Experimental Study of the Microhardness and Microstructure of a Copper Specimen Using the Taylor Impact Test

Abstract

:1. Introduction

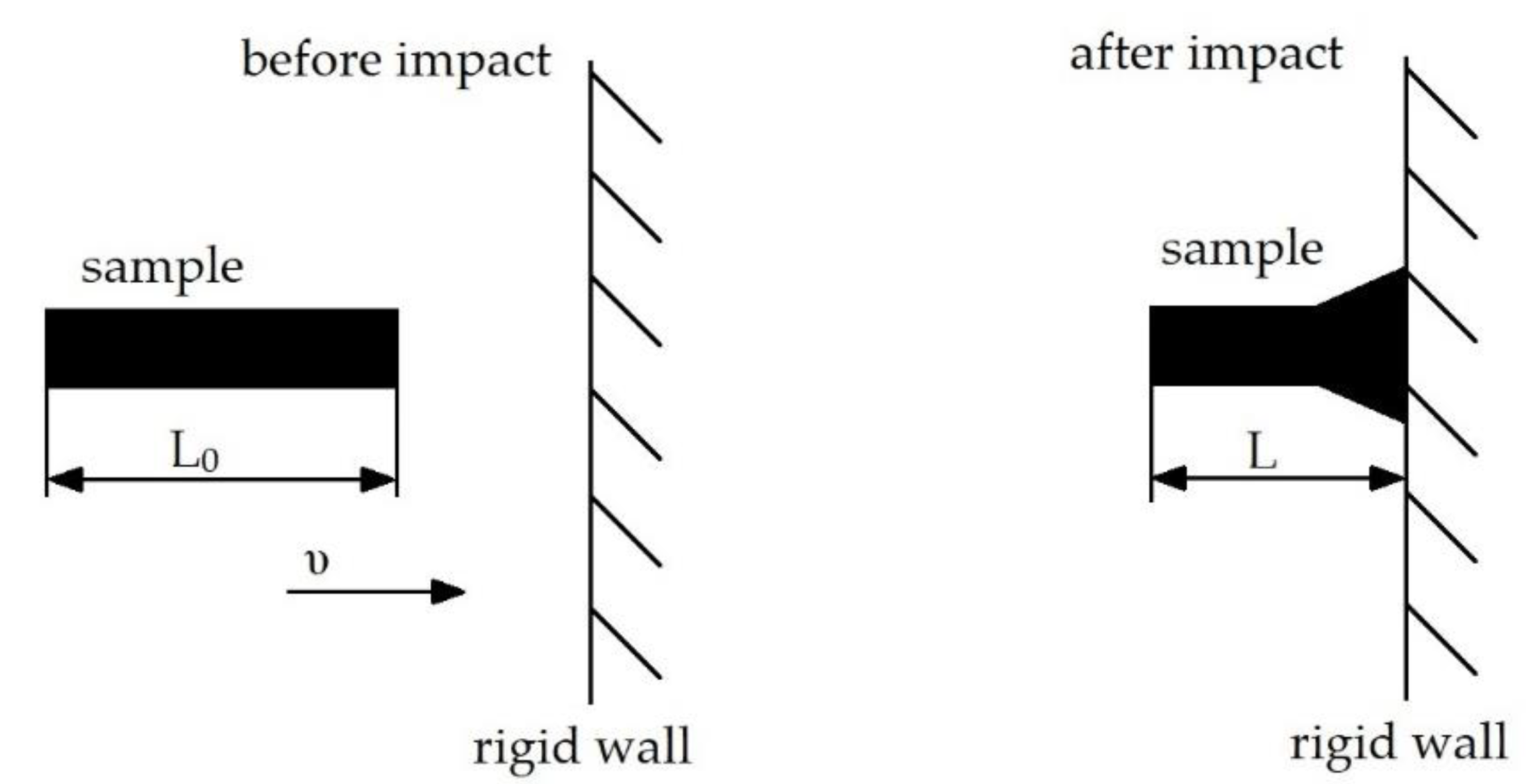

2. Materials and Methods

3. Results and Discussion

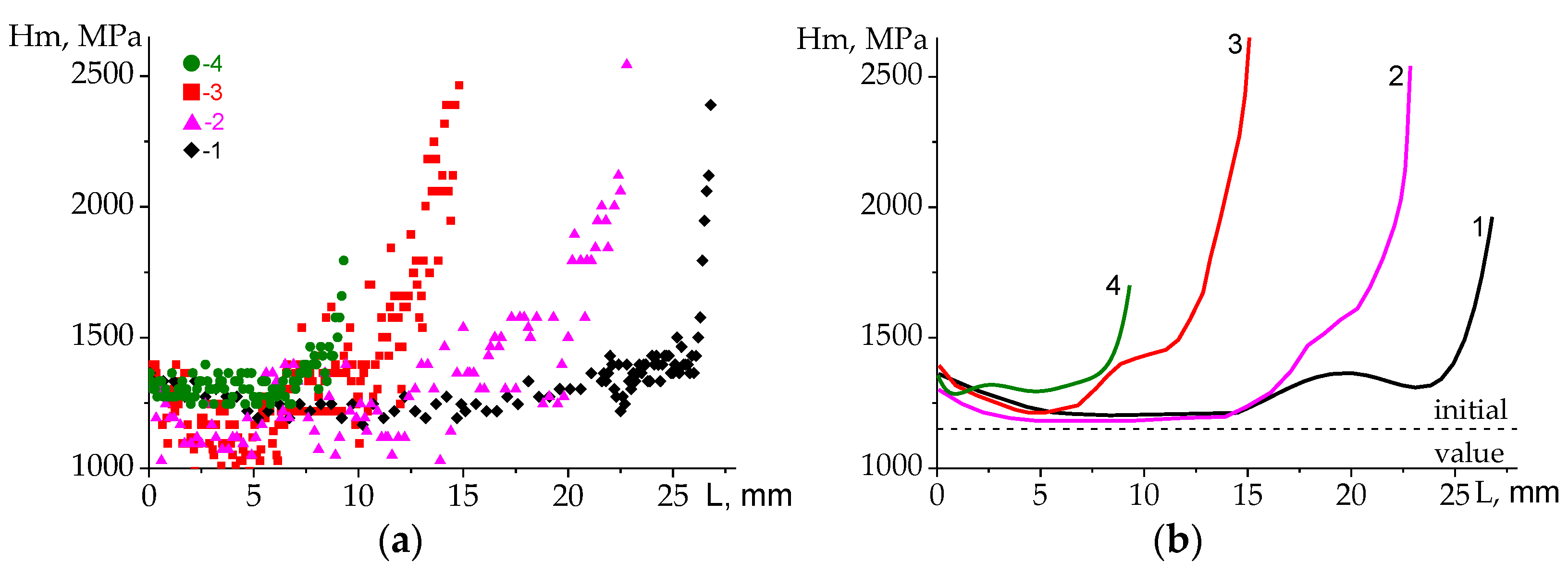

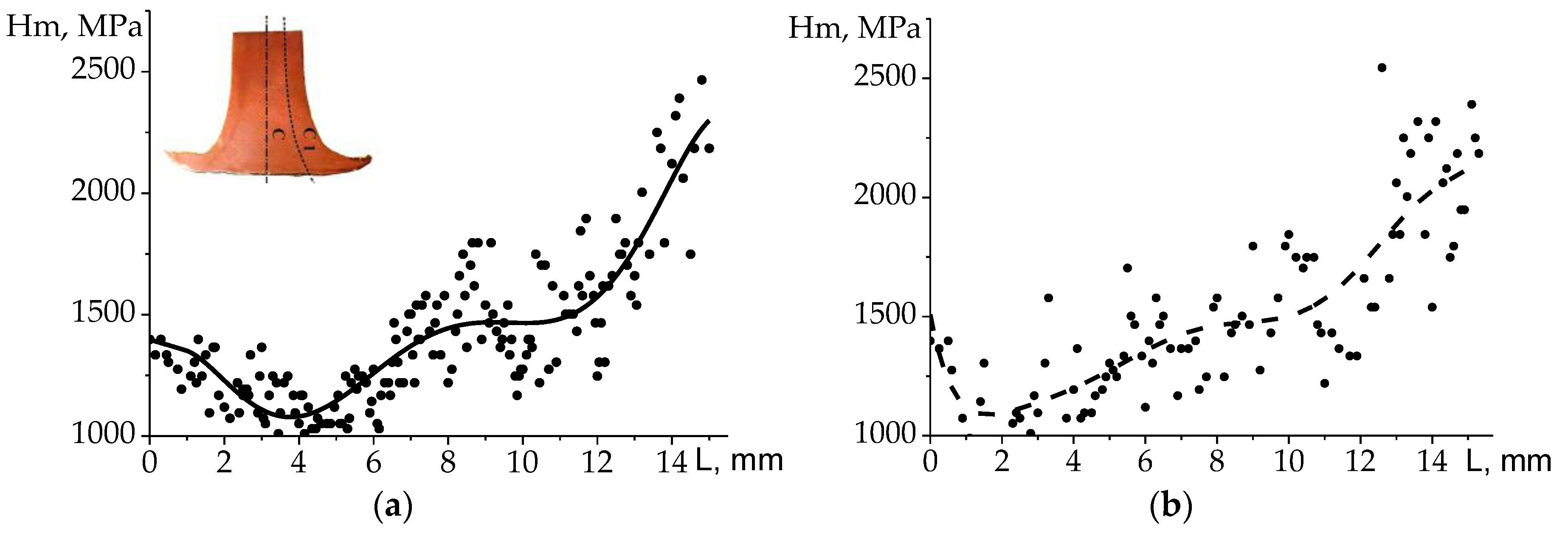

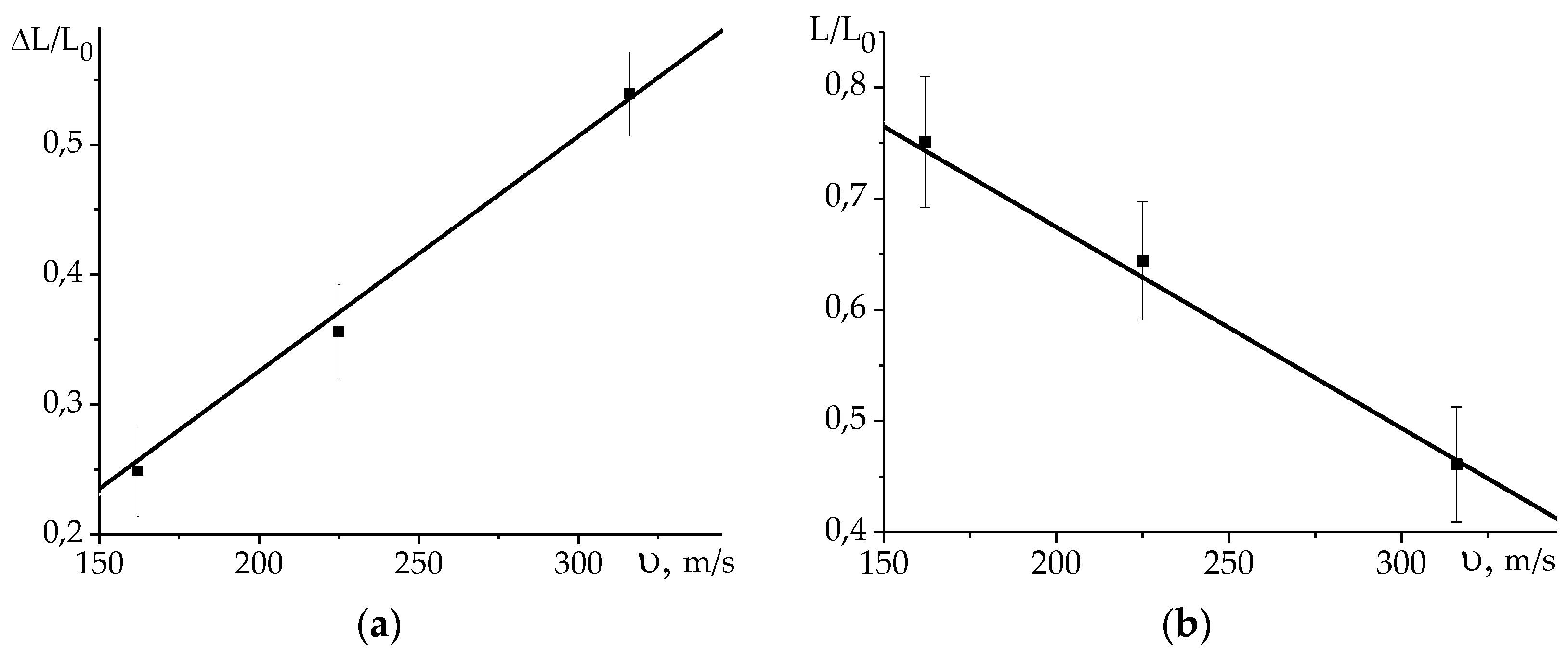

3.1. Microhardness

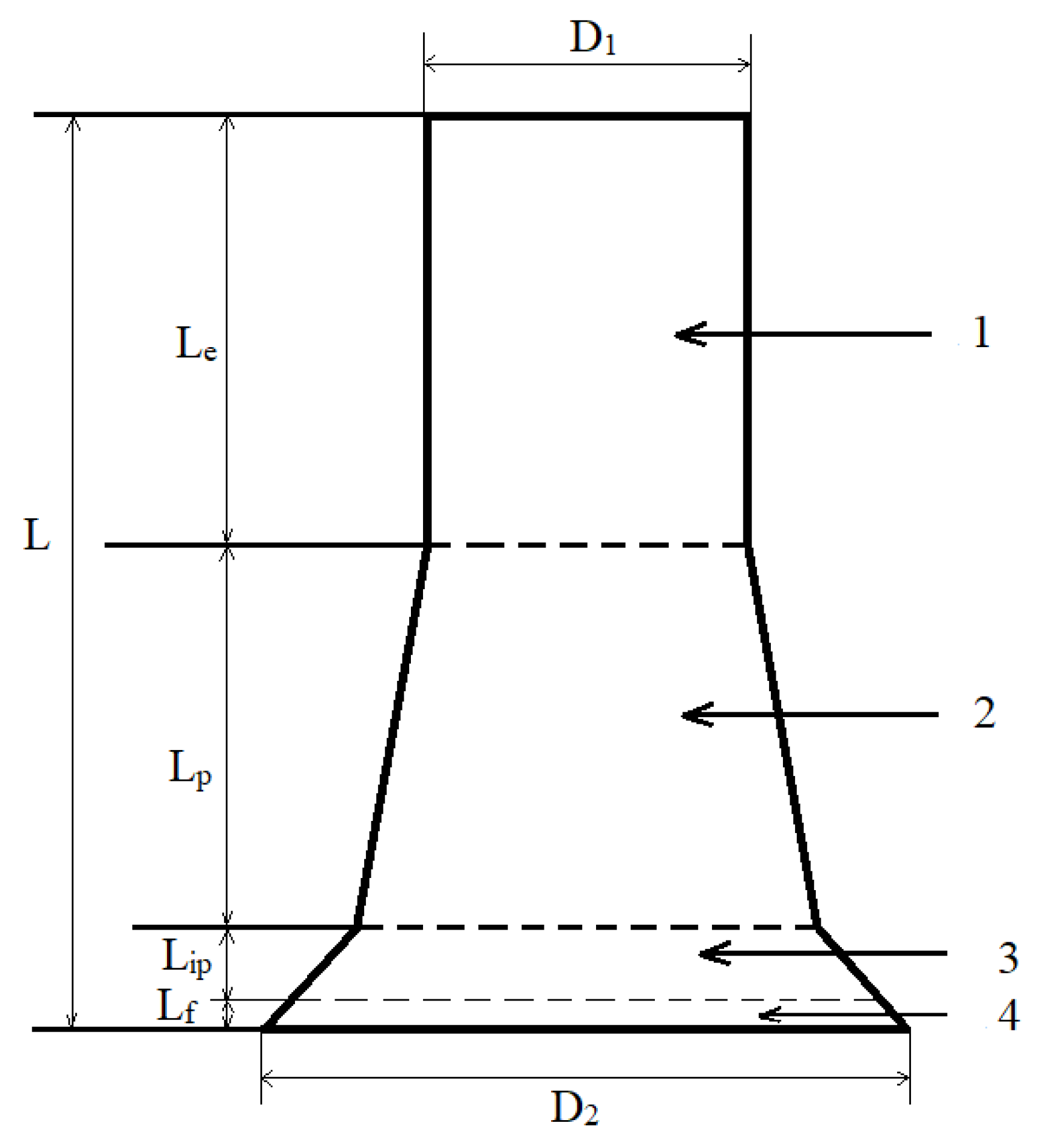

3.2. Deformation Zones of Cylindrical Specimens

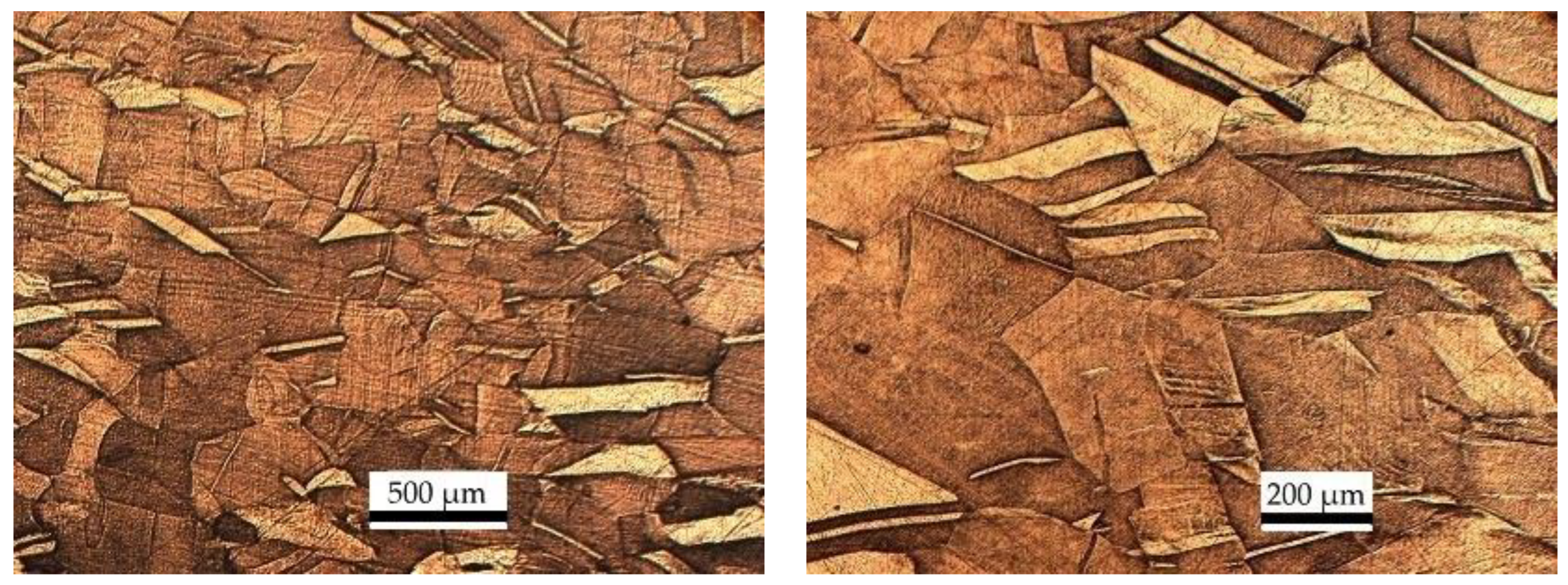

