Use of Numerical Methods for the Design of Thermal Protection of an RFID-Based Contactless Identification System of Ladles

Abstract

1. Introduction

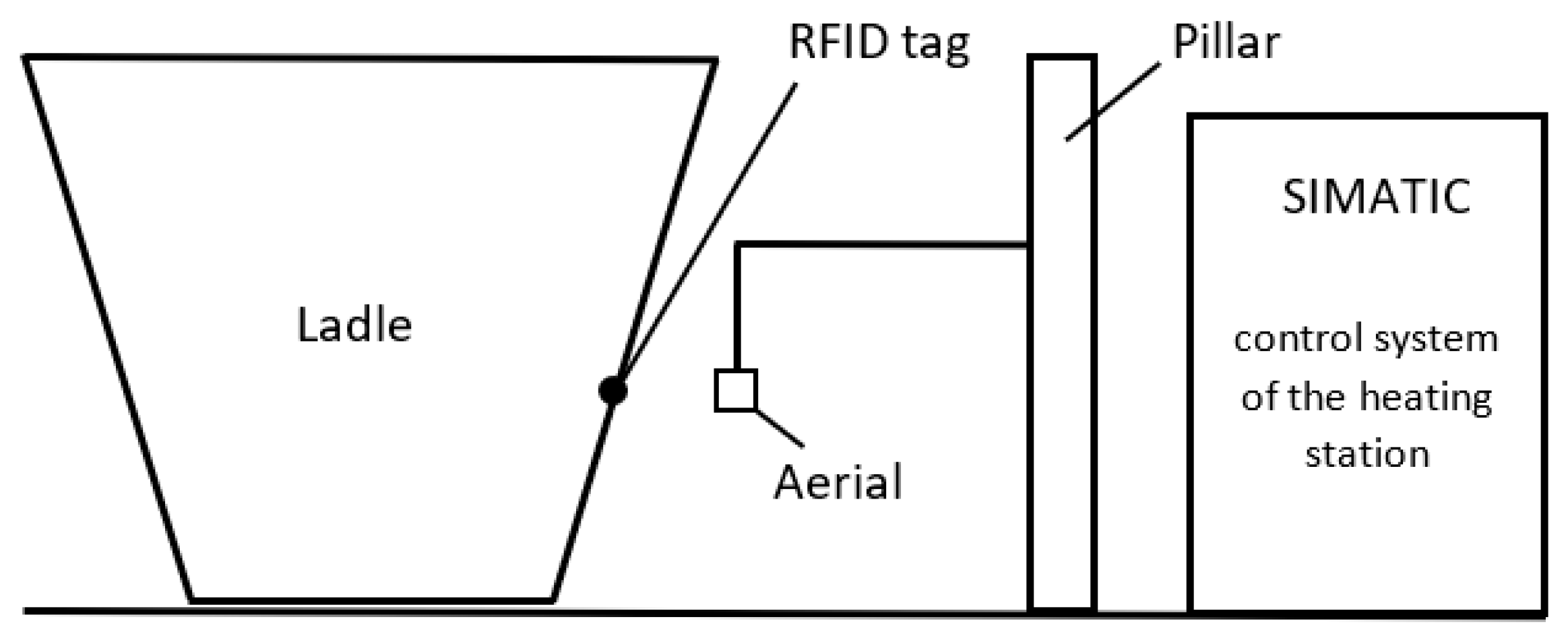

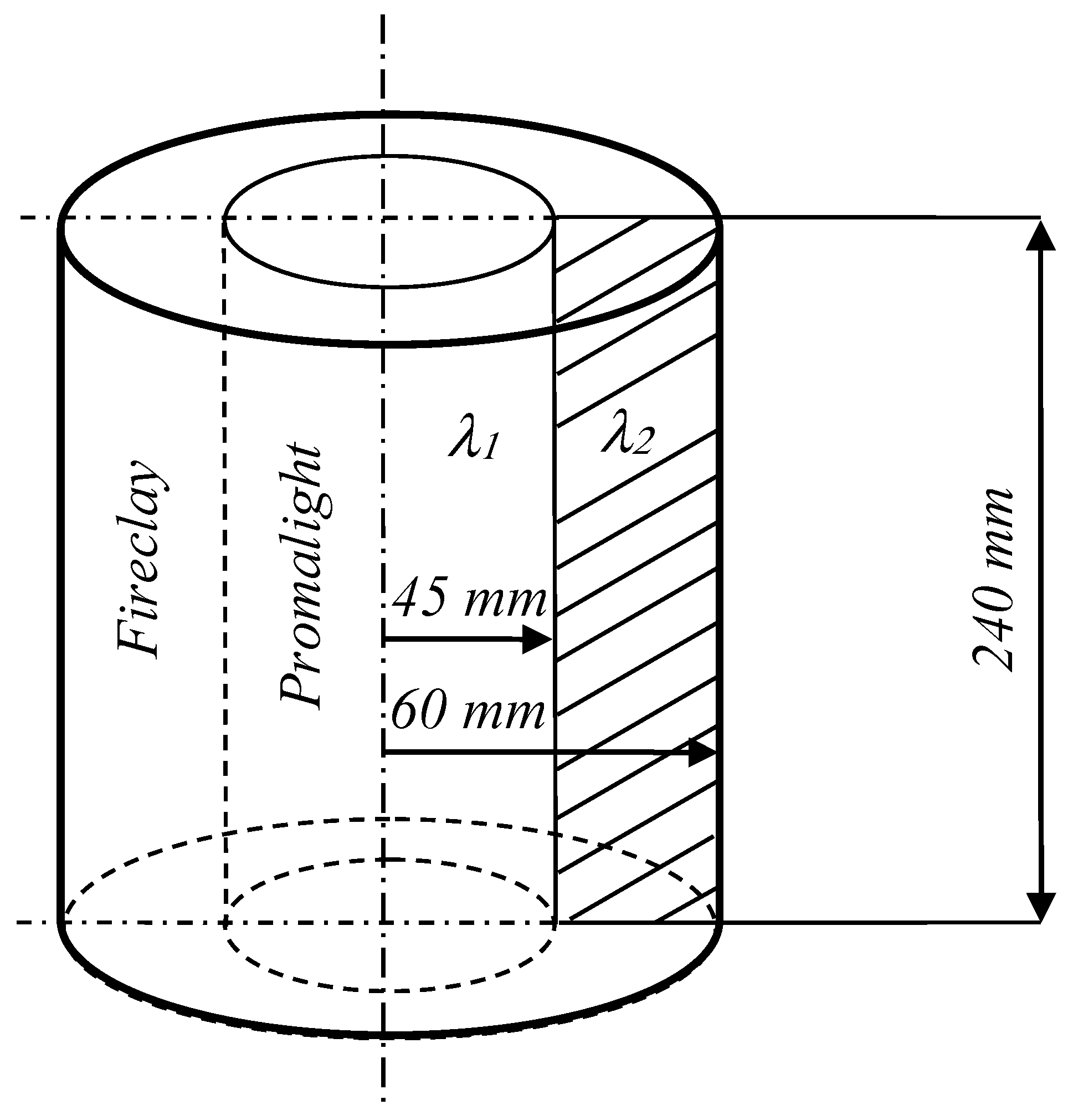

2. Materials and Methods

3. Results

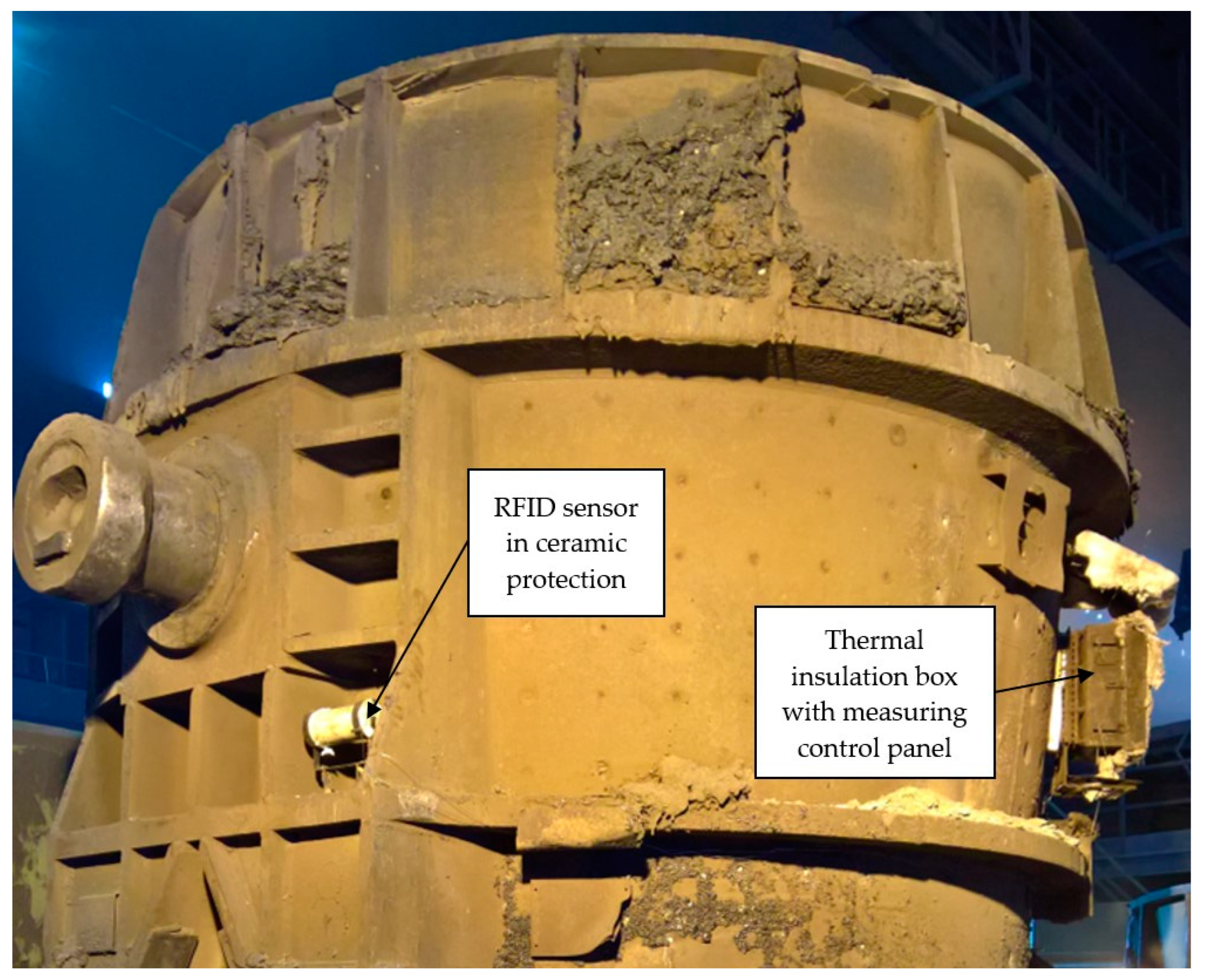

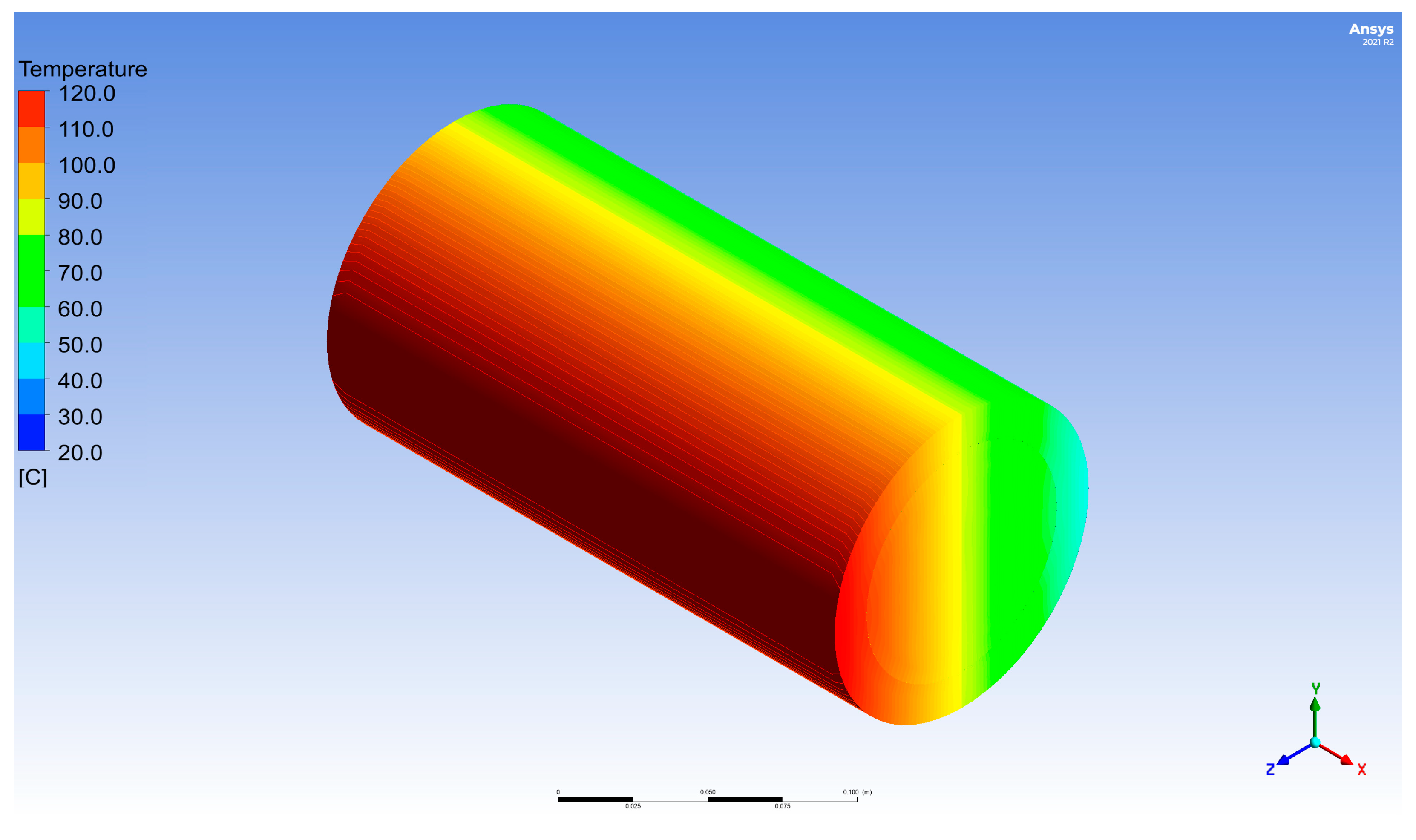

