Effects of Specimen Thickness and Non-Isothermal Process on Creep Behavior of AA2024 Aluminum Alloy

Abstract

1. Introduction

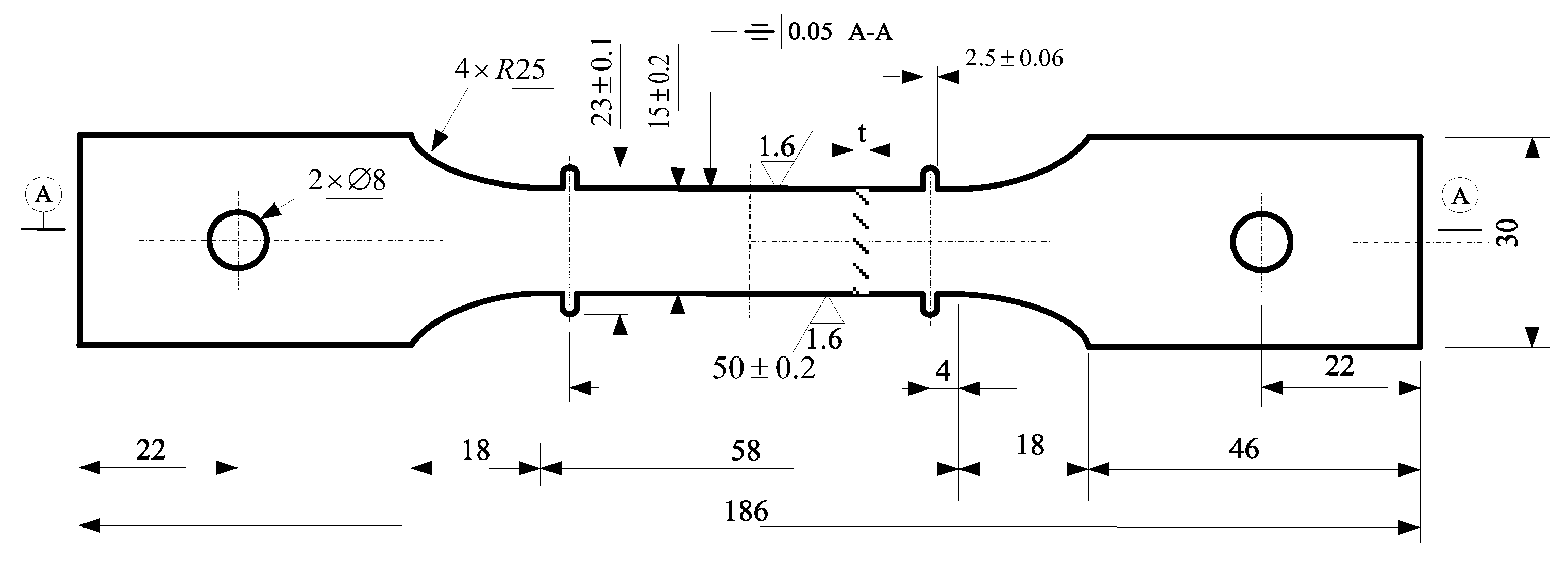

2. Material and Experimental

2.1. Materials

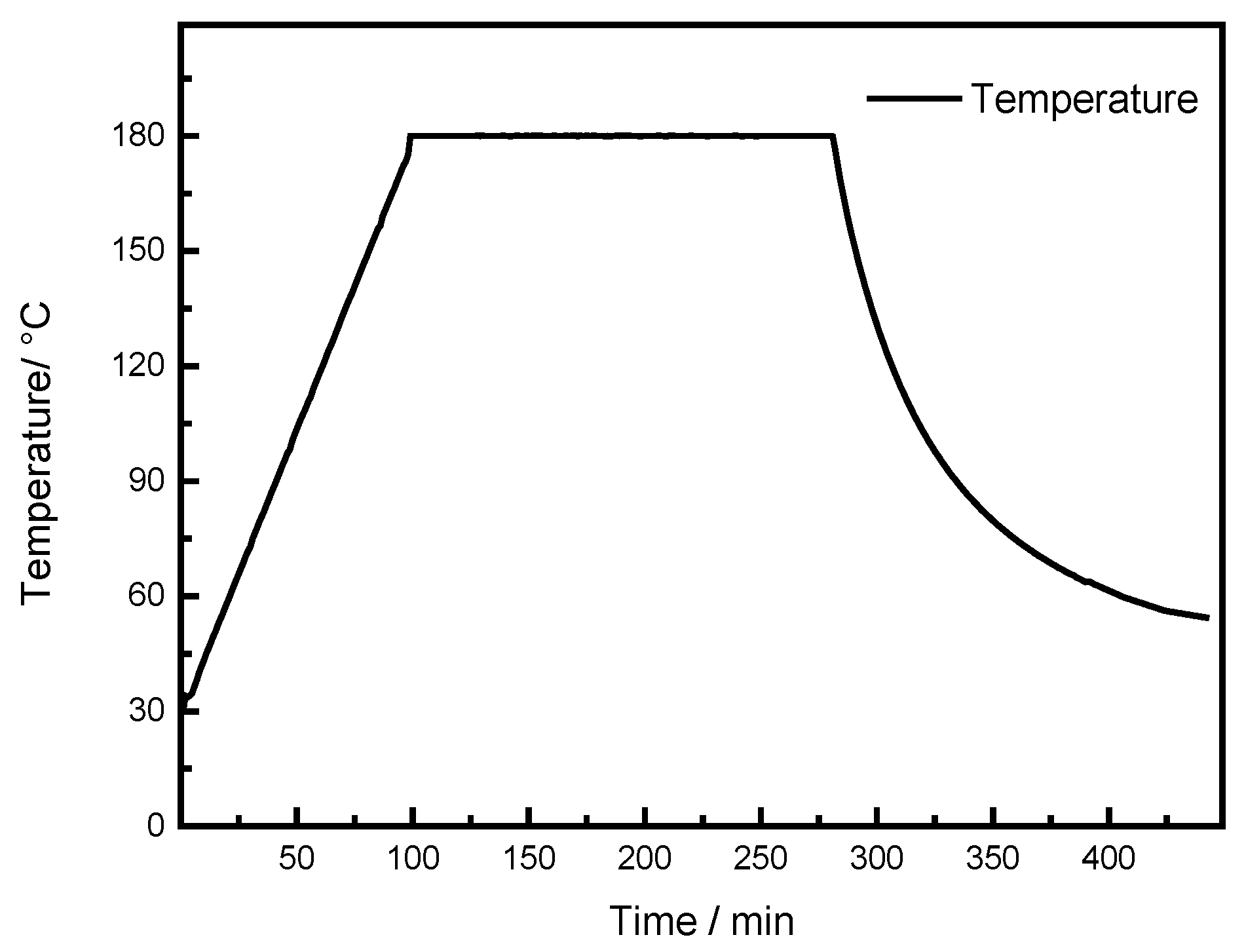

2.2. Treatment

2.3. Microstructural Analysis

