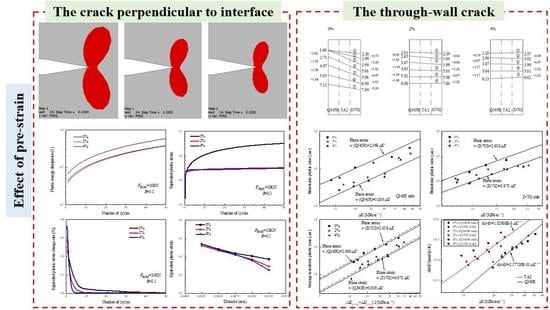

Effect of Pre-Strain on Crack Growth Behavior of Zr702/TA2/Q345R Composite Plate

Abstract

1. Introduction

2. Material, Fatigue Crack Growth Test and Finite Element Method

2.1. Material

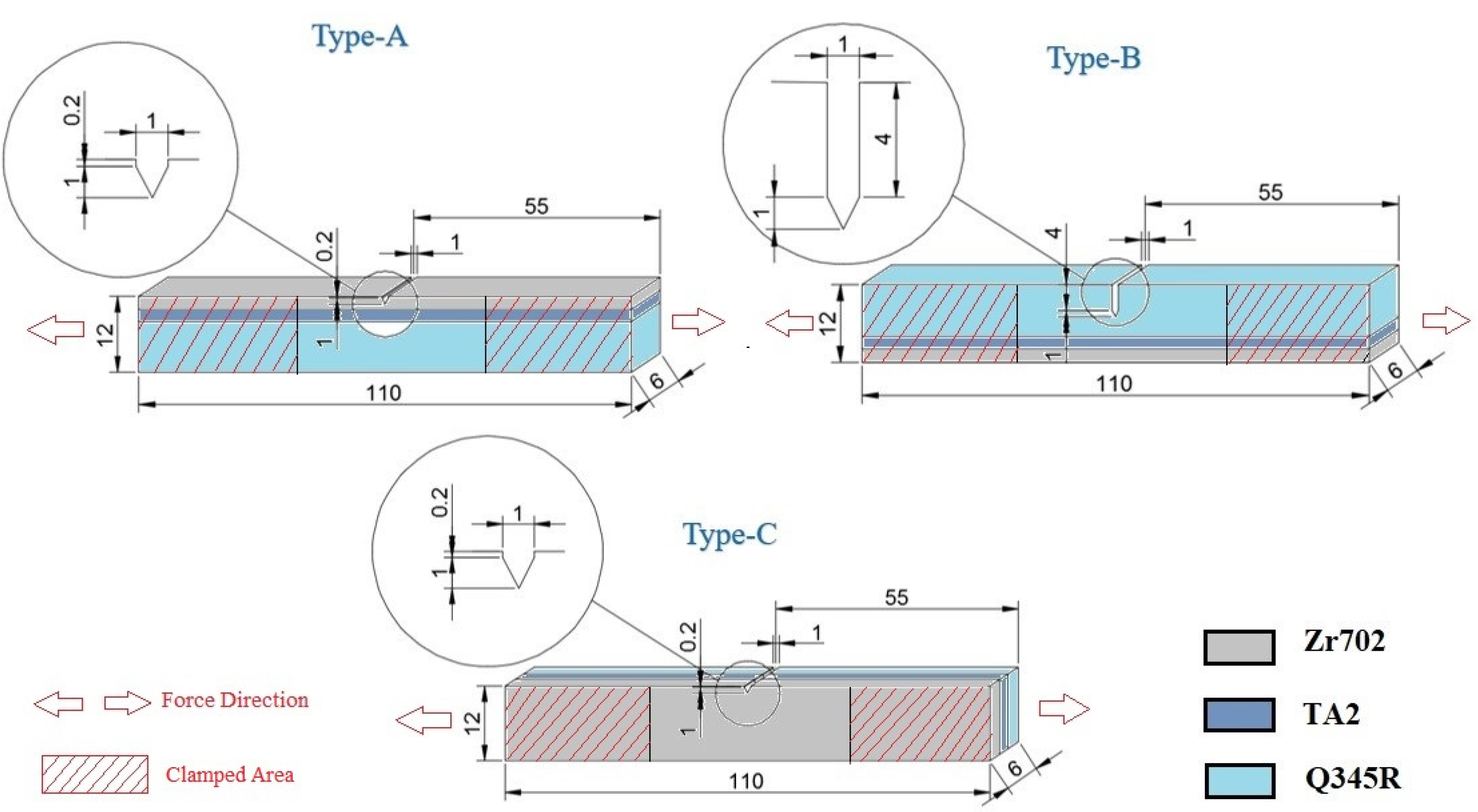

2.2. Specimen Design and Fatigue Crack Growth Test

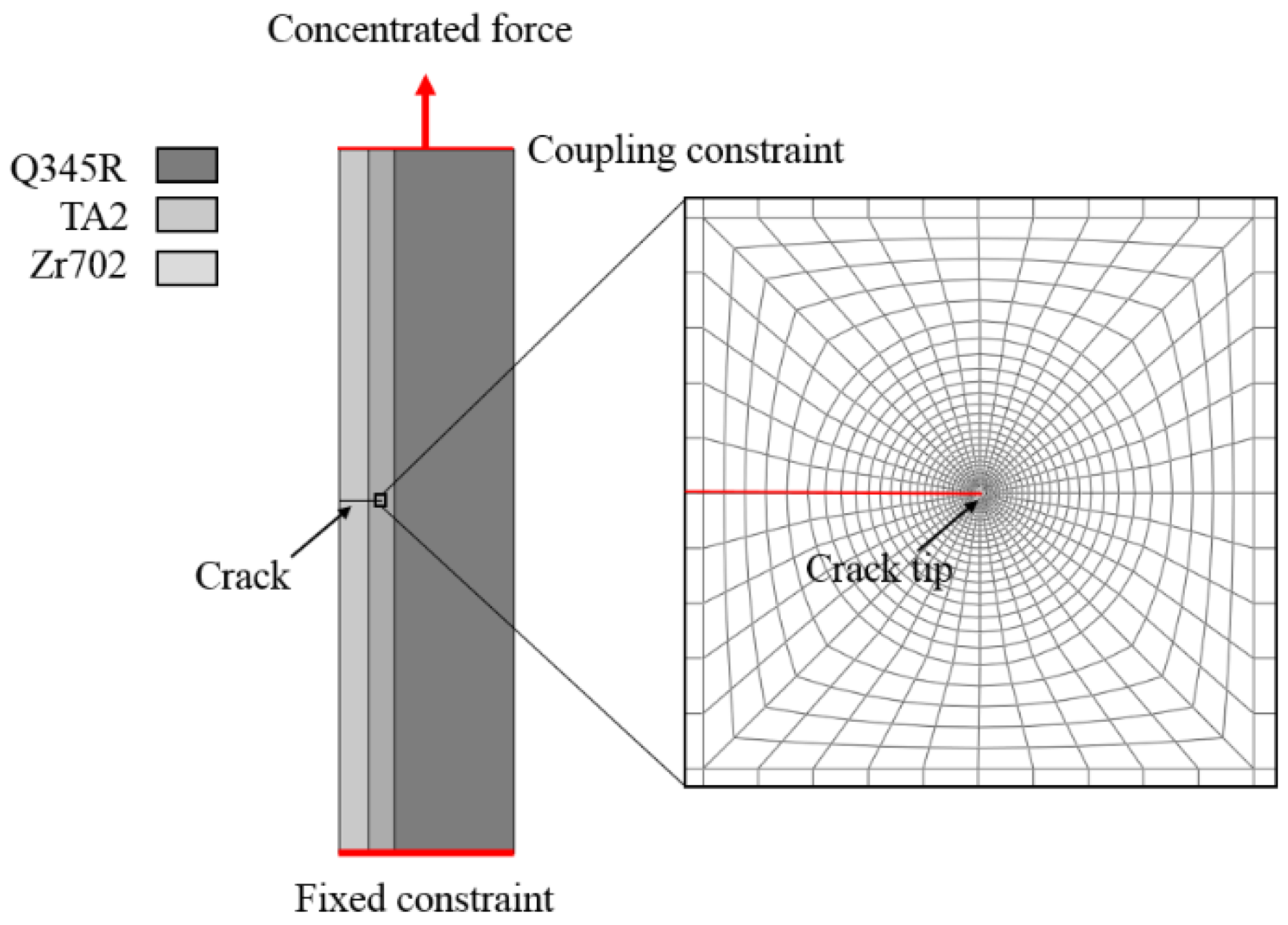

2.3. Finite Element Method (FEM)

3. Results and Discussion

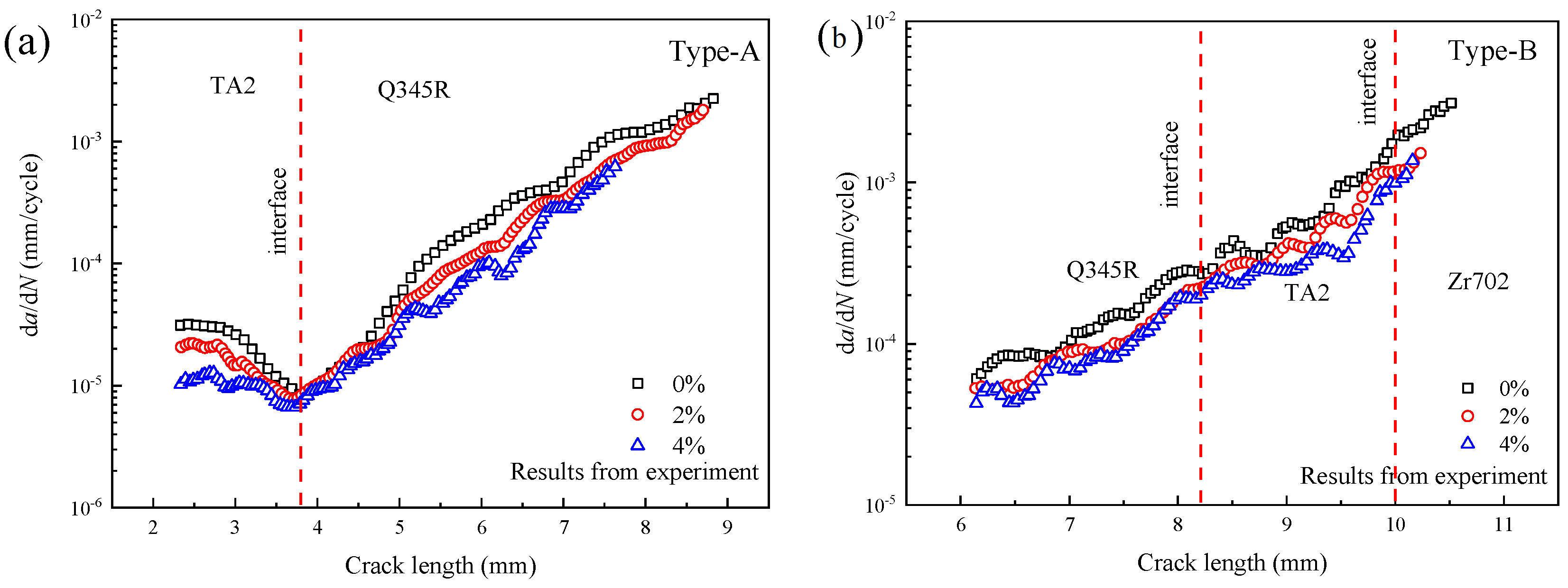

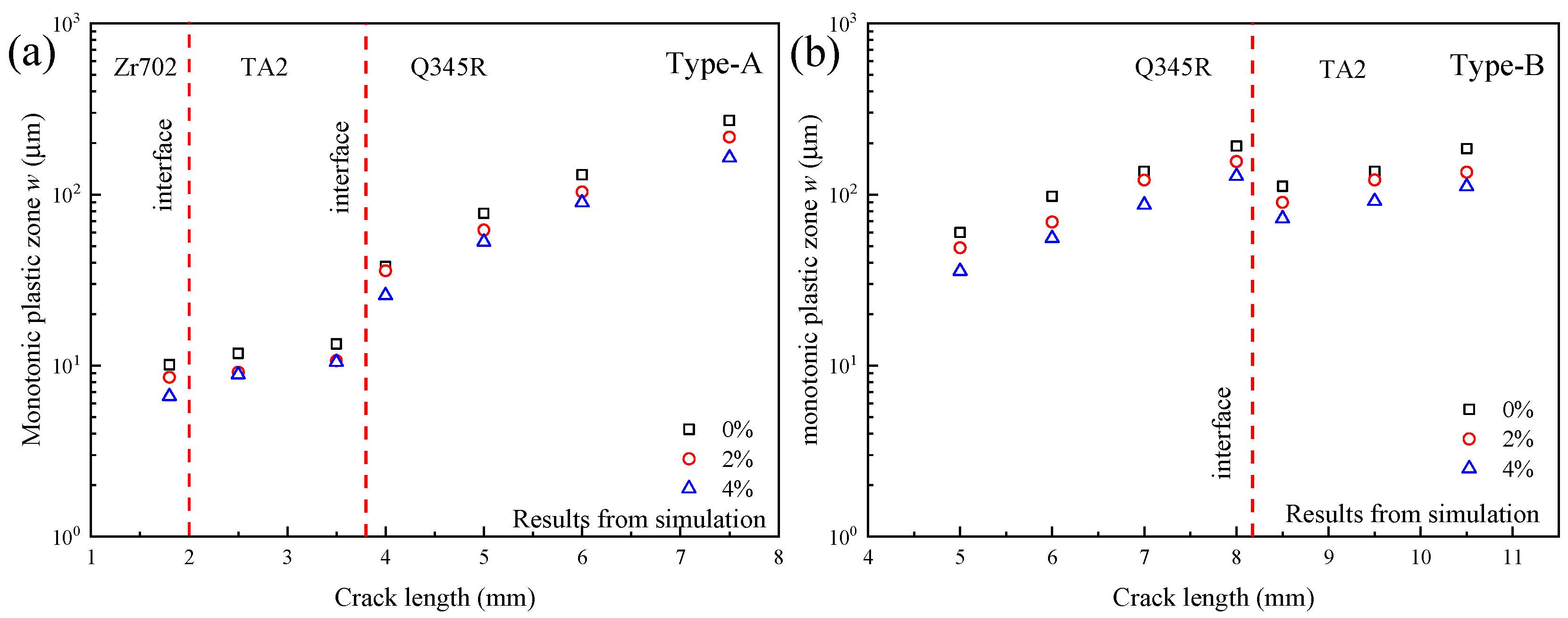

