Influence of Wire Geometry on the Mechanical Behavior of the TiNi Design

Abstract

1. Introduction

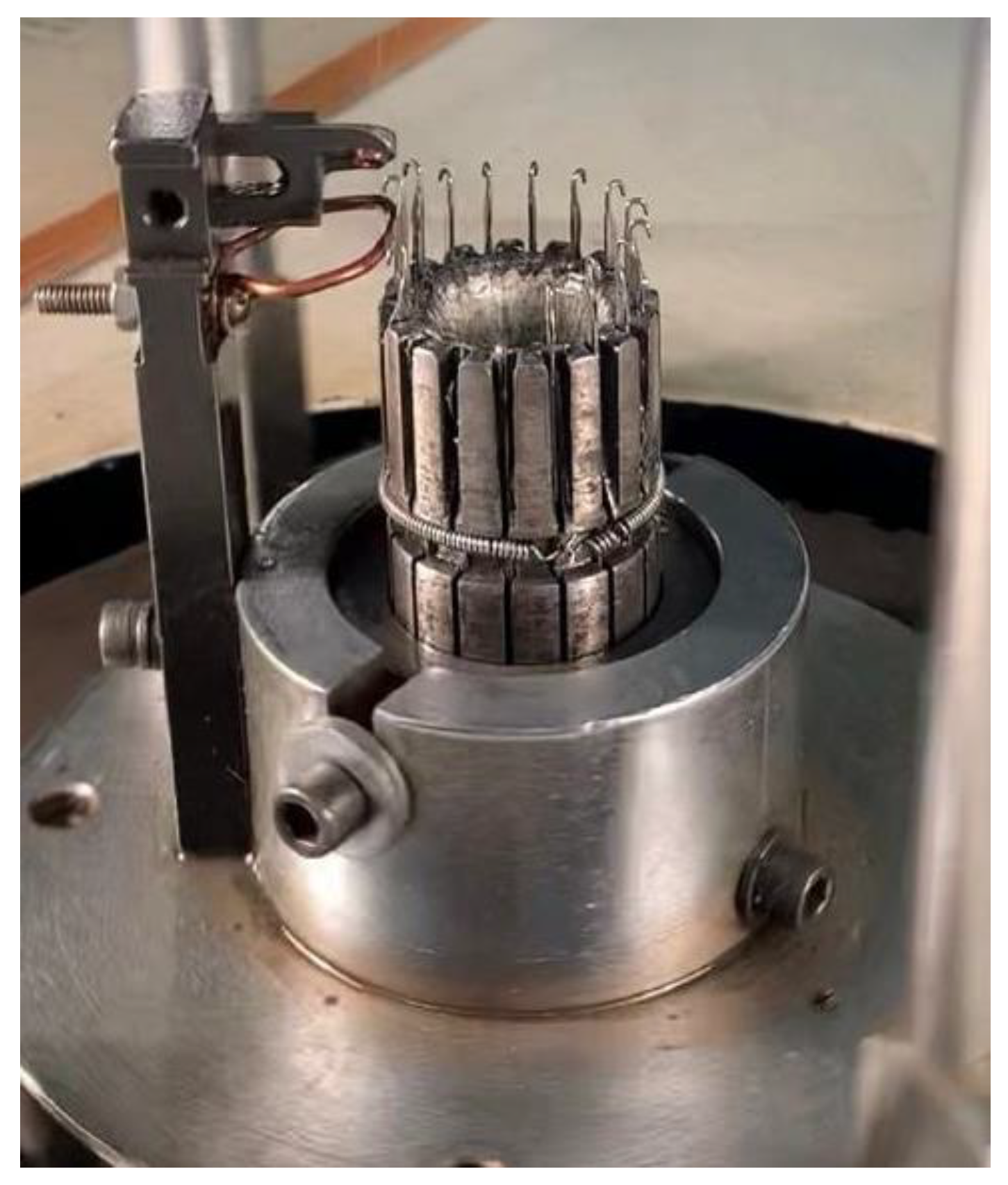

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results