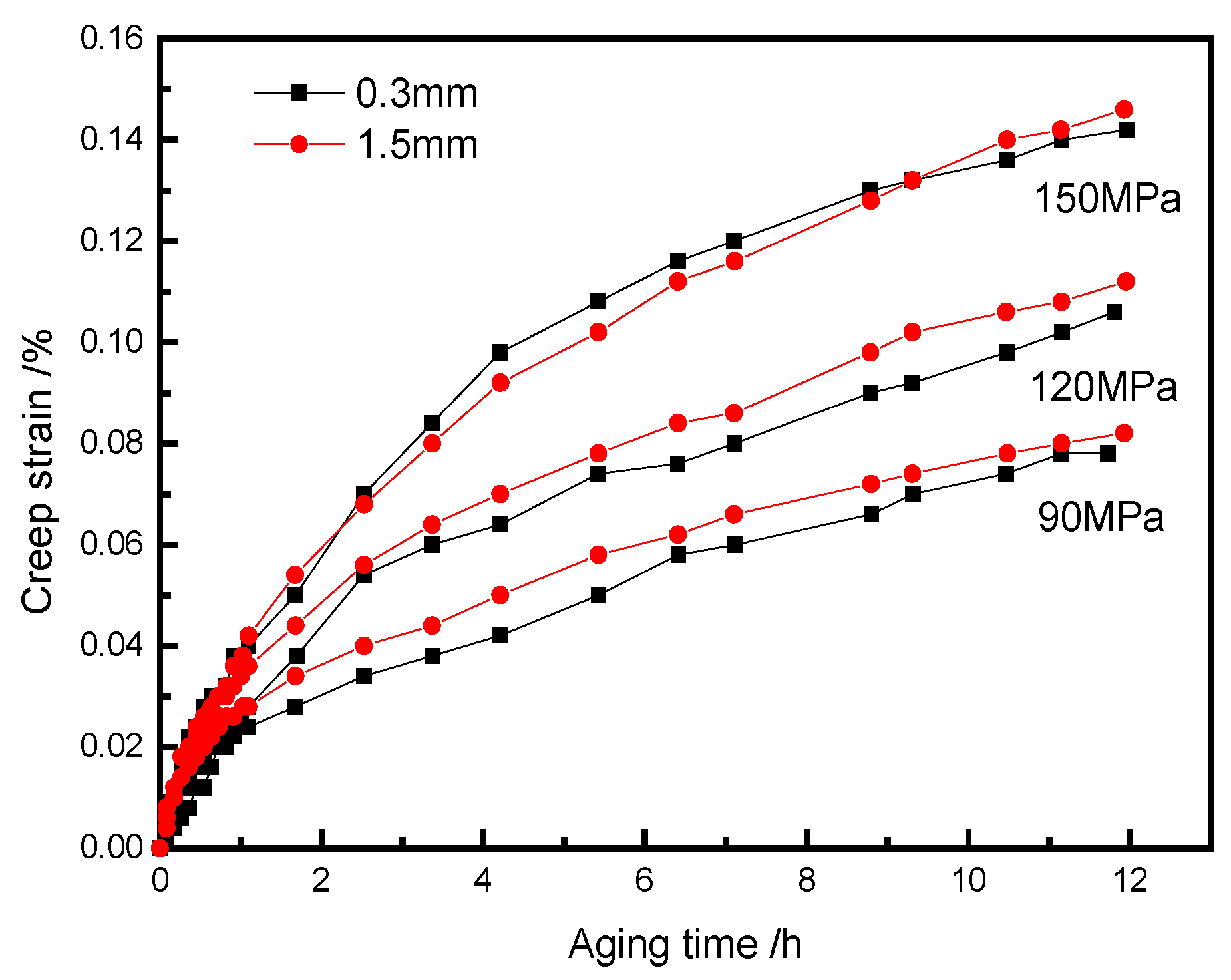

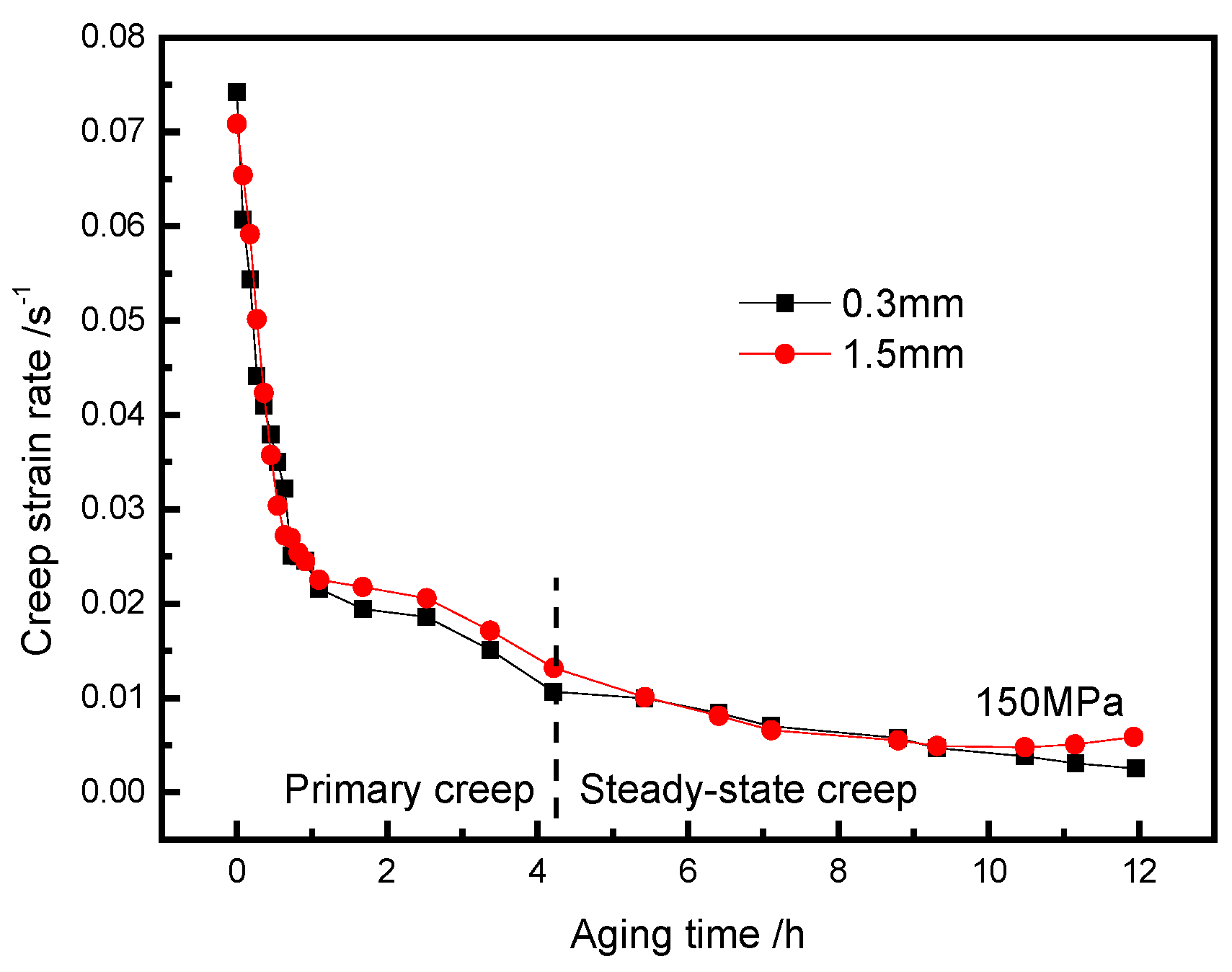

3. Thickness Effect on the Creep Behavior of AA2024 Aluminum Alloy Applied in FMLs

3.1. Creep Strain Behavior

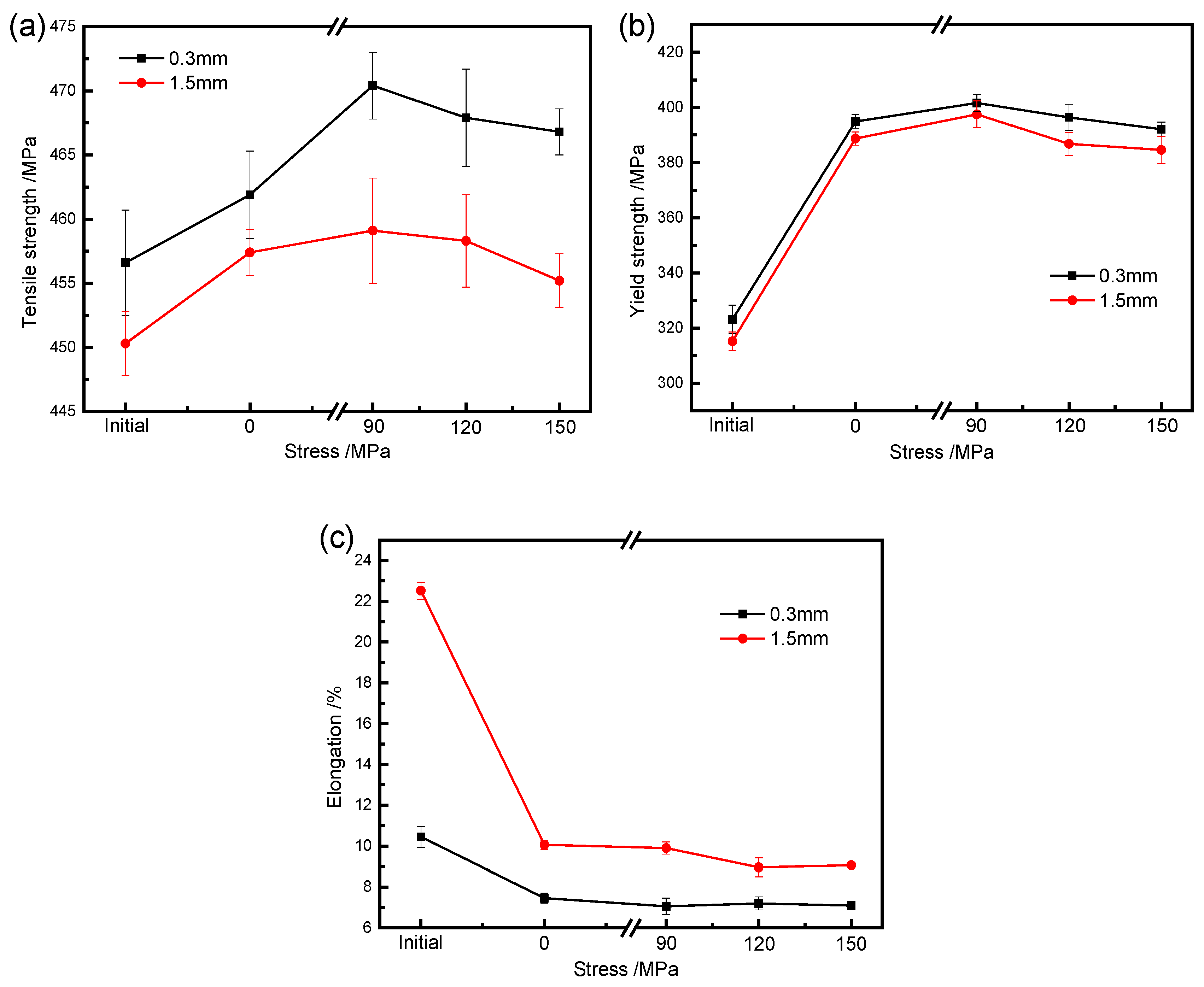

3.2. Mechanical Properties

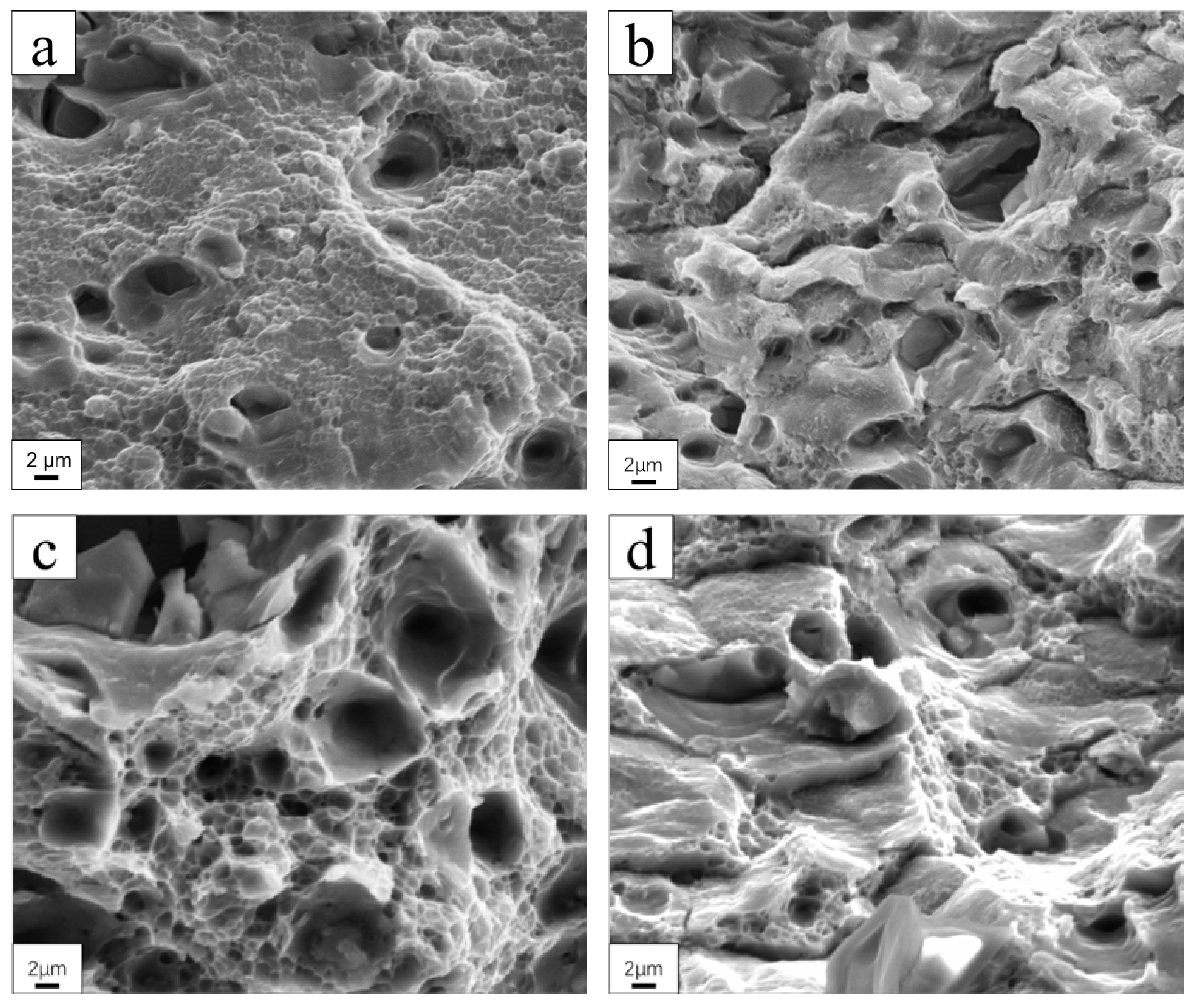

