Abstract

Aluminum thermal welding joints are widely used in the maintenance welding of heavy-haul railways due to their easy handling and high efficiency. However, due to their inherent welding characteristics, welding results in certain differences in the material’s physical properties at the welding zone compared to adjacent base materials, leading to the occurrence of short-wave irregularity under long-term wheel–rail interactive forces. In order to explore the evolution characteristics of weld irregularity, dynamic characteristics, and plastic deformation under long-term wheel–rail impact, a detailed tracking test was conducted on a normal aluminum weld, and the process from being put on the track to being damaged and replaced was evaluated. At the same time, a rigid–flexible coupling model was established for subsequent analysis, and plastic damage was analyzed using the finite element model. The results show that the service life of the weld can be divided into three different stages: the initial stage, the intermediate stage, and the damage stage. In the damage stage, a temporary separation occurred between the wheel and rail, leading to a sudden change in the wheel–rail interaction. The weight of 250 MT at the weld reached the repairment control limit. The concentration effect of equivalent plastic deformation was most serious at 2~5 mm below the rail head.

1. Introduction

At present, China’s heavy-haul railways mainly use continuously welded rail, which can eliminate a large number of rail joints, improve the regularity of the lines, and ensure transportation safety [1,2,3]. However, there are still a lot of aluminum thermal welds near stations or in areas where the main line has been damaged and requires maintenance. Due to the characteristics of easy manipulation and short welding time, rail repair and normal joint connection are often conducted via thermit welding at heavy-haul lines. At the same time, owing to the effect of welding techniques, the environment, and operating processes, the quality of aluminum thermal welds is always uneven, resulting in severe weld damage under long-term heavy-haul wheel–rail impact [4,5,6].

One of the main reasons for the rapid growth of weld damage is the large wheel–rail load caused by the existing weld short-wave irregularity. Therefore, obtaining the evolution characteristics of weld irregularity is crucial for subsequent research on wheel–rail impact, weld damage, and fatigue.

Recently, many researchers have performed extensive research on wheel–rail loads and weld damage.

In terms of weld irregularity and dynamic response, Zhai et al. [7,8,9] established a subway train-track model through vehicle–track coupling dynamics theory and analyzed the influence of irregularity wavelength and depth. Nekane et al. [10] established a wheel–rail coupling model for heavy-haul railways and calculated the effects of different vehicle speeds and sleeper spacing on rail deformation and stress. Xiao et al. [11] established a vehicle–track coupling model, utilized sine and cosine functions to describe weld irregularities, and calculated the influence of vehicle speed, axle load, and irregularities on the vehicle–rail impact. Steenbergen et al. [12] established a wheel–weld model using the vehicle–rail dynamics, studied the relationship between the geometric characteristics of different welds and the P1 and P2 forces, and provided similar calculation formulas. Wen et al. [13] discussed the wheel–rail contact stress and contact area when a wheel passes through a weld with different ride conditions. Lu et al. [14] explored the dynamic response of wheel polygonal wear coupling with welds and evaluated the safety limits of wheel wear and weld irregularities. Grossoni et al. [15] calculated the P1 and P2 forces at the rail joint using a vehicle–track coupling model. Tajalli et al. [16] studied the dynamic characteristics when rails undergo breakage and the impact on vehicle safety through indoor experiments, on-site testing, and theoretical analysis.

In terms of research on weld fatigue and damage, Deng et al. [17] recorded, in detail, the plastic deformation and squats caused by the weld through long-term monitoring for up to 5 years and revealed the causes of these defects through numerical simulation analysis. Mutton et al. [18] analyzed the microscopic characteristics of damaged welds and identified the reasons for their cracking under wheel rolling contact. Hasan et al. [19] performed a detailed study on weld fracture and proposed some maintenance measures. Liu et al. [20] calculated the contact stress between the vehicle and rail in multi-body dynamics software and then imported the contact force into finite element analysis to calculate the weld fatigue characteristics. Skyttebo et al. [21] analyzed the distribution of residual stress at weld through experiments and numerical simulations and used fracture mechanics to calculate crack propagation. Romano et al. [22] used probability and statistical methods to analyze the weld fracture and found that fracture not only occurs due to the lowest temperature but also due to the influence of temperature gradients throughout the year. Su et al. [23] explored the rail heat-affected zone fatigue and ratcheting at various positions in the flash weld through fatigue tests. Ghazanfari et al. [24] tested welds and established a thermal coupling model to study the temperature and residual stress during rail welding, analyzed the causes of weld damage, and found that the maximum temperature and the total welding time during the welding process have a significant impact on welding quality.

