The Effect of Ti Content in the Filler Powder on Interfacial Microstructure and Mechanical Properties of C/C Composites/T2-Copper Joints via Thermo-Compensated Resistance Brazing Welding

Abstract

1. Introduction

2. Experiment

2.1. Materials

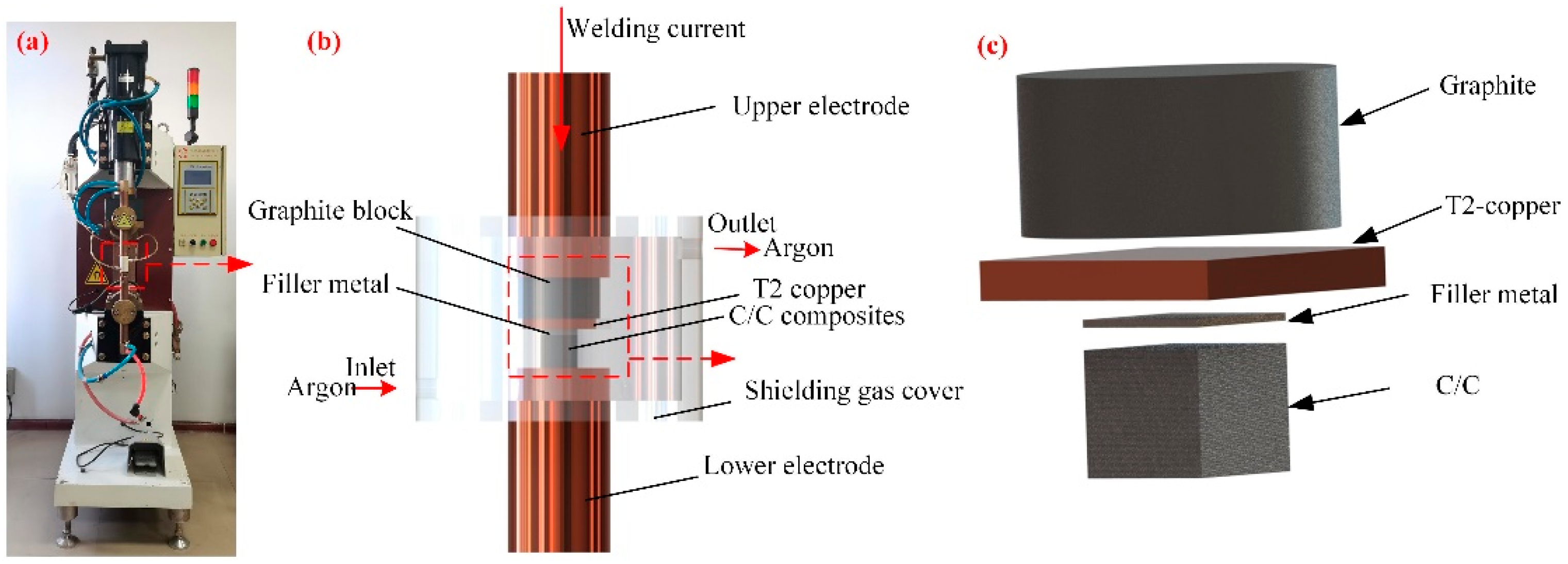

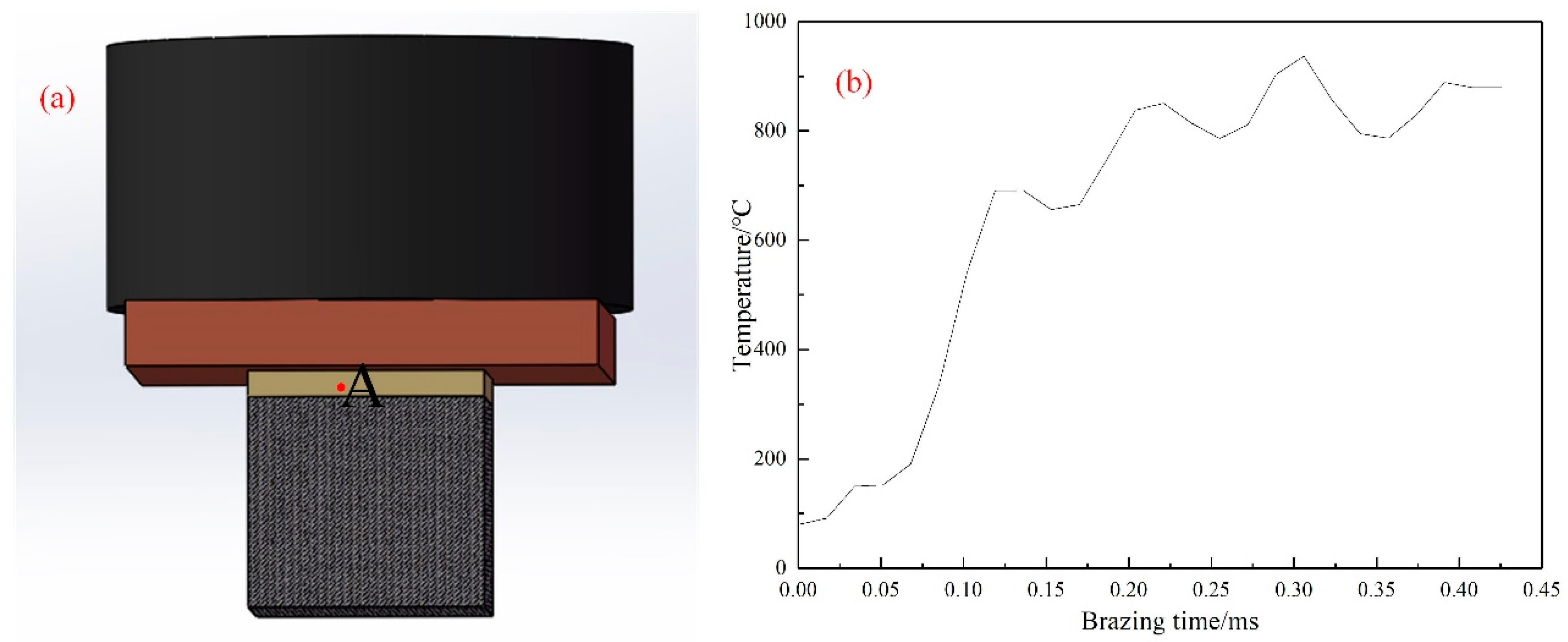

2.2. Equipment

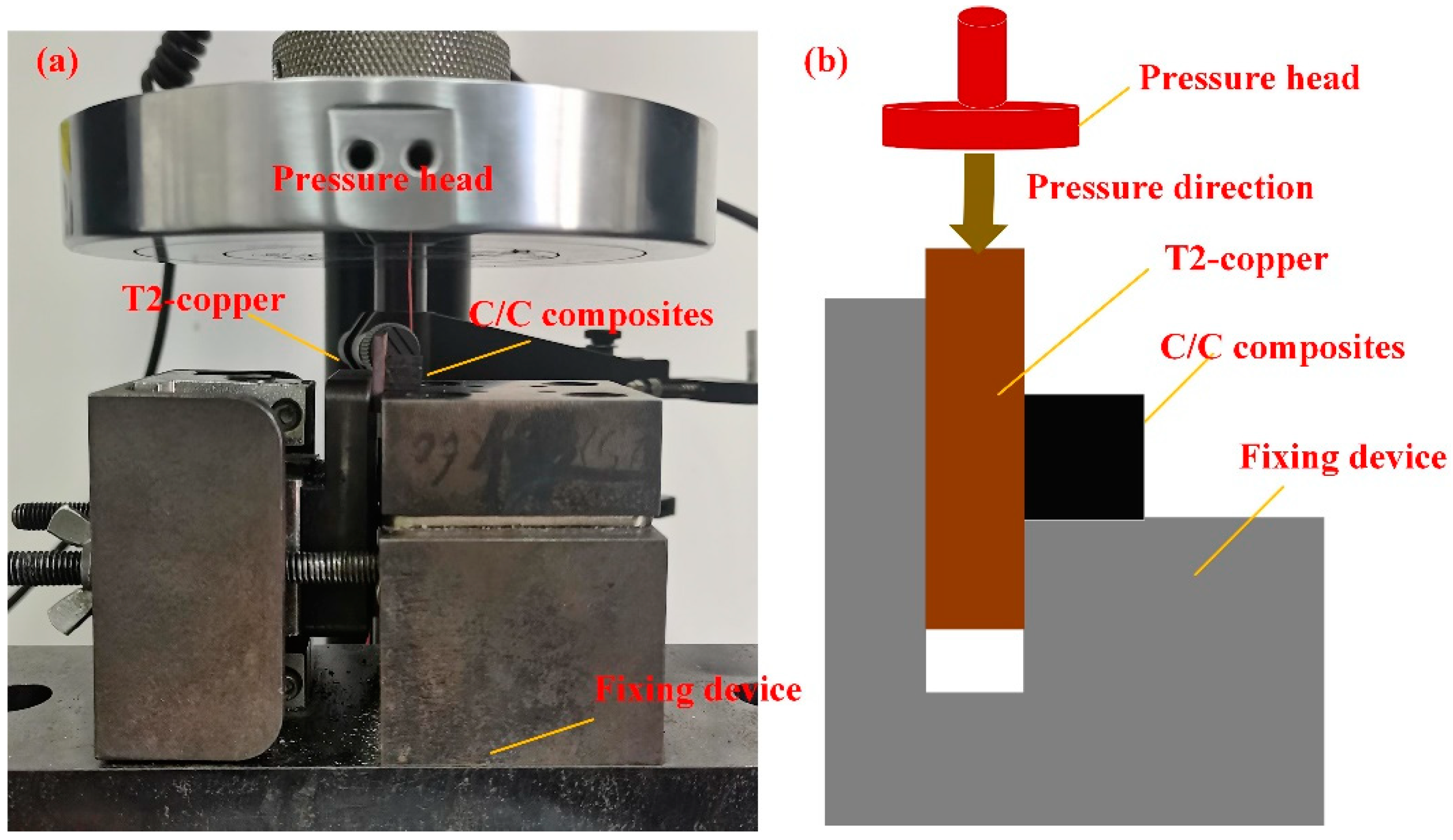

2.3. Microstructural Analysis and Shear Strength Test

3. Results and Discussion

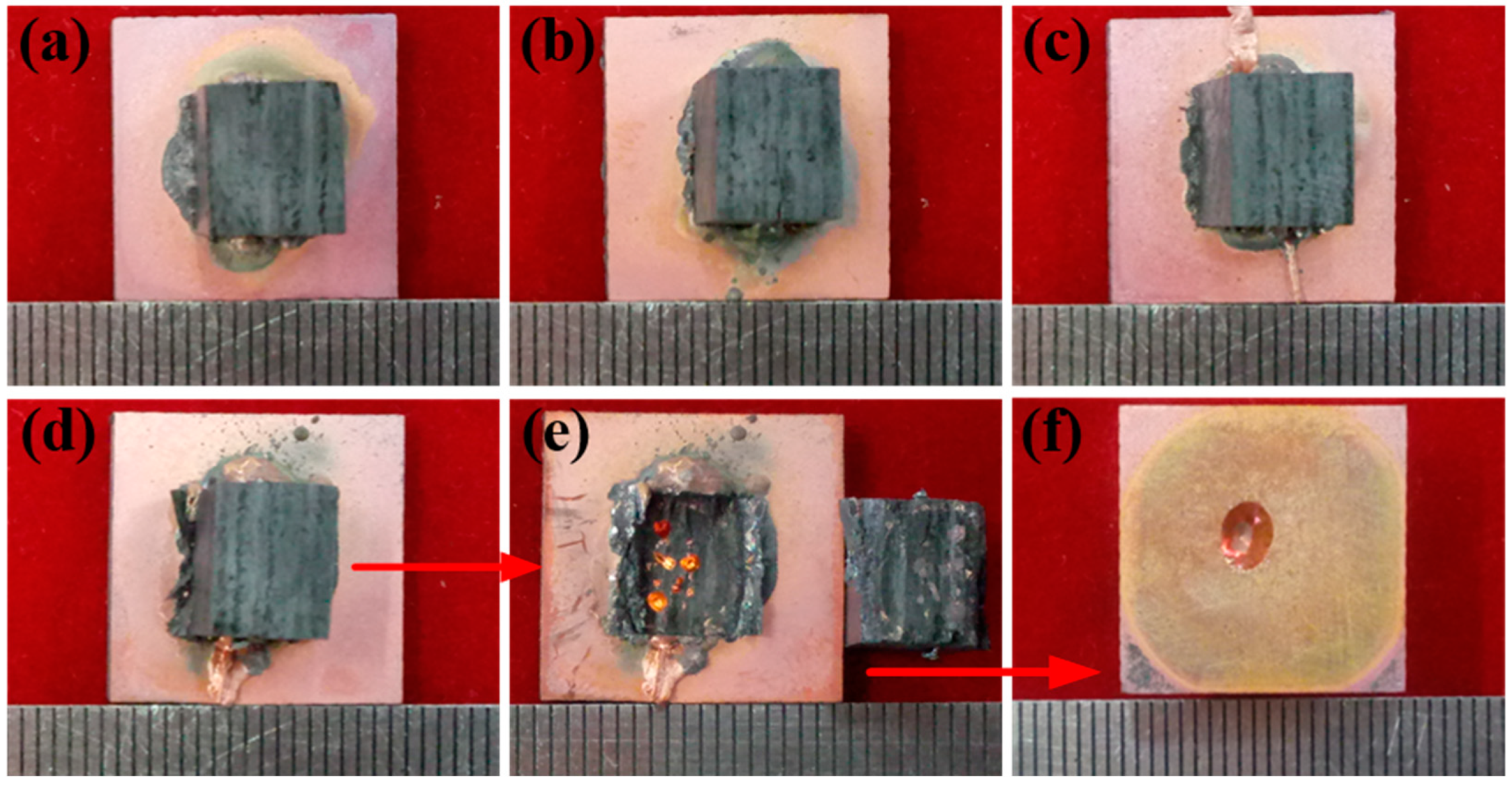

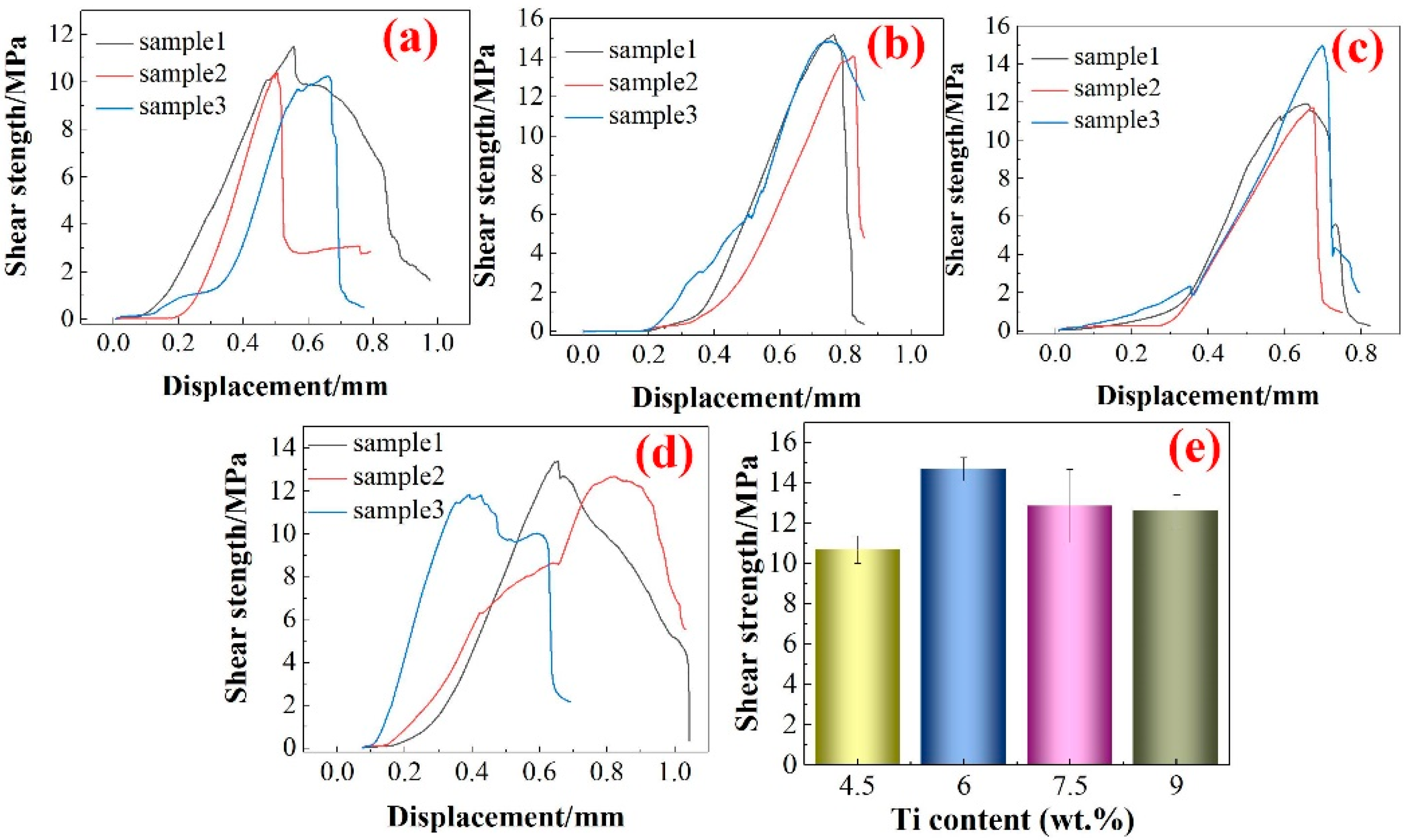

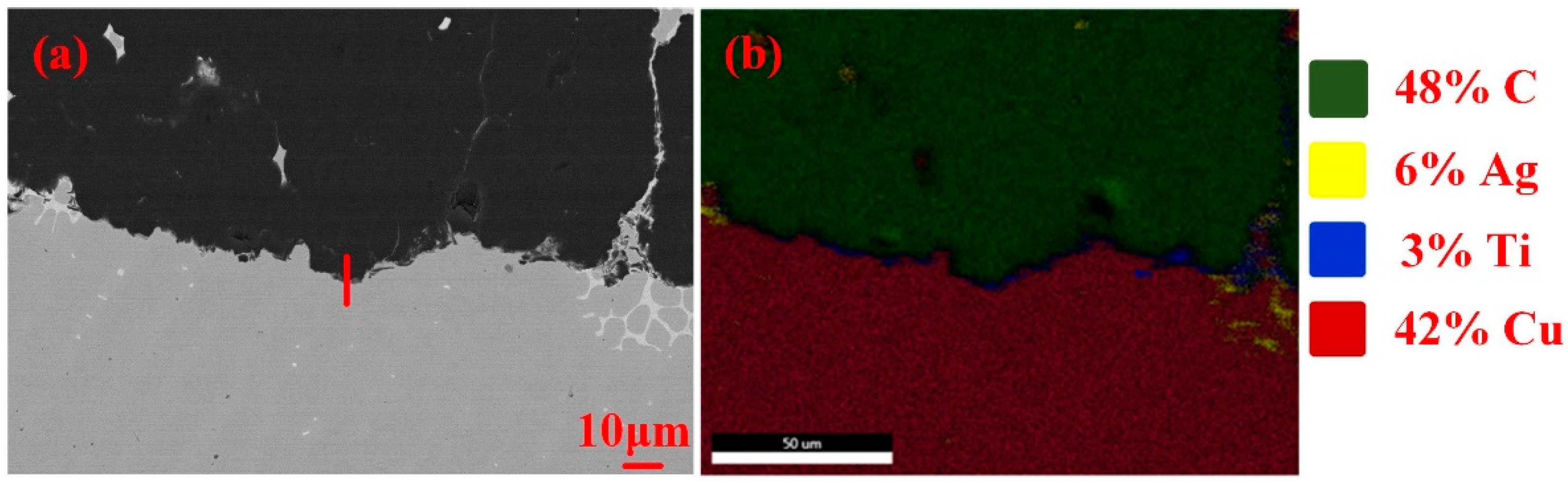

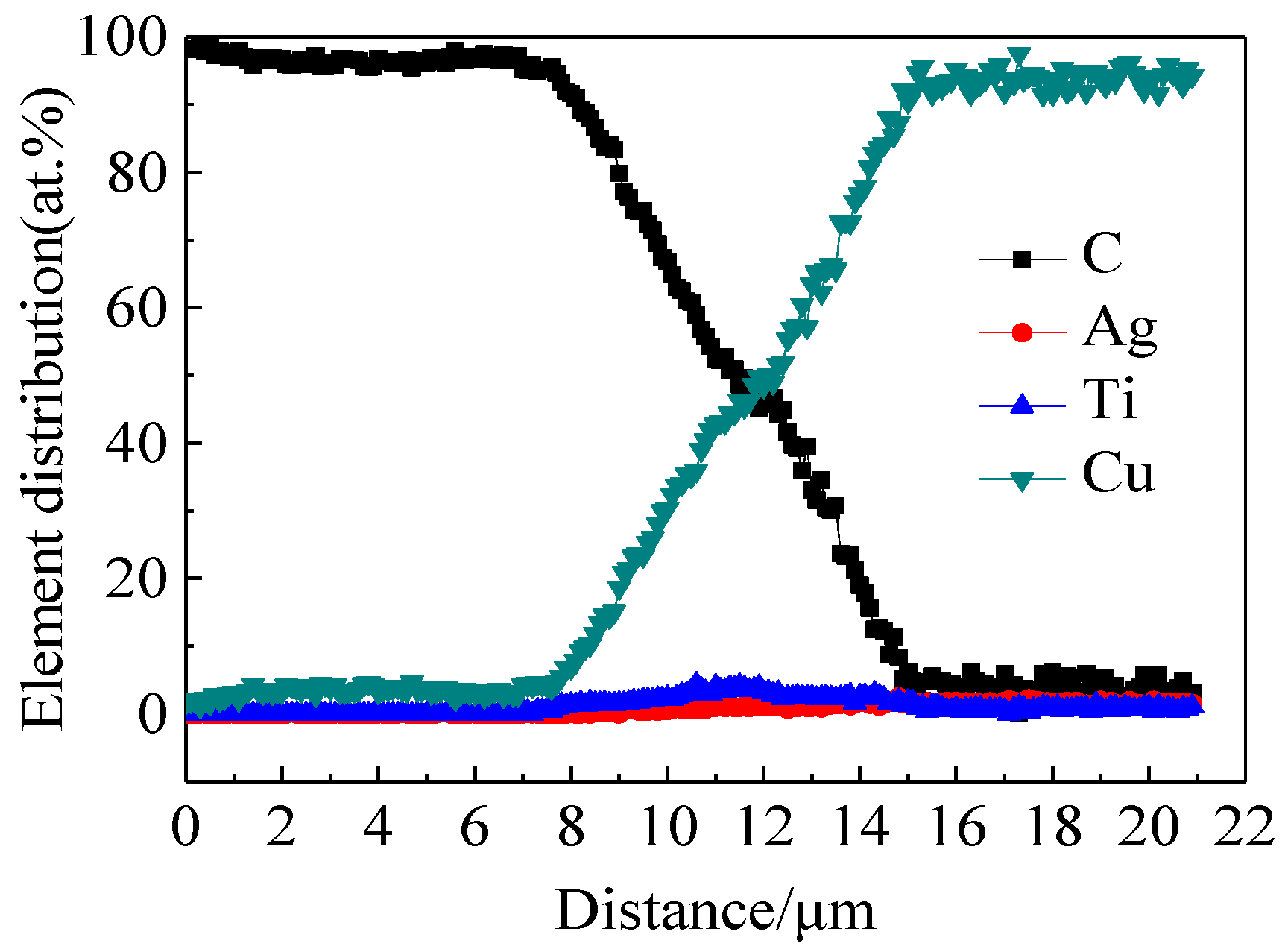

