Study on High-Temperature Low-Cycle Fatigue Behavior of the FGH96 Superalloy Based on Internal Stress Division

Abstract

:1. Introduction

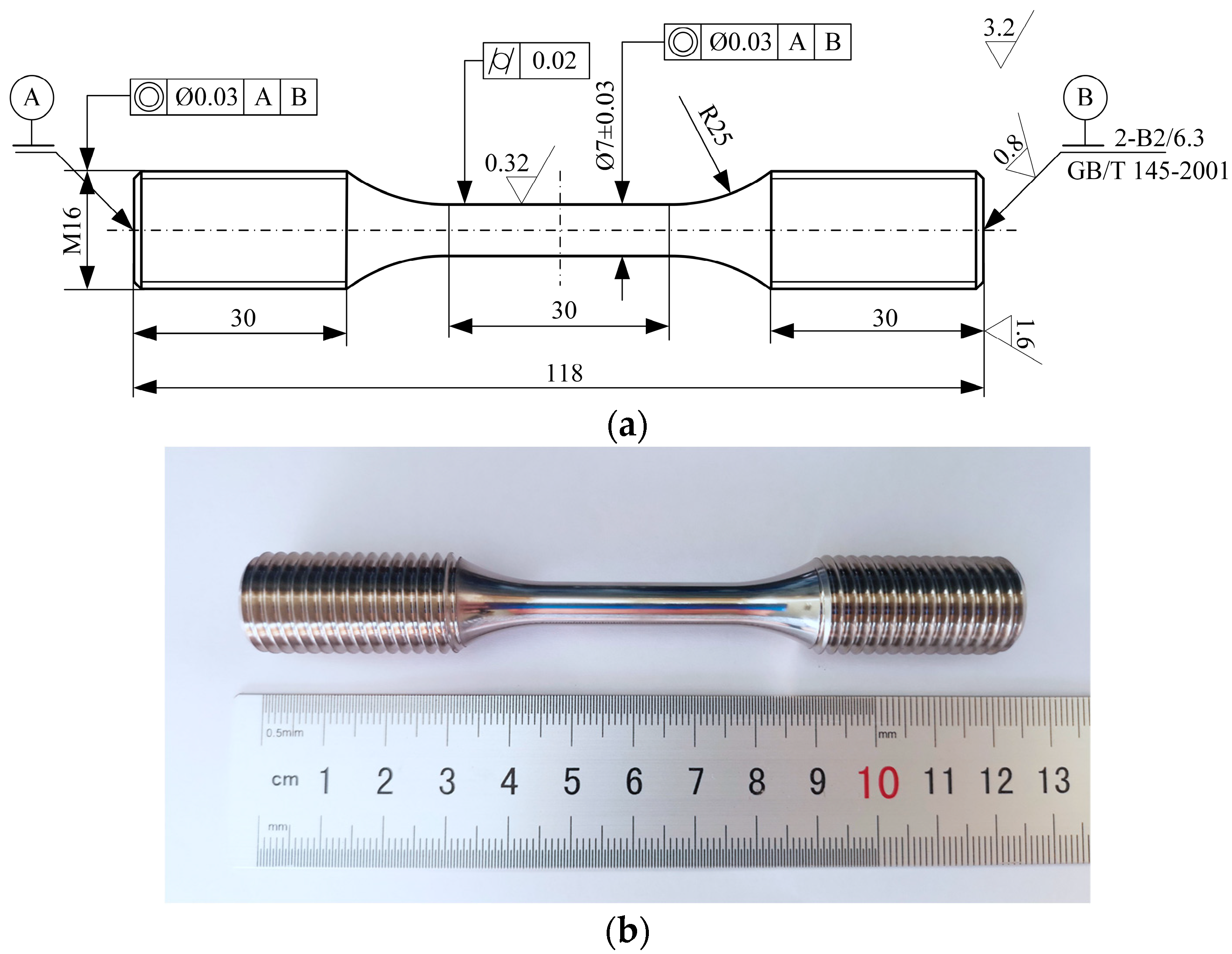

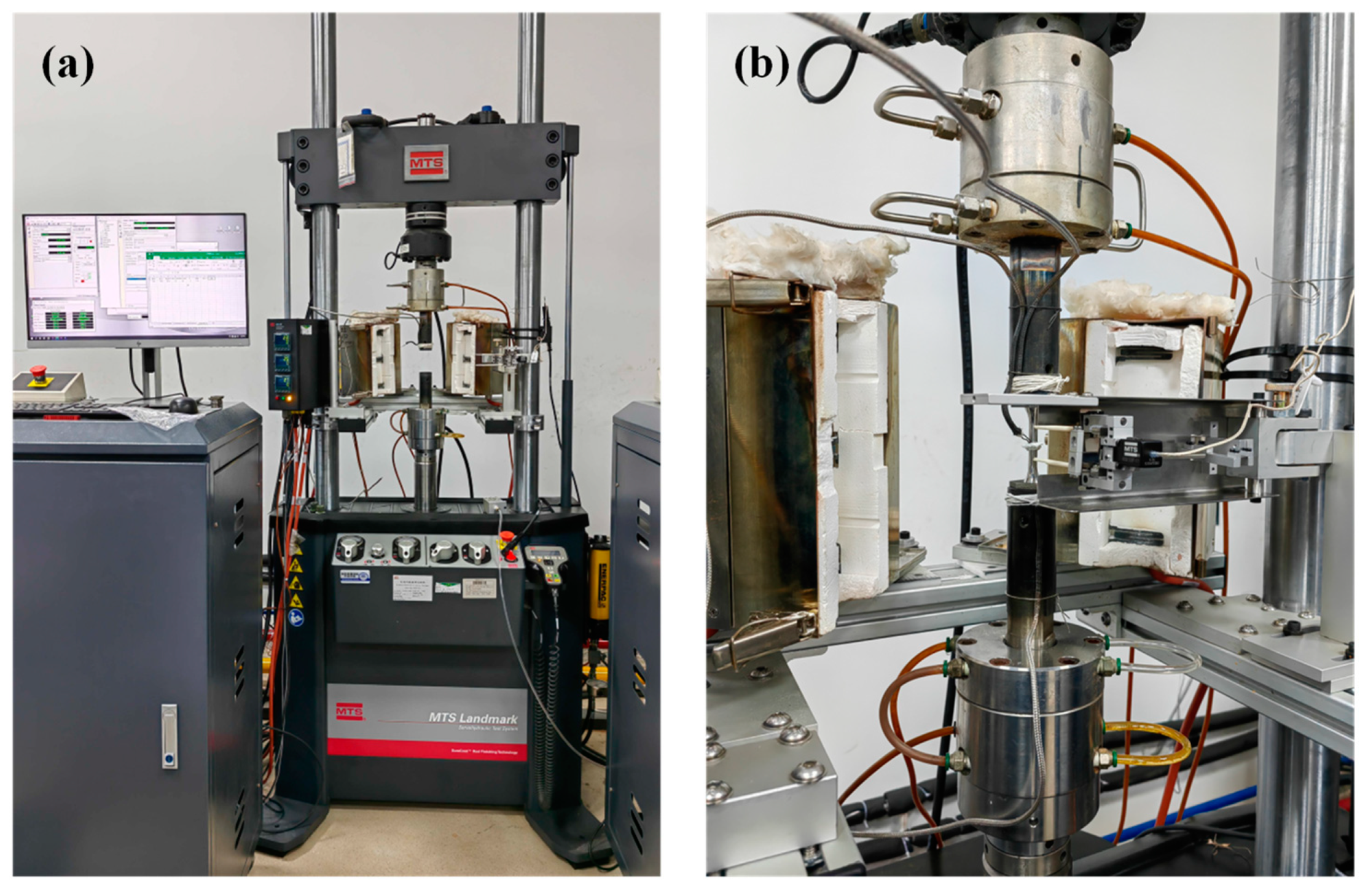