From the above research, it can be inferred that most scholars are mainly focused on the simplification of weld irregularity and model simulation, while little research has been conducted on weld irregularity changes and damage evolution characteristics throughout its service life. This study involves an investigation of the evolution of weld irregularity from the new welding to the occurrence of damage. Through a rigid–flexible coupling analysis using Abaqus and Simpack, the evolution characteristics of wheel–weld impact load and fatigue during its entire service life are calculated. Finally, the standards for welds state repairment are obtained, which can provide the necessary scientific foundation for any other similar welds’ state repair.

2. Irregularities Testing

In order to further analyze the characteristics of weld irregularities, a large number of tests were conducted on the site using a rail surface straightness tester. The monitoring location is located on the busiest heavy-haul railway line in China, the Da-qin Heavy-Haul Railway. It uses laser scanning technology to obtain the size of weld irregularities within a 1 m range of the welded joint and then sends it to the tester’s mobile app through Bluetooth. The test length was 1 m, and the test step was 2 mm. By testing a large number of new welds on the heavy-haul railway site, the characteristics of the irregularity distribution of the new welds were obtained, as shown in Figure 1.

Figure 1.

Weld irregularities. (a) On-site testing; (b) new weld test result.

From Figure 1, it can be seen that, overall, the new welds are convex, with some joints having an unevenness amplitude of 1 mm. In order to study the relationship between the total weight and the irregularity amplitude of the weld, a typical weld was selected for long-term monitoring. The irregularity from welding completion to the occurrence of damage and, ultimately, replacement (for more than 200 days, converted to a total weight of 300 MT (million tons)) was tested using the rail straightness tester [25]. The monitoring results are shown in Figure 2.

Figure 2.

Typical three stages of weld irregularity evolution. (a) Weld irregularities with total weight variation; (b) weld phased map.

From Figure 2a, it can be seen that the weld irregularities on site shows a continuous decreasing trend throughout the entire life, and the concavity in the middle heat-affected zone (HAZ) is most significant. Based on extensive on-site research and testing, combined with the requirements of the “TG/GW102-2019 Regular Speed Railway Line Repair Rules” [26], the weld irregularities are divided into three different states throughout its life, as shown in Figure 2b.

From Figure 2b, it can be seen that the initial state is convex. In the initial state, the weld irregularity is generally convex, with a slight concave nature on both sides in the HAZ.

Intermediate state: The weld irregularity is partially concave. The characteristic of this stage is that the HAZ begins to show concavity, but the concave value has not yet reached the standard (TG/GW102-2019 Regular Speed Railway Line Repair Rules) weld defect repairment limit of 0.5 mm.

Damaged state: The irregularity shows concavity. The characteristic of this stage is that the weld HAZ is concave, with a concave value of 0.58 mm, exceeding the standard limit requirement of 0.5 mm.

3. Numerical Simulation Analysis

3.1. Theoretical Basis of Model

Due to the low computing speed and limited computing resources, the three major vehicle components, which are car body, bogies, and wheelsets, are generally considered as rigid bodies for calculation. Heavy-haul trains often have hundreds freight vehicles, and the interaction between the wheels and welds is more complex; the forces between them are also much stronger [27]. Therefore, it is necessary to establish a rigid flexible coupling model to calculate the coupling interaction between vehicles and flexible rail joints. In the calculation process, the flexible vehicle uses the moving mixed coordinate method to describe the vehicle’s flexible deformation.

The mixed coordinate method uses the flexible bodies of modal coordinates and rigid body coordinates to establish a coupling model. The principle is to establish a moving coordinate system for the moving vehicle, and the displacement and deformation are considered as the superposition of the rigid vehicle body motion in the flexible foundation coordinate system. In the modeling process, firstly, the moving coordinate system of the flexible body is fixed through the actual calculated boundary conditions. Secondly, the actual situation of the foundation is processed by finite element discretization, and the mode superposition method is used to solve the stress, deformation, and vibration of the flexible body [28].

For the flexible vibration and stress deformation of heavy-haul freight trains, the numerical simulation software ABAQUS 2018 can be used to establish a three-dimensional finite element model of the car body and carry out a modal analysis of the substructure. The free modal information of the car body can be extracted in finite element software, and its dynamic mode can be solved by using the modal superposition method [29]. In the floating coordinate system, the vibration equation of the vehicle is represented as follows:

In the formula, is the displacement, velocity, and acceleration vector matrix of the flexible wheelsets; is the mass matrix of the heavy-haul train in the finite element model; is the stiffness matrix of the flexible car body element; is the damping matrix of the flexible vehicle body unit.

