In-Situ Thermography Investigation of Crack Growth in Armco Iron under Gigacycle Fatigue Loading

Abstract

:1. Introduction

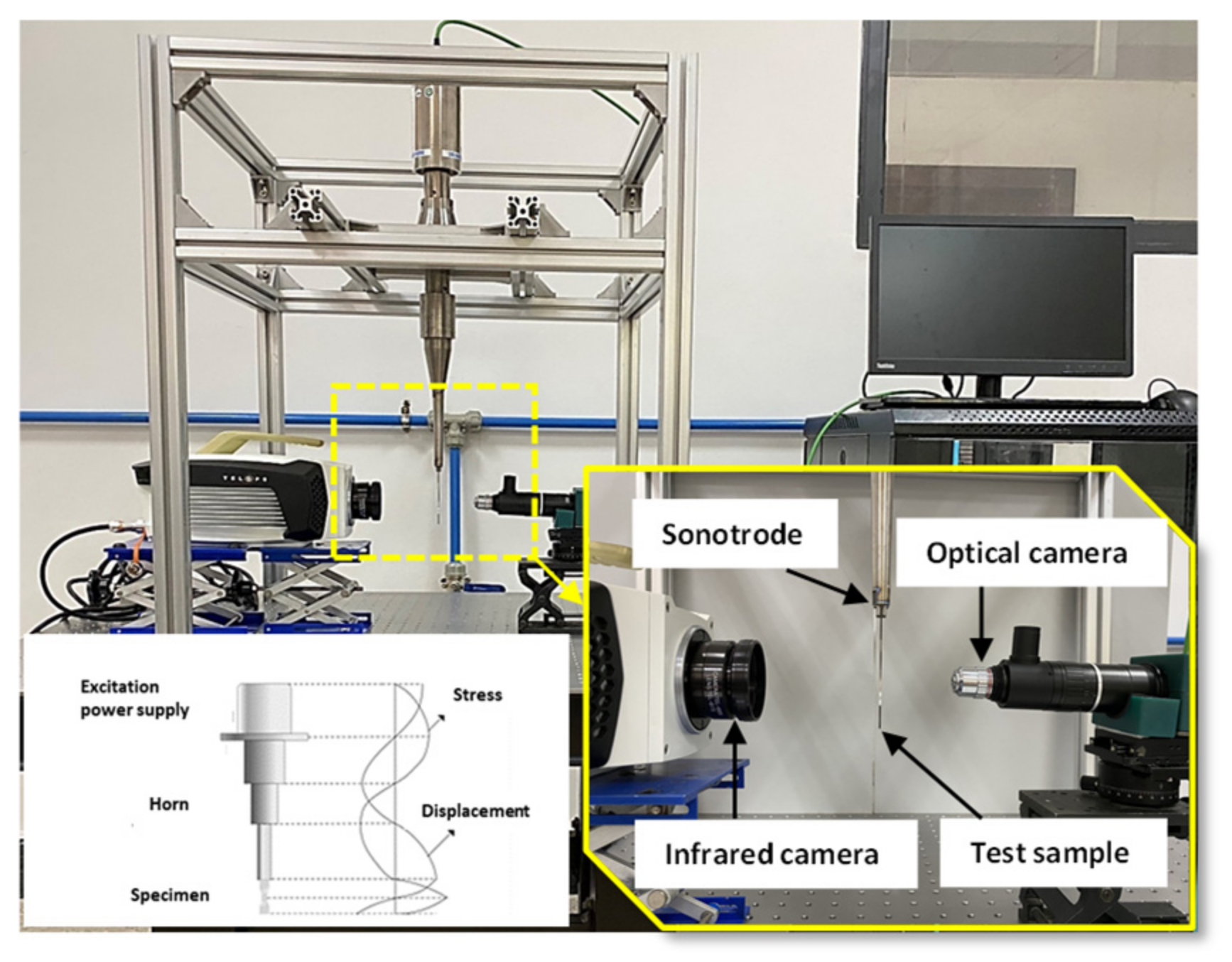

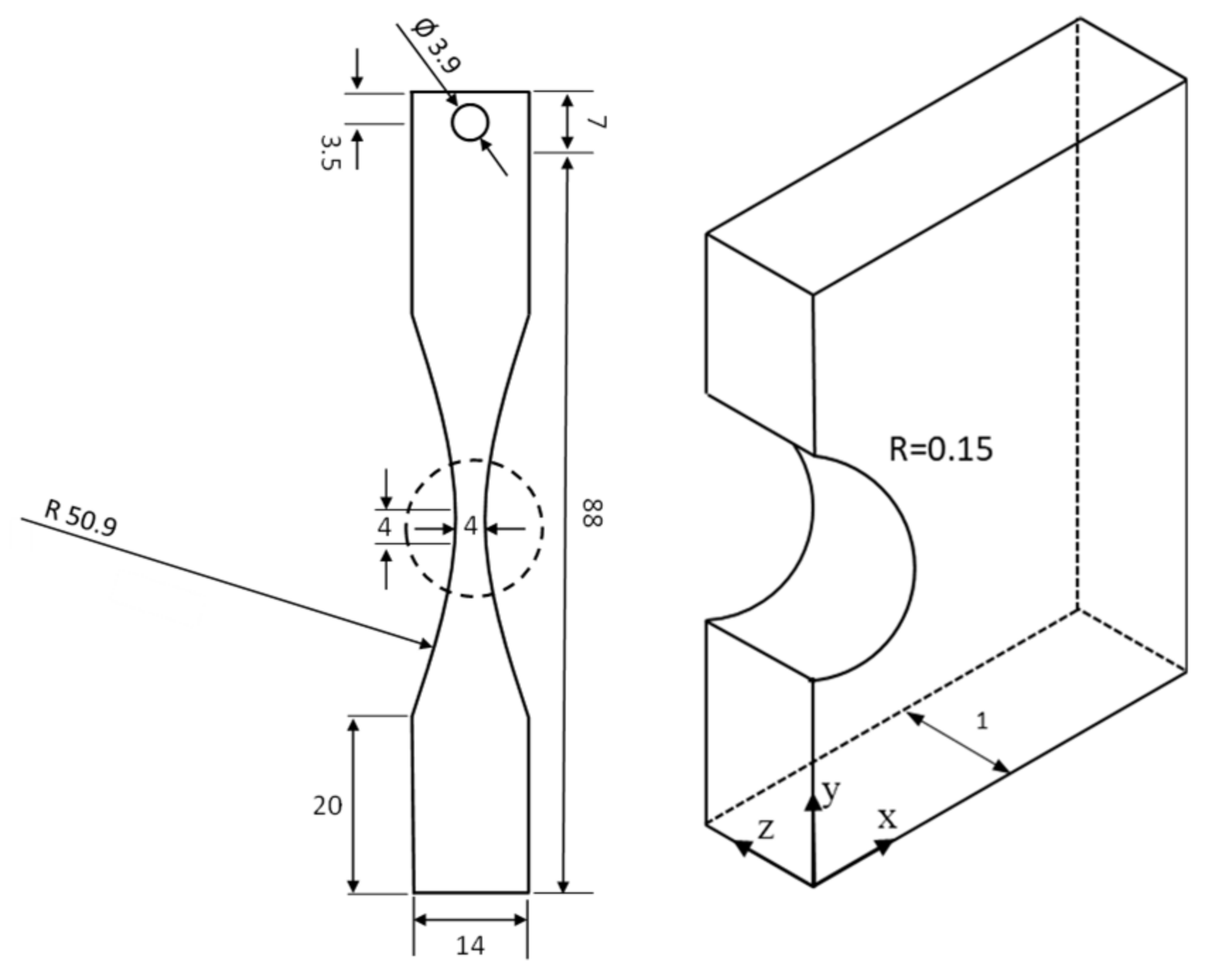

2. Experimental Procedures

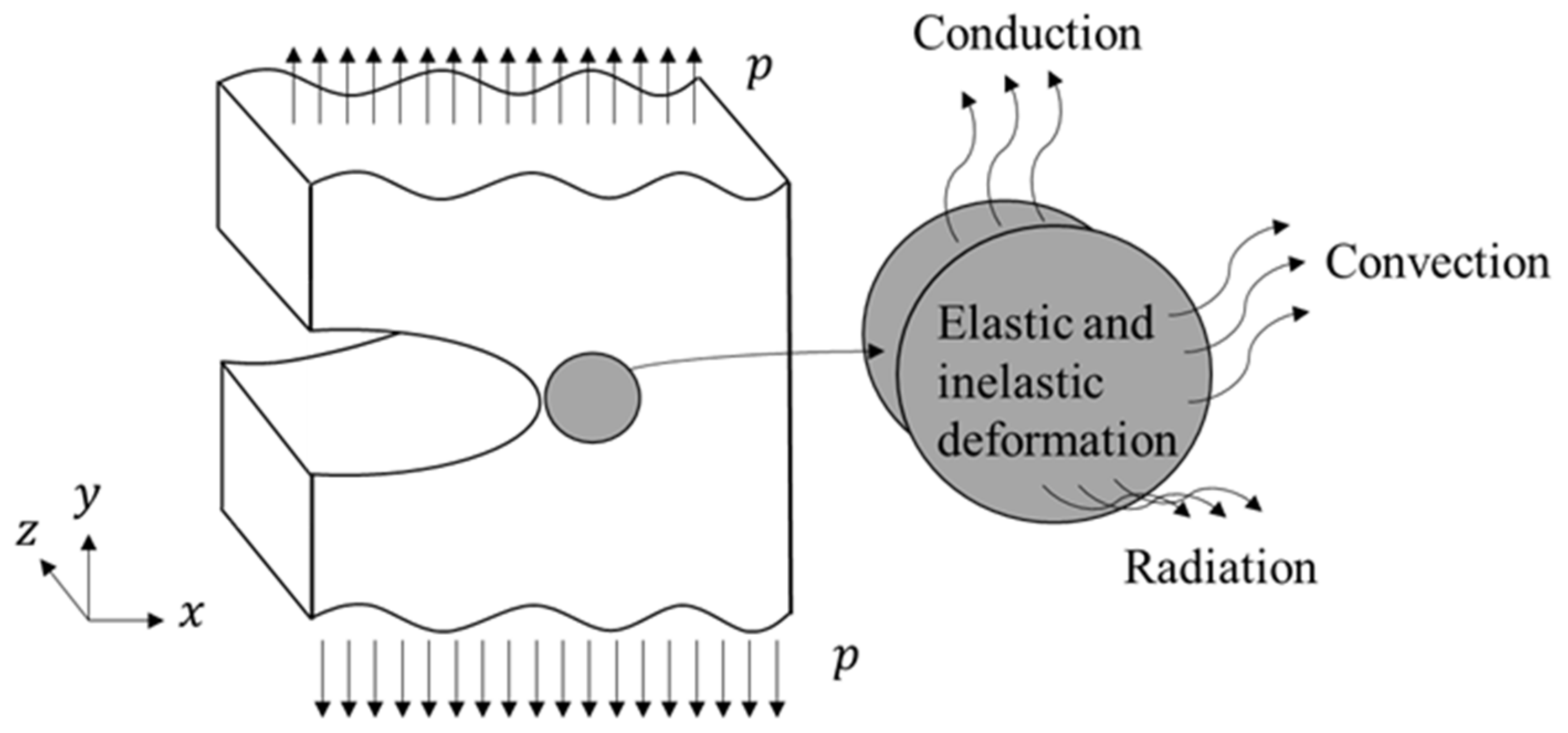

3. Theory and Formulation

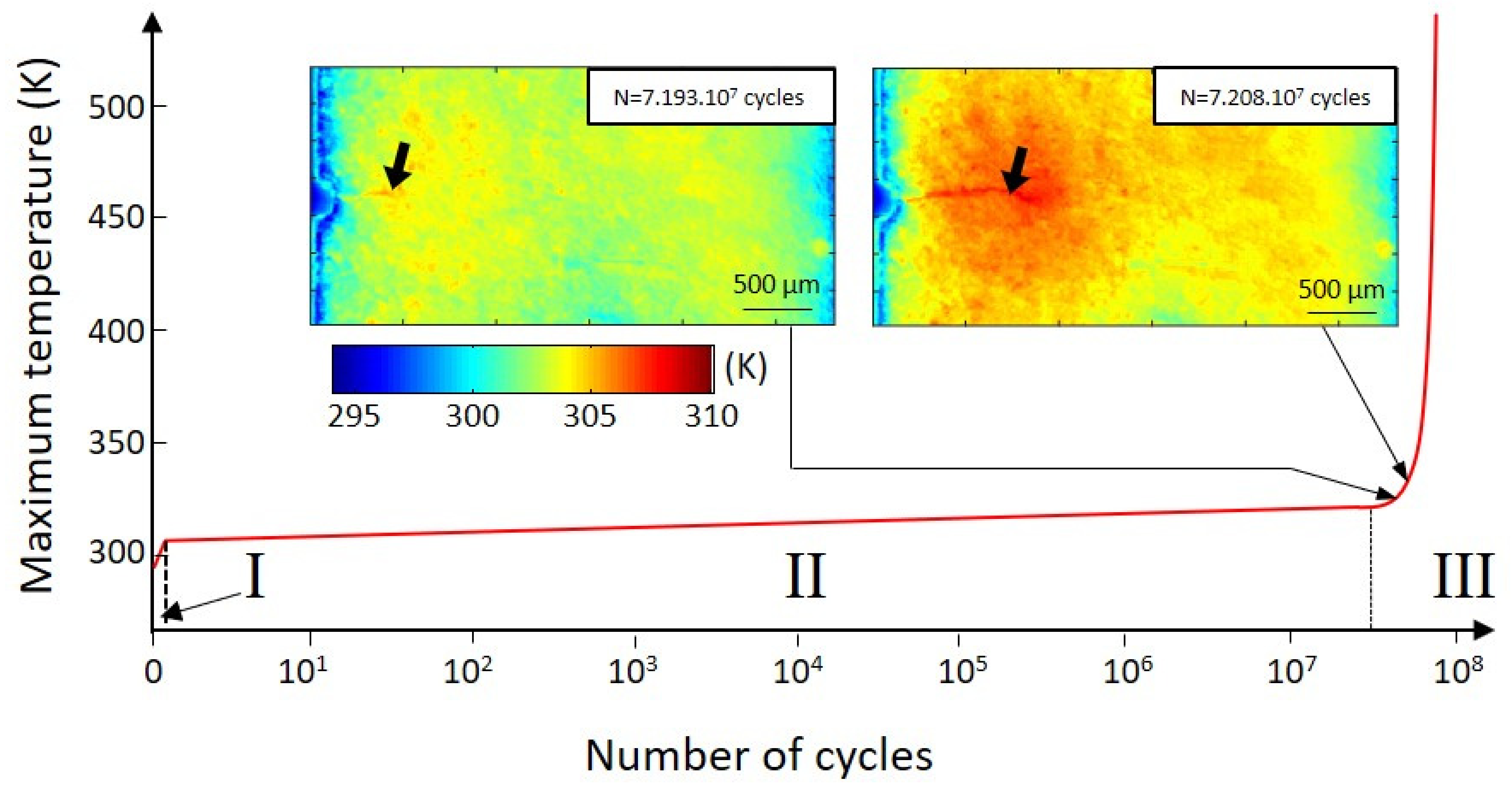

4. Results and Discussion

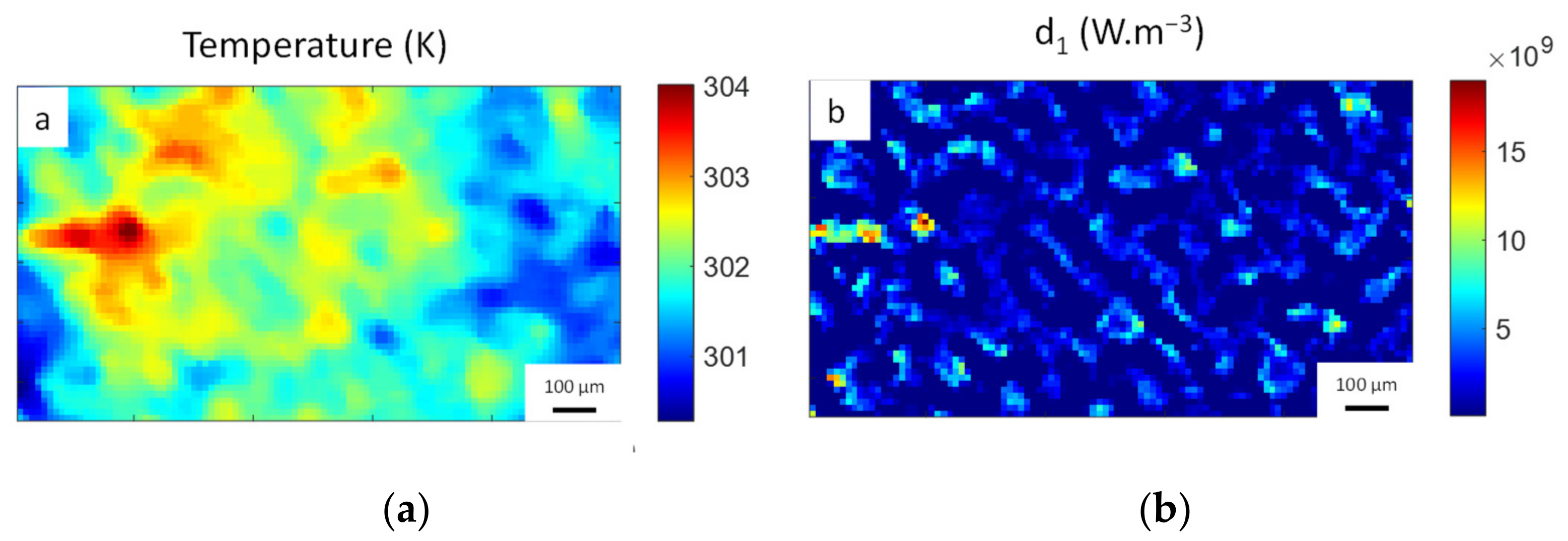

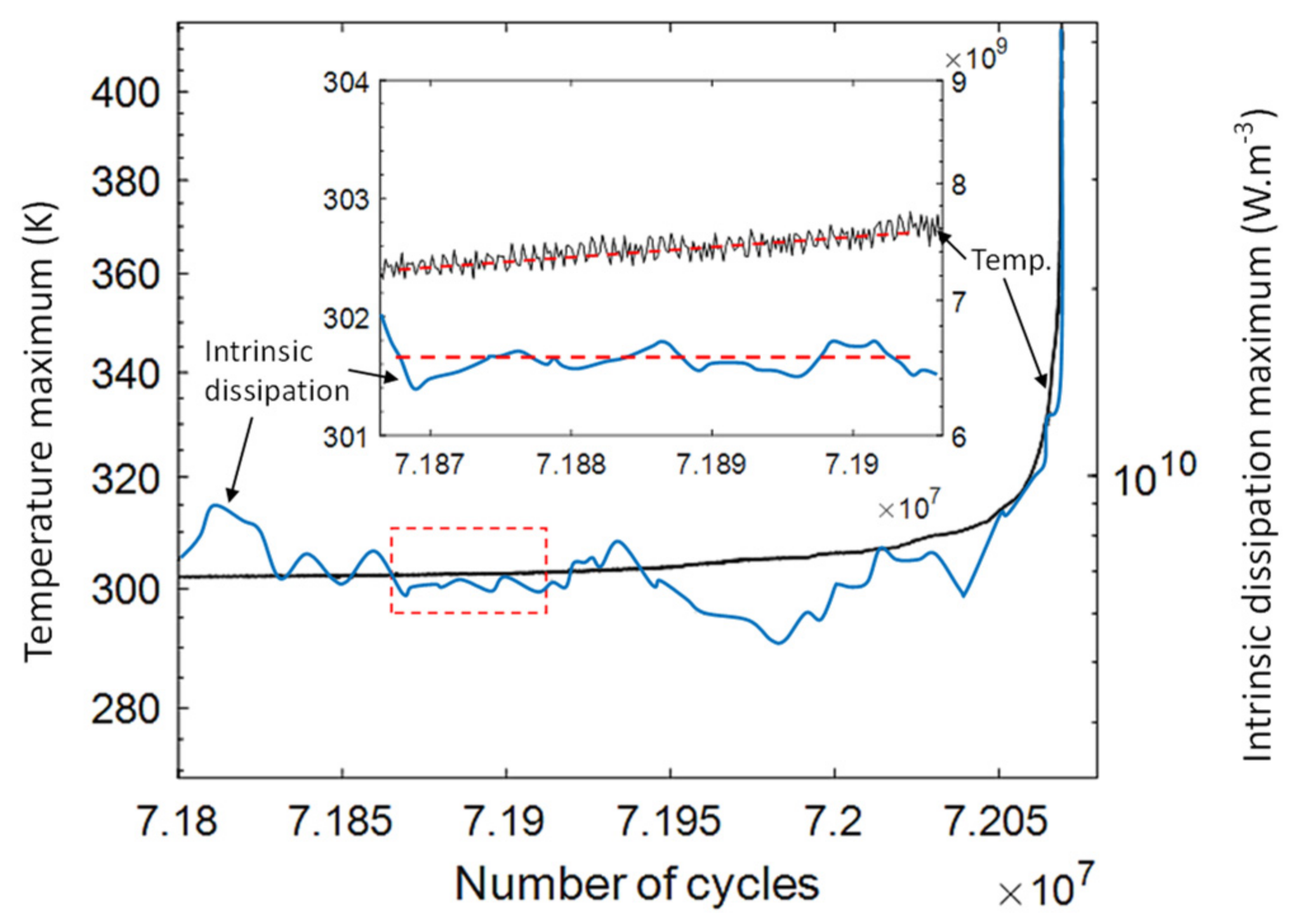

4.1. Temperature

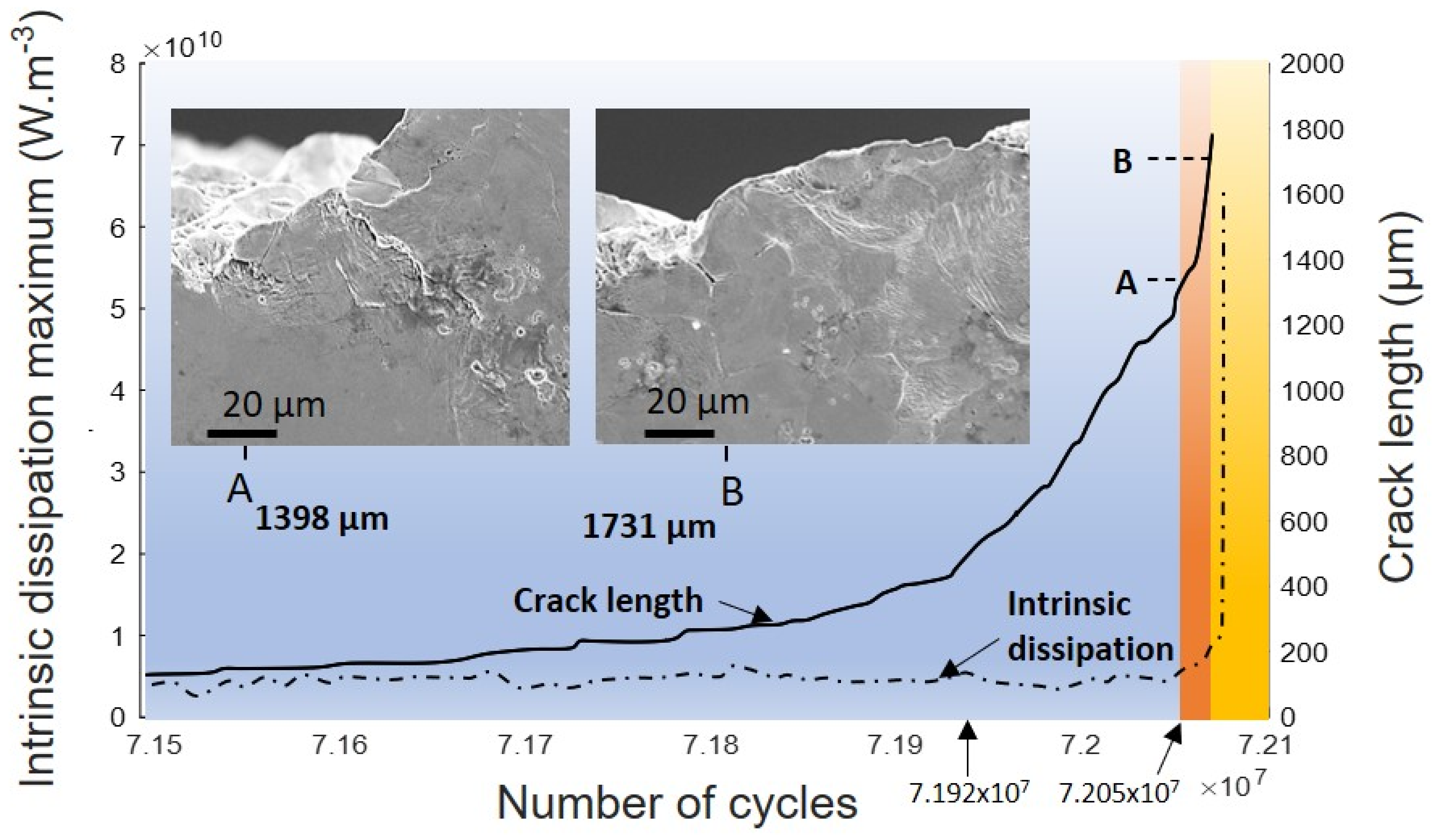

4.2. Intrinsic Dissipation

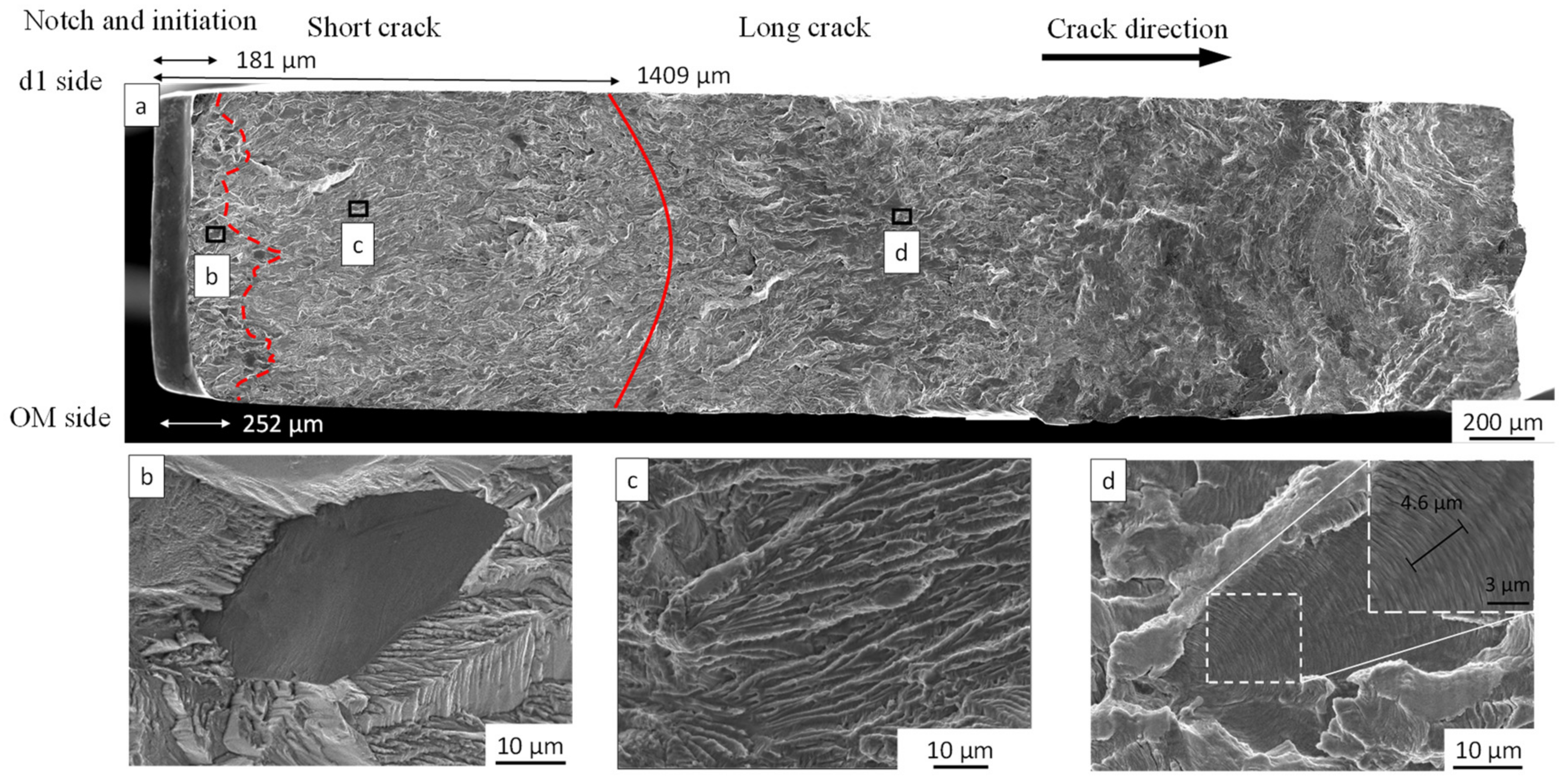

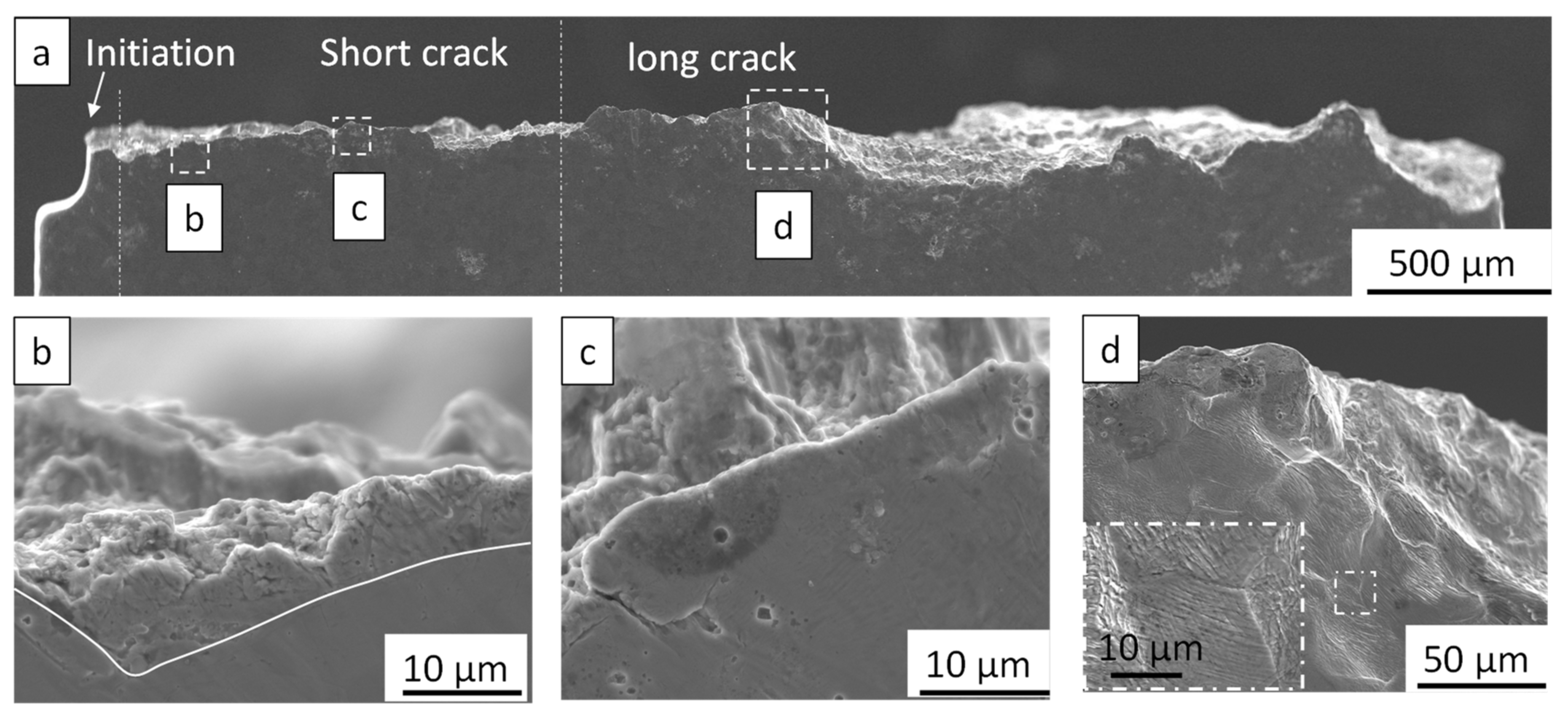

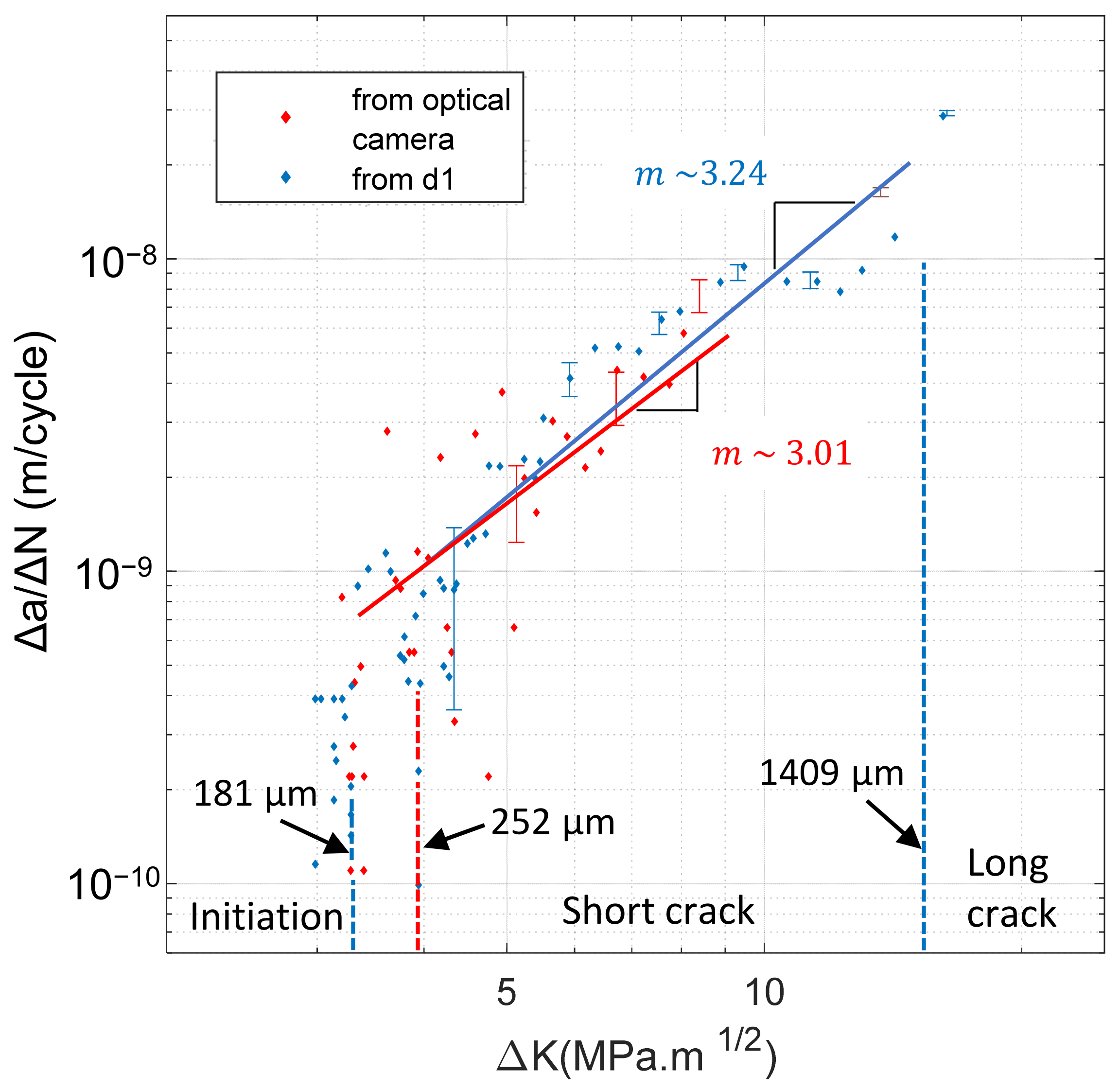

4.3. Graphy

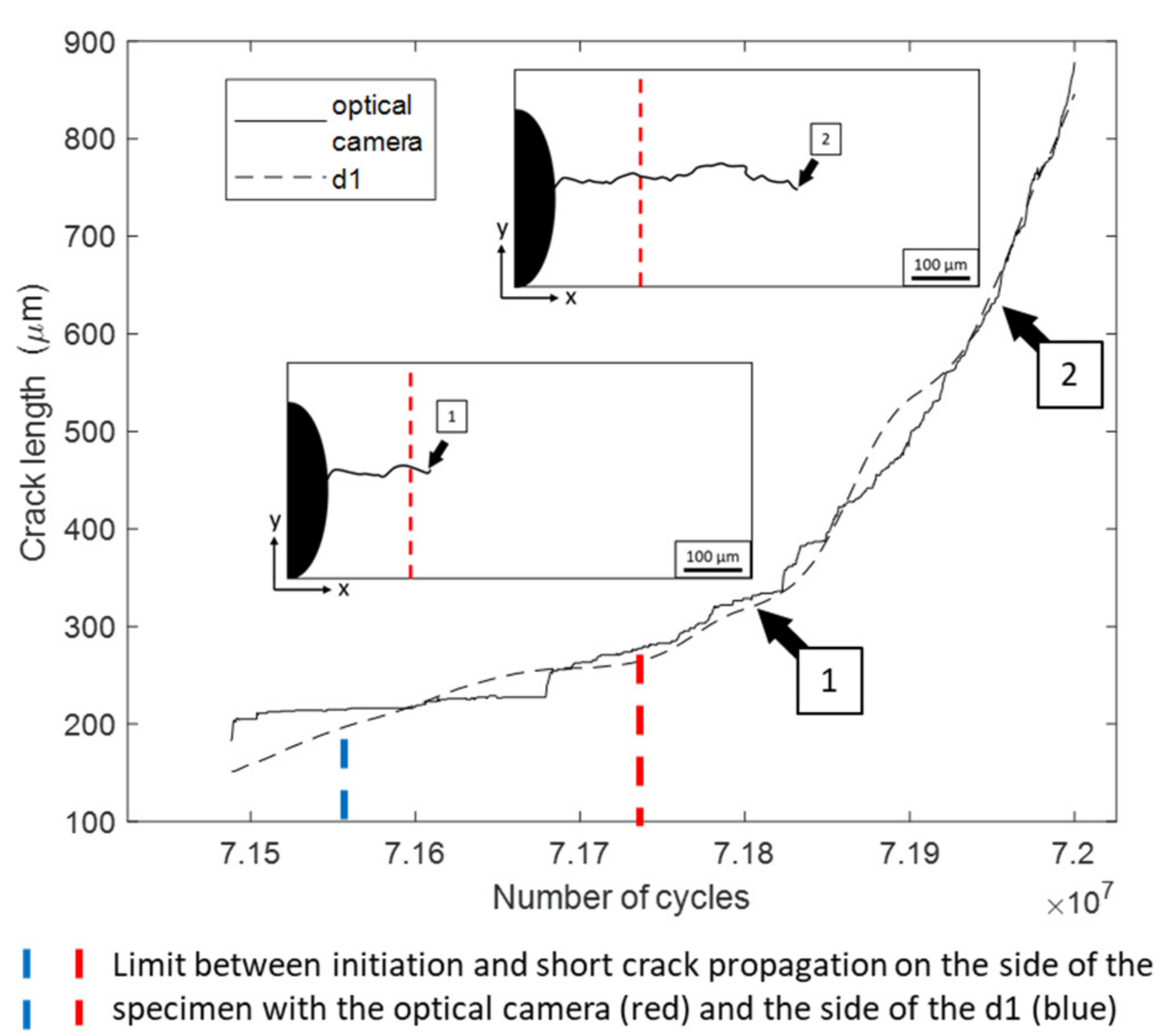

4.4. Evolution of the Crack Tip Position

4.5. Discussion

4.5.1. Comparison between the Optical and Thermography

4.5.2. Uncertainty

5. Conclusions