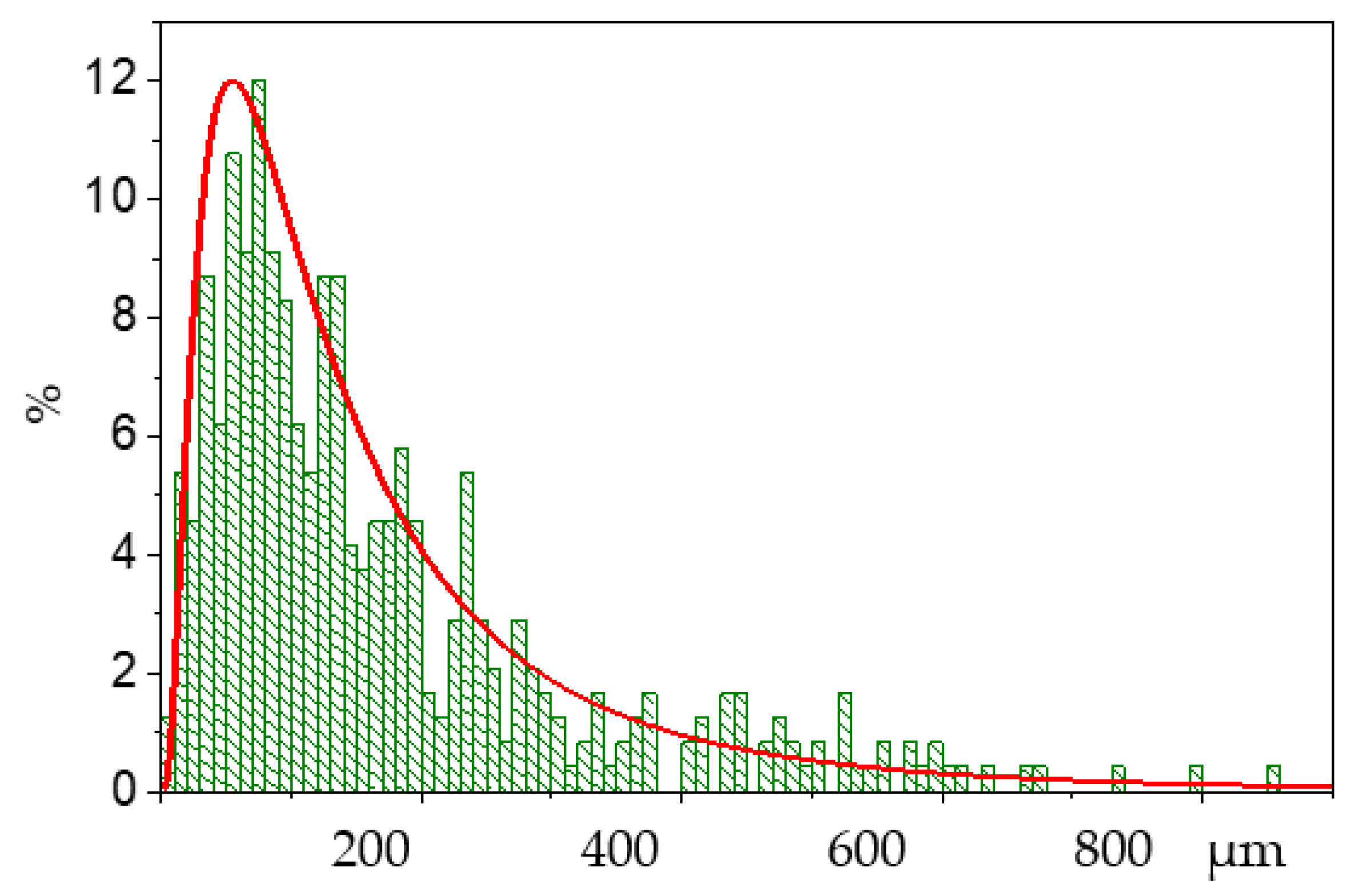

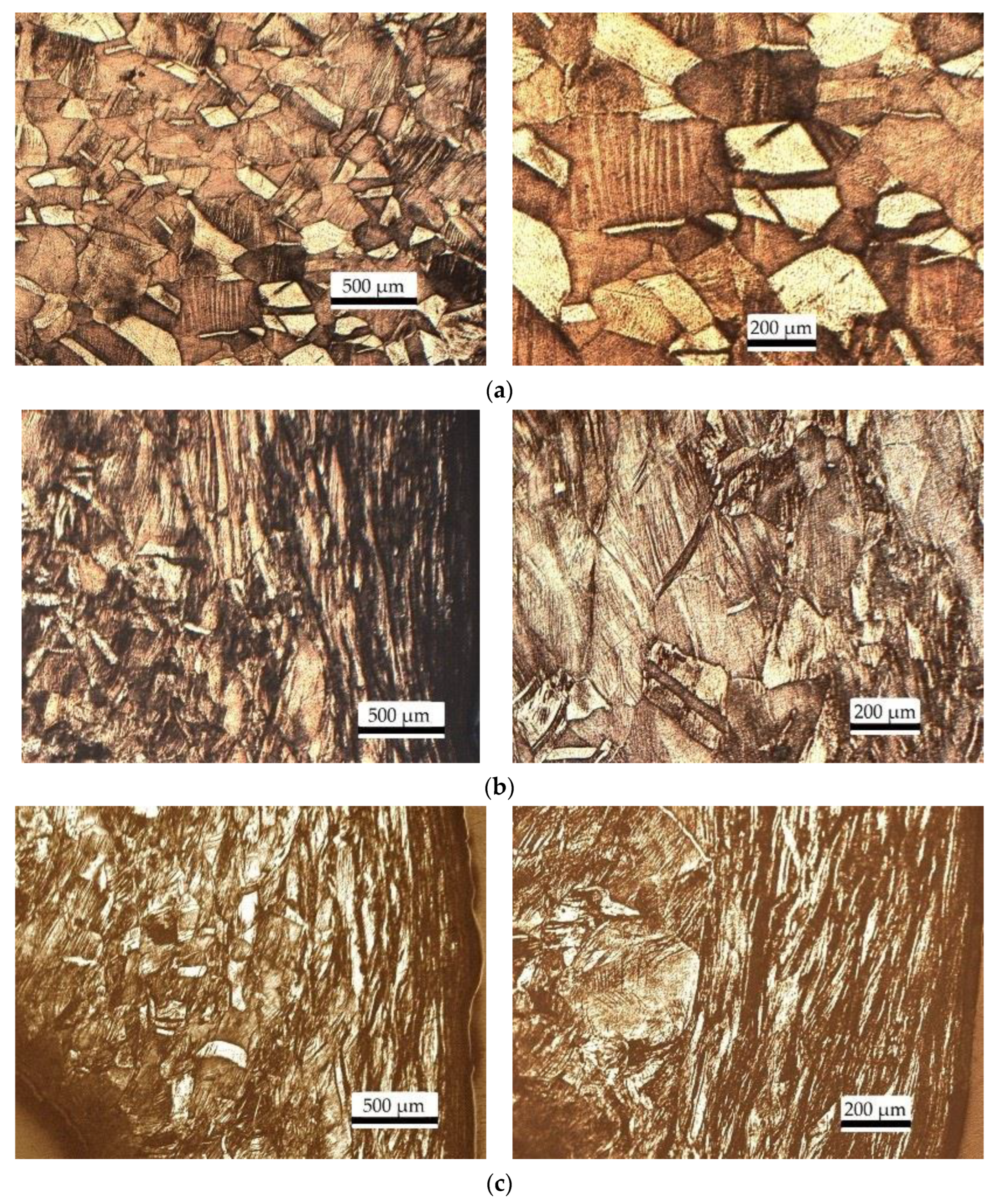

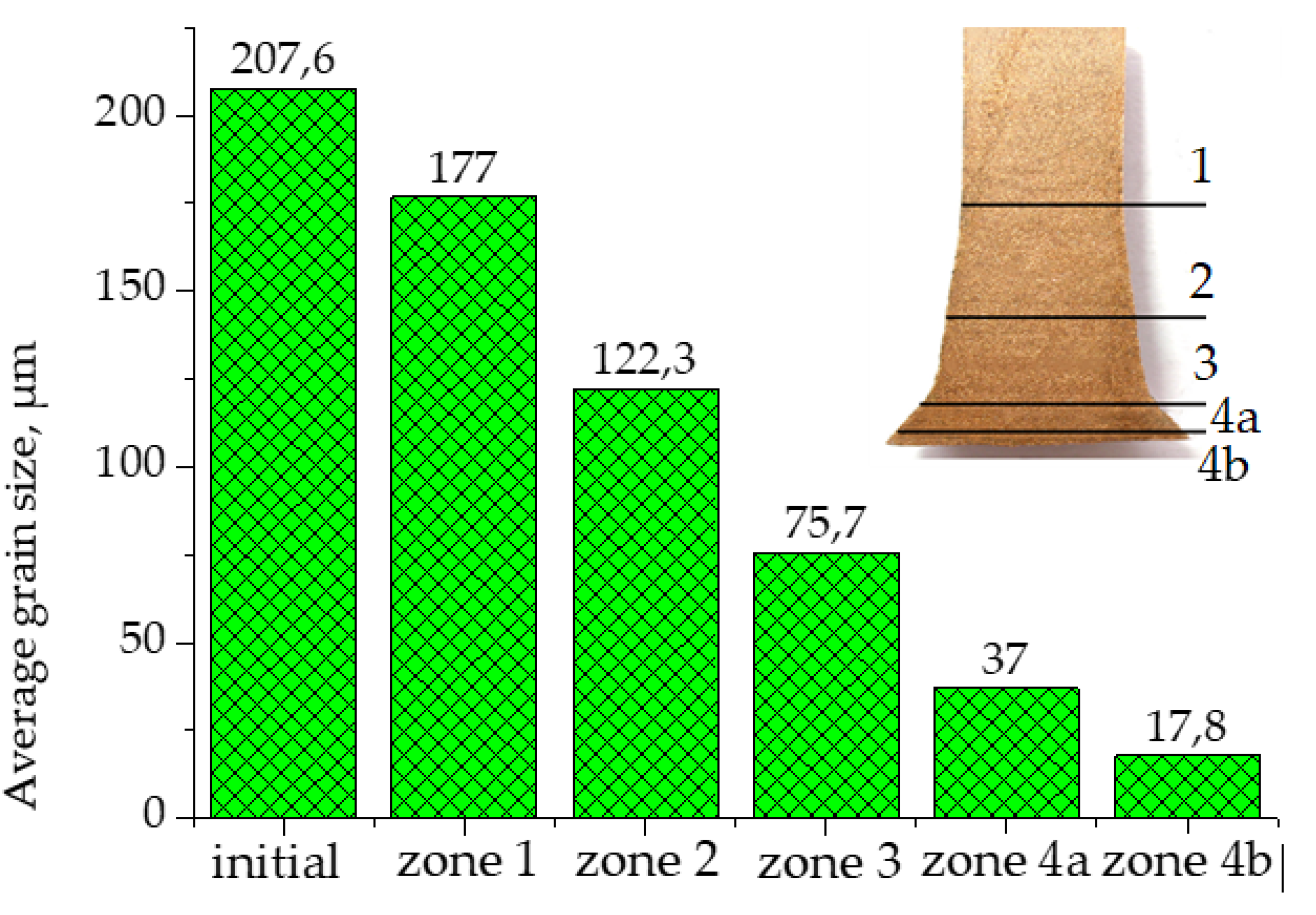

3.3. Microstructure

4. Conclusions

- Analysis of the microhardness distribution and the average grain size of the microstructure has revealed four deformation zones of copper specimens after impact onto a rigid wall: a zone of deformations close to elastic, a zone of plastic deformations, a zone of intense plastic deformations, and a zone of material