Based on the modal superposition principle, the deformation of vehicle vibration in the coordinate system is expressed as follows:

By substituting Equation (2) into Equation (1), the differential equation of flexible vibration of the vehicle body can be decoupled into a system of differential equations related to the first N modes:

In the formula, is the displacement vector matrix corresponding to the order flexible mode; is the natural frequency of the mode; is the equivalent damping ratio corresponding to the mode; is the external load vector matrix; is the internal force of the modal coordinate system.

Rewrite the above equation into matrix form as follows:

In the formula, is the external load matrix in the global coordinate system; is the internal force matrix acting on the vehicle body; is the stiffness matrix; and is the damping matrix, which can be expressed as follows:

In the formula, is the i-th natural frequency of the flexible body, and , are the mass damping and stiffness damping of the flexible body. Taking the modal damping ratio as the structural damping ratio , the Rayleigh damping coefficient can be expressed as follows:

Based on the above equation, it can be concluded that the differential equation for the rigid flexible coupling vibration of a flexible body is as follows:

In the equation, is the nonlinear force provided by all substructure system nonlinear springs and damping elements; is the wheel–rail contact force.

3.2. Material Parameters

The vehicle is a heavy-haul C80 train, and the vehicle parameters are shown in Table 1. The track consists of rails, fasteners, sleepers, and ballast. The types of each component are described in Table 2.

Table 1.

Vehicle calculation parameters.

Table 2.

Calculation parameters of track.

The parameters of the vehicles are shown in Table 1.

The relevant calculation parameters of the track structure in the model are shown in Table 2.

The fastener is simulated using a spring damping element, with a vertical stiffness of 100 MN/m and a vertical damping of 6 × 104 N.s/m. The spacing between sleepers is 0.6 m.

3.3. Contact Relationships

There are normal and tangential contact relationships in wheel–rail contact. In the calculation of multi-body dynamics, the equivalent elastic virtual penetration method is used for the wheel–rail normal contact calculation [30]. When solving the normal contact spot and contact force, the method simplifies the contact deformation between wheel and rail into equivalent elastic deformation and discretizes the contact spot into several strip rectangles along the longitudinal direction, so that the contact problem can be solved using the nonlinear contact method. During the calculation of normal contact force, the contact boundary equation is as follows:

In the formula, is the longitudinal contact gap between the wheel and rail, R is the radius of the wheel, and is the value of penetration between the wheel and rail contacts. When the wheel rail contacts on the contact boundary, it can be obtained from the above equation:

Considering the vehicle’s head shaking in the contact calculation, it can be considered that the wheel–rail rolling contact conforms to the Hertz contact theory, thus obtaining the contact boundary as follows:

In addition, in actual calculations, the contact spot is equivalent to an approximate ellipse; that is, when , assuming that the transverse distribution is similar to the longitudinal boundary, there are:

where is the length of the longitudinal half axis at , because the elastic deformation at the contact point is equal to the permeability. The normal contact force and the maximum contact stress are as follows:

In the equation, μ is the Poisson’s ratio, and E is the elastic modulus.

The proposed simplified contact algorithm is used to calculate the wheel–rail tangential contact force. In the calculation of wheel–rail tangential force, the contact spot is regarded as a quasi-ellipse and discretized into several discrete strips along the rolling direction. A map of the FASTSIM [31] algorithm is shown in Figure 3.

Figure 3.

FASTSIM algorithm principle diagram.

The viscous tangential force uses the Mohr Coulomb friction law; that is, if the contact stress at the point satisfies the contact boundary , then the point located in the adhesion zone and its longitudinal and transverse stresses are as follows:

Otherwise, the point located in the sliding zone and its tangential force are as follows:

In the equation, and are the tangential stresses at the contact spot; and are their increments.

The shear modulus of the wheelset and the rail in the vehicle track system is and , the Poisson’s ratio is and , and the tensile elastic modulus is E. It can be concluded that G and E after the wheel track composition are as follows:

In the equation, G and satisfy .

The value of elastic modulus is 2.1 × 1011 Pa, the friction coefficient is 0.28, and the contact damping is 10,000 N.s/m. According to Kalker theory [32], the longitudinal and transverse creep forces and spin forces Tx, Ty, Mz of wheel–rail contact are as follows:

3.4. Model Establishment

Before confirming the flexible track, it is necessary to determine the length of the rail and the boundary conditions of the track, which require model analysis of the rail in Abaqus. The first 60 representative modal calculation results of the selected rail are shown in Figure 4.

Figure 4.

Rail modal analysis. (a) First mode 0.836 Hz; (b) third mode 2.30 Hz; (c) seventh mode 11.122 Hz; (d) eleventh mode 19.458 Hz; (e) fifteenth mode 33.003 Hz; (f) twenty-fourth mode 68.42 Hz; (g) twenty-eighth mode 86.475 Hz; (h) twenty-ninth mode 88.402 Hz; (i) fifty-ninth mode 260.27 Hz.