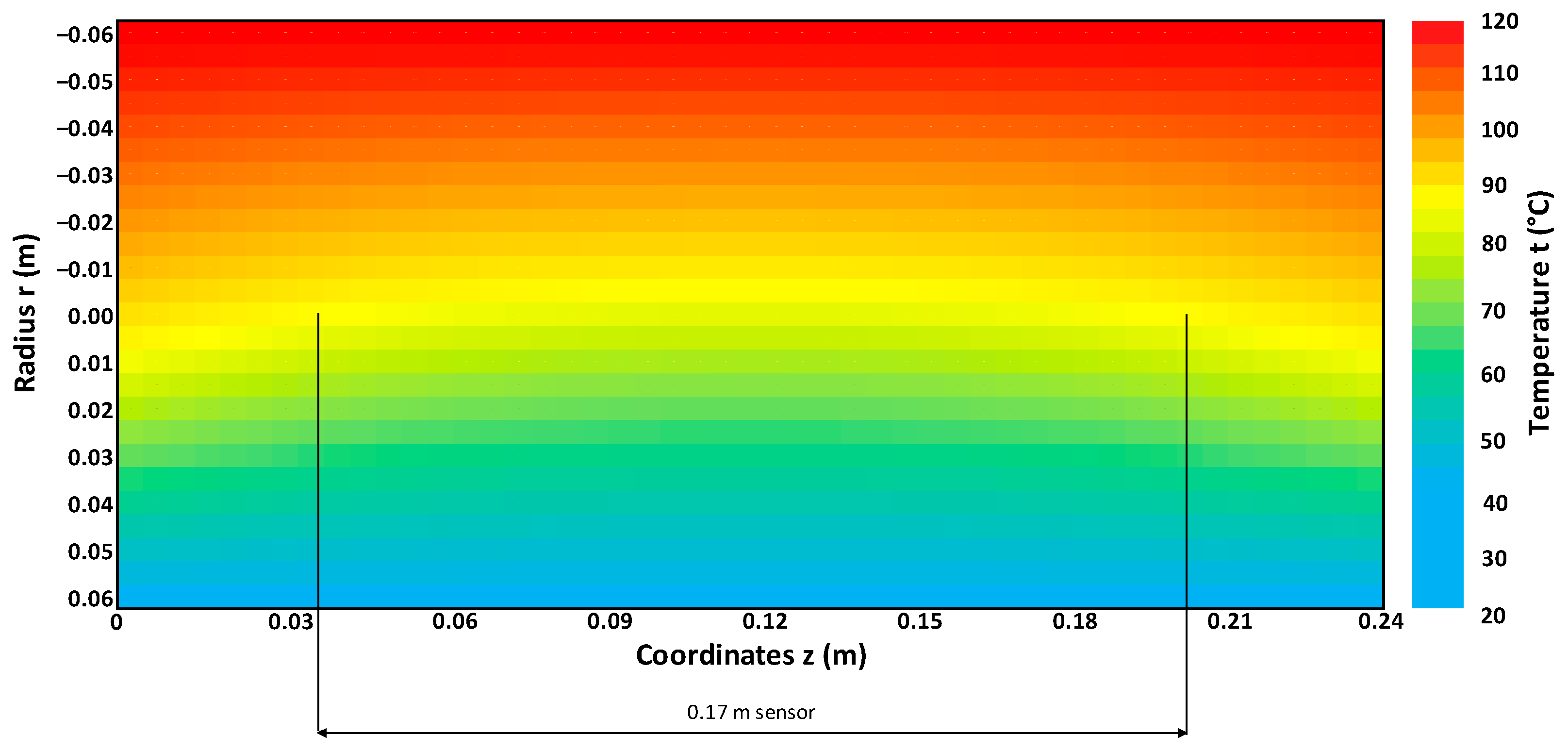

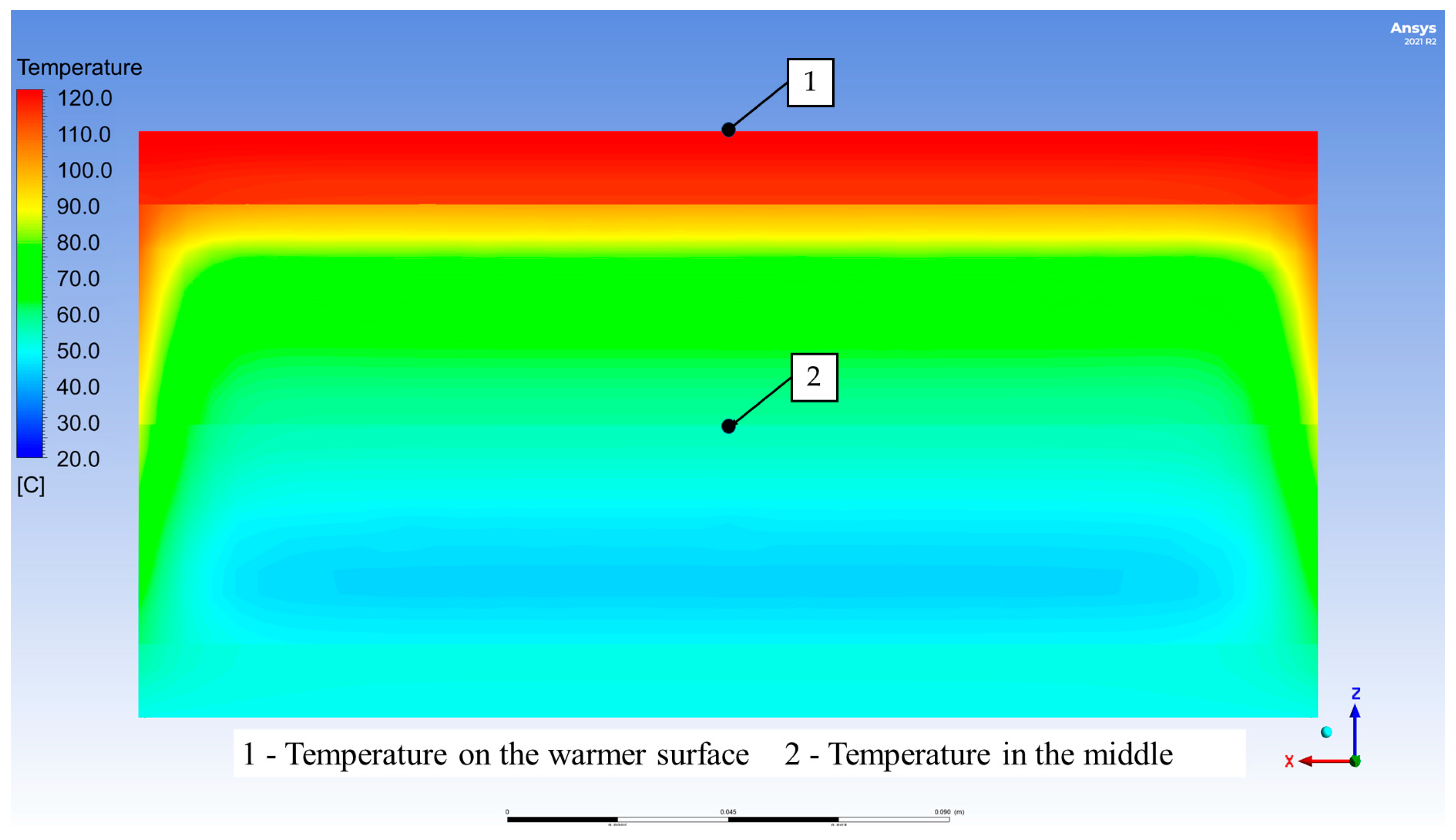

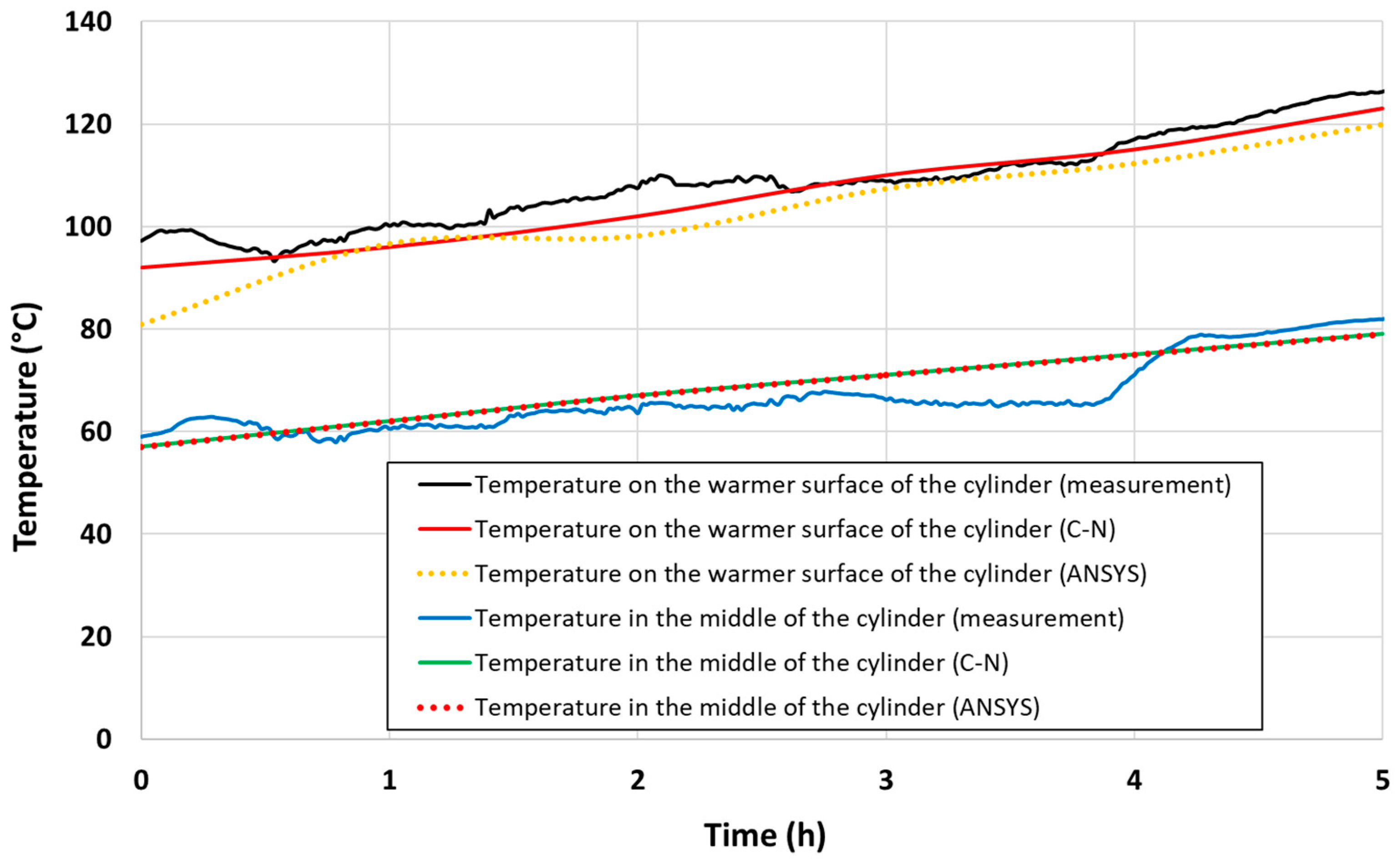

3.1. Verification of the Usability of the Numerical Simulations in Operating Conditions

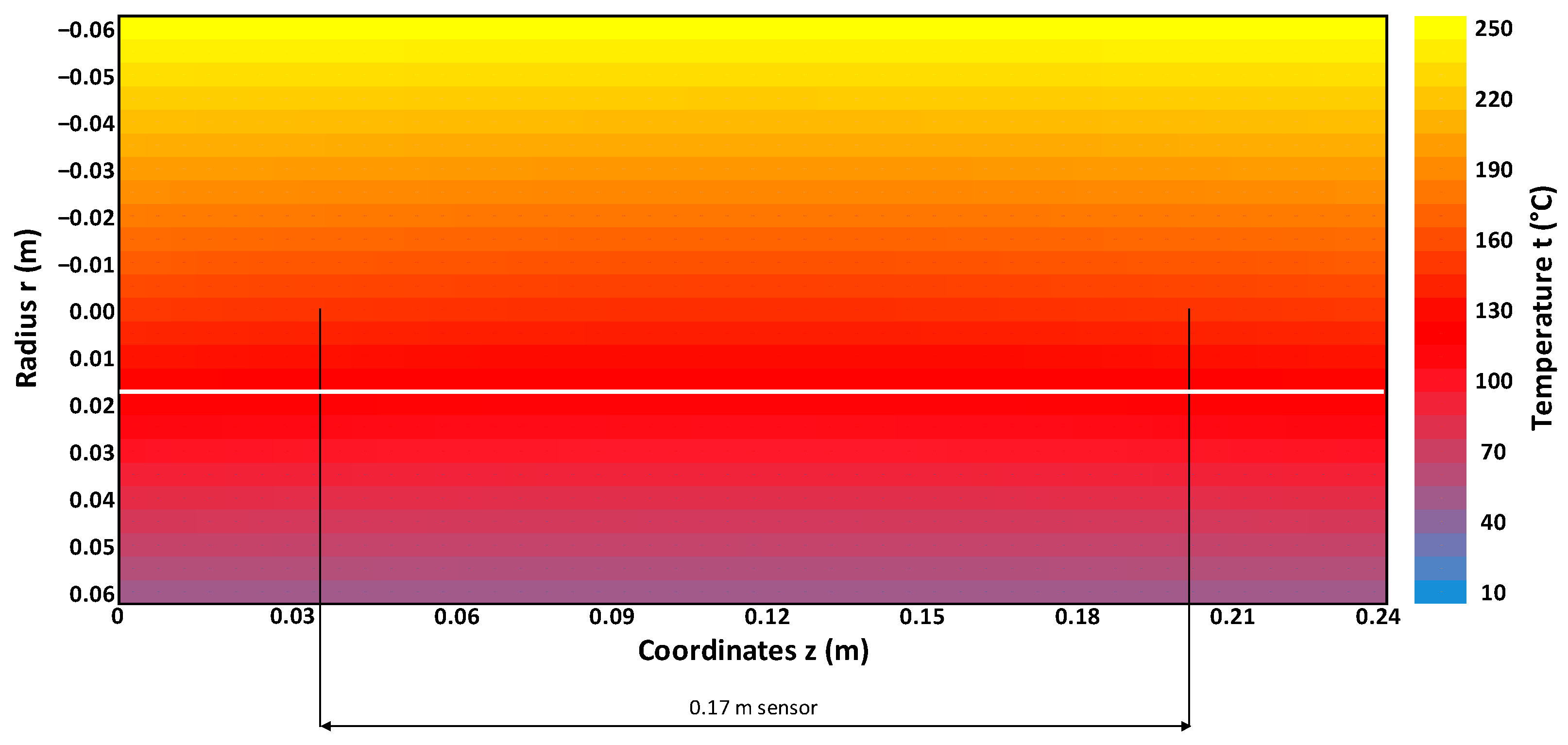

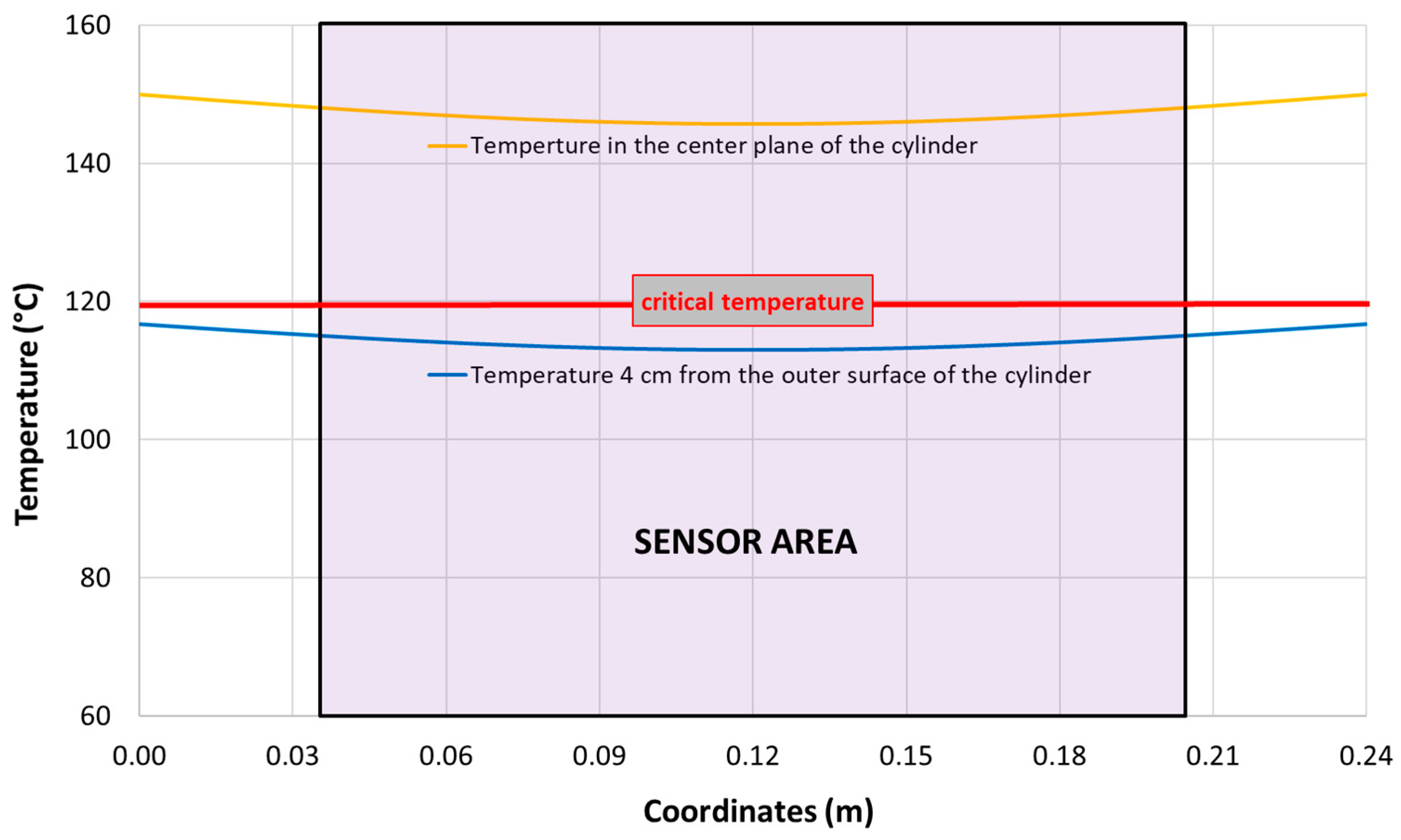

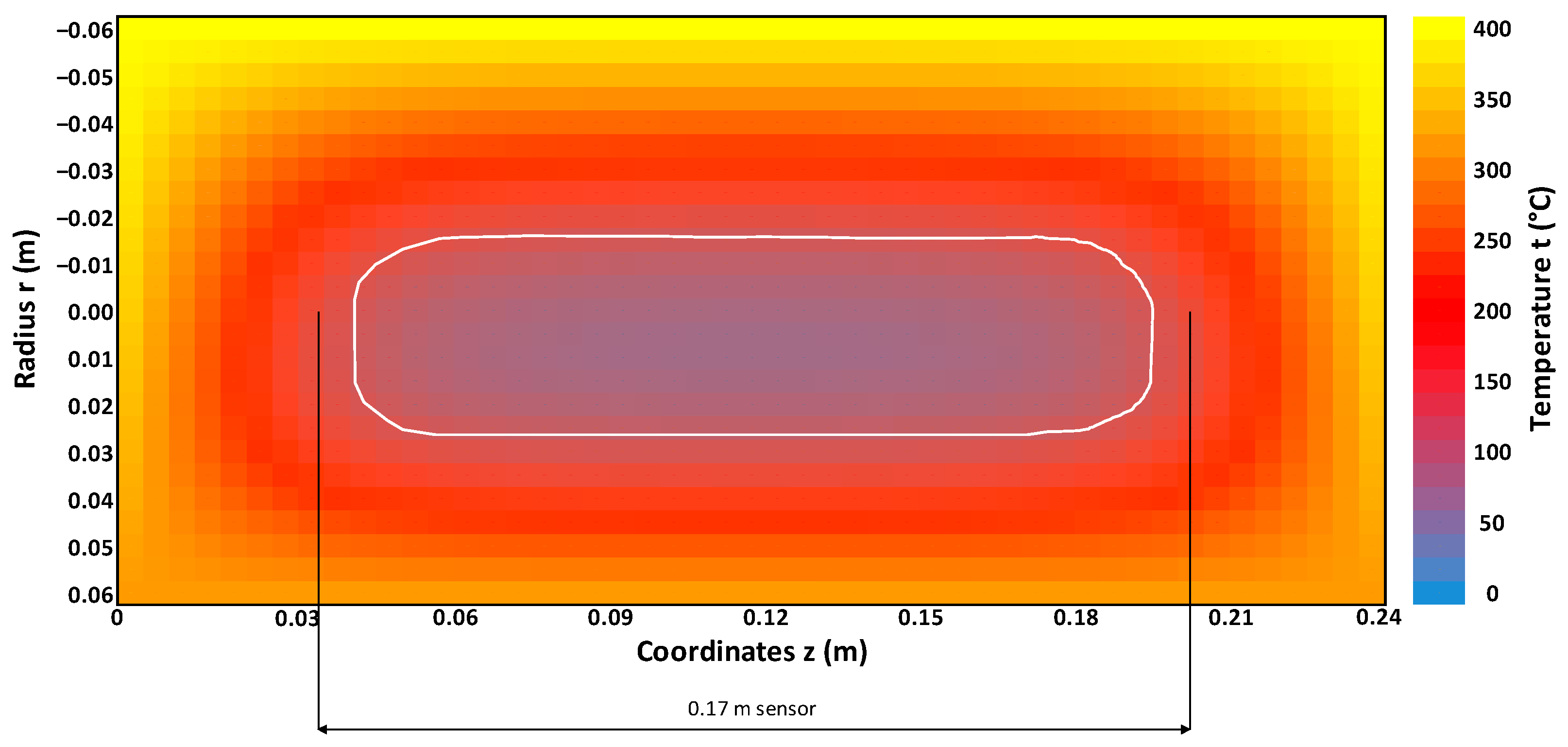