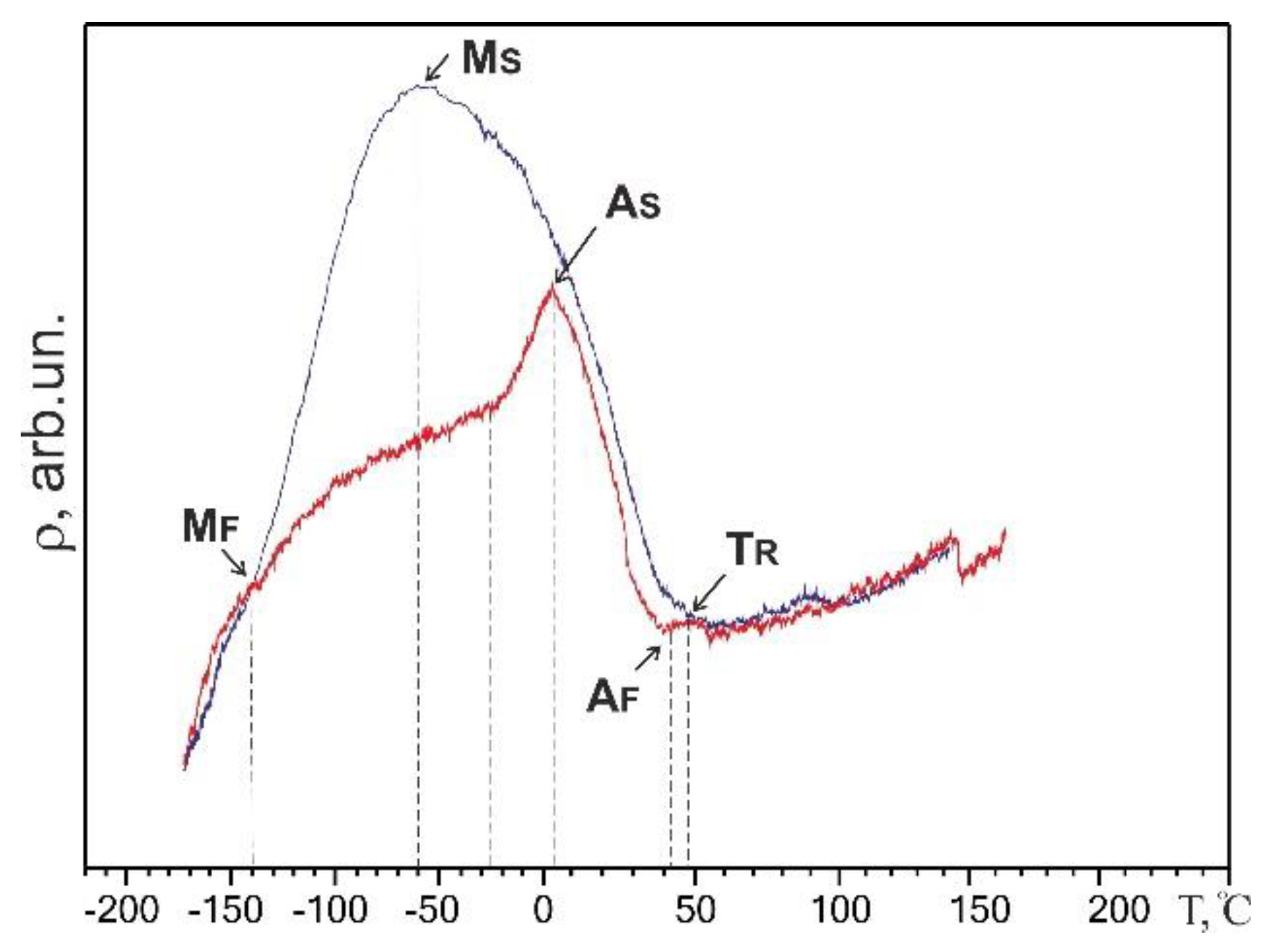

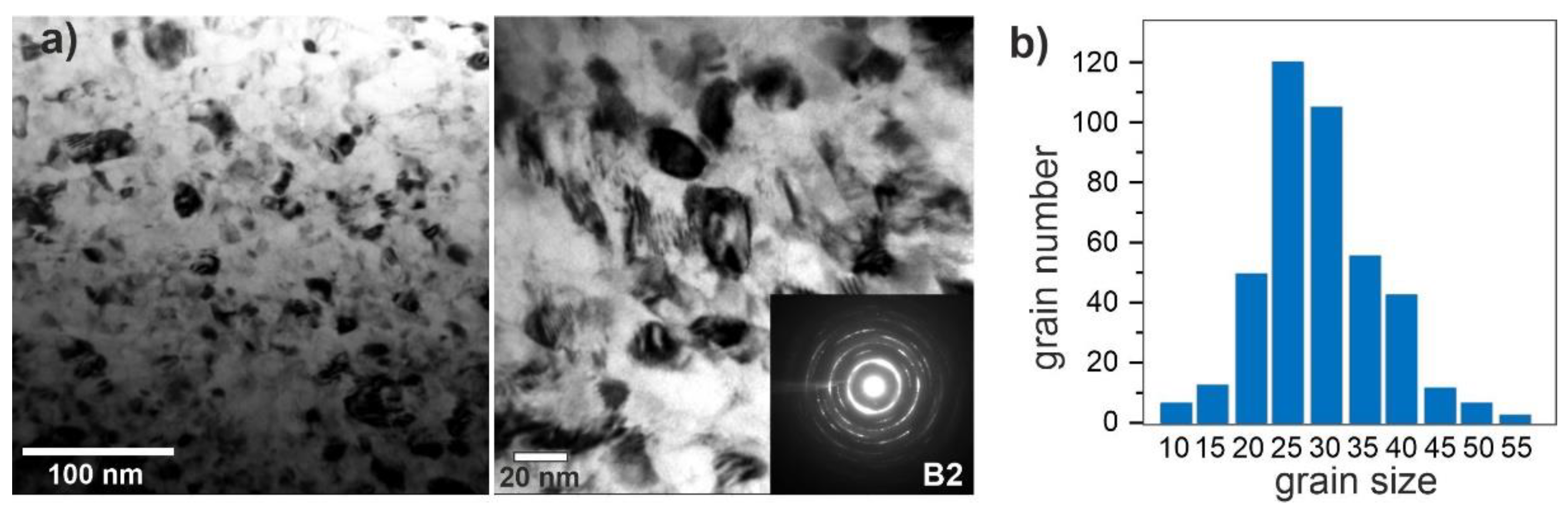

3.1. TiNi Wire Tests and Characterization

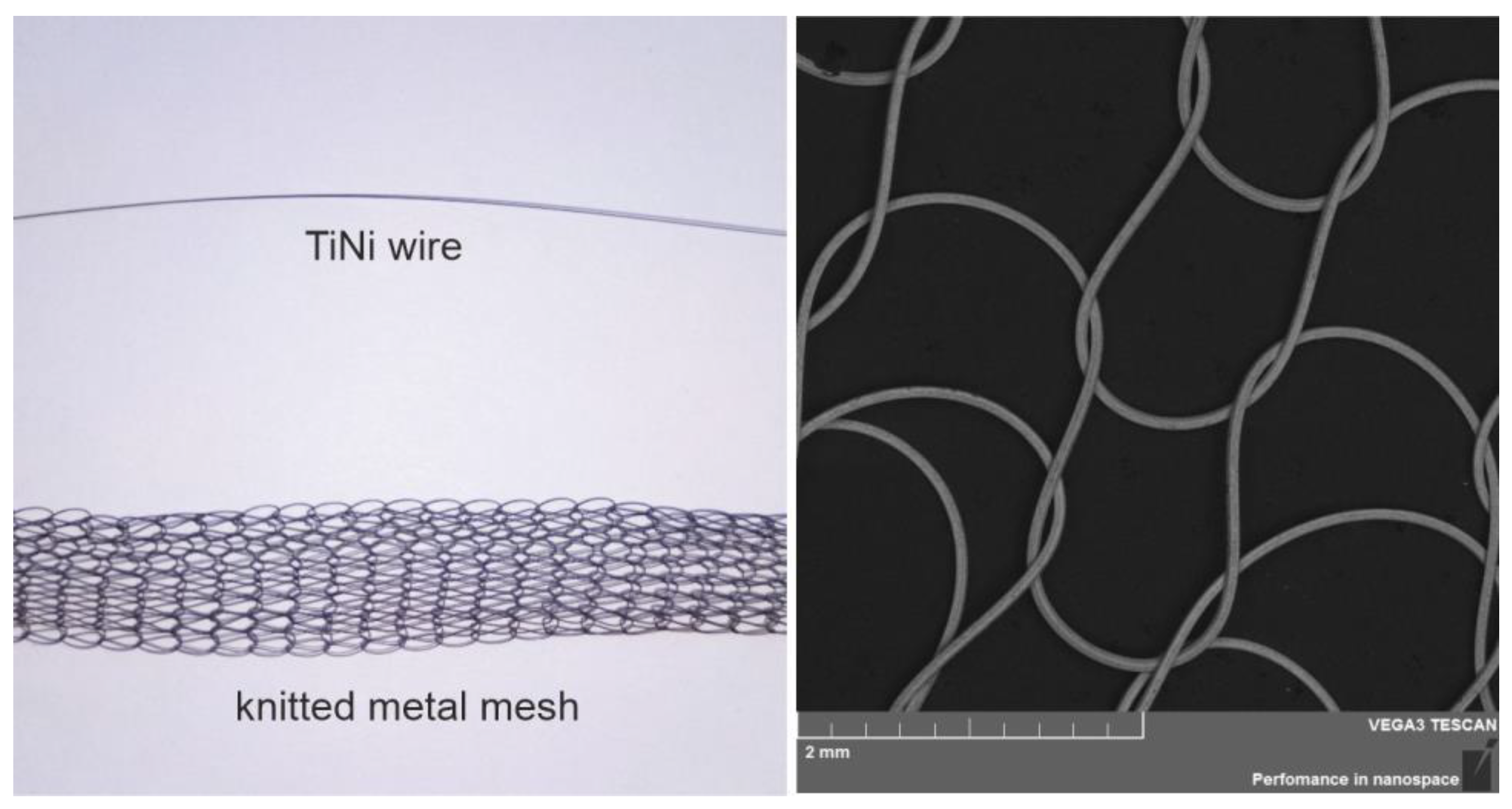