The frequency distribution characteristics of the first few important free modes of the flexible rail are shown in Figure 4.

In the process of model establishment, the heavy-haul train was simplified into one body, two bogies, and four wheelsets. The vehicle and bogie are connected by primary suspension, while the bogie and wheelset are connected by secondary suspension. The suspension system is simulated using spring damping units [33]. The model considers the nonlinear stiffness characteristics of the primary and secondary suspension springs.

The vehicle–track rigid–flexible coupling model established through the theory of rigid–flexible coupling is shown in Figure 5. The flexible body is imported into the established heavy-duty truck model through a nonlinear track, where the fasteners are achieved by establishing spring damping elements between the reference control coupling points between the rails and sleepers in SIMPACK and assigning corresponding parameters, as shown in Figure 5.

Figure 5.

Partially enlarged diagram of vehicle–track model. (a) Coupled model; (b) track model.

From Figure 5, it can be seen that the vehicle–track coupling model has been established.

3.5. Result Analysis

By combining the numerical simulation results with the on-site measurement results, the correctness of the numerical simulation is verified, as shown in Figure 6.

Figure 6.

Verification of numerical simulation results.

From the above figure, it can be seen that the numerical simulation calculation results are basically similar in value and change law to the on-site test results, thus verifying the reliability of the calculation model.

The wheel–rail interaction forces, the fatigue index, and rail vibration under different weld service states were calculated, and the results are shown below.

3.5.1. Evolution Characteristics of Wheel–Rail Vertical Force in Different Weld States

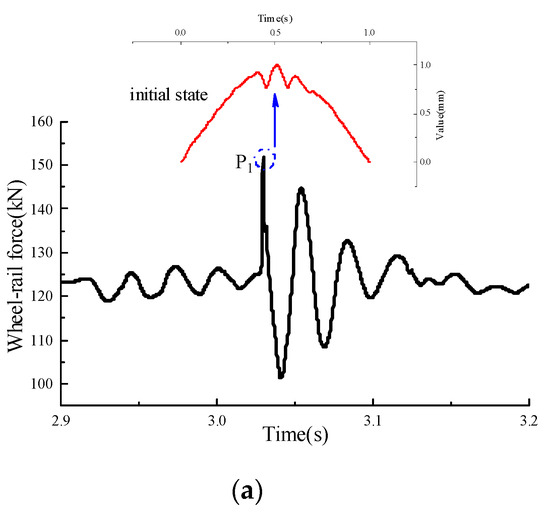

The actual measurement values of the weld irregularities in Figure 2 were input into the established vehicle–track coupling model, and the wheel–rail interactive force under different states was calculated, as shown in Figure 7.

Figure 7.

Evolution of wheel–rail vertical force with different weld irregularities. (a) Initial state; (b) intermediate state; (c) damaged state.

- (1)

- Initial state weld

When the weld is in the initial state, the overall shape of the weld is convex. When a heavy-haul train passes through the weld, there is a significant fluctuation within 0.1 s, with a high-frequency impact force P1 of 161.6 kN. Afterwards, the wheel–rail force gradually stabilizes after 0.1 s, indicating that the vehicle has already passed the weld.

When the weld is in the intermediate state, while the wheel passes through the weld, there are obvious high-frequency impact forces P1 and low-frequency impact forces P2; their forces are 242 kN and 232 kN. It can be observed that P1 is a high-frequency impact force with a duration of less than 0.002 s, while the P2 force has a long duration.

When the weld is in a damaged state, there is a concave shape in the middle of the irregularity. When a heavy-haul train passes through the weld, there is a significant fluctuation in the wheel–rail force, with a maximum of 300 kN. After about 2.7 s, the wheel rail force tends to 0 kN. At this stage, there is a wheel–rail short separation state, resulting in no contact between the wheels and rails. This may be due to the vehicle shaking greatly when passing through the damaged weld.

Similarly, the wheel–rail force time history variation during the entire service life was calculated, as shown in Figure 8.

Figure 8.

Time history diagram of wheel–rail force in different weld service states.

From Figure 8, it can be seen that, under different weld service states, the wheels will cause a significant wheel–rail impact when passing through the weld. With a continuous increase in freight volume, the wheel–rail force and concave value at the weld show an exponential increased trend. According to the regulations (TG/GW102-2019 General Speed Railway Line Repair Rules), it is obtained that when the weld concave value reaches 0.5 mm, in the damage treatment stage, it will reach 0.5 mm, corresponding to a freight volume of 250 million tons, which means that the total weight of 250 million tons at the weld reaches the repairment limit.

An FFT transformation on the time history curve of the wheel–rail force is shown in Figure 8, by which we obtained the frequency domain distribution of wheel–rail force, as shown in Figure 9.

