial production [

1]. This sector has been influenced by the new guidelines of the global sustainable development targets proposed by the United Nations [

2]. These propose the transition of industries towards sustainable production. In the case of the welding industry and given its importance, this is a new challenge. This is an industry in which legislation on environmental, sustainability, and production issues are practically non-existent. Given this current situation in the sector, it is up to society to develop new knowledge and techniques that will enable the objectives of sustainable development to be achieved. For instance, through knowledge of the environmental impacts associated with the various activities carried out in this industry. With the aim of being able to mitigate or reduce them. Additionally, through the efficient use and consumption of resources. However, not only natural resources and raw materials, but also economic resources.

In Spain, metal welding jobs are of notable significance, as it has been determined that 25,597 people work in this profession [

3] in the field of structural welding [

4]. Metal welding processes have different typologies and specifications that depend on a multitude of factors and criteria. Some of these factors are the understanding of the internal microstructure of the weld. For example, the research by Shen et al., where they characterise the internal microstructure. As well as the mechanical properties of the weld made using Gas Metal Arc Welding (GMAW) technology. Using a filler material of 308 stainless steel [

5]. In addition to other related studies [

6,

7]. Other criteria to be highlighted are resistance both to stress and to the conditions to which welds may be subjected, aesthetic criteria depending on the applications and final uses of the products to be welded, environmental criteria in terms of consumption and inputs, and, of key importance, economic criteria. All these factors, along with the existence of a wide range of different types of welding, and bearing in mind that welding cannot always be performed in a workshop but rather is carried out on site or on production lines [

8], demonstrate that welding is not a straightforward endeavour and constitutes a very interesting field of research.

Furthermore, thanks to the recent implementation of Industry 4.0, which involves the digitisation of production processes by analysing vast swathes of data, along with the integration of technologies and automation of manufacturing, it is possible to obtain real-time information that informs and empowers live decision-making [

9]. The industry evolution towards automation currently underway is also driven by increased customer expectations in terms of environmental awareness and carbon footprint reduction [

10]. However, putting these new technologies and automation into practice in small- and medium-sized enterprises requires financial investment and resources that not all companies have. This fact represents a drawback for many businesses. According to Gonzalez and Vanti, in order to foster sustainable economic growth in Spain, investment in R&D, innovation, digitisation, and digital transformation must be bolstered [

11].

Welding is an indispensable manufacturing process that involves joining two or three metals (similar or dissimilar) by heating them to a molten state, which allows them to be joined together and solidify into a fixed joint [

12]. The use of welding processes is widespread in sectors such as automotive [

13], railway, shipbuilding [

14,

15], aerospace [

16,

17], and civil construction [

18,

19]. The most widely used welding processes are Shielded Metal Arc Welding (SMAW); Gas Metal Arc Welding (GMAW), which notably include Metal Inert Gas (MIG) and Metal Active Gas (MAG); TIG, also called Gas Tungsten Arc Welding (GTAW); Ultrasonic Welding (USW); Laser-Beam Welding (LBW); Friction Stir Welding (FSW); and Electron Beam Welding (EBW) [

