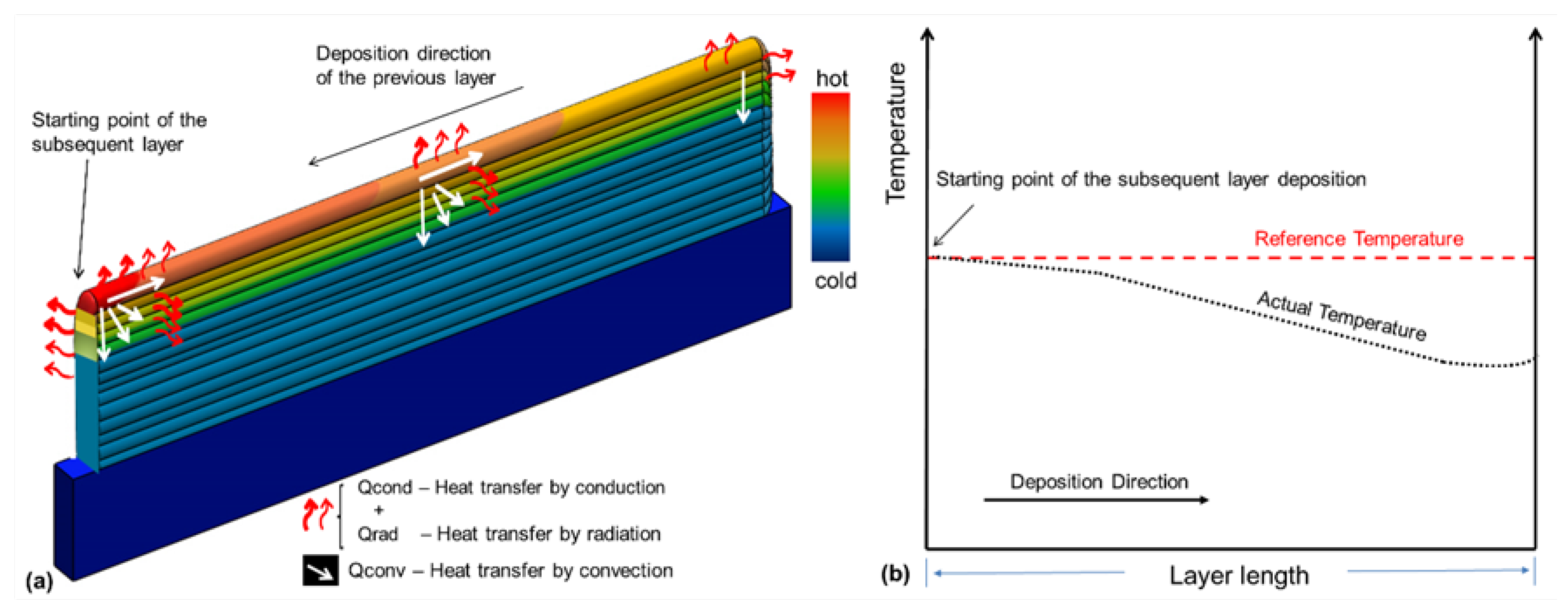

3.1. Existence of a Natural Temperature Gradient along the Wall (Temperature Measurement along the Wall without Electric Arc)