fracture. The lengths of the deformation zones have been determined depending on the impact velocity;

- Microhardness and microstructure have been found to vary throughout a cylindrical copper specimen in the impact velocity range of 162–416 m/s. This also applies to the first zone of deformation, the region of approximately elastic deformation, where the microhardness value is higher than the initial value by an average of 9–12%. The average grain size is lower by 15% at an impact velocity of 316 m/s;

- The maximum average value of microhardness in the copper specimen after impact with a rigid target reaches 1800–2700 MPa at an impact velocity of 316 m/s, which is 1.6–2.3 times higher than the initial value. The minimum average grain size of the specimen microstructure at the impact velocity of 316 m/s reaches 17.8 μm, which is 11.7 times smaller than the initial value.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Taylor, G.I. The testing of materials at high rates of loading. J. Inst. Civ. Eng. 1946, 26, 486–519. [Google Scholar] [CrossRef]

- Taylor, G.I. The use of flat ended projectiles for determining yield stress. 1: Theoretical considerations. Proc. R. Soc. Lond. A 1948, 194, 289–299. [Google Scholar] [CrossRef]

- Whiffin, A.C. The use of flat ended projectiles for determining yield stress. 2: Tests on various metallic materials. Proc. R. Soc. Lond. A 1948, 194, 300–322. [Google Scholar] [CrossRef] [Green Version]

- Carrington, W.E.; Gayler, M.L.V. The use of flat ended projectiles for determining yield stress. 3: Changes in microstructure caused by deformation at high striking velocities. Proc. R. Soc. Lond. A 1948, 194, 323–331. [Google Scholar] [CrossRef] [Green Version]

- Sobczyk, K.; Chmielewski, R.; Kruszka, L.; Rekucki, R. Strength Characterization of Soils’ Properties at High Strain Rates Using the Hopkinson Technique—A Review of Experimental Testing. Materials 2022, 15, 274. [Google Scholar] [CrossRef] [PubMed]