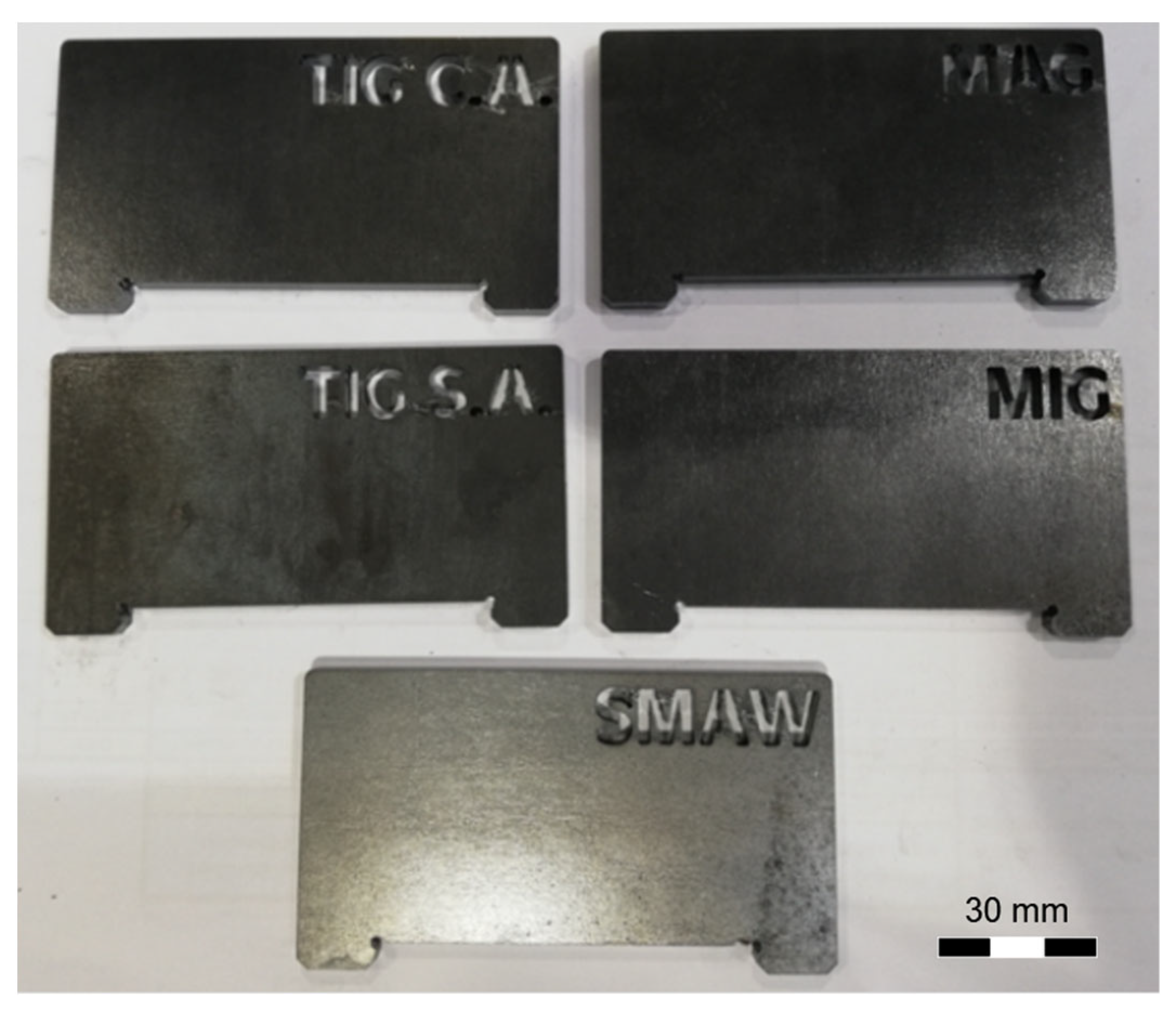

20]. MIG/MAG, TIG, and SMAW processes are the most versatile, economical, generic, and commonly used in the majority of the aforementioned sectors; thus, these are evaluated in the present study [

21,

22].

Working with the foundation of the various welding technologies available, current research focuses on examining specific welding cases in order to obtain the mechanical, thermal, and durability characteristics of a particular type of welding technology. For example, Sattarpanah et al. used finite element analysis to evaluate the thermal behaviour of TIG-welded stainless steels. The relationship between welding speed, bead width, and penetration depth is evident. As an increase in current and decrease in welding speed result in the weld bead width increasing, as well as the depth of penetration. Due to the fact that the input energy (derived from the increased current) is increased and the energy that it transmitted to the material. Therefore, the molten volume of material increases [

23]. Another case study was from Jun et al., which examined the feasibility of welding armour steel plates with GMAW and Flux Cored Arc Welding (FCAW) technology [

13]. On the other hand, other research evaluated the filler material used in welding. For instance, Liu et al. assessed welding for a fuel tank with filler materials of different chemical compositions [

16]. Therefore, at present, the field of research dedicated to welding is centred around evaluating specific cases so as to draw conclusions and improve the process. However, several research initiatives addressing environmental and economic sustainability have already come about in this area.

A study by Epping and Zhang evaluated the transfer from SMAW welding technology to robotic welding with GMAW technology for companies. They carried an economic, social, and environmental analysis. The results showed that GMAW welding led to a cost reduction of 42.51% in the case study. Likewise, in environmental categories such as the consumption of fossil fuels, it was lower due to the reduction in the manufacture of the parts. Finally, in social impacts such as the health and safety of workers, there were benefits: with robotic welding, the distance between the worker and the hazardous materials involved in welding increased. It also reduced the amount of fumes generated by the welding process. Specially, a decrease of 68.97% [

24].