- The conversion temperature into the intrinsic dissipation allows us to realize the damage state during crack propagation. During the short cracking, very little plasticity is visible at the material’s surface, and the level of d1 is low. On the contrary, plasticity is predominant during the long cracking, and the d1 increases sharply. This issue indicates that the d1 value can be implemented as an indicator of the crack length.

- The obtained results show that there exists a physical correlation between intrinsic dissipation and deformations. This fact is more apparent at the material surface than those obtained based on the thermal field. The temperature level keeps increasing during the short cracking, while the intrinsic dissipation shows a stable level, while the plasticity level does not grow during the short cracking.

- The small size of a crack makes it challenging to be detected by an optical camera even with high magnification. During the beginning of the crack propagation, the generated heat source at the crack tip facilitates its detection by an infrared camera. By utilizing full-field analysis, the maximum value of d1 on 2D images of the sample surface is a suitable method to indicate the position of a crack, thus measuring its length and defining its FCGR.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Density | |

| Specific heat capacity | |

| External heat source | |

| Isotropic conduction tensor | |

| Heat transfer coefficient | |

| Thickness of the specimen | |

| Temperature difference (T–T0) on the material surface | |

| T0 | Temperature reference |

| Intrinsic dissipation | |

| Heat loss by convection and radiation | |

| Thermomechanical coupling | |

| Cauchy stress tensor | |

| Plastic strain tensor | |

| Uncertainty on the measurement of the crack growth rate | |

| Uncertainty on the number of cycles | |

| Average value of the frequency | |

| Cycle number variation | |

