2. The Mathematical Model

Consider the growth of a right infinite columnar crystal with an initial radius of a circular column in a convective undercooled melt. It is assumed that the melt is undercooled to a temperature ( is the melting equilibrium temperature of a pure substance; the melt undercooling is defined as ). The convection in the undercooled melt is driven by a forced flow when the melt is placed on a rotational disk. The convection velocity near the columnar crystal can be decomposed into a superposition of uniform flow and linear flow, in which it is assumed that the convection velocity of the flow field is driven by the shear flow, , where and are represented as unit vectors in the rectangular coordinate system, and are the rectangular coordinates , and are the constant shear rates and the bars over , and and denote the dimensional quantities. The growing interface of the columnar crystal is expressed as in the polar coordinate system (r,θ), where is the polar angle, is the dimensional time, and the bars over and denote the dimensional quantities. The interface of the column crystal separates the solid phase () from the liquid phase ().

Let

and

denote the velocity and reduced pressure in the liquid phase, respectively, and

and

denote the temperatures in the liquid phase and solid phase, respectively. The growth of the columnar crystal satisfies the following equations. The continuity equation

the Navier–Stokes equation

where

is the Laplace operator,

is the gradient operator,

is the reduced pressure,

is dynamic viscosity of the melt, and

is the density of the melt. The densities of the solid and liquid phases are assumed to be equal.

The temperature equations are given as follows:

where

and

are the thermal diffusion coefficients of the liquid phase and solid phase, respectively.

At the interface

, the total mass conservation and tangential non slip of the interface hold that

where

and

are the unit normal vector and unit tangent vector of the interface, respectively.

At the interface

, the Gibbs–Thomson condition and energy conservation condition hold that

where

is the moving velocity of the interface;

is the mean curvature of the interface;

is the crystalline latent heat per unit volume;

is the anisotropic interface energy,

, in which

is the isotropic interface energy that gives the average magnitude of interface energy;

is the anisotropy parameter; and

is a positive integer, where

. In this paper,

for

is taken and

is the interface kinetics parameter, and

and

are the thermal conductivity coefficients of the liquid phase region and the solid phase region, respectively.

For the asymptotic analysis of the above problem in Equations (1)–(8), we introduce the nondimensionalization transformation

where

is the constant pressure specific heat,

is the velocity scale from the characteristic velocity of the interface,

,

is the time scale,

is the pressure scale, and

is the temperature scale. Equations (1)–(4) are transferred into the dimensionless governing equations:

where

is the relative undercooling parameter,

is the Prandtl number, and

is the ratio of the thermal diffusivity in the liquid phase to the thermal diffusivity in the solid phase

The crystal–melt interface conditions (5)–(8) are transferred into the dimensionless interface conditions:

where

is the interface energy parameter

The far-field condition is that, as

In the cylindrical coordinate system,

, in which

and

act as the basis vectors, and

and

are the two components. The shear flow is expressed as

,

where

Finally, the initial condition for the interface is that at time

,

For the sake of simplicity, it is assumed that the buoyancy effects are neglected.

3. Asymptotic Solution and Analysis

For typical metals, the quantity

is of a magnitude from tens to several hundred degrees. The relative undercooling parameter

is practically small,

. With the slow variable

introduced

the equations in Equations (10)–(13) become

The interface conditions in Equations (14)–(17) become

The far-field conditions in Equations (18) and (19) and the initial condition for the interface in Equation (20) maintain the same values.

Taking

as a small parameter and writing

temporally, we seek the asymptotic solution of the form

The columnar interface is expanded into

where

,

,

, ⋯.

The interface curvature is expanded into

Substituting (29) into Equations (21)–(28) together with Equations (18)–(20), and equating the coefficients of the like terms

in the power series of

, we derive the equations for each order approximation. The leading order approximations for the flow field and the temperature fields satisfy the equations

which are subject to the interface conditions, namely, at the interface

,

The far-field temperature condition is, as

,

,

The flow driven condition

The initial condition for the interface is that at time

,

For the flow field, when the shear flow is superimposed, the flow field throughout the melt is modified by the additional fluid velocities. After carrying out some algebra, we have the leading order approximations

and

:

The leading order approximation solutions for the temperature fields are expressed as

where the leading order interface

satisfies the ordinary differential equation

With the initial condition in Equation (40), Equation (46) has the implicit solution

From Equation (46), as

,

, the columnar crystal decays, whereas as

,

, the columnar crystal grows. Setting

yields a critical value of

. Returning to the dimensional quantity of the critical value

, we define the critical nucleation radius of the columnar crystal

as

The first order approximation solutions for the temperature fields satisfy the equations

which are subject to the interface conditions at the interface

,

The far-field temperature condition is that as

,

,

The initial condition for the interface is that

From Equations (48) and (49) and the interface condition in Equation (51), the first order approximation solutions of Equations (48) and (49) are in the following forms with three modes:

,

, and

.

where the derivation of the notations

,

,

,

,

,

,

,

, and

are listed in

Appendix A. In summary, the asymptotic solution of the columnar crystals is obtained as:

The growth velocity of the columnar crystal is

where the notations

,

and

are listed in the

Appendix A.