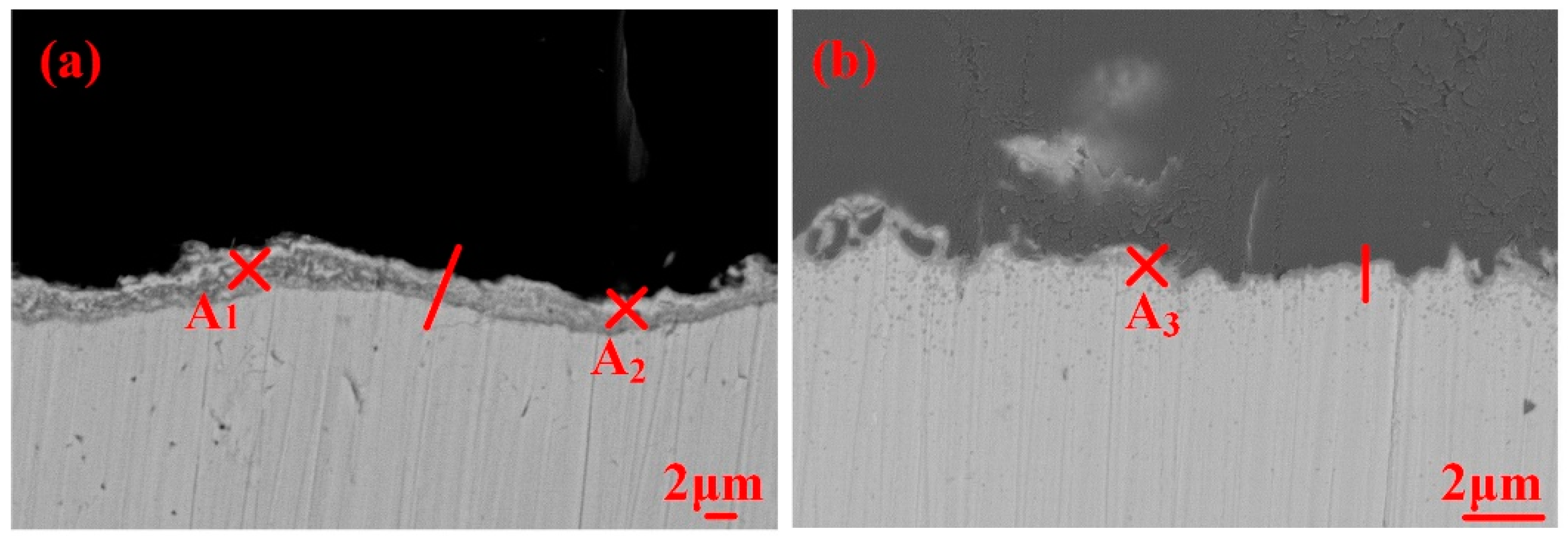

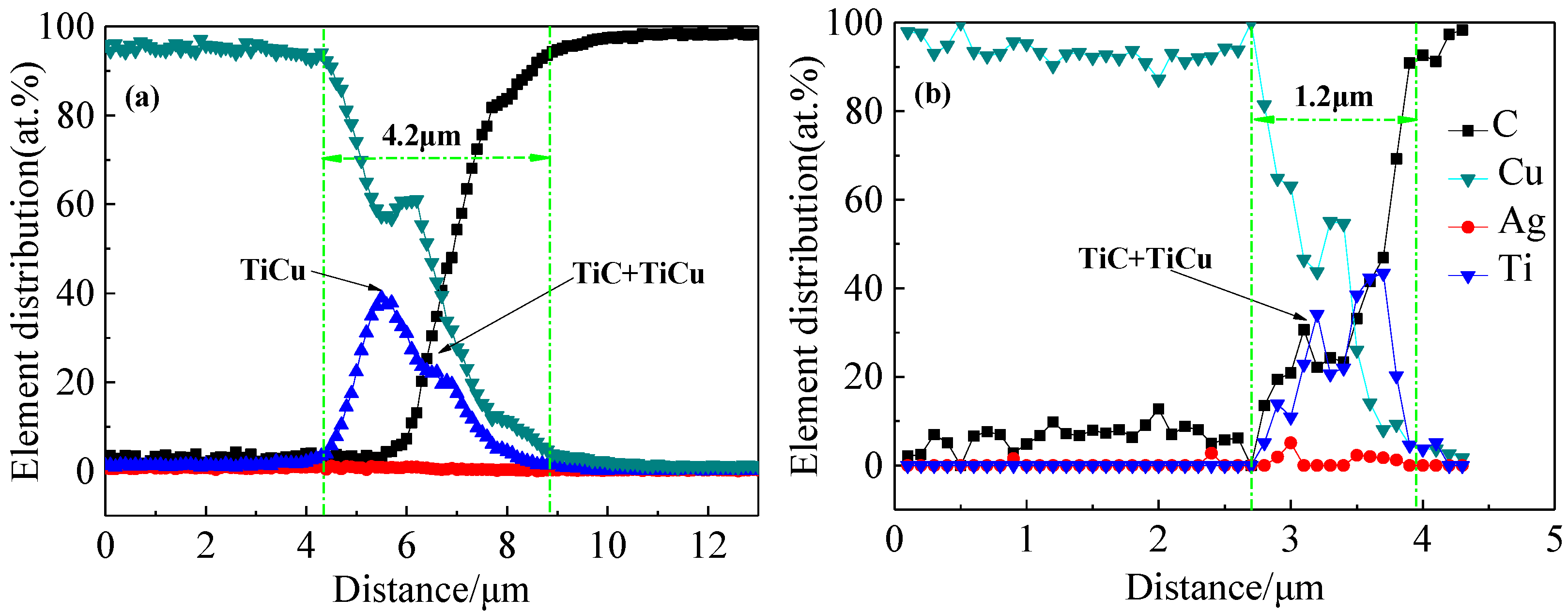

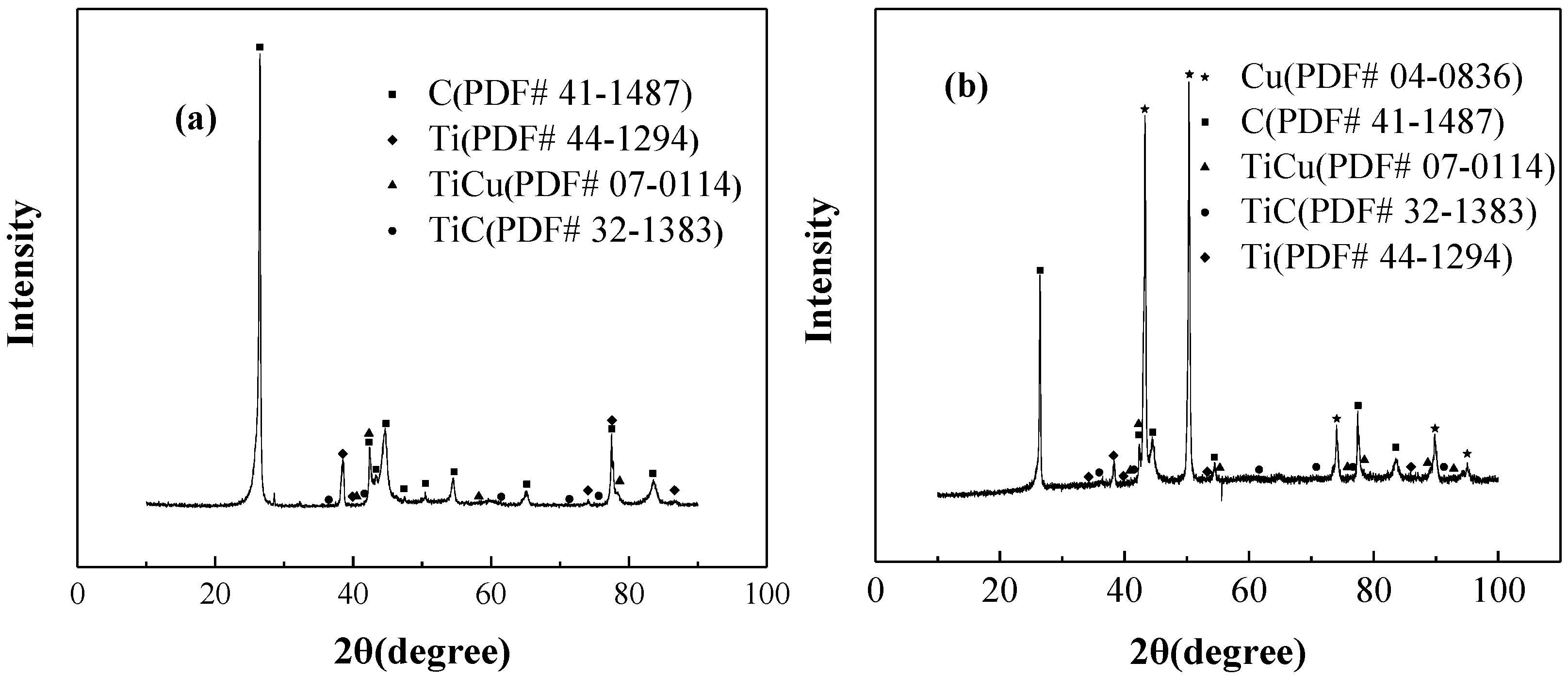

3.1. The Effect of Ti Content in the Composite Filler Metal on the Joint

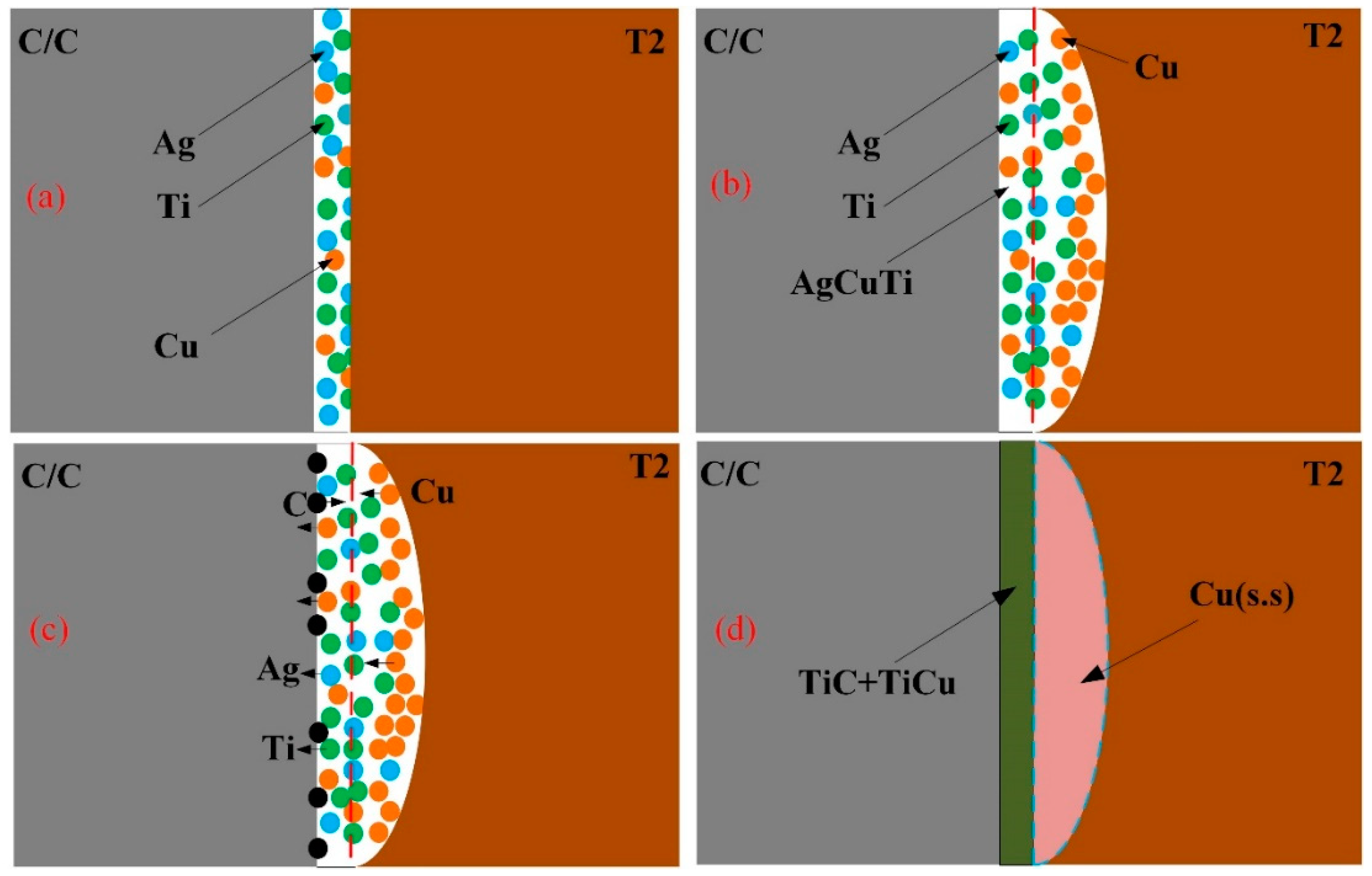

3.2. Thermodynamic Analysis and Microstructure Evolution of the Welded Joint

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huo, C.; Guo, L.; Cao, A.; Wang, Z.; Wang, C.; Kou, G.; Zhang, Y. The Degradation Behavior of C/C Composites in High-Energy Atomic Oxygen. Vacuum 2017, 146, 120–129. [Google Scholar] [CrossRef]

- Yi, Z.; Ran, L.; Yi, M. Differences in Microstructure and Properties of C/C Composites Brazed with Ag-Cu-Ti and Ni-Cr-P-Ti Pasty Brazing Filler. Vacuum 2019, 168, 108804. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, Y.; Bao, J.; Yang, G. A Novel Active Braze Composition Design Route for C/C Composite Using Fe as Active Element. Carbon 2021, 181, 177–192. [Google Scholar] [CrossRef]

- Shokati, A.A.; Zhou, N.Y.; Wen, J.Z. Dissimilar Joining of Carbon/Carbon Composites to Ti6Al4V Using Reactive Resistance Spot Welding. J. Alloys Compd. 2019, 772, 418–428. [Google Scholar] [CrossRef]

- Dhara, S.; Das, A. Impact of Ultrasonic Welding on Multi-Layered Al–Cu Joint for Electric Vehicle Battery Applications: A Layer-Wise Microstructural Analysis. Mater. Sci. Eng. A 2020, 791, 139795. [Google Scholar] [CrossRef]

- Fujii, H.T.; Endo, H.; Sato, Y.S.; Kokawa, H. Interfacial Microstructure Evolution and Weld Formation during Ultrasonic Welding of Al Alloy to Cu. Mater. Charact. 2018, 139, 233–240. [Google Scholar] [CrossRef]

- Zhang, L.J.; Zhang, G.F.; Ning, J.; Zhang, X.J.; Zhang, J.X. Microstructure and Properties of the Laser Butt Welded 1.5-Mm Thick T2 Copper Joint Achieved at High Welding Speed. Mater. Des. 2015, 88, 720–736. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, G.; Li, M.; Lin, J.; Ma, Q.; Zhang, A.; Zhong, Z.; Qi, J.; Feng, J. Three-Dimensional Graphene-Reinforced Cu Foam Interlayer for Brazing C/C Composites and Nb. Carbon 2017, 118, 723–730. [Google Scholar] [CrossRef]