Another study by Sarkar et al. indicated that TIG welding of 1 mm aluminium sheets had a higher environmental impact than MIG welding, around 1.3 times higher on average, but this increase could be ameliorated by implementing automation techniques in the TIG process [

25]. Research by Favi et al. revealed that the environmental loads of SMAW and GTAW were greater than those of GMAW processes and that, in addition, the variables intensity, voltage, and operator skill influence SMAW and GTAW processes to a greater extent than GMAW processes [

26]. On the other hand, a study by Demir and Furlan analysed the impacts and environmental viability of traditional welding processes such as SMAW, GTAW, and GMAW as compared to modern processes such as LBW, revealing that LBW processes performed better than traditional methods for small thicknesses in aluminium and that LBW techniques required fewer subsequent finishing and cleaning operations [

27]. A study by Afzal et al. examined the environmental impact of GTAW welding processes compared to LBW processes, using experiments on AISI-304 stainless steel, and concluded that LBW processes had lower impacts, even compared those GTAW processes without material input, due to many factors, including speed [

28].

In addition to the environmental aspects, one of the most important factors when designing products and planning welding processes is cutting manufacturing costs. To achieve this cost reduction, process optimization is used. Process optimizations consist of studying the process, including the variables involved (material, energy, staff), and determining how these can be reduced without losing minimum product quality. One of the most popular options is the automation of welding. With the use of robotized welding, parameters such as wire feed speed, amperage, and shielding gas glow rate can be controlled more efficiently. These costs are often underestimated. On the other hand, competent preventive maintenance of the equipment involved in welding can considerably reduce downtime due to failures. This fact has already been highlighted by other studies for the past two decades [

29]. The economic significance of welding processes in Europe and their economic impact on European industry has been notable for some years now [

30]. A decade ago, the term “sustainable manufacturing” was defined in the USA as the creation of manufactured products using processes that minimise negative environmental impacts; conserve energy and natural resources; are safe for employees, communities, and consumers; and are economically sound [

31]. Some studies have analysed the economic impact of a welding process and searched for methods or tools to reduce costs [

32]. Methods have also been developed to support the selection of the most suitable welding process based on economic criteria [

33,

34,

35].

However, the actual experience of carrying out welding processes for a product in a company points to different selection criteria. These criteria help the company to determine which welding technology is most suitable. The selection criteria must satisfy the customer’s requirements. These requirements are usually of an aesthetic and technical nature. To this end, the company, depending on its material and human resources, determines the means necessary to carry out the welding work. Thus, the decisions to be made are complex and involve more specific factors. To facilitate this decision-making process, complex integrated decision-making systems are available on the market; they are parameterised and have different variables depending on pre-established requirements [

36]. However, it is not feasible to implement such selection models in small- and medium-sized companies.

Therefore, this study aims to obtain economic and environmental knowledge about the most widely used welding processes. To this end, the economic costs of each type of welding technology were examined by measuring the most characteristic parameters (consumption of filler material, electrical energy, protective gas). These indicate the total economic cost of producing a weld depending on the technology. In addition, an environmental analysis was carried out to determine which welding technologies had the greatest impact on the environment and on human health. This research contributes new data on the economic and environmental costs generated by using one welding technology or another, and it does not focus solely on a specific case study, as most recent research has tended to do.

4. Conclusions

The conclusions drawn by this study are:

The results obtained in the LCA show that the welds using the greatest amount of shielding gas had the greatest impact on the impact categories. As a result, TIG technology had a higher environmental impact than MIG, MAG, and SWAM technologies.

These differences are especially salient in impact categories such as GWP, wherein CO2 emissions in case study two using TIG technology increased by 93.29% as compared to case study five using SMAW technology and by 77.42% for MAG technology in case nine.

The production of shielding gas is largely responsible for the environmental impacts produced by the case studies. This is highlighted by case two (TIG welding with filler). The LCA analysis of this case demonstrates that shielding gas production accounts for, on average, 94.07% of the impact in all the impact categories. Following shielding gas is the chemical composition of the weld bead with 30.62% of impact for the abiotic depletion elements category. Electricity consumption has an average impact of 2.11%.

During the welding process, harmful gases are released that affect human health. According to the final human health indicator, the greater the consumption of shielding gas the higher the impact on this indicator. This is highlighted by the behaviour of case two (TIG welding), with an effect of 3.51 × 10−6 DALY. Additionally, in other welding cases with less consumption of shielding gas, such as case nine (MAG welding), there is a 77.83% reduction, which translates into a score of 7.78 × 10−7.

However, having demonstrated the danger of harmful gases to human health, it is nevertheless concluded that they can be controlled and removed. Therefore, their impact on the worker can be minimal. For instance, in welding workshops, the use of gas filter masks is compulsory. In this way, fumes from the welding process can be filtered out. Additionally, these can be prevented from being inhaled by the worker. In addition, the workshops have specific work areas for welding. These spaces are protected with extractors, which absorb gases that are harmful to health.