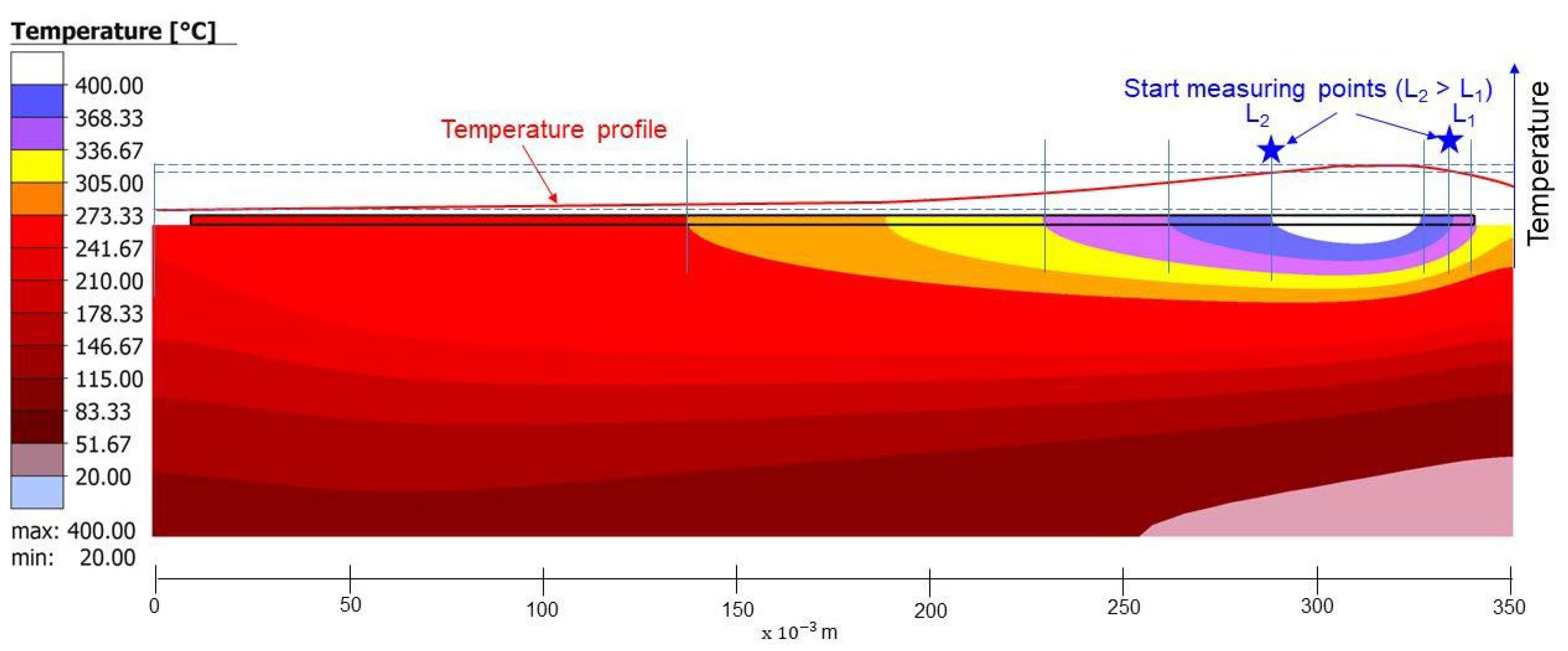

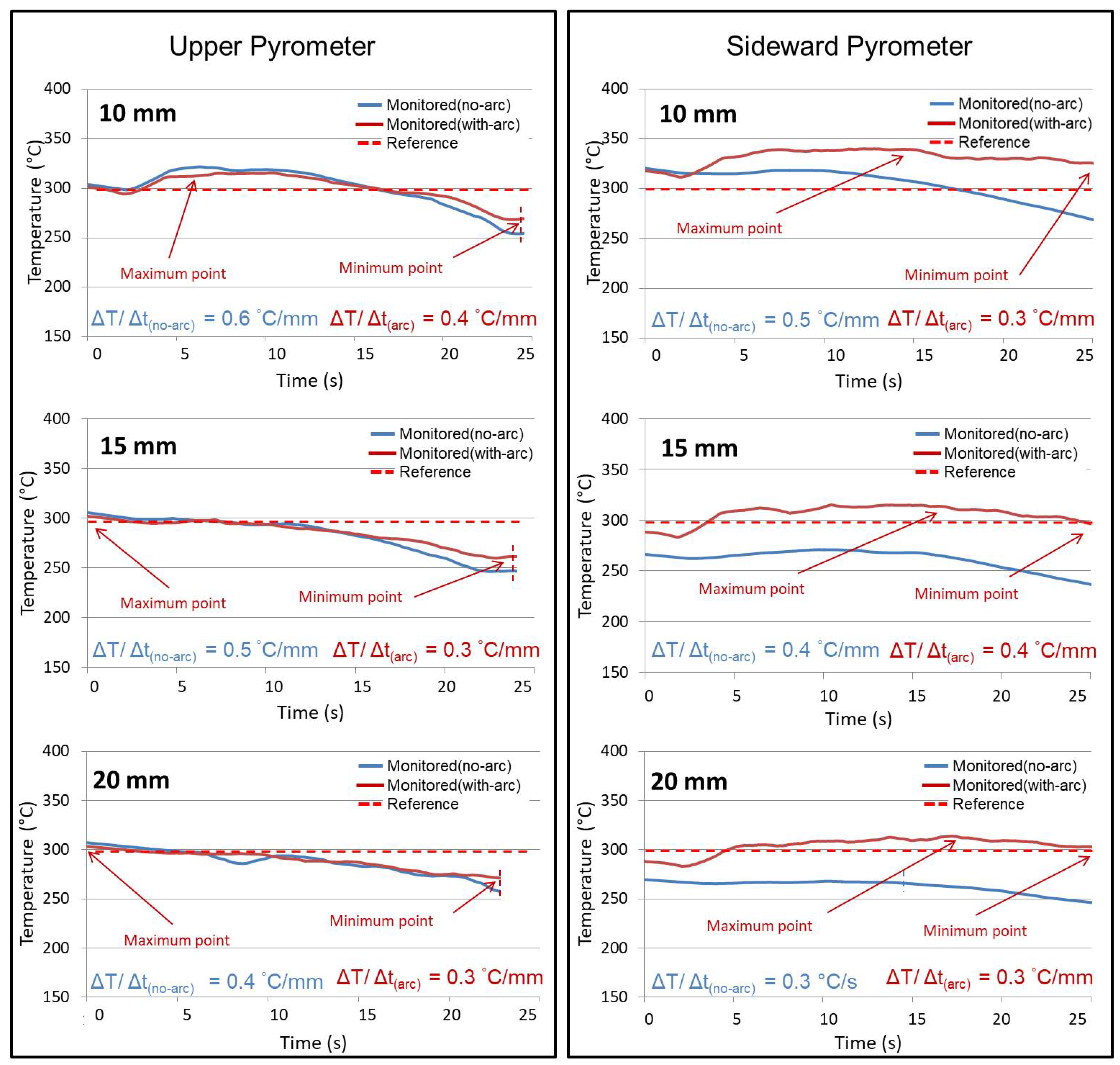

Figure 8 presents the temperature profiles for a hypothetical layer without the arc, consequently with no deposition (and delivered heat). The figure shows data from the fourth layer as representative of all experiments since very similar behavior was observed when comparing the temperature profiles between layers 2 and 4 of the same experiment. This is due to the constancy of the method and devices. The temperature profiles were individually obtained for the two pyrometer strategies, with the measurement points at 10 mm, 15 mm and 20 mm away from the heat source. As can be seen, the temperature gradients per unit of layer length in the no-arc condition ΔT/Δl

(no-arc) were also calculated for each condition and are presented in

Figure 8. To estimate ΔT/Δl

(no-arc), the difference between the representative maximum and minimum temperatures from the profiles (within the monitored range) was determined and then divided by the elapsed time between them.

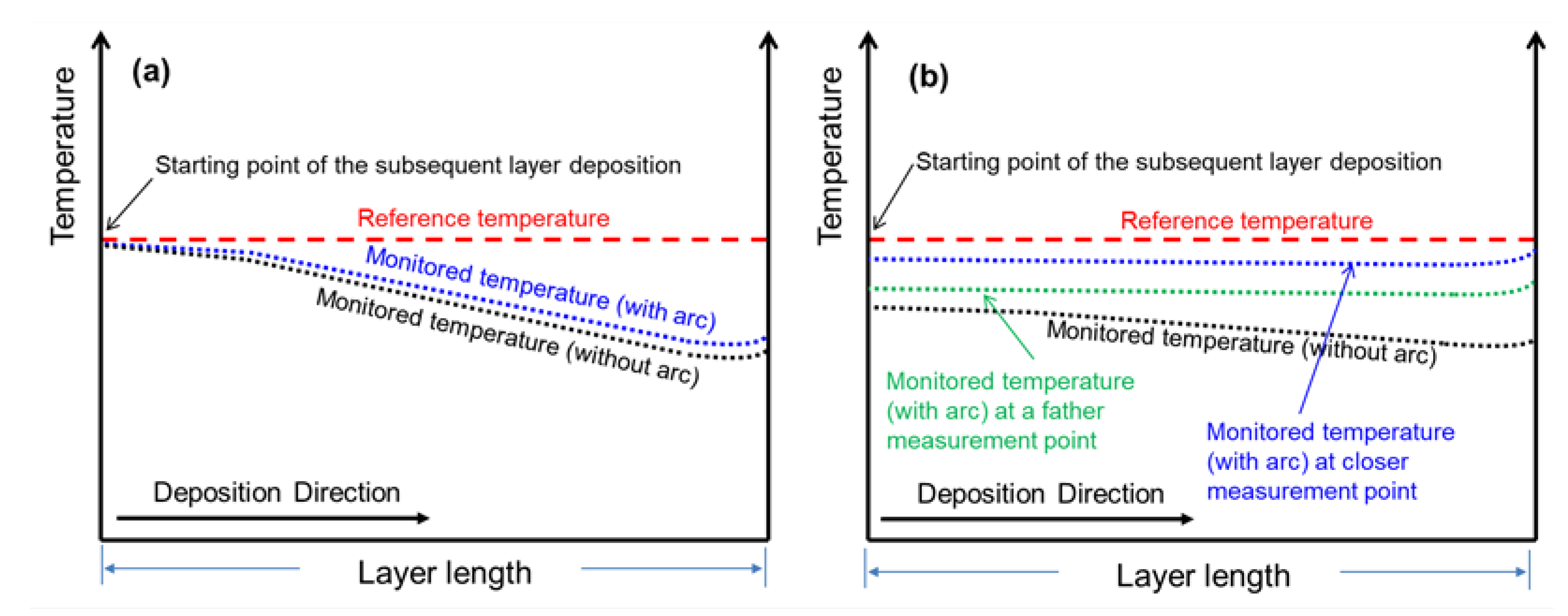

Regarding the Upper Pyrometer strategy plots, there is generally a tendency for reducing temperatures during the hypothetical deposition time, in agreement with the profile idealized in

Figure 1a. However, there is an apparent influence of the “L” distance on the temperature profiles. Using L = 10 mm, there is a maximum temperature point at a range from approximately 5 s to 7 s (the temperature is about 25 °C above the 300 °C set to start the pyrometer displacement), not seem when setting the other “L”. The authors suggest two explanations for this maximum. First, the melt pool in an arc welding/deposition presents a higher temperature at the symmetrical line of the heat source and it is characterized by a temperature profile that is more elongated on its back than its front. Consequently, the heat source centerline is not positioned at the wall edge, but at a certain distance from the edge. This temperature profile will be maintained when the arc is extinguished, considering the same heat diffusion towards all sides of the pool (only the isotherms values will progressively reduce). This is confirmed by the simulation shown in

Figure 9, in which the Goldak heat source was used in the model. Therefore, at a given distance from the edge of the wall, the temperature will be higher (around 320 s in

Figure 9). A second concurrent explanation is based on the fact that the heat losses are slightly higher at the edge than at a given short distance from the edge since there is more surface area for convective heat transfer.