3.1. Effect of Pre-Strain on the Crack Growth Behavior of the Crack Perpendicular to the Interface

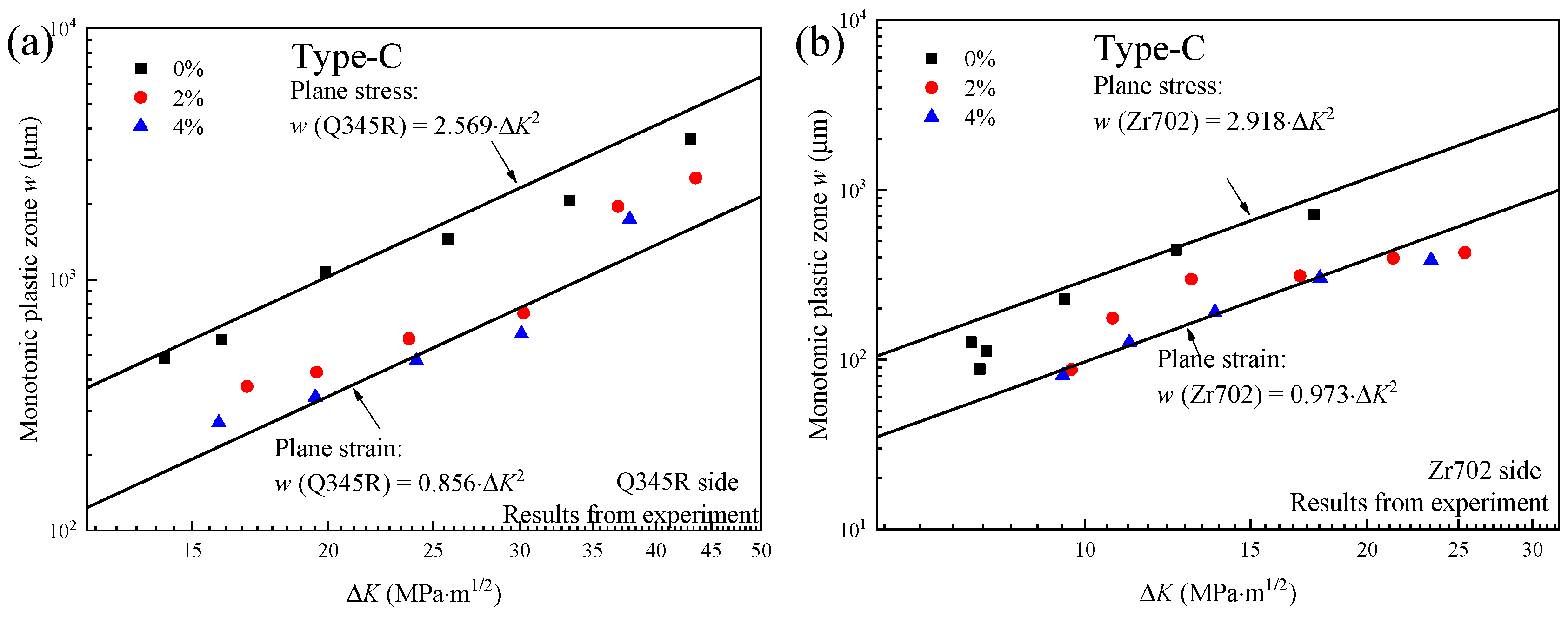

3.1.1. The da/dN and Monotonic Plastic Zone

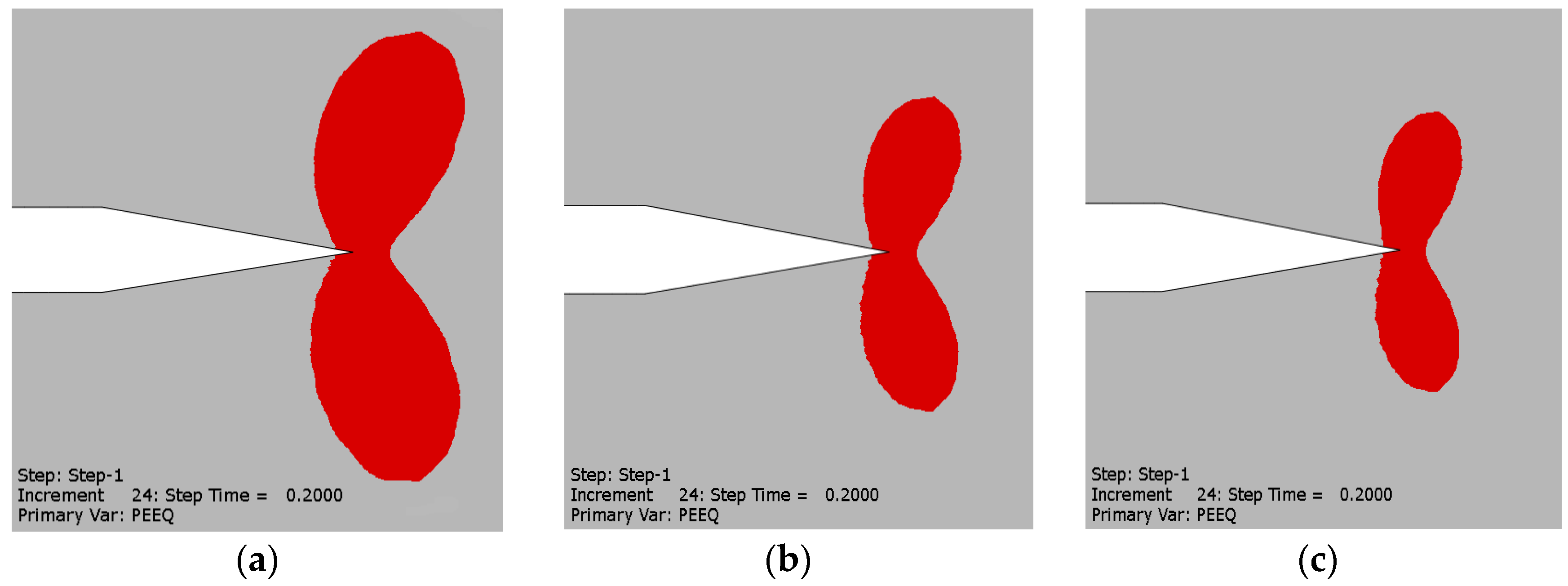

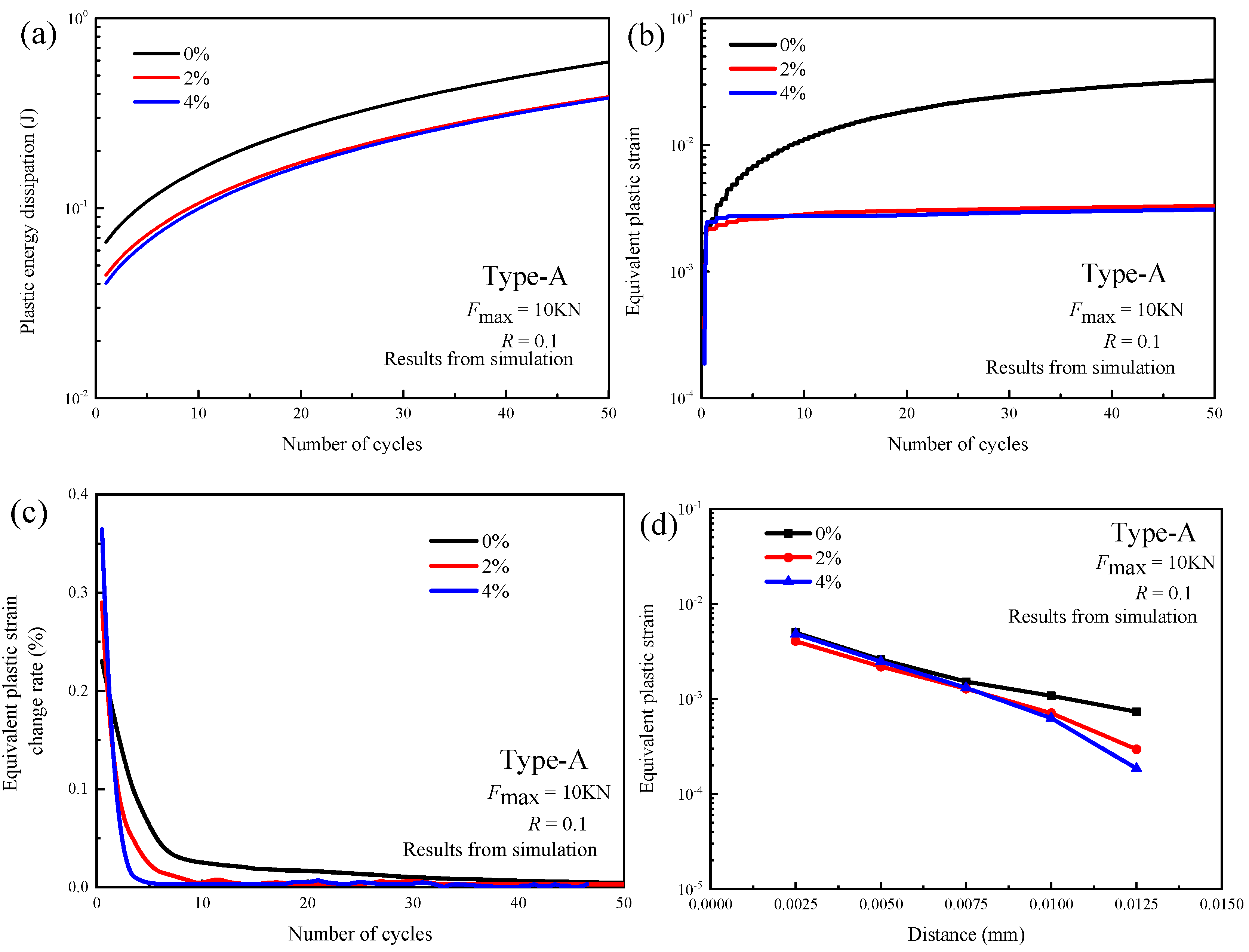

3.1.2. Cyclic Plastic Deformation of Crack Tip

3.2. Effect of Pre-Strain on the Crack Growth Behavior of the Through-Wall Crack

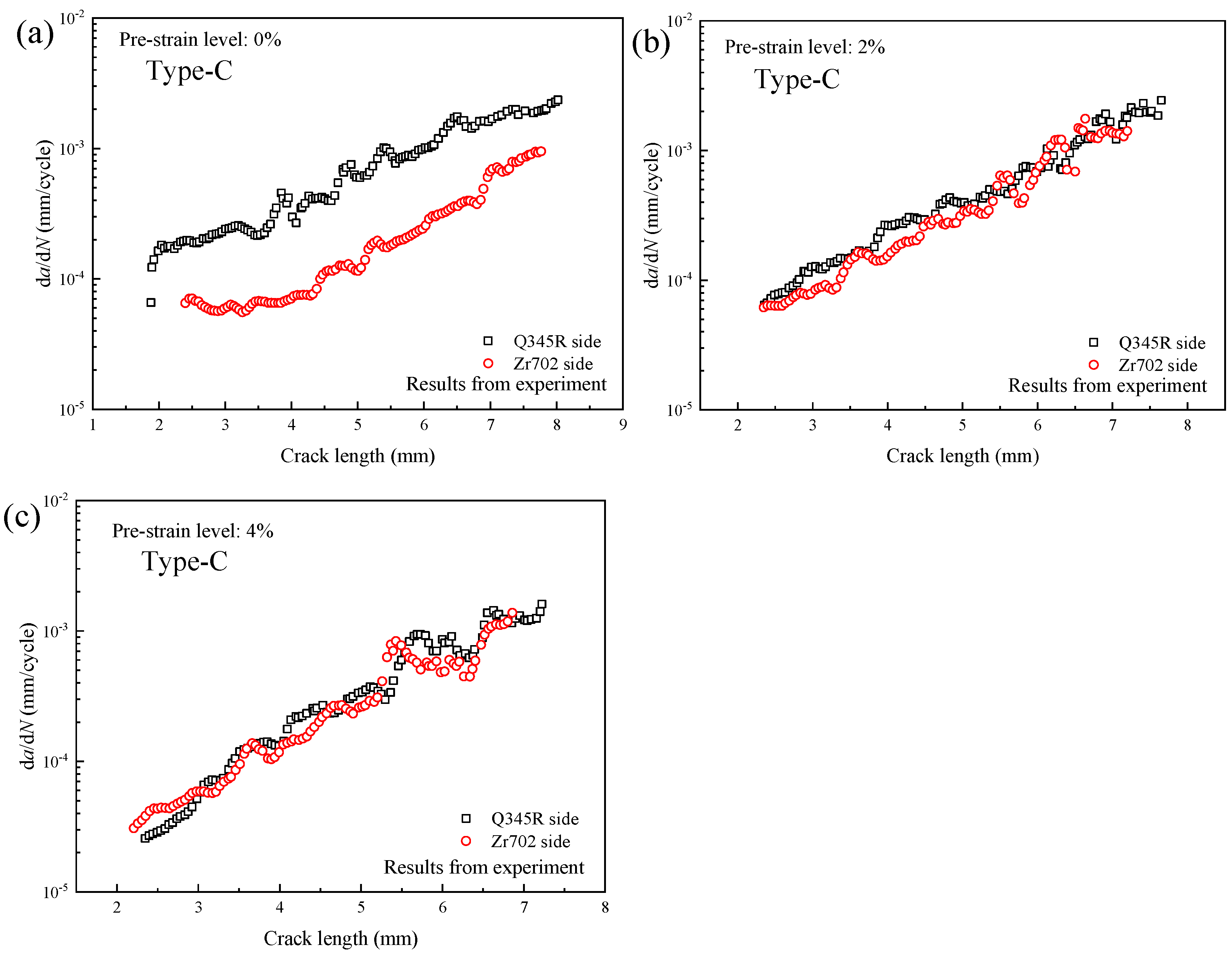

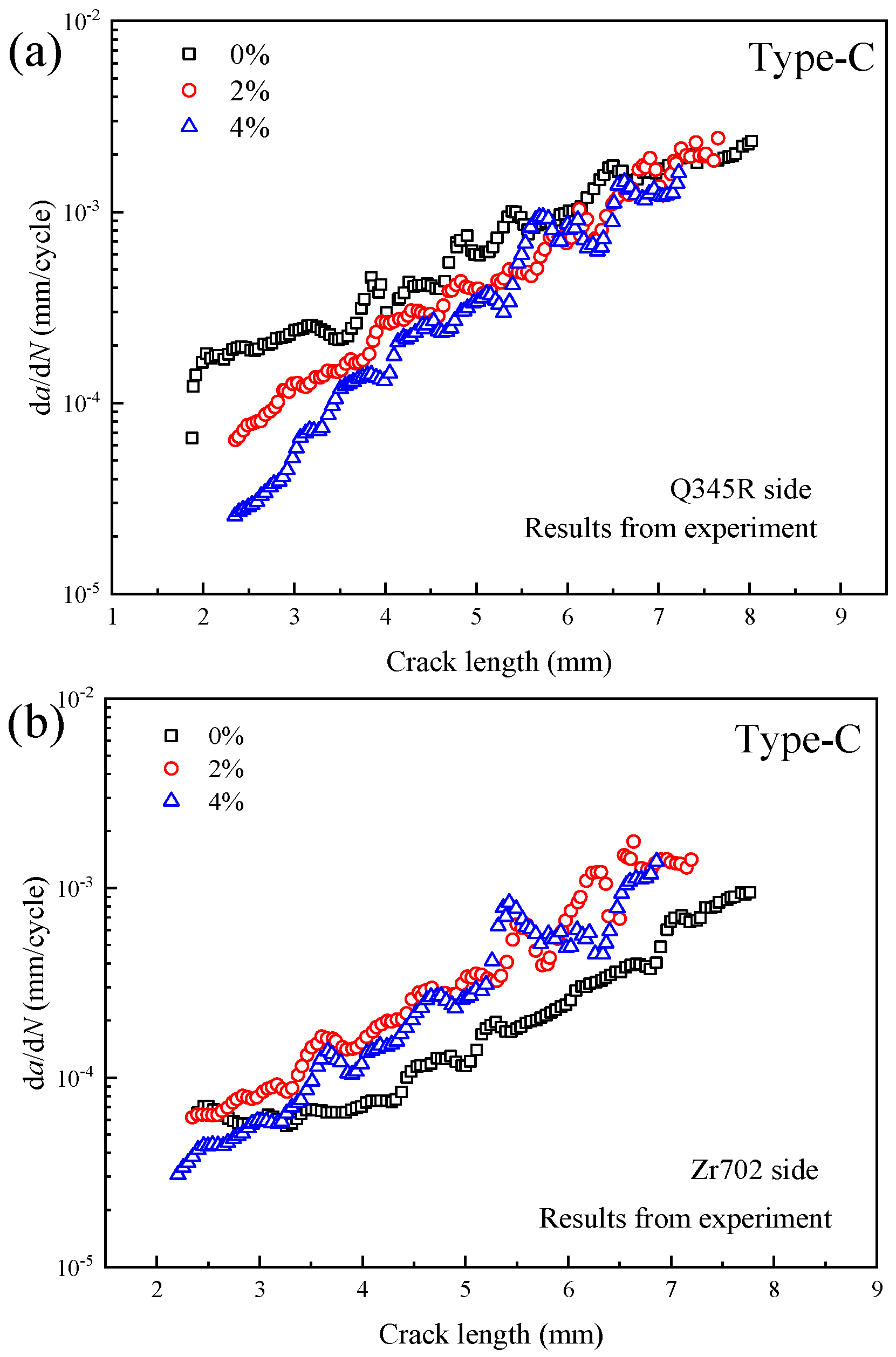

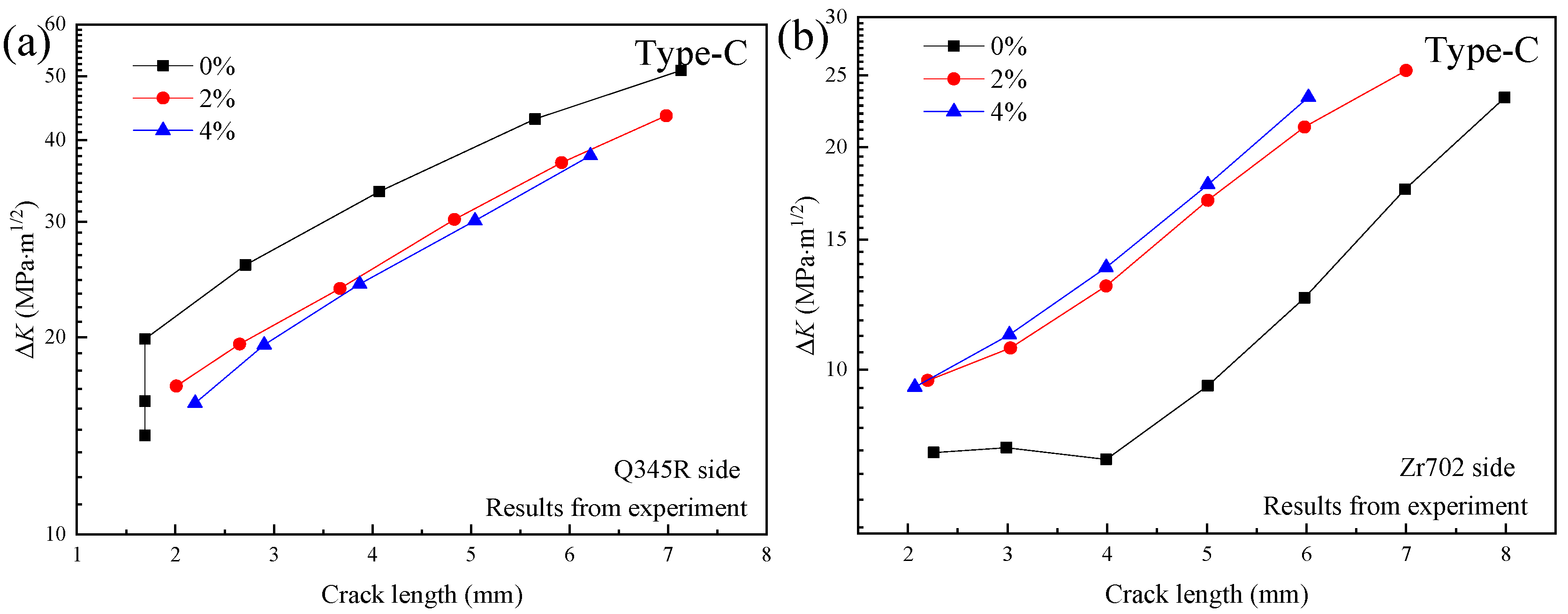