2. Experimental Materials and Methods

2.1. Experimental Materials

2.2. Fatigue Test Equipment and Method

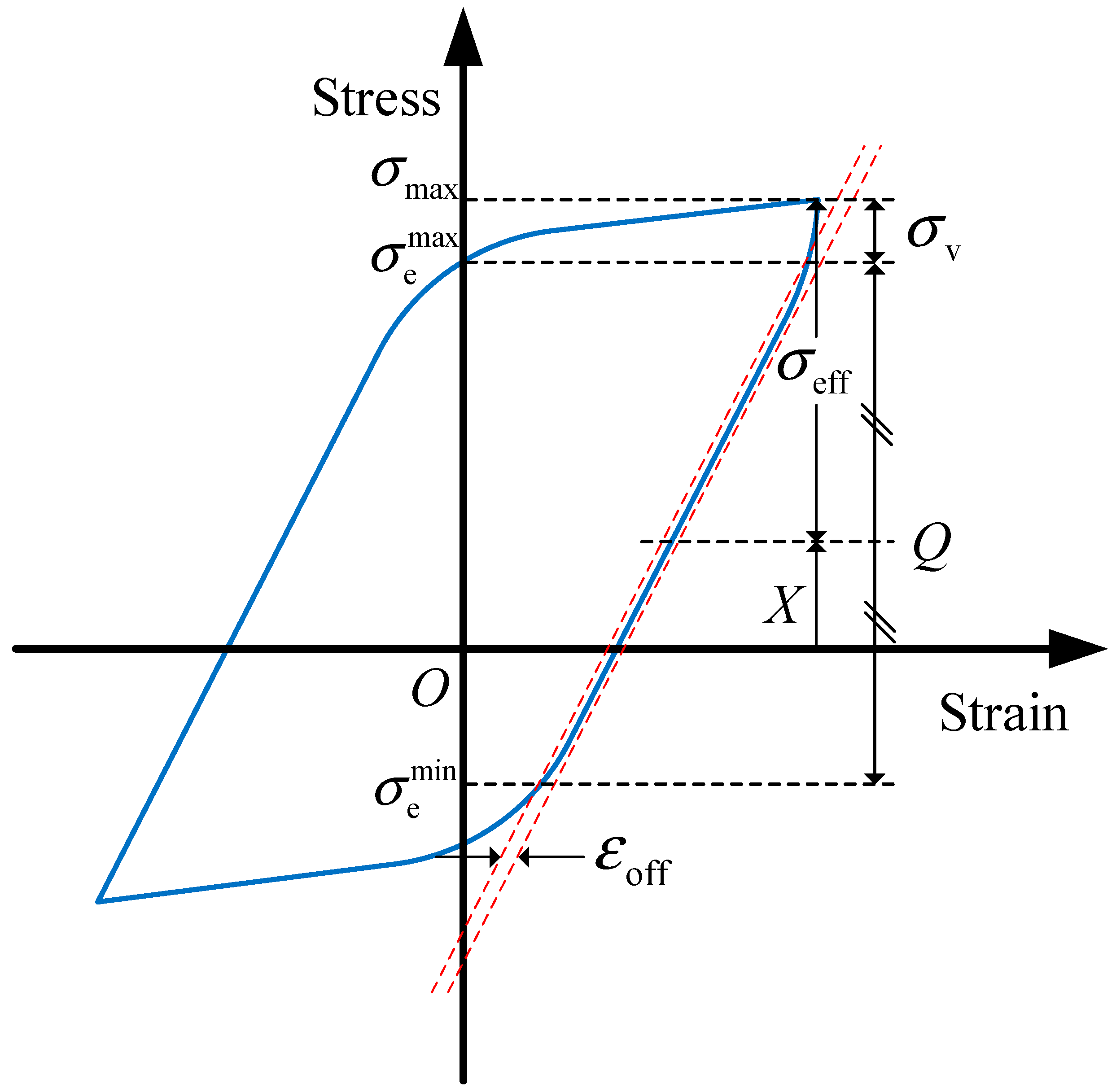

2.3. Cottrell’s Internal Stress Division Method