3.2. Knitted TiNi Mesh Tests and Characterization

4. Conclusions

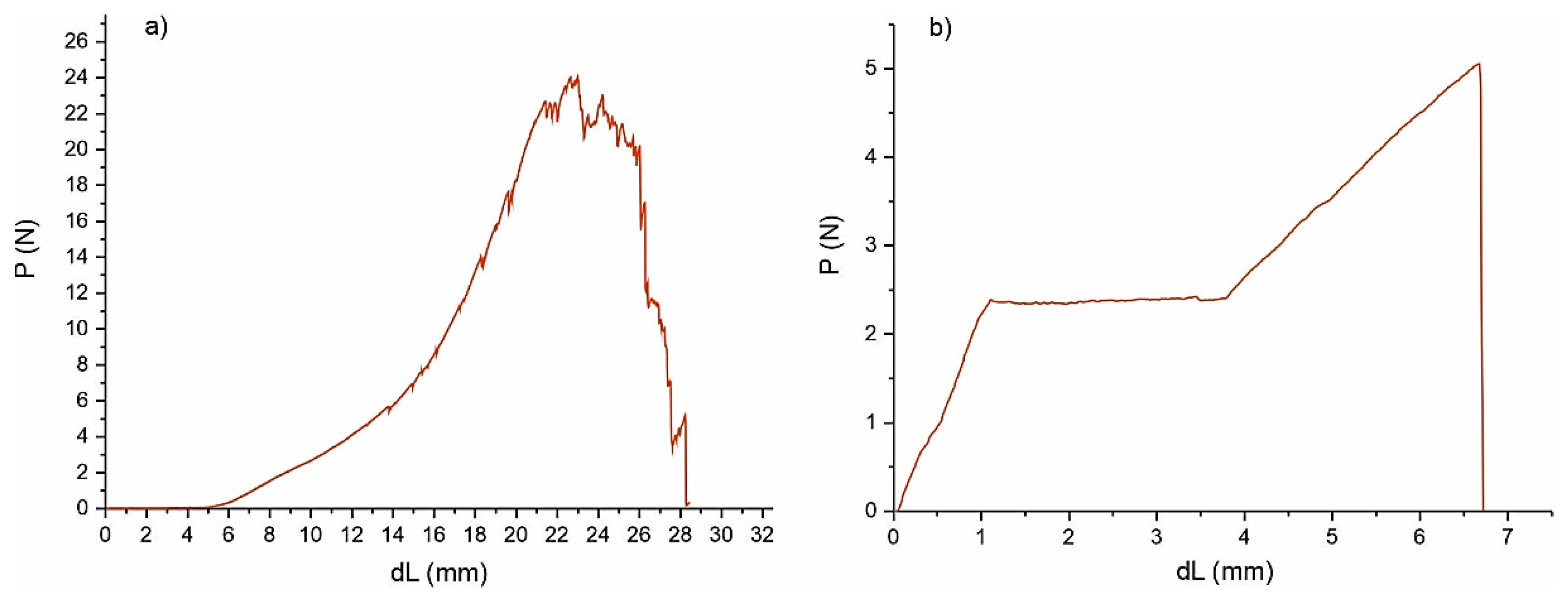

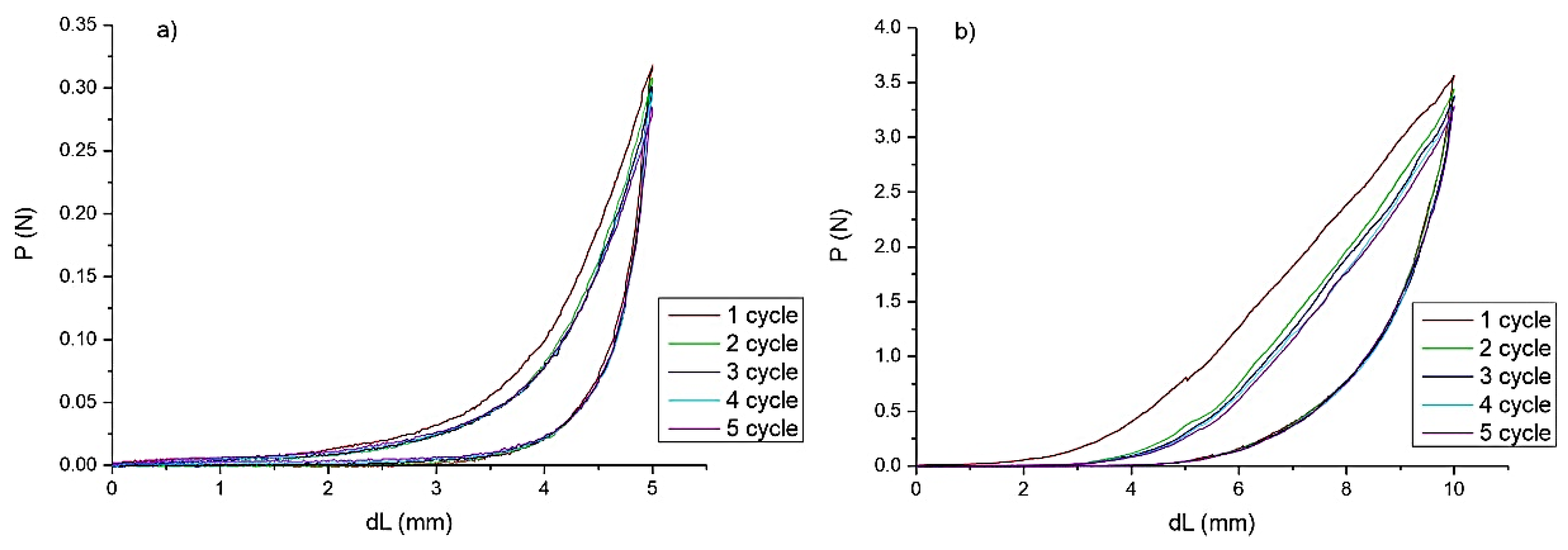