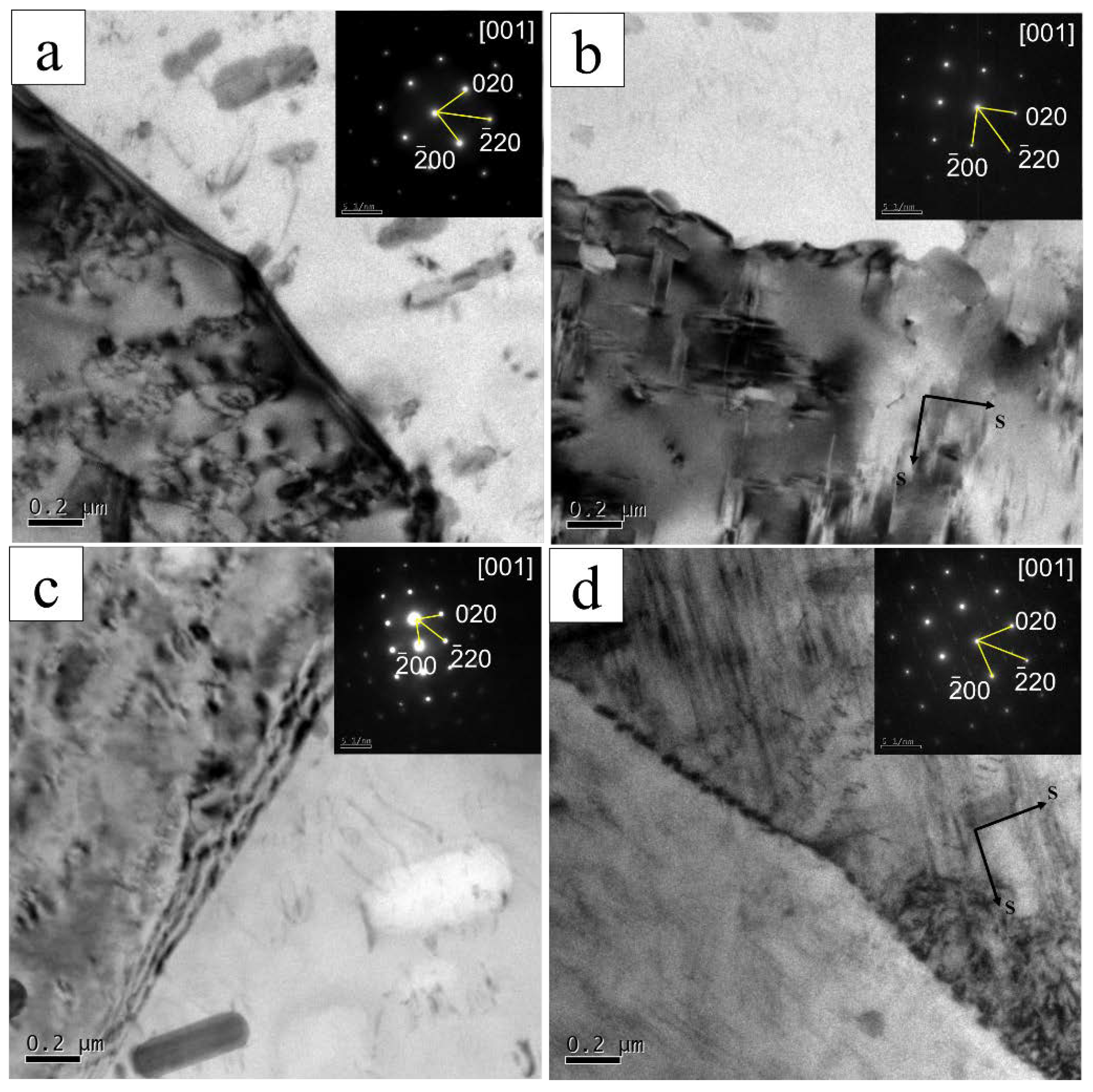

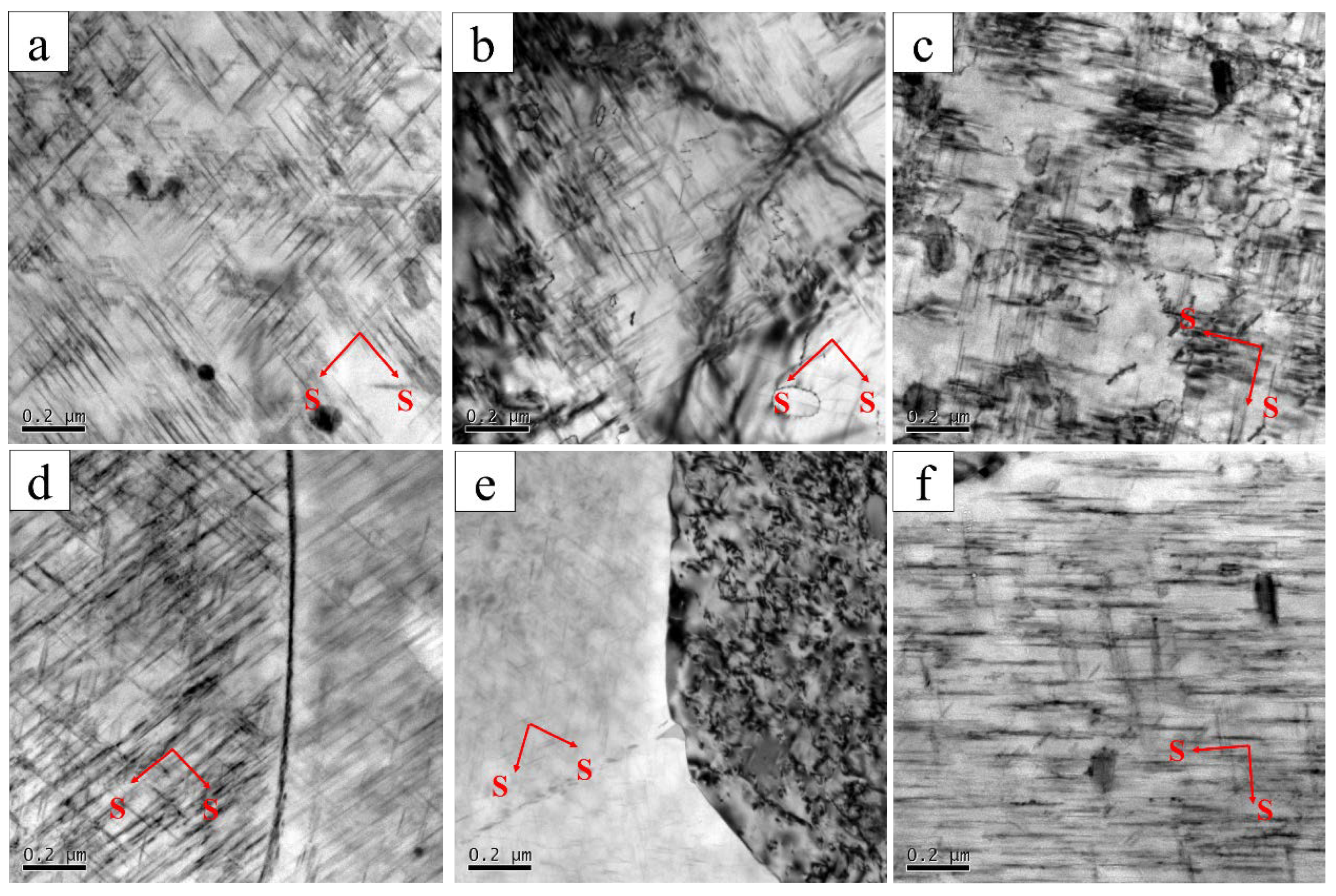

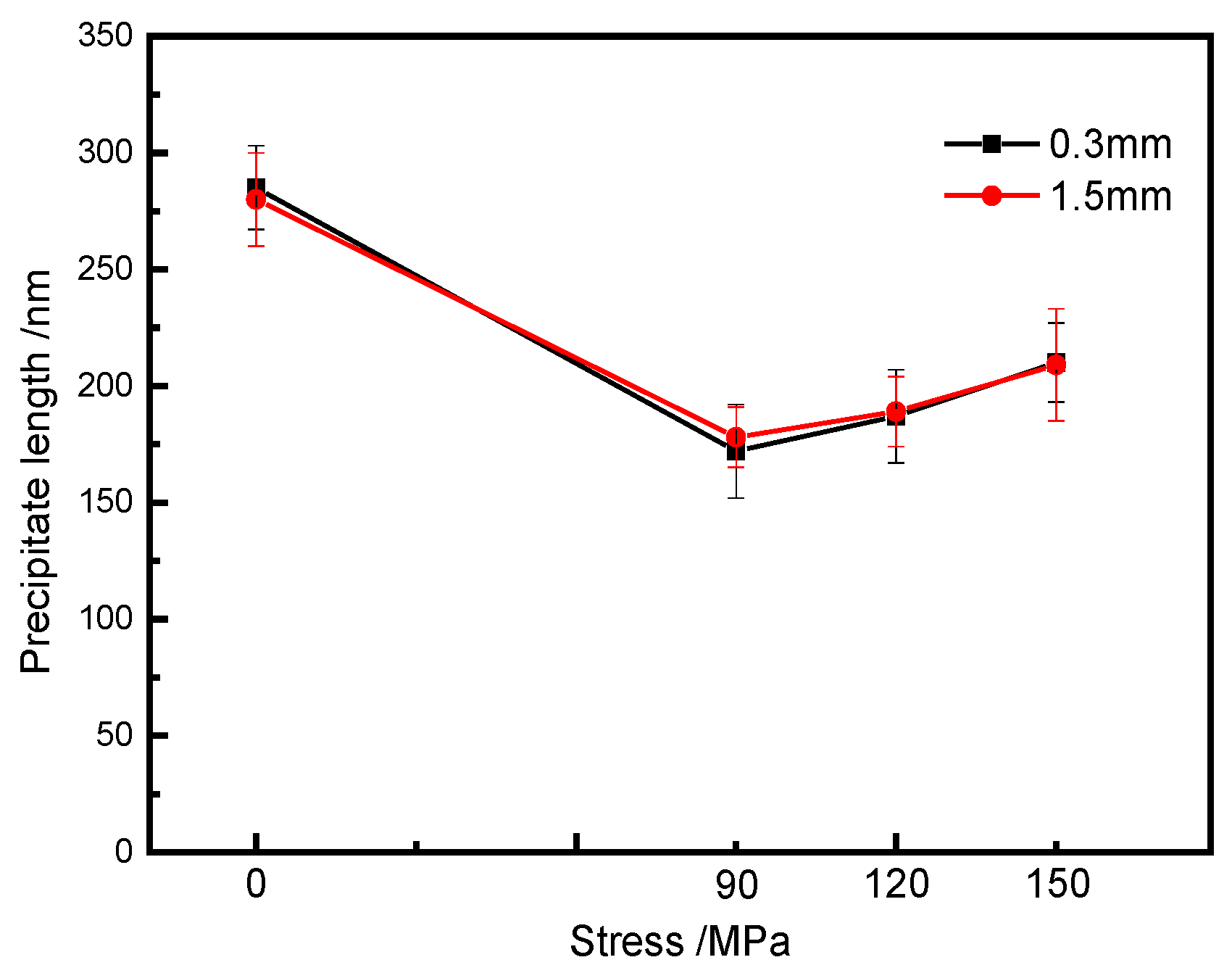

3.3. Microstructure Evolution

3.4. Discussion

4. Non-Isothermal Creep Constitutive and Numerical Modeling

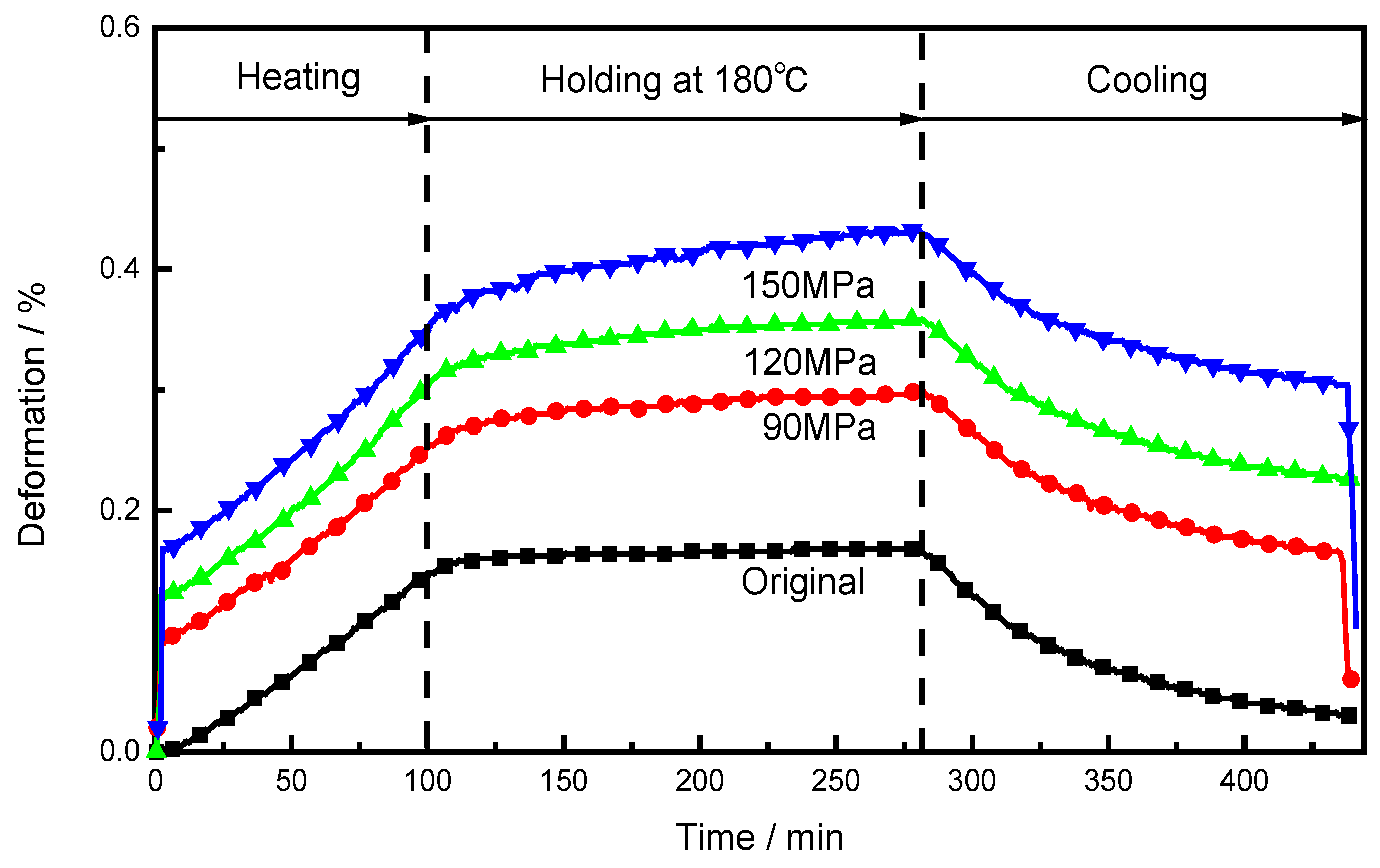