Therefore, the temperature profile close to the layer surface presents a maximum at a short distance (between “L1” and “L2”), as depicted in

Figure 9, decaying continuously from this point up to the right edge of the wall. This reasoning justifies why only with the shortest start measuring point distance from the heat source (represented by “L1” in

Figure 9, equal to 10 mm in the experiments) a maximum is presented in

Figure 8 (for “L” equal or greater than 15 mm, the pyrometer would be already pointing at positions that the temperature was naturally falling (beyond L2 of

Figure 9).

It is interesting also to note that the temperature gradient per unit of length (ΔT/Δl(no-arc)) tended to decrease when measured with the Upper Pyrometer at different “L” distances (from 0.6 °C/mm to 0.3 °C/mm, when “L” increased from 10 mm to 20 mm, respectively). This reduction was also expected because cooling by conduction (main mechanisms at lower temperatures) is less efficient when the temperature difference shortens.

Analyzing the sideward strategy plots, in which the reference temperature is that measured by the upper pyrometer (having no relationship between the pyrometer measurands), the shorter the distance “L”, the higher the measured temperatures (it can even exceed the reference temperature if “L” is short) and the more uniform the profiles, as emphasized in

Figure 8). There is also a trend for the temperature to start falling during the torch translation time after some distance from the left edge. For the same reason as for the Upper Pyrometer strategy, the temperature gradient (ΔT/Δl

(no-arc)) tended to decrease (from 0.5 °C/mm to 0.3 °C/mm, for L = 10 mm to 20 mm, respectively). However, the loss of temperature uniformity starts progressively longer as “L” becomes more distant. This is justified by a more homogeneously distributed temperature in the wall when the Sideward Pyrometer pointer is farther from the latest deposited layer. This latter observation has already been observed, both through finite element simulations [

14,

15], and thermographic evaluations [

12,

16,

17].