| Stress intensity factor range | |

| Crack length variation | |

| Time uncertainty | |

| Uncertainty in the measurement of the crack tip position | |

| Time | |

| Uncertainty on the measurement of the frequency | |

| Crack length | |

| Depth of the notch | |

| Width of the specimen | |

| Material constant | |

| Material constant |

References

- Bathias, C. Piezoelectric fatigue testing machines and devices. Int. J. Fatigue 2006, 28, 1438–1445. [Google Scholar] [CrossRef]

- Sangid, M.D. The physics of fatigue crack initiation. Int. J. Fatigue 2013, 57, 58–72. [Google Scholar] [CrossRef]

- Mughrabi, H. Microstructural mechanisms of cyclic deformation, fatigue crack initiation and early crack growth. Phil. Trans. R. Soc. 2015, 373, 132–147. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wagner, D.; Wang, C.; Huang, Z.; Bathias, C. Surface crack initiation mechanism for body-centered cubic materials in the gigacycle fatigue domain. Int. J. Fatigue 2016, 93, 292–300. [Google Scholar] [CrossRef]

- Wang, C.; Wagner, D.; Wang, Q.Y.; Bathias, C. Gigacycle fatigue initiation mechanism in Armco iron. Int. J. Fatigue 2012, 45, 91–97. [Google Scholar] [CrossRef]

- Zimmermann, M. Diversity of damage evolution during cyclic loading at very high numbers of cycles. Int. Mater. Rev. 2012, 57, 73–91. [Google Scholar] [CrossRef]

- Chan, K.S. Roles of microstructure in fatigue crack initiation. Int. J. Fatigue 2010, 32, 1428–1447. [Google Scholar] [CrossRef]

- Sadriji, B.; Raka, B.; Brugier, F.; Guilhem, Y.; Soria, D. Short versus long cracks fatigue crack growth rate, a novel experimental approach. In Proceedings of the 12th International Fatigue Congress, Poitiers, France, 27 May–1 January 2018. [Google Scholar]

- Connors, W.C. Fatigue striation spacing analysis. Mater. Charact. 1994, 33, 245–253. [Google Scholar] [CrossRef]

- Makkonen, M. Predicting the total fatigue life in metals. Int. J. Fatigue 2009, 31, 1163–1175. [Google Scholar] [CrossRef]

- Hong, Y.S.; Sun, C.Q. The nature and the mechanism of crack initiation and early growth for very-high-cycle fatigue of metallic materials—An overview. Theor. Appl. Fract. Mech. 2017, 92, 331–350. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.K.; Wang, Q.Y. Investigation of crack initiation and propagation behavior of AISI 310 stainless steel up to very high cycle fatigue. Int. J. Fatigue 2013, 54, 38–46. [Google Scholar] [CrossRef]

- Ouarabi, M.O. Influence de la Fréquence de Chargement sur la Résistance L’amorçage et la Croissance des Fissures de Fatigue Dans des Aciers Utilisées Pour des Applications Mécaniques Exigeantes. Master’s Thesis, University Paris Nanterre, Ville d’Avray, France, 2018. [Google Scholar]

- Paris, P.C.; Erdogan, F. A critical analysis of crack propagation laws. J. Basic Eng. 1963, 85, 528–533. [Google Scholar]