It is easily testified that the asymptotic solution in (59)–(61) does not satisfy the initial conditions for the temperature fields. This is caused by the early-time behavior of crystal growth from the assumption

. In order to solve for the early-time behavior, we introduce the fast time variable

and seek the inner solution with respect to time (see

Appendix B). Consequently, we can match the inner solution with the solution in Equations (58)–(62) and obtain the uniformly valid asymptotic solution of the columnar crystal growth in the whole melt region. Since the phase transformation occurs near the interface, the asymptotic solution in (59)–(61) shows the variations in the temperature and the interface of the columnar crystal during the growth of the columnar crystal.

With the asymptotic solution in (58)–(62), we use the following physical parameters of a Cu–Fe alloy with face-centered cubic (f.c.c) structures and analyze the interface morphologies of the columnar crystal under the influence of an anisotropic interface energy and the shear effect of the forced flow.

The physical parameters of a Cu–Fe alloy are as follows: K (Fe), J s−1m−1 K−1 (Cu), J s−1m−1 K−1 (Fe), J kg−1 K−1 (Cu), J kg−1 K−1 (Fe), γ = 0.1010 J m−1 (Fe), J m−3 (Fe), kg m−3 (Cu), and kg m−3 (Fe).

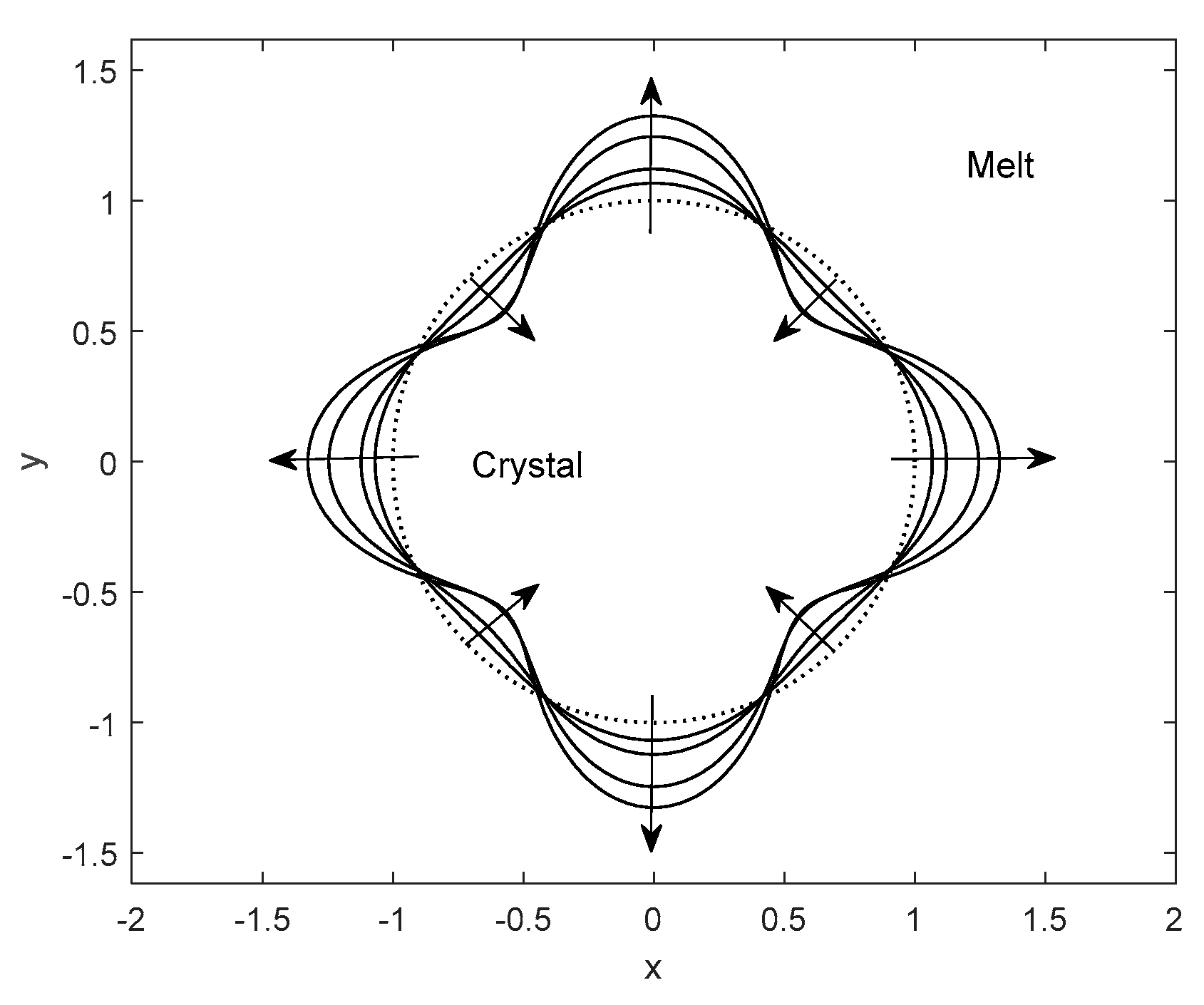

Figure 1,

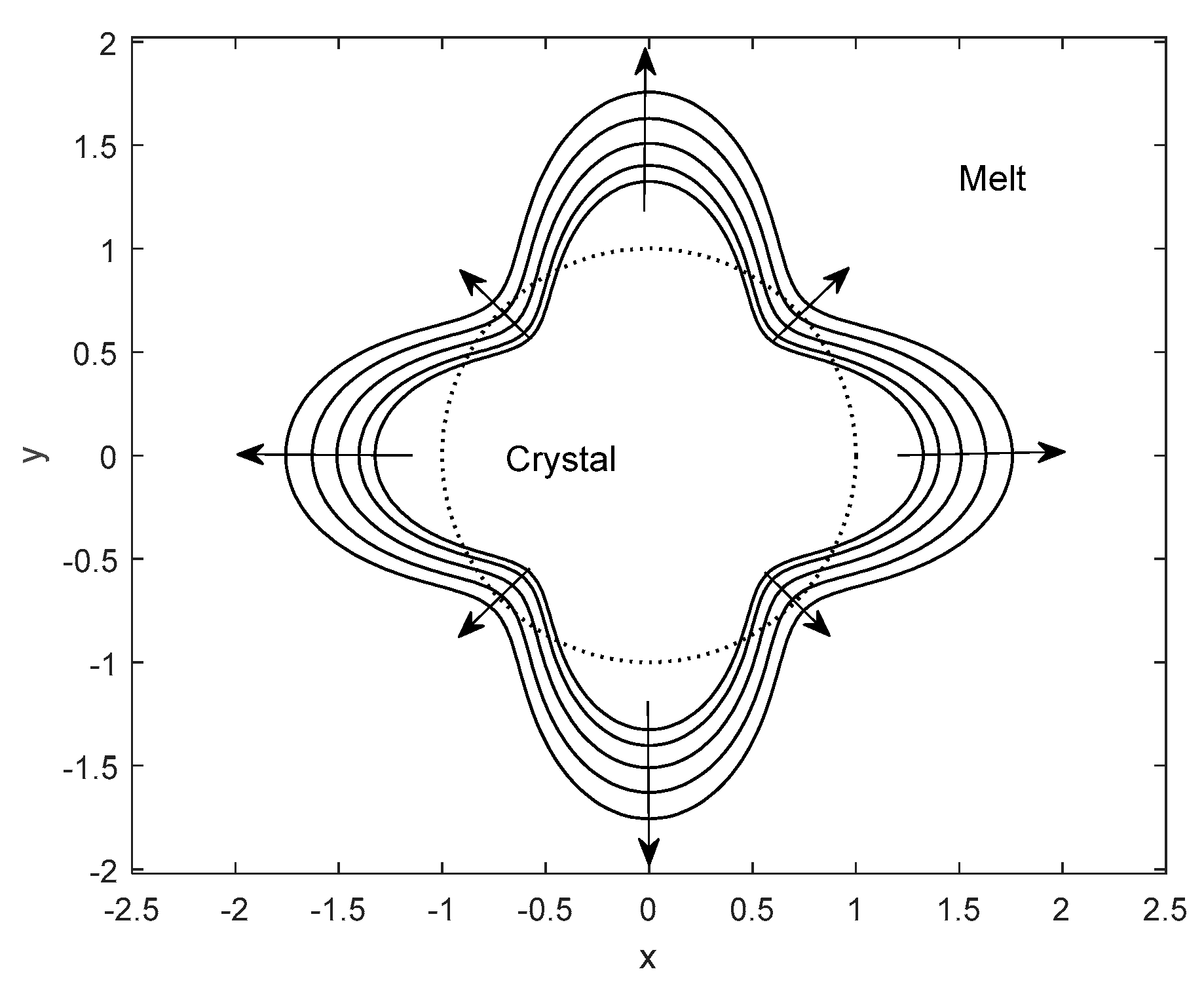

Figure 2,

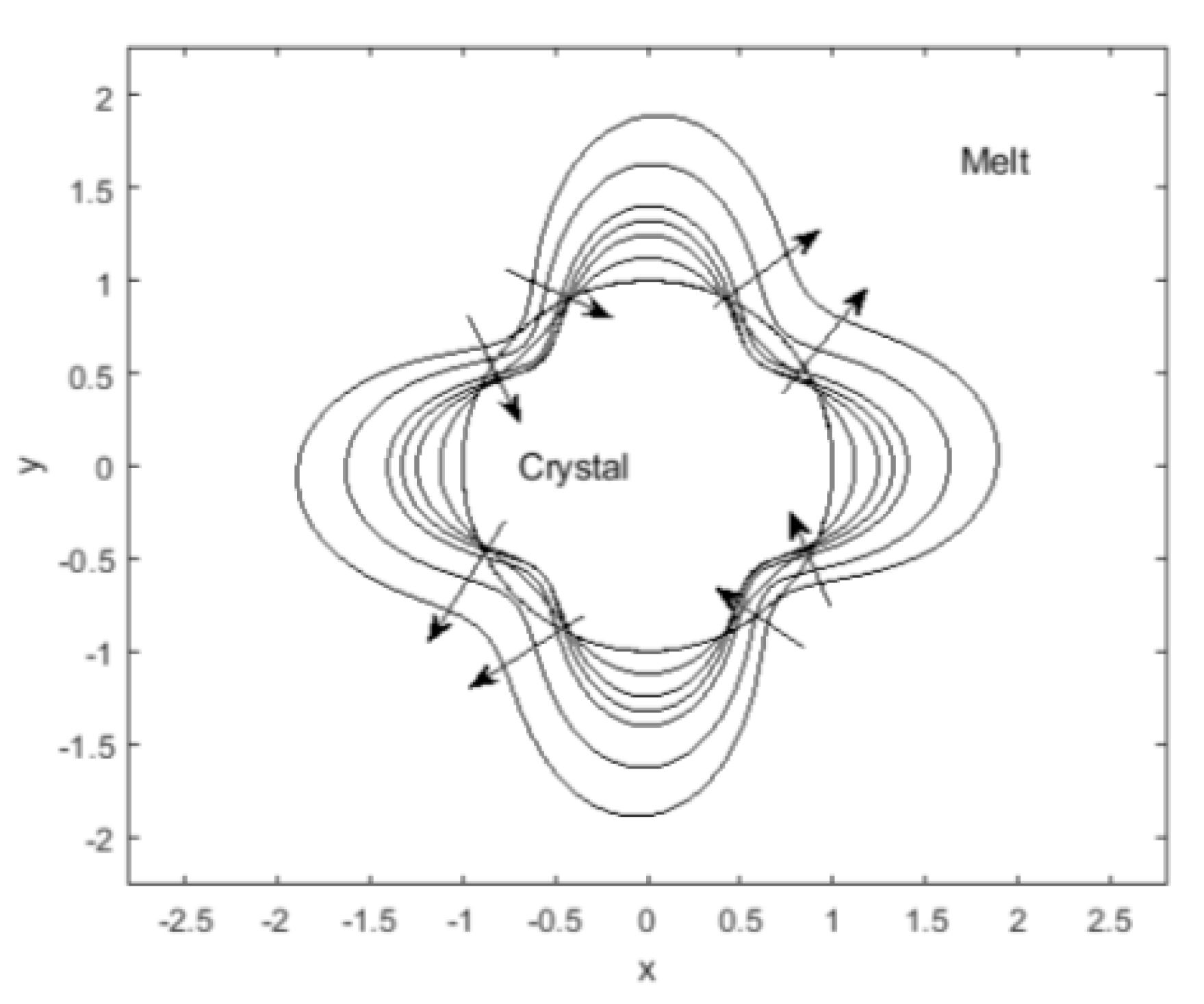

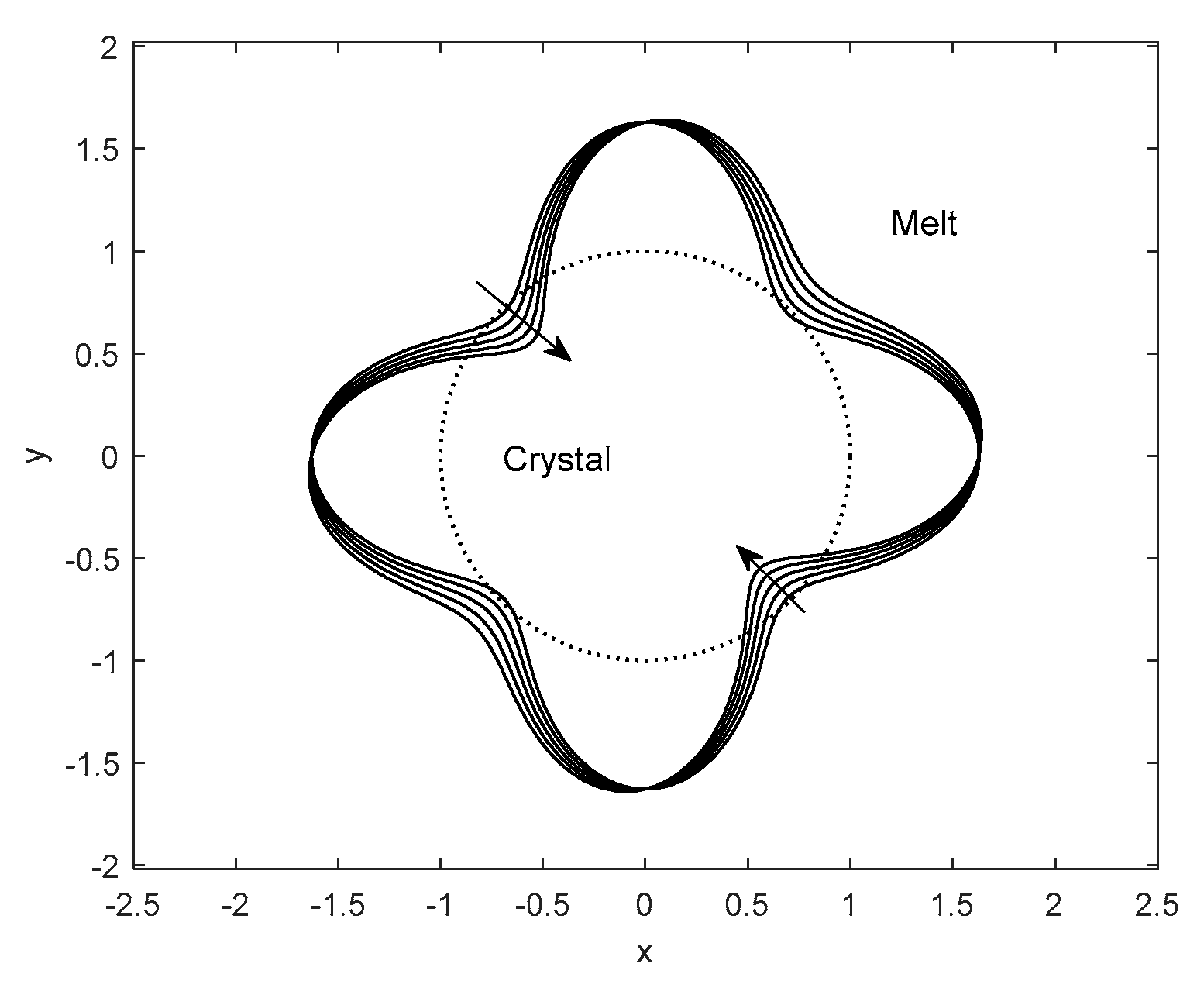

Figure 3 and

Figure 4 show the interface morphologies of a columnar crystal growing in an undercooled melt under the influence of an anisotropic interface energy and forced flow.

Figure 1 shows the cross-sectional curves of the interface morphology of a columnar crystal growing in an undercooled melt under the influence of anisotropic interface energy. It is seen that during the initial growth times from

to