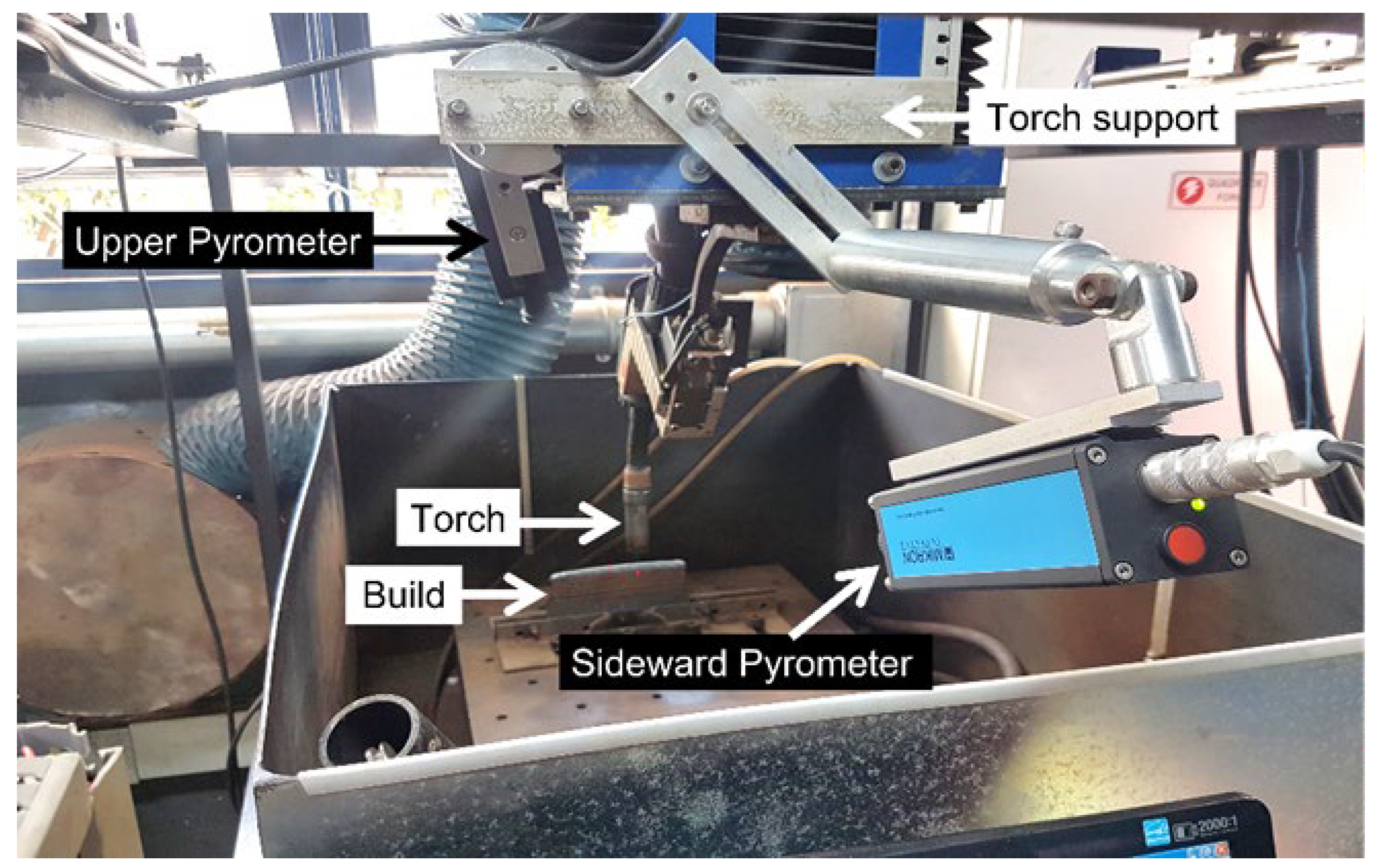

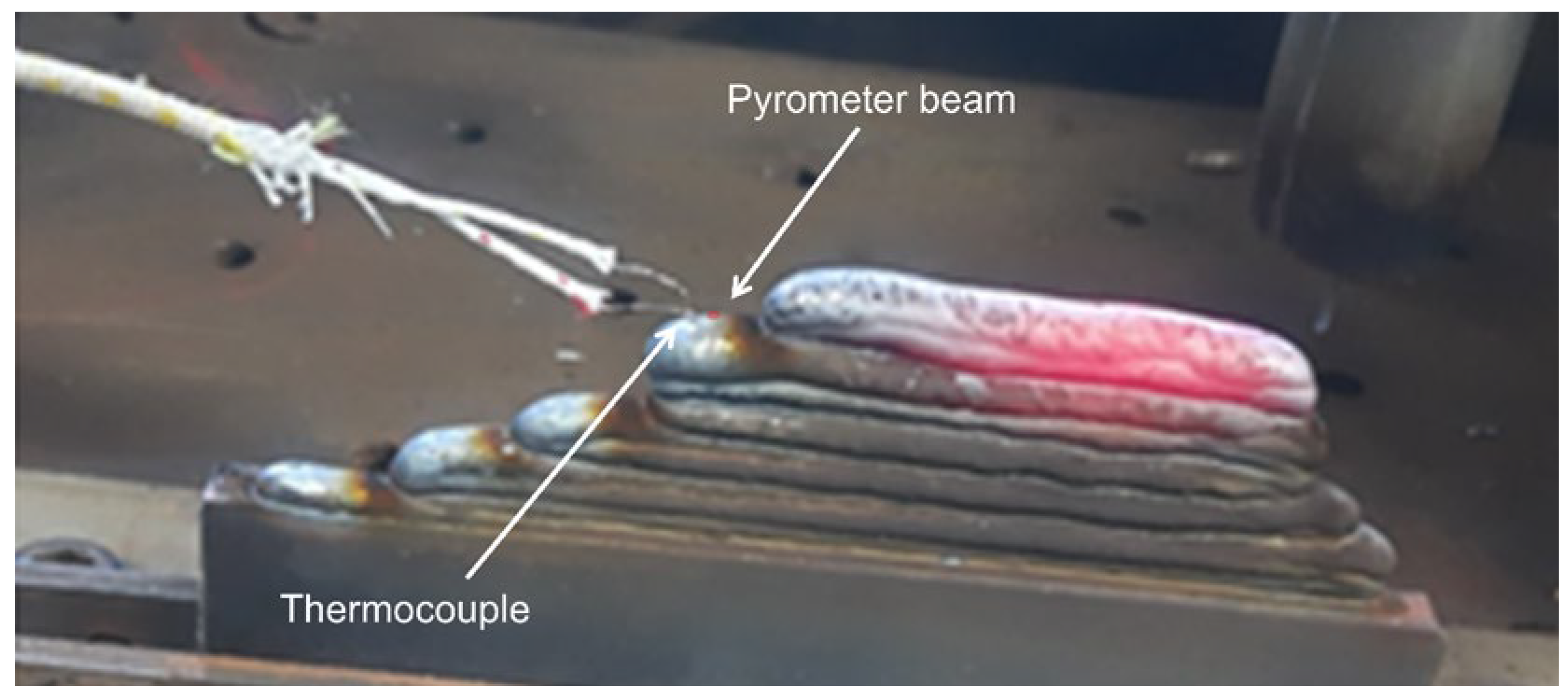

3.2. Temperature Measurements along the Wall with Electric Arc

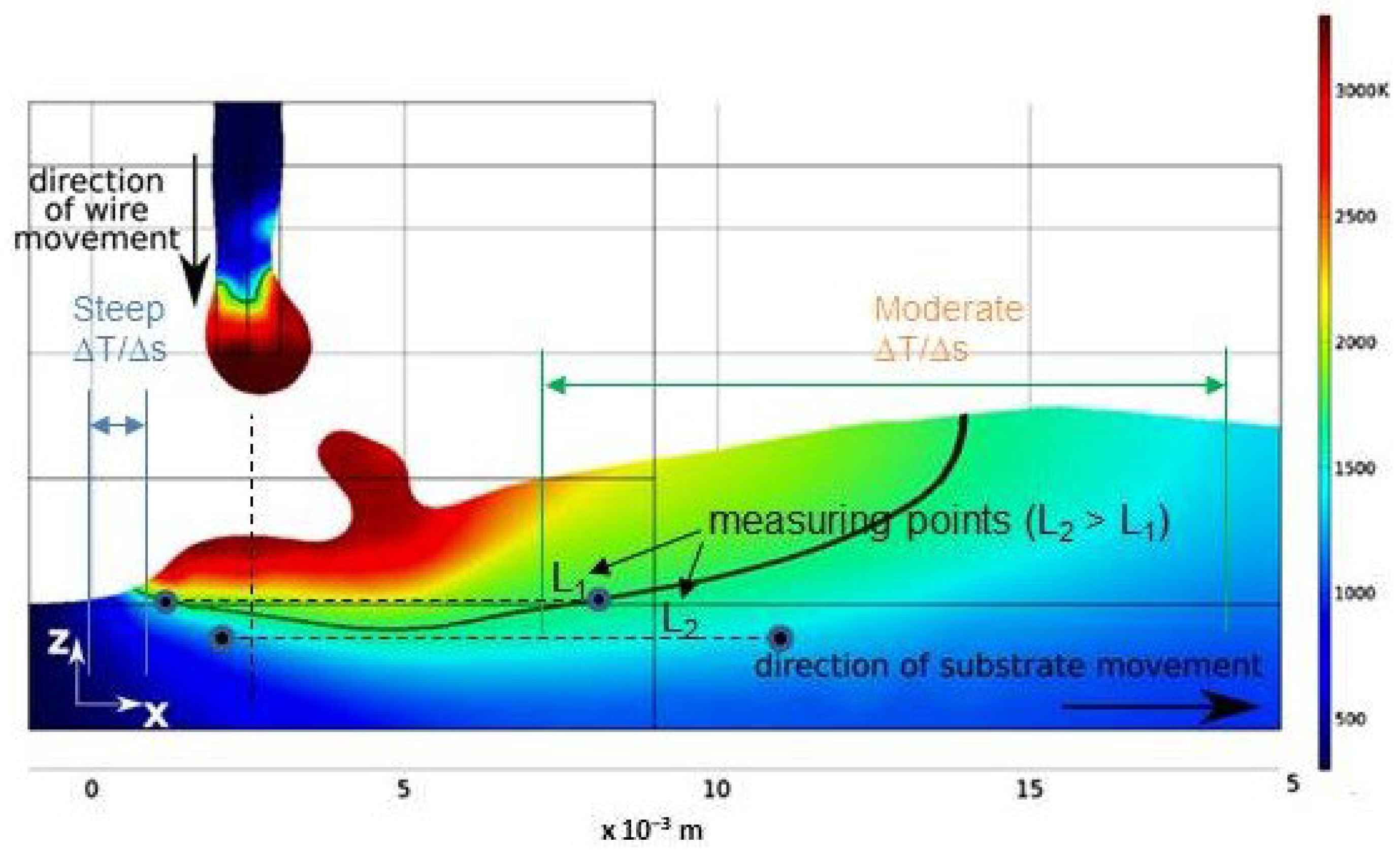

In terms of temperature monitoring using the Upper Pyrometer strategy (sensor in front of the arc), now with the presence of the electric arc, it would be expected that the arc heat could affect to a certain extent the monitored temperatures. This influence magnitude would depend on the distance “L” for a given arc (energy). However, typical molten pool isotherms of an electric arc used in WAAM (as seen in

Figure 10) teach us that the front pool temperature gradient (ΔT/Δs) is very steep. Then, “L” would have to be very short to influence the temperature ahead of the moving heat source. On the other hand, considering now the pyrometer distances (“L”) from the top surface of the layer (Sideward Strategy), the dashed horizontal lines overlapping the simulation representation in

Figure 10 suggest temperature decreases when “L” is made longer (farther from the layer under deposition). These lines delimited by black dot marks also suggest how long the temperature would be constant at each “L” position.

Having no influence of the arc on the temperature ahead of the heat source, one can imagine that the temperature profile from the Upper Pyrometer strategy would match the profile with no arc (as illustrated in

Figure 11a). The monitored temperature curve would maintain a negative gradient in the direction of the layer deposition. Under the Sideward strategy, in turn, the presence of the electric arc would affect the monitored temperature according to the “L” distances (

Figure 11b). The heat arc influence can even make up the natural falling temperatures along the deposited layer length.