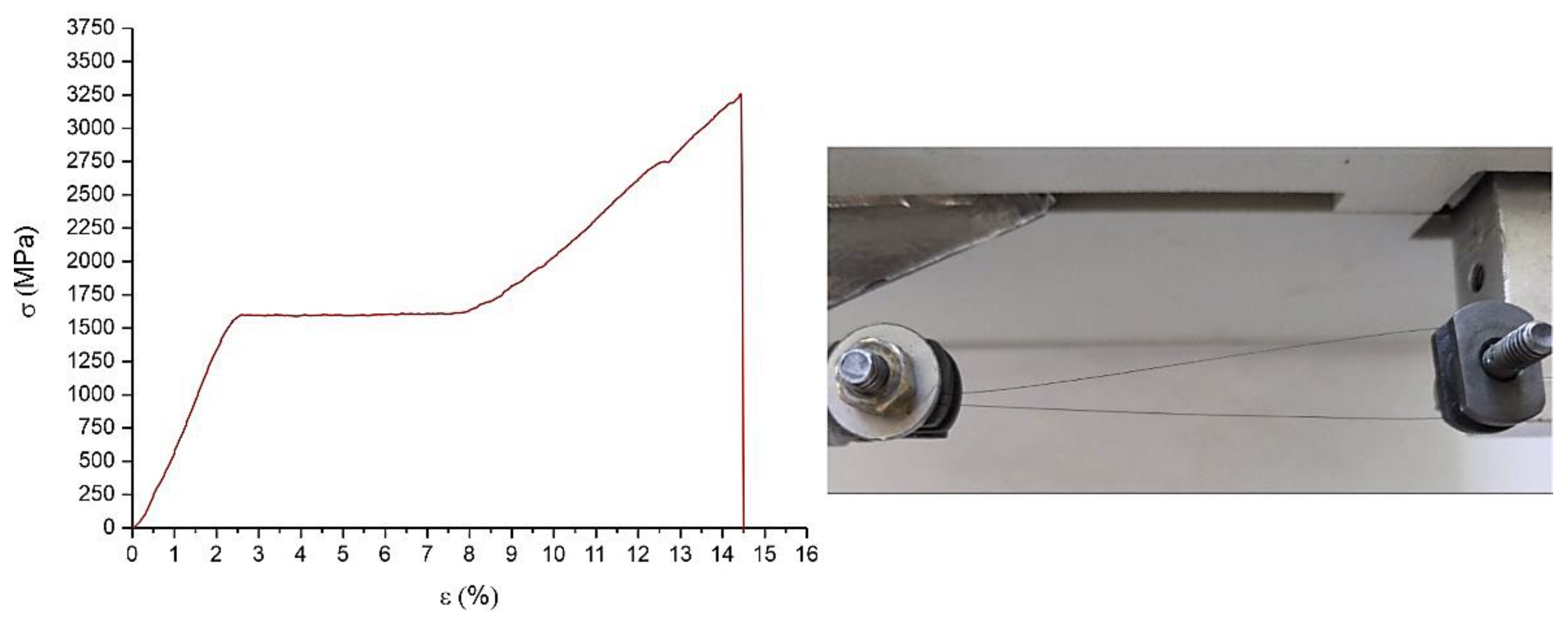

- The strain diagrams demonstrate that a 60 μm diameter TiNi wire shows uniaxial tensile strength of 1800 MPa with a maximum strain of 13%. It was revealed that during low-cycle tests, the wire exhibits superelasticity with reversible inelastic deformation of 4%, mechanical hysteresis of 320 MPa, and martensitic shear stress of 830 MPa.