3.2. Numerical Simulations during the Ladle Work Campaign

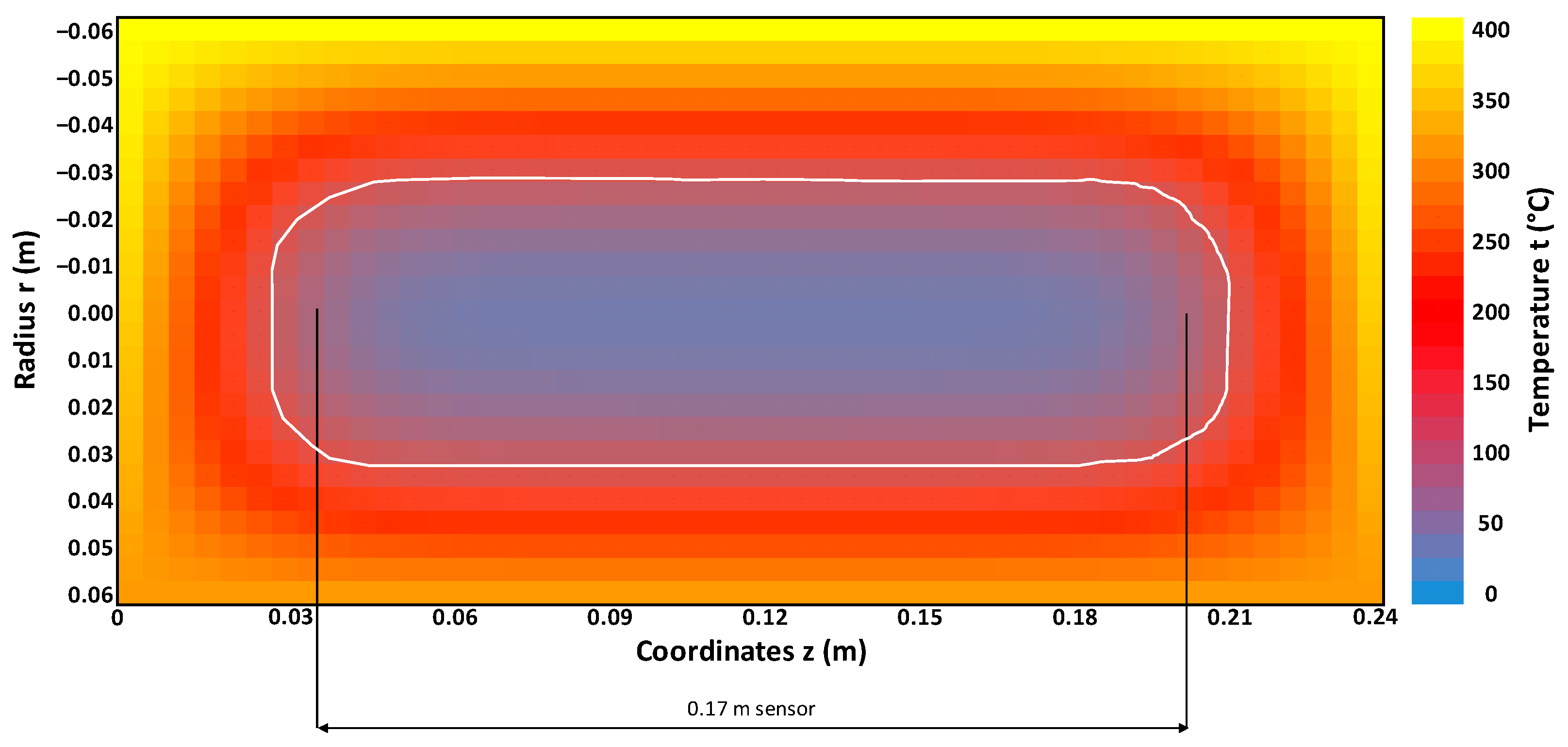

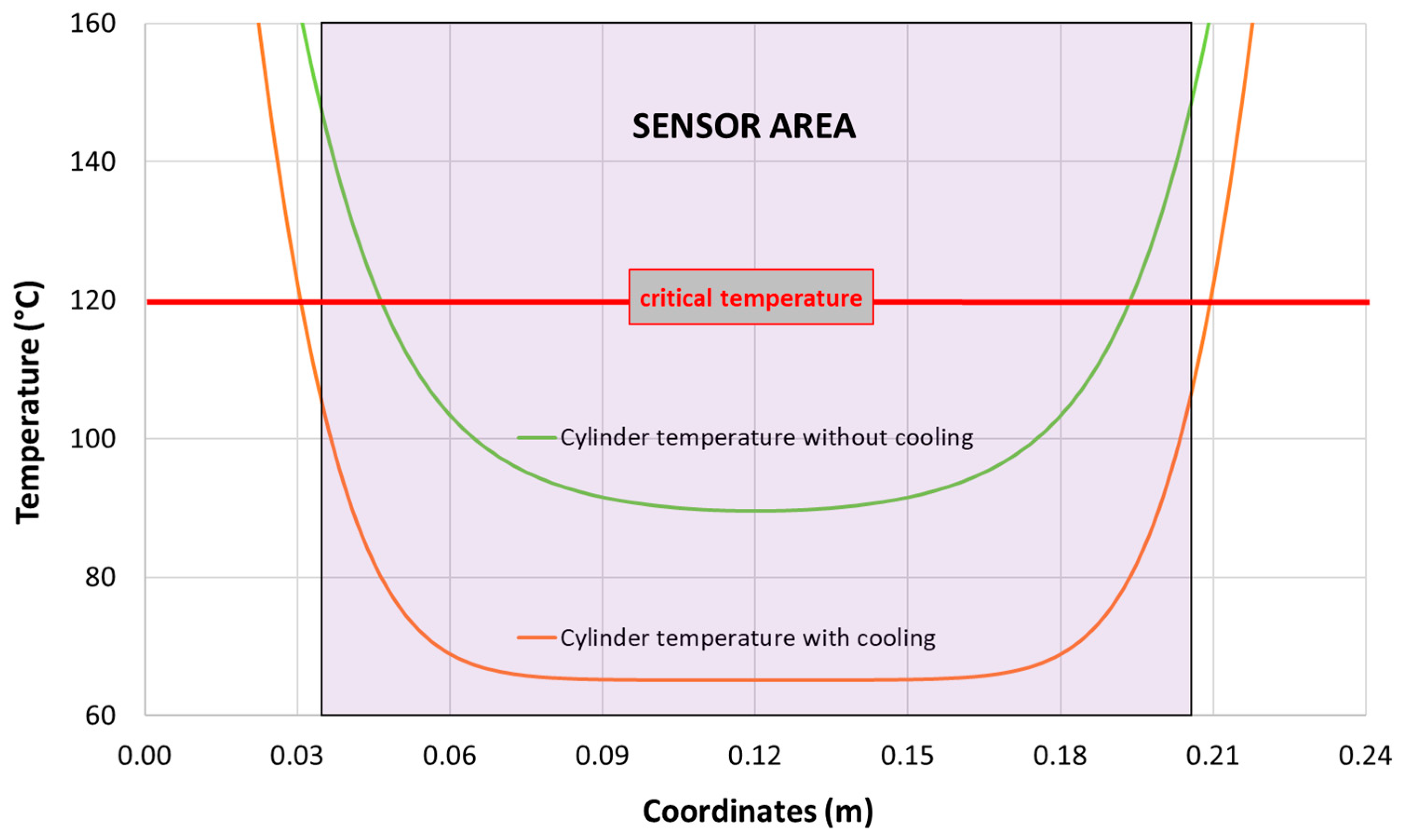

3.3. Numerical Simulations for Caisson Vacuum Stations

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Siddiqui, M.I.H.; Kim, M.