The actual temperature profiles during the deposition (with arc) of layers obtained using the two strategies are shown in

Figure 12. To evaluate the effect of the arc, the experimental temperature profiles without the presence of the arc are also replicated in this figure. Considering first the Upper Pyrometer strategy (left side of

Figure 12), the temperature profiles with and without the arc maintain the same behavior and very similar values for the three “L” settings (assuming inconstancies from experimental sources), except after 15–20 s of deposition. This suggests that the arc heat does not significantly affect the measurement points (as idealized by

Figure 11a). However, when comparing the temperature gradients along the layer length between a no-arc (ΔT/Δl

(no-arc)) and with the arc (ΔT/Δl

(arc)) conditions, one can see a temperature drop for all “L” distances when the arc was present. This is a piece of evidence that there is some arc heat effect, fully justified by the conductive heat diffusion. In addition, it can be seen that the longer “L” the steeper the temperature gradient.

Considering now the Sideward strategy, the temperature profiles with an arc exhibit changes compared to the no-arc condition for the three evaluated measurement points (as predicted in

Figure 11b). Roughly, there is a tendency for the actual temperature not to change along with the deposition (except for signal oscillations due to the experimental uncertainties). However, it is verified that the actual temperatures are higher or equal to the reference temperature (being higher for shorter “L”). However, as already warned, the reference temperature is defined by the Upper Pyrometer. Hypothetically, if the reference temperature were determined instead by the sideward pyrometer (considering the deposition of a new layer when the sideward pyrometer reached a given temperature), the actual interlayer temperature would be equal to the defined reference temperature (whatever its value was).

Comparing the two measurement strategies and taking the condition with the arc, the average temperature tends to be more constant for a longer layer deposition distance through the sideward pyrometer, yet with more oscillation (see

Figure 9 how the lower temperature isotherms are flatter than higher temperatures ones). There is no clear trend for ΔT/Δl

(arc) concerning the different measuring positions (“L”), as seen for the non-arc condition. By using the Sideward strategy, it is possible to approach an “L” distance (longer) in which the temperature monitored along with the deposition would not suffer a very significant influence by the natural thermal gradient along the deposited layer length (see

Figure 10 that iso-temperatures distance increases when “L” is increased). However, this would be at the expense of reducing the measurement sensitivity, due to a more uniform temperature distribution when “L” turns longer (increasing uncertainties).

3.3. General Discussion: Strategies, Limitations and Features

The results presented in

Section 3.1 and

Section 3.2 show that the two pyrometry measurement strategies present different features. The features are related to both different temperatures reached with each strategy at the same measuring point positions and their variation along the deposited layer length. In particular,

Section 3.1 aimed to demonstrate a natural temperature drop along the wall, from the beginning to the end of the torch translation time. This means that the temperature of a thin wall is not the same throughout its extension before starting the deposition of a new layer. This fall in temperature depends on the measurement strategy, measurement position, reference temperature, material, wall dimension, and arc energy. Thus, taking a temperature value at a point on the wall (by definition called interlayer temperature or IT, a term not entirely correct), is no guarantee of the same thermal condition throughout the deposition of a layer.