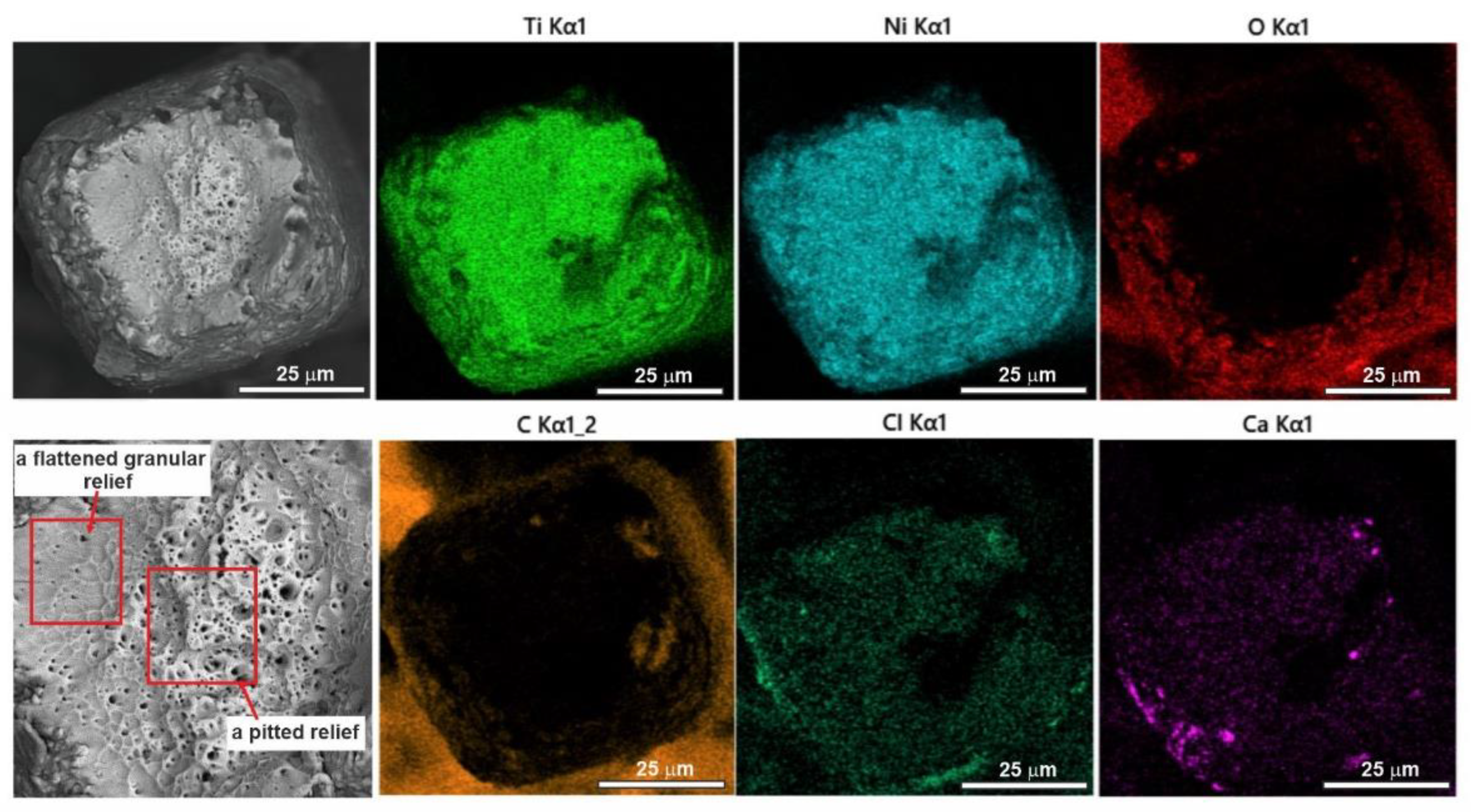

- After uniaxial tension to rupture, the fracture surface comprises two zones that exhibit a flattened granular and pitted relief, which is typical of the ductile fracture of TiNi austenite. Elemental analysis showed a uniform distribution of titanium and nickel in the matrix. An increased oxygen content in the surface layers indicates the oxide sheath formation. Carbon-, calcium-, silicon- and chlorine-based inclusions were found in the surface layer. The relief features and elemental distribution revealed brittle fracture of the sheath enriched in non-metallic phases and ductile fracture of the center consisting of the viscous TiNi phase.

- The pattern of the temperature dependence curve of the electrical resistance and that of the temperature of direct and reverse martensitic transformation: TR = 49 °C, MS = −60 °C, Mf = −140 °C, AS = 2 °C, and Af = 40 °C, indicate a two-stage martensitic transformation of B2→R→B19′, which is responsible for the superelasticity effect. The data obtained using transmission electron microscopy also confirm that at room temperature, the TiNi wire has a nanocrystalline structure of B2 austenite grains with an average size of 25 nm.

- The uniaxial tension to fracture of knitted metal mesh made from TiNi wire shows that its fracture requires significant loads up to 3500 MPa compared to the fracture of wire, and the tension diagrams of knitted metal mesh show no yield section associated with the martensite transformation. The cyclic tension of knitted metal mesh within the physiological load by 10 and 20% is characterized by the change in reversible deformation from a superelastic mechanism to a hyperelastic one.

- Under changed experimental conditions for a single wire, the effect of the wire geometry on its mechanical properties was assessed. Under uniaxial tension of the wire, which maximally follows the pattern of the wire geometry in the knitted metal mesh, the critical martensitic shear stresses were observed to increase up to 1500 MPa, and the tensile strength was found to grow up to 3250 MPa.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fu, Y.Q.; Du, H.J.; Huang, W.; Zhang, S.; Hu, M. TiNi based thin films in MEMS applications: A review. Sens. Actuators A 2004, 112, 395–408. [Google Scholar] [CrossRef]

- Chernyshova, A.; Kolomiets, L.; Chekalkin, T.; Chernov, V.; Sinilkin, I.; Gunther, V.; Marchenko, E.; Baigonakova, G.; Kang, J.H. Fertility-Sparing Surgery Using Knitted TiNi Mesh Implants and Sentinel Lymph Nodes: A 10-Year Experience. J. Investig. Surg. 2020, 13, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Margan, N.B. Medical shape memory alloy applications—The market and its products. Mater. Sci. Eng. A 2004, 378, 16–23. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Y.; Jiang, Y.; Zhou, R. Superelastic behaviors of biomedical porous NiTi alloy with high porosity and large pore size prepared by spark plasma sintering. J. Alloy Compd. 2015, 644, 513–522. [Google Scholar] [CrossRef]

- Heller, L.; Seiner, H.; Šittner, P.; Sedlák, P.; Tyc, O.; Kadeřávek, L. On the plastic deformation accompanying cyclic martensitic transformation in thermomechanically loaded NiTi. Int. J. Plast. 2018, 111, 53–71. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti-Ni-based shape memory alloys. Progress Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Pushin, V.G.; Prokoshkin, S.D.; Valiev, R.Z. Part 1. Structure, Phase Transformations and Properties. TiNi Shape Memory Alloys; Ural Branch of the Russian Academy of Sciences: Ekaterinburg, Russia, 2006; 438p. [Google Scholar]

- Miyazaki, S. The Shape Memory Mechanism Associated with the Martensitic Transformation in Ti-Ni alloys—I. Self-accommodation. Acta Metall. 1989, 37, 1873–1884. [Google Scholar] [CrossRef]