- Meng, Y.; Yang, Y.; Wang, W.; Dou, Q.; Suo, T. A new technique for performing tortional split Hopkinson bar experiments at high temperatures. Int. J. Impact Eng. 2022, 168, 104314. [Google Scholar] [CrossRef]

- Liu, C.; Wang, W.; Suo, T.; Tang, Z.; Guo, Y.; Li, Y. Achieving Combined Tension-Torsion Split Hopkinson Bar test based on electromagnetic loading. Int. J. Impact Eng. 2022, 168, 104287. [Google Scholar] [CrossRef]

- Pashkov, S.V.; Zelepugin, S.A. Probabilistic approach in modelling dynamic fracture problems. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 10681–10689. [Google Scholar] [CrossRef]

- Tolkachev, V.F.; Zelepugin, S.A. Analysis of the Penetrability of Porous Rod Strikers. Tech. Phys. 2019, 64, 1780–1784. [Google Scholar] [CrossRef]

- Yanov, D.V.; Bodrov, A.S.; Pakhnutova, N.V.; Zelepugin, S.A. Simulation of dynamic channel-angular pressing of copper samples with allowance for experimental data of loading. Vestn. Tomsk. Gos. Universiteta. Mat. I Mekhanika 2019, 60, 141–151. (In Russian) [Google Scholar] [CrossRef]

- Ivanova, O.V.; Cherepanov, R.O.; Zelepugin, S.A. Numerical simulation of solid-phase chemical transformations in thermite mixtures under shock-wave loading. J. Phys. Conf. Ser. 2022, 2154, 012005. [Google Scholar] [CrossRef]

- Critescu, N. The unloading in symmetric longitudinal impact of two elastic-plastic bars. Int. J. Mech. Sci. 1970, 12, 723–738. [Google Scholar] [CrossRef]

- Forde, L.C.; Proud, W.G.; Walley, S.M. Symmetrical Taylor impact studies of copper. Proc. Math. Phys. Eng. Sci. 2009, 465, 769–790. [Google Scholar] [CrossRef]

- Moćko, W.; Janiszewski, J.; Radziejewska, J.; Grązka, M. Analysis of deformation history and damage initiation for 6082-T6 aluminium alloy loaded at classic and symmetric Taylor impact test conditions. Int. J. Impact Eng. 2015, 75, 203–213. [Google Scholar] [CrossRef]

- Wilkins, M.L.; Guinan, M.W. Impact of cylinders on a rigid boundary. J. Appl. Phys. 1973, 44, 1200–1206. [Google Scholar] [CrossRef]

- Gust, W.H. High impact deformation of metal cylinders at elevated temperatures. J. Appl. Phys. 1982, 53, 3566–3575. [Google Scholar] [CrossRef]

- Bogomolov, A.N.; Gorel’skii, V.A.; Zelepugin, S.A.; Khorev, I.E. Behavior of bodies of revolution in dynamic contact with a rigid wall. J. Appl. Mech. Tech. Phys. 1986, 27, 149–152. [Google Scholar] [CrossRef]

- Pakhnutova, N.V.; Boyangin, E.N.; Shkoda, O.A.; Zelepugin, S.A. Microhardness and Dynamic Yield Strength of Copper Samples upon Impact on a Rigid Wall. Adv. Eng. Res. 2022, 22, 224–231. [Google Scholar] [CrossRef]

- Włodarczyk, E.; Sarzynski, M. Strain energy method for determining dynamic yield stress in Taylor’s test. Eng. Trans. 2017, 65, 499–511. [Google Scholar]

- Scott, N.R.; Nelms, M.D.; Barton, N.R. Assessment of reverse gun taylor cylinder experimental configuration. Int. J. Impact Eng. 2021, 149, 103772. [Google Scholar] [CrossRef]

- Bayandin, Y.V.; Ledon, D.R.; Uvarov, S.V. Verification of Wide-Range Constitutive Relations for Elastic-Viscoplastic Materials Using the Taylor–Hopkinson Test. J. Appl. Mech. Tech. Phys. 2021, 62, 1267–1276. [Google Scholar] [CrossRef]

- Volkov, G.A.; Bratov, V.A.; Borodin, E.N.; Evstifeev, A.D.; Mikhailova, N.V. Numerical simulations of impact Taylor tests. J. Phys. Conf. Ser. 2020, 1556, 012059. [Google Scholar] [CrossRef]

- Long, D.; Liu, S.; Zhu, J.; Liu, Y.; Zhou, S.; Yuan, X.; Orlov, D. Improving Texture and Microstructure Homogeneity in High-Purity Ta Sheets by Warm Cross Rolling and Annealing. Metals 2021, 11, 1665. [Google Scholar] [CrossRef]

- Acosta, C.A.; Hernandez, C.; Maranon, A.; Casas-Rodriguez, J.P. Validation of material constitutive parameters for the AISI 1010 steel from Taylor impact tests. Mater. Des. 2016, 110, 324–331. [Google Scholar] [CrossRef]

- Revil-Baudard, B.; Cazacu, O.; Flater, P.; Kleiser, G. Plastic deformation of high-purity α-titanium: Model development and validation using the Taylor cylinder impact test. Mech. Mater. 2015, 80, 264–275. [Google Scholar] [CrossRef]

- Nguyen, T.; Fensin, S.J.; Luscher, D.J. Dynamic crystal plasticity modeling of single crystal tantalum and validation using Taylor cylinder impact tests. Int. J. Plast. 2021, 139, 102940. [Google Scholar] [CrossRef]