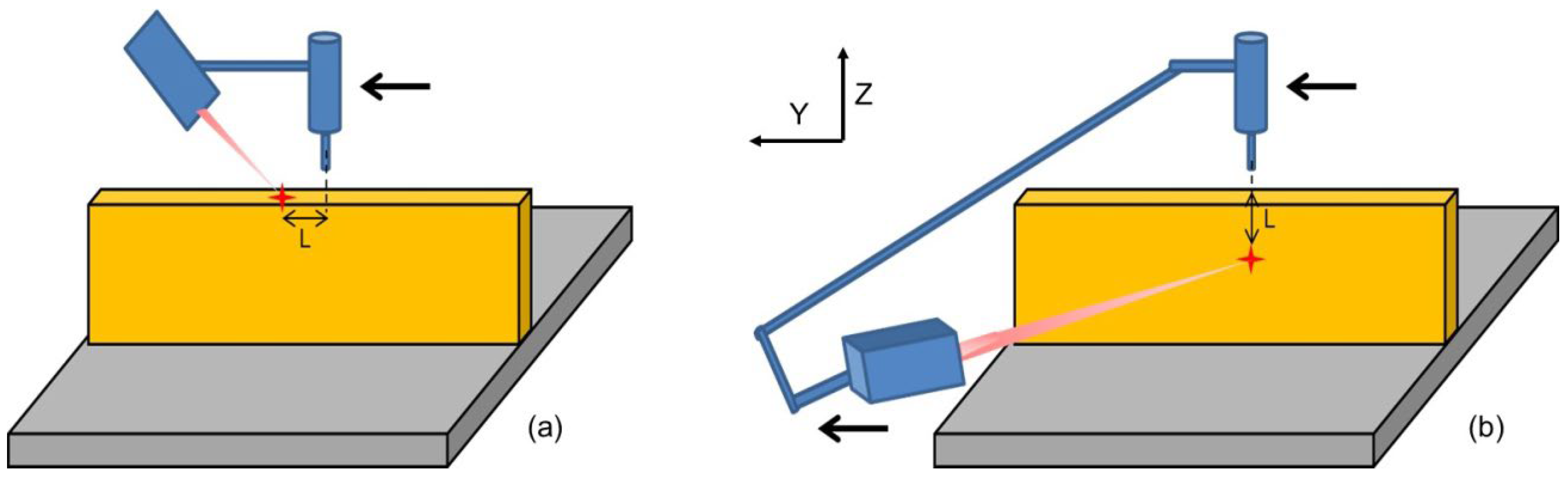

Assuming the use of pyrometry measurement for keeping the same IT in an open-loop control (no feedback), in general, both strategies would work well. Even the Upper Pyrometer strategy with a stationary pyrometer (instead of the moving position one described in

Figure 2) because the measurand for open-loop control would be a reference temperature at a given position that should be repeated for all layers (whatever its value is). However, care must be taken considering the case of the Upper Pyrometer strategy for this purpose. When applied to long walls, the difference between the chosen reference temperature and the actual temperature over the entire wall length can be significant. Therefore, it would not allow achieving the overall objective of this measurement (which is to maintain the geometric quality of thin-wall WAAM constructions). The usage of the Sideward strategy, in turn, appears to be more adequate for open-loop control, since the actual average temperature changes little along with the deposition for a given reference temperature. However, the sensitivity can be low if the “L” distance is long (the temperature will be more homogenous with a minor variation of the temperature per length gradient). On the other hand, the measurement will be more inaccurate (influence of the arc) if the “L” distance is too short.

However, one must be aware that geometrical constancy layer after layer is not the only target when processing WAAM. The temperature field under the bead also governs the microstructural formation of the wall. This moves the result discussion to the meaning of the measured temperature (what it represents), in addition to the temperature value (as a measurement quantity). Under this view, the Sideward strategy would provide the most adequate temperature representation. However, as demonstrated in the experiments, the actual temperature variation along the layer length measured by the upper pyrometer did not imply a variation of temperature under the bead—as the Upper Pyrometer was translating with the Sideward Pyrometer along the wall, while the temperature was falling in the first sensor, it was kept constant to some extent in the second one. Thus, either of the two approaches can be used in open-loop control for metallurgical control. The reference value could be higher or lower, depending on the distance “L”, as long as it is defined as the measurement point and the reference value for the IT (i.e., 200 °C, 300 °C, 400 °C, or other value). These parameters will depend on the results already experienced in the procedure qualification. The principal would always use the same method and the same reference temperature.

From the measurement flexibility perspective, the Upper Pyrometer strategy would provide easier sensor mechanical positioning. This strategy allows monitoring even from the first layers, which cannot be achieved with the Sideward Pyrometer strategy. On the other hand, the Sideward strategy can evaluate the temperature in both deposition directions (the Upper Pyrometer strategy would only allow measurement in all layers if the deposition was not bidirectional; another possibility is using two pyrometers, one on each side of the torch). The Sideward strategy virtually eliminates the limitation of the Upper Pyrometer strategy at the end of the wall (when the target of the sensor exits the wall). It is worth mentioning that the use of limited length linear walls in WAAM is not the typical case for applications in manufacturing parts in the industry. However, a finite length linear wall is a fundamental method for the study of the process performance, materials, and development of new technologies.

Expanding the use of the strategies for more complex geometries (considering curves and direction changing), both strategies can face challenges in terms of measurement flexibility. It would be necessary to implement a system to rotate the pyrometers concerning the torch central axis (the sensor target point must not leave the wall surface, and the distance from the measurement point to the arc must not change) to maintain the focal distance. The larger geometric variations on the sideward face of the walls and the need for the rotation system could project an even greater challenge for the Sideward strategy.

Finally, it is important to consider the potential capacity for production feedback control (closed-loop control). Whether for geometric or microstructural homogeneity, the objective is to correct the deposition process parameters to maintain the molten pool at the same temperature during the deposition. The more constant the measured temperature, the better, since the temperature at a given position from the fusion line is proportional to the pool volume, i.e., wall geometry, and cooling rates, i.e., metallurgical definitions. With the Upper Pyrometer strategy, the temperature variation along the wall length does not correlate with the pool temperature. Therefore, the results suggest that only the Sideward Pyrometer strategy could be applied in this case. However, there would still be the measurement sensitivity problem (the greater or lesser temperature variation per unit “L” distance). In the Sideward strategy, even without significantly varying temperature monitored along the layer, the higher the “L”, the lower the temperature for a given welding energy. Furthermore, the smaller the quantity to be measured, the more significant the measurement uncertainties due to the drop in sensitivity (from a metrological point of view).

In summary,

Table 2 presents the functionalities of the two strategies used for monitoring the IT, considering the representativeness criteria of the IT, measurement flexibility, and the potential for closed-loop control, as above discussed. The choice will depend on the work goals. The experiments led to a better understanding of the interlayer temperature (an essential variable in WAAM) meaning, often confused with the traditional welding term interpass temperature.