Microstructure and Properties of Press-Bonded Dissimilar Stainless Steel and Mild Carbon Steel Ingots

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

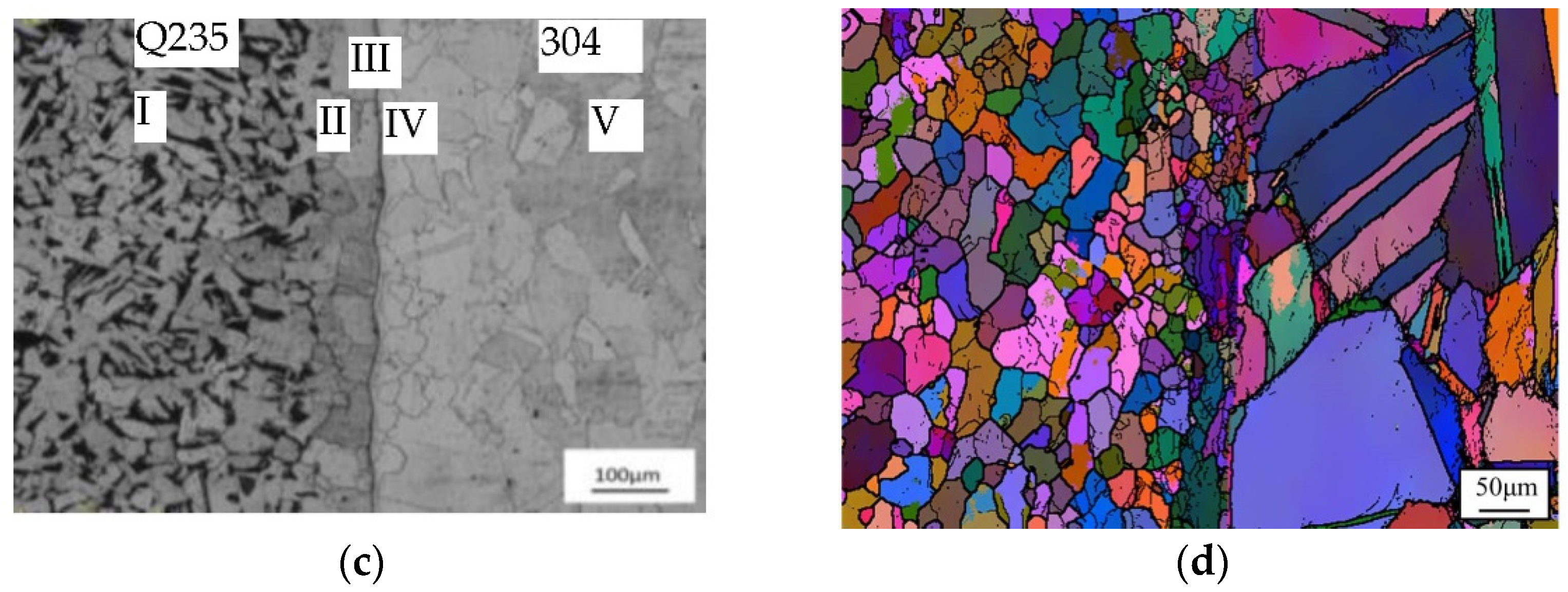

3.1. Microstructure

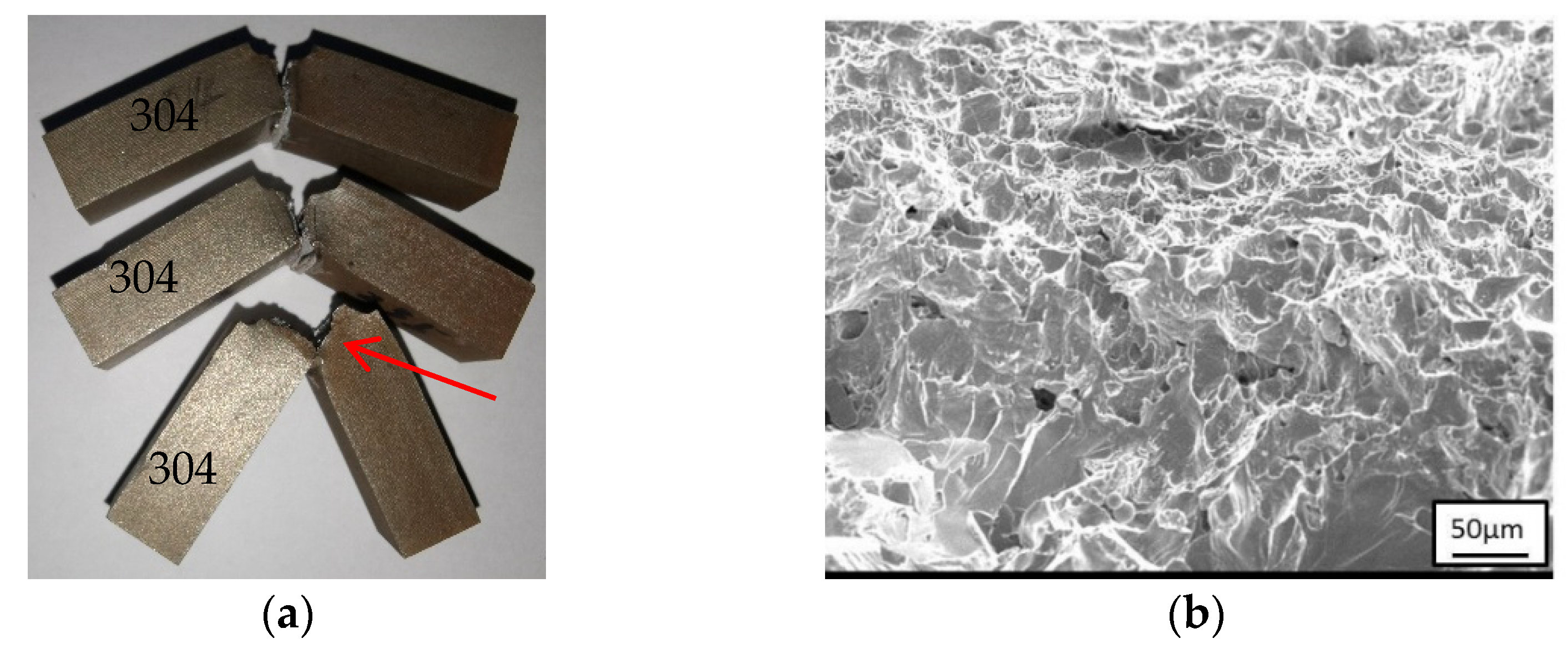

3.2. Mechanical Properties

4. Conclusions

- A strong, high-quality, dissimilar steel ingot of mild carbon steel and austenitic stainless steel can be fabricated by press bonding;

- There is a soft ferrite stabilized zone and a hard carbide transition zone along the bonding interface;

- The mechanical properties are dependent on those of the mild carbon steel and not on the bonding interface; the carbides do not impair the mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Medovar, B.I.; Boyko, G.A. Electroslag Technology; Springer Inc.: New York, NY, USA, 1991; pp. 184–189. [Google Scholar]

- Kazakov, N.F. Diffusion Bonding of Materials; Mir Publishers: Moscow, Russia, 1985; pp. 10–12. [Google Scholar]

- Lesuer, D.R.; Syn, C.K.; Sherby, O.D.; Wadsworth, J. Mechanical behaviour of laminated metal composites. Int. Mater. Rev. 1996, 41, 169–197. [Google Scholar] [CrossRef]

- Sherby, O.D.; Wadsworth, J.; Caligiuri, R.D.; Eiselstein, L.E.; Snyder, B.C.; Whalen, R.T. Superplastic bonding of ferrous laminates. Scr. Metall. 1979, 13, 941–946. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Q.D. Coupled deformation and diffusion process at the stainless steel/carbon steel interface in the deformation bonding process. Strength Mater. 2018, 50, 818–823. [Google Scholar] [CrossRef]