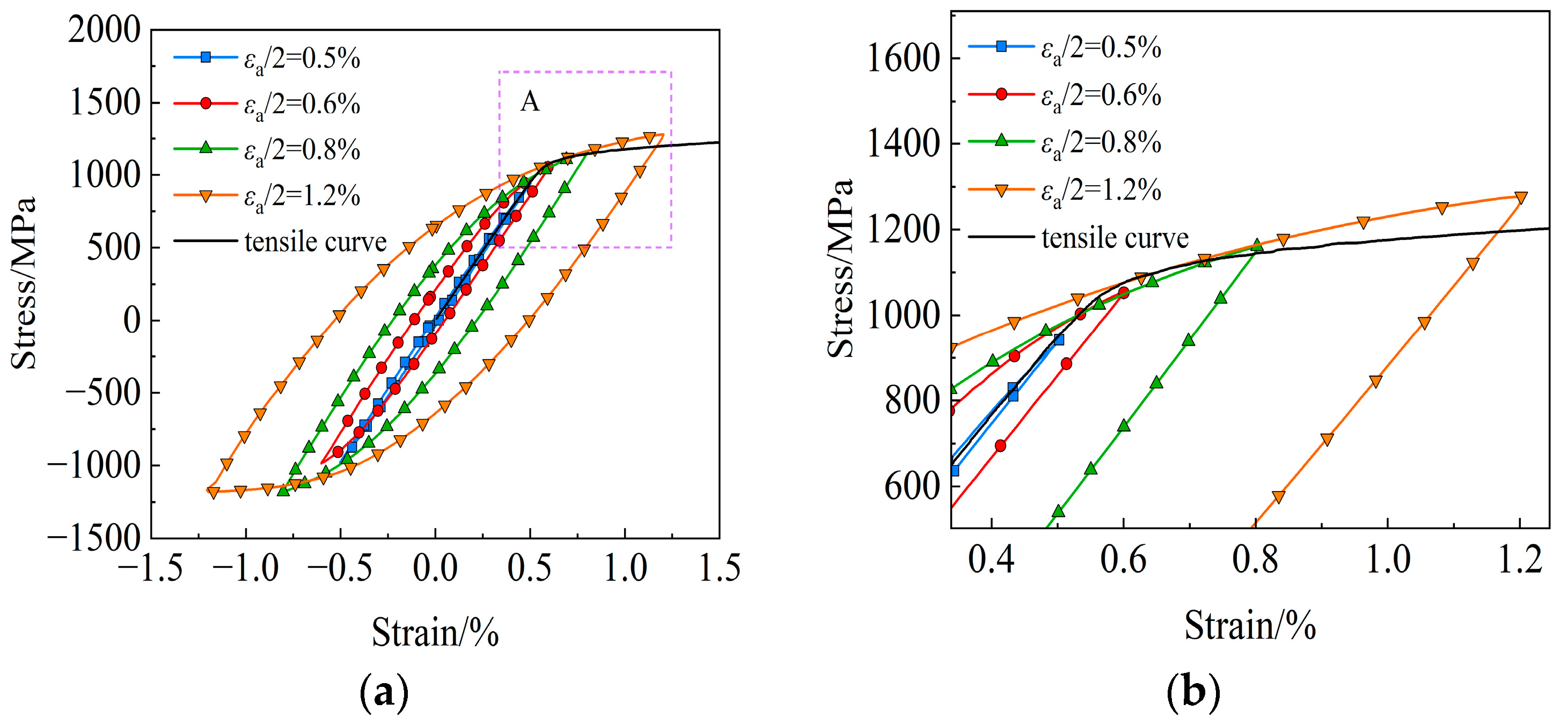

3. Results and Discussion

3.1. Cyclic Softening/Hardening Properties

3.2. Internal Stress Evolution

3.3. Microscopic Mechanism of Internal Stress Evolution

4. Conclusions

- (1)

- The different cyclic softening/hardening characteristics of the FGH96 superalloy under different strain amplitudes are closely related to the evolution of internal stress.