- Luo, Y.; Bian, H.; Niu, H.W.; Song, Y.Y.; Chen, Z.B.; Song, X.G.; Wang, M.R. Interfacial Microstructure and Mechanical Properties of C/C Composites and Nb Joints Brazed with Cu75Pt25 Filler Metal. Vacuum 2018, 157, 202–209. [Google Scholar] [CrossRef]

- Shi, X.; Jin, X.; Lin, H.; Jing, J.; Li, L.; Wang, C. Joining of SiC Nanowires-Toughened SiC Coated C/C Composites and Nickel Based Superalloy (GH3044) Using Ni71CrSi Interlayer. J. Alloys Compd. 2017, 693, 837–842. [Google Scholar] [CrossRef]

- Huang, D.; Zhang, M.; Huang, Q.; Wang, L.; Tong, K. Mechanical Property, Oxidation and Ablation Resistance of C/C–ZrB2–ZrC–SiC Composite Fabricated by Polymer Infiltration and Pyrolysis with Preform of Cf/ZrB2. J. Mater. Sci. Technol. 2017, 33, 481–486. [Google Scholar] [CrossRef]

- Zhang, K.; Xia, L.; Zhang, F.; He, L. Active Brazing of C/C Composite to Copper by AgCuTi Filler Metal. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2016, 47, 2162–2176. [Google Scholar] [CrossRef]

- Zhou, Y.H.; Liu, D.; Niu, H.W.; Song, X.G.; Yang, X.D.; Feng, J.C. Vacuum Brazing of C/C Composite to TC4 Alloy Using Nano-Al2O3 Strengthened AgCuTi Composite Filler. Mater. Des. 2016, 93, 347–356. [Google Scholar] [CrossRef]