- Li, H.; Yang, C.; Sun, L.X.; Li, M.Q. Hot press bonding of γ-TiAl and TC17 at a low bonding temperature by imposing plastic deformation and post heating. Mater. Lett. 2017, 187, 4–6. [Google Scholar] [CrossRef]

- Huschka, M. Press cycle for multilayer bonding. Circuit World 1990, 16, 40–45. [Google Scholar] [CrossRef]

- Amirkhanlou, S.; Ketabchi, M.; Parvin, N.; Khors, S.; Bahrami, R. Accumulative press bonding: A novel manufacturing process of nanostructured metal matrix composites. Mater. Des. 2013, 51, 367–374. [Google Scholar] [CrossRef]

- Lee, H.; Yoon, B.; Yi, Y. Fabrication of titanium parts by massive diffusion bonding. J. Mater. Process. Technol. 2008, 201, 280–284. [Google Scholar] [CrossRef]

- Sun, M.; Xu, B.; Xie, B.; Li, D.; Li, Y. Leading manufacture of the large-scale weldless stainless steel forging ring: Innovative approach by the multilayer hot-compression bonding technology. J. Mater. Sci. Technol. 2021, 71, 84–86. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, J.; Sun, M.; Xu, B.; Cao, Y.; Li, D. A hot compression bonding method for manufacturing large high-speed homogeneous steels. J. Mater. Res. Technol. 2022, 17, 507–522. [Google Scholar] [CrossRef]

- Xie, B.; Sun, M.; Xu, B.; Wang, C.; Zhang, J.; Zhao, L.; Li, D.; Li, Y. Evolution of interfacial characteristics and mechanical properties for 316LN stainless steel joints manufactured by hot-compression bonding. J. Mater. Process. Technol. 2020, 283, 116733. [Google Scholar] [CrossRef]