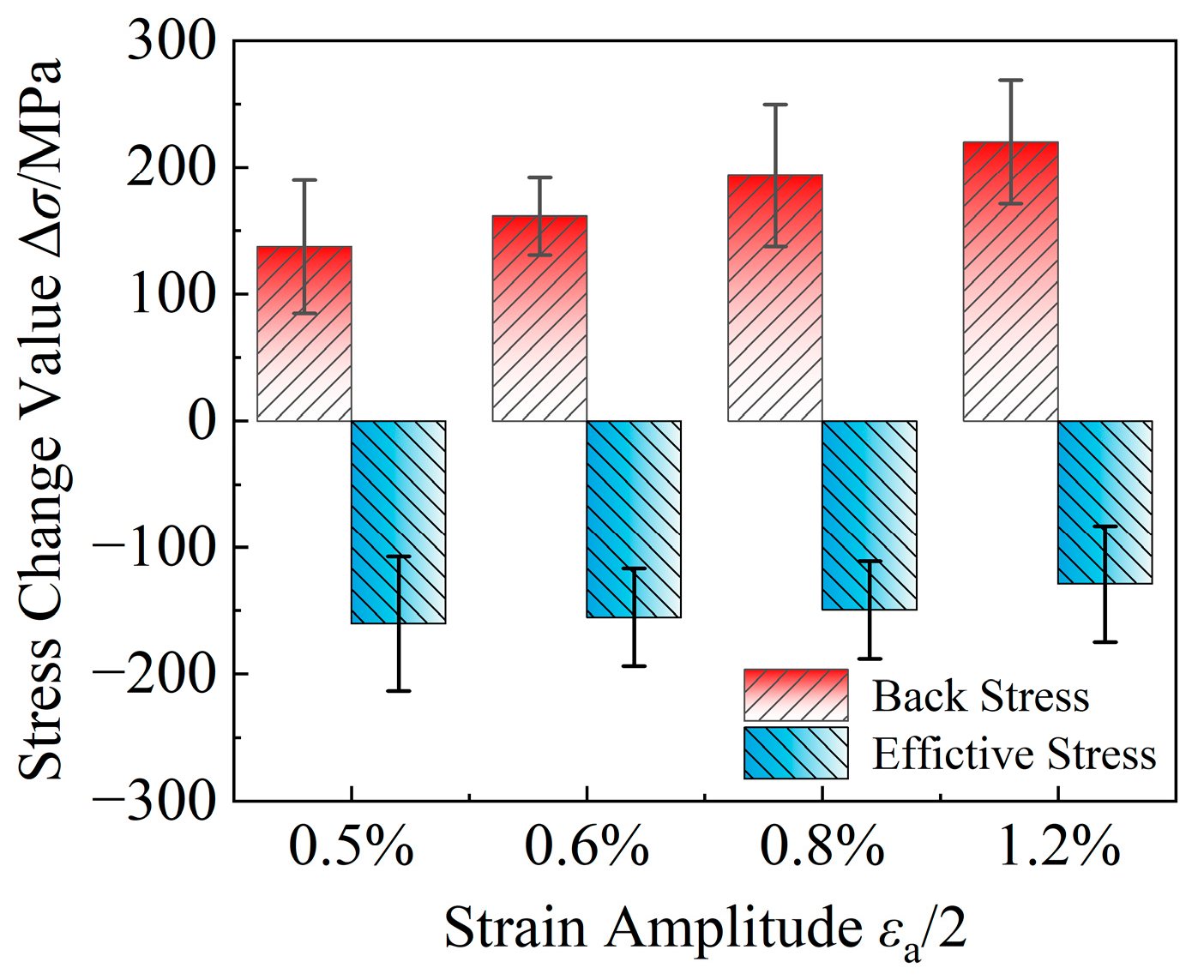

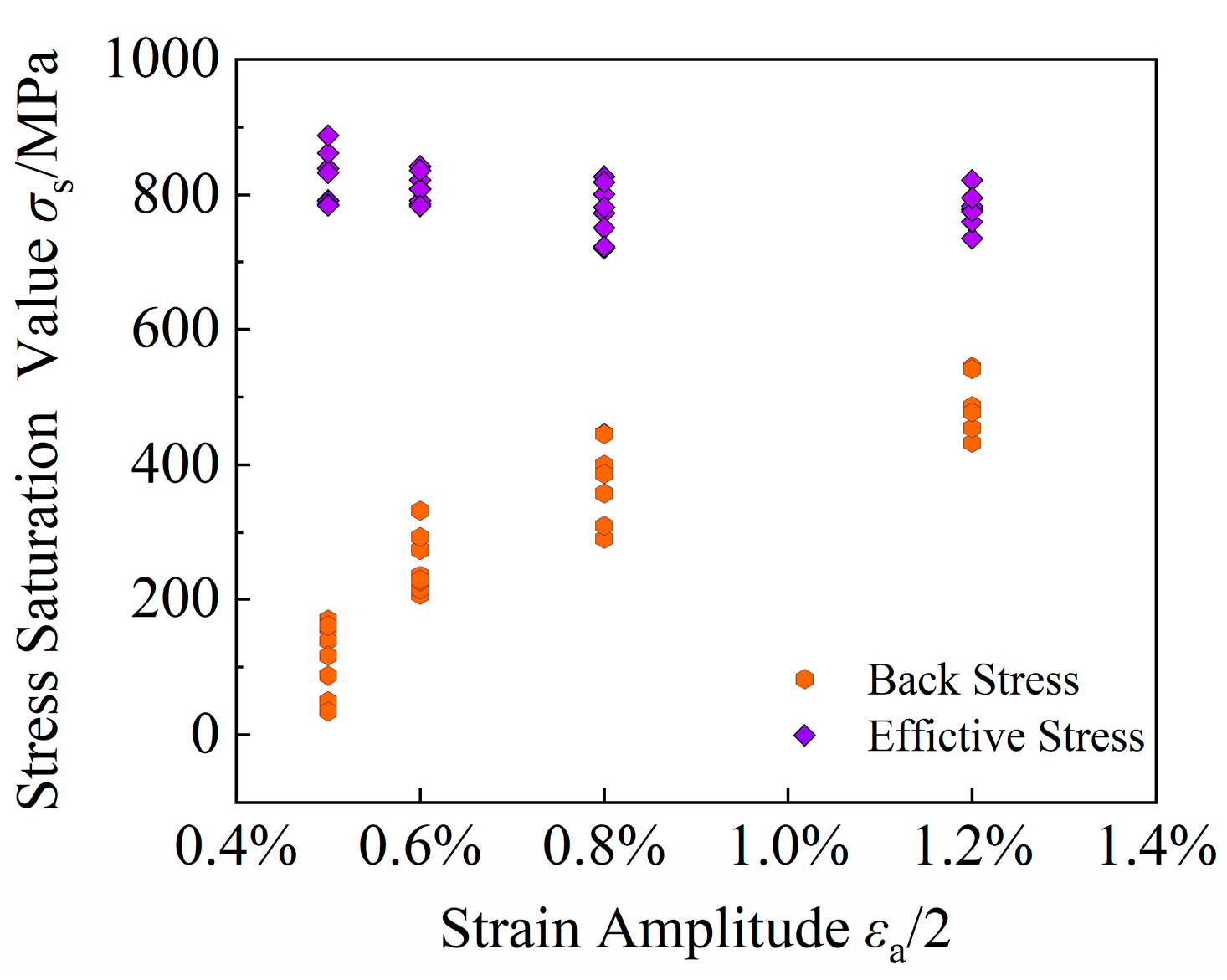

- (2)

- During the entire cycle, the back stress shows a hardening trend in the early stage, and the effective stress mainly shows a softening trend. The magnitude of the strain amplitude has a great influence on the back stress of the FGH96 superalloy, but the effect on the effective stress is not significant.

- (3)

- In the early cycle, affected by the competition between back stress hardening and effective stress softening, the FGH96 superalloy exhibits different cyclic softening/hardening characteristics under different strain amplitudes. In the late cycles, affected by the joint softening of back stress and effective stress, the FGH96 superalloy shows cyclic softening characteristics at all strain amplitudes.

- (4)

- The dislocation density gradient caused by dislocation accumulation leads to the rapid increase of the FGH96 superalloy’s back stress at high strain amplitude in the early cycles. The reduction in the effective stress of the FGH96 superalloy is due to the reduction in dislocation density caused by the enhanced cross-slip.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bai, Y.; Yang, S.; Zhu, M.; Fan, C. Study on Microstructure and Fatigue Properties of FGH96 Nickel-Based Superalloy. Materials 2021, 14, 6298. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Gu, H.; Liu, Y.; Miura, H.; Zhang, X.-C.; Tu, S.-T. Surrogate-modeling-assisted creep-fatigue reliability assessment in a low-pressure turbine disc considering multi-source uncertainty. Reliab. Eng. Syst. Safety 2023, 240, 109550. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, Z.; Lv, J.; Liu, X.; Zheng, L.; Liu, J. Oxidation Property of a Fourth-Generation Powder Metallurgy FGH4108 Nickel-Based Superalloy. Metals 2023, 13, 945. [Google Scholar] [CrossRef]

- Liu, A.; Zhang, Y.T.; Wang, X.S.; Xu, W.; Zhang, Y.; He, Y.H. Evaluation of the influences of the stress ratio, temperatures, and local microstructure on small fatigue crack propagation behavior of the FGH96 superalloy. Int. J. Fatigue 2023, 171, 107573. [Google Scholar] [CrossRef]

- Li, L.; Liu, F.; Nie, S.; Wang, Q.; Zhao, R.; Zhang, Y.; Feng, H.; Lin, X. Effect of Thermal Cycling on Grain Evolution and Micro-Segregation in Selective Laser Melting of FGH96 Superalloy. Metals 2023, 13, 121. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, J.; Shang, H.; Sha, A.; Cheng, Y.; Duan, H. Experiment and Modelling of the Pre-Strain Effect on the Creep Behaviour of P/M Ni-Based Superalloy FGH96. Materials 2023, 16, 3874. [Google Scholar] [CrossRef] [PubMed]