- Jenko, M.; Godec, M.; Kocijan, A.; Rudolf, R.; Dolinar, D.; Ovsenik, M.; Gorenšek, M.; Mozetic, M. A new route to biocompatible Nitinol based on a rapid treatment with H2/O2 gaseous plasma. Appl. Surf. Sci. 2019, 473, 976–984. [Google Scholar] [CrossRef]

- Tsuchiya, K.; Hada, Y.; Koyano, T.; Nakajima, K.; Ohnuma, M.; Koike, T.; Todaka, Y.; Umemoto, M. Production of TiNi amorphous/nanocrystalline wires with high strength and elastic modulus by severe cold drawing. Scr. Mater. 2009, 60, 749–752. [Google Scholar] [CrossRef]

- Yawny, A.; Olbricht, J.; Sade, M.; Eggeler, G. Pseudoelastic cycling and ageing effects at ambient temperature in nanocrystalline Ni-rich NiTi wire. Mater. Sci. Eng. A 2008, 481–482, 86–90. [Google Scholar] [CrossRef]

- Chen, Y.; Tyc, O.; Molnárová, O.; Heller, L.; Šittner, P. Tensile deformation of superelastic NiTi wires in wide temperature and microstructure ranges. Shape Mem. Superelasticity 2019, 5, 42–62. [Google Scholar] [CrossRef]

- Marandi, L.; Sen, I. In-vitro mechanical behavior and high cycle fatigue characteristics of NiTi-based shape memory alloy wire. Int. J. Fatigue 2021, 148, 106226. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, X.; Qian, M. Reversible elastocaloric effects with small hysteresis in nanocrystalline Ni-Ti microwires. AIP Adv. 2018, 8, 125002. [Google Scholar] [CrossRef]

- Zheng, Y.; Jiang, F.; Li, L.; Yang, H.; Liu, Y. Effect of ageing treatment on the transformation behaviour of Ti–50.9 at.% Ni alloy. Acta Mater. 2008, 56, 736–745. [Google Scholar] [CrossRef]

- Soul, H.; Isalgue, A.; Yamny, A.; Torra, V.; Lovey, F.C. Pseudoelastic fatigue of NiTi wires: Frequency and size effects on damping capacity. Smart Mater. Struct. 2010, 19, 085006. [Google Scholar] [CrossRef]

- Mahtabi, M.J.; Shamsaei, N.; Mitchell, M.R. Fatigue of Nitinol: The state-of-the-art and ongoing challenges. J. Mech. Behav. Biomed. Mater. 2015, 50, 228–254. [Google Scholar] [CrossRef] [PubMed]

- Tobushi, H.; Shimeno, Y.; Hachisuka, T.; Tanaka, K. Influence of strain rate on superelastic properties of TiNi shape memory alloy. Mech. Mater. 1998, 30, 141–150. [Google Scholar] [CrossRef]

- Ammar, O.; Haddar, N.; Dieng, L. Experimental investigation of the pseudoelastic behaviour of NiTi wires under strain- and stress-controlled cyclic tensile loadings. Intermetallics 2017, 81, 52–61. [Google Scholar] [CrossRef]

- Pilch, O.; Šittner, J.; Haušild, P. Investigation of the Precipitation Processes in NiTi Filaments. In Proceedings of the International Conference on Martensitic Transformations: Chicago; The Minerals, Metals & Materials Series; Stebner, A., Olson, G., Eds.; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Sedmák, P.; Šittner, P.; Pilch, J.; Curfs, C. Instability of cyclic superelastic deformation of NiTi investigated by synchrotron X-ray diffraction. Acta Mater. 2015, 94, 257–270. [Google Scholar] [CrossRef]

- Qin, Y. Applications of advanced technologies in the development of functional medical textile materials. In Medical Textile Materials; Woodhead Publishing: Cambridge, UK, 2016; pp. 55–70. [Google Scholar]

- Robertson, S.W.; Pelton, A.R.; Ritchie, R.O. Mechanical fatigue and fracture of Nitinol. Int. Mater. Rev. 2012, 57, 1–37. [Google Scholar] [CrossRef]

- Upadhyay, K.; Subhash, G.; Spearot, D. Visco-hyperelastic constitutive modeling of strain rate sensitive soft materials. J. Mech. Phys. Solids 2020, 135, 103777. [Google Scholar] [CrossRef]

- Morch, A.; Astruc, L.; Witz, J.-F.; Lesaffre, F.; Lecomte-Grosbras, P.; Soulat, D.; Brieu, M. Modeling of anisotropic hyperelastic heterogeneous knitted fabric reinforced composites. J. Mech. Phys. Solids 2019, 127, 47–61. [Google Scholar] [CrossRef]

- Muralidhar, B.A. Tensile and compressive behaviour of multilayer flax-rib knitted preform reinforced epoxy composites. Mater. Des. 2013, 49, 400–405. [Google Scholar] [CrossRef]

- Weinberg, C.A.; Cai, S.; Schaffer, J.; Abel, J. Multifunctional Spun Yarns and Textiles from Nickel-Titanium Microfilaments. Adv. Mater. Technol. 2020, 5, 1901146. [Google Scholar] [CrossRef]

- Gunter, S.V.; Marchenko, E.S.; Yasenchuk, Y.F.; Baigonakova, G.A.; Volinsky, A.A. Portable universal tensile testing machine for studying mechanical properties of superelastic biomaterials. Eng. Res. Express 2021, 3, 045055. [Google Scholar] [CrossRef]