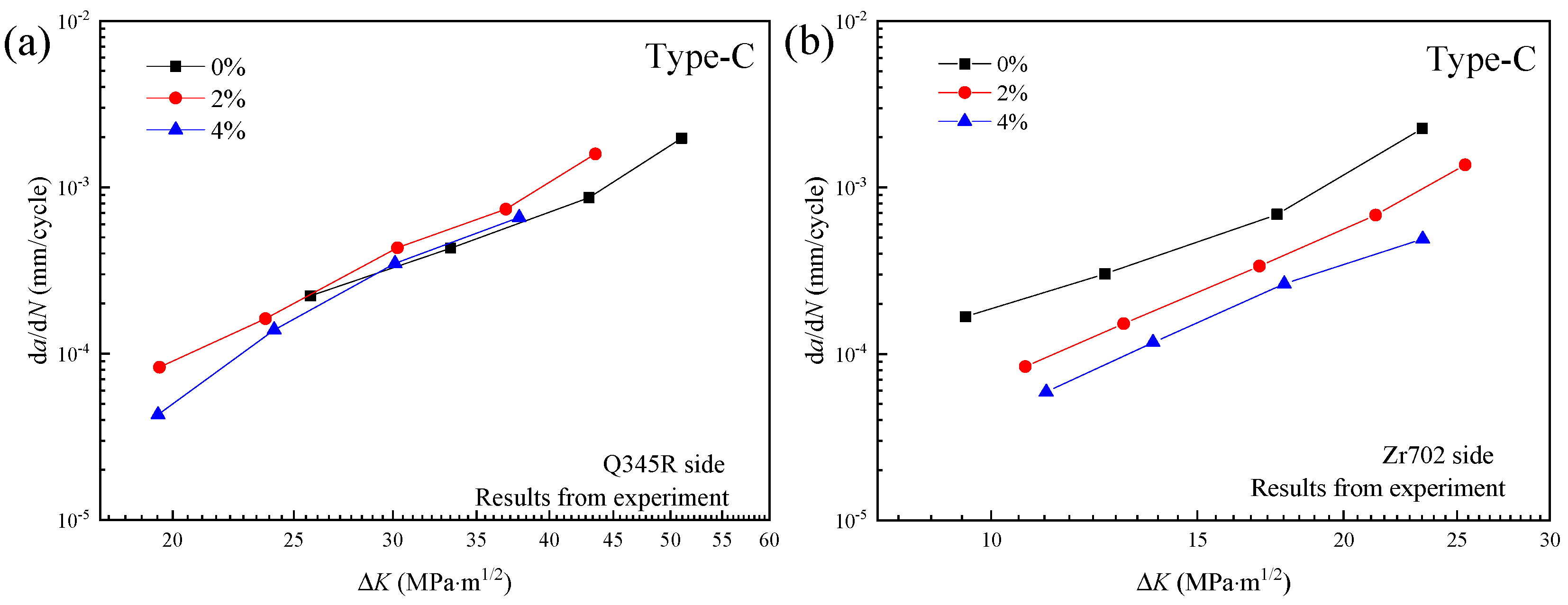

3.2.1. The Growth Rate of Two-Sided Cracks

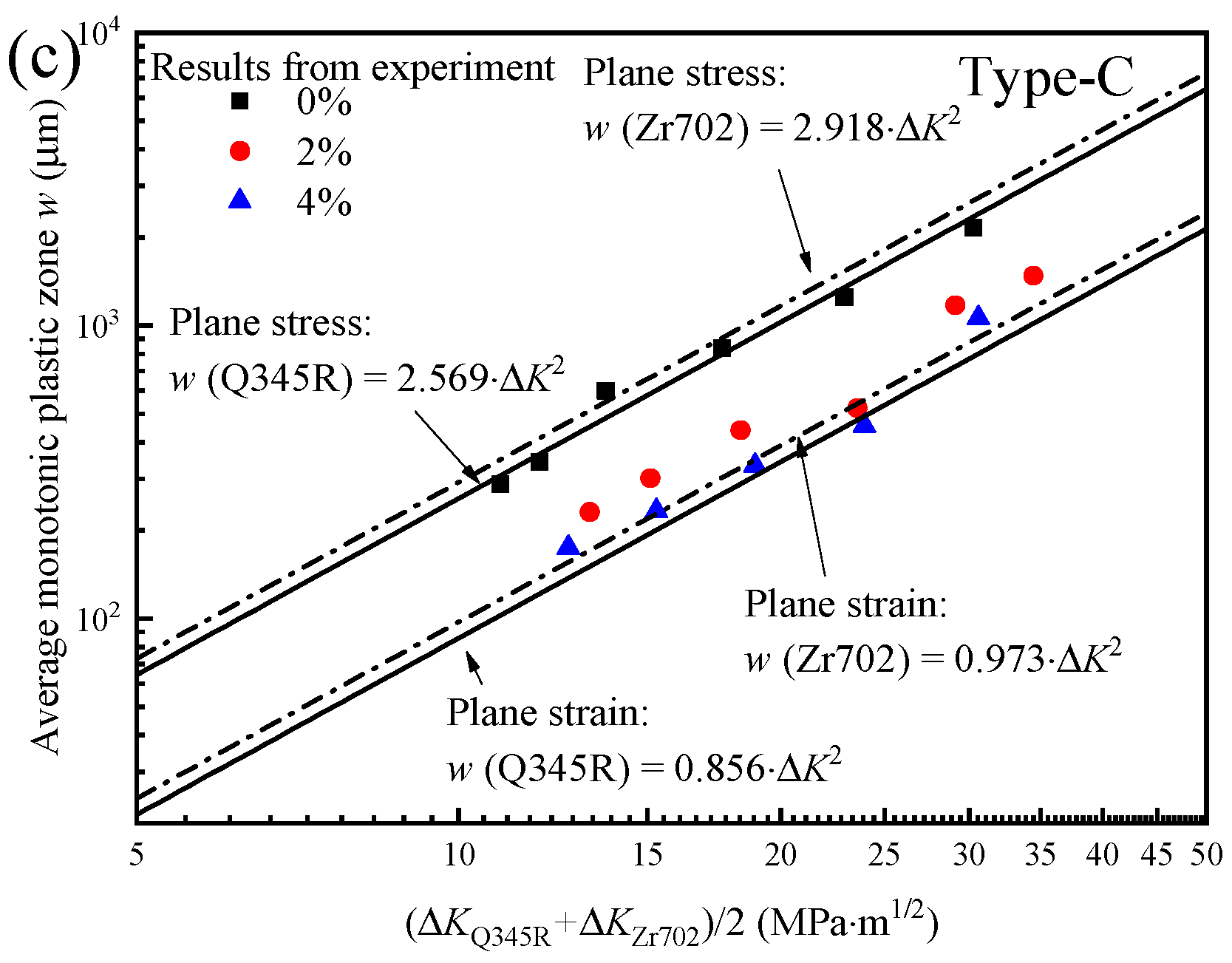

3.2.2. Plastic Deformation of Crack Tip

3.2.3. Crack Growth Characteristics on Both Sides

4. Conclusions

- The yield strength of the component materials increases with the pre-strain level. This results in the decrease in the monotonic plastic zone and the degree of monotonic damage for the crack perpendicular to the interface.