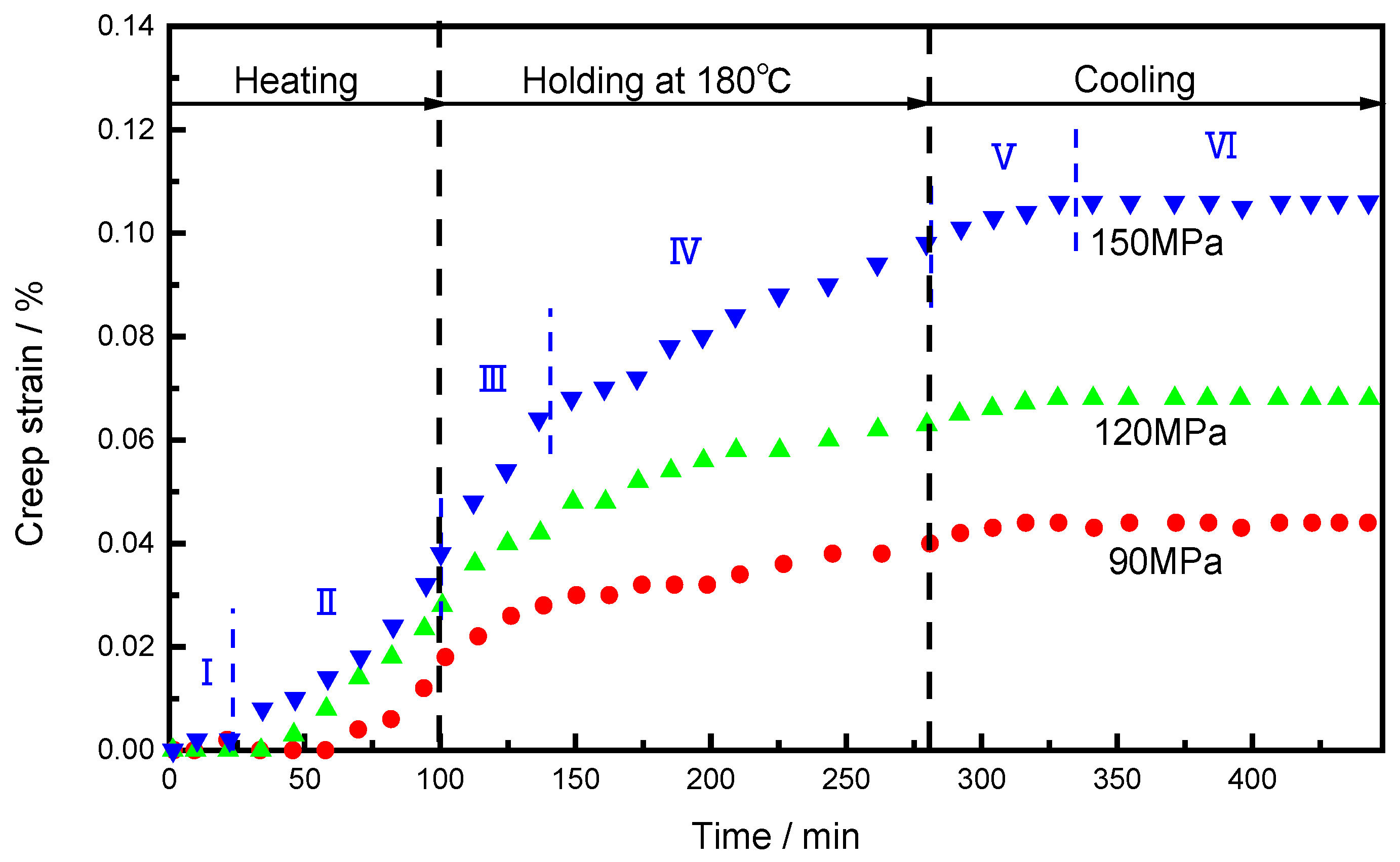

4.1. The Non-Isothermal Creep Behavior of AA2024 Aluminum Alloy

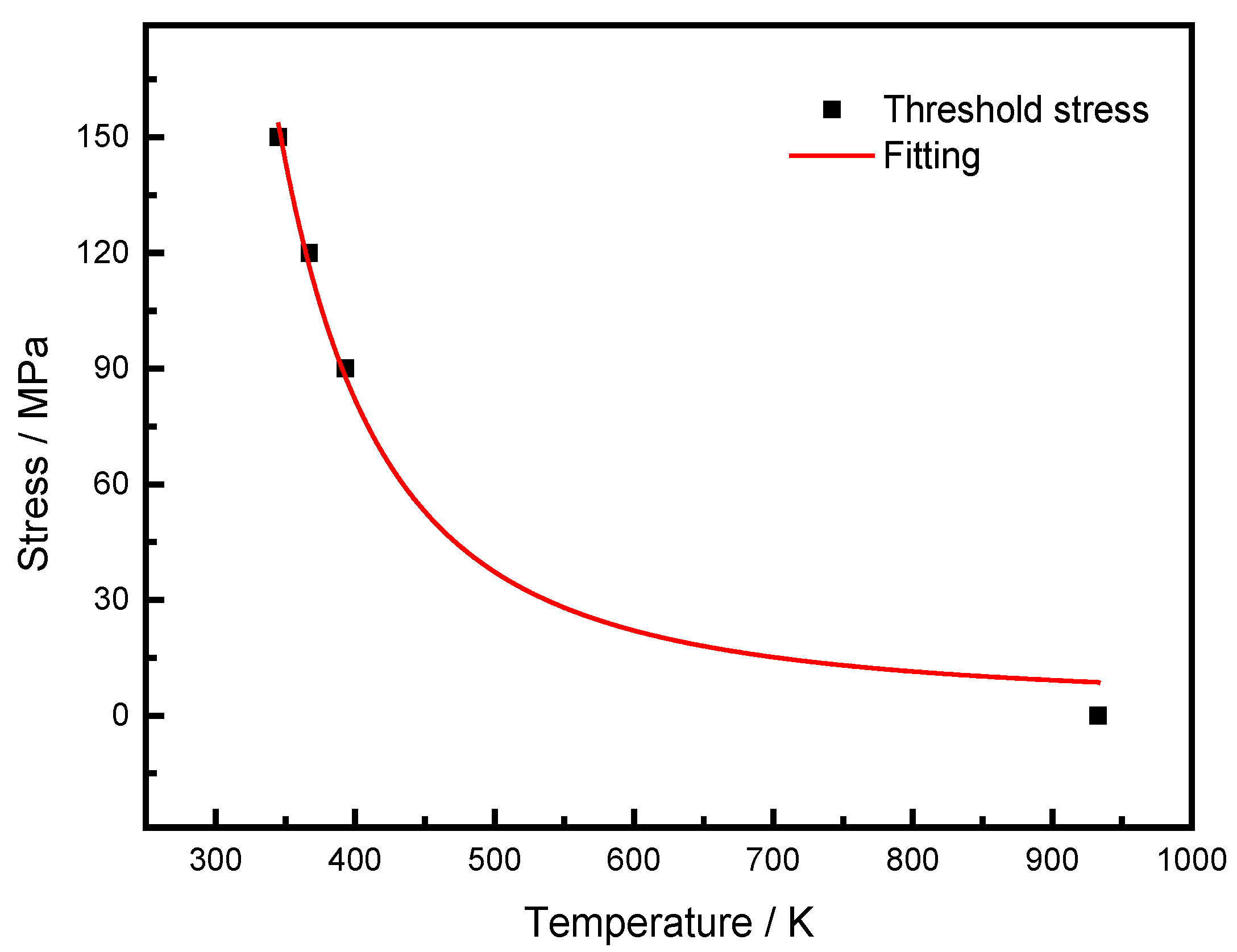

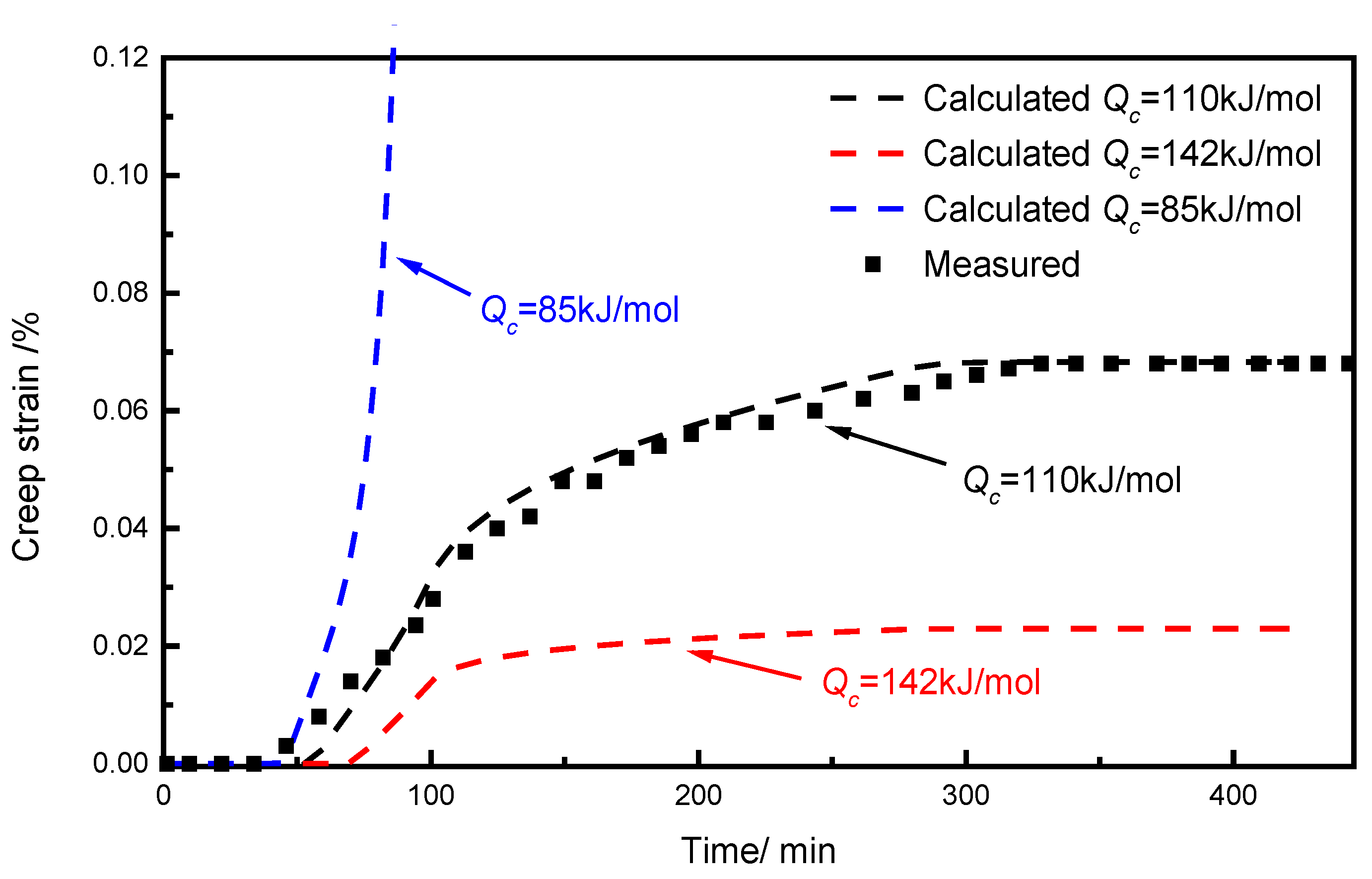

4.2. Constitutive Modeling

4.3. Finite Elements Simulation Modeling

4.4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jata, K.V. Lightweight Alloys for Aerospace Applications; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Hirschab, J. Superior light metals by texture engineering: Optimized aluminum and magnesium alloys for automotive applications. Acta Mater. 2013, 61, 818–843. [Google Scholar] [CrossRef]

- Vermeeren, C.A.J.R. An Historic Overview of the Development of Fibre Metal Laminates. Appl. Compos. Mater. 2003, 10, 189–205. [Google Scholar] [CrossRef]

- Chai, G.B.; Manikandan, P. Low velocity impact response of fibre-metal laminates—A review. Compos. Struct. 2014, 107, 363–381. [Google Scholar] [CrossRef]