- Antunes, F.V.; Ferreira, M.S.C.; Branco, R.; Prates, P.; Gardin, C.; Sarrazin-Baudoux, C. Fatigue crack growth versus plastic CTOD in the 304L stainless steel. Eng. Fract. Mech. 2019, 214, 487–503. [Google Scholar] [CrossRef]

- Ma, X.F.; Zhai, H.L.; Zuo, L.; Zhang, W.J.; Rui, S.S.; Han, Q.N. Fatigue short crack propagation behavior of selective laser melted Inconel 718 alloy by in-situ SEM study: Influence of orientation and temperature. Int. J. Fatigue 2020, 139, 105739. [Google Scholar]

- Hertzberg, R.W. Deformation and Fracture Mechanics of Engineering Materials; John Wiley & Sons: New York, NY, USA, 1976. [Google Scholar]

- Wang, X.G.; Ran, H.R.; Jiang, C.; Fang, Q.H. An energy dissipation-based fatigue crack growth model. Int. J. Fatigue 2018, 114, 167–176. [Google Scholar] [CrossRef]

- Mukherjee, A.; Banerjee, A. Analysis of Acoustic Emission Signal for Crack Detection and Distance Measurement on Steel Structure. Acoust. Aust. 2021, 49, 133–149. [Google Scholar] [CrossRef]

- Palumbo, D.; De Finis, A.; Demelio, G.P.; Galietti, U. Damage monitoring in fracture mechanics by evaluation of the heat dissipated in the cyclic plastic zone ahead of the crack tip with thermal measurements. Eng. Fract. Mech. 2017, 181, 65–76. [Google Scholar] [CrossRef]

- Bilotta, G.; Arzaghi, M.; Henaff, G.; Benoit, G.; Halm, D. Hydrogen induced intergranular failure in Armco iron under fatigue crack propagation. In Proceedings of the ASME 2016 Pressure Vessels and Piping Conference PVP2016, Vancouver, BC, Canada, 17–21 July 2016. [Google Scholar]

- Herbig, M.; King, A.; Reischig, P.; Proudhon, H.; Lauridsen, E.M.; Marrow, J.; Buffière, J.; Ludwig, W. 3-D growth of a short fatigue crack within a polycrystalline microstructure studied using combined diffraction and phase-contrast X-ray tomography. Acta Mater. 2011, 59, 590–601. [Google Scholar] [CrossRef] [Green Version]

- Bufford, D.C.; Stauffer, D.; Mook, W.; Syed, A.; Boyce, B.L.; Hattar, K. High Cycle Fatigue in the Transmission Electron Microscope. Nano Lett. 2016, 16, 4946–4953. [Google Scholar] [CrossRef]

- Messager, A.; Junet, A.; Palin-Luc, T.; Buffiere, J.Y.; Saintier, N.; Ranc, N.; El May, M.; Gaillard, Y.; King, A.; Bonnin, A.; et al. In situ synchrotron ultrasonic fatigue testing device for 3D characterisation of internal crack initiation and growth. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 558–567. [Google Scholar] [CrossRef]

- He, C.; Wu, Y.J.; Peng, L.M.; Su, N.; Chen, Q.; Yuan, S.C.; Liu, Y.J.; Wang, Q.Y. Effect of microstructure on small fatigue crack initiation and early propagation behavior in Mg-10Gd-3Y-0.3Zr alloy. Int. J. Fatigue 2019, 119, 311–319. [Google Scholar] [CrossRef]

- Pilchak, A.L. Fatigue crack growth rates in alpha titanium: Faceted vs. striation growth. Scr. Mater. 2013, 68, 277–280. [Google Scholar] [CrossRef]

- Plekhov, O.; Fedorova, A.; Kostina, A.; Panteleev, I. Theoretical and experimental study of strain localization and energy dissipation at fatigue crack tip. Procedia Mater. Sci. 2014, 3, 1020–1025. [Google Scholar] [CrossRef] [Green Version]

- Rice, J.R.; Levy, N. Local Heating by Plastic Deformation at a Crack Tip, in Physics of Strength and Plasticity; M.I.T Press: Cambridge, MA, USA, 1969. [Google Scholar]

- Chrysochoos, A. Infrared thermography applied to the analysis of material behavior: A brief overview. Quant. InfraRed Thermogr. J. 2012, 9, 193–208. [Google Scholar] [CrossRef] [Green Version]

- Fargione, G.; Geraci, A.; La Rosa, G.; Risitano, A. Rapid determination of the fatigue curve by the thermographic method. Int. J. Fatigue 2002, 24, 11–19. [Google Scholar] [CrossRef]

- Tchankov, D.S.; Vesselinov, K.V. Fatigue life prediction under random loading using total hysteresis energy. Int. J. Press. Vessel. Pip. 1998, 75, 955–960. [Google Scholar] [CrossRef]

- Lagoda, T. Energy models for fatigue life estimation under uniaxial random loading: Part I: The model elaboration. Int. J. Fatigue 2001, 23, 467–480. [Google Scholar] [CrossRef]

- Lee, B.L.; Kim, K.S.; Nam, K.M. Fatigue analysis under variable amplitude loading using an energy parameter. Int. J. Fatigue 2003, 25, 621–631. [Google Scholar] [CrossRef]

- Bär, J.; Seifert, S. Investigation of energy dissipation and plastic zone size during fatigue crack propagation in a high-alloyed steel. Procedia Mater. Sci. 2014, 3, 408–413. [Google Scholar] [CrossRef] [Green Version]

- Meneghetti, G.; Ricotta, M. Evaluating the heat energy dissipated in a small volume surrounding the tip of a fatigue crack. Int. J. Fatigue 2016, 92, 605–615. [Google Scholar] [CrossRef]

- Risitano, A.; Clienti, C.; Risitano, G. Determination of Fatigue Limit by Mono-Axial Tensile Specimens Using Thermal Analysis. Key Eng. Mater. 2011, 452–453, 361–364. [Google Scholar] [CrossRef]

- Chrysochoos, A.; Louche, H. An infrared image processing to analyse the calorific effects accompanying strain localization. Int. J. Eng. Sci. 2000, 38, 1759–1788. [Google Scholar] [CrossRef]

- Blanche, A.; Chrysochoos, A.; Ranc, N.; Favier, V. Dissipation assessments during dynamic very high cycle fatigue tests. Exp. Mech. 2015, 55, 699–709. [Google Scholar] [CrossRef]

- Ranc, N.; Blanche, A.; Ryckelynck, D.; Chrysochoos, A. POD Preprocessing of IR Thermal Data to Assess Heat Source Distributions. Exp. Mech. 2015, 55, 725. [Google Scholar] [CrossRef] [Green Version]

- Connesson, N.; Maquin, F.; Pierron, F. Dissipated energy measurements as a marker of microstructural evolution: 316L and DP600. Acta Mater. 2011, 59, 4100–4115. [Google Scholar] [CrossRef]

- Guo, Q.; Zaïri, F.; Guo, X. An intrinsic dissipation model for high-cycle fatigue life prediction. Int. J. Mech. Sci. 2018, 140, 163–171. [Google Scholar] [CrossRef]

- Ding, F.; Feng, M.L.; Jiang, Y.Y. Modeling of fatigue crack growth from a notch. Int. J. Plast. 2007, 23, 1167–1188. [Google Scholar] [CrossRef]

- Wang, C.; Blanche, A.; Wagner, D.; Chrysochoos, A.; Bathias, C. Dissipative and microstructural effects associated with fatigue crack initiation on an Armco iron. Int. J. Fatigue 2014, 58, 152–157. [Google Scholar] [CrossRef] [Green Version]

- Mughrabi, H. Wechselverformung und Ermüdungsbruch von α–Eisenvielkristallen. Int. J. Mater. Res. 1975, 66, 719–724. [Google Scholar] [CrossRef]