- Kong, W.; Wang, Y.; Chen, Y.; Liu, X.; Yuan, C. Investigation of uniaxial ratcheting fatigue behaviours and fracture mechanism of GH742 superalloy at 923 K. Mater. Sci. Eng. A 2022, 831, 142173. [Google Scholar] [CrossRef]

- Xuan, F.; Zhao, P. Cyclic Viscoplasticity Behaviour and Constitutive Theory of High Temperature Structures; Science Press: Beijing, China, 2021; p. 55. [Google Scholar]

- Cottrell, A. Dislocations and Plastic Flow in Cristals; Oxford University Press: London, UK, 1953; Volume 111. [Google Scholar]

- Xu, H.; Ye, D.; Mei, L. A study of the back stress and the friction stress behaviors of Ti-6Al-4V alloy during low cycle fatigue at room temperature. Mater. Sci. Eng. A 2017, 700, 530–539. [Google Scholar] [CrossRef]

- Zhao, P.; Xuan, F.-Z.; Wu, D.-L. Cyclic softening behaviors of modified 9–12%Cr steel under different loading modes: Role of loading levels. Int. J. Mech. Sci. 2017, 131–132, 278–285. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, C.; Zhou, D.; Zhe, Y.; Meng, L.; Zhu, X.; Zhang, D. Effect of stacking fault energy on microstructural feature and back stress hardening in Cu-Al alloys subjected to surface mechanical attrition treatment. Mater. Sci. Eng. A 2019, 740–741, 235–242. [Google Scholar] [CrossRef]

- Wang, N.; Yu, H.; Zhao, P.; Zhang, J.-M.; Gong, J.-G.; Xuan, F.-Z. Cyclic deformation response of austenitic Ni-based alloy: Mechanical behavior, internal stress evolution and microstructural feature. Mater. Sci. Eng. A 2022, 850, 143522. [Google Scholar] [CrossRef]

- Yin, P.; Zhang, W.; Zhang, Y.; Yang, Q.; Liang, F.; Chang, L.; Zhou, C. Cyclic deformation mechanism and fracture behaviour of 316L stainless steel under thermomechanical fatigue loading. J. Mater. Res. Technol. 2023, 24, 4484–4499. [Google Scholar] [CrossRef]

- Zheng, X.T.; Wu, K.W.; Wang, W.; Yu, J.Y.; Xu, J.M.; Ma, L.W. Low cycle fatigue and ratcheting behavior of 35CrMo structural steel at elevated temperature. Nucl. Eng. Des. 2017, 314, 285–292. [Google Scholar] [CrossRef]

- Liang, F.; Zhang, W.; Chen, F.; Yin, P.; Yang, Q.; Chang, L.; Zhou, C. Experimental and constitutive modelling studies of type 316L stainless steel based on internal stress under low cycle fatigue and creep-fatigue interaction. Int. J. Fatigue 2023, 175. [Google Scholar] [CrossRef]

- Wang, C.; Xuan, F.-Z.; Zhao, P.; Guo, S.-J. Effect of cyclic loadings on stress relaxation behaviors of 9–12%Cr steel at high temperature. Mech. Mater. 2021, 156, 103787. [Google Scholar] [CrossRef]

- Xu, L.-Y.; Fan, J.-S.; Yang, Y.; Tao, M.-X.; Tang, Z.-Y. An improved elasto-plastic constitutive model for the exquisite description of stress-strain hysteresis loops with cyclic hardening and softening effects. Mech. Mater. 2020, 150, 103590. [Google Scholar] [CrossRef]

- Zhong, Y.-L.; Wang, Y.-B.; Xiang, Y.; Li, G.-Q. Constitutive model for cyclic behavior of mild steel under various strain amplitudes. J. Constr. Steel Res. 2022, 196, 107396. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, W.; Guo, Y.; Liang, F.; Yin, P.; Chang, L.; Zhou, C. A universal constitutive model considering strain range dependence effect and transient behaviour for both cyclic softening and hardening steels. Eng. Fract. Mech. 2023, 290, 109481. [Google Scholar] [CrossRef]

- Li, Z.; Qin, H.; Xu, K.; Xie, Z.; Ji, P.; Jia, M. Fatigue Behavior of the FGH96 Superalloy under High-Temperature Cyclic Loading. Materials 2023, 16, 5883. [Google Scholar] [CrossRef]

- GB/T 145-2001; Center Holes. Standardization Administration of the People’s Republic of China (SAC): Beijing, China, 2001.