, some part of the interface of the columnar crystal in the <110> growth directions decays inwardly, whereas the other part of the interface grows outwardly in the <100> preferred growth directions.

Figure 2 shows that when the inward decay proceeds up to a certain distance, the parts of the interface of the columnar crystal in the <110> growth directions begin to grow outwardly. During the initial growth process, the inward decay of the part of the interface induced by the anisotropic interface energy results in the smaller inner radius, which is less than the critical nucleation radius

. The local inward growth and outward growth of the columnar crystal deforms the interface of the columnar crystal and forms the remarkable ear-like interface shape with some parts concave and other parts convex. As the anisotropic interface energy parameters increase, the interface increases in the <100> preferred growth directions and decreases in the <110> growth directions. The columnar crystal with a smaller inner radius than the critical nucleation radius

tends to be locally re-melted or broken.

Figure 3 shows the interface morphology of the columnar crystal under the influence of the forced flow. When affected by the shear flow, the ‘ear-like’ interface shape of the columnar crystal induced by the anisotropic effect of the interface energy is deformed. As the shear rate increases, the ‘ear-like’ interface of the columnar crystal is distorted and recedes further inward near the angles of

, leading to the splitting tendency of the columnar crystal (as seen in

Figure 4). This phenomenon implies that the shear effect of the forced flow aggravates the local melting tendency that was caused by the possession of a smaller inner radius than the critical nucleation radius

, leading to the splitting of the distorted columnar crystal during the initial crystal growth to form finer crystals.