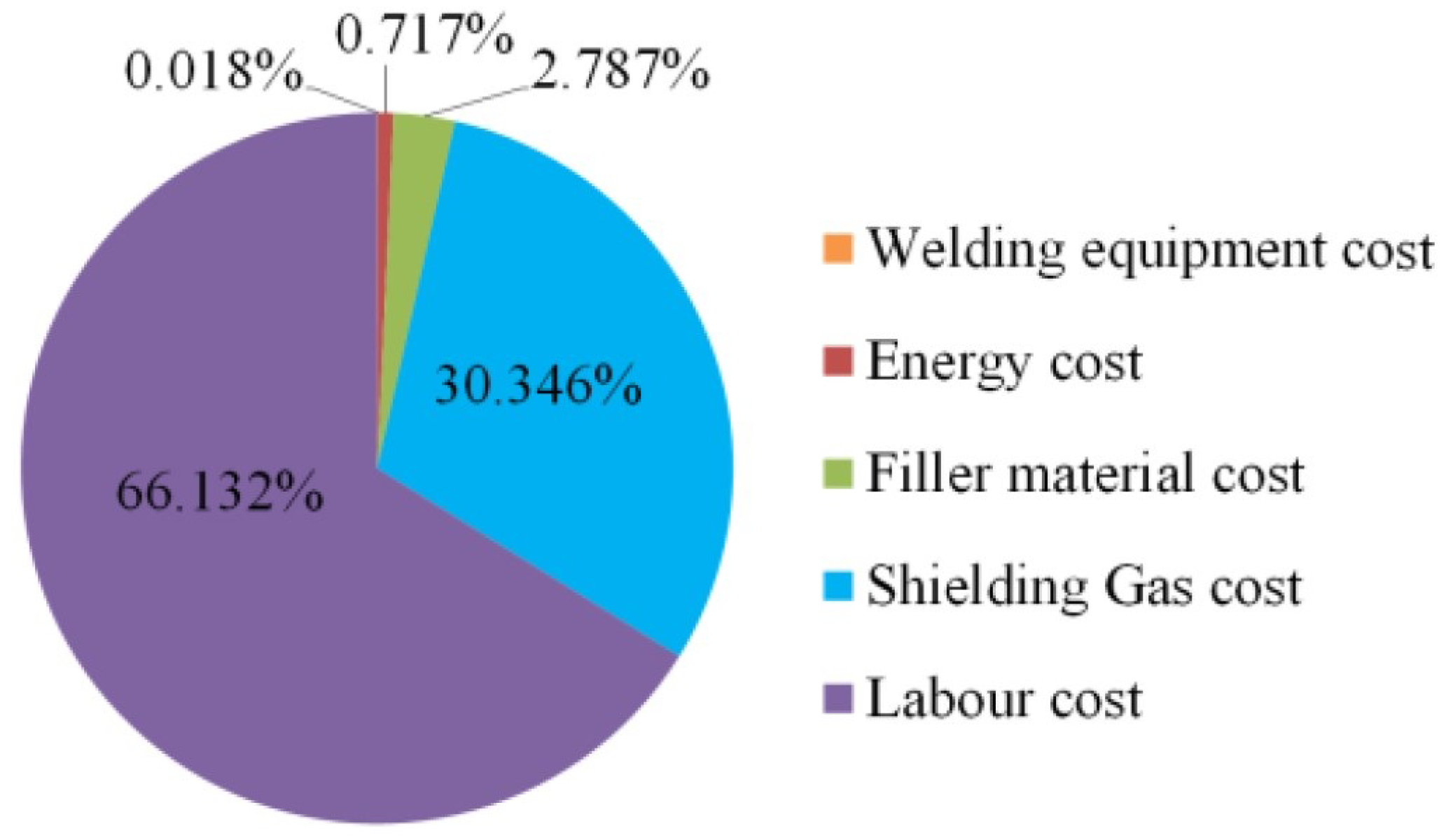

The foremost economic cost of the FU is labour. This is a direct consequence of welding execution time. Therefore, the case studies with the longest execution times, such as cases two, seven, and one, are those with the highest associated economic costs.

The costs derived from electrical energy during the welding process, although they varied across the different cases studied, have been proven to have a negligible economic impact. For example, in case study five (SMAW welding), which has the highest consumption of electrical energy, the energy cost has an impact of just 3.95% of the total FU.

The economic differences between the three metallic materials studied, when their use is compared for just one type of welding, are most notable in TIG welding. In the TIG process with filler, the material with the highest cost is carbon steel, as seen in case study one, which is 23.7% more expensive than the same process using stainless steel, as in case study six. Meanwhile, for the MIG process, the economic differences are less significant, for example, case study three using carbon steel is 16.4% more expensive than with stainless steel as in case study eight, and aluminium in case twelve falls between these two values.