- The pre-strain leads to the loss of plastic deformation ability in advance, and the equivalent plastic strain at the crack tip decreases, so the cyclic damage decreases.

- The effect of pre-strain on the strengthening of Q345R is not as strong as that of Zr702 and TA2, so the crack growth on the Zr702 side of the through-wall crack is more restrained.

- The pre-strain increases the resistance to crack growth of Zr702 and TA2, makes the overall crack growth characteristics close to the cracks in Q345R, and leads to the decrease in the interaction effect between the cracks on both sides and the weakening of the toughening effect of Q345R.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- White, B.C.; White, R.E.; Jordon, J.B.; Allison, P.G.; Rushing, T.; Garcia, L. The effect of tensile pre-straining on fatigue crack initiation mechanisms and mechanical behavior of AA7050 friction stir welds. Mater. Sci. Eng. 2018, 736, 228–238. [Google Scholar] [CrossRef]

- Stashkov, A.N.; Nichipuruk, A.P.; Ogneva, M.S. The effect of plastic strain and the orthogonal bias field on the processes of magnetization of low-carbon steel. Russ. J. Nondestruct. Test. 2012, 48, 686–692. [Google Scholar] [CrossRef]

- Al-Rubaie, K.; Barroso, E.; Godefroid, L. Fatigue crack growth analysis of pre-strained 7475–T7351 aluminum alloy. Int. J. Fatigue 2006, 28, 934–942. [Google Scholar] [CrossRef]

- Mehmanparast, A.; Davies, C.M.; Dean, D.W.; Nikbin, K. Effects of plastic pre-straining level on the creep deformation, crack initiation and growth behaviour of 316H stainless steel. Int. J. Press. Vessel. Pip. 2016, 141, 1–10. [Google Scholar] [CrossRef]

- Wang, D.; Ma, Z.Y. Effect of pre-strain on microstructure and stress corrosion cracking of over-aged 7050 aluminum alloy. J. Alloys Compd. 2009, 469, 445–450. [Google Scholar] [CrossRef]

- Auzoux, Q.; Allais, L.; Caes, C.; Monnet, I.; Gourgues, A.; Pineau, A. Effect of pre-strain on creep of three AISI 316 austenitic stainless steels in relation to reheat cracking of weld-affected zones. J. Nucl. Mater. 2010, 400, 127–137. [Google Scholar] [CrossRef]