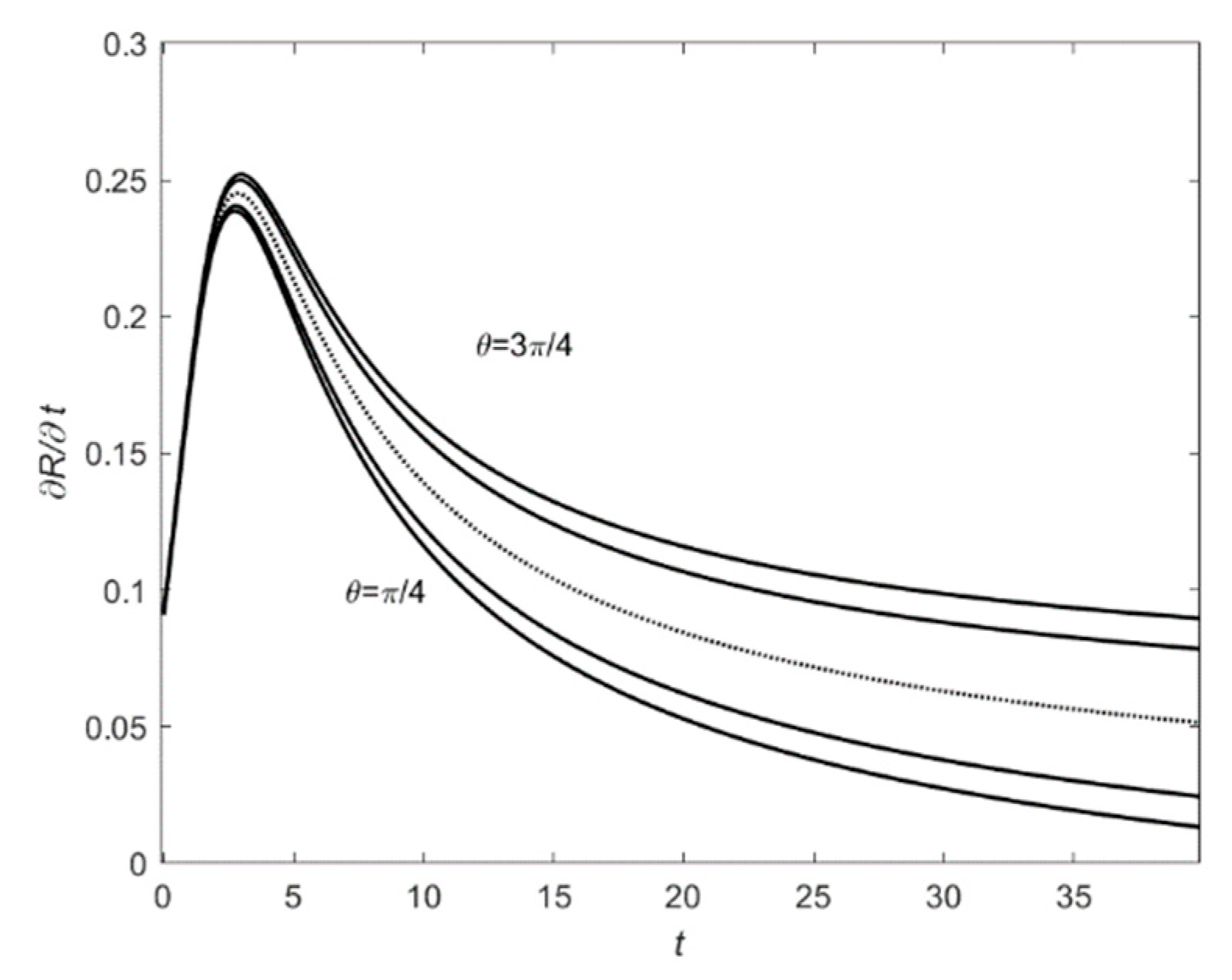

Figure 5 shows the variations in the interface growth velocity along different growth directions under the shear effect of the forced flow. The shear flow causes the different growth velocity of the interface at different growth directions, leading to the distortion of the interface. With the growth of the columnar crystal, the interface of the columnar crystal is further distorted. As a result, the interface of the columnar crystal tends to split into several smaller crystals.