- GB/T 26077-2021; Metallic Materials—Fatigue Testing—Axial-Strain-Controlled Method. Standardization Administration of the People’s Republic of China (SAC): Beijing, China, 2021.

- Kuhlmann-Wilsdorf, D.; Laird, C. Dislocation behavior in fatigue II. Friction stress and back stress as inferred from an analysis of hysteresis loops. Mater. Sci. Eng. 1979, 37, 111–120. [Google Scholar] [CrossRef]

- Liu, X.; Tao, C.; Feng, Y. Damage Behavior and Life Prediction of Powder Metallurgy Superalloys; Aviation Industry Press: Beijing, China, 2018; p. 34. [Google Scholar]

- Abedi, H.R.; Hanzaki, A.Z.; Azami, M.; Kahnooji, M.; Rahmatabadi, D. The high temperature flow behavior of additively manufactured Inconel 625 superalloy. Mater. Res. Express 2019, 6, 116514. [Google Scholar] [CrossRef]

- Guo, Q.; Hou, H.; Pan, Y.; Pei, X.; Song, Z.; Liaw, P.K.; Zhao, Y. Hardening-softening of Al0.3CoCrFeNi high-entropy alloy under nanoindentation. Mater. Des. 2023, 231, 112050. [Google Scholar] [CrossRef]

- Guo, G.; Ding, C. Mechanical Testing of Aeronautical Materials; China Machine Press: Beijing, China, 2020; p. 241. [Google Scholar]

- Niu, X.; Zhu, S.; He, J. Defect tolerant fatigue assessment of AM materials: Size effect and probabilistic prospects. Int. J. Fatigue 2022, 160, 106884. [Google Scholar] [CrossRef]

- Cao, W.; Yang, J.; Zhang, H. Unified constitutive modeling of Haynes 230 including cyclic hardening/softening and dynamic strain aging under isothermal low-cycle fatigue and fatigue-creep loads. Int. J. Plast. 2021, 138, 102922. [Google Scholar] [CrossRef]

- Nguyen, T.; Yoon, K.; Park, J.; Baek, U. Characterization of Strain-Controlled Low-Cycle fatigue and fracture behavior of P91 steel at elevated temperatures. Eng. Fail. Anal. 2022, 133, 105887. [Google Scholar] [CrossRef]

- Li, B.; Yang, J.; Wang, Z.; Chen, G.; Chen, X. Low cycle fatigue behavior of 316LN stainless steel: Effects of temperature, strain rate and strain amplitude. Int. J. Fatigue 2023, 175, 107767. [Google Scholar] [CrossRef]

- Pham, M.-S.; Holdsworth, S.R. Evolution of Relationships Between Dislocation Microstructures and Internal Stresses of AISI 316 L During Cyclic Loading at 293 K and 573 K (20 °C and 300 °C). Metall. Mater. Trans. A 2014, 45, 738–751. [Google Scholar] [CrossRef]

| Element | Ni | Cr | Co | W | Mo | Ti | Al |

|---|---|---|---|---|---|---|---|

| wt./% | Bal. | 15.43 | 12.94 | 4.12 | 4.11 | 3.51 | 2.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Qin, H.; Xu, K.; Xie, Z.; Ji, P.; Jia, M. Study on High-Temperature Low-Cycle Fatigue Behavior of the FGH96 Superalloy Based on Internal Stress Division. Metals 2023, 13, 1705. https://doi.org/10.3390/met13101705

Li Z, Qin H, Xu K, Xie Z, Ji P, Jia M. Study on High-Temperature Low-Cycle Fatigue Behavior of the FGH96 Superalloy Based on Internal Stress Division. Metals. 2023; 13(10):1705. https://doi.org/10.3390/met13101705

Chicago/Turabian StyleLi, Zhengguang, Haiqin Qin, Kejun Xu, Zhenbo Xie, Pengcheng Ji, and Mingming Jia. 2023. "Study on High-Temperature Low-Cycle Fatigue Behavior of the FGH96 Superalloy Based on Internal Stress Division" Metals 13, no. 10: 1705. https://doi.org/10.3390/met13101705

APA StyleLi, Z., Qin, H., Xu, K., Xie, Z., Ji, P., & Jia, M. (2023). Study on High-Temperature Low-Cycle Fatigue Behavior of the FGH96 Superalloy Based on Internal Stress Division. Metals, 13(10), 1705. https://doi.org/10.3390/met13101705