- Martelli, S.; Costi, J.J. Real-time replication of three-dimensional and time-varying physiological loading cycles for bone and implant testing: A novel protocol demonstrated for the proximal human femur while walking. J. Mech. Behav. Biomed. Mater. 2021, 124, 104817. [Google Scholar] [CrossRef] [PubMed]

- Jiang, M.; Lawson, Z.T.; Erel, V.; Pervere, S.; Nan, T.; Robbins, A.B.; Feed, A.D.; Moreno, M.R. Clamping soft biologic tissues for uniaxial tensile testing: A brief survey of current methods and development of a novel clamping mechanism. J. Mech. Behav. Biomed. Mater. 2019, 103, 103503. [Google Scholar] [CrossRef] [PubMed]

- Henderson, B.S.; Cudworth, K.F.; Wale, M.E.; Siegel, D.N.; Lujan, T.J. Tensile fatigue strength and endurance limit of human meniscus. J. Mech. Behav. Biomed. Mater. 2022, 127, 105057. [Google Scholar] [CrossRef]

- Nasakina, E.O.; Sevostyanov, M.A.; Baikin, A.V.S.A.S.; Seryogin, A.V.; Konushkin, S.V.; Sergienko, A.V.L.K.V.; Leonov, A.V.; Kolmakov, A.G. Applications of Nanostructural NiTi Alloys for Medical Devices. In Shape Memory Alloys—Fundamentals and Applications; OOO Universal Printing House “Alpha Print”: Rijeka, Croatia, 2017. [Google Scholar]

- James, B.; Foulds, J.; Eiselstein, L. Failure analysis of NiTi wires used in medical applications. J. Fail. Anal. Prev. 2005, 5, 82–87. [Google Scholar] [CrossRef]

- Frolova, A.V.; Tsarenko, Y.V.; Rubanik, V.V.; Stolyarov, V.V.; Rubanik, V.V. Tensile Strain of Alloys with the Martensitic Transformation under the External Impact. Bull. Russ. Acad. Sci. Phys. 2019, 83, 1289–1293. [Google Scholar] [CrossRef]

- Racek, J.; Stora, M.; Šittner, P.; Heller, L.; Kopeček, J.; Petrenec, M. Monitoring Tensile Fatigue of Superelastic NiTi Wire in Liquids by Electrochemical Potential. Shape Mem. Superelasticity 2015, 1, 204–230. [Google Scholar] [CrossRef][Green Version]

- Buslaeva, E.M. Materials Science: Textbook, 2nd ed.; IPR Media: Saratov, Russia, 2019; 149p. [Google Scholar]

- Maziz, A.; Concas, A.; Khaldi, A.; Stålhand, J.; Persson, N.-K.; Jager, E.W.H. Knitting and weaving artificial muscles. Sci. Adv. 2017, 3, e1600327. [Google Scholar] [CrossRef] [PubMed]

- Li, W. Damage Models for Soft Tissues: A Survey. J. Med. Biol. Eng. 2016, 36, 285–307. [Google Scholar] [CrossRef] [PubMed]

- Amnuaypornsri, S.; Sakdapipanich, J.; Tanaka, Y. Green strength of natural rubber: The origin of the stress-strain behavior of natural rubber. J. Appl. Polym. Sci. 2009, 111, 2127–2133. [Google Scholar] [CrossRef]

- De Tommasi, D.; Marzano, S.; Puglisi, G.; Zurlo, G. Damage and healing effects in rubber-like balloons. Int. J. Solids Struct. 2009, 46, 3999–4005. [Google Scholar] [CrossRef][Green Version]

- Zhu, Y.; Kang, G.; Kan, Q.; Yu, C. A finite viscoelastic–plastic model for describing the uniaxial ratchetting of soft biological tissues. J. Biomech. 2014, 47, 996–1003. [Google Scholar] [CrossRef]

- Zhu, Y.; Kang, G.; Yu, C.; Poh, L.H. Logarithmic rate based elasto-viscoplastic cyclic constitutive model for soft biological tissues. J. Mech. Behav. Biomed. Mater. 2016, 61, 397–409. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baigonakova, G.; Marchenko, E.; Kovaleva, M.; Vorozhtsov, A. Influence of Wire Geometry on the Mechanical Behavior of the TiNi Design. Metals 2022, 12, 1131. https://doi.org/10.3390/met12071131

Baigonakova G, Marchenko E, Kovaleva M, Vorozhtsov A. Influence of Wire Geometry on the Mechanical Behavior of the TiNi Design. Metals. 2022; 12(7):1131. https://doi.org/10.3390/met12071131

Chicago/Turabian StyleBaigonakova, Gulsharat, Ekaterina Marchenko, Marina Kovaleva, and Alexander Vorozhtsov. 2022. "Influence of Wire Geometry on the Mechanical Behavior of the TiNi Design" Metals 12, no. 7: 1131. https://doi.org/10.3390/met12071131

APA StyleBaigonakova, G., Marchenko, E., Kovaleva, M., & Vorozhtsov, A. (2022). Influence of Wire Geometry on the Mechanical Behavior of the TiNi Design. Metals, 12(7), 1131. https://doi.org/10.3390/met12071131