- Zarei, H.; Fallah, M.; Minak, G.; Bisadi, H.; Daneshmehr, A.R. Low velocity impact analysis of Fiber Metal Laminates (FMLs) in thermal environments with various boundary conditions. Compos. Struct. 2016, 149, 170–183. [Google Scholar] [CrossRef]

- Bieniaś, J.; Dadej, K.; Surowska, B. Interlaminar fracture toughness of glass and carbon reinforced multidirectional fiber metal laminates. Eng. Fract. Mech. 2017, 175, 127–145. [Google Scholar] [CrossRef]

- Safari, M.; Salamat-Talab, M.; Abdollahzade, A.; Akhavan-Safar, A.; da Silva, L.F.M. Experimental investigation, statistical modeling and multi-objective optimization of creep age forming of fiber metal laminates. Proc. Inst. Mech. Eng. Part L 2020, 234, 1389–1398. [Google Scholar] [CrossRef]

- Zafar, R.; Lang, L.; Zhang, R. Experimental and numerical evaluation of multilayer sheet forming process parameters for light weight structures using innovative methodology. Int. J. Mater. Form. 2016, 9, 35–47. [Google Scholar] [CrossRef]

- Vermeeren, C.A.J.R.; Beumler, T.; De Kanter, J.L.C.G.; Van Der Jagt, O.C.; Out, B.C.L. Glare Design Aspects and Philosophies. Appl. Compos. Mater. 2003, 10, 257–276. [Google Scholar] [CrossRef]

- Soutis, C. Fibre reinforced composites in aircraft construction. Prog. Aerosp. Sci. 2005, 41, 143–151. [Google Scholar] [CrossRef]

- Zhu, A.W.; Starke, E.A. Stress aging of Al–xCu alloys: Experiments. Acta Mater. 2001, 49, 2285–2295. [Google Scholar] [CrossRef]

- Safari, M.; De Sousa, R.A.; Fernandes, F.; Salamat-Talab, M.; Abdollahzadeh, A. Creep Age Forming of Fiber Metal Laminates: Effects of Process Time and Temperature and Stacking Sequence of Core Material. Materials 2021, 14, 7881. [Google Scholar] [CrossRef]

- Li, Y.; Rong, Q.; Shi, Z.; Sun, X.; Meng, L.; Lin, J. An accelerated springback compensation method for creep age forming. Int. J. Adv. Manuf. Technol. 2019, 102, 121–134. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Hauggaard, A.B.; Baweja, S.; Ulm, F.J. Microprestress-Solidification Theory for Concrete Creep. I: Aging and Drying Effects. J. Eng. Mech. 1997, 123, 1188–1194. [Google Scholar] [CrossRef]

- Zhan, L.; Lin, J.; Dean, T.A. A review of the development of creep age forming: Experimentation, modelling and applications. Int. J. Mach. Tools Manuf. 2011, 51, 1–17. [Google Scholar] [CrossRef]

- Arabi, R.; Zohdi, H.; Shahverdi, H.R.; Bozorg, M.; Hadavi, S.M.M. Influence of multi-step heat treatments in creep age forming of 7075 aluminum alloy: Optimization for springback, strength and exfoliation corrosion. Mater. Charact. 2012, 73, 8–15. [Google Scholar] [CrossRef]

- Zhan, L.; Li, W.; Ma, Q.; Liu, L. The Influence of Different External Fields on Aging Kinetics of 2219 Aluminum Alloy. Metals 2016, 6, 201. [Google Scholar] [CrossRef]

- Yang, Y.; Zhan, L.; Shen, R.; Yin, X.; Li, X.; Li, W.; Huang, M.; He, D. Effect of pre-deformation on creep age forming of 2219 aluminum alloy: Experimental and constitutive modelling. Mater. Sci. Eng. A 2017, 683, 227–235. [Google Scholar] [CrossRef]

- Gonzalez-Canche, N.G.; Flores-Johnson, E.A.; Carrillo, J.G. Mechanical characterization of fiber metal laminate based on aramid fiber reinforced polypropylene. Compos. Struct. 2017, 172, 259–266. [Google Scholar] [CrossRef]

- Floreen, S. The creep fracture characteristics of nickel-base superalloy sheet samples. Eng. Fract. Mech. 1979, 11, 55–60. [Google Scholar] [CrossRef]

- Mills, W.J.; Hertzberg, R.W. The effect of sheet thickness on fatigue crack retardation in 2024-T3 aluminum alloy. Eng. Fract. Mech. 1975, 7, 705–711. [Google Scholar] [CrossRef]

- Mahmoud, S.; Lease, K. The effect of specimen thickness on the experimental characterization of critical crack-tip-opening angle in 2024-T351 aluminum alloy. Eng. Fract. Mech. 2003, 70, 443–456. [Google Scholar] [CrossRef]

- Lebert, A.A.; Besson, J.; Gourgues, A.F. Fracture of 6056 aluminum sheet materials: Effect of specimen thickness and hardening behavior on strain localization and toughness. Mater. Sci. Eng. A 2005, 395, 186–194. [Google Scholar] [CrossRef]

- Pindera, M.J.; Williams, T.O.; Macheret, Y. Time-dependent response of aramid-epoxy-aluminum sheet, ARALL, laminates. Polym. Compos. 1989, 10, 328–336. [Google Scholar] [CrossRef]

- Daghigh, V.; Khalili, S.M.R.; Eslami Farsani, R. Creep behavior of basalt fiber-metal laminate composites. Compos. Part B Eng. 2016, 91, 275–282. [Google Scholar] [CrossRef]

- Abouhamzeh, M.; Sinke, J.; Benedictus, R. A large displacement orthotropic viscoelastic model for manufacturing-induced distortions in Fibre Metal Laminates. Compos. Struct. 2019, 209, 1035–1041. [Google Scholar] [CrossRef]

- Zhan, L.; Wu, X.; Wang, X.; Yang, Y.; Liu, G.; Xu, Y. Effect of Process Parameters on Fatigue and Fracture Behavior of Al-Cu-Mg Alloy after Creep Aging. Metals 2018, 8, 298. [Google Scholar] [CrossRef]

- Wu, X.; Zhan, L.; Zhao, X.; Wang, X.; Chang, T. Effects of surface pre-treatment and adhesive quantity on interface characteristics of fiber metal laminates. Compos. Interfaces 2020, 27, 829–843. [Google Scholar] [CrossRef]

- Radmilovic, V.; Kilaas, R.; Dahmen, U.; Shiflet, G.J. Structure and morphology of S-phase precipitates in aluminum. Acta Mater. 1999, 47, 3987–3997. [Google Scholar] [CrossRef]

- Xu, Y.; Zhan, L.; Xu, L.; Huang, M. Experimental research on creep aging behavior of Al-Cu-Mg alloy with tensile and compressive stresses. Mater. Sci. Eng. A 2017, 682, 54–62. [Google Scholar] [CrossRef]

- Fu, R.; Xu, H.; Luan, G.; Dong, C.; Zhang, F.; Li, G. Top surface microstructure of friction-stir welded aa2524-t3 aluminum alloy joints. Mater. Charact. 2012, 65, 48–54. [Google Scholar] [CrossRef]

- Dan, W.J.; Zhang, W.G.; Li, S.H.; Lin, Z.Q. An experimental investigation of large-strain tensile behavior of a metal sheet. Mater. Des. 2007, 28, 2190–2196. [Google Scholar] [CrossRef]

- Zhang, F.; Levine, L.E.; Allen, A.J.; Campbell, C.E.; Creuziger, A.A.; Kazantseva, N.; Ilavsky, J. In situ structural characterization of geing kinetics in aluminum alloy 2024 across angstrom-to-micrometer length scales. Acta Mater. 2016, 111, 385–398. [Google Scholar] [CrossRef] [PubMed]

- Charai, A.; Walther, T.; Alfonso, C.; Zahra, A.M.; Zahar, C.Y. Coexistence of clusters, GPB zones, S″-, S′- and S-phases in an Al–0.9% Cu–1.4% Mg alloy. Acta Mater. 2000, 48, 2751–2764. [Google Scholar] [CrossRef]

- Singh, C.V.; Warner, D.H. Mechanisms of Guinier–Preston zone hardening in the athermal limit. Acta Mater. 2010, 58, 5797–5805. [Google Scholar] [CrossRef]