Figure 9.

Frequency distribution changes of wheel–rail force with service freight.

From Figure 9, it can be seen that when the weld is in the initial state, the wheel–rail force only has a peak value around 51 Hz throughout the entire spectrum distribution range. When the weld is in the intermediate state, high-frequency components 163 Hz and 632 Hz appear in the spectrum. When the weld is in a damaged state, the main frequency components in the spectrum distribution are 51 Hz and 801 Hz. It can be seen that as the weld service time increases, some high-frequency impact loads will gradually appear.

3.5.2. Plastic Deformation Analysis of Rail

The plastic constitutive model of steel rails adopts J-C model [34]. When the temperature influence is not considered, the J-C dynamic constitutive model can be simplified as follows:

Under the reference strain rate, the J-C model formula can be simplified as , and the J-C constitutive parameters of the weld are shown in Table 3. The load applied to the contact patch size is performed through programming, and the load amplitude is calculated through the model established in Section 3.4.

Table 3.

Dynamic J-C constitutive parameters of weld.

The rails and sleepers are simulated using solid C3D8 elements, while the fasteners are simulated using spring elements. A 1 mm refined mesh is applied to the rail head, and a gradually loosened mesh is used in the adjacent areas. The spacing between the sleepers is 0.6 m. We applied displacement boundaries in three directions at the bottom of the sleeper, longitudinal displacement boundary conditions at both ends of the rail, and torsional boundary conditions in different directions at each fastener. The calculation model is shown in Figure 10.

Figure 10.

Plasticity calculation model of rail.

Figure 10 shows the established plastic fatigue calculation model for welds. The wheel–rail force calculated in Section 3.4 was applied to the actual contact spot on the right side of Figure 10, and the plastic damage of the weld under different wheel–rail forces was calculated, as shown in Figure 11.

Figure 11.

Stress and strain nephogram of rail head.

(1) Figure 11 shows the weld in its initial state when the total weight is 10 million tons.

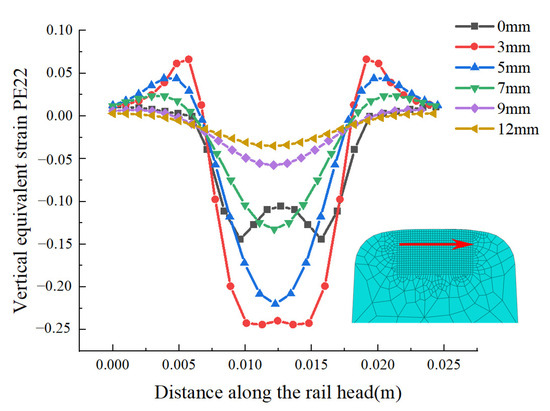

From Figure 11, it can be seen that there is a significant stress concentration area below the surface of the rail head in the middle of the wheel–rail contact area, and equivalent plastic deformation also occurred. The equivalent plastic strain distribution along the rail head surface below 0 mm, 3 mm, 5 mm, 7 mm, 9 mm, and 12 mm is calculated, as shown in Figure 12.

Figure 12.

Distribution of equivalent plastic strain at different depths below rail head.

From Figure 12, it can be seen that under the wheel–rail cyclic load applied to the rail head, plastic deformation will quickly occur within a range of about 20 mm in the initial stage of cyclic load, and then the plastic deformation tends to stabilize. The vertical equivalent plastic strain concentration effect is most obvious 3 mm below the rail head, with a maximum plastic strain of 0.019. The plasticity is lowest 12 mm below the rail head, and there is no plastic deformation. It can be seen that under the cyclic load, there will be plastic deformation on the surface of the rail head within a range of 12 mm, with the maximum plastic deformation occurring at a depth of 3 mm below the rail head.

The weld stress calculation results in Figure 11 were extracted vertically downwards along the rail head at positions A and B, producing Figure 13.

Figure 13.

Mises stress distribution of rail vertically downward along rail head.

From Figure 13, it can be seen that the Mises stress at the middle position A reaches its maximum at a depth of 5 mm, while the stress at the edge position B reaches its maximum at a depth of 3 mm. It can be seen that within the entire wheel–rail contact patch, the stress is highest within a range of 3 mm to 5 mm below the rail head surface, which is prone to stress concentration and can lead to fatigue damage and further issues. The Mises stress in the middle position A gradually increases within 0~5 mm, reaching a maximum of 795 MPa around 5 mm. The stress below 5 mm decreases continuously with increasing depth.

(2) Figure 14 shows the weld in an intermediate state when the total weight passing through is 170 million tons.

Figure 14.

Stress and strain nephogram of rail head.