- Iannitti, G.; Bonora, N.; Testa, G.; Ruggiero, A. High-rate characterization of additively manufactured Ti-6Al-4V using Taylor cylinder impact test: Experiments. Mater. Des. Process. Commun. 2021, 3, e192. [Google Scholar] [CrossRef]

- Takagi, S.; Yoshida, S. Development of estimation method for material property under high strain rate condition utilizing experiment and analysis. Int. J. Press. Vessel. Pip. 2022, 199, 104771. [Google Scholar] [CrossRef]

- Ho, C.S.; Mohd Nor, M.K. An Experimental Investigation on the Deformation Behaviour of Recycled Aluminium Alloy AA6061 Undergoing Finite Strain Deformation. Met. Mater. Int. 2020, 27, 4967–4983. [Google Scholar] [CrossRef]

- Rodionov, E.S.; Lupanov, V.G.; Gracheva, N.A.; Mayer, P.N.; Mayer, A.E. Taylor Impact Tests with Copper Cylinders: Experiments, Microstructural Analysis and 3D SPH Modeling with Dislocation Plasticity and MD-Informed Artificial Neural Network as Equation of State. Metals 2022, 12, 264. [Google Scholar] [CrossRef]

- Lee, S.; Yu, K.; Huh, H.; Kolman, R.; Arnoult, X. Dynamic Hardening of AISI 304 Steel at a Wide Range of Strain Rates and Its Application to Shot Peening Simulation. Metals 2022, 12, 403. [Google Scholar] [CrossRef]

- Armstrong, R.W. Constitutive Relations for Slip and Twinning in High Rate Deformations: A Review and Update. J. Appl. Phys. 2021, 130, 245103. [Google Scholar] [CrossRef]

- Gao, C.; Iwamoto, T. Instrumented Taylor Impact Test for Measuring Stress-Strain Curve through Single Trial. Int. J. Impact Eng. 2021, 157, 103980. [Google Scholar] [CrossRef]

- Jia, B.; Rusinek, A.; Xiao, X.; Wood, P. Simple Shear Behavior of 2024-T351 Aluminum Alloy over a Wide Range of Strain Rates and Temperatures: Experiments and Constitutive Modeling. Int. J. Impact Eng. 2021, 156, 103972. [Google Scholar] [CrossRef]

- Li, J.-C.; Chen, G.; Huang, F.-L.; Lu, Y.-G. Load Characteristics in Taylor Impact Test on Projectiles with Various Nose Shapes. Metals 2021, 11, 713. [Google Scholar] [CrossRef]

- Li, J.-C.; Chen, G.; Lu, Y.-G.; Huang, F.-L. Investigation on the Application of Taylor Impact Test to High-G Loading. Front. Mater. 2021, 8, 717122. [Google Scholar] [CrossRef]

- Sen, S.; Banerjee, B.; Shaw, A. Taylor Impact Test Revisited: Determination of Plasticity Parameters for Metals at High Strain Rate. Int. J. Solids Struct. 2020, 193–194, 357–374. [Google Scholar] [CrossRef]

- Khristenko, Y.F.; Zelepugin, S.A.; Gerasimov, A.V. New light-gas guns for the high-velocity throwing of mechanical particles. ARPN J. Eng. Appl. Sci. 2017, 12, 6606–6610. [Google Scholar]

- Lapshin, O.; Shkoda, O.; Ivanova, O.; Zelepugin, S. Discrete one-stage mechanochemical synthesis of titanium-nitride in a high-energy mill. Metals 2021, 11, 1743. [Google Scholar] [CrossRef]

| Cu | Fe | Ni | Zn | Pb | O |

| >99.9 | <0.005 | <0.002 | <0.004 | <0.005 | <0.05 |

| S | As | Sb | Sn | Bi | |

| <0.004 | <0.002 | <0.002 | <0.002 | <0.001 |

| υ, m/s | L, mm | Le, mm | Lp, mm | Lip, mm | Lf, mm | D1, mm | D2, mm |

|---|---|---|---|---|---|---|---|

| 0 | 34.5 | 0 | 0 | 0 | 0 | 7.8 | 7.8 |

| 162 | 26.1 | 12.34 | 10.63 | 3.13 | 0 | 7.8 | 12.7 |

| 225 | 22.5 | 9.78 | 9.51 | 2.28 | 0.93 | 7.8 | 15.8 |

| 316 | 16.1 | 5.87 | 6.83 | 2.26 | 1.14 | 7.9 | 21.4 |

| 416 | 9.3 | 3.5 | 1.38 | 2.41 | 2.01 | 7.9 | 31.28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zelepugin, S.A.; Pakhnutova, N.V.; Shkoda, O.A.; Boyangin, E.N. Experimental Study of the Microhardness and Microstructure of a Copper Specimen Using the Taylor Impact Test. Metals 2022, 12, 2186. https://doi.org/10.3390/met12122186

Zelepugin SA, Pakhnutova NV, Shkoda OA, Boyangin EN. Experimental Study of the Microhardness and Microstructure of a Copper Specimen Using the Taylor Impact Test. Metals. 2022; 12(12):2186. https://doi.org/10.3390/met12122186

Chicago/Turabian StyleZelepugin, Sergey A., Nadezhda V. Pakhnutova, Olga A. Shkoda, and Evgenii N. Boyangin. 2022. "Experimental Study of the Microhardness and Microstructure of a Copper Specimen Using the Taylor Impact Test" Metals 12, no. 12: 2186. https://doi.org/10.3390/met12122186

APA StyleZelepugin, S. A., Pakhnutova, N. V., Shkoda, O. A., & Boyangin, E. N. (2022). Experimental Study of the Microhardness and Microstructure of a Copper Specimen Using the Taylor Impact Test. Metals, 12(12), 2186. https://doi.org/10.3390/met12122186