- Li, D.F.; O Dowd, N.P.; Davies, C.M.; Nikbin, K.M. A review of the effect of prior inelastic deformation on high temperature mechanical response of engineering alloys. Int. J. Press. Vessel. Pip. 2010, 87, 531–542. [Google Scholar] [CrossRef]

- Tahami, F.V.; Daeisorkhabi, A.H.; Biglari, F.R. Creep constitutive equations for cold-drawn 304L stainless steel. Mater. Sci. Eng. A 2010, 527, 4993–4999. [Google Scholar] [CrossRef]

- Xu, Y.; Zhan, L.; Huang, M.; Shen, R.; Ma, Z.; Xu, L.; Wang, K.; Wang, X. Deformation behavior of Al-Cu-Mg alloy during non-isothermal creep age forming process. J. Mater. Process. Technol. 2018, 255, 26–34. [Google Scholar] [CrossRef]

- Li, Y.; Shi, Z.; Lin, J.; Yang, Y.L.; Huang, B.M.; Chung, T.F.; Yang, J.R. Experimental investigation of tension and compression creep-ageing behaviour of AA2050 with different initial tempers. Mater. Sci. Eng. A 2016, 657, 299–308. [Google Scholar] [CrossRef]

- Li, Y.; Shi, Z.; Lin, J.; Yang, Y.L.; Balint, D.S. A unified constitutive model for asymmetric tension and compression creep-ageing behaviour of naturally aged Al-Cu-Li alloy. Int. J. Plast. 2017, 89, 130–149. [Google Scholar] [CrossRef]

- Wang, M.; Zhan, L.; Yang, Y.; Yang, L.; Huang, M. Effect of pre-deformation on aging creep of Al–Li–S4 alloy and its constitutive modeling. Trans. Nonferrous Met. Soc. China 2015, 25, 1383–1390. [Google Scholar] [CrossRef]

- Kowalewski, Z.L.; Hayhurst, D.R.; Dyson, B.F. Mechanisms-based creep constitutive equations for an aluminium alloy. J. Strain Anal. Eng. Des. 1994, 29, 309–316. [Google Scholar] [CrossRef]

- Yang, Y.; Zhan, L.; Shen, R.; Liu, J.; Li, X.; Huang, M.; He, D.; Chang, Z.; Ma, Y.; Wan, L. Investigation on the creep-age forming of an integrally-stiffened AA2219 alloy plate: Experiment and modeling. Int. J. Adv. Manuf. Technol. 2018, 95, 2015–2025. [Google Scholar] [CrossRef]

- Lin, C.T.; Kao, P.W.; Jen, M.H.R. Thermal residual strains in carbon fibre-reinforced alurninium laminates. Composites 1994, 25, 303–307. [Google Scholar] [CrossRef]

- Khan, A.S.; Liu, J.; Yoon, J.W.; Nambori, R. Strain rate effect of high purity aluminum single crystals: Experiments and simulations. Int. J. Plast. 2015, 67, 39–52. [Google Scholar] [CrossRef]

- Dorn, J.E. Creep and Fracture of Metals at High Temperatures; National Physical Laboratory: Teddington, UK, 1956. [Google Scholar]

- Mordike, B.L.; Haasen, P. The influence of temperature and strain rate on the flow stress of α-iron single crystals. Philos. Mag. 1962, 7, 459–474. [Google Scholar] [CrossRef]

- Conrad, H. On the Mechanism of Yielding and Flow in Iron; North American Aviation, Atomics International Division: Canoga Park, CA, USA, 1961. [Google Scholar]

- Chang, Y.J.; Nam, S.W.; Ginsztler, J. Activation processes of stress relaxation during hold time in 1Cr–Mo–V steel. Mater. Sci. Eng. A 1999, 264, 188–193. [Google Scholar]

- Montemayor, J.; Gómez Ramírez, R.; Carrillo, E. High-temperature creep on KBr single crystals. Phys. Status Solidi A 1976, 38, 67–72. [Google Scholar] [CrossRef]

- Zhao, Y.; Fang, Q.; Liu, Y.; Wen, P.; Liu, Y. Creep behavior as dislocation climb over NiAl nanoprecipitates in ferritic alloy: The effects of interface stresses and temperature. Int. J. Plast. 2015, 69, 89–101. [Google Scholar] [CrossRef]

- Alhamidi, A.; Horita, Z. Grain refinement and high strain rate superplasticity in alumunium 2024 alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2015, 622, 139–145. [Google Scholar] [CrossRef]

- Malas, J.C.; Venugopal, S.; Seshacharyulu, T. Effect of microstructural complexity on the hot deformation behavior of aluminum alloy 2024. Mater. Sci. Eng. A 2004, 368, 41–47. [Google Scholar] [CrossRef]

- Lin, Y.C.; Xia, Y.; Chen, M.; Jiang, Y.; Li, L. Modeling the creep behavior of 2024-T3 Al alloy. Comput. Mater. Sci. 2013, 67, 243–248. [Google Scholar] [CrossRef]

- Sherby, O.D.; Lytton, J.L.; Dorn, J.E. Activation energies for creep of high-purity aluminum. Acta Metall. 1957, 5, 219–227. [Google Scholar] [CrossRef]

- Shi, C.; Mao, W.; Chen, X.G. Evolution of activation energy during hot deformation of AA7150 aluminum alloy. Mater. Sci. Eng. A 2013, 571, 83–91. [Google Scholar] [CrossRef]

- Feng, D.; Zhang, X.; Liu, S.; Wu, Z.; Tan, Q. Rate controlling mechanisms in hot deformation of 7A55 aluminum alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 28–35. [Google Scholar] [CrossRef]

| Stress/MPa | Creep Stain (%), Percentage of Total Creep Strain | |||||

|---|---|---|---|---|---|---|

| Heating | Holding | Cooling | Total | Increment | ||

| Isothermal | 90 MPa | 0, 0 | 0.034, 100% | 0, 0 | 0.034 | - |

| 120 MPa | 0, 0 | 0.056, 100% | 0, 0 | 0.056 | - | |

| 150 MPa | 0, 0 | 0.072, 100% | 0, 0 | 0.072 | - | |

| Non-isothermal | 90 MPa | 0.018, 40.9% | 0.022, 50.0% | 0.004, 9.1% | 0.044 | 29.4% |

| 120 MPa | 0.028, 41.2% | 0.035, 51.5% | 0.005, 7.3% | 0.068 | 21.4% | |

| 150 MPa | 0.038, 35.8% | 0.06, 56.6% | 0.008, 7.6% | 0.106 | 47.2% | |

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Creep constant for steady-state stage | A | 2.59 × 108 | h−1 |

| Creep constant for steady-state stage | B | 0.375 | MPa−1 |

| Creep constant for primary stage | h | 2.335 | MPa |

| Creep constant for primary stage | H* | 0.917 | - |

| Stress-dependent hardening index | m0 | 0.904 | - |

| Stress sensitivity coefficient | m1 | 0.508 | - |

| Creep apparent activation energy | Qc | 110.2 | kJ·mol−1 |

| Hardening apparent activation energy | QH | 19.98 | kJ·mol−1 |

| Stress-temperature coefficient | C1 | 1.6 | MPa |

| Stress-temperature coefficient | C2 | 1574 | K |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Zhan, L.; Yang, Y.; Xu, Y.; Zhang, Q.; Yang, X. Effects of Specimen Thickness and Non-Isothermal Process on Creep Behavior of AA2024 Aluminum Alloy. Metals 2023, 13, 409. https://doi.org/10.3390/met13020409

Wu X, Zhan L, Yang Y, Xu Y, Zhang Q, Yang X. Effects of Specimen Thickness and Non-Isothermal Process on Creep Behavior of AA2024 Aluminum Alloy. Metals. 2023; 13(2):409. https://doi.org/10.3390/met13020409

Chicago/Turabian StyleWu, Xintong, Lihua Zhan, Youliang Yang, Yongqian Xu, Qiliang Zhang, and Xiaobo Yang. 2023. "Effects of Specimen Thickness and Non-Isothermal Process on Creep Behavior of AA2024 Aluminum Alloy" Metals 13, no. 2: 409. https://doi.org/10.3390/met13020409

APA StyleWu, X., Zhan, L., Yang, Y., Xu, Y., Zhang, Q., & Yang, X. (2023). Effects of Specimen Thickness and Non-Isothermal Process on Creep Behavior of AA2024 Aluminum Alloy. Metals, 13(2), 409. https://doi.org/10.3390/met13020409