From the cloud map, it can be seen that there is a significant stress concentration and plastic deformation below the rail head. The distribution of equivalent plastic strains along the rail head surface below 0 mm, 3 mm, 5 mm, 7 mm, 9 mm, and 12 mm is proposed, as shown in Figure 15.

Figure 15.

Distribution of equivalent plastic strain at different depths below rail head surface.

From Figure 15, it can be seen that under the wheel cyclic load, plastic deformation will quickly occur within about 20 mm in the initial stage of cyclic load, and then the plastic deformation tends to stabilize. The strain concentration is most clear at 3 mm, with a maximum plastic strain of 0.25. The vertical equivalent plasticity is the smallest at 12 mm.

(3) The weld is in a damaged state, and the total weight at the weld is 300 million tons. The result is shown in Figure 16.

Figure 16.

Stress and strain nephogram of rail head.

From the cloud map, it can be seen that there is significant stress concentration and plastic deformation below the rail head. The distribution of equivalent plastic strains along the rail head surface below 0 mm, 3 mm, 5 mm, 7 mm, 9 mm, and 12 mm is proposed, as shown in Figure 17.

Figure 17.

Distribution of equivalent plastic strain at different depths.

From Figure 17, it can be seen that under the wheel cyclic load, a certain plastic deformation will quickly occur within a horizontal range of about 20 mm in the initial stage, and then the plastic deformation tends to stabilize. The strain concentration effect is most obvious at 3 mm, with a maximum plastic strain of 0.8. The plasticity is smallest at 12 mm, and there is no plastic deformation. It can be seen that under the cyclic load, there will be certain plastic deformation on the surface of the rail head.

The weld stress calculation results in Figure 16 were extracted vertically downwards along the rail head at positions A and B in Figure 18, and we then obtained Figure 18.

Figure 18.

Mises stress distribution of rail downward along rail head.

From Figure 18, it can be seen that the Mises stress reaches its maximum at a depth of 3 mm. It can be seen that within the entire wheel–rail contact patch, the stress is highest within 3 mm below the rail head surface, which can easily lead to stress concentration and corresponding fatigue damage. The Mises stress in the middle position gradually increases within 0~3 mm, reaching a maximum of 1789 MPa around 3 mm.

We put the maximum plastic deformation of the rail head under different freight volumes in the same graph, producing Figure 19.

Figure 19.

Plastic deformation of rail head under different freight volumes.

From Figure 19, it can be seen that as the freight volume increases, the plastic deformation of the rail head will gradually appear in an elliptical distribution along the transverse direction. Particularly, when the freight volume exceeds 190 MTs, the plastic deformation significantly increases. When the freight volume is 300 MTs, the vertical equivalent plastic deformation reaches its maximum.

4. Conclusions

In this study, we tested the irregularity of the aluminum thermal weld in a heavy-haul railway throughout its entire service life, and we established a heavy-haul train weld foundation through the rigid–flexible coupling method, revealing the wheel–rail interaction force and damage evolution characteristics of the welds throughout the service life.

- (1)

- More than 200 days of irregularity monitoring was conducted on the welds, and the weld irregularities’ evolution characteristics with freight volume were obtained. Overall, the weld irregularity showed a trend of convexity to concavity throughout its service life. According to the weld irregularity evolution characteristics, the weld can be divided into three different states: initial state, where the shape of the weld shows a convex nature; the intermediate state, where the weld appears partially concave in the HFZ; damaged status, where the weld HZF is concave and the concave value exceeds the limit by 0.5 mm.

- (2)

- The wheel–weld interaction force evolution characteristics show that under different service states, wheels can cause a significant wheel–rail impact when passing through the weld. With a continuous increase in freight volume, the wheel–rail force and concave value show an exponential increasing trend. The weight of 250 MT at the weld reached the repairment control limit.

- (3)

- The frequency domain analysis of wheel–rail force shows that when the weld is in the initial state, the peak force frequency only exists at 51 Hz throughout the spectrum distribution; when in the intermediate state, 163 Hz and 632 Hz high-frequency components appear; when in the damaged state, the main frequency components in the distribution are 51 Hz and 801 Hz. As the weld service time increases, some high-frequency impact loads will gradually appear.

- (4)

- At the initial stage of cyclic load application, the weld will quickly experience plastic deformation within a range of about 20 mm horizontally on the rail head, and then the plastic deformation tends to stabilize. The concentration effect of vertical equivalent plastic strain is most clear at 2~5 mm below the rail head. Under the wheel–rail cyclic load, plastic deformation can be seen on the rail head surface within a range of 12 mm, with the maximum plastic deformation occurring at a depth of about 2~5 mm below the rail head.