- Chu, R.Q.; Cai, Z.; Li, S.X.; Wang, Z.G. Fatigue crack initiation and propagation in an α-iron polycrystal. Mater. Sci. Eng. 2001, 313, 64–68. [Google Scholar] [CrossRef]

- Favier, V.; Blanche, A.; Wang, C.; Phung, N.L.; Ranc, N.; Wagner, D.; Bathias, C.; Chrysochoos, A.; Mughrabi, H. Very high cycle fatigue for single phase ductile materials: Comparison between α-iron, copper and α-brass polycrystals. Int. J. Fatigue 2016, 93, 326–338. [Google Scholar] [CrossRef] [Green Version]

- Young, C.; Subbarayan, G. Maximum Entropy Models for Fatigue Damage in Metals with Application to Low-Cycle Fatigue of aluminum 2024-T351. Entropy 2019, 21, 967. [Google Scholar] [CrossRef] [Green Version]

- Yun, H.; Modarres, M. Measures of Entropy to Characterize Fatigue Damage in Metallic Materials. Entropy 2019, 21, 804. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Osara, J.A.; Bryant, M.D. Thermodynamics of Fatigue: Degradation-Entropy Generation Methodology for System and Process Characterization and Failure Analysis. Entropy 2019, 21, 685. [Google Scholar] [CrossRef] [Green Version]

- Chrysochoos, A.; Huon, V.; Jourdan, F.; Muracciole, J.M.; Peyroux, R.; Wattrisse, B. Use of full-field digital image correlation and infrared thermography measurements for the thermomechanical analysis of material behaviour. Strain 2010, 46, 117–130. [Google Scholar] [CrossRef]

- Guo, Q.; Guo, X.L.; Fan, J.L.; Syed, R.; Wu, C.W. An energy method for rapid evaluation of high-cycle fatigue parameters based on intrinsic dissipation. Int. J. Fatigue 2015, 80, 136–144. [Google Scholar] [CrossRef]

- Yang, H.; Kumar Sinha, S.; Feng, Y.; McCallen, D.B.; Jeremić, B. Energy dissipation analysis of elastic-plastic materials. Comput. Methods Appl. Mech. Eng. 2018, 331, 309–326. [Google Scholar] [CrossRef] [Green Version]

- Luong, M.P. Infrared thermographic scanning of fatigue in metals. Nucl. Eng. Des. 1995, 158, 363–376. [Google Scholar] [CrossRef] [Green Version]

- Teng, Z.J.; Wu, H.R.; Boller, C.; Starke, P. Thermodynamic entropy as a marker of high-cycle fatigue damage accumulation: Example for normalized SAE 1045 steel. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 2854–2866. [Google Scholar] [CrossRef]

- Wang, X.G.; Feng, E.S.; Jiang, C. A microplasticity evaluation method in very high cycle fatigue. Int. J. Fatigue 2017, 94, 6–15. [Google Scholar] [CrossRef] [Green Version]

- Teng, Z.J.; Wu, H.R.; Boller, C.; Starke, P. A unified fatigue life calculation based on intrinsic thermal dissipation and microplasticity evolution. Int. J. Fatigue 2020, 131, 105370. [Google Scholar] [CrossRef]

- Maquin, F.; Pierron, F. Heat dissipation measurements in low stress cyclic loading of metallic materials: From internal friction to micro-plasticity. Mech. Mater. 2009, 41, 928–942. [Google Scholar] [CrossRef]

- Boulanger, T.; Chrysochoos, A.; Mabru, C.; Galtier, A. Calorimetric analysis of dissipative and thermoelastic effects associated with the fatigue behavior of steels. Int. J. Fatigue 2004, 26, 221–229. [Google Scholar] [CrossRef]

- Bathias, C.; Paris, P.C. Gigacycle Fatigue in Mechanical Practice; Marcel Dekker Inc.: New York, NY, USA, 2005. [Google Scholar]

- Meneghetti, G.; Ricotta, M. The heat energy dissipated in the material structural volume to correlate the fatigue crack growth rate in stainless steel specimens. Int. J. Fatigue 2018, 115, 107–119. [Google Scholar] [CrossRef]

- Sih, G.C. Multiscale Fatigue Crack Initiation and Propagation of Engineering Materials: Structural Integrity and Microstructural Worthiness, 1st ed.; Springer: Cham, Switzerland, 2008. [Google Scholar]

- Tada, H.; Paris, P.C.; Irwin, R. The Stress Analysis of Cracks Handbook, 3rd ed.; ASME Press: New York, NY, USA, 2000. [Google Scholar]

- Pippan, R. Threshold and effective threshold of fatigue crack propagation in ARMCO iron. Mater. Sci. Eng. 1991, 138, 1–13. [Google Scholar] [CrossRef]

- Lieurade, H.P.; Lemaître, J.; Lachat, J.C. Résistance à la Fatigue; Béranger, G., Henry, G., Sanz, G., Lavoisier, S., Eds.; Le livre de l’acier: Paris, France, 1994; pp. 275–329. [Google Scholar]

| C | Mn | P | S | Cu | N | Si | Al | Cr | Mo | Ni | Sn |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.001 | 0.050 | 0.005 | 0.003 | 0.007 | 0.0022 | 0.003 | 0.005 | 0.014 | 0.002 | 0.013 | 0.002 |

| C (m·cycle−1·MPa·m1/2) | m |

|---|---|

| 3.9 × 10−12 < C < 5.32 × 10−11 | 2.53 < m < 3.15 |

| Crack Length (µm) | ΔKeff (MPa·m1/2) | Δa/ΔN (m/cycle) | u(Δa/ΔN) (m/cycle) | Uncertainty Relative (%) |

|---|---|---|---|---|

| 300 | 4.3359 | 8.6945 × 10−10 | 2.9298 × 10−8 | 58.5 |

| 500 | 5.9186 | 4.1389 × 10−9 | 5.1187 × 10−10 | 12.3 |

| 700 | 7.5353 | 6.2420 × 10−9 | 5.1565 × 10−10 | 8.2 |

| 900 | 9.3140 | 9.0510 × 10−9 | 5.2131 × 10−10 | 5.7 |

| 1100 | 11.3245 | 8.5580 × 10−8 | 5.2708 × 10−10 | 6.1 |

| 1300 | 13.6817 | 1.6358 × 10−8 | 5.3729 × 10−10 | 3.3 |

| 1500 | 16.3508 | 2.9298 × 10−8 | 5.4037 × 10−10 | 1.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Postel, V.; Petit, J.; Wang, C.; Tan, K.; Ranc-Darbord, I.; Wang, Q.; Wagner, D. In-Situ Thermography Investigation of Crack Growth in Armco Iron under Gigacycle Fatigue Loading. Metals 2022, 12, 870. https://doi.org/10.3390/met12050870

Postel V, Petit J, Wang C, Tan K, Ranc-Darbord I, Wang Q, Wagner D. In-Situ Thermography Investigation of Crack Growth in Armco Iron under Gigacycle Fatigue Loading. Metals. 2022; 12(5):870. https://doi.org/10.3390/met12050870

Chicago/Turabian StylePostel, Victor, Johann Petit, Chong Wang, Kai Tan, Isabelle Ranc-Darbord, Qingyuan Wang, and Daniele Wagner. 2022. "In-Situ Thermography Investigation of Crack Growth in Armco Iron under Gigacycle Fatigue Loading" Metals 12, no. 5: 870. https://doi.org/10.3390/met12050870

APA StylePostel, V., Petit, J., Wang, C., Tan, K., Ranc-Darbord, I., Wang, Q., & Wagner, D. (2022). In-Situ Thermography Investigation of Crack Growth in Armco Iron under Gigacycle Fatigue Loading. Metals, 12(5), 870. https://doi.org/10.3390/met12050870