- Guo, W.; Wang, L.; Zhu, Y.; Chu, P.K. Microstructure and Mechanical Properties of C/C Composite/TC4 Joint with Inactive AgCu Filler Metal. Ceram. Int. 2015, 41, 7021–7027. [Google Scholar] [CrossRef]

- Liu, D.; Song, Y.; Zhou, Y.; Song, X.; Fu, W.; Feng, J. Brazing of C/C Composite and Ti-6Al-4V with Graphene Strengthened AgCuTi Filler: Effects of Graphene on Wettability, Microstructure and Mechanical Properties. Chin. J. Aeronaut. 2018, 31, 1602–1608. [Google Scholar] [CrossRef]

- Zhang, S.; Yuan, Y.; Su, Y.; Song, X. Interfacial Microstructure and Mechanical Properties of Brazing Carbon/Carbon Composites to Stainless Steel Using Diamond Particles Reinforced Ag-Cu-Ti Brazing Alloy. J. Alloys Compd. 2017, 719, 108–115. [Google Scholar] [CrossRef]

- Wang, J.; Kezhi, L.I.; Song, X.; Guo, L.; Wei, L.I.; Zhaoqian, L.I. The Study on Joining Carbon/Carbon Composites Using Ti―Ni―Si Compound. Mater. Sci. Eng. A 2012, 547, 12–18. [Google Scholar] [CrossRef]

- Ikesheoji, T.-T.; Amanuma, T.; Suzumura, A.; Yamazaki, T. Shear Strength of Brazed Joint Between Titanium and C/C Composites With Various Cross-Ply Angles. J. Solid Mech. Mater. Eng. 2011, 5, 1022–1028. [Google Scholar] [CrossRef][Green Version]

- Yuan, X.; Li, C.; Chen, J.; Li, X.; Liang, X.; Pan, X. Resistance Spot Welding of Dissimilar DP600 and DC54D Steels. J. Mater. Process. Technol. 2017, 239, 31–41. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, H.; Wang, B.; Gao, C.; Sun, Z.; He, P. Dissimilar Metal Joining of Q235 Mild Steel to Ti6Al4V via Resistance Spot Welding with Ni–Cu Interlayer. J. Mater. Res. Technol. 2021, 15, 4086–4101. [Google Scholar] [CrossRef]

- Tahri, C.; Bertoni, C.; Feulvarch, E.; Klocker, H.; Bergheau, J.M. Numerical Simulation of the Resistance Braze Welded Assembly of a Copper Inconel 601 Ground Electrode and a Steel Shell. Numer. Heat Transf. Part A Appl. 2020, 78, 73–93. [Google Scholar] [CrossRef]

- Ji, H.; Li, M.; Lu, Y.; Wang, C. Mechanical Properties and Microstructures of Hybrid Ultrasonic Resistance Brazing of WC-Co/BeCu. J. Mater. Process. Technol. 2012, 212, 1885–1891. [Google Scholar] [CrossRef]

- Zhang, P.; Fang, Z.; Li, S. Microstructure and Interfacial Reactions of Resistance Brazed Lap Joints between Tc4 Titanium Alloy and 304 Stainless Steel Using Metal Powder Interlayers. Materials 2021, 14, 180. [Google Scholar] [CrossRef] [PubMed]

- Vodă, M.; Codrean, C.; Chicot, D.; Şerban, V.A.; Uţu, D.; Linul, E.; Buzdugan, D. Characterization of Brazed Joints by Electrical Resistance Spot Brazing with Ni-Based Amorphous Self-Flux Alloys. J. Manuf. Process. 2019, 37, 617–627. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Song, X.G.; Tan, C.W.; Hu, S.P.; Cao, J.; Feng, J.C. Microstructural Evolution of Si3N4/Ti6Al4V Joints Brazed with Nano-Si3N4 Reinforced AgCuTi Composite Filler. Vacuum 2017, 142, 58–65. [Google Scholar] [CrossRef]

- Song, Y.; Liu, D.; Hu, S.; Song, X.; Cao, J. Graphene Nanoplatelets Reinforced AgCuTi Composite Filler for Brazing SiC Ceramic. J. Eur. Ceram. Soc. 2019, 39, 696–704. [Google Scholar] [CrossRef]

- Song, X.; Zhao, Y.; Hu, S.; Cao, J.; Fu, W.; Feng, J. Wetting of AgCu-Ti Filler on Porous Si3N4 Ceramic and Brazing of the Ceramic to TiAl Alloy. Ceram. Int. 2018, 44, 4622–4629. [Google Scholar] [CrossRef]

- Zhu, W.; Chen, J.; Jiang, C.; Hao, C.; Zhang, J. Effects of Ti Thickness on Microstructure and Mechanical Properties of Alumina-Kovar Joints Brazed with Ag-Pd/Ti Filler. Ceram. Int. 2014, 40, 5699–5705. [Google Scholar] [CrossRef]

- Jin, Y.; Jiahao, S.; Chenkai, G.; Yixuan, Z.; Hongbing, L.; Ovliera, J.P.; Caiwang, T.; Zhishui, Y. Effect of Heat Input on Interfacial Microstructure, Tensile and Bending Properties of Dissimilar Al/Steel Lap Joints by Laser Welding-Brazing. Opt. Laser Technol. 2021, 142, 107218. [Google Scholar] [CrossRef]

- Shamsolhodaei, A.; Oliveira, J.P.; Schell, N.; Maawad, E.; Panton, B.; Zhou, Y.N. Controlling Intermetallic Compounds Formation during Laser Welding of NiTi to 316L Stainless Steel. Intermetallics 2020, 116, 106656. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Shen, J.; Zeng, Z.; Park, J.M.; Choi, Y.T.; Schell, N.; Maawad, E.; Zhou, N.; Kim, H.S. Dissimilar Laser Welding of a CoCrFeMnNi High Entropy Alloy to 316 Stainless Steel. Scr. Mater. 2022, 206, 114219. [Google Scholar] [CrossRef]

- Wang, W.; Liu, Y.; Wang, G.; Tan, C.; Cao, W. Vacuum Brazing ZSCfcomposite Ceramics to TC4 Alloy with Ag-Cu Filler. J. Mater. Res. Technol. 2020, 9, 8627–8635. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, G.; Cao, W.; Xu, H.; Huang, Z.; Zhu, D.; Tan, C. Brazing ZrB2-SiC Ceramics to Ti6Al4V Alloy with TiCu-Based Amorphous Filler. J. Manuf. Process. 2017, 30, 516–522. [Google Scholar] [CrossRef]

- Singh, M.; Shpargel, T.P.; Morscher, G.N.; Asthana, R. Active Metal Brazing and Characterization of Brazed Joints in Titanium to Carbon-Carbon Composites. Mater. Sci. Eng. A 2005, 412, 123–128. [Google Scholar] [CrossRef]