Author Contributions

G.L.: methodology, original draft preparation, project administration, software; N.Z.: investigation, review and editing; W.H.: project administration, writing—review and editing; G.S.: project administration, supervision; H.X.: methodology, data curation, validation; L.H.: investigation, supervision, visualization; X.L.: translation, visualization. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Guangzhou Construction Group Technology Plan Project (Grant no. [2022]-KJ005, [2023]-KJ013, [2023]-KJ014, [2024]-KJ043) and Guangzhou Municipal Government Group Technology Plan Project ([2023]-SZKJ10).

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

Authors G.L., N.Z., W.H., G.S. and X.L. were employed by the company Guangzhou Construction Group Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Liu, G.; Xiao, H.; Shi, G.; Zhang, M.; Nadakatti, M.M. Field testing and performance optimization of a weld reinforcement device in heavy haul railways. J. Rail Rapid Transit 2023, 237, 55–64. [Google Scholar] [CrossRef]

- An, B.; Wang, P.; Xiao, J.; Chen, R. Dynamic response of wheel-rail interaction at rail weld in high-speed railway. Shock Vib. 2017, 2017, 5634726. [Google Scholar] [CrossRef]

- Choi, J.Y.; Sang, W.Y.; Jee, S.C.; Kim, S.H. Comparative study of wheel-rail contact impact force for jointed rail and continuous welded rail on light-rail transit. Appl. Sci. 2020, 10, 2299. [Google Scholar] [CrossRef]

- Xu, J.; Wang, P.; Gao, Y.; Chen, J.; Chen, R. Geometry evolution of rail weld irregularity and the effect on wheel-rail dynamic interaction in heavy haul railways. Eng. Fail. Anal. 2017, 81, 31–44. [Google Scholar] [CrossRef]

- Li, W.; Xiao, G.; Wen, Z.; Xiao, X.; Jin, X. Plastic deformation of curved rail at rail weld caused by train-track dynamic interaction. Wear 2011, 271, 311–318. [Google Scholar] [CrossRef]

- Rezanov, V.A.; Martyushev, N.V.; Kukartsev, V.V.; Tynchenko, V.S.; Kukartsev, V.A.; Grinek, A.V.; Skeeba, V.Y.; Lyosin, A.V.; Karlina, A.I. Study of melting methods by electric resistance welding of rails. Metals 2022, 12, 2135. [Google Scholar] [CrossRef]

- Zhai, W.; Gao, J. Dynamic effect and safety limits of rail weld irregularity on high-speed railways. Sci. Sin. Technol. 2014, 44, 697–706. [Google Scholar] [CrossRef]

- Gao, J.; Zhai, W.; Guo, Y. Wheel-rail dynamic interaction due to rail weld irregularity in high-speed railways. J. Rail Rapid Transit 2016, 232, 249–261. [Google Scholar] [CrossRef]

- Zhai, W.; Wang, K.; Cai, C. Fundamentals of vehicle-track coupled dynamics. Veh. Syst. Dyn. 2009, 47, 1349–1376. [Google Scholar] [CrossRef]

- Nekane, C.; Ernesto, G.V.N.; Javier, S. On the study of train track dynamic interactions caused by rail weld on discrete supported rails. Wear 2014, 314, 291–298. [Google Scholar]

- Xiao, G.; Xiao, X.; Guo, J.; Wen, Z.; Jin, X. Track dynamic behavior at rail welds at high speed. Acta Mech. Sin. 2010, 26, 449–465. [Google Scholar] [CrossRef]

- Steenbergen, M.J.M.M.; Esveld, C. Relation between the geometry of rail welds and the dynamic wheel-rail response: Numerical simulations for measured welds. J. Rail Rapid Transit 2006, 220, 409–423. [Google Scholar] [CrossRef]

- Wen, Z.; Xiao, G.; Xiao, X.; Jin, X.; Zhu, M. Dynamic vehicle-track interaction and plastic deformation of rail at rail welds. Eng. Fail. Anal. 2009, 16, 1221–1237. [Google Scholar] [CrossRef]

- Lulu, G.B.; Chen, R.; Wang, P.; Xu, J.; An, B.; Chen, J. Influence of out of round wheels on the vehicle-flexible track interaction at rail welds. J. Rail Rapid Transit 2021, 235, 313–327. [Google Scholar] [CrossRef]

- Grossoni, I.; Shackleton, P.; Bezin, Y.; Jaiswal, J. Longitudinal rail weld geometry control and assessment criteria. Eng. Fail. Anal. 2017, 80, 352–367. [Google Scholar] [CrossRef]

- Tajalli, M.R.; Zakeri, J.A. Numerical experimental study of contact impact forces in the vicinity of a rail breakage. Eng. Fail. Anal. 2020, 81, 31–44. [Google Scholar] [CrossRef]