-H. Two-Phase Numerical Modeling of Grade Intermixing in a Steelmaking Tundish. Metals 2019, 9, 40. [Google Scholar] [CrossRef]

- Jančar, D.; Klárová, M.; Tvardek, P.; Vlček, J.; Hašek, P.; Ovčačík, F. Utilization of casting ladle lining enthalpy for heating gas saving in the course of ladle preheating. Metalurgija 2014, 53, 159–162. Available online: https://hrcak.srce.hr/110059 (accessed on 1 June 2022).

- Balog, M.; Szilágyi, E.; Dupláková, D.; Minďaš, M. Effect verification of external factor to readability of RFID transponder using least square method. Measurement 2016, 94, 233–238. [Google Scholar] [CrossRef]

- Chen, H.; Chen, Y.; Yang, L. Intelligent early structural health prognosis with nonlinear system identification for RFID signal analysis. Comput. Commun. 2020, 157, 150–161. [Google Scholar] [CrossRef]

- Hardi, E.; Veigt, M.; Koerdt, M.; Herrmann, A.S.; Freitag, M. Monitoring of the vacuum infusion process by integrated RFID transponder. Procedia Manuf. 2020, 52, 20–25. [Google Scholar] [CrossRef]

- Deng, F.; Wen, K.; Zeng, H.; Xie, Z. Novel metal-oxide arrester monitoring technology based on RFID sensor and mind evolutionary computation. Electr. Power Syst. Res. 2021, 192, 106859. [Google Scholar] [CrossRef]

- Duan, K.-K.; Cao, S.-Y. Emerging RFID technology in structural engineering—A review. Structures 2020, 28, 2404–2414. [Google Scholar] [CrossRef]