- Xiong, J.H.; Huang, J.H.; Zhang, H.; Zhao, X.K. Brazing of Carbon Fiber Reinforced SiC Composite and TC4 Using Ag-Cu-Ti Active Brazing Alloy. Mater. Sci. Eng. A 2010, 527, 1096–1101. [Google Scholar] [CrossRef]

| Ti | Fe | Si | Mn | Mg | O | C | N | Cl | H |

|---|---|---|---|---|---|---|---|---|---|

| 99.5 | 0.08 | 0.02 | 0.01 | 0.05 | 0.30 | 0.02 | 0.03 | 0.04 | 0.02 |

| Welding Current | Welding Pressure | Welding Time |

|---|---|---|

| 8 kA | 0.1 MPa | 60 ms |

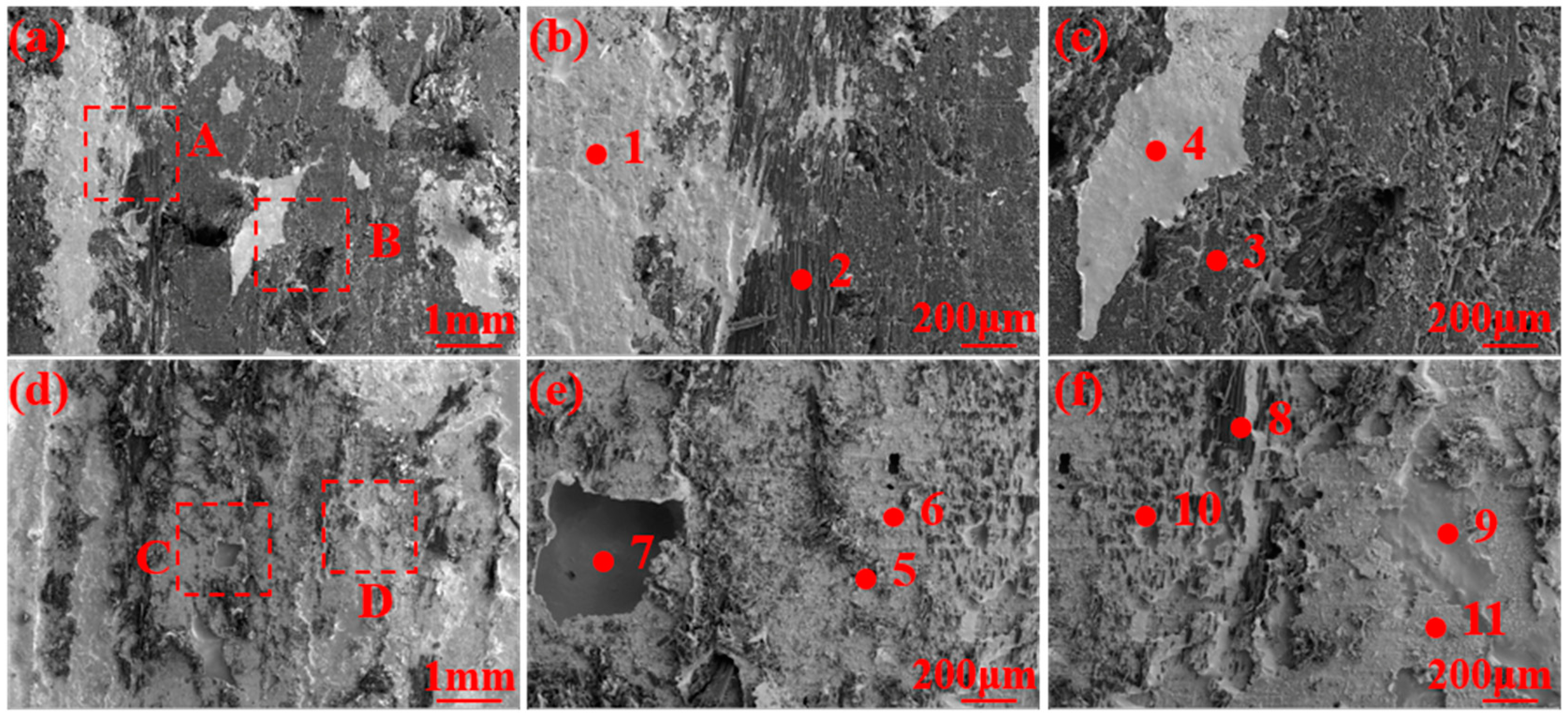

| Element | C | Ag | Ti | Cu | Possible Phase |

|---|---|---|---|---|---|

| A1 | 28.15 | 0.49 | 31.93 | 39.43 | TiC + TiCu |

| A2 | 84.29 | 0.04 | 7.66 | 8.01 | C + less TiCu |

| A3 | 35.11 | 0.36 | 26.62 | 37.91 | TiC + TiCu |

| Element | C | Ag | Ti | Cu | Possible Phase |

|---|---|---|---|---|---|

| 1 | 66.93 | 3.02 | 5.21 | 24.83 | C |

| 2 | 99.37 | 0.02 | 0.36 | 0.24 | C |

| 3 | 86.76 | 0.70 | 6.26 | 6.28 | C |

| 4 | 18.38 | 2.28 | 3.47 | 75.88 | Cu (s,s) |

| 5 | 45.75 | 9.12 | 14.54 | 30.59 | TiC + TiCu |

| 6 | 78.81 | 5.64 | 6.54 | 9.02 | C |

| 7 | 64.86 | 2.72 | 2.76 | 29.66 | C |

| 8 | 99.88 | 0.01 | 0.01 | 0.10 | C |

| 9 | 19.08 | 0.73 | 2.80 | 77.38 | Cu (s,s) |

| 10 | 78.59 | 8.62 | 3.15 | 9.65 | C |

| 11 | 18.41 | 14.56 | 46.28 | 20.75 | TiC + TiCu |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, J.; Miao, X.; Zhang, H.; Wang, B.; Qu, C. The Effect of Ti Content in the Filler Powder on Interfacial Microstructure and Mechanical Properties of C/C Composites/T2-Copper Joints via Thermo-Compensated Resistance Brazing Welding. Metals 2022, 12, 815. https://doi.org/10.3390/met12050815

Yu J, Miao X, Zhang H, Wang B, Qu C. The Effect of Ti Content in the Filler Powder on Interfacial Microstructure and Mechanical Properties of C/C Composites/T2-Copper Joints via Thermo-Compensated Resistance Brazing Welding. Metals. 2022; 12(5):815. https://doi.org/10.3390/met12050815

Chicago/Turabian StyleYu, Jiang, Xinglin Miao, Hongtao Zhang, Bo Wang, and Changming Qu. 2022. "The Effect of Ti Content in the Filler Powder on Interfacial Microstructure and Mechanical Properties of C/C Composites/T2-Copper Joints via Thermo-Compensated Resistance Brazing Welding" Metals 12, no. 5: 815. https://doi.org/10.3390/met12050815

APA StyleYu, J., Miao, X., Zhang, H., Wang, B., & Qu, C. (2022). The Effect of Ti Content in the Filler Powder on Interfacial Microstructure and Mechanical Properties of C/C Composites/T2-Copper Joints via Thermo-Compensated Resistance Brazing Welding. Metals, 12(5), 815. https://doi.org/10.3390/met12050815