- Deng, X.; Li, Z.; Qian, Z.; Xiao, Q.; Dollevoet, R. Pre-cracking development of weld-induced squats due to plastic deformation: Five-year field monitoring and numerical analysis. Int. J. Fatigue 2019, 127, 431–444. [Google Scholar] [CrossRef]

- Mutton, P.; Cookson, J.; Qiu, C.; Welsby, D. Microstructural characterization of rolling contact fatigue damage in flash butt welds. Wear 2016, 366, 368–377. [Google Scholar] [CrossRef]

- Hasan, N. Heavy haul operation: Issues and remedies. J. Transp. Eng. Part A Syst. 2020, 146, 04020036. [Google Scholar] [CrossRef]

- Liu, Z.; Shi, X.; Tsang, K.S.; Hoh, H.J.; Pang, J.H.L. Dynamic finite element modeling and fatigue damage analysis of thermite welds. Fatigue Fract. Eng. Mater. Struct. 2019, 43, 119–136. [Google Scholar] [CrossRef]

- Skyttebol, A.; Josefson, B.L.; Ringsberg, J.W. Fatigue crack growth in a welded rail under the influence of residual stresses. Eng. Fract. Mech. 2005, 71, 271–285. [Google Scholar] [CrossRef]

- Romano, S.; Manenti, D.; Beretta, S.; Zerbst, U. Semi-probabilistic method for residual lifetime of aluminothermic welded rails with foot cracks. Thero. Appl. Fract. Mec. 2016, 85, 398–411. [Google Scholar] [CrossRef]

- Su, H.; Li, J.; Lai, Q.; Pun, C.L.; Mutton, P. Ratcheting behaviour of flash butt welds in heat-treated hypereutectoid steel rails under uniaxial and biaxial cyclic loadings. Int. J. Mech. Sci. 2020, 176, 105539. [Google Scholar] [CrossRef]

- Ghazanfari, M.; Tehrani, P.H. Experimental and numerical investigation of the characteristics of flash-butt joints used in continuously welded rails. J. Rail Rapid Transit 2020, 234, 65–79. [Google Scholar] [CrossRef]

- Zhang, D.W.; Xu, P.J.; Zhai, W.M.; Zhang, X. Long term evolution mechanism of the rail weld irregularity in metro lines based on the wear theory. Wear 2020, 444–445, 203160. [Google Scholar] [CrossRef]

- TG/GW102-2019; Regular Speed Railway Line Repair Rules. China Railway Publishing House: Beijing, China, 2019.

- Costa, J.N.; Antunes, P.; Magalhães, H.; Pombo, J.; Ambrósio, J. A finite element methodology to model flexible tracks with arbitrary geometry for railway dynamics applications. Comput. Struct. 2021, 254, 106519. [Google Scholar] [CrossRef]

- Ji, Z.; Yang, G.; Liu, Y.; Jiang, Q. Analysis of vertical vibration characteristics of the vehicle-flexible track coupling system under wind load and track irregularity. J. Rail Rapid Transit 2018, 232, 2444–2455. [Google Scholar] [CrossRef]

- Recuero, A.M.; Escalona, J.L. Dynamics of the coupled railway vehicle-flexible track system with irregularities using a multibody approach with moving modes. Veh. Syst. Dyn. 2014, 52, 45–67. [Google Scholar] [CrossRef]

- Baeza, L.; Vila, P.; Xie, G.; Iwnicki, S.D. Prediction of rail corrugation using a rotating flexible wheelset coupled with a flexible track model and an on-Hertzian/non-steady contact model. J. Sound. Vib. 2011, 330, 4493–4507. [Google Scholar] [CrossRef]

- Yang, Z.; Deng, X.; Li, Z. Numerical modeling of dynamic frictional rolling contact with an explicit finite element method. Tribol. Int. 2019, 129, 214–231. [Google Scholar] [CrossRef]

- Marques, F.; Magalhães, H.; Pombo, J.; Ambrósio, J.; Flores, P. A three-dimensional approach for contact detection between realistic wheel and rail surfaces for improved railway dynamic analysis. Mech. Mach. Theory 2020, 149, 103825. [Google Scholar] [CrossRef]

- Ling, L.; Zhang, Q.; Xiao, X.; Wen, Z.; Jin, X. Integration of car-body flexibility into train-track coupling system dynamics analysis. Veh. Syst. Dyn. 2018, 56, 485–505. [Google Scholar] [CrossRef]

- Shin, H.; Kim, J.B. A Phenomenological constitutive equation to describe various flow stress behaviors of materials in wide strain rate and temperature regimes. J. Eng. Mater. Technol. 2010, 132, 021009. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).