- Mishima, T.; Kang, M.; Aono, Y.; Noguchi, H. Method for the evaluation of mode I fatigue crack growth rate of prestrained materials. Int. J. Fatigue 2007, 29, 1737–1743. [Google Scholar] [CrossRef]

- Tang, L.; Qian, C.; Wang, Z.; Li, H. Experimental study of the strain-strengthening effect on the mixed mode notch-crack fatigue propagation in austenitic stainless steel 06Cr19Ni10. Eng. Fract. Mech. 2015, 134, 54–60. [Google Scholar] [CrossRef]

- Yin, S.M.; Yang, F.; Yang, X.M.; Wu, S.D.; Li, S.X.; Li, G.Y. The role of twinning-detwinning on fatigue fracture morphology of Mg-3%Al-1%Zn alloy. Mater. Sci. Eng. A 2008, 494, 397–400. [Google Scholar] [CrossRef]

- Le, M.Q.; Batra, R.C. Crack propagation in pre-strained single layer graphene sheets. Comput. Mater. Sci. 2014, 84, 238–243. [Google Scholar] [CrossRef]

- Mehmanparast, A.; Davies, C.M.; Dean, D.W.; Nikbin, K. Material pre-conditioning effects on the creep behaviour of 316H stainless steel. Int. J. Press. Vessel. Pip. 2013, 108–109, 88–93. [Google Scholar] [CrossRef]

- Mehmanparast, A.; Davies, C.M.; Nikbin, K. Creep-fatigue crack growth testing and analysis of pre-strained 316H stainless steel. Procedia Struct. Integr. 2016, 2, 785–792. [Google Scholar] [CrossRef]

- Mehmanparast, A.; Davies, C.M.; Dean, D.W.; Nikbin, K. The influence of pre-compression on the creep deformation and failure behaviour of Type 316H stainless steel. Eng. Fract. Mech. 2013, 110, 52–67. [Google Scholar] [CrossRef]

- Zhou, B.B.; Zhou, C.Y.; Yu, X.C.; Chang, L.; Li, J.; Miao, X.; Ye, C.; Zhang, B. Investigation on the fatigue crack behavior of Zr702/TA2/Q345R composite plate with a crack normal to interface. Fatigue Fract. Eng. Mater. Struct. 2019, 43, 20–35. [Google Scholar] [CrossRef]

- Li, J.; Zhang, P.; Lu, L.; Lv, F.; Miao, X.-T.; Chang, L.; Zhou, B.-B.; He, X.-H.; Zhou, C.-Y. Effect of pre-strain on fatigue crack growth behavior for commercial pure titanium at ambient temperature. Int. J. Fatigue 2018, 117, 27–38. [Google Scholar] [CrossRef]

- Basan, R.; Franulovic, M.; Prebil, I.; Kunc, R. Study on Ramberg-Osgood and Chaboche models for 42CrMo4 steel and some approximations. J. Constr. Steel Res. 2017, 136, 65–74. [Google Scholar] [CrossRef]

- Zhou, B.B.; Zhou, C.Y.; Chang, L.; Yu, X.C.; Ye, C.; Zhang, B.J. Investigation on fatigue crack growth behavior of Zr702/TA2/Q345R explosive welding composite plate with a through-wall crack. Compos. Struct. 2020, 236, 111845. [Google Scholar] [CrossRef]

- Chen, C.; Lv, B.; Wang, F.; Zhang, F. Low-cycle fatigue behavior of pre-hardening Hadfield steel. Mater. Sci. Eng. A 2017, 695, 144–153. [Google Scholar] [CrossRef]

| Material | Elastic Modulus (GPa) | Poisson Ratio | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|

| Zr702 | 90.3 | 0.33 | 314 | 499 |

| TA2 | 90 | 0.34 | 330 | 383 |

| Q345R | 203 | 0.3 | 352 | 522 |

| Specimen Type | Load Ratio | Load Amplitude ΔF/N | Pre-Strain Level/% |

|---|---|---|---|

| Type-A | 0.1 | 9000 | 0 |

| 2 | |||

| 4 | |||

| Type-B | 0.1 | 4356 | 0 |

| 2 | |||

| 4 | |||

| Type-C | 0.1 | 9000 | 0 |

| 2 | |||

| 4 |

| Pre-Strain Level (%) | Material | σ0 (MPa) | C1 | γ1 | C2 | γ2 |

|---|---|---|---|---|---|---|

| 0% | Zr702 | 314 | 1759 | 199 | 1758 | 18 |

| TA2 | 330 | 2067 | 26 | 1765 | 24 | |

| Q345R | 352 | 1752 | 20 | 2071 | 7 | |

| 2% | Zr702 | 340 | 594 | 13 | 594 | 13 |

| TA2 | 411 | 1104 | 69 | 1685 | 14 | |

| Q345R | 395 | 3492 | 20 | 338 | 2 | |

| 4% | Zr702 | 354 | 512 | 3 | 395 | 35 |

| TA2 | 441 | 1478 | 34 | 378 | 17 | |

| Q345R | 452 | 638 | 16 | 1652 | 12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, B.; Zhou, C.; Zhang, Y.; Chang, L.; Zhou, C.; Ye, C.; Zhang, B. Effect of Pre-Strain on Crack Growth Behavior of Zr702/TA2/Q345R Composite Plate. Metals 2022, 12, 2187. https://doi.org/10.3390/met12122187

Zhou B, Zhou C, Zhang Y, Chang L, Zhou C, Ye C, Zhang B. Effect of Pre-Strain on Crack Growth Behavior of Zr702/TA2/Q345R Composite Plate. Metals. 2022; 12(12):2187. https://doi.org/10.3390/met12122187

Chicago/Turabian StyleZhou, Binbin, Chao Zhou, Yawen Zhang, Le Chang, Changyu Zhou, Cheng Ye, and Bojun Zhang. 2022. "Effect of Pre-Strain on Crack Growth Behavior of Zr702/TA2/Q345R Composite Plate" Metals 12, no. 12: 2187. https://doi.org/10.3390/met12122187

APA StyleZhou, B., Zhou, C., Zhang, Y., Chang, L., Zhou, C., Ye, C., & Zhang, B. (2022). Effect of Pre-Strain on Crack Growth Behavior of Zr702/TA2/Q345R Composite Plate. Metals, 12(12), 2187. https://doi.org/10.3390/met12122187