- Xie, B.; Sun, M.; Xu, B.; Wang, C.; Jiang, H.; Li, D.; Li, Y. Oxidation of stainless steel in vacuum and evolution of surface oxide scales during hot-compression bonding. Corros. Sci. 2019, 147, 41–52. [Google Scholar] [CrossRef]

- Kurt, B.; Çalik, A. Interface structure of diffusion bonded duplex stainless steel and medium carbon steel couple. Mater. Charact. 2009, 60, 1035–1040. [Google Scholar] [CrossRef]

- Kurt, B.; Orhan, N.; Ozel, S. Interface microstructure of diffusion bonded austenitic stainless steel and medium carbon steel couple. Sci. Technol. Weld. Join. 2007, 12, 197–201. [Google Scholar] [CrossRef]

- Kurt, B. The interface morphology of diffusion bonded dissimilar stainless steel and medium carbon steel couples. J. Mater. Process. Technol. 2007, 190, 138–141. [Google Scholar] [CrossRef]

- Kurt, B.; Eroglu, M. Diffusion bonding between high chromium white iron and austenitic stainless steel. Sci. Technol. Weld. Join. 2007, 12, 467–471. [Google Scholar] [CrossRef]

- Vigraman, T.; Narayanasamy, R.; Ravindran, D. Microstructure and mechanical property evaluation of diffusion-bonded joints made between SAE 2205 steel and AISI 1035 steel. Mater. Des. 2012, 35, 156–169. [Google Scholar] [CrossRef]

- Davies, G.A.; Ponter, A.B.; Menzies, I.A. The diffusion of chromium in iron and low carbon steels. Acta Metall. 1967, 15, 1799–1804. [Google Scholar] [CrossRef]

- Stanley, J.K. The diffusion and solubility of carbon in alpha. Met. Trans. 1949, 185, 725–761. [Google Scholar] [CrossRef]

- Achter, M.R.; Smoluchowski, R. Diffusion in grain boundaries and their structures. J. Appl. Phys. 1951, 22, 1260–1264. [Google Scholar] [CrossRef]

- Bokshtein, S.Z.; Gubareva, M.A.; Kontorovich, I.E.; Moroz, L.M. Peculiarities of the diffusion of carbon in iron. Met. Sci. Heat Treat. 1961, 3, 6–9. [Google Scholar] [CrossRef]

- Kelly, P.; Hills, D.A.; Nowell, D. Models for plastic constraint in brazed or diffusion-bonded joints between ceramic components. Acta Metall. Mater. 1992, 40, 2149–2154. [Google Scholar] [CrossRef]

- Pridans, J.; Bilello, J.C. Plastic constraint as a mechanism for film strengthening. Acta Metall. 1972, 20, 1339–1346. [Google Scholar] [CrossRef]

| Elements | C | Cr | Ni | Mn | S | P | Si | Fe |

|---|---|---|---|---|---|---|---|---|

| Q235 | 0.22 | - | - | 0.30 | 0.05 | 0.045 | 0.35 | Balance |

| SUS 304 | 0.05 | 17.48 | 8.1 | 0.99 | 0.003 | 0.035 | 0.37 | Balance |

| Material | Yielding Strength Sy (MPa) | Ultimate Tensile Strength Su (MPa) | %Elongation (%) | CUN Energy (J) | Fatigue Endurance (MPa) |

|---|---|---|---|---|---|

| Q235 (BD) | 238 | 440 | 30 | 120 | |

| 304 (BD) | 326 | 780 | 35 | 190 | |

| Q235 | 233 | 430 | 28 | 111 | 170 |

| 304 | 313 | 720 | 34 | 184 | |

| Q235/304 joint | 236 | 430 | 18 | 118 | 170 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, X.; Lu, Z. Microstructure and Properties of Press-Bonded Dissimilar Stainless Steel and Mild Carbon Steel Ingots. Metals 2022, 12, 2142. https://doi.org/10.3390/met12122142

Huang X, Lu Z. Microstructure and Properties of Press-Bonded Dissimilar Stainless Steel and Mild Carbon Steel Ingots. Metals. 2022; 12(12):2142. https://doi.org/10.3390/met12122142

Chicago/Turabian StyleHuang, Xuqiang, and Zhaoyang Lu. 2022. "Microstructure and Properties of Press-Bonded Dissimilar Stainless Steel and Mild Carbon Steel Ingots" Metals 12, no. 12: 2142. https://doi.org/10.3390/met12122142

APA StyleHuang, X., & Lu, Z. (2022). Microstructure and Properties of Press-Bonded Dissimilar Stainless Steel and Mild Carbon Steel Ingots. Metals, 12(12), 2142. https://doi.org/10.3390/met12122142