- Zhang, Y.; Bai, L. Rapid structural condition assessment using radio frequency identification (RFID) based wireless strain sensor. Autom. Constr. 2015, 54, 1–11. [Google Scholar] [CrossRef]

- El Masri, I.; Lescop, B.; Talbot, P.; Vien, G.N.; Becker, J.; Thierry, D.; Rioual, S. Development of a RFID sensitive tag dedicated to the monitoring of the environmental corrosiveness for indoor applications. Sens. Actuators B Chem. 2020, 322, 128602. [Google Scholar] [CrossRef]

- Tatiparthi, S.R.; De Costa, Y.G.; Whittaker, C.N.; Hu, S.; Yuan, Z.; Zhong, R.Y.; Zhuang, W.-Q. Development of radio-frequency identification (RFID) sensors suitable for smart-monitoring applications in sewer systems. Water Res. 2021, 198, 117107. [Google Scholar] [CrossRef]

- Jančar, D.; Tvardek, P.; Machů, M.; Velička, M.; Vlček, J.; Ovčačíková, H. Design of protection of contactless identification system for ladles. In Proceedings of the 39th Meeting of Departments of Fluid Mechanics and Thermodynamics, Horní Bečva, Czech Republic, 13–15 October 2021. [Google Scholar]

- Chaskalovic, J. Mathematical and Numerical Methods for Partial Differential Equations. Applications for Engineering Sciences, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 1–372. [Google Scholar]

- Woodford, C.; Phillips, C. Numerical Methods with Worked Examples: Matlab Edition, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 1–266. [Google Scholar]

- Zhu, J.; Lin, W. Efficient Computation of Heat Distribution of Processed Materials under Laser Irradiation. Mathematics 2021, 9, 1368. [Google Scholar] [CrossRef]

- Fredman, T. A model for rapid computation of dynamic heat conduction in steelmaking ladle linings. IFAC Proc. 2000, 33, 369–373. [Google Scholar] [CrossRef]

- Phanomchoeng, G.; Chantranuwathana, S.; Charunyakorn, P. On line Ladle Lining Temperature Estimationby Using Bounded Jacobian Nonlinear Observe. J. Iron Steel Res. Int. 2016, 23, 792–799. [Google Scholar] [CrossRef]

- Li, L.; Li, X.; Zhu, Z.; Li, B. Numerical modeling of multiphase flow in gas stirred ladles: From a multiscale point of view. Powder Technol. 2020, 373, 14–25. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, P.; Yuan, F. Effects of ladle lid or online preheating on heat preservation of ladle linings and temperature drop of molten steel. Energy 2021, 214, 118896. [Google Scholar] [CrossRef]

- Lu, B.; Meng, X.; Zhu, M. Numerical analysis for the heat transfer behavior of steel ladle as the thermoelectric waste-heat source. Catal. Today 2018, 318, 180–190. [Google Scholar] [CrossRef]

- Damhofa, F.; Brekelmansb, W.A.M.; Geers, M.G.D. Predictive FEM simulation of thermal shock damage in the refractory lining of steelmaking installations. J. Mater. Processing Technol. 2011, 211, 2091–2105. [Google Scholar] [CrossRef]

- Hahn, D.W.; Özişik, M.N. Heat Conduction, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2012; pp. 1–752. [Google Scholar]

- Kalbasi, R.; Alaeddin, S.M.; Akbari, M.; Afrand, M. Analytical Solution of Heat Conduction in a Symmetrical Cylinder Using the Solution Structure Theorem and Superposition Technique. Symmetry 2019, 11, 1522. [Google Scholar] [CrossRef]

- Kulacki, F.A. Handbook of Thermal Science and Engineering, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1–3075. [Google Scholar]

- Brenn, G. Analytical Solutions for Transport Processes: Fluid Mechanics, Heat and Mass Transfer, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2017; p. 315. [Google Scholar]

- Mori, C.N.T.; Romão, E.C. Numerical simulation by finite difference method of 2D convection-diffusion in cylindrical coordinates. Appl. Math. Sci. 2015, 9, 6157–6165. [Google Scholar] [CrossRef][Green Version]

- Taler, J.; Duda, P. Solving Direct and Inverse Heat Conduction Problems, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2006; pp. 1–915. [Google Scholar]

- López-Cornejo, M.S.; Vergara-Hernández, H.J.; Arreola-Villa, S.A.; Vázquez-Gómez, O.; Herrejón-Escutia, M. Numerical Simulation of Wire Rod Cooling in Eutectoid Steel under Forced-Convection. Metals 2021, 11, 224. [Google Scholar] [CrossRef]

- Joachimiak, M. Analysis of Thermodynamic Parameter Variability in a Chamber of a Furnace for Thermo-Chemical Treatment. Energies 2021, 14, 2903. [Google Scholar] [CrossRef]

- Selmer, I.; Farrell, P.; Smirnova, I.; Gurikov, P. Comparison of Finite Difference and Finite Volume Simulations for a Sc-Drying Mass Transport Model. Gels 2020, 6, 45. [Google Scholar] [CrossRef]

- Idelsohn, S.R. Numerical Simulations of Coupled Problems in Engineering, 1st ed.; Springer: Cham, Switzerland, 2014; pp. 1–422. [Google Scholar]

| Material | Density (kg m−3) | Thermal CONDUCTIVITY at 200 °C (W/m·K) | Specific Heat Capacity at 200 °C (J/kg·K) | Refractoriness (°C) | Crushing Strength (N/mm2) |

|---|---|---|---|---|---|

| Promalight 1000 | 280 | 0.022 | 875 | 1000 | 0.32 |

| Fireclay | 1950 | 0.965 | 846 | 1740 | 10.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jančar, D.; Machů, M.; Velička, M.; Tvardek, P.; Vlček, J. Use of Numerical Methods for the Design of Thermal Protection of an RFID-Based Contactless Identification System of Ladles. Metals 2022, 12, 1163. https://doi.org/10.3390/met12071163

Jančar D, Machů M, Velička M, Tvardek P, Vlček J. Use of Numerical Methods for the Design of Thermal Protection of an RFID-Based Contactless Identification System of Ladles. Metals. 2022; 12(7):1163. https://doi.org/10.3390/met12071163

Chicago/Turabian StyleJančar, Dalibor, Mario Machů, Marek Velička, Petr Tvardek, and Jozef Vlček. 2022. "Use of Numerical Methods for the Design of Thermal Protection of an RFID-Based Contactless Identification System of Ladles" Metals 12, no. 7: 1163. https://doi.org/10.3390/met12071163

APA StyleJančar, D., Machů, M., Velička, M., Tvardek, P., & Vlček, J. (2022). Use of Numerical Methods for the Design of Thermal Protection of an RFID-Based Contactless Identification System of Ladles. Metals, 12(7), 1163. https://doi.org/10.3390/met12071163