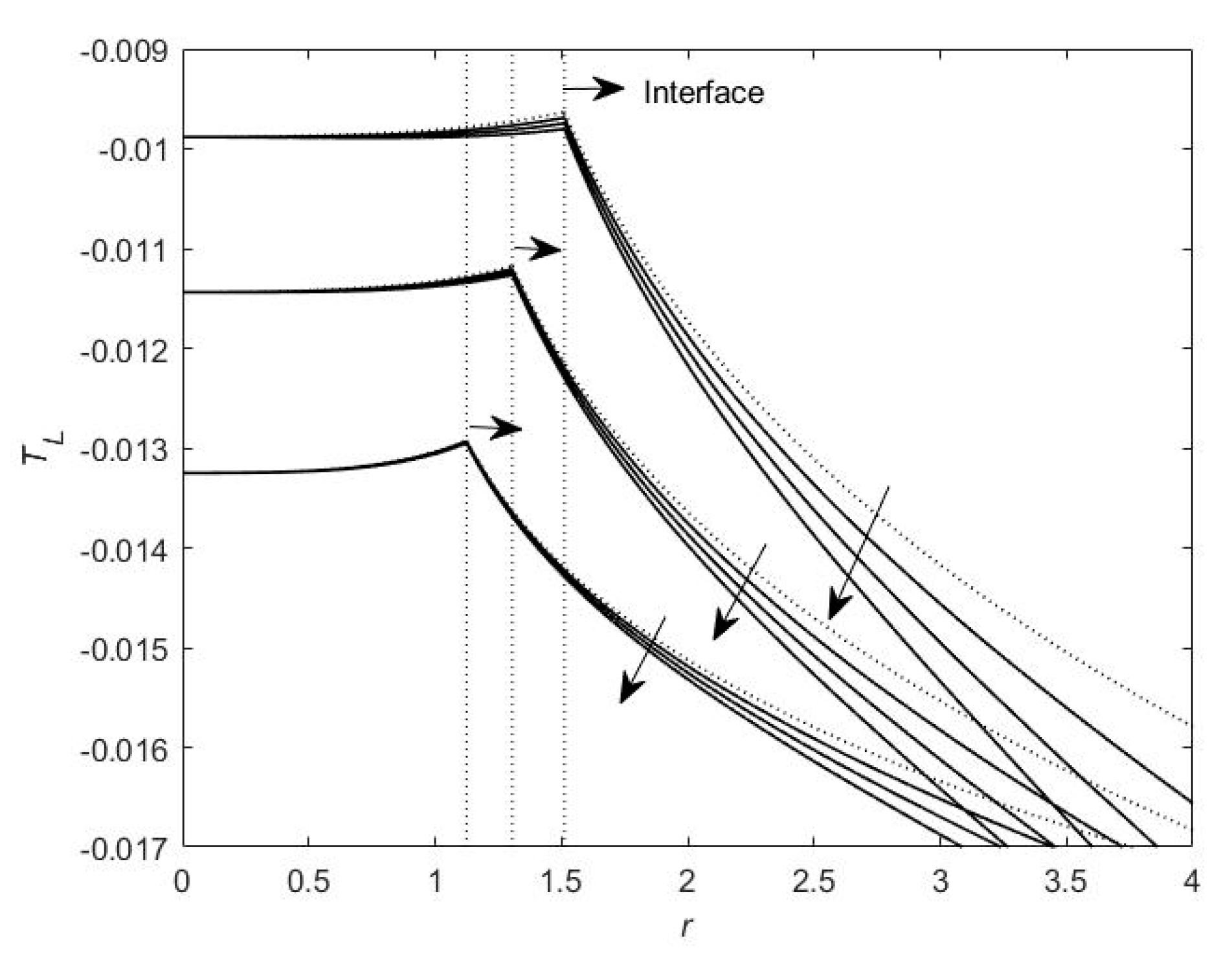

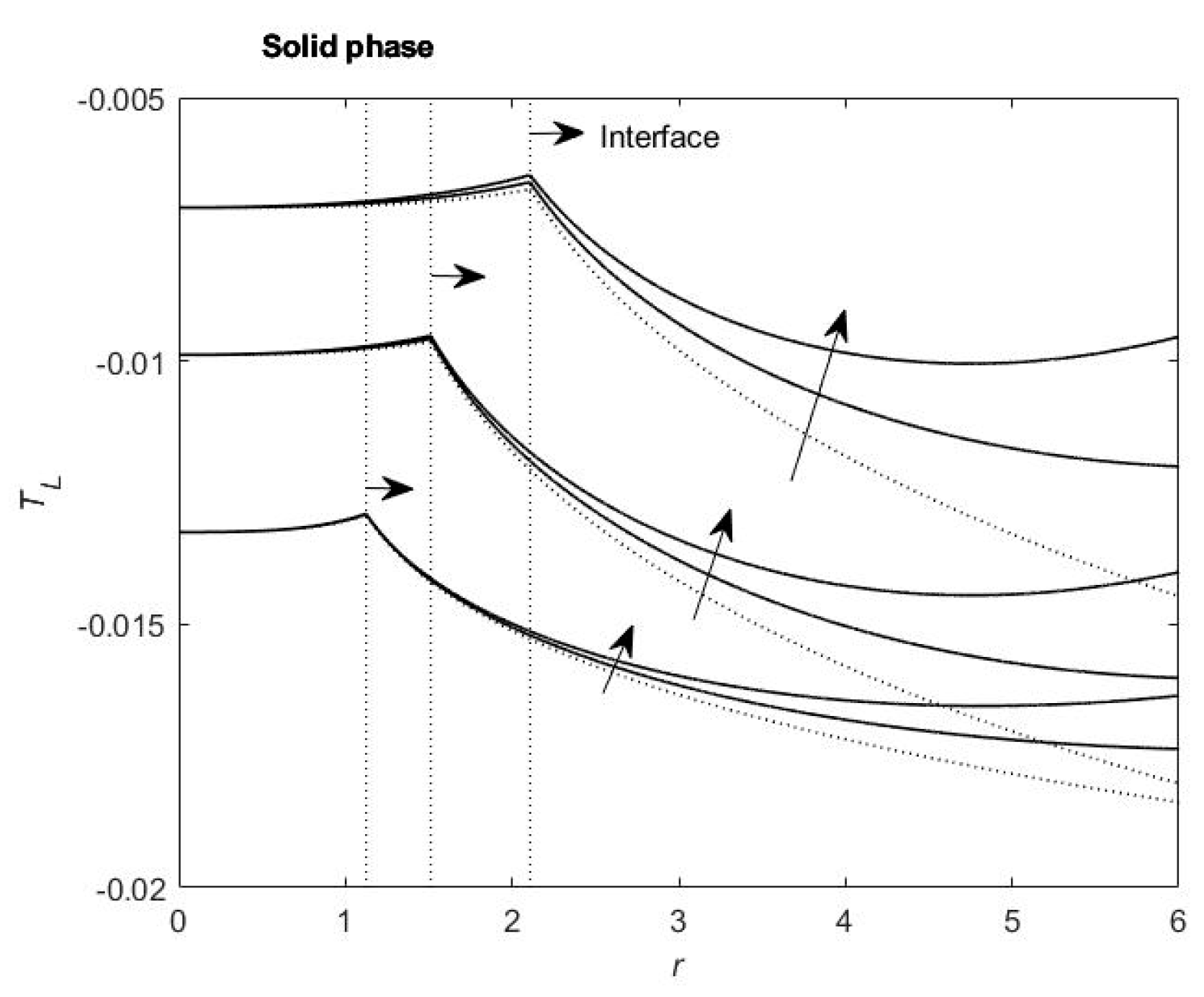

Figure 6 and

Figure 7 show the variations in the temperature near the interface along different growth directions under the shear effect of the forced flow at different times. It can be observed that along some growth directions (

Figure 6), the shear flow induces the larger interface temperature gradient, whereas along other growth directions (

Figure 7), it decreases the interface temperature gradient. The increase in the interface temperature gradient enhances the growth velocity of the interface, but the decrease in the interface temperature gradient depresses the growth velocity of the interface. Due to the shear flow around the columnar crystal, the temperature gradient along the direction from the polar angle causes the accelerated growth of some parts of the interface but the accelerated extrusion of other parts of the interface. When the growth of the columnar crystal (the interface where the arrows point) is oriented to the right, the interface of the columnar crystal is distorted. Since the inward growth of the interface in the initial stage of crystal growth led to a smaller inner radius than the critical nucleation radius of the columnar crystal

, the interface of the columnar crystal splits into multiple smaller crystals in the initial stage of crystal growth. Each split particle is of the same order of magnitude in the initial stage of crystal growth. Under the shear effect of the forced flow, they will continuously split until the end of solidification to refine the microstructures

As an application, we have conducted the calculation of the microstructural formation of the second phase nanoparticles in a centrifugal casting experiment of as-cast Cu–Fe–Co alloys [

6,

7,

9]. The relevant physical parameters are as follows: the equilibrium temperature of Fe

K, the solidification equilibrium temperature of Cu is taken as

K, the latent heat per unit volume of Fe

J m

−3, the surface tension of Fe is

J m

−2, the density of Fe

kg m

−3, the specific heat of Fe

J kg

−1 K

−1, the sound velocity

m s

−1, the mole mass fraction of Fe

kg mol

−1, the gas constant

J kg

−1 K

−1, the kinetic coefficient of Fe:

m s

−1 K

−1, the anisotropy parameter of interface kinetics is taken as

β = 0.25; and the melt on a disk below it rotates at 300 rpm. From the heat preservation to the end of solidification, the undercooling near the surface of the Fe particles in the matrix of a Cu alloy is in the range of 110~375 K; the critical radius for nucleation

is in the range of 0.33~0.85 nm. According to our theoretical result, the relative undercooling parameter

is in the range of 0.20~0.58; the nanoparticles formed in the Cu–Fe–Co alloy melt are of the same order of magnitude as the critical radius for nucleation. Since the anisotropy of the interface kinetics induces the local inward growth of the nuclei after nucleation, the nuclei have radii less than the critical radius of nucleation

and thus tend to split. Under the shear effect of the forced flow, the nuclei are deformed and distorted. As a result, the interface of the particle splits or is broken into multiple finer particles in the initial stage of growth after nucleation. The finer particles repeat the same process to form particles at a nano scale. We should understand that even if one nucleus has split into several smaller particles in the melt, it is hard to judge whether these smaller particles have just split from this particle. By contrast, it was observed that if the shear flow is not exerted in the melt, the dispersed iron nano particles’ second phase and nano grains are difficult to obtain in the Cu–Fe–Co